Published online by Cambridge University Press: 20 July 2015

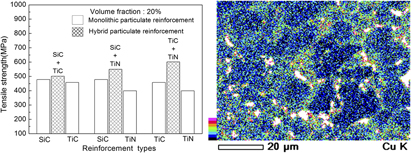

We investigated improvements to the mechanical properties of iron matrix composites for the case where the surfaces of the reinforcing particles are coated with copper and a hybrid mixture of different types of reinforcing ceramic particles (hybrid particles mixture) is used. Copper coating on the surfaces of SiC, TiC, and TiN particles can eliminate interfacial defects to significantly improve the composites' mechanical properties. The addition of uncoated hybrid particles mixture has little effect on the tensile strength improvement of composites compared with composites reinforced by monolithic particles, whereas copper-coated hybrid reinforcement has a significant effect. Any composite reinforced with copper-coated hybrid particles mixture will always have higher strength than that reinforced with monolithic particles. Our findings suggest that the load transfer between the matrix and reinforcing particles improved because of different elastic moduli, coefficients of thermal expansion and reaction heats of different types of reinforcing particles.