Introduction

Late Bronze Age (c. 950–800/750 BC) metallurgy is considered a well-developed activity. It was performed by skilled craftsmen relying on a set of recipes for copper-base alloys specifically tailored to produce different objects. It is surprising, therefore, that a small assemblage of socketed axes discovered at Karmin in south-west Poland, a site known for the deposition of four significant hoards in the Late Bronze Age, was found to be made of nearly pure copper.

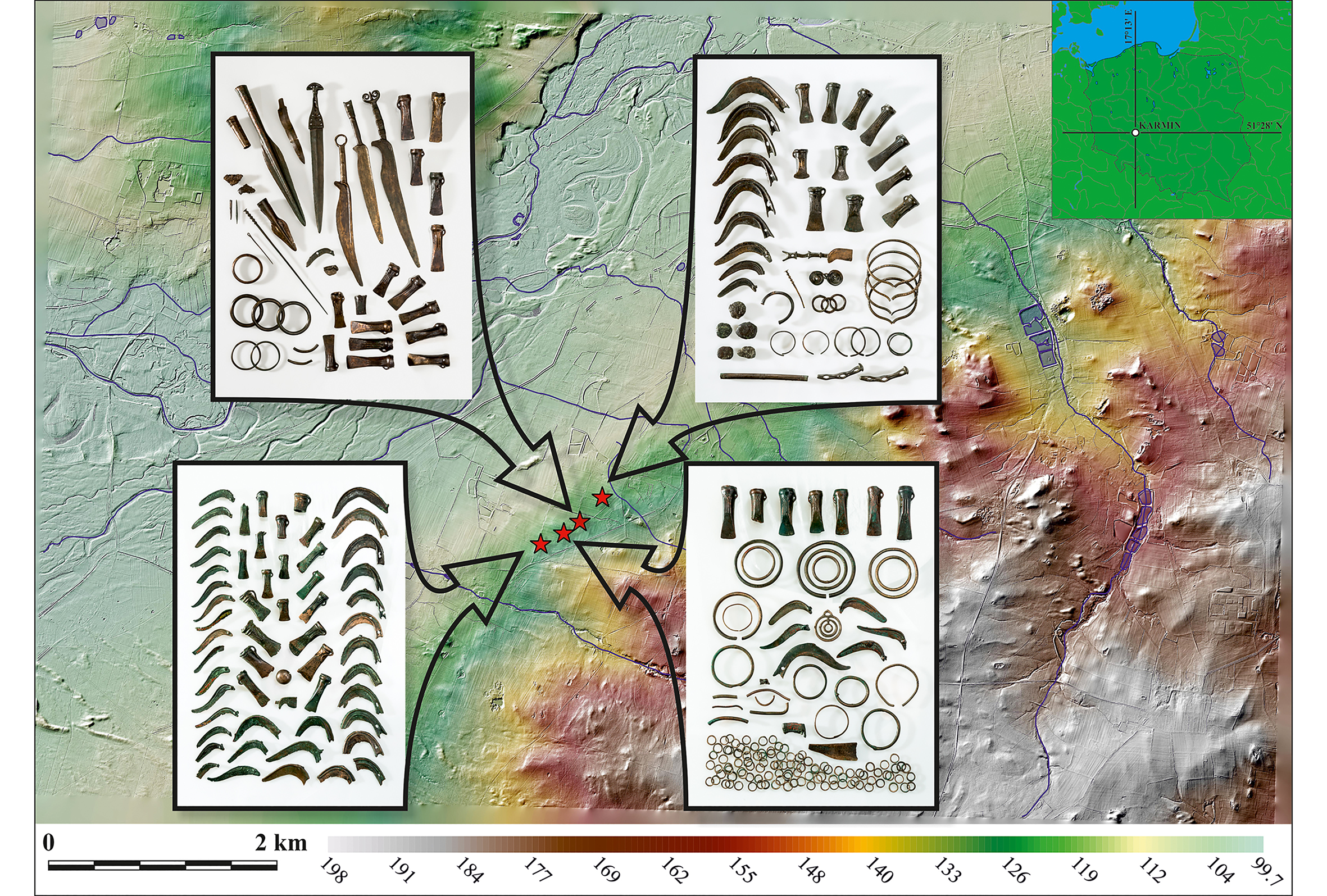

The hoards discovered at Karmin were found contained within ceramic vessels; these contained metal tools, weapons and ornaments, and are well known to Central European archaeologists (Baron et al. Reference Baron2019). The linear arrangement of the hoards is extraordinary (Figure 1). Landscape studies of the local area indicate that the deposits were located at the point where the wide Barycz Valley narrowed and may have marked the route towards the so called Milicz Gate. The hoards are contemporaneous, dating to Hallstatt B2-3 (i.e. Montelius V (950–800/750 BC)).

Figure 1. Map showing the locations of the four Karmin hoards, with the content of each hoard as an inset (drawn by M. Maciejewski; photographs by T. Gąsior).

Axes and sickles were the most numerous artefacts in the four deposits. This is typical of Late Bronze Age metal tool hoards across Europe (Fontijn Reference Fontijn2002: 215). In hoard IV (discovered in 2017), there were 15 complete axes and one damaged axe, all looped and socketed as is most common for that period (Figure 2).

Figure 2. Axes from Karmin hoard IV; red inventory numbers denote copper axes, brown numbers indicate axes made of bronze (photographs by T. Gąsior).

Methods

After grinding and polishing small areas with a sufficient quantity of the metallic phase, we analysed the chemical composition of the surfaces of the axes using an ED-XRF spectrometer (Spectro Midex). We also analysed production, use-wear and destruction traces using a microscope (a Dino-Lite portable digital microscope). The device was calibrated using certified reference materials containing both modern and historical raw materials: IARM-159A (MBH Analytical Ltd, UK), BCR-691 (Institute for Reference Materials and Measurements, EU) and group BB of the Institute of Non-ferrous Metals in Gliwice (Poland).

Results

The elemental composition of the axes from the deposit is presented in Table 1, which also includes a separate group of objects made almost entirely of copper and contaminated only with some natural inclusions. These are mostly Sb (antimony) and Pb (lead), which are the most common components of faded or discoloured copper ores usually called Fahlerz (Henderson Reference Henderson2000: 211).

Table 1. Elemental composition of the axes; copper objects are shaded (+ = content below 0.1% wt.; LOD = below detection limit).

All the tools from hoard IV retain evidence of their method of production. Each has visible remains of a single-channel runner and casting seam, demonstrating that they were manufactured using two-piece casting moulds. Noticeable casting defects such as mould shifts (Figure 3) also prove that they were mould cast.

Figure 3. Mould shift on axe 24 (photograph by J. Baron).

Traces of preparation for use are usually hammer marks on various parts of the worked object: at the casting seam, on the socket and on the cutting edge of both frontal and lateral surfaces (Figure 4). The objects have deep traces of hammering, flattened lines along the sides below the loop and traces of softer hammering on the frontal surface of the cutting edge. These marks suggest the use of a variety of tools to prepare the axes. Traces of sharpening or grinding are visible on the blades of all the objects (Figure 5: 1–3). All the specimens bear traces of use-wear, mostly fractures, notches, slight bending, edge rounding or blunting and cracks (Figure 5).

Figure 4. Hammering traces on: 1) casting seam; 2) socket; 3–4) blade: lateral surface; 5) blade: frontal surface. Inventory number in square inset (photographs by K. Nowak).

Figure 5. Traces of use wear on copper axes: 1–3) fractures and grinding traces; 4–5) bluntness observed as rounded blade. Inventory number in square inset (photographs by B. Miazga).

Discussion

Copper is rarely found in Late Bronze Age inventories and where it does exist it is usually present as shapeless lumps (Bartelheim & Niederschlag Reference Bartelheim and Niederschlag1992) instead of finished artefacts (Harding Reference Harding2000: 202). The objects from hoard IV represent a type of locally produced socketed axe, which was one of the most commonly deposited tools of that period. All traces of production and use-wear are similar to those observed on bronze axes. This proves that craftsmen were able to adapt their technology to suit the properties of each metal, and the objects were probably made in the same workshop. The objects show traces of standard preparations for regular use: removal of casting seams and hardening to some degree by hammering (Tylecote Reference Tylecote1976), as seen on the sockets and blades after grinding. The use-wear also matched intensively used bronze objects: rounded blades, fractures and cracks, which are all commonly seen in these tools (Roberts & Ottaway Reference Roberts and Ottaway2003).

Copper is more difficult to cast than its alloys due to its higher melting point, lower castability and hardness, faster cooling and lower brittleness (Jantzen Reference Jantzen2008: 7). Why, then, were these axes made from a raw material that was difficult to work with? The significance of metal in the Late Bronze Age was determined not only by its functionality, but also its symbolic meaning and aesthetic value (Bradley Reference Bradley1998: 82; Pare Reference Pare and Pare2000: 24–25). The latter is indicated by the manipulation of alloy to obtain a particularly desirable colour in finished objects (Nørgaard Reference Nørgaard2018: 95). Colour was also considered important for estimating the composition, and thus the quality, of a product (Jantzen Reference Jantzen2008: 9). This is not true of the Karmin axes, however, which are all similar in colour despite differing compositions. Their colour was documented immediately after their discovery in 2017 and again after conservation work in 2018.

The Late Bronze Age in Central Europe (ending around the first half of the eighth century BC) is characterised by an increase in small personal items (mostly clothing accessories) deposited in numerous cremation burials (Mierzwiński Reference Mierzwiński2003: 140). This resulted in an increased demand for raw materials and a subsequent tin shortage (Horst Reference Horst1971: 204–205; Jockenhövel Reference Jockenhövel, Belardelli and Peroni1996: 214; Mierzwiński Reference Mierzwiński2003: 140). A consequence of this was not only intense recycling of existing bronze items, but also flexible adaptation of manufacturing patterns. We argue, therefore, that these axes were produced by highly skilled metalworkers proving their adaptive skills in a time of shortage of raw materials.

Acknowledgements

We thank two anonymous reviewers for their valuable comments on the manuscript. The project was supported by the Polish Ministry of Culture and National Heritage (3469/18/FPK/NID).