Article contents

Selective laser melting of graphene oxide–reinforced Ti–48Al–2Cr–2Nb: Improved manufacturability and mechanical strength

Published online by Cambridge University Press: 06 April 2020

Abstract

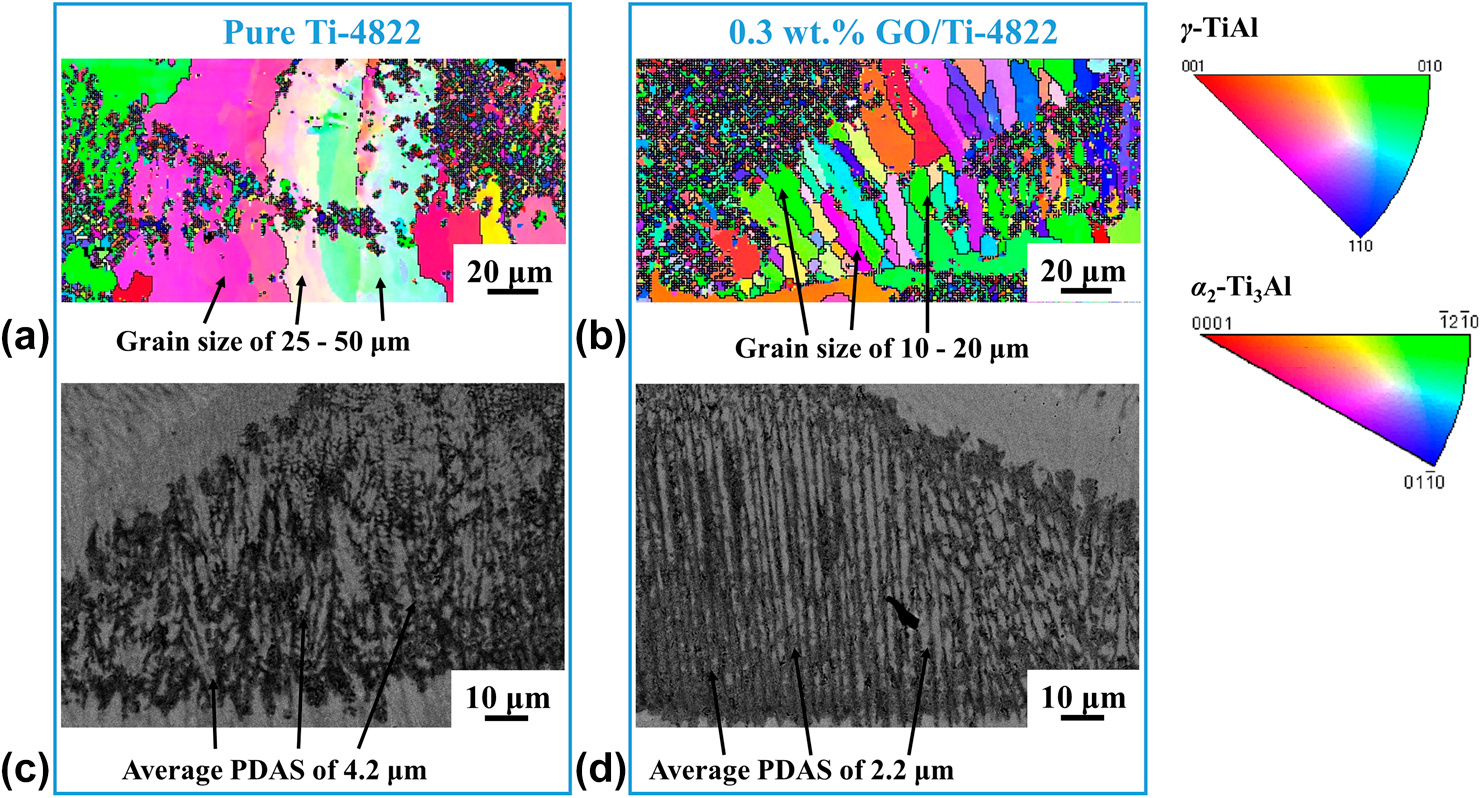

Severe cracking and unsatisfied mechanical performance are the major challenges of manufacturing titanium aluminide (TiAl) components by selective laser melting (SLM). In this work, graphene oxide (GO) sheets were introduced onto the metal powder surface to improve the manufacturability of SLM of a Ti–48Al–2Cr–2Nb (at.%) alloy and enhance the mechanical strength of the laser-fabricated parts. The effect of laser power and GO content on the macromorphology of single-track processing was investigated, showing that the crack-free track could be obtained with the addition of 0.1–0.5 wt.% GO under a laser power of 110 W. In addition, the characterization of multilayer buildups via electron backscatter diffraction and backscatter electron imaging reveals the grain refinement during SLM of GO/TiAl nanocomposites. Finally, the strength of the as-built samples was examined using micro-hardness test, showing a maximal increase of 21.9% by adding 0.3 wt.% GO into the TiAl powders from laser-fabricated samples without GO.

Keywords

- Type

- Article

- Information

- Journal of Materials Research , Volume 35 , Issue 15: Focus Issue: Additive Manufacturing of Metals: Complex Microstructures and Architecture Design , 14 August 2020 , pp. 1998 - 2005

- Copyright

- Copyright © Materials Research Society 2020

References

- 7

- Cited by