1. Introduction

Granular materials are abundant in the natural world, in industrial processes and in our everyday lives. Indeed, after fluids, granular materials are the most common material used by mankind in a wide range of processes in the bulk chemical, civil, pharmaceutical, mining, agricultural and food industries (Merrow Reference Merrow1984; Bates Reference Bates1997; Shinbrot & Muzzio Reference Shinbrot and Muzzio2000; Richard et al. Reference Richard, Nicodemi, Delannay, Ribiere and Bideau2005). Despite their widespread use, our ability to model their behaviour using continuum theories lags far behind that of computational fluid dynamics for liquids. This is because the rheology of granular flows is more complex, and not yet fully understood (GDR MiDi 2004; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2006), with aggregates of grains simultaneously behaving as a solid, a liquid or a gas in disparate spatially and temporally evolving regions. Physicists and engineers have therefore relied heavily on discrete element method/discrete particle model (DEM/DPM) numerical simulations to understand particle flow behaviour and optimize the design of industrial systems (Cundall & Strack Reference Cundall and Strack1979; Silbert et al. Reference Silbert, Ertaş, Grest, Halsey, Levine and Plimpton2001; Cleary & Sawley Reference Cleary and Sawley2002; GDR MiDi 2004; da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005; Zhu et al. Reference Zhu, Zhou, Yang and Yu2008; Ketterhagen, Ende & Hancock Reference Ketterhagen, Ende and Hancock2009; Chialvo, Sun & Sundaresan Reference Chialvo, Sun and Sundaresan2012; Weinhart et al. Reference Weinhart, Hartkamp, Thornton and Luding2013; Vo et al. Reference Vo, Nezamabadi, Mutabaruka, Delenne and Radjai2020). However, as the number of particles increases, DEM/DPM simulations rapidly become prohibitively computationally expensive, which restricts their use to small systems, with usually less than a few million particles. There is therefore a pressing need to develop reliable and efficient continuum methods, that do not need to resolve each individual particle and particle collision.

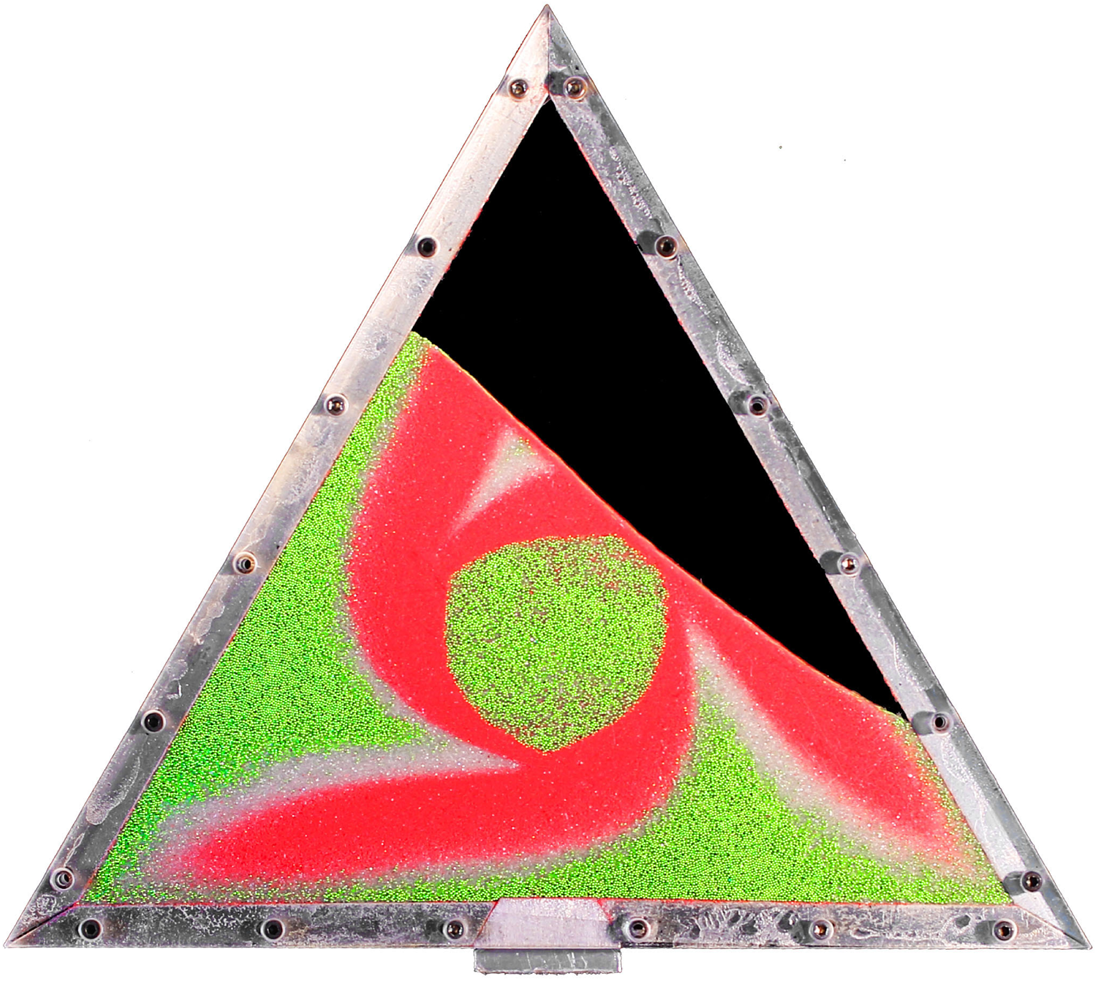

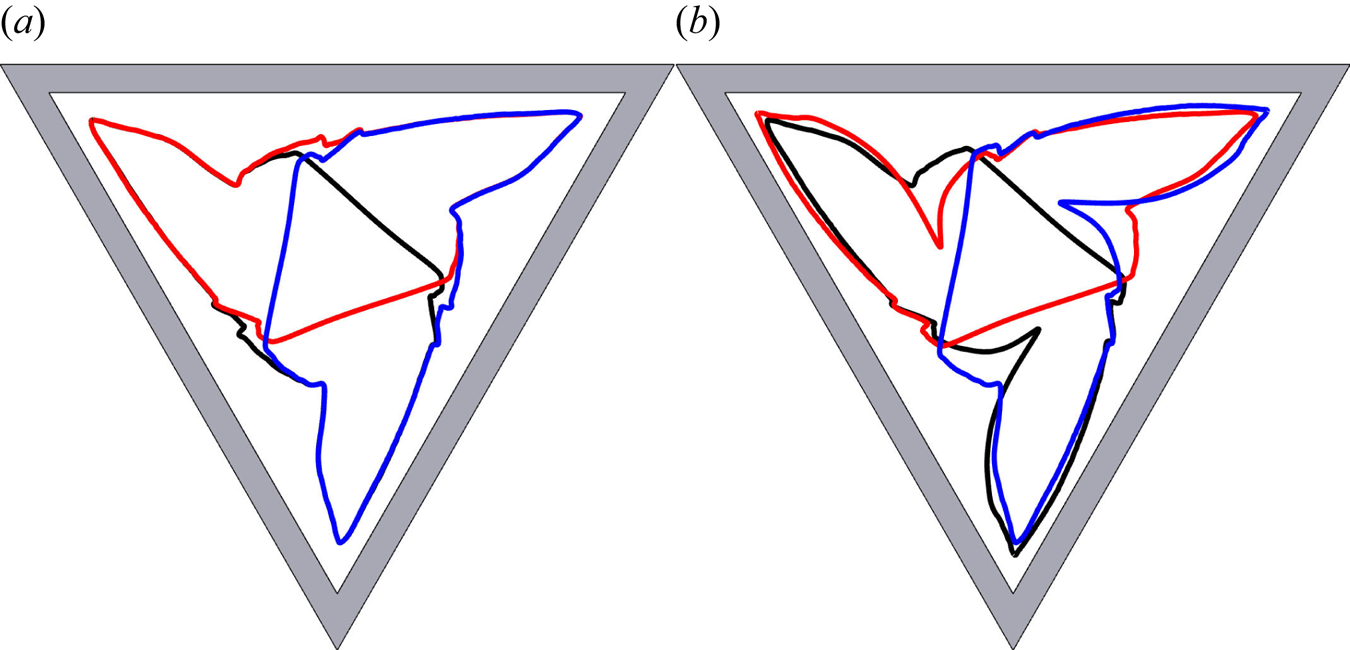

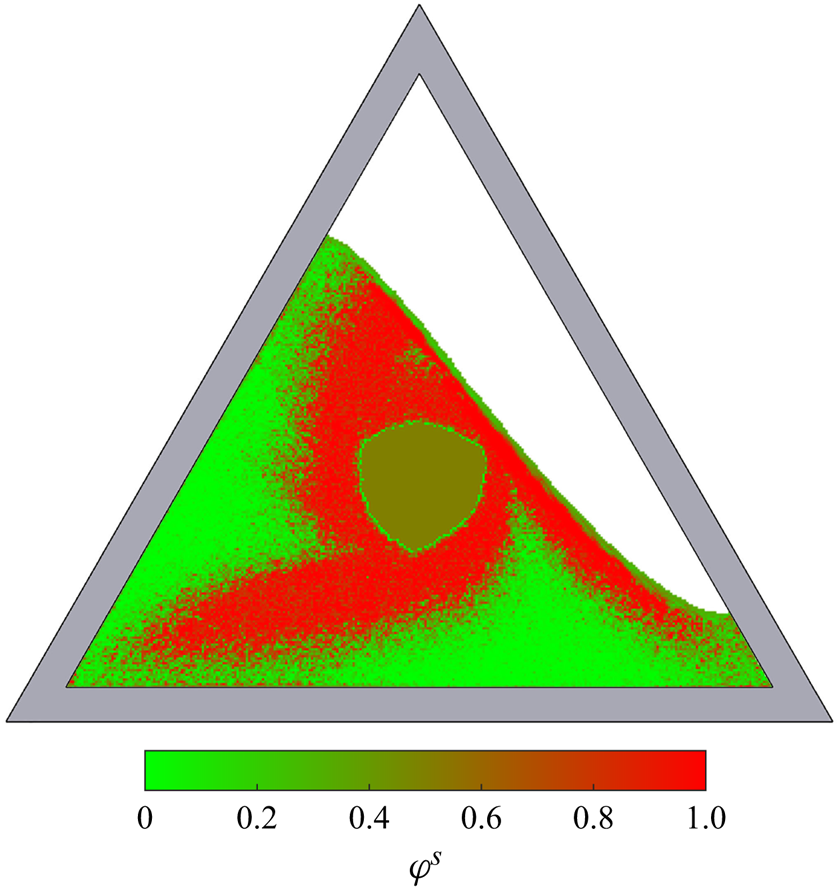

As a prototypical example of a non-trivial granular flow, this paper focuses on the mixing and segregation of particles in a partially filled thin triangular rotating drum (Mounty Reference Mounty2007). Similar flows in elliptical and square drums were first investigated by Hill et al. (Reference Hill, Khakhar, Gilchrist, McCarthy and Ottino1999) and Ottino & Khakhar (Reference Ottino and Khakhar2000), who showed experimentally that the combination of flow and segregation produced beautiful quasi-periodic patterns. An example of the pattern formed in a triangular drum, 70 % filled with a mixture of large green, medium white and small red glass beads, is shown in figure 1. The full time-dependent evolution can be seen in supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.1022. Two arms of small and medium particles rapidly form, which radiate out from the central core towards the drum corners, forming a striking pattern. Experiments in square, pentagonal and hexagonal drums (not shown) also produce a series of arms, but with progressively reduced length as the number of sides is increased. This paper therefore focuses exclusively on the triangular drum, which has the longest arms.

Figure 1. Image of a triangular rotating drum experiment 70 % filled with large green (600–800 ![]() $\mathrm {\mu }$m), medium white (400–500

$\mathrm {\mu }$m), medium white (400–500 ![]() $\mathrm {\mu }$m) and small red (125–160

$\mathrm {\mu }$m) and small red (125–160 ![]() $\mathrm {\mu }$m) glass beads in a 30:40:30 mix. The drum rotates clockwise with a rotation rate of

$\mathrm {\mu }$m) glass beads in a 30:40:30 mix. The drum rotates clockwise with a rotation rate of ![]() $\varOmega =-{\rm \pi} /48$ rad s

$\varOmega =-{\rm \pi} /48$ rad s![]() $^{-1}$. Most of the grains are in solid-body rotation but a thin avalanche develops at the free surface, within which all the segregation occurs. After just two revolutions this produces a stunning quasi-periodic pattern of small- and medium-particle rich arms radiating towards the corners of the drum that are surrounded by large grains. There is also a central undisturbed core, which just rotates with the drum. Supplementary movie 1 shows the full time-dependent evolution.

$^{-1}$. Most of the grains are in solid-body rotation but a thin avalanche develops at the free surface, within which all the segregation occurs. After just two revolutions this produces a stunning quasi-periodic pattern of small- and medium-particle rich arms radiating towards the corners of the drum that are surrounded by large grains. There is also a central undisturbed core, which just rotates with the drum. Supplementary movie 1 shows the full time-dependent evolution.

As the drum rotates, most of the grains are in solid-body rotation, but a thin avalanche forms above a critical free-surface angle and transports grains rapidly downslope. Grains in the avalanche are progressively deposited along its lower reach, and are slowly rotated (with the drum) back up to where they re-enter the avalanche along its upper reach. The flow is akin to that formed in the rolling regime of a circular rotating drum, where a steady-state avalanche can form (Henein, Brimacombe & Watkinson Reference Henein, Brimacombe and Watkinson1983; Rajchenbach Reference Rajchenbach1990; Metcalfe et al. Reference Metcalfe, Shinbrot, McCarthy and Ottino1995; Gray & Hutter Reference Gray and Hutter1997; Gray Reference Gray2001). However, unlike a circular drum, the geometrical shape occupied by the grains constantly changes as the triangular drum rotates, which precludes the formation of a steady state. As a result, the free-surface position as well as the maximum avalanche depth and length are functions of time. Hill et al. (Reference Hill, Khakhar, Gilchrist, McCarthy and Ottino1999) and Ottino & Khakhar (Reference Ottino and Khakhar2000) showed that for monodisperse particles rotating in elliptical and square drums, the resulting flow field leads to chaotic advection of tracer particles. A similar result holds for triangular drums (Mounty Reference Mounty2007). Moreover, if the drum is more than half full, then a central core of grains can form that are never entrained into the avalanche and essentially just rotate with the drum (although there is some very slow creep, Socie et al. Reference Socie, Umbanhowar, Lueptow, Jain and Ottino2005). This corresponds to the central green region in figure 1.

Particle-size segregation adds an important ordering mechanism on top of these deceptively simple chaotic flows. Particles in the slightly dilated rapidly shearing thin surface avalanche are able to segregate by size, with the largest grains being pushed towards the surface by force imbalances and the small grains percolating down to the base under the action of gravity (Gray & Ancey Reference Gray and Ancey2011; Gray Reference Gray2018; Trewhela, Ancey & Gray Reference Trewhela, Ancey and Gray2021). This leads to the development of an inversely graded particle-size distribution, with the largest grains concentrated at the surface and the smallest ones at the base. In the lower reach of the avalanche, particles are continuously and progressively deposited into the underlying solid rotating body. Since the smallest particles are at the base of the avalanche, they are deposited first, closer to the centre of the drum, while the largest particles at the surface of the avalanches are deposited last, closest to the drum wall.

In a circular rotating drum the particle-size segregation leads to the development of a radial particle-size distribution with the smallest particles concentrated in a ring around the central core and the largest grains in another ring adjacent to the drum wall (Gray & Hutter Reference Gray and Hutter1997; Gray & Ancey Reference Gray and Ancey2011). In the triangular rotating drum the particle-size distribution is considerably more complicated, but broadly speaking the largest grains are still concentrated next to the drum wall and the smallest ones are closest to the central core. However, the combination of particle-size segregation and the complex underlying bulk flow allows a pattern to develop, with the small and medium sized particles forming arms that are surrounded by large particles. The arms start from a position adjacent to the central core, and radiate out with a clockwise rotation to point towards the corners of the drum. This pattern forms after only two drum revolutions and is quasi-periodic, never truly settling down, but repeating in a closely similar way.

Partially filled non-circular rotating drums provide a simple example of complex granular flow with spatially and temporally evolving solid-like and liquid-like regions. Accurately modelling such flows with continuum theories is still a challenge. Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) developed a fully coupled theory capable of modelling both the bulk flow and the particle-size segregation. The theory is based on the incompressible ![]() $\mu (I)$ rheology for granular flows, in which the friction

$\mu (I)$ rheology for granular flows, in which the friction ![]() $\mu$ is a function of the non-dimensional inertial number

$\mu$ is a function of the non-dimensional inertial number ![]() $I$ (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006). Rather than using the classical

$I$ (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006). Rather than using the classical ![]() $\mu (I)$ curve, Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) use a modified functional form that introduces a creep state at low inertial numbers and asymptotes to a linear dependence at high inertial numbers (Barker & Gray Reference Barker and Gray2017). This partially regularized form of the theory ensures that it is mathematically well-posed over a much wider range of inertial numbers than the original theory (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015).

$\mu (I)$ curve, Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) use a modified functional form that introduces a creep state at low inertial numbers and asymptotes to a linear dependence at high inertial numbers (Barker & Gray Reference Barker and Gray2017). This partially regularized form of the theory ensures that it is mathematically well-posed over a much wider range of inertial numbers than the original theory (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015).

The inertial number ![]() $I=\dot \gamma d/(p/\rho _*)^{1/2}$, where

$I=\dot \gamma d/(p/\rho _*)^{1/2}$, where ![]() $\dot \gamma$ is the shear rate,

$\dot \gamma$ is the shear rate, ![]() $d$ is the particle diameter,

$d$ is the particle diameter, ![]() $p$ is the pressure and

$p$ is the pressure and ![]() $\rho _*$ is the intrinsic density of the grains. The fact that the rheology is locally particle-size dependent, is profound. It implies that, in general, the local flow behaviour is dependent on the evolving particle-size distribution. Modelling particle-size segregation patterns in rotating drums is therefore not necessarily just a matter of developing a theory for a monodisperse bulk flow (or parameterizing the velocity and pressure fields using the results of DEM/DPM simulations), and then solving for the particle-size segregation. In general, it is necessary to consider the feedback that the particle-size distribution has on the bulk flow dynamics. In some flows the feedback can have a significant effect, such as in segregation-induced fingering instabilities, bulbous flow fronts, stratification patterns and petal formation in cylindrical drums (Williams Reference Williams1968; Gray & Hutter Reference Gray and Hutter1997; Makse et al. Reference Makse, Havlin, King and Stanley1997; Pouliquen, Delour & Savage Reference Pouliquen, Delour and Savage1997; Pouliquen & Vallance Reference Pouliquen and Vallance1999; Zuriguel et al. Reference Zuriguel, Gray, Peixinho and Mullin2006; Gray & Ancey Reference Gray and Ancey2009; Woodhouse et al. Reference Woodhouse, Thornton, Johnson, Kokelaar and Gray2012; Baker, Johnson & Gray Reference Baker, Johnson and Gray2016b; Denissen et al. Reference Denissen, Weinhart, Te Voortwis, Luding, Gray and Thornton2019; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021). In other flows, the feedback can be more subtle, and prescribed fields may be sufficient to capture the main features of the segregation as well as the bulk dynamics (e.g. Wiederseiner et al. Reference Wiederseiner, Andreini, Epely-Chauvin, Moser, Monnereau, Gray and Ancey2011; Schlick et al. Reference Schlick, Fan, Umbanhowar, Ottino and Lueptow2015; Deng et al. Reference Deng, Fan, Theuerkauf, Jacob, Umbanhowar and Lueptow2020). The problem is that there is no way of knowing a priori whether the feedback in a particular flow will be significant or not.

$\rho _*$ is the intrinsic density of the grains. The fact that the rheology is locally particle-size dependent, is profound. It implies that, in general, the local flow behaviour is dependent on the evolving particle-size distribution. Modelling particle-size segregation patterns in rotating drums is therefore not necessarily just a matter of developing a theory for a monodisperse bulk flow (or parameterizing the velocity and pressure fields using the results of DEM/DPM simulations), and then solving for the particle-size segregation. In general, it is necessary to consider the feedback that the particle-size distribution has on the bulk flow dynamics. In some flows the feedback can have a significant effect, such as in segregation-induced fingering instabilities, bulbous flow fronts, stratification patterns and petal formation in cylindrical drums (Williams Reference Williams1968; Gray & Hutter Reference Gray and Hutter1997; Makse et al. Reference Makse, Havlin, King and Stanley1997; Pouliquen, Delour & Savage Reference Pouliquen, Delour and Savage1997; Pouliquen & Vallance Reference Pouliquen and Vallance1999; Zuriguel et al. Reference Zuriguel, Gray, Peixinho and Mullin2006; Gray & Ancey Reference Gray and Ancey2009; Woodhouse et al. Reference Woodhouse, Thornton, Johnson, Kokelaar and Gray2012; Baker, Johnson & Gray Reference Baker, Johnson and Gray2016b; Denissen et al. Reference Denissen, Weinhart, Te Voortwis, Luding, Gray and Thornton2019; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021). In other flows, the feedback can be more subtle, and prescribed fields may be sufficient to capture the main features of the segregation as well as the bulk dynamics (e.g. Wiederseiner et al. Reference Wiederseiner, Andreini, Epely-Chauvin, Moser, Monnereau, Gray and Ancey2011; Schlick et al. Reference Schlick, Fan, Umbanhowar, Ottino and Lueptow2015; Deng et al. Reference Deng, Fan, Theuerkauf, Jacob, Umbanhowar and Lueptow2020). The problem is that there is no way of knowing a priori whether the feedback in a particular flow will be significant or not.

In order to take account of segregation-induced feedback on the bulk flow, this paper adopts the fully coupled framework developed by Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021). Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) showed that this theory was able to capture the qualitative features of the segregation patterns observed in the thin square rotating drum experiments of Hill et al. (Reference Hill, Khakhar, Gilchrist, McCarthy and Ottino1999), but it over predicted the avalanche depth and under predicted its speed. The transparent front and back sidewalls (which allow observation of the patterns) impose a significant frictional force on the flow (Taberlet et al. Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2005). In particular, Jop et al. (Reference Jop, Forterre and Pouliquen2005) showed that sidewalls generate granular flows that are thinner and faster than those in wider channels. In order to make quantitative comparisons between the theory and experiments it is therefore necessary to include these sidewall friction effects into the general theory. This paper therefore makes careful quantitative comparisons between a fully coupled theory, which includes sidewall friction, and experiments in a thin triangular rotating drum.

The paper is structured as follows: In § 2 the governing equations are introduced and generalized to account for sidewall friction, and § 3 summarizes the numerical method. This is used in § 4 to compare simulations with experiments performed in a 70 % filled triangular rotating drum with a 50:50 bidisperse mixture of large and small particles. The effect of the sidewalls is quantified in § 5 by comparing these results with equivalent simulations performed in the absence of sidewall friction. Sections 6 and 7 study the effect of changing the fill level and mixture composition, and § 8 compares tridisperse simulations to experiments.

2. Governing equations

2.1. The partially regularized  $\mu (I)$ rheology

$\mu (I)$ rheology

Consider a body of granular material containing particles of differing sizes, shapes and frictional properties, but with a constant intrinsic grain density ![]() $\rho _*$. The solids volume fraction

$\rho _*$. The solids volume fraction ![]() $\varPhi$ is also assumed to be constant, so that the bulk density

$\varPhi$ is also assumed to be constant, so that the bulk density ![]() $\rho = \varPhi \rho _*$ is constant. Mass balance then implies that the bulk flow field

$\rho = \varPhi \rho _*$ is constant. Mass balance then implies that the bulk flow field ![]() $\boldsymbol {u}$ is incompressible,

$\boldsymbol {u}$ is incompressible,

where ![]() $\boldsymbol {\nabla }$ is the gradient operator and

$\boldsymbol {\nabla }$ is the gradient operator and ![]() $\boldsymbol {\cdot }$ is the dot product. Although shear and gravity-driven segregation relies on the formation of void spaces inside a flowing mixture, the bulk solids volume fraction in granular avalanches has been shown to remain approximately constant, and incompressibility is therefore a reasonable assumption (Tripathi & Khakhar Reference Tripathi and Khakhar2011). The momentum balance is

$\boldsymbol {\cdot }$ is the dot product. Although shear and gravity-driven segregation relies on the formation of void spaces inside a flowing mixture, the bulk solids volume fraction in granular avalanches has been shown to remain approximately constant, and incompressibility is therefore a reasonable assumption (Tripathi & Khakhar Reference Tripathi and Khakhar2011). The momentum balance is

where ![]() $p$ is the pressure,

$p$ is the pressure, ![]() $\boldsymbol{D}=\boldsymbol{\nabla u}+\boldsymbol{\nabla u}^T$ is the strain rate and

$\boldsymbol{D}=\boldsymbol{\nabla u}+\boldsymbol{\nabla u}^T$ is the strain rate and ![]() $\boldsymbol {g}$ is the constant gravitational acceleration vector. The

$\boldsymbol {g}$ is the constant gravitational acceleration vector. The ![]() $\mu (I)$ rheology (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006) relates the deviatoric stress to the strain-rate tensor

$\mu (I)$ rheology (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006) relates the deviatoric stress to the strain-rate tensor ![]() $\boldsymbol {D}$ through a granular viscosity

$\boldsymbol {D}$ through a granular viscosity

where the second invariant of the strain-rate tensor is

In terms of this second invariant, the inertial number becomes

where ![]() $d$ is the grain diameter. The

$d$ is the grain diameter. The ![]() $\mu (I)$ rheology is an empirical law that was formulated using dimensional analysis alongside evidence from DEM/DPM simulations and experiments across a range of steady-state monodisperse flow geometries (GDR MiDi 2004). Jop et al. (Reference Jop, Forterre and Pouliquen2005) derived the classical functional form

$\mu (I)$ rheology is an empirical law that was formulated using dimensional analysis alongside evidence from DEM/DPM simulations and experiments across a range of steady-state monodisperse flow geometries (GDR MiDi 2004). Jop et al. (Reference Jop, Forterre and Pouliquen2005) derived the classical functional form

from the basal friction measurements of Pouliquen & Forterre (Reference Pouliquen and Forterre2002). This starts at the static friction ![]() $\mu _s$ at

$\mu _s$ at ![]() $I=0$ and asymptotes to the dynamic friction

$I=0$ and asymptotes to the dynamic friction ![]() $\mu _d$ for large inertial numbers. The range of inertial numbers over which this transition occurs is controlled by the parameter

$\mu _d$ for large inertial numbers. The range of inertial numbers over which this transition occurs is controlled by the parameter ![]() $I_0$. Barker et al. (Reference Barker, Schaeffer, Bohorquez and Gray2015) found that this formulation was well-posed for inertial numbers in the range

$I_0$. Barker et al. (Reference Barker, Schaeffer, Bohorquez and Gray2015) found that this formulation was well-posed for inertial numbers in the range ![]() $[I_1^N,I_2^N]$ provided that the difference

$[I_1^N,I_2^N]$ provided that the difference ![]() $\mu _d-\mu _s$ was sufficiently large. The lower and upper neutral stability limits

$\mu _d-\mu _s$ was sufficiently large. The lower and upper neutral stability limits ![]() $I_1^N$ and

$I_1^N$ and ![]() $I_2^N$ are found by substituting (2.6) into equation (3.9) of Barker & Gray (Reference Barker and Gray2017) and determining the values of

$I_2^N$ are found by substituting (2.6) into equation (3.9) of Barker & Gray (Reference Barker and Gray2017) and determining the values of ![]() $I$ for which the condition

$I$ for which the condition ![]() $C=0$. When the inertial number is too low (

$C=0$. When the inertial number is too low (![]() $I< I_1^N$) or too high (

$I< I_1^N$) or too high (![]() $I>I_2^N$), the system leads to unbounded growth of small perturbations (ill-posedness) in the high wavenumber limit. This leads to grid-dependent results in numerical simulations (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015; Barker & Gray Reference Barker and Gray2017; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017), and indicates that important physics is missing in the model.

$I>I_2^N$), the system leads to unbounded growth of small perturbations (ill-posedness) in the high wavenumber limit. This leads to grid-dependent results in numerical simulations (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015; Barker & Gray Reference Barker and Gray2017; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017), and indicates that important physics is missing in the model.

The issue of ill-posed behaviour can be resolved by the inclusion of higher gradients (Goddard & Lee Reference Goddard and Lee2017), non-locality (Kamrin & Koval Reference Kamrin and Koval2012; Kamrin Reference Kamrin2019) or compressibility (Barker et al. Reference Barker, Schaeffer, Shearer and Gray2017; Heyman et al. Reference Heyman, Delannay, Tabuteau and Valance2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019), but these all add further complexity to the equations. A simple, but practical, approach that retains the structure of the incompressible Navier–Stokes equations (2.1)–(2.2), is to modify the shape of the ![]() $\mu (I)$ curve to increase the theory's range of well-posedness. In the small inertial number limit, Barker & Gray (Reference Barker and Gray2017) solved for the boundary between well- and ill-posed regions in parameter space to motivate the alternative

$\mu (I)$ curve to increase the theory's range of well-posedness. In the small inertial number limit, Barker & Gray (Reference Barker and Gray2017) solved for the boundary between well- and ill-posed regions in parameter space to motivate the alternative ![]() $\mu (I)$ function,

$\mu (I)$ function,

\begin{equation} \mu(I) = \begin{cases} \displaystyle \sqrt{\frac{\alpha}{\log\left(\dfrac{A}{I}\right)}} & \text{for } I \leq I_1^N, \\ \displaystyle \frac{\mu_{s} I_{0}+\mu_{d} I+\mu_{\infty} I^2}{I_{0}+I} & \text{for } I > I_1^N, \end{cases} \end{equation}

\begin{equation} \mu(I) = \begin{cases} \displaystyle \sqrt{\frac{\alpha}{\log\left(\dfrac{A}{I}\right)}} & \text{for } I \leq I_1^N, \\ \displaystyle \frac{\mu_{s} I_{0}+\mu_{d} I+\mu_{\infty} I^2}{I_{0}+I} & \text{for } I > I_1^N, \end{cases} \end{equation}

where ![]() $\alpha \lesssim 2$ ensures that the lower branch is well-posed for

$\alpha \lesssim 2$ ensures that the lower branch is well-posed for ![]() $I\in [0,I_1^N]$,

$I\in [0,I_1^N]$, ![]() $\mu _{\infty }$ is a new material constant and the constant

$\mu _{\infty }$ is a new material constant and the constant

ensures that the function (2.7) is continuous at ![]() $I=I_1^N$. The function (2.7) implies that the friction

$I=I_1^N$. The function (2.7) implies that the friction ![]() $\mu =0$ at

$\mu =0$ at ![]() $I=0$. The partially regularized theory therefore does not have a static yield stress, but instead creeps for inertial numbers

$I=0$. The partially regularized theory therefore does not have a static yield stress, but instead creeps for inertial numbers ![]() $I \leq I_1^N$. This makes little practical difference to numerical simulations, which already necessitate high viscosity regularization (see § 3).

$I \leq I_1^N$. This makes little practical difference to numerical simulations, which already necessitate high viscosity regularization (see § 3).

Since ![]() $I_1^N\ll 1$, it follows that the upper branch of (2.7) closely approximates the original function (2.6) for

$I_1^N\ll 1$, it follows that the upper branch of (2.7) closely approximates the original function (2.6) for ![]() $I_1^N< I\ll 1$. At large inertial numbers the upper branch asymptotes to

$I_1^N< I\ll 1$. At large inertial numbers the upper branch asymptotes to ![]() $\mu =\mu _d+\mu _\infty I$, instead of tending to the constant value

$\mu =\mu _d+\mu _\infty I$, instead of tending to the constant value ![]() $\mu _d$. This is consistent with the high speed chute flow experiments of Holyoake & McElwaine (Reference Holyoake and McElwaine2012) and Barker & Gray (Reference Barker and Gray2017), which showed there was a linear dependence on

$\mu _d$. This is consistent with the high speed chute flow experiments of Holyoake & McElwaine (Reference Holyoake and McElwaine2012) and Barker & Gray (Reference Barker and Gray2017), which showed there was a linear dependence on ![]() $I$ at large inertial numbers. Such experiments therefore provide a means of determining the new material constant

$I$ at large inertial numbers. Such experiments therefore provide a means of determining the new material constant ![]() $\mu _\infty$. Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) showed that the creep state at small inertial numbers and the linear dependence of

$\mu _\infty$. Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) showed that the creep state at small inertial numbers and the linear dependence of ![]() $\mu$ on

$\mu$ on ![]() $I$ at large inertial numbers significantly extends the range of well-posedness from

$I$ at large inertial numbers significantly extends the range of well-posedness from ![]() $I=0$ to

$I=0$ to ![]() $I^N_2\simeq 17$. It is for this reason that the theory is known as the partially regularized

$I^N_2\simeq 17$. It is for this reason that the theory is known as the partially regularized ![]() $\mu (I)$ rheology, as it does not guarantee well-posedness, but instead makes the well-posed range much larger than that of the original theory (Jop et al. Reference Jop, Forterre and Pouliquen2006), where

$\mu (I)$ rheology, as it does not guarantee well-posedness, but instead makes the well-posed range much larger than that of the original theory (Jop et al. Reference Jop, Forterre and Pouliquen2006), where ![]() $I^N_2\simeq 0.28$ (Barker & Gray Reference Barker and Gray2017).

$I^N_2\simeq 0.28$ (Barker & Gray Reference Barker and Gray2017).

2.2. Generalized polydisperse segregation theory

The granular material is assumed to consist of ![]() $n$ discrete particle species

$n$ discrete particle species ![]() $\nu$ that have differing particle diameters

$\nu$ that have differing particle diameters ![]() $d^\nu$, but the same intrinsic grain density

$d^\nu$, but the same intrinsic grain density ![]() $\rho _*$. Each species has a volume fraction per unit granular volume

$\rho _*$. Each species has a volume fraction per unit granular volume ![]() $\phi ^{\nu } \in [0,1]$, which satisfies the summation constraint

$\phi ^{\nu } \in [0,1]$, which satisfies the summation constraint

All of the existing bidisperse and polydisperse theories for particle-size segregation (e.g. Bridgwater, Foo & Stephens Reference Bridgwater, Foo and Stephens1985; Savage & Lun Reference Savage and Lun1988; Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Fan & Hill Reference Fan and Hill2011; Gray & Ancey Reference Gray and Ancey2011; Schlick et al. Reference Schlick, Fan, Umbanhowar, Ottino and Lueptow2015; Gray Reference Gray2018; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021) can be recast in the form of a general segregation–advection–diffusion equation for each species ![]() $\nu$,

$\nu$,

where ![]() $\boldsymbol {F^{\nu }}$ and

$\boldsymbol {F^{\nu }}$ and ![]() $\boldsymbol {\mathcal {D}^{\nu }}$ are the segregation and diffusive flux vectors for species

$\boldsymbol {\mathcal {D}^{\nu }}$ are the segregation and diffusive flux vectors for species ![]() $\nu$, respectively. By summing (2.10) over each species and applying the summation constraint (2.9), the incompressibility condition (2.1) is satisfied provided

$\nu$, respectively. By summing (2.10) over each species and applying the summation constraint (2.9), the incompressibility condition (2.1) is satisfied provided

For a bidisperse mixture, the segregation flux function should satisfy the constraint that no segregation occurs when the volume fraction of either species is zero (Bridgwater et al. Reference Bridgwater, Foo and Stephens1985). The simplest form therefore has a linear dependence on the species volume fractions, as proposed for a bidisperse mixture by Gray & Thornton (Reference Gray and Thornton2005). This was later generalized for a polydisperse mixture (Gray & Ancey Reference Gray and Ancey2011; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021) by a summation of the segregation flux functions over each bidisperse sub-mixture, to give

where ![]() $f_{\nu \lambda }$ is the segregation velocity magnitude and

$f_{\nu \lambda }$ is the segregation velocity magnitude and ![]() $\boldsymbol {e}_{\nu \lambda }$ is the unit vector along the segregation direction. This satisfies the summation constraint (2.11) provided

$\boldsymbol {e}_{\nu \lambda }$ is the unit vector along the segregation direction. This satisfies the summation constraint (2.11) provided

In Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) the diffusive flux vector is defined by analogy with the Maxwell–Stefan equations (Maxwell Reference Maxwell1867)

so that, in general, the diffusion rate ![]() $\mathcal {D}_{\nu \lambda }$ may vary between sub-mixtures, while still satisfying (2.11), provided

$\mathcal {D}_{\nu \lambda }$ may vary between sub-mixtures, while still satisfying (2.11), provided ![]() $\mathcal {D}_{\nu \lambda }=\mathcal {D}_{\lambda \nu }$. When the diffusion rate is the same across all sub-mixtures, (2.14) reduces to the standard equation for Fickian diffusion.

$\mathcal {D}_{\nu \lambda }=\mathcal {D}_{\lambda \nu }$. When the diffusion rate is the same across all sub-mixtures, (2.14) reduces to the standard equation for Fickian diffusion.

2.3. Segregation induced feedback on the bulk flow

The inertial number (2.5) is particle-size dependent. Hence, even if the particles have identical microscopic frictional properties, the local friction ![]() $\mu$ and, hence, the bulk flow behaviour will depend on the local particle size (GDR MiDi 2004). Particle-size segregation can therefore feedback on the local flow dynamics. By defining a volume fraction weighted mean particle size

$\mu$ and, hence, the bulk flow behaviour will depend on the local particle size (GDR MiDi 2004). Particle-size segregation can therefore feedback on the local flow dynamics. By defining a volume fraction weighted mean particle size

it is possible to generalize the inertial number definition (2.5) to polydisperse mixtures

\begin{equation} I = \frac{2\bar d \|\boldsymbol{D}\|}{\sqrt{p/\rho_*}}. \end{equation}

\begin{equation} I = \frac{2\bar d \|\boldsymbol{D}\|}{\sqrt{p/\rho_*}}. \end{equation}This is sufficient to capture simple frictional feedback from the evolving particle-size distribution of otherwise identical particles (Rognon et al. Reference Rognon, Roux, Naaïm and Chevoir2007; Tripathi & Khakhar Reference Tripathi and Khakhar2011; Denissen et al. Reference Denissen, Weinhart, Te Voortwis, Luding, Gray and Thornton2019; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021). This implies that, for the same flow depth, small particles will flow faster than large grains, so long as non-local wall effects do not come into play (Pouliquen & Forterre Reference Pouliquen and Forterre2002; Kamrin & Koval Reference Kamrin and Koval2014; Edwards & Gray Reference Edwards and Gray2015; Edwards et al. Reference Edwards, Russell, Johnson and Gray2019; Rocha, Johnson & Gray Reference Rocha, Johnson and Gray2019).

There are more complex effects in which the frictional properties of the particles differ due to their shape and/or microscopic surface properties. For each pure phase ![]() $\nu$, this can often be accounted for by modifying the parameters

$\nu$, this can often be accounted for by modifying the parameters ![]() $\mu _{s}^\nu$,

$\mu _{s}^\nu$, ![]() $\mu _{d}^\nu$,

$\mu _{d}^\nu$, ![]() $\mu _{\infty }^\nu$ and

$\mu _{\infty }^\nu$ and ![]() $I_0^\nu$ in the friction law (2.7). The local effective friction of the mixture can then be defined as the volume fraction weighted average of the constituent frictions,

$I_0^\nu$ in the friction law (2.7). The local effective friction of the mixture can then be defined as the volume fraction weighted average of the constituent frictions,

This leads naturally to a new definition for the granular viscosity (2.3), which replaces ![]() $\eta$ in the bulk momentum balance (2.2)

$\eta$ in the bulk momentum balance (2.2)

The combination of (2.16) and (2.17) allows the frictional differences caused by variations in particle size and surface properties to feedback on the bulk motion. This is crucial for segregation-induced flow fingering, which frequently occurs in geophysical mass flows, and is responsible for longer run out (Pouliquen et al. Reference Pouliquen, Delour and Savage1997; Pouliquen & Vallance Reference Pouliquen and Vallance1999; Iverson & Vallance Reference Iverson and Vallance2001; Iverson Reference Iverson2003; Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012; Woodhouse et al. Reference Woodhouse, Thornton, Johnson, Kokelaar and Gray2012; Kokelaar et al. Reference Kokelaar, Graham, Gray and Vallance2014; Baker et al. Reference Baker, Johnson and Gray2016b; Edwards et al. Reference Edwards, Rocha, Kokelaar, Johnson and Gray2023).

2.4. The feedback of the bulk flow on particle-size segregation and diffusion

Each particle species ![]() $\nu$ is transported by the bulk velocity field

$\nu$ is transported by the bulk velocity field ![]() $\boldsymbol {u}$ in the segregation– advection–diffusion equation (2.10). The particle-size distribution is therefore directly affected by the local velocity

$\boldsymbol {u}$ in the segregation– advection–diffusion equation (2.10). The particle-size distribution is therefore directly affected by the local velocity ![]() $\boldsymbol {u}$. The local shear rate

$\boldsymbol {u}$. The local shear rate ![]() $\dot \gamma =2||\boldsymbol {D}||$ and the pressure

$\dot \gamma =2||\boldsymbol {D}||$ and the pressure ![]() $p$ also affect the segregation and diffusion through the functional dependence of the segregation velocity magnitude

$p$ also affect the segregation and diffusion through the functional dependence of the segregation velocity magnitude ![]() $f_{\nu \lambda }$ and diffusion rate

$f_{\nu \lambda }$ and diffusion rate ![]() $\mathcal {D}_{\nu \lambda }$ between each species

$\mathcal {D}_{\nu \lambda }$ between each species ![]() $\nu$ and

$\nu$ and ![]() $\lambda$ pair.

$\lambda$ pair.

Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) surveyed the existing literature for specific functional forms. In particular, dimensional analysis demands that the diffusion rate scales with the shear rate times the particle-size squared, times an arbitrary function of the inertial number. This scaling was implied by the analysis of Scott & Bridgwater (Reference Scott and Bridgwater1975) on the relationship between particle percolation velocity and diffusion, and has been extensively confirmed by experimental observations (Bridgwater Reference Bridgwater1980; Natarajan, Hunt & Taylor Reference Natarajan, Hunt and Taylor1995; Utter & Behringer Reference Utter and Behringer2004; Katsuragi, Abate & Durian Reference Katsuragi, Abate and Durian2010) and numerical simulations (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019). The simplest model for the diffusion rate between each species ![]() $\nu$ and

$\nu$ and ![]() $\lambda$ is therefore

$\lambda$ is therefore

where ![]() $\mathcal {A}$ is a universal constant specified in table 1. Note that the diffusion is therefore assumed to be the same for each species pair, and hence, the diffusive flux (2.14) reduces to standard Fickian diffusion. Campbell (Reference Campbell1997) found that diffusion in granular shear flows was anisotropic, and Utter & Behringer (Reference Utter and Behringer2004) studied monodisperse Couette flow experiments using flat disc-shaped particles, from which they measured a radial diffusion coefficient of

$\mathcal {A}$ is a universal constant specified in table 1. Note that the diffusion is therefore assumed to be the same for each species pair, and hence, the diffusive flux (2.14) reduces to standard Fickian diffusion. Campbell (Reference Campbell1997) found that diffusion in granular shear flows was anisotropic, and Utter & Behringer (Reference Utter and Behringer2004) studied monodisperse Couette flow experiments using flat disc-shaped particles, from which they measured a radial diffusion coefficient of ![]() $\mathcal {A}=0.108$ and a tangential diffusion coefficient of

$\mathcal {A}=0.108$ and a tangential diffusion coefficient of ![]() $\mathcal {A}=0.223$. Evidence from bidisperse DEM/DPM shear-cell simulations with spherical particles implies that the anisotropy is only slight, and that instead

$\mathcal {A}=0.223$. Evidence from bidisperse DEM/DPM shear-cell simulations with spherical particles implies that the anisotropy is only slight, and that instead ![]() $\mathcal {A}\in (0.03,0.05)$ (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019; Artoni et al. Reference Artoni, Larcher, Jenkins and Richard2021; Bancroft & Johnson Reference Bancroft and Johnson2021). Therefore isotropic diffusion can be reasonably assumed, and

$\mathcal {A}\in (0.03,0.05)$ (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019; Artoni et al. Reference Artoni, Larcher, Jenkins and Richard2021; Bancroft & Johnson Reference Bancroft and Johnson2021). Therefore isotropic diffusion can be reasonably assumed, and ![]() $\mathcal {A}=0.04$ is used here.

$\mathcal {A}=0.04$ is used here.

Table 1. Parameter values used in the numerical simulations. The value of the universal constant ![]() $\mathcal {A}$ in the diffusivity (2.19) is based on the DEM/DPM simulations of (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019; Artoni et al. Reference Artoni, Larcher, Jenkins and Richard2021; Bancroft & Johnson Reference Bancroft and Johnson2021). The values of the universal constants

$\mathcal {A}$ in the diffusivity (2.19) is based on the DEM/DPM simulations of (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019; Artoni et al. Reference Artoni, Larcher, Jenkins and Richard2021; Bancroft & Johnson Reference Bancroft and Johnson2021). The values of the universal constants ![]() $\mathcal {B}$ and

$\mathcal {B}$ and ![]() $\mathcal {C}$ in the segregation law (2.20) are based on those suggested by the single-intruder experiments of Trewhela et al. (Reference Trewhela, Ancey and Gray2021), although

$\mathcal {C}$ in the segregation law (2.20) are based on those suggested by the single-intruder experiments of Trewhela et al. (Reference Trewhela, Ancey and Gray2021), although ![]() $\mathcal {B}$ is corrected for the absence of an interstitial fluid. The remaining non-dimensional constants

$\mathcal {B}$ is corrected for the absence of an interstitial fluid. The remaining non-dimensional constants ![]() $\mathcal {E}$,

$\mathcal {E}$, ![]() $a$ and

$a$ and ![]() $\phi ^s_c$ are also taken from Trewhela et al. (Reference Trewhela, Ancey and Gray2021).

$\phi ^s_c$ are also taken from Trewhela et al. (Reference Trewhela, Ancey and Gray2021).

Trewhela et al. (Reference Trewhela, Ancey and Gray2021) performed single-intruder shear-box experiments to derive a scaling law for segregation of large and small particles in a bidisperse mixture. This law is now generalized to polydisperse systems. For a sub-mixture composed of particles ![]() $\nu$ and

$\nu$ and ![]() $\lambda$, the segregation velocity magnitude is

$\lambda$, the segregation velocity magnitude is

where ![]() $\mathcal {B}$ and

$\mathcal {B}$ and ![]() $\mathcal {C}$ are universal constants determined by Trewhela et al. (Reference Trewhela, Ancey and Gray2021) (given in table 1). The function

$\mathcal {C}$ are universal constants determined by Trewhela et al. (Reference Trewhela, Ancey and Gray2021) (given in table 1). The function ![]() $\mathcal {F}_{\nu \lambda }$ accounts for packing effects and the segregation-rate dependence on the generalized grain-size ratio

$\mathcal {F}_{\nu \lambda }$ accounts for packing effects and the segregation-rate dependence on the generalized grain-size ratio

where ![]() $R_{\nu \lambda }=R_{\lambda \nu }>1$. The scaling law (2.20) is able to capture a variety of phenomena observed in slightly dilated, bidisperse, sheared granular flows, where kinetic sieving and squeeze expulsion are the dominant segregation mechanisms (Middleton Reference Middleton1970; Bridgwater et al. Reference Bridgwater, Foo and Stephens1985; Savage & Lun Reference Savage and Lun1988; Gray Reference Gray2018).

$R_{\nu \lambda }=R_{\lambda \nu }>1$. The scaling law (2.20) is able to capture a variety of phenomena observed in slightly dilated, bidisperse, sheared granular flows, where kinetic sieving and squeeze expulsion are the dominant segregation mechanisms (Middleton Reference Middleton1970; Bridgwater et al. Reference Bridgwater, Foo and Stephens1985; Savage & Lun Reference Savage and Lun1988; Gray Reference Gray2018).

Kinetic sieving is a shear driven process that allows smaller particles to percolate down under the action of gravity, while squeeze expulsion describes the process in which particles are squeezed upwards to maintain bulk incompressibility. Dimensional analysis suggests that the segregation rate should have the dimensions of a velocity, and (2.20) assumes that ![]() $f_{\nu \lambda }$ behaves like

$f_{\nu \lambda }$ behaves like ![]() $\dot \gamma \bar d=2||\boldsymbol {D}||\bar d$, which automatically implies that the segregation flux function

$\dot \gamma \bar d=2||\boldsymbol {D}||\bar d$, which automatically implies that the segregation flux function ![]() $f_{\nu \lambda }\phi ^\nu \phi ^\lambda$ is asymmetric (Gajjar & Gray Reference Gajjar and Gray2014; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015). By performing experiments with a density matched interstitial fluid, Vallance & Savage (Reference Vallance and Savage2000) showed that segregation shuts off in the absence of gravity (see also Thornton, Gray & Hogg Reference Thornton, Gray and Hogg2006). The effect of gravity is included indirectly in the round bracketed term in (2.20) through a dependence on the reciprocal of the non-dimensionalized pressure

$f_{\nu \lambda }\phi ^\nu \phi ^\lambda$ is asymmetric (Gajjar & Gray Reference Gajjar and Gray2014; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015). By performing experiments with a density matched interstitial fluid, Vallance & Savage (Reference Vallance and Savage2000) showed that segregation shuts off in the absence of gravity (see also Thornton, Gray & Hogg Reference Thornton, Gray and Hogg2006). The effect of gravity is included indirectly in the round bracketed term in (2.20) through a dependence on the reciprocal of the non-dimensionalized pressure ![]() $p/(\rho _* g\bar d)$. If the shear rate is constant, this form implies that the deeper one goes into the mixture, the lower the segregation rate becomes. This was observed directly in Trewhela et al. (Reference Trewhela, Ancey and Gray2021) experiments, i.e. the intruders did not rise linearly with time in response to a spatially uniform shear rate, but were either percolated down or squeezed up faster near the free surface. The constant

$p/(\rho _* g\bar d)$. If the shear rate is constant, this form implies that the deeper one goes into the mixture, the lower the segregation rate becomes. This was observed directly in Trewhela et al. (Reference Trewhela, Ancey and Gray2021) experiments, i.e. the intruders did not rise linearly with time in response to a spatially uniform shear rate, but were either percolated down or squeezed up faster near the free surface. The constant ![]() $\mathcal {C}$ in (2.20) was included to avoid a singularity at zero pressure. Further evidence of the pressure dependence of segregation is provided in the papers of Golick & Daniels (Reference Golick and Daniels2009), Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018) and Bancroft & Johnson (Reference Bancroft and Johnson2021).

$\mathcal {C}$ in (2.20) was included to avoid a singularity at zero pressure. Further evidence of the pressure dependence of segregation is provided in the papers of Golick & Daniels (Reference Golick and Daniels2009), Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018) and Bancroft & Johnson (Reference Bancroft and Johnson2021).

Trewhela et al. (Reference Trewhela, Ancey and Gray2021) found that for moderate grain-size ratios of large and small particles (i.e. for ![]() $R_{sl}\in [1,4.17]$, where

$R_{sl}\in [1,4.17]$, where ![]() $s$ and

$s$ and ![]() $l$ denote small and large particles, respectively), the segregation rate of large intruders had a linear dependence on

$l$ denote small and large particles, respectively), the segregation rate of large intruders had a linear dependence on ![]() $(R_{sl}-1)$. However, the segregation rate of a small intruder obeyed a quadratic law of the form

$(R_{sl}-1)$. However, the segregation rate of a small intruder obeyed a quadratic law of the form ![]() $(R_{sl}-1)+\mathcal {E}(R_{sl}-1)^2$, where

$(R_{sl}-1)+\mathcal {E}(R_{sl}-1)^2$, where ![]() $\mathcal {E}$ was a non-dimensional constant. The additional quadratic dependence arose because small intruders find it increasingly easy to percolate through a matrix of large grains as the particle-size ratio approaches the spontaneous percolation limit at around

$\mathcal {E}$ was a non-dimensional constant. The additional quadratic dependence arose because small intruders find it increasingly easy to percolate through a matrix of large grains as the particle-size ratio approaches the spontaneous percolation limit at around ![]() $R_{sl}\simeq 6$. Trewhela et al. (Reference Trewhela, Ancey and Gray2021) extended their model to intermediate concentrations by assuming that

$R_{sl}\simeq 6$. Trewhela et al. (Reference Trewhela, Ancey and Gray2021) extended their model to intermediate concentrations by assuming that

where the function

\begin{equation} \varLambda(\phi^s)=\begin{cases} \displaystyle 1-\frac{\phi^s}{\phi^s_c} & \text{for } \phi^s \leq \phi^s_c, \\ \displaystyle 0 & \text{for } \phi^s > \phi^s_c, \end{cases} \end{equation}

\begin{equation} \varLambda(\phi^s)=\begin{cases} \displaystyle 1-\frac{\phi^s}{\phi^s_c} & \text{for } \phi^s \leq \phi^s_c, \\ \displaystyle 0 & \text{for } \phi^s > \phi^s_c, \end{cases} \end{equation}

gives the right ![]() $\mathcal {F}_{sl}$ dependence in the limit as

$\mathcal {F}_{sl}$ dependence in the limit as ![]() $\phi ^s\rightarrow 0,1$ and shuts off the quadratic dependence when the small-particle concentration exceeds

$\phi ^s\rightarrow 0,1$ and shuts off the quadratic dependence when the small-particle concentration exceeds ![]() $\phi ^s_c$ (defined in table 1). Trewhela et al. (Reference Trewhela, Ancey and Gray2021) showed that this functional form was capable of quantitatively capturing the spatial and temporal evolution of the particle-size distribution measured in the refractive-index-matched shear-box experiments of van der Vaart et al. (Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015).

$\phi ^s_c$ (defined in table 1). Trewhela et al. (Reference Trewhela, Ancey and Gray2021) showed that this functional form was capable of quantitatively capturing the spatial and temporal evolution of the particle-size distribution measured in the refractive-index-matched shear-box experiments of van der Vaart et al. (Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015).

However, there is evidence from experiments and DEM/DPM simulations suggesting that for 50:50 mixtures of large and small particles in geometries for which the velocity and shear rate are functions of space and time, the segregation intensity is maximal near a grain-size ratio of ![]() $R_{sl}=2$ (Golick & Daniels Reference Golick and Daniels2009; Thornton et al. Reference Thornton, Weinhart, Luding and Bokhove2012), whereas the formulation (2.22) is monotonically increasing with the size ratio. Trewhela et al. (Reference Trewhela, Ancey and Gray2021) therefore suggested an alternative size-ratio dependency that captures this effect, within the framework of the incompressible segregation theory

$R_{sl}=2$ (Golick & Daniels Reference Golick and Daniels2009; Thornton et al. Reference Thornton, Weinhart, Luding and Bokhove2012), whereas the formulation (2.22) is monotonically increasing with the size ratio. Trewhela et al. (Reference Trewhela, Ancey and Gray2021) therefore suggested an alternative size-ratio dependency that captures this effect, within the framework of the incompressible segregation theory

where ![]() $a$ is a constant defined in table 1. The numerator in (2.24) is the same as (2.22), but the denominator now includes a reduction factor

$a$ is a constant defined in table 1. The numerator in (2.24) is the same as (2.22), but the denominator now includes a reduction factor ![]() $1 + a(R_{sl}-1)^2\phi ^s\phi ^l$, which shuts off when

$1 + a(R_{sl}-1)^2\phi ^s\phi ^l$, which shuts off when ![]() $\phi ^s=0$ and

$\phi ^s=0$ and ![]() $\phi ^l=0$, and reduces the segregation rate at intermediate configurations. The idea is that this factor parameterizes the enhanced packing of mixtures of particles of different sizes, which is thought to reduce the segregation rate. Trewhela et al. (Reference Trewhela, Ancey and Gray2021) showed that for a 50:50 mix, (2.24) predicts a peak segregation rate at

$\phi ^l=0$, and reduces the segregation rate at intermediate configurations. The idea is that this factor parameterizes the enhanced packing of mixtures of particles of different sizes, which is thought to reduce the segregation rate. Trewhela et al. (Reference Trewhela, Ancey and Gray2021) showed that for a 50:50 mix, (2.24) predicts a peak segregation rate at ![]() $R_{sl}\simeq 1.66$, which is very close to the maximum at

$R_{sl}\simeq 1.66$, which is very close to the maximum at ![]() $R_{sl}=1.7$ observed in the DEM/DPM simulations of Thornton et al. (Reference Thornton, Weinhart, Luding and Bokhove2012). The bidisperse simulations in §§ 4–7 of this paper are performed using the functional form (2.24). Almost nothing is known about how the segregation rate and the packing behaves in polydisperse sheared granular mixtures. The tridisperse simulations presented in § 8 therefore use a trivial pairwise generalization of (2.24) as an illustration.

$R_{sl}=1.7$ observed in the DEM/DPM simulations of Thornton et al. (Reference Thornton, Weinhart, Luding and Bokhove2012). The bidisperse simulations in §§ 4–7 of this paper are performed using the functional form (2.24). Almost nothing is known about how the segregation rate and the packing behaves in polydisperse sheared granular mixtures. The tridisperse simulations presented in § 8 therefore use a trivial pairwise generalization of (2.24) as an illustration.

2.5. Sidewall friction

It has long been known that confining lateral sidewalls play an important role in granular flow experiments (Greve & Hutter Reference Greve and Hutter1993; Taberlet et al. Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003; Jop et al. Reference Jop, Forterre and Pouliquen2005; Baker, Barker & Gray Reference Baker, Barker and Gray2016a). In rotating drum flows the additional friction introduced by sidewalls results in avalanches that are significantly thinner and faster than flows without sidewall friction (Hill et al. Reference Hill, Khakhar, Gilchrist, McCarthy and Ottino1999; Ottino & Khakhar Reference Ottino and Khakhar2000; Jop et al. Reference Jop, Forterre and Pouliquen2005; Mounty Reference Mounty2007). As a result, the two-dimensional square rotating drum simulations of Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) could not be compared directly to experiments. In principle, a Coulomb friction boundary condition could be imposed on the sidewalls and then the governing equations could be solved in three dimensions for any width of drum. However, in this paper the influence of sidewall friction is incorporated into the governing equations by width averaging the momentum balance equation (2.2). This reduces the problem to a two-dimensional one, which is much more computationally efficient.

Consider then a three-dimensional granular flow confined within a narrow channel between ![]() $y=0$ and

$y=0$ and ![]() $y=W$, where there can be slip at the sidewalls and only weak velocity gradients in the

$y=W$, where there can be slip at the sidewalls and only weak velocity gradients in the ![]() $y$ direction. Proceeding in a similar manner to Jop et al. (Reference Jop, Forterre and Pouliquen2005), assuming a Coulomb friction boundary condition at the lateral sidewalls implies

$y$ direction. Proceeding in a similar manner to Jop et al. (Reference Jop, Forterre and Pouliquen2005), assuming a Coulomb friction boundary condition at the lateral sidewalls implies

where ![]() $\boldsymbol {n}$ is an outward pointing normal to the sidewall,

$\boldsymbol {n}$ is an outward pointing normal to the sidewall, ![]() $\mu _W$ is a constant wall friction coefficient and the term

$\mu _W$ is a constant wall friction coefficient and the term ![]() $-\boldsymbol {u}/|\boldsymbol {u}|$ ensures that friction acts against the flow. The three-dimensional mass and momentum balance equations, defined analogously with (2.1) and (2.2), may then be integrated across the channel width in a similar fashion to the depth-averaged approach for a shallow system (Gray Reference Gray2001; Gray & Edwards Reference Gray and Edwards2014). Width-integrated variables are defined by

$-\boldsymbol {u}/|\boldsymbol {u}|$ ensures that friction acts against the flow. The three-dimensional mass and momentum balance equations, defined analogously with (2.1) and (2.2), may then be integrated across the channel width in a similar fashion to the depth-averaged approach for a shallow system (Gray Reference Gray2001; Gray & Edwards Reference Gray and Edwards2014). Width-integrated variables are defined by

for any variable ![]() $f$, and when variations in the

$f$, and when variations in the ![]() $y$ direction are small,

$y$ direction are small, ![]() $\widetilde {fg}\simeq \tilde f\tilde g$ for any two variables

$\widetilde {fg}\simeq \tilde f\tilde g$ for any two variables ![]() $f$ and

$f$ and ![]() $g$. Integrating and applying the boundary conditions (2.25) results in a two-dimensional system for which the mass and momentum balances become

$g$. Integrating and applying the boundary conditions (2.25) results in a two-dimensional system for which the mass and momentum balances become

where ![]() $\boldsymbol {\nabla }=(\partial /\partial x, \partial /\partial z)^T$, the two-dimensional gradient operator. Since there is no lateral flow and small velocity gradients in the

$\boldsymbol {\nabla }=(\partial /\partial x, \partial /\partial z)^T$, the two-dimensional gradient operator. Since there is no lateral flow and small velocity gradients in the ![]() $y$ direction,

$y$ direction, ![]() $\boldsymbol {u}/|\boldsymbol {u}|\simeq \tilde {\boldsymbol {u}}/|\tilde {\boldsymbol {u}}|$, and the tilde notation may be dropped on the understanding that the variables

$\boldsymbol {u}/|\boldsymbol {u}|\simeq \tilde {\boldsymbol {u}}/|\tilde {\boldsymbol {u}}|$, and the tilde notation may be dropped on the understanding that the variables ![]() $(\boldsymbol {u}, p, \eta, \boldsymbol {D})$ from this point onwards refer to width-averaged quantities of the form (2.26). The final term in the momentum balance equation (2.28) models the influence of sidewall friction on the bulk flow. This alteration provides a straightforward method of capturing three-dimensional wall friction effects in a two-dimensional framework.

$(\boldsymbol {u}, p, \eta, \boldsymbol {D})$ from this point onwards refer to width-averaged quantities of the form (2.26). The final term in the momentum balance equation (2.28) models the influence of sidewall friction on the bulk flow. This alteration provides a straightforward method of capturing three-dimensional wall friction effects in a two-dimensional framework.

3. Numerical method

The mass (2.27) and momentum balances (2.28) are solved in conservative form,

where ![]() $\varrho$ is the mixture density and

$\varrho$ is the mixture density and ![]() $\boldsymbol {\otimes }$ is the dyadic product. In order to handle the evolving free surface, Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) used a two-fluid approach in which an excess air phase was considered in addition to the grains. As a result, the governing equations can be numerically solved in a fixed domain, rather than using a deformable grid that adjusts to the evolving free surface, or a particle-based numerical method, i.e. smooth particle hydrodynamics or the material point method. The solids volume fraction,

$\boldsymbol {\otimes }$ is the dyadic product. In order to handle the evolving free surface, Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) used a two-fluid approach in which an excess air phase was considered in addition to the grains. As a result, the governing equations can be numerically solved in a fixed domain, rather than using a deformable grid that adjusts to the evolving free surface, or a particle-based numerical method, i.e. smooth particle hydrodynamics or the material point method. The solids volume fraction, ![]() $\varPhi$, remains unchanged throughout the mixture, with the excess air considered separately to the background interstitial air, which has volume fraction

$\varPhi$, remains unchanged throughout the mixture, with the excess air considered separately to the background interstitial air, which has volume fraction ![]() $1-\varPhi$ per unit mixture volume. For a bidisperse granular mixture of small and large particles with excess air, there are volume fractions

$1-\varPhi$ per unit mixture volume. For a bidisperse granular mixture of small and large particles with excess air, there are volume fractions ![]() $\varphi ^s$,

$\varphi ^s$, ![]() $\varphi ^l$ and

$\varphi ^l$ and ![]() $\varphi ^a$, respectively. The mixture density

$\varphi ^a$, respectively. The mixture density ![]() $\varrho$ and viscosity

$\varrho$ and viscosity ![]() $\eta$ are therefore defined as volume fraction weighted averages including the excess air phase

$\eta$ are therefore defined as volume fraction weighted averages including the excess air phase

The density of air ![]() $\varrho ^a$ is a constant and

$\varrho ^a$ is a constant and ![]() $\varrho ^g=\varPhi \rho _*\gg \varrho ^a$, where the superscript

$\varrho ^g=\varPhi \rho _*\gg \varrho ^a$, where the superscript ![]() $g$ denotes the granular phase. The granular viscosities

$g$ denotes the granular phase. The granular viscosities ![]() $\eta ^g$ are derived from (2.18) and the viscosity of air

$\eta ^g$ are derived from (2.18) and the viscosity of air ![]() $\eta ^a$ is assumed to be constant. All the relevant numerical parameters are specified in table 2. The excess air is of sufficiently low density and viscosity that it does not affect the motion of the grains, and is purely a numerical convenience.

$\eta ^a$ is assumed to be constant. All the relevant numerical parameters are specified in table 2. The excess air is of sufficiently low density and viscosity that it does not affect the motion of the grains, and is purely a numerical convenience.

Table 2. Parameters for the large and small glass beads, the air phase and the triangular drum. The physical parameters for glass beads are adapted from those used by Rocha et al. (Reference Rocha, Johnson and Gray2019) and Mangeney et al. (Reference Mangeney, Bouchut, Thomas, Vilotte and Bristeau2007), to model the experiments of Félix & Thomas (Reference Félix and Thomas2004). These parameters are used to determine ![]() $I_0$ using the definition given by Jop et al. (Reference Jop, Forterre and Pouliquen2005), and

$I_0$ using the definition given by Jop et al. (Reference Jop, Forterre and Pouliquen2005), and ![]() $\mu _\infty$ is chosen to ensure a well-posed partially regularized

$\mu _\infty$ is chosen to ensure a well-posed partially regularized ![]() $\mu (I)$ curve up to

$\mu (I)$ curve up to ![]() $I=17.0189$.

$I=17.0189$.

The two-fluid approach uses the counter-gradient transport method (Rusche Reference Rusche2002; Weller Reference Weller2008) to sharpen the air–grain interface. This can lead to grid-dependent bubbles of excess air becoming trapped within the high viscosity granular matrix (Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021). In order to remove these bubbles, Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) used the advection–segregation–diffusion equations (2.10) to rapidly expel the excess air from the grains. Instead of solving a bidisperse segregation problem, Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) therefore solved a three-phase segregation problem. The segregation of both the grains and the excess air was assumed to align with gravity, and it was assumed that air–grain diffusion was zero. This implies that the advection–segregation–diffusion equation (2.10) produces a system of three conservation laws,

where the overall concentration of grains is

The granular segregation velocity magnitude ![]() $f_{sl}$ is defined by the scaling law (2.20) with

$f_{sl}$ is defined by the scaling law (2.20) with ![]() $\mathcal {F}_{sl}$ given by (2.24), and

$\mathcal {F}_{sl}$ given by (2.24), and ![]() $f_{ag}=f_{as}=f_{al}$ assumed to equal a sufficiently large constant (defined in table 2) to expel the excess air rapidly from the grains. The sum of (3.4)–(3.6) reduces to the bulk incompressibility relation (3.1). Moreover, when there is no excess air

$f_{ag}=f_{as}=f_{al}$ assumed to equal a sufficiently large constant (defined in table 2) to expel the excess air rapidly from the grains. The sum of (3.4)–(3.6) reduces to the bulk incompressibility relation (3.1). Moreover, when there is no excess air ![]() $\varphi ^a=0$, they reduce to the bidisperse advection–segregation–diffusion equations (Gray & Chugunov Reference Gray and Chugunov2006; Gray Reference Gray2018).

$\varphi ^a=0$, they reduce to the bidisperse advection–segregation–diffusion equations (Gray & Chugunov Reference Gray and Chugunov2006; Gray Reference Gray2018).

Equations (3.1)–(3.2) are of the form of the incompressible Navier–Stokes equations and the pressure–velocity coupling is solved by the PISO algorithm in OpenFOAM (Issa Reference Issa1986), while the concentration equations (3.4)–(3.6) are solved using the multidimensional universal limiter for explicit solution algorithm (Weller Reference Weller2006). The velocity solution and coupling to the mixture composition are calculated explicitly, leading to a Courant–Friedrichs–Lewy (CFL) criterion incorporating the local viscosity (Moukalled, Mangani & Darwish Reference Moukalled, Mangani and Darwish2016), where the CFL number is defined as

This should be limited to a characteristic value for the time integration scheme (such as unity for forward Euler). In most multi-phase flows the convective term dominates and the second, viscous term is neglected. The reverse is true for static granular material as the strain rate tends to zero and the viscosity thus becomes infinite, with the resulting requirement that time steps become infinitesimally small. To avoid infinitesimal time steps, a high, constant cutoff value ![]() $\eta _{max}$ is used for the viscosity (see, e.g. Lagrée, Staron & Popinet Reference Lagrée, Staron and Popinet2011; Staron, Lagrée & Popinet Reference Staron, Lagrée and Popinet2012), which is redefined as

$\eta _{max}$ is used for the viscosity (see, e.g. Lagrée, Staron & Popinet Reference Lagrée, Staron and Popinet2011; Staron, Lagrée & Popinet Reference Staron, Lagrée and Popinet2012), which is redefined as

This means that a Newtonian viscosity is activated as ![]() $\|\boldsymbol {D} \|\to 0$ or

$\|\boldsymbol {D} \|\to 0$ or ![]() $p\to \infty$. Smaller time steps are nevertheless required relative to low viscosity simulations as the viscosity continues to dominate the

$p\to \infty$. Smaller time steps are nevertheless required relative to low viscosity simulations as the viscosity continues to dominate the ![]() $\mathrm {CFL}$ number. Finally, since the partially regularized

$\mathrm {CFL}$ number. Finally, since the partially regularized ![]() $\mu (I)$ rheology (2.7) does not have a yield stress and instead enters a creep regime for small values of the inertial number to maintain well-posedness (Barker & Gray Reference Barker and Gray2017), it is not able to model static material, as detailed in § 2.1. It is important to note that although the

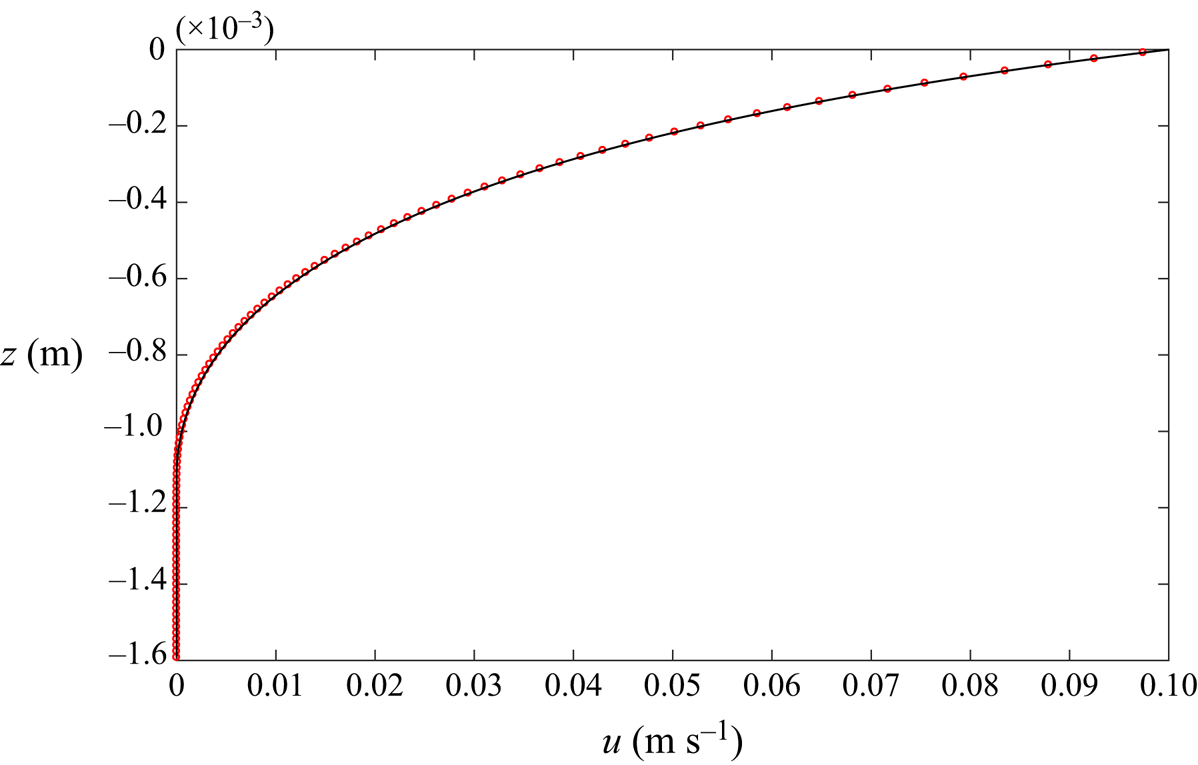

$\mu (I)$ rheology (2.7) does not have a yield stress and instead enters a creep regime for small values of the inertial number to maintain well-posedness (Barker & Gray Reference Barker and Gray2017), it is not able to model static material, as detailed in § 2.1. It is important to note that although the ![]() $\mu (I)$ rheology of Jop et al. (Reference Jop, Forterre and Pouliquen2005) does have a yield stress, the maximum viscosity cutoff (3.9) introduces a creep state numerically. This is, however, not sufficient to guarantee well-posedness of the equations (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015; Barker & Gray Reference Barker and Gray2017; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017). The partially regularized theory of Barker & Gray (Reference Barker and Gray2017), used here, is therefore strongly preferable due its significantly extended region of well-posedness. The numerical method has been extensively tested by Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021), and the influence of the wall friction term is further tested in Appendix A against a semi-infinite shear-box solution between lateral sidewalls.

$\mu (I)$ rheology of Jop et al. (Reference Jop, Forterre and Pouliquen2005) does have a yield stress, the maximum viscosity cutoff (3.9) introduces a creep state numerically. This is, however, not sufficient to guarantee well-posedness of the equations (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015; Barker & Gray Reference Barker and Gray2017; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017). The partially regularized theory of Barker & Gray (Reference Barker and Gray2017), used here, is therefore strongly preferable due its significantly extended region of well-posedness. The numerical method has been extensively tested by Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021), and the influence of the wall friction term is further tested in Appendix A against a semi-infinite shear-box solution between lateral sidewalls.

4. Segregation and flow of a bidisperse mixture in a triangular rotating drum

4.1. Experimental set-up

Experiments were conducted in a triangular rotating drum with equilateral sides of length ![]() $L=0.257$ m. This was formed from an aluminium outer frame that was confined between two transparent polymethyl methacrylate (PMMA) plates (separated by a gap of width

$L=0.257$ m. This was formed from an aluminium outer frame that was confined between two transparent polymethyl methacrylate (PMMA) plates (separated by a gap of width ![]() $W=3\times 10^{-3}$ m) and screwed together. Before assembly, the PMMA walls were cleaned with anti-static spray and dried to prevent smaller particles sticking to the sidewalls. The glass beads used in the experiments were sourced from Sigmund Lindner GmbH. The larger green glass beads were sieved to a diameter

$W=3\times 10^{-3}$ m) and screwed together. Before assembly, the PMMA walls were cleaned with anti-static spray and dried to prevent smaller particles sticking to the sidewalls. The glass beads used in the experiments were sourced from Sigmund Lindner GmbH. The larger green glass beads were sieved to a diameter ![]() $d^l = 600\unicode{x2013}800$

$d^l = 600\unicode{x2013}800$ ![]() $\mathrm {\mu }$m, while the smaller red beads had a diameter

$\mathrm {\mu }$m, while the smaller red beads had a diameter ![]() $d^s = 300\unicode{x2013}400$

$d^s = 300\unicode{x2013}400$ ![]() $\mathrm {\mu }$m. The desired volumes of large and small grains were measured separately, mixed together and then filled into the drum through a gap in the aluminium frame, which was then tightly closed with a stopper. The exact volume of grains in the drum can vary slightly from the individual combined large and small volumes due to enhanced packing of the mixture (Golick & Daniels Reference Golick and Daniels2009; Thornton et al. Reference Thornton, Weinhart, Luding and Bokhove2012). If necessary, additional grains were added to obtain the desired fill. For the particle-size ratios used in this paper these packing effects were small, and the theory, which is incompressible, appears to be able to capture the observed dynamics and the segregation patterns to a high degree of accuracy.

$\mathrm {\mu }$m. The desired volumes of large and small grains were measured separately, mixed together and then filled into the drum through a gap in the aluminium frame, which was then tightly closed with a stopper. The exact volume of grains in the drum can vary slightly from the individual combined large and small volumes due to enhanced packing of the mixture (Golick & Daniels Reference Golick and Daniels2009; Thornton et al. Reference Thornton, Weinhart, Luding and Bokhove2012). If necessary, additional grains were added to obtain the desired fill. For the particle-size ratios used in this paper these packing effects were small, and the theory, which is incompressible, appears to be able to capture the observed dynamics and the segregation patterns to a high degree of accuracy.

Particles of different sizes have a strong propensity to segregate. In order to obtain an approximately homogenous initial condition, the drum was oriented horizontally and shaken to induce segregation in the direction normal to the lateral transparent sidewalls. The large green beads therefore segregated to the front (observable) wall, with the small red beads concealed behind them against the rear wall. At any given cross-section of the drum an approximately uniform initial mixture of large and small particles was generated. The back of the drum was then attached to an ElectroCraft S642-1B/T servo motor and a modulation speed control unit to control the rotation rate. The axis of rotation coincided with the centre of the triangle. The drum was narrow enough that cross-slope particle diffusion, within the flowing avalanche, was sufficient to smooth out any lateral variation across it. The final pattern was therefore approximately uniform across the gap, except in the central core, which never entered the avalanche. This initial condition therefore has the additional advantage that the undisturbed core appears to the observer from the front as a uniform region of green particles, providing a strong contrast with the predominantly small red particles that are deposited adjacent to the core. The sidewall friction ![]() $\mu _W=\tan (15.5^\circ )$ is a material property of both the glass beads and the PMMA, and is measured empirically from the angle of failure for a bidisperse mixture of static grains on a gradually inclined PMMA surface (see table 2).

$\mu _W=\tan (15.5^\circ )$ is a material property of both the glass beads and the PMMA, and is measured empirically from the angle of failure for a bidisperse mixture of static grains on a gradually inclined PMMA surface (see table 2).

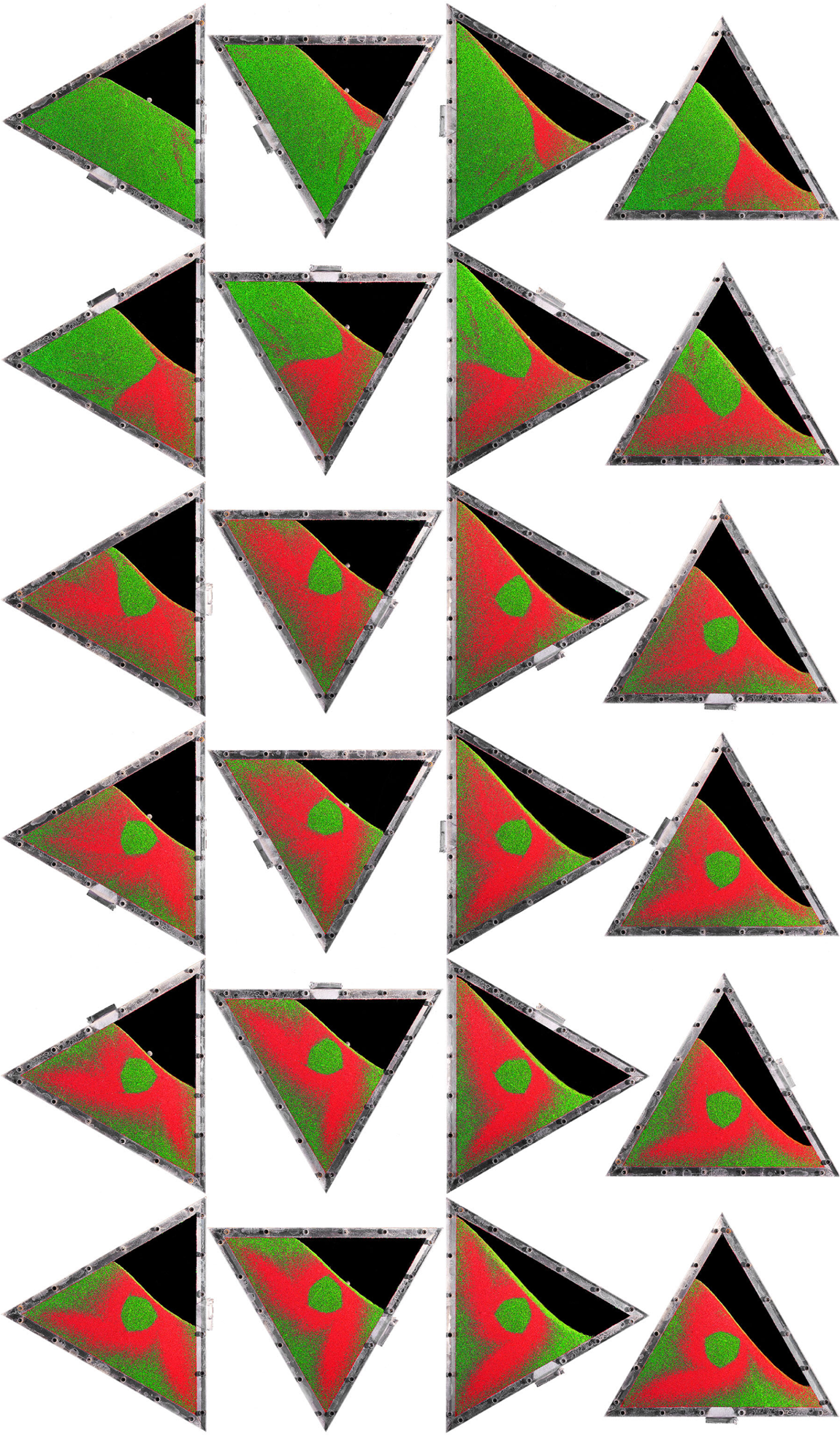

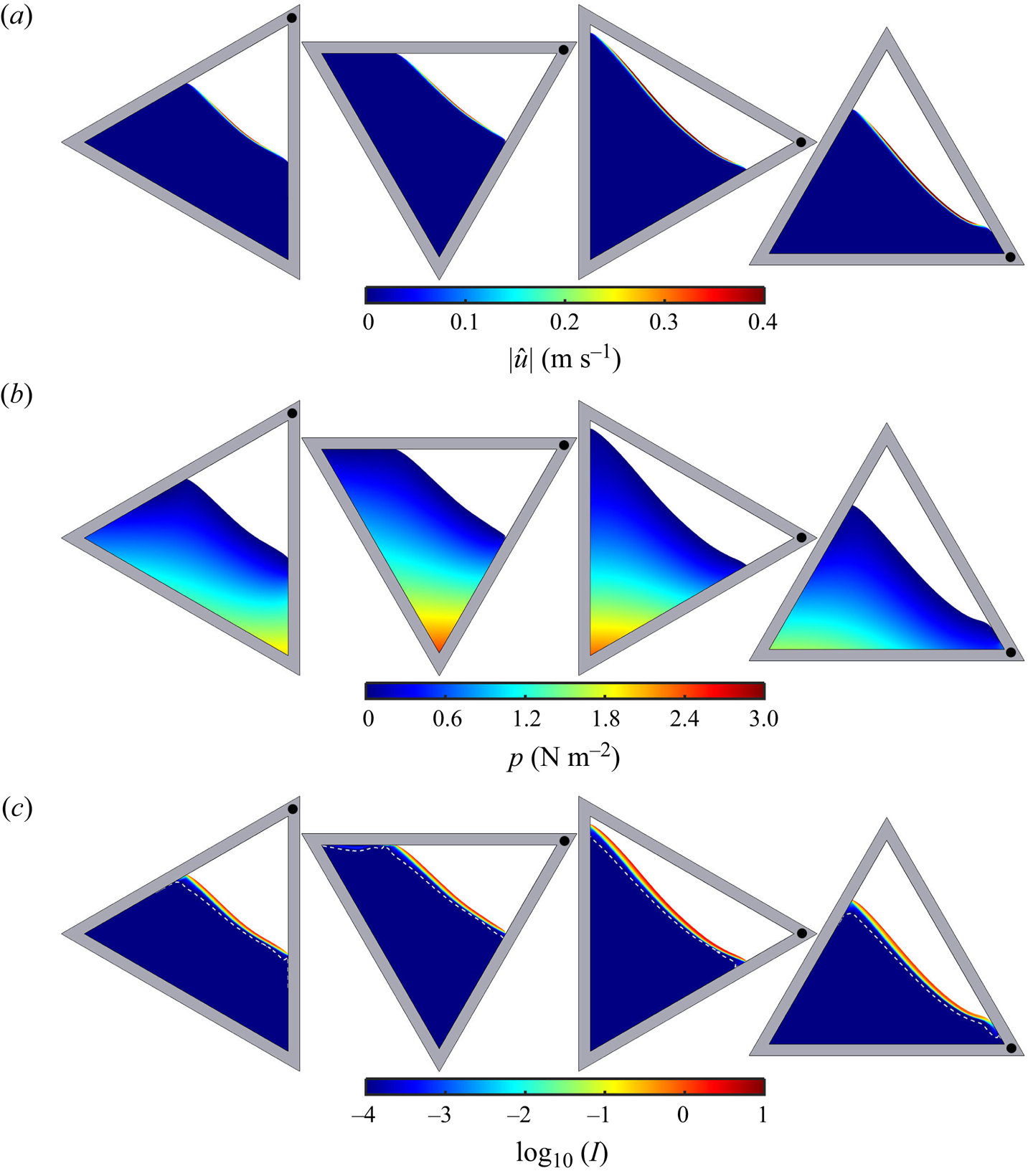

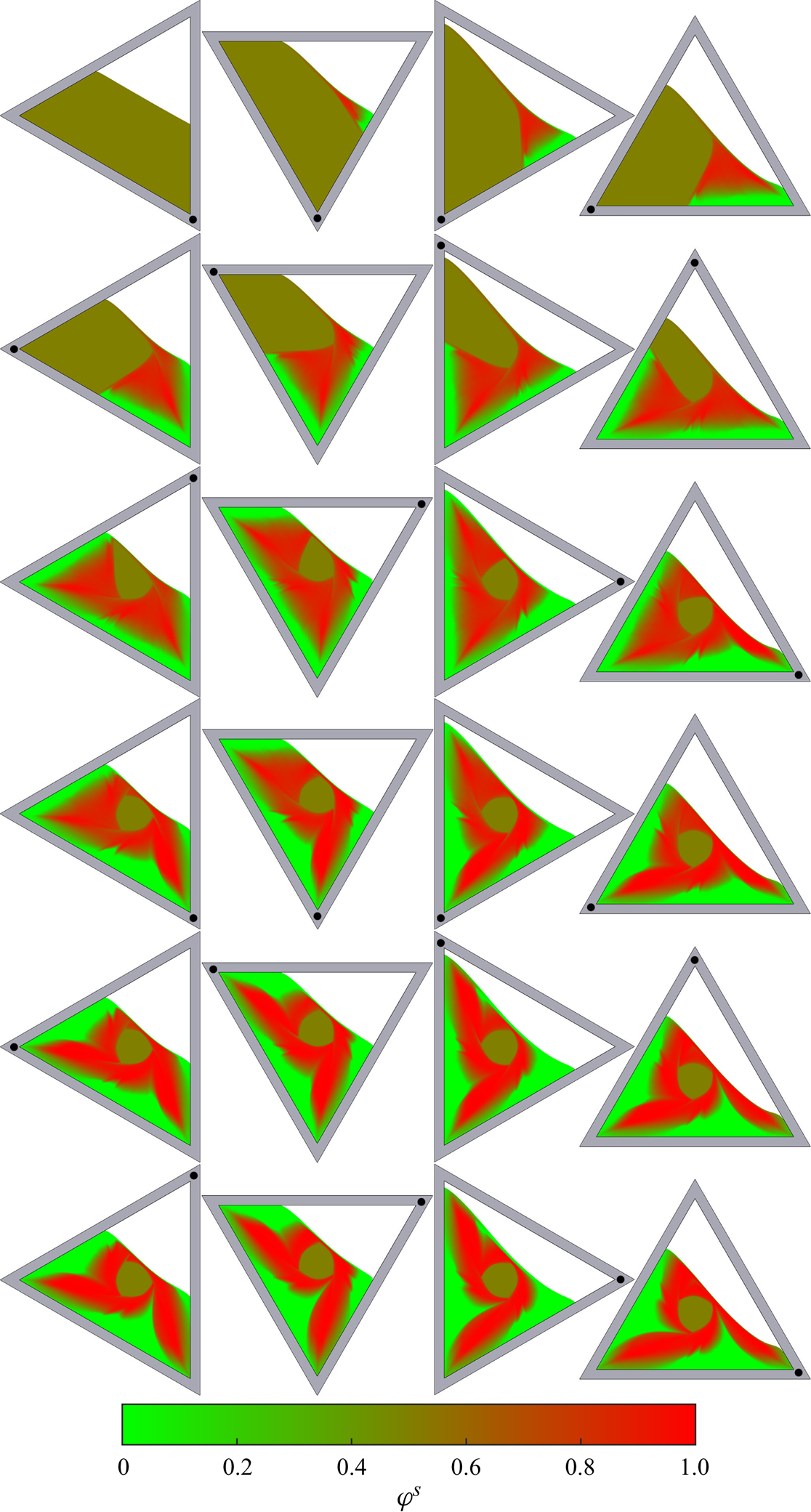

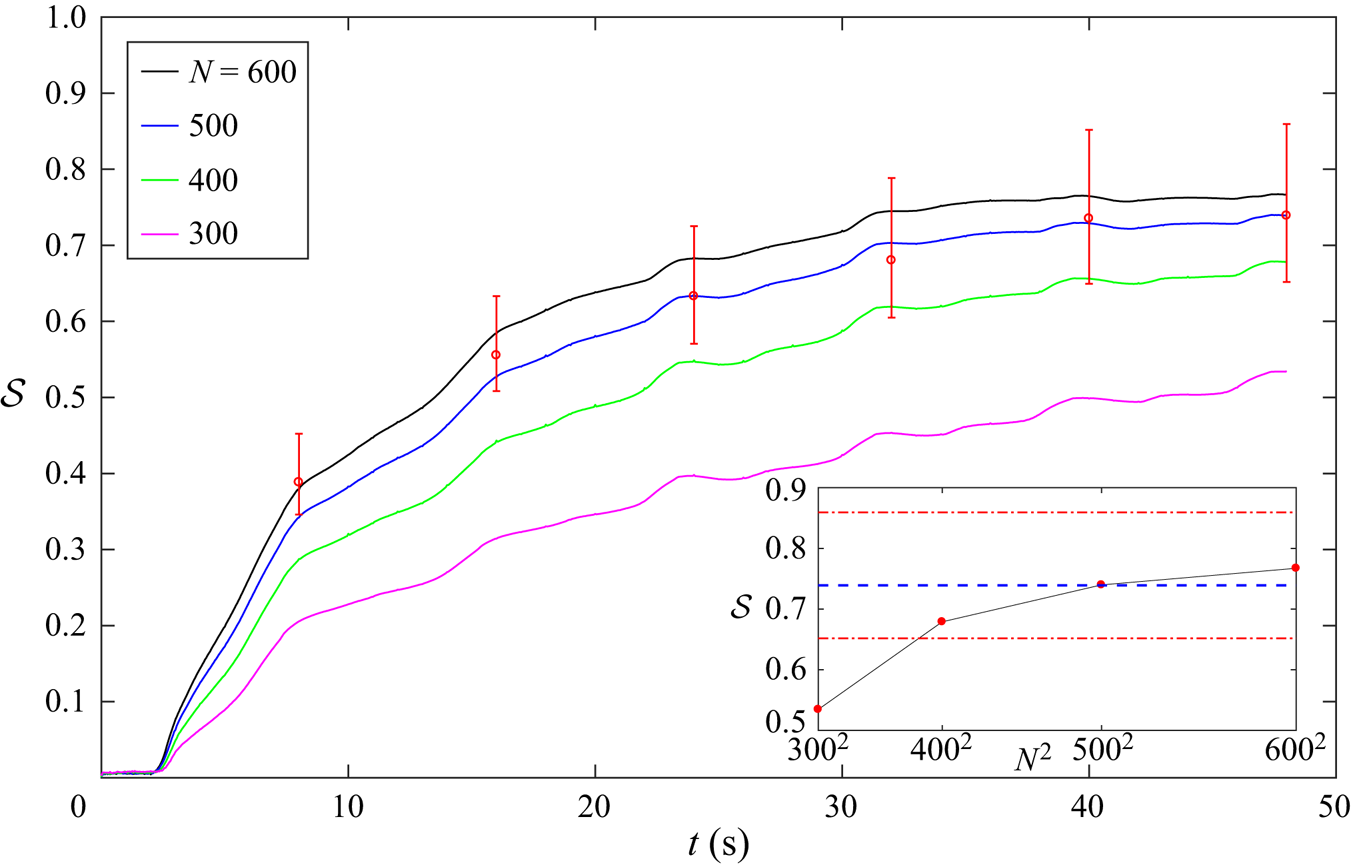

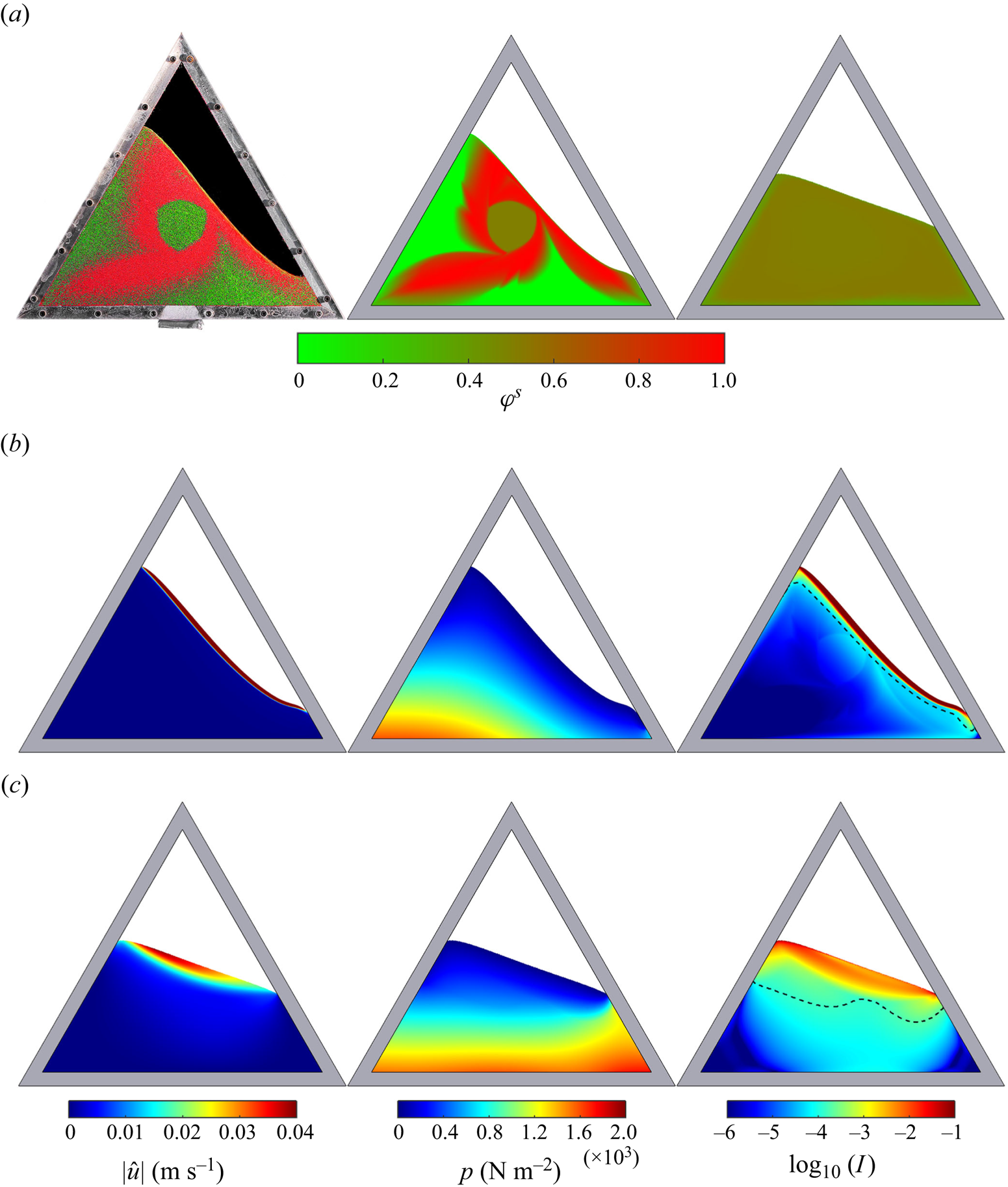

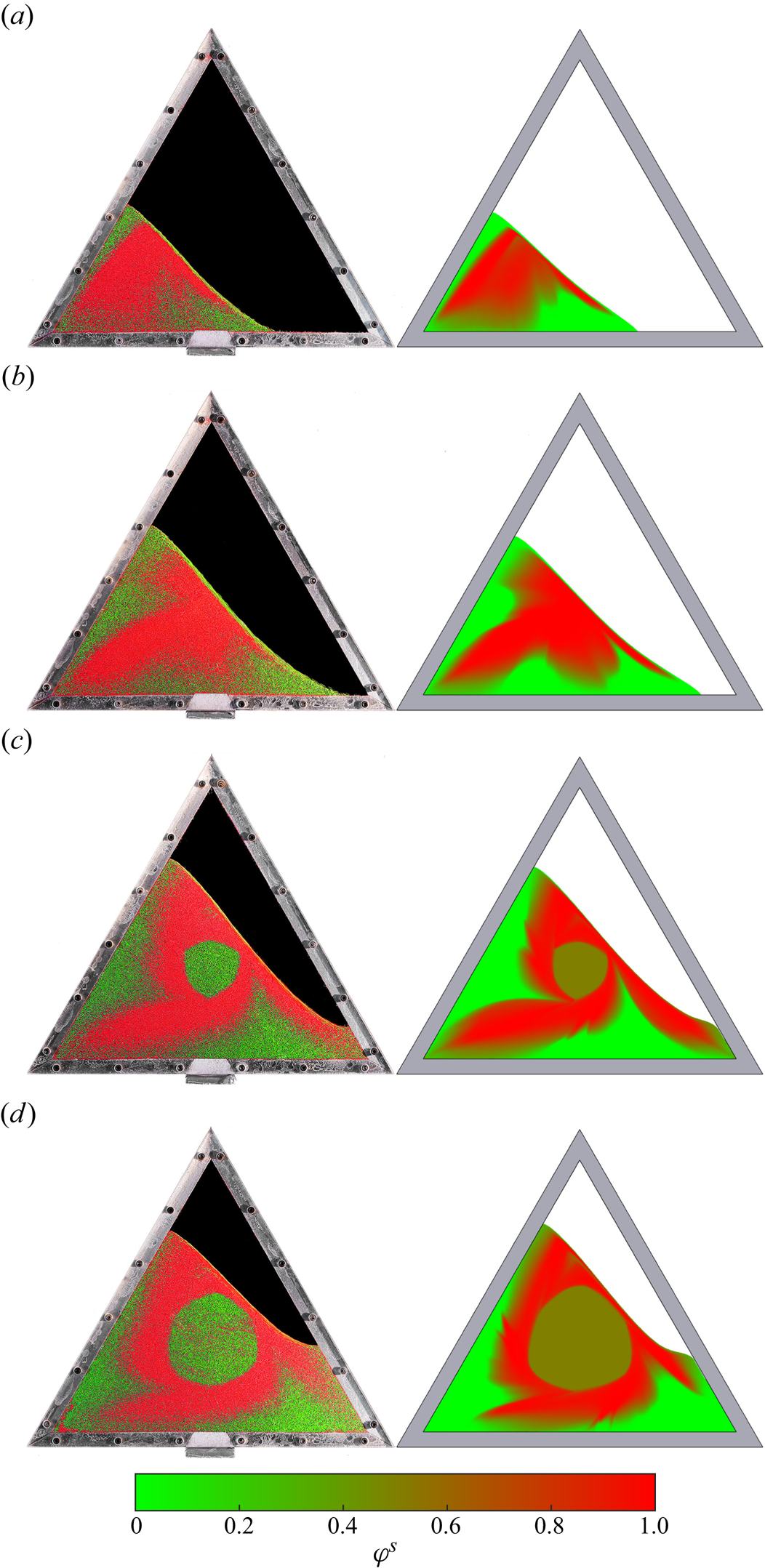

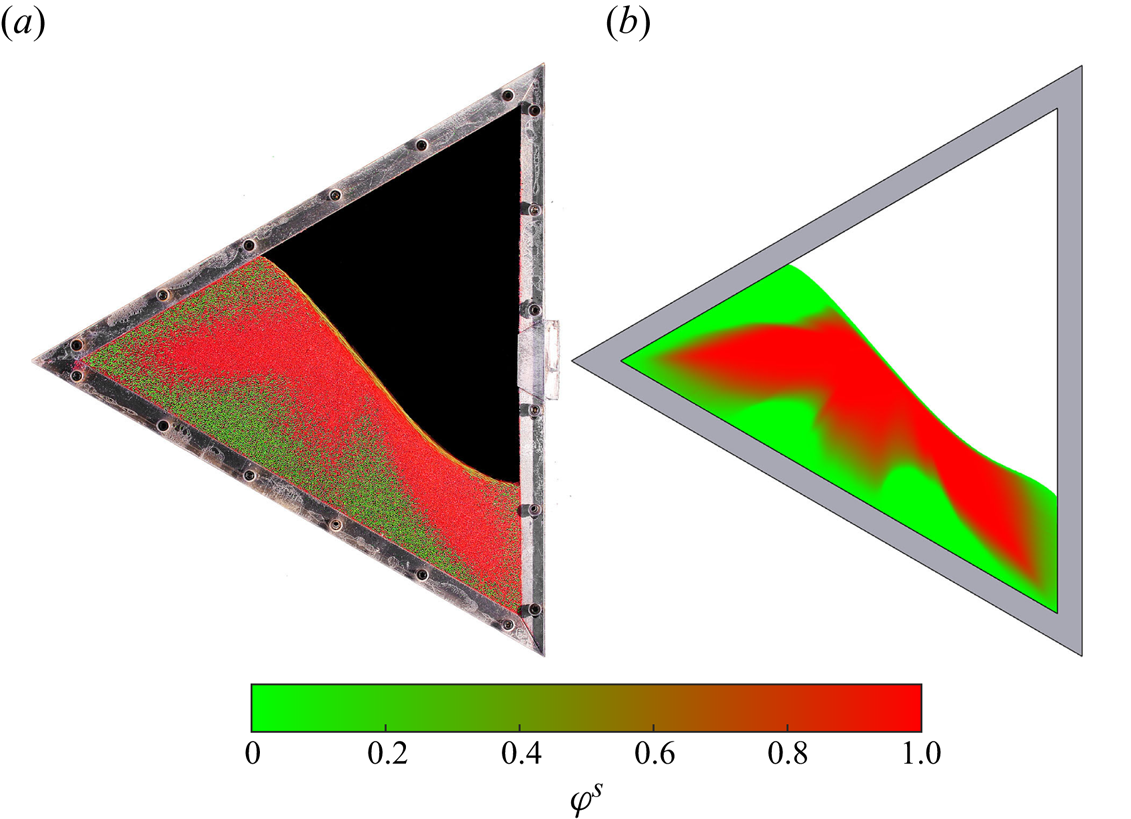

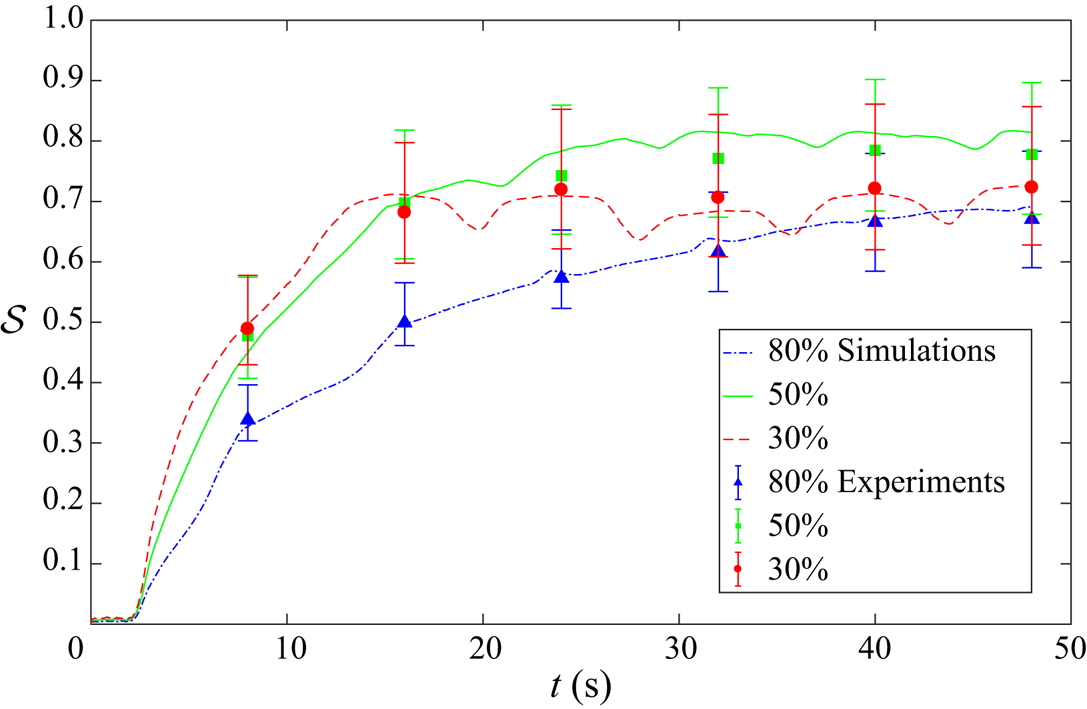

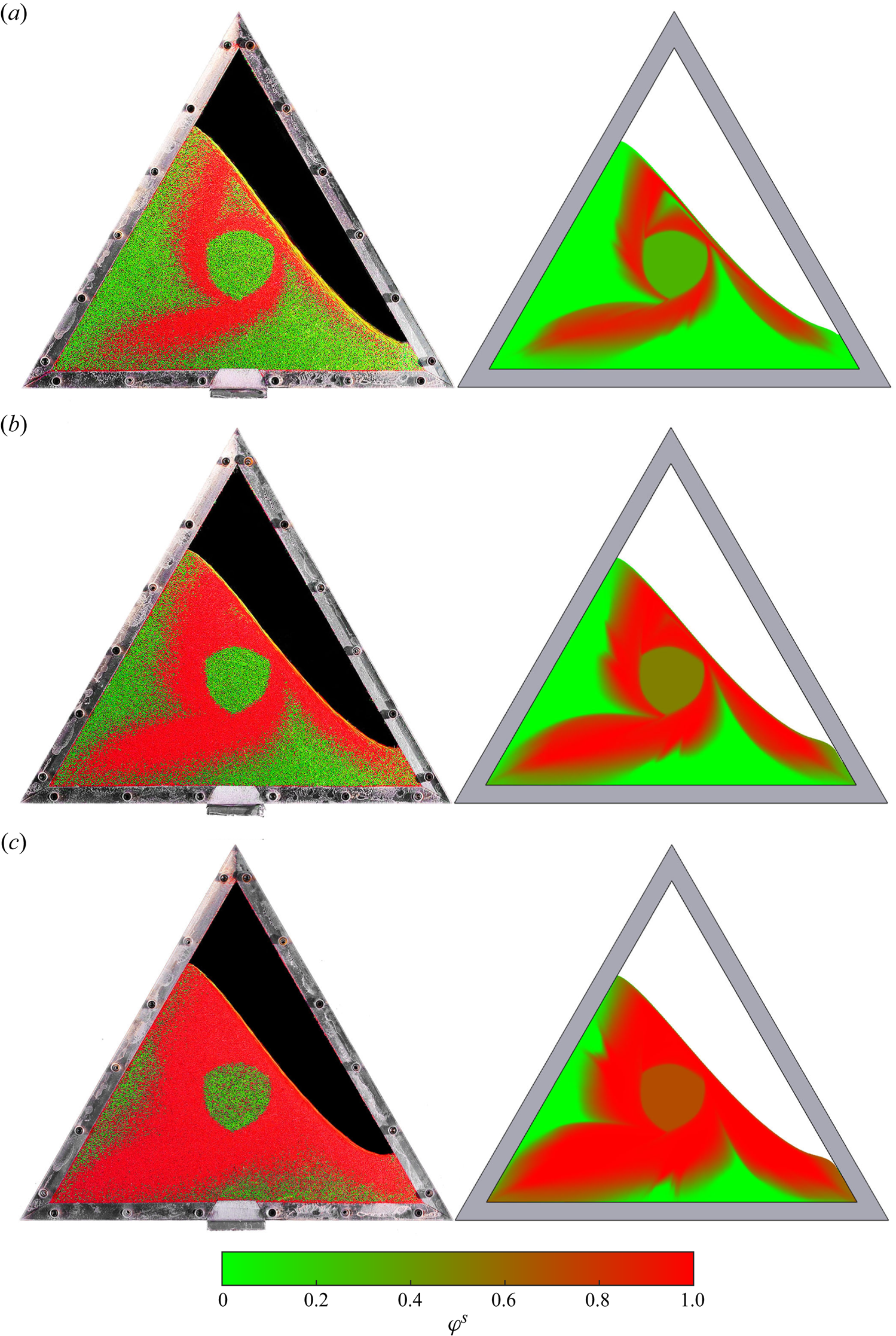

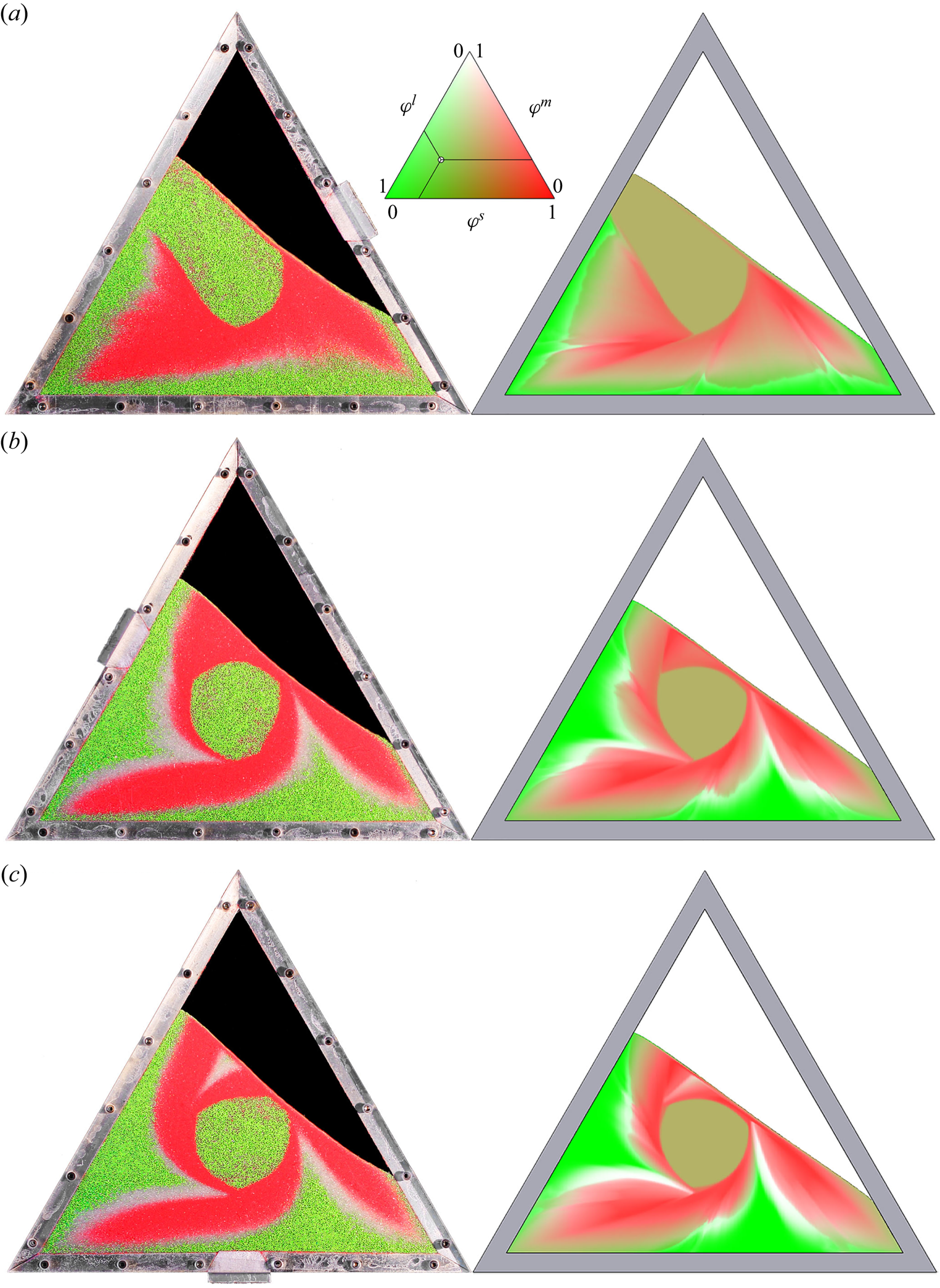

Figure 2 shows a series of photographs of the evolving pattern that develops when a 50:50 bidisperse mixture of large and small grains is rotated in a 70 % filled triangular drum rotating at 2.5 rpm. Supplementary movie 2 shows the full time-dependent evolution. The granular free surface, which was initially horizontal, inclines until a critical angle is exceeded, and a thin surface avalanche forms. The particles segregate very efficiently from one another in the surface avalanche, with the large particles rising to the surface and the small particle percolating down to the base, where they are first to deposit into the underlying solid rotating body of grains. As a result, the large green grains end up adjacent to the drum wall and the smaller red particles deposit closer to the central core. The complex flow field allows a quasi-periodic pattern to develop after just two rotations, which has small-particle rich arms that radiate outwards and point towards the corners of the triangle. A full discussion of the experimental results is deferred until the particle-size distribution of the numerical simulation is introduced in § 4.4.

Figure 2. Experimental photos of a 70 % filled drum with a 50:50 mixture of large green (![]() $d^l = 600\unicode{x2013}800$

$d^l = 600\unicode{x2013}800$ ![]() $\mathrm {\mu }$m) and small red (

$\mathrm {\mu }$m) and small red (![]() $d^s = 300\unicode{x2013}400$

$d^s = 300\unicode{x2013}400$ ![]() $\mathrm {\mu }$m) glass beads rotating at 2.5 rpm. Solid-body rotation occurs in the first 2 seconds. The sequence starts at

$\mathrm {\mu }$m) glass beads rotating at 2.5 rpm. Solid-body rotation occurs in the first 2 seconds. The sequence starts at ![]() $t=2$ s and progresses in increments of 2 s (30

$t=2$ s and progresses in increments of 2 s (30![]() $^\circ$ rotation), from left to right, top to bottom, up to

$^\circ$ rotation), from left to right, top to bottom, up to ![]() $t=48$ s (two revolutions). Once the surface avalanche develops, the mixture gradually segregates into a structure of small-particle arms. The protruding stopper provides a reference point for the rotation. Supplementary movie 2 shows the full time-dependent evolution and is available in the online supplementary material.

$t=48$ s (two revolutions). Once the surface avalanche develops, the mixture gradually segregates into a structure of small-particle arms. The protruding stopper provides a reference point for the rotation. Supplementary movie 2 shows the full time-dependent evolution and is available in the online supplementary material.

4.2. Coordinate system, boundary and initial conditions for the simulations

In order to simulate the segregation of the grains in the experimental rotating drum, a fixed Cartesian coordinate system ![]() $Oxz$ is defined with the origin

$Oxz$ is defined with the origin ![]() $O$ at the axis of rotation and the

$O$ at the axis of rotation and the ![]() $z$ coordinate pointing in the opposite direction to gravity. The large- and small-particle diameters are assumed to take average values

$z$ coordinate pointing in the opposite direction to gravity. The large- and small-particle diameters are assumed to take average values ![]() $d^l = 700$

$d^l = 700$ ![]() $\mathrm {\mu }$m and

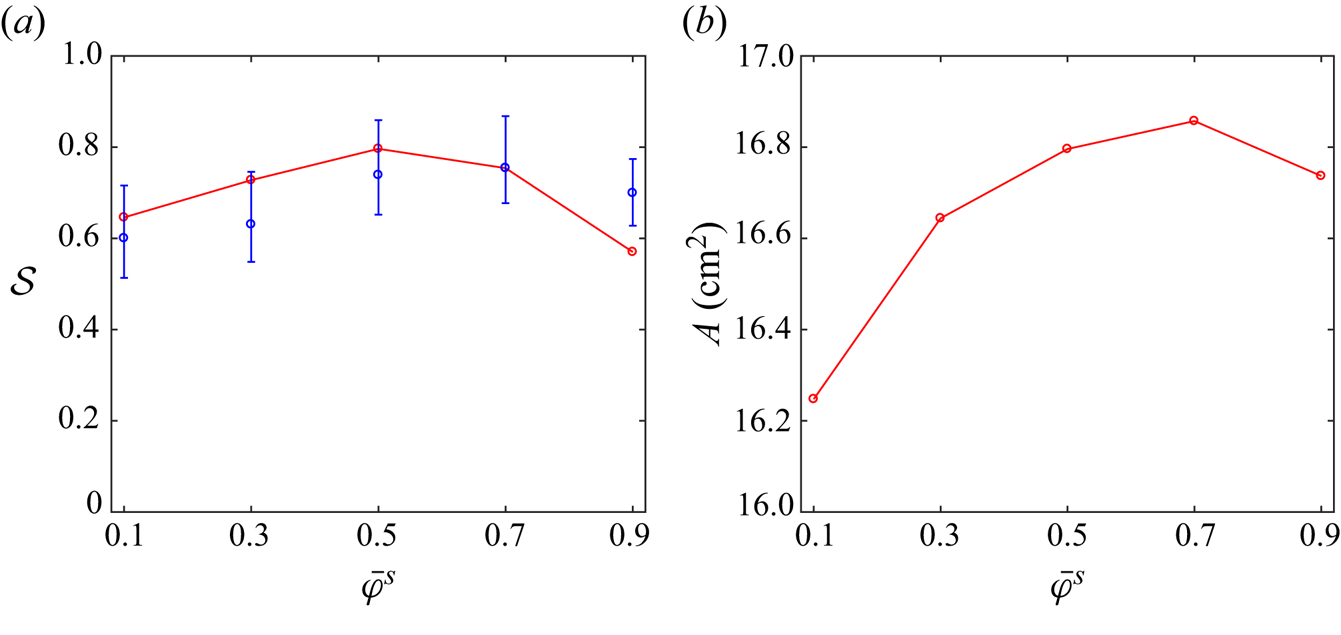

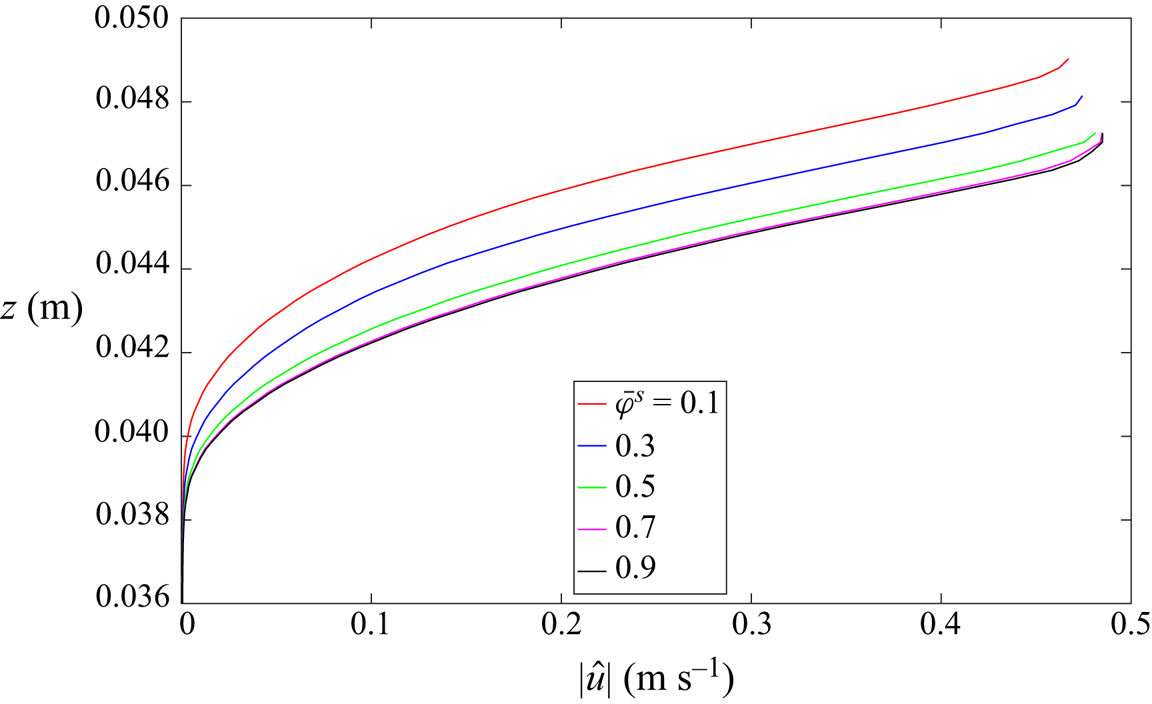

$\mathrm {\mu }$m and ![]() $d^s = 350$