Published online by Cambridge University Press: 08 June 2015

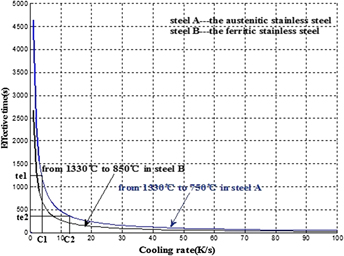

An interesting experimental phenomenon was obtained by Mintz that the hot ductility of an austenitic steel decreases with decreasing strain rate whereas that of a ferritic steel increases. However, the mechanism is still unclear. In this study, the critical time and critical cooling rate of nonequilibrium grain-boundary segregation (NGS) are calculated. It is shown that for Mintz's thermal cycle prior to tensile testing, the effective time of the austenitic steel is shorter than the critical time and that of the ferritic steel is longer than the critical time. When the strain rate decreases, the elastic stress aging time increases. As a result, for the austenitic steel, the grain-boundary segregation of impurity increases, thereby reducing the hot ductility, whereas for the ferritic steel, the segregation of impurity decreases, thereby enhancing the hot ductility. Consequently, the hot ductility loss of both austenitic and ferritic stainless steels is induced by NGS of impurity.