Published online by Cambridge University Press: 16 August 2022

Based on experimental data acquired with particle image velocimetry, we examine turbulent boundary layers that are subjected to an abrupt change in wall roughness in the streamwise direction. Three different sandpapers (P24, P36 and P60) together with a smooth wall are used to form a number of different surface transition cases, including both R  $\rightarrow$ S (where upstream surface is rough and second surface is either smooth or smoother compared with the upstream surface) and S

$\rightarrow$ S (where upstream surface is rough and second surface is either smooth or smoother compared with the upstream surface) and S  $\rightarrow$ R (where upstream surface is smoother compared with the downstream surface; both surfaces are rough). This enables us to investigate the effect of the surface transition strength (

$\rightarrow$ R (where upstream surface is smoother compared with the downstream surface; both surfaces are rough). This enables us to investigate the effect of the surface transition strength ( $M = \ln [y_{02}/y_{01}]$, where

$M = \ln [y_{02}/y_{01}]$, where  $y_{01}$ and

$y_{01}$ and  $y_{02}$ are the roughness lengths of the upstream and downstream surfaces, respectively) on the growth of the internal boundary layer (IBL) and the corresponding flow structure. The results show that for each surface transition group (i.e. R

$y_{02}$ are the roughness lengths of the upstream and downstream surfaces, respectively) on the growth of the internal boundary layer (IBL) and the corresponding flow structure. The results show that for each surface transition group (i.e. R  $\rightarrow$ S and S

$\rightarrow$ S and S  $\rightarrow$ R), the thickness of the IBLs is proportional to the strength of the surface transition, and that the IBLs are thicker for the S

$\rightarrow$ R), the thickness of the IBLs is proportional to the strength of the surface transition, and that the IBLs are thicker for the S  $\rightarrow$ R cases compared with their R

$\rightarrow$ R cases compared with their R  $\rightarrow$ S counterparts for similar

$\rightarrow$ S counterparts for similar  $|M|$, when normalised by the initial boundary layer thickness (

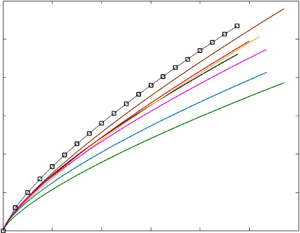

$|M|$, when normalised by the initial boundary layer thickness ( $\delta _0$). The results also show that the growth rates of the IBLs could be represented by a power law, consistent with the previous studies. However, despite a wide range of scatter in the literature for the power-law exponent, an average value of

$\delta _0$). The results also show that the growth rates of the IBLs could be represented by a power law, consistent with the previous studies. However, despite a wide range of scatter in the literature for the power-law exponent, an average value of  $0.75$ (varies between

$0.75$ (varies between  $0.71$ and

$0.71$ and  $0.8$ with no clear trend) is obtained in the present study considering all the surface transition cases. The pre-factor for the power-law fit, on the other hand, is found to be related to the strength of the surface transition. In addition to the variations in the velocity defect and diagnostic plots with the growth of the IBLs, sweep and ejection events appear to differ significantly (depending on the type of the step change). Two-point spatial correlations, moreover, show that the structure is more elongated in the wall-normal and streamwise directions, as the flow accelerates over the downstream surface (i.e. R

$0.8$ with no clear trend) is obtained in the present study considering all the surface transition cases. The pre-factor for the power-law fit, on the other hand, is found to be related to the strength of the surface transition. In addition to the variations in the velocity defect and diagnostic plots with the growth of the IBLs, sweep and ejection events appear to differ significantly (depending on the type of the step change). Two-point spatial correlations, moreover, show that the structure is more elongated in the wall-normal and streamwise directions, as the flow accelerates over the downstream surface (i.e. R  $\rightarrow$ S cases). For the reverse transition cases (i.e. S

$\rightarrow$ S cases). For the reverse transition cases (i.e. S  $\rightarrow$ R, where the flow decelerates over the downstream rougher surface), however, the correlation coefficients shrink in size in both directions.

$\rightarrow$ R, where the flow decelerates over the downstream rougher surface), however, the correlation coefficients shrink in size in both directions.