Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Strozewski, Benjamin

Sly, Michael K.

Flores, Katharine M.

and

Skemer, Philip

2021.

Viscoplastic Rheology of α‐Quartz Investigated by Nanoindentation.

Journal of Geophysical Research: Solid Earth,

Vol. 126,

Issue. 9,

Chang, Yuling

Haase, Christian

Szeliga, Danuta

Madej, Lukasz

Hangen, Ude

Pietrzyk, Maciej

and

Bleck, Wolfgang

2021.

Compositional heterogeneity in multiphase steels: Characterization and influence on local properties.

Materials Science and Engineering: A,

Vol. 827,

Issue. ,

p.

142078.

Baral, Paul

Orekhov, Andrey

Dohmen, Ralf

Coulombier, Michaël

Raskin, Jean Pierre

Cordier, Patrick

Idrissi, Hosni

and

Pardoen, Thomas

2021.

Rheology of amorphous olivine thin films characterized by nanoindentation.

Acta Materialia,

Vol. 219,

Issue. ,

p.

117257.

Tang, Xuhai

Xu, Jingjing

Zhang, Yiheng

Zhao, Haifeng

Paluszny, Adriana

Wan, Xue

and

Wang, Zhengzhi

2022.

The Rock-Forming Minerals and Macroscale Mechanical Properties of Asteroid Rocks.

SSRN Electronic Journal ,

Zhang, Yiheng

Tang, Xuhai

Xu, Jingjing

Wan, Xue

Wang, Zhengzhi

and

Zhao, Haifeng

2022.

The Rock-Forming Minerals and Macroscale Mechanical Properties of Asteroid Rocks.

SSRN Electronic Journal ,

Jentner, Robin M.

Srivastava, Kinshuk

Scholl, Sebastian

Best, James P.

Kirchlechner, Christoph

and

Dehm, Gerhard

2022.

Unsupervised Clustering of Nanoindentation Data for Microstructural Reconstruction: Challenges in Phase Discrimination.

SSRN Electronic Journal ,

Cheng, Changjun

Zhang, Xiaofu

Haché, Michel J. R.

and

Zou, Yu

2022.

Magnetron co-sputtering synthesis and nanoindentation studies of nanocrystalline (TiZrHf)x(NbTa)1−x high-entropy alloy thin films.

Nano Research,

Vol. 15,

Issue. 6,

p.

4873.

Dehm, Gerhard

Jentner, Robin M.

Best, James P.

Srivastava, Kinshuk

Scholl, Sebastian

and

Kirchlechner, Christoph

2022.

Unsupervised Clustering of Nanoindentation Data for Microstructural Reconstruction: Challenges in Phase Discrimination.

SSRN Electronic Journal ,

Wheeler, Jeffrey M.

Gan, Bin

and

Spolenak, Ralph

2022.

Combinatorial Investigation of the Ni–Ta System via Correlated High‐Speed Nanoindentation and EDX Mapping.

Small Methods,

Vol. 6,

Issue. 2,

Wagner, Marius A.

Engel, Jona

Hadian, Amir

Clemens, Frank

Rodriguez-Arbaizar, Mikel

Carreño-Morelli, Efrain

Wheeler, Jeffrey M.

and

Spolenak, Ralph

2022.

Filament extrusion-based additive manufacturing of 316L stainless steel: Effects of sintering conditions on the microstructure and mechanical properties.

Additive Manufacturing,

Vol. 59,

Issue. ,

p.

103147.

Rabbi, M. Fazle

Khafagy, Khaled H.

Garvie, Laurence A. J.

Asphaug, Erik

Cotto-Figueroa, Desireé

and

Chattopadhyay, Aditi

2022.

Characterization of Minerals, Metals, and Materials 2022.

p.

17.

Kalali, Deekshith G.

Seekala, Harita

Phani, P. Sudharshan

Bhanu Sankara Rao, K.

and

Rajulapati, Koteswararao V.

2023.

High speed nanoindentation aided correlative study between local mechanical properties and chemical segregation in equiatomic MoNb and MoNbTi alloys.

Journal of Materials Research,

Vol. 38,

Issue. 11,

p.

2919.

Jentner, R.M.

Srivastava, K.

Scholl, S.

Gallardo-Basile, F.J.

Best, J.P.

Kirchlechner, C.

and

Dehm, G.

2023.

Unsupervised clustering of nanoindentation data for microstructural reconstruction: Challenges in phase discrimination.

Materialia,

Vol. 28,

Issue. ,

p.

101750.

Rossi, Edoardo

Wheeler, Jeffrey M.

and

Sebastiani, Marco

2023.

High-speed nanoindentation mapping: A review of recent advances and applications.

Current Opinion in Solid State and Materials Science,

Vol. 27,

Issue. 5,

p.

101107.

Nguyen, Hoan D.

Wang, Wei

Yao, Xupei

Sagoe-Crentsil, Kwesi

and

Duan, Wenhui

2023.

Porosity-Modulus Mapping enhanced nanomechanical analysis of heterogeneous materials.

Journal of Materials Science,

Vol. 58,

Issue. 24,

p.

10058.

Cheng, Changjun

Feng, Renfei

Haché, Michel J.R.

Zhang, Xiaofu

and

Zou, Yu

2023.

Phase formability and nanomechanical properties in nanostructured multi-principal element alloys: Combinatorial and data-driven studies.

Materials Today Nano,

Vol. 24,

Issue. ,

p.

100403.

Tang, Xuhai

Xu, Jingjing

Zhang, Yiheng

Zhao, Haifeng

Paluszny, Adriana

Wan, Xue

and

Wang, Zhengzhi

2023.

The rock-forming minerals and macroscale mechanical properties of asteroid rocks.

Engineering Geology,

Vol. 321,

Issue. ,

p.

107154.

Gordon, S.

Besharatloo, H.

Wheeler, J.M.

Rodriguez-Suarez, T.

Roa, J.J.

Jiménez-Piqué, E.

and

Llanes, L.

2023.

Micromechanical mapping of polycrystalline cubic boron nitride composites by means of high-speed nanoindentation: Assessment of microstructural assemblage effects.

Journal of the European Ceramic Society,

Vol. 43,

Issue. 7,

p.

2968.

Huang, Tai-Jan

Niverty, Sridhar

Sundar, Arun

and

Chawla, Nikhilesh

2023.

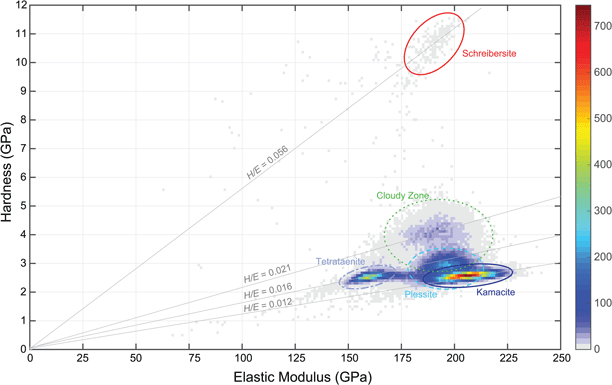

Microstructural characterization and mechanical behavior of Aba Panu meteorite by correlative microscopy and nanoindentation.

Materials Characterization,

Vol. 205,

Issue. ,

p.

113331.

Seehaus, Mattis

Lee, Sang-Hyeok

Stollenwerk, Tobias

Wheeler, Jeffrey M.

and

Korte-Kerzel, Sandra

2023.

Estimation of directional single crystal elastic properties from nano-indentation by correlation with EBSD and first-principle calculations.

Materials & Design,

Vol. 234,

Issue. ,

p.

112296.