Article contents

Drag reduction by a flexible hairy coating

Published online by Cambridge University Press: 01 August 2022

Abstract

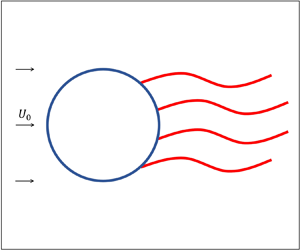

The hydrodynamic mechanism of drag reduction by a flexible hairy coating was explored using the penalty immersed boundary method. A two-dimensional flexible hairy coating is constituted by multiple flexible filaments. A simulation of a cylinder without a hairy coating at a Reynolds number of 100 was also performed for comparison. The results of the simulations show good agreement with the experimental data by Niu & Hu (Phys. Fluids, vol. 23, 2011, 101701), where maximum drag reduction of 22% was attained at a particular length, bending rigidity, coating density and coating angle of the hairy coating. The hydrodynamic mechanism of drag reduction was characterized in terms of the wake pattern, shape deformation and kinetic energy of the hairy coating. The effect of a non-uniform bending rigidity of the hairy coating on drag reduction was explored. A stable streamline shape of the hairy coating was found to delay the vortex formation and stabilize the recirculation zone, resulting in decreased form drag. Active flapping of the hairy coating with enhanced vortex shedding is adverse to drag reduction. A hairy coating with a stiff base and flexible trailing edge is beneficial to maintaining a stable shape.

JFM classification

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2022. Published by Cambridge University Press

References

- 11

- Cited by