Article contents

The microstructural evolution and thermal stability of nanocrystalline ball-milled Ni–15 at.% W powder

Published online by Cambridge University Press: 11 March 2013

Abstract

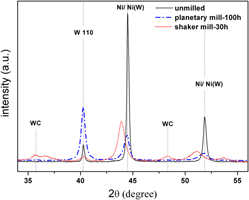

A mixture of pure Ni powder and pure W powder with a nominal composition Ni–15 at.% W was subjected to ball milling in a planetary mill and in a shaker mill. The microstructural evolution upon milling and upon subsequent annealing in the temperature range from 25 to 800 °C was investigated using ex situ and in situ x-ray diffraction integral breadth (single-line and Williamson–Hall) methods and whole powder pattern modeling as well as scanning electron microscopy, transmission electron microscopy, and differential scanning calorimetry. A nanocrystalline Ni(W) solid solution phase develops upon ball milling, with a higher W content by milling in the shaker mill as compared to the planetary mill. Grain coarsening studies indicated a very high stability of the nanocrystalline state, up to almost about 500 °C. Results of annealing at higher temperatures showed that, while the dissolved W content increased in the Ni matrix, a high stability against grain coarsening occurs, which can be ascribed to the presence of (segregated) W atoms at the grain boundaries.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2013

References

REFERENCES

- 5

- Cited by