Published online by Cambridge University Press: 28 March 2018

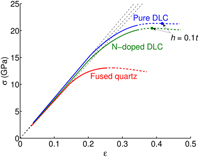

A method for extracting the substrate-independent stress–strain curves of thin films was developed using spherical nanoindentation to investigate the yield behavior of diamond-like carbon (DLC) thin films with Young’s moduli of ∼73 GPa and ∼76 GPa. The resulting stress–strain curves showed that these films commence yielding at ∼13 GPa and ∼14 GPa, respectively. These yield strength values agree with the critical pressure necessary to initiate the transformation of sp2-bonded carbon into significantly harder sp3-bonded carbon, indicating that the yielding of the materials is associated with the sp2-to-sp3 phase transition. The ability of a DLC film to accommodate a progressively increasing contact stress with strain beyond the yield point while dissipating part of the accumulated strain energy, as evidenced in this work, implies a unique mechanism of the brittle material for passively mitigating contact deformation and fracture in tribological applications.