Introduction

Italy was the first country in the world to employ aircraft and airships in a conflict (Libya 1911–1912), albeit with limited results and using Italian airships and French planes. France was indeed the leader of the aviation industry in Europe, and the orders given by the Regia Aeronautica were to equip Italy’s air force with foreign aircrafts at the time of the outbreak of the First World War. However, during the war, Italy’s air force freed itself from foreign dependence, with French planes being largely replaced by Italian aircrafts. These included Caproni bombers, Macchi fighter planes, Pomilio reconnaissance aircraft, and the Savoia–Verduzio–Ansaldo (SVA), which was one of the fastest combat aircraft built by Ansaldo.Footnote 1

At the end of the First World War, alongside large engineering groups such as FIAT and Ansaldo, the following medium-sized companies continued to operate in the aeronautical sector: Caproni, SIAI, Breda, Macchi, and Piaggio. Caproni was the aircraft company that saw the fastest growth during the interwar years. Gianni Caproni, indeed, as well as being an engineer capable of designing different types of aircraft, was also a successful entrepreneur who expanded his business through the vertical integration of the production process, thus creating the largest Italian aeronautical group in terms of numbers of affiliates and employees. At the end of June 1937, the Caproni Group was the leading Italian aircraft producer in terms of business revenues from aeronautical production, which equalled 325.7 million lire, while in 1938 the aeronautical sector was led once again by Caproni with its 10,199 employees, followed by SIAI with 5,113, Piaggio with 4,644, and FIAT with 4,273.Footnote 2

Giovanni Battista Caproni was born in Arco in Trentino in 1886, earned a degree in engineering at the University of Munich, and then enrolled in Liège where he attended an electrical engineering course. He built his first motor plane, the Ca.1, in the courtyard of his family home near Lake Garda.Footnote 3 However, given the difficulties in finding enough space for taking off and landing, he left Trentino and moved to Lombardy, where he obtained permission from the military authorities to use a flat and easily adaptable area in Cascina Malpensa for use as an airfield (the area is very close to what we know today as the Milan Malpensa Airport). With his brother, he set up the Società d’Aviazione Fratelli Caproni in 1910.Footnote 4 Despite his ingenuity (he patented 158 inventions, many of which contributed to the development of modern aeronautical science), his first aircraft models did not immediately achieve the hoped-for success and his company was refounded several times with new partners.Footnote 5 When in 1915 Colonel Giulio Douhet (commander of the Aviators Battalion and friend and collaborator of Caproni since he was seconded to Malpensa in 1913) urged Gianni Caproni to study the feasibility of a large bomber capable of rivaling airships, reaching and seriously damaging distant objectives, the three-engine Ca.30 (or Ca.3) was conceived; generous state orders soon followed.Footnote 6 The First World War represented for Caproni an opportunity to grow; huge orders came in from the military, and even U.S. personnel were struck by his three-engine bomber’s potential and reliability.Footnote 7

With the advent of fascism (1922), the aircraft construction industry faced both the advantages and the disadvantages of all Italian business in those years. The fascist era signaled the beginning of protection from social conflict and foreign competition and a sizeable amount of war-related orders in the 1930s.Footnote 8 Indeed, the fascist regime’s imperial endeavors meant a significant reprise of aviation construction for the aircraft industry and, for Caproni, the decision to go ahead with the formation of a large integrated group totally self-sufficient in the production and export of aircrafts and spare parts.Footnote 9 From Istituto di Ricostruzione Industriale (IRI;1933),Footnote 10 a newly born state holding, he bought the Officine Meccaniche Reggiane (based in Reggio Emilia) the biggest engineering company in Emilia-Romagna, which within a few years started manufacturing and exporting some of the best fighter aircrafts ever produced in Italy.

Based on different archival sources, this paper would like to shed light on how it was that, despite Italy’s technological obsolescence in the aeronautical field, which resulted in the country accumulating significant delays in terms of innovative capacity, modern plant organization, and the production of cutting-edge engines, a company that mainly centered on the production of railway material was able to come up with the most technologically innovative fighter planes (namely, the Re.2000 and subsequent models), which quickly rose to prominence in the Italian and foreign markets, and were ordered in great quantities (see Appendix 1). Hence, if the research question aims to uncover what factors allowed the success of the Officine Meccaniche Reggiane, these are the most plausible answers. First, the role of the new owner—the risk taker and forward-looking entrepreneur Gianni Caproni. His personality traits along with his entrepreneurial history seem to match up well with the theory of charismatic/creative entrepreneurship, which includes boldness, imaginativeness, and a willingness to take calculated risks.Footnote 11 As a Schumpeterian entrepreneur, he created a world that differed from the preexisting one, by introducing innovative products and methods of production and opening new markets in unexplored territories.Footnote 12 Second, also knowledge transfer was the key to Reggiane’s success story. Knowledge and technological development have always easily crossed borders, and so they did in the case of aircraft building. Knowledge is also one of the most relevant sources of a firm’s competitive advantage, and, according to many authors, firms capable of developing an effective process of knowledge transfer and increasing internal skills successfully advance their business competitiveness.Footnote 13 This was the case of the Reggiane, which also mastered the swift diffusion of technology within the firm.Footnote 14

The main argument of this paper rests on delving deeply into the company’s history, managerial choices, risk-taking attitudes, and a well-implemented knowledge transfer in order to explain an otherwise almost incomprehensible degree of international business success in such a competitive sector.

The Officine Meccaniche Reggiane (OMR) and the New Beginning in the Aircraft Sector

The Officine Meccaniche Reggiane (the “Reggiane Engineering Workshops”) was founded in 1904 as a little-known company that, nevertheless, was quickly to gain an excellent reputation in the field of railway construction. After the First World War, the company also began producing industrial machinery for mills, pasta factories, and brick factories, together with ploughs and reaping machinery for the farming sector. The 1929 economic crisis had a serious negative impact on the company and on the Italian railway sector, which at the time was the company’s main customer, and losses soon became unbearable, resulting in the company’s share capital coming under the control of a large mixed bank, the Banca Commerciale Italiana (Comit). Despite a 60 percent fall in sales, the losses made by the company’s industrial operations were contained, and the production levels achieved by its plants were defined “good” by external financial inspectors.Footnote 15 However, the Comit bank was also on the verge of collapse and was only saved by its nationalization. As said, in 1933 the Italian State set up Istituto per la Ricostruzione Industriale (IRI) and took over the shareholdings of the three largest mixed banks (Comit, Credit, and Banco di Roma). Two subsidiaries of the Caproni Group (Aeroplani Caproni and Isotta Fraschini) acquired the majority of OMR’s shares from IRI, under the close supervision of Gianni Caproni, who saw an opportunity to take advantage of part of the company’s property, which extended over approximately 120,000 square meters, for the purposes of aircraft construction.Footnote 16 Caproni aimed to revive the fortunes of the company by guiding it toward the development of the aviation sector, which in this way compensated for the persistent lack of demand from the railway sector. He expanded the factory and set up proper facilities for aircraft construction, reabsorbed labor redundancies, and, thanks to the resumption of military activities in Tripolitania (a region in the northwestern part of Libya) that gave a certain impetus to the production of military aircrafts, he began to build airplanes for deployment in the Ethiopian war.Footnote 17

The OMR’s buildings were located in Reggio Emilia and were fitted with plant and machinery designed for traditional mechanical engineering, to which new buildings and special mechanical equipment were added for the production of aircraft engines and aeronautical constructions in wood and metal (see Picture 1). A large workshop (100 × 40 m2) was built (without the use of intermediate pillars) for large aircraft assembly operations, and a precision engineering department was set up for the construction of selected engine parts. An airfield was also laid out in the area in front of the aircraft workshops, and this was subsequently expanded and equipped with buildings and hangars to become the military airport of Reggio Emilia.Footnote 18 The Reggiane factory was also well connected to local infrastructure because it stood in the immediate vicinity of the town’s railway station to which it was linked by double tracks.

Picture 1. The Reggiane aircraft workshop (all pictures from ARER).

The 1936 and 1937 balance sheets show that the cost of these new plants amounted to a total of 25,291,973.65 lire. The Reggiane paid for this by means of a mortgage loan granted by Istituto Mobiliare Italiano, IMI, a public bank) worth 15,742,000 lire and through a share capital increase of 16,740,000 lire. As a result, almost exclusively of these new investments, totaling approximately 31.7 million lire in machinery and equipment for aircraft construction, production revenue rose from 42,975,189.20 lire in 1936 to 108,030,666.90 lire in 1937.Footnote 19

It should be noted that in these first two years of aeronautical production, the OMR workshops operated under license granted by third parties, in the case of both engines and aircraft.Footnote 20 Indeed, despite its renaissance as a company boasting an aeronautical department in full operation as of 1937 and with global orders worth 122 million lire (compared to 22 million lire the year before), the OMR did not design its own models but availed itself of the services of specialized technicians and engineers from the Aeroplani Caproni workshops, in the case of aircraft, and from Isotta Fraschini, in the case of aircraft engines. As Appendix 1 shows, the OMR began to build the Savoia Marchetti SM.79 three-engined bomber under license, while the P.32 bis was a fast bomber based on the Piaggio P.32, and the two record-breaking Procellaria aircraft were derived from the Pegna-designed Caproni Ca. 405 (which unfortunately suffered continuous accidents and turned into a loss-making enterprise). Before switching to “American production,” the OMR’s accounts show a net profit of 3.679 million lire in the first quarter of 1938, against a loss of almost 8 million lire for the year, mainly due to problems with aircraft production. When the pilot Mario Gamna crashed during a test flight (on 25 February 1938), the order for 16 P.32-bis planes was canceled, while one accident after the other totally disrupted the Procellaria trials.Footnote 21 The production of aircraft engines, which was probably more in tune with what the company used to do, proved less problematic: Together with the manufacture of several types of aircraft engine under license (granted by Piaggio and Fiat), 1938 also saw the start of construction of the OMR’s own-designed engines (Re.103, Re.105, etc.).

However, the uneasy transition to aircraft production called for a new perspective and for the fresh input of external human capital. Gianni Caproni realized that, in order to modernize the company’s construction techniques and to ensure rapid advances, he had to look to the U.S.’s cutting-edge technology and to American experts capable of transferring modern aviation know-how to Reggio Emilia.

The Transfer of Knowledge: The role of Roberto Longhi

The person Caproni turned to was Roberto Longhi, an aeronautical engineer of Italian origin who had graduated in the United States and then stayed on to work there. In the 1920s, he managed to acquire knowledge and industrial skills among the most advanced of the time while working at Bellanca Aircraft, Wright Aero, the Fernic Aircraft Corporation, and the Uppercut-Burnelli Aircraft Corporation of Keyport, New Jersey, a division of General Motors. In 1930, Longhi was eager to start his own business, and indeed he took over a company called Pacer Aircraft, renamed it New Pacer Aircraft Corporation, and built a fighter plane for a competition held by the American Air Force in August 1931. Unfortunately, the depression following the stock market crash of 1929 led those banks that had survived the financial crisis to become very prudent and little inclined to grant loans. Longhi, despite obtaining the approval of the inspectors of the American Commercial Department, could not find the funds needed to fly the aircraft to Washington for military approval and, as a consequence, lost almost all of his savings and was forced to go back to working for Uppercut.Footnote 22

Longhi designed single-engine and multiengine aircrafts for civil and military use and cooperated with prestigious names in the U.S. aeronautical industry. In 1933, his racer design won the Newark Air Race Association competition for racing aircraft. It was the first aircraft to feature stainless steel construction and an engine cooling system built into the plane’s wing. Aerodynamic tests using a scale model of the racer, conducted in the wind tunnel at the New York University College of Engineering at the beginning of 1933 and again in the summer of 1935, proved highly successful, as indicated in a letter written by Alexander Klamin, professor of aeronautical engineering at the Guggenheim School of Aeronautics. Klamin reported as follows: “The general aerodynamic design is excellent. The fuselage lines, wing, profile, fairings between fuselage and wing all fairings of landing gear are in accordance with best aerodynamic practice… From an aerodynamic point of view the design is excellent and in general the design is very well adapted to high-speed racing.”Footnote 23 These results generated the interest of the American Air Force, as evidenced by a letter from Lou Reichers (2nd Lieutenant, Air Res. U.S. Army) to Longhi sent on September 7, 1935:

I’m thoroughly impressed with the simplicity of production and believe it would be a distinct contribution to the advancement of the science of aviation… The remarkable calculated performance surpassing anything ever constructed for land planes would make this the ideal military plane for high speed interceptor duty particularly that the US Army Air Corps has developed high speed bombers that have obsoleted all present types of military pursuit planes by virtue of their higher speed. For reasons of national defence this plane should be constructed.Footnote 24

The innovative characteristics of the plane were widely recognized: its stainless steel construction, a radiator integrated into the plane’s wing, an oil cooling system, and the refined shape of the air foil offering unusual stability for a high-speed racing plane.

In January 1936, Longhi returned to his family in Bergamo (he obtained a year’s leave from Uppercut on grounds of ill health), and during his stay there, an old family friend, Giannino Ferrari, introduced Longhi to Gianni Caproni. The latter convinced him to work (at least temporarily because Longhi wanted to return to the United States) with engineer Cesare Pallavicino at one of the Caproni Group’s affiliates called Caproni Aeronautica Bergamasca (CAB) on the development of the AP-1 (a ground-attack aircraft).Footnote 25 This joint-working venture lasted a mere five months, after which Longhi decided to go back to work for the Uppercut Corporation (given his growing divergences with Pallavicino). While Longhi was waiting for his visa to return to the United States, Caproni asked him to take a look at the OMR workshops and to lend a hand to engineer Pegna, who at the time was preparing two aircraft for the Istres–Damascus–Paris air race. Longhi accepted the proposal, but the two Procellaria planes in question were doomed from the start. As previously mentioned, the aircraft suffered several breakdowns and in the end were not set up in time, and the deadline for the tender bid came and went. However, at the farewell banquet the managing director of the Reggiane—engineer Giovanni Degola—gave Longhi a check for 75,000 lire as recompense for his work in Reggio Emilia. Gianni Caproni’s parting words were: “You will be back with us in less than a year, as it is my intention to begin building an all-metal fighter aircraft here in Reggio Emilia.”Footnote 26

On his return to the United States in July 1937, Longhi wrote to Caproni, suggesting that he should purchase the license for the production of one of the two most advanced American fighter aircrafts, either the Curtiss P-36 Hawk or the Seversky P-35. Caproni ultimately failed to do so; however, in November 1937 Antonio Alessio, deputy general manager of the Reggiane, was sent to New York to visit a number of aeronautical companies and to bring Longhi back to Italy. The job offer envisaged the construction of a modern all-metal fighter aircraft and the management of the company’s design department, on the basis of a five-year (renewable) contract.Footnote 27 Longhi recalls how he was clearly informed that: “no financial issue would get in the way, and this offer would be very difficult to reject.”Footnote 28

Longhi also accompanied the OMR’s business visit to numerous aeronautical (and nonaeronautical) plants, together with Antonio Alessio and engineer Fidia Piattelli) in order to see at first hand new working methods and production innovations in the aviation industry. Between the 2nd and the 15th of December, the team of experts visited quite a few U.S. aeronautical engine and aircraft production plants (including Martin, Sikorsky, Chance-Vought, Grumman, and Seversky) and realized that all of them were manufacturing duraluminum airplanes and very advanced military mono- and biplanes.

The mission’s report reveals that the team swiftly obtain the permission for the visit from the U.S. War Department (the most “difficult to access” was the American Armament Co. factory in Newark, “because it is monitored by inspectors from the War Department”; yet the visit went well and it was reported that “approximately 20 P.36 aircraft models are produced per month”)Footnote 29 and that the Italian engineers were not that impressed by the top-notch American engine’s producers (Pratt & Whitney and Wright, who boasted global dominance in the field of air cooling), insofar as the quality of engines was concerned because this did “not appear superior to European production quality, including that of Italy.”Footnote 30 What did strike the mission was the speed and mechanization of construction operations with a production capacity of 375 engines per month in both companies.Footnote 31 Different conclusions were reached with regard to aviation manufacture. In this case, the team of Italian experts, after recognizing that “American aeronautical construction has now definitively stabilized through the production of duralumin shells,” were surprised by the inner workings of U.S. production.

A more intense search for simpler construction formulas, greater production agility, a more mature and specialized workforce, much cheaper equipment, undoubtedly refined aerodynamic shapes (more advanced than the German ones), a range of constructive solutions resulting from a more decisive trend towards simplicity, pragmatism, and parsimony. The most advanced aircrafts appearing somewhat closer to naval than aeronautical structures”.

It was indeed this structural unification, together with successful technological standardization resulting from in-depth studies and experience, that enabled U.S. producers to “attain an optimal level of construction which clearly represents the reason for the development and superiority of American construction methods.”Footnote 32 This was an enriching experience to take back to Italy.

Before the OMR mission returned to Italy, it was Longhi himself who proposed the terms of his employment: 7,000 lire, half of which to be paid on entry into service and half on testing the aircraft, together with reimbursement of the costs of travel back from the United States for himself and his family, a monthly salary of 5,000 lire (the average salary for a senior manager in Italy was around 3,000 lire at the time), and a production bonus of at least 10,000 lire per aircraft.Footnote 33 Caproni willingly accepted Longhi’s demands, and in the last week of February 1938, Roberto Longhi began working at OMR as head of the metal aircraft testing workshop (soon after he was appointed technical manager), with the task of designing full-metal fighter airplanes (modeled on the Seversky P.35). The task was challenging, and it involved resolving three enormous problems: the fact that the company’s workforce did not know how to carry out metalworking operations on aircraft; the lack of light alloys available in the Italian market; and the need for further investment in the aircraft workshop. The first problem was faced initially by hiring expert workers from other firms and then by setting up a special school with proper courses to train technicians in sheet metal working for aircraft construction. Soon, these specialized workers ended up being paid twice as much as the regular workforce.Footnote 34 The training school was set up in a newly constructed building with a floor space of 1200 m², complete with a workshop equipped with approximately fifty machines, teaching rooms, and even shower facilities for workers.Footnote 35 The second problem was tackled by asking Montecatini (the largest chemical company in Italy) to help supply an autarchic light alloy called “chitonal” (or superchitonal). Gianni Caproni had to personally speak to the Montecatini board of directors in order to convince them to produce the much-needed sheet metals, while OMR’s general manager, fearing difficulties and possible delays, urged President Franco Ratti to talk to General Giuseppe Valle and have him intervene to speed things up.Footnote 36 The first supplies from Montecatini arrived in September 1938.

In the meantime, Longhi imported from Cleveland Pneumatic (which he had visited in December 1937 with the OMR’s mission) automatic machines for bending and bombing sheet metal and profiles, and pneumatic hammers for the pounding needed to build metal aircraft. Finally, a new department was designed for mass production, making use of rotating structures (only employed in the United States at the time) and featuring among the most advanced in Europe.Footnote 37 Engineer Brocchi, the person who wrote IMI’s technical report on the company in 1941 (to decide on whether it should be granted new loans) was sincerely impressed by the modernity of OMR’s aeronautical production. In his own words:

The aviation workshop is utterly functional, it extends over 45,000 square meters, with excellent industrial-type warehouses equipped with the necessary and well-lit water, heat, electrical, sometimes compressed air systems. Large spans allow easy movement of the departments if necessary. Particularly notable for the width of the span and the full headroom in the attic, are two sheds with a cellular metal structure (and one with arches in reinforced concrete) used for the assembly of the airplanes, each measuring 100×42 m and without any intermediate pillar. The layout of the departments is excellent, the working design is based on pre-established production lines, starting with the warehouses and including the assembling of the groups and of the complex units. The machinery is top of the range, or in any case of good national and foreign brands… The total investment for this workshop amounts to over 45 million lire. In my opinion this is one of the best establishments of its kind in terms of manufacturing facilities and organization of production.Footnote 38

The Best Models Ever Built: The Re.2000 Series

The first airplane designed by Longhi and built with a metal shell structure for OMR was the Re.2000 Falco I fighter monoplane. This aircraft was to be submitted for the purposes of the competition organised by the Ministry of Aeronautics on May 24, 1939. The Re.2000 was the first of a long series of modern fighters. It was a single-engined, single-seater, low-wing monoplane that could be employed both as an interceptor-fighter and as a great range fisher (see Picture 2). The fuselage was made of superchitonal and had a monocoque structure. The cockpit featured a sliding hood that could be unhooked in flight, whereas the seat had a cushion frame with a parachute. Two great innovations related to the five-spar wing with built-in fuel tanks and electrically operated retractable landing gear and tailwheel. The Re.2000 was fueled by a 1000 hp Piaggio P. XI RC 40 twin star, air-cooled radial engine.

Picture 2. The Re. 2000.

The aircraft proved superior to its competitors, not only thanks to the power installed but also in terms of its maneuverability, stability, and other key qualities. During flight tests conducted at Guidonia in August 1939, the Falco I performed better than the Macchi M.C.200 Saetta, the Messerschmitt Bf. 109, and the Fiat C.R. 42 in terms of speed, maneuverability, and flight autonomy.Footnote 39 A letter sent to President Ratti by his team in Guidonia reads as follows:

The aircraft has favourably impressed everyone in Guidonia. The Re.2000 is undoubtedly the best existing Italian fighter. No other Italian aircraft has a completely metal, shell structure (monocoque) like that. Its structure, dimensions, wing curve, controls, manoeuvres, and engine power are extremely rational and cannot be found in any other aircraft.Footnote 40

Despite its remarkable performance, it did not win the Ministry of Aeronautics competition due to the negative opinion of the military jury, who could not understand the new idea of locating the fuel tanks in the wings. Nevertheless, it immediately proved of genuine interest to foreign air forces: By the end of the war, 322 out of 379 Re.2000 totally produced had been built for the foreign market while prewar orders had reached 1,468 planes (see Appendix 1).

At first, OMR only received an order for two aircraft from the Regia Aeronautica (Italy’s Royal Air Force); however, in August 1939, 200 Re.2000 were provisionally ordered. This order, indeed, had to be temporarily suspended due to the abovementioned technical reservations. At the same time, the Ministry asked OMR to redesign the aircraft by mounting the German Daimler Benz DB 601 engine (regrettably, Italy’s capacity in engine construction lagged behind that of Germany, and the Piaggio 1000 CV was only a prototype).Footnote 41 Longhi set to work to introduce the requested changes in August 1939, and at the end of June 1940 the Re.2001, a prototype quite different from its predecessor, left the testing department (see Picture 3). Just before then, on June 10, 1940, Italy entered the war.

Picture 3. The Re. 2001.

The tests satisfied the competent authorities: General Francesco Pricolo (undersecretary of state and chief of staff of the Air Force since November 10, 1939) was reported as saying that “this (Re.2001) is the best aircraft I have ever seen, there can be no doubting that.”Footnote 42 The war was placing such pressure on the Regia Aeronautica that it decided to convert the pending order for the 200 Re.2000s into the same number of Re.2001s, and authorized their serial construction. The written order (still visible in OMR’s archives) arrived on October 31 for an amount of about 100 million lire.Footnote 43 At the same time, the Ministry commissioned another 200 Re.2001 from Breda, 100 from Caproni Taliedo, and 50 from Caproni Predappio (which rose to 100 Re.2001 on January 13, 1941).Footnote 44 OMR and Longhi built the best fighter ever produced in Italy. The Ministry, however, was not a reliable client and unfortunately the war made the procurement of raw materials really complicated. In the end, only a few models were regularly delivered out of those ordered due to various factors that had nothing to do with the excellent quality of the aircraft. Such factors included the continuous small modifications requested by the Ministry (delaying production), the slowness and setbacks afflicting Alfa Romeo’s construction of the DB 601 engines and deliveries to the Reggiane factory, and more in general, first the fact that the Air Force Ministry stubbornly farmed orders out to all the companies involved in the aeronautical cycle and, second, the delays in the supply of raw materials from abroad. As to the first issue, orders were subdivided in order to support all producers (but in particular those massively producing for the war effort too such as Fiat for instance)Footnote 45 and avoid the introduction of mass production methods in the aviation industry given the risk of increasing unemployment and social unrest.Footnote 46 As to the second issue, the shortages of raw materials undermined any effort to modernize the air force and hit the Reggiane particularly hard. Between July and October 1941, the continuous deficiency of primary supplies convinced the Ministry to reduce the OMR order from 200 to just 110 Re.2001 to cancel the orders stipulated with Breda and Caproni Taliedo and to reduce the order sent to Caproni Predappio to only ten items. Similarly, a few months later, an order for 550 Re.2001 Organizzazione Roma (OR; a model designed for aircraft carriers),Footnote 47 commissioned in April 1942, was soon after reduced and transformed into an order for fifty night fighters, while the Ministry and its engineers were never satisfied and incessantly requested that small modifications be made which, in OMR’s mind “significantly hinder the production rate … If we add to this the contradictory orders coming from the Military authorities and the shortage of engines, the frequent interruptions in the continuity of production are fully understandable.”Footnote 48 Arguments between OMR and the Ministry also concerned the final price of the aircraft, which according to the company had to be raised by 21 percent as a result of the continuous changes requested, soaring raw material prices, and increases due to the necessary overtime work.Footnote 49 The last orders for the Re.2001 were placed in June 1942 (for a total of 130 aircrafts) and in 1943 (for 120 aircrafts), but they were never completed because of developments in the war leading to the armistice signed on September 8, 1943.Footnote 50

The next aircraft in the series to be built was the Re.2002, which Longhi developed closely from the Re.2000 and which undeniably stands as one of the best Italian fighter bombers ever designed. After experiencing the difficulty of procuring the DB 601 engines, Longhi decided to go back to radial engines and chose the Piaggio P. XIX Rc 45. The Italian Air Force purchased a total of 149 Re.2002, and they crewed the fifth squadron of scammers up against the Anglo-American forces during the landings in Sicily.Footnote 51 OMR also built 76 Re.2002 for the Luftwaffe, which flew them in France. However, orders greatly exceeded actual production. Between September 1942 and March 1943 the Ministry of Aeronautics ordered 698 Re.2002 aircraft. By September 8, 1943, only 149 planes had been delivered by OMR to Italy’s airforce, while fifty-three were close to completion. After September 8, the German Command, which now held power over northern Italy, ordered OMR to complete at least eighty-three Re.2002 planes and asked the firm to schedule the building of a further 500 such aircraft.Footnote 52 This new series of planes should have been fitted with star-shaped BMW 801 (1600 hp) engines, but the OMR never fulfilled the order for this new series; on January 7 and 8, 1944, the company’s plant was severely bombed and as a consequence it lost 65 percent of its buildings extending over an area of 146,616 m².Footnote 53

The subsequent models in the series included two unsuccessful prototypes of the Re.2003 (a reconnaissance and survey low-wing, two-seater, single-engine monoplane, whose fuselage was in duraluminum with a monocoque structure), and “the most beautiful fighter” ever produced by the company, the Re.2005 Saggittario (February 1942, see Picture 4). The latter seemed a sure-fire bet: with a fuselage that was much more streamlined than its predecessors and with far better weaponry, a more powerful engine and a landing gear whose main parts retracted by means of external rotation (a novelty because all other models retracted in a backward manner). Equipped with a DB 605 A-I engine, the airplane reached a speed of 678 km/h at 7000 m. and “was undeniably outstanding for its excellent speed and manoeuvrability, good range and powerful armaments. It was even superior to similar models possessed by the leading air-powers of that time”.Footnote 54

Picture 4. The Re. 2005.

However, this superaircraft did not win the ministerial competition, as the Fiat G. 55 and C. 205 were preferred.Footnote 55 Nevertheless, soon thereafter the Ministry had second thoughts and decided to order thirty-six experimental planes and 750 Re.2005 aircraft from OMR, and 1000 Re.2005 from Caproni Aeronautics of Bergamo, from Aerfer of Naples, and from Breda of Milan. The 8th of September 1943 put a stop to all of these ambitious orders, which could not be met due to the late nature of such orders and to shortcomings on the supply side. Just two prototypes and thirty-seven Re.2005s had been built and delivered by then. Finally, only one prototype was ever produced of the last two of Longhi’s models, the Re.2006 and the Re.2007 (see Appendix 1).Footnote 56

It is clear from this brief report that the Italian Royal Air Force was not immediately convinced and did not fully sustain OMR’s efforts to supply Italy with up-to-date fighters. The military forces’ doubts and scarce understanding of technological progress marked the beginning of a stop-and-go order routine that became detrimental. The Administrative Director Belelli summed up the situation in a note to the management on May 4, 1942, which read:

The Reggio factory has made considerable sacrifices for the start-up of aeronautical production. Production has taken place under exceptionally uneconomic conditions due to the continuous vicissitudes of work progress and the relative achievements. Orders that were initially placed were subsequently suspended, reduced in entity, or cancelled altogether, entailing considerable economic losses. The company has made considerable efforts to create a production chain like that of a modern industry, but in practice such a production system could not be implemented due to the continuous reduction in the original orders.Footnote 57

The company was able to acquire advanced technological skills and personnel from other companies and from the United States and to set up a technical training school on its premises together with the most advanced aeronautical workshops. All of this resulted in OMR being at the forefront of the industry; “but this was precisely their Achilles heel as it was the subject of criticism from the Ministry of Aeronautics regarding certain solutions adopted.”Footnote 58 The military experts probably felt jeopardized by the new techniques, and they opposed them in principle, but they also aimed at farming orders out to all the Italian companies involved in the aeronautical cycle.Footnote 59

The Success of Foreign Sales and the Political Constraints

As said at the beginning, many foreign countries were impressed by the Re.2000, and responded with great interest and placed significant orders for this aircraft. On December 27, 1939, an agreement was signed between OMR and the Hungarian War Ministry to supply that country with seventy Re.2000 and to grant permission to the Magyar Aeronautics to manufacture the aircraft under license. Thus, in March 1940 the Magyar Aeronautics Commission visited the workshops in Reggio Emilia in order to better plan the construction of the Re.2000 at the Budapest MAVAG factories. In November of the same year, building plans, equipment, and technicians were sent to Budapest to start production. Even Longhi spent some time at MAVAG (from June 16 to July 10, 1940) to iron out certain production problems. By 1944, 191 Re.2000 (there denominated HEJA) had been built in Hungary under license. Furthermore, in November 1940 a contract was signed by Reggiane to supply the Swedish Air Forces with sixty Falco I (denominated J-20), which being the fastest fighter aircraft in service, was employed to intercept foreign planes caught violating the borders of a neutral Sweden.Footnote 60

The success of the Re.2000 in the foreign market indeed appeared unstoppable, and new contracts were signed with various countries between 1939 and 1941 for the provision of 1250 such planes; however, political factors, the outbreak of war, and the chronic lack of raw materials, prevented these foreign contracts from being fulfilled. In the autumn of 1939, a British committee led by Lord Hardwich and Col. Thornton came to Italy to negotiate the purchase of a large number of a certain fighter plane. After careful inspections of all the Italian factories engaged in this type of construction, the British opted for the purchase of the Re.2000. The visit of this British mission lasted a month and concentrated on two companies, Fiat and Reggiane, and their very best aircrafts. In the end, the British chose the Re.2000 because the Fiat aircraft was “an infinitely inferior model that didn’t bear comparison” with the Re. 2000.”Footnote 61 The English government intended to order 1000 Re.2000, and Gianni Caproni even called the British Embassy to say that he confidently expected the Duce’s ratification of the contracts under negotiation.Footnote 62 In order to celebrate the agreement, Caproni organized a gathering in honor of the English mission headed by the British ambassador in Rome, held at the Chess Club in February 1939. However, during the night Caproni’s hopes were dashed, as Mussolini called him personally to inform him that no contract could be signed with the British for political reasons and that even Hitler had warned him against endorsing such an agreement.

Between 1940 and 1941, Switzerland and Spain each asked for fifty Re.2000 to be supplied, while Yugoslavia requested fifty aircraft plus the production licence, and Finland joined in with an order for 100 planes. However, the Italian government, in view of the scarcity of raw materials these nations could offer in exchange (unlike in the cases of Hungary and Sweden) refused to authorize such orders.Footnote 63

OMR, and the Caproni Group in general, were badly impacted by the Italian government’s decision to severely limit foreign sales, and after Italy’s entry into war, Caproni realized his only chance of increasing production was through contracts with the state, and consequently he concentrated on trying to obtain new orders from the Ministry of Aeronautics and on soliciting General Rodolfo Graziani’s favourable intercession.

Financial Problems

By the end of 1938, OMR’s aeronautical operations represented its most important business, worth 60 million lire, followed by its railway division that had orders worth 35 million lire and its machinery division, whose mills and pasta production machinery each secured orders for 14 million lire.Footnote 64 However, the biggest problem encountered in 1938 was the financial one. Investment in the construction of a modern aeronautical workshop had been very substantial, and this sector was particularly expensive from this point of view. OMR’s debts grew and were exacerbated by the reluctance to grant fresh loans on the part of banks and public financial actors. The market’s growing distrust of OMR was to some degree due precisely to the fact that the company had joined the Caproni group, whose rapid expansion entailed a sharp increase in its financial exposure (at the end of the 1930s the Caproni Group comprised about twenty-six companies, employing more than thirty thousand people and producing about a quarter of Italy’s aircraft and the lion’s share of the sector’s exports).Footnote 65

As OMR told an IMI inspector:

Following the financial difficulties of the Caproni group which arose around April of the current year, a situation of distrust gradually affected the credit enjoyed by the various companies. The last to suffer was the Reggiane, which in recent months has seen all the banks refuse new loans on the state contracts entrusted to it… our financial plan for the next four months foresees new loans for L.31 million while over the same period we will pay off our liabilities on state contracts for the same amount…. That is to say, that to ensure our company’s regular industrial operations we only need to stipulate new loans in an equal amount to the old ones that have expired.Footnote 66

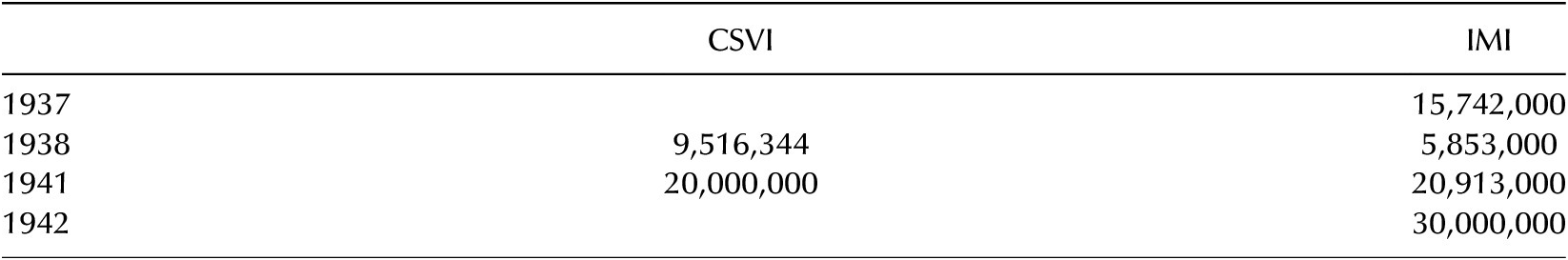

Thus, it was that under pressure from the Bank of Italy, Mussolini appointed General Graziani as head of a newly established Caproni Group Supervisory and Control Committee in 1938. The general expressed his enthusiastic support for the company’s production targets, and the committee supported all funding applications submitted by the Caproni Group. This made it possible to restore trust in the Group on the part of banks and public investors (IMI and CSVI—the Bank of Italy’s financial branch for industry) and to find fresh loans.Footnote 67 Therefore, IMI, which had displayed a certain hesitation in regard to Degola’s requests for help in August 1938, became a fully fledged financier of OMR, together with CSVI. In 1938, of the 30,048,914-lire loan CSVI granted to the Caproni Group, 9,516,344 lire were allocated to OMR, while 5,8 million came from IMI (see Table 1).

Table 1. OMR’s financial exposure vis-à-vis CSVI and IMI

Source: Archivio Storico della Banca d’Italia (ASBIT herinafter), CSVI - Sede principale, pratt. n. 76, fasc. 1 and ASIMI, SM 1486.1 Richiesta di nuovo mutuo 23/12/42.

OMR’s financial exposure to IMI and CSVI (less depreciation) amounted to 23.9 million lire on May 28, 1940.Footnote 68 With Italy’s entry into the war in June 1940, financing policies became more generous, and Graziani urged the CSVI to expand credit to the Caproni Group by 95 million lire (in the end, a sum of 88 million lire was granted), 20 million of which went to OMR, while IMI granted a series of fresh loans during the war years (see Table 1).Footnote 69

Clearly, thanks also to these additional loans and growing orders following the outbreak of the war, the turnover of the Caproni Group’s main companies grew rapidly: OMR ranked second behind Isotta Fraschini as far as total turnover was concerned, which grew from 127 to 566 million lire between 1938 and 1943 (see Table 2).

Table 2. Turnover of the main companies of the Gruppo Caproni 1938–1943

* Only largest affiliated companies: IF, Reggiane, AC, CAB, CEMSA, Aeronautica Sicula, FNA, Caproni Trento, ORLA

Note: L.1=L.1.000.000.

Source: Archivio Provinciale di Trento, Fondo Caproni (APTC). Note personali.

Figure 1 shows the rapid rise in turnover and profit of the OMR company which between 1938 and 1942 also saw orders rise from 213 to 925 million lire, and the workforce increase from 5,210 to 9,000 units.

Figure 1. OMR turnover and profit 1935-1943 (millions of lire).

Source: ASIMI, SM 1714.2 Reggiane Officine Meccaniche SA Milano Pratica 1714 Relazione Marcantonio 22-9-46, ASIMI, ISP 1 Società anonimia “Reggiane” Officine Meccaniche Italiane, ASIMI SM 1486.1 Richiesta di nuovo mutuo 23/12/42.

By 1942, the OMR and part of the Italian aviation production had reached the technological level of the main foreign competitors. The Reggiane Re.2005 followed by Fiat G.55 and Macchi 205V were finally the equivalent of Allied fighters, but only 391 of these models were produced from the spring of 1942 (to the armistice) because increasing shortages of raw materials and labor put an end to the sector’s growth possibilities.Footnote 70

OMR after the War

At the end of the Second World War, the Italian aviation industry disappeared as a result of the peace treaty, which ended aircraft construction in Italy as punishment for its participation in the war, resulting in a long-term crisis of the sector. OMR obtained funding from IMI for restoration operations, and it resumed the production of “traditional products” from the pre-Caproni period, such as railway material, Fiat 666 bodies, and various engineering works. In the words of the IMI inspector pronounced in September 1946:

After Italy’s liberation, aeronautical production was abandoned, while the production of other traditional items was resumed, including, first and foremost, railways and rolling stock, together with the related repair work. The company currently employs 4,500 workers and 650 office employees, but approximately 1,300 workers and 120 employees are excess to current requirements.Footnote 71

OMR had already stipulated loan agreements with IMI amounting to 420 million lire by October 1946; however, in 1947 a new loan application was submitted for a further 1,150 million lire. At this point, the supervisory authorities began to get concerned:

Evidently such a strong increase in loan applications denotes that OMR’s administration is not in control of events and we are concerned about the possible financial consequences of additional financing. Indeed, the company has not been able to implement the established program, ending up making its workers carry out the unnecessary complete renovation of the buildings and thus securing work for a large number of workers, something which was not in the company’s duties and in any case was not the aim of Law 449 governing industrial financing. At the same time the situation of the superfluous workers has worsened further.Footnote 72

Redundancy and financial issues—which according to the IMI inspector were the major problems faced by the companyFootnote 73—became pressing as the constant “turmoil of the workforce was forcing the unstable company into an abyss.”Footnote 74

In the meanwhile, the Caproni Group asked and obtained help also from the Fondo Industria Meccanica (FIM), a special fund set up by the Italian government in 1947 to finance engineering firms needing to invest in reconstruction and modernization. The fund’s achievements proved rather limited in the end: Between 1947 and 1950, the FIM granted loans to thirty-seven companies, said loans amounting to a total of 66 billion lire; but only 23 billion had been reimbursed by recipients by the end of 1950.Footnote 75 The Gruppo Caproni was among those companies unable to pay back its loan, which amounted to 15.4 billion lire, of which the OMR plant had received 1.6 billion lire.Footnote 76 These companies were all taken over by the FIM, which became the actual owner of the Group. The FIM’s shares held in OMR (L. 1,075,000,000) represented 98.35 percent of that company’s total capital.

It was a politically unstable, financially delicate situation for OMR, which in 1950 was still able to obtain 975,000 dollars of Marshall Plan quota loans for the purchase of machinery and plant on the American market.Footnote 77 Yet, on October 5, 1950, the company was occupied by its workers, and production ground to a halt. At this point, the American authorities in Rome began to worry about the loss of Marshall Plan funds, as only seven out of twenty-eight machines had been unloaded at the port of Genoa and installed in the factory. The U.S. machines that remained in Genoa were slowly becoming superfluous and unusable. Landon Thorne of the Economic Cooperation Administration (ECA) office in Rome wrote to the Italian Prime Minister De Gasperi asking him to resolve “this unsatisfactory use of ERP funds, since $69,000 of foundry machinery has not been installed.”Footnote 78

In 1951, a new course of action was taken: On May 22, the FIM requested and obtained the compulsory winding up of OMR, and on October 5, the occupation of the plant ended thanks to the intervention of the FIM, which used its new powers to set up Nuove Reggiane, a new company that took over those plants in good condition, rehired part of the labor force, and began production once again.Footnote 79 The FIM also endowed the Nuove Reggiane with a sum to cover payables to employees.Footnote 80 The new company then collected the ERP shipment that had been left with Genoa customs and equipped the factories with modern American machinery. De Gasperi wrote to Thorne:

The constitution of the Nuove Reggiane has permitted collection of the machinery, albeit with considerable delays. The new company has installed 23 machines out of the 28 purchased, while the remaining 5 are destined for the foundry, but require modifications to the external systems.Footnote 81

In the years that followed, the workforce fell to 1,700 and production centered on “many sectors, including ammunitions, railway construction and repairs, sugar refinery plant and diesel engines.”Footnote 82 From the beginning of the 1950s to 1962, the Nuove Reggiane changed hands from one public owner to another: from the Fim, to Breda Finanziaria, and then to EFIM.Footnote 83

Conclusion

Despite a certain vivacity of production for the civil and military markets, in the 1930s Italian aircraft companies seemed doomed to generalized industrial obsolescence.Footnote 84 The Italian aeronautical industry was falling well behind other such industries in terms of innovative capacity, the modern organization of plants for mass production, and the construction of advanced engines: all, that is, except for OMR.Footnote 85 The architect of this transformation was Gianni Caproni, who bought a company boasting a remarkable industrial tradition from the Italian state and transformed it into an avant-garde aeronautical enterprise. He believed in the possibility of upgrading the company’s factory, and he invested money in this project. The Reggiane’s success story firstly rests on the personality of the new owner, Caproni, who can be added to the list of creative entrepreneurs and contribute to our understating of what the driving forces to success are. He surely had a creative mindset to develop his own revolutionary business ideas in a completely new field but also to recognize the need to embrace new business paths when his own innovating capacities had dried up (turning indeed to the United States, where flight technology was most advanced). Caproni never settled down to run his business “as other people run their businesses,” but he was keen on “carrying out new combinations” and accepting the challenge of new innovations.Footnote 86 He had a vision as an entrepreneur, a unique picture of what he wanted his venture to become, but he also had the capacity to take calculated risks and face the unexpected. When he realized that there were no light alloys on the Italian market to build full-metal fighters, Caproni called Montecatini to urge said company to produce chitonal, an autarchic substitute. He relied on massive investments, but he had a big group and the financial support from the major financial institutions.

Knowledge transfer was the other component of the Reggiane’s success story. New technological skills were imported thanks to specific missions sent to the United States to learn from the aircraft companies employing cutting-edge technology and the mobility and migration of knowledgeable experts, such as the Italian-American engineer Roberto Longhi. In the first case, Caproni and the management team in Reggiane decided to send a study mission to visit American aircraft producers with the aim of transforming the engineering factory into an aircraft producer on the technological frontier. Quite interestingly, the United States was not worried about technological transfer in strategic industries to a fascist country close to Nazi Germany. As seen, according to the mission report “we rapidly obtained the visit permit from the U.S. War Department.” In the second case, regarding the attraction of human knowledge transfer, money did the trick. Caproni chose to hire an experienced Italian-American aeronautical engineer (with innovative ideas and designs), accepting without hesitation the costly contractual terms proposed.

Also, knowledge transfer was possible because the receiving company took the right steps when transferring knowledge from the source context to the new context. When Caproni bought the Reggiane to transform it into an aircraft factory, at first expert workers were hired from other firms, then a special school to prepare the workforce for the aviation sector was set up, and finally these specialized workers ended up being paid twice as much as the regular workforce. Therefore, the transfer process generated human capital ready to absorb new technical improvements, with skills and expertise that soon proved one of the most important variables in the picture. In the case of Reggiane the conveyance of knowledge worked also because the recipient workers and staff respected and believed in the competence of the new engineer and manager, Roberto Longhi. Trust between all individuals involved in the knowledge transfer process facilitated the flow of information, while the new director’s organizational capacity allowed the swift transfer of the new technology into the plant’s production process.

At the end of the 1930s, the Reggiane represented an exception in Italy’s close and autarkic panorama (it should not be forgotten that Italy at the time was under a dictatorship and was trying to implement its unfeasible autarkic vision of self-sustainable industrial production), it invested in American machinery and human capital inputs that became a rare and valuable asset and the main source of competitive advantage. Roberto Longhi revolutionized aeronautical production and made American-style premium fighter aircraft, namely his Re.2000 and successive models, which became the best and most innovative fighters ever produced in Italy. OMR changed radically from being a railway supplies producer to become the most modern aeronautical factory in Italy. Observers at the time praised the Reggiane aviation workshops’ design, layout, and predisposition for chain production as among the most advanced in Europe. However, despite the undisputable primacy of the Re.2000 and subsequent models (which impressed foreign missions as well), total production inclusive of prototypes and items produced abroad (under license) satisfied just one-sixth of total orders, as shown in Appendix 1. There were two problems here. The first problem was a political one: Despite Caproni’s efforts, Mussolini had long before chosen Italy’s ally and consequently forbade the sale of Italian fighter planes to the nation’s future enemies. An order for a total of 1250 Re.2000 fighters was lost for political reasons. Secondly, the present study confirms the idea that life is never easy for radical innovators, and the technological breakthroughs in aeronautical construction, triggered by innovative advances in the fields of design, material structure, and aerodynamics, were not accepted by the military and political leaders of the time. As we have seen, due to the Ministry’s traditional mentality and scant understanding of the revolutionary solutions adopted for the construction of the Re.2000 and subsequent models, the orders were constantly being amended and downsized. Also, as said, the Military Administration parceled out orders among each aircraft producer in order to keep all factories alive and discourage the introduction of mass production in the aircraft sector to protect employment.

Notwithstanding erratic internal demand, raw material supply failures, and financial and political problems, the Re.2000 series without question led the field in terms of speed, range, minimum wing load, take-off space requirements, evolutionary qualities, and ease of take off and landing. Caproni’s entrepreneurial capabilities, the speed with which OMR accepted and introduced production changes and technological innovations in a completely new field, clearly account for what was an otherwise almost inexplicable international business success story in such a competitive sector. Finally, it should not be forgotten that the wealth of knowledge and the passion inherited and transmitted to the Emilia area by the pioneering activities of OMR were the driving forces behind the entrepreneurial challenge that was to give rise to the mechanics and mechatronics district after the Second World War.

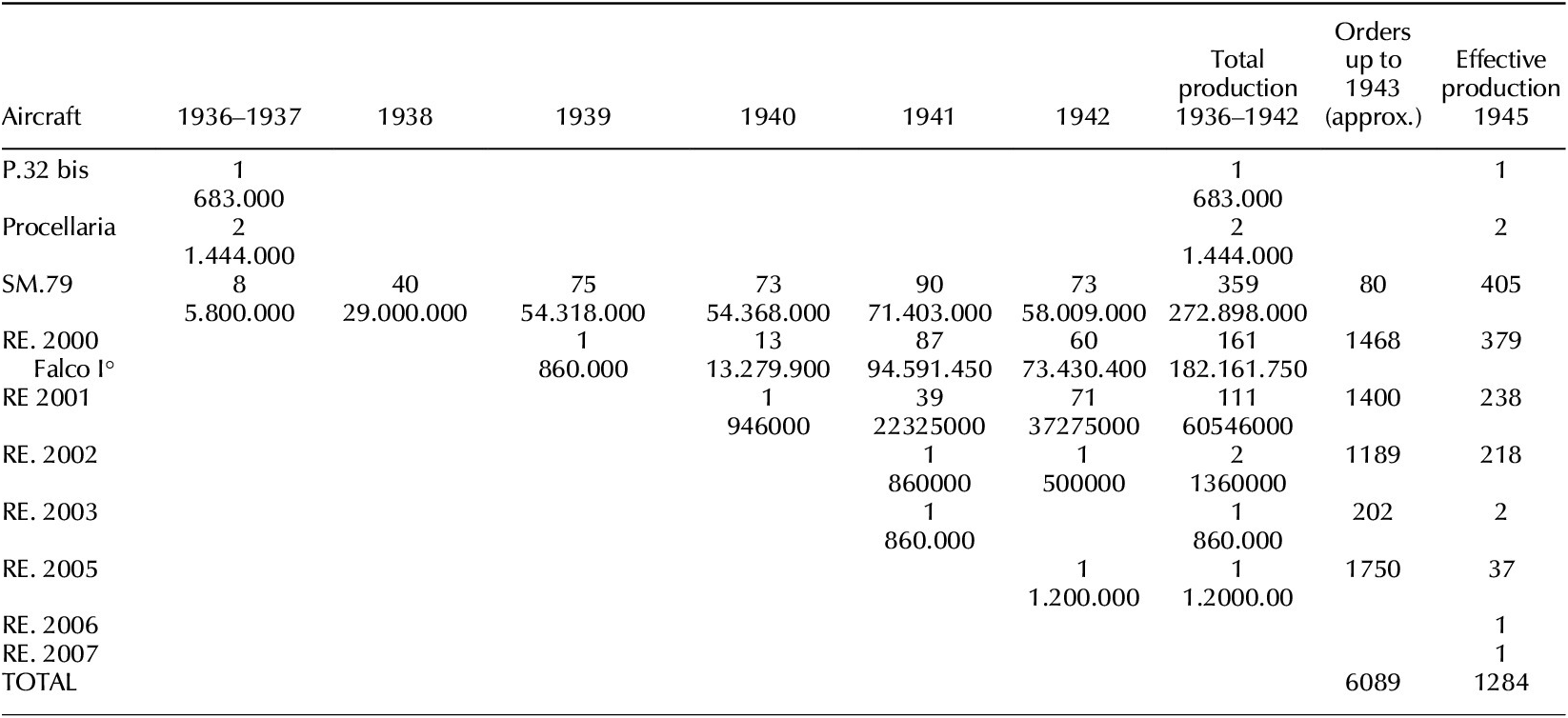

Appendix 1

Table A1. Reggiane’s aircraft production in numbers and lire 1936–1945 (orders and effective production)

Source: ARER, Produzione velivoli fino al 31 agosto 1942, Previsione produzione velivoli 5 agosto 1942 e Produzione ditte raggruppamento Caproni 28 dicembre 1942; ARER, Fondo Apostolo, Velivoli Caproni-Reggiane costruiti dal 1936 al 1945.