Published online by Cambridge University Press: 02 December 2021

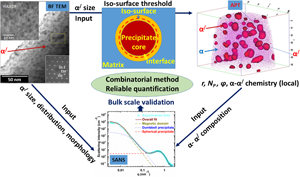

The quantitative characterization of small nano-sized precipitates poses genuine challenges and is often deficient in accuracy due to the inherent limitations inevitably associated with the individual experimental techniques. A convenient solution is to utilize multiple complementary techniques. The present work demonstrates an effective way to reliably quantify nano-sized precipitates using a combination of complementary techniques of atom probe tomography (APT), small angle neutron scattering (SANS), and transmission electron microscopy (TEM). As a case study, the size (radius, r), number density (NP), volume fraction (ϕ), and chemical composition of Cr-rich α′ precipitates are determined in Fe–20 at% Cr alloy, thermally aged at 773 K for 1,000 h. This combinatorial approach utilizes the strength of each technique in such a way that the overall accuracy of quantitative precipitation analysis improves significantly. For example, the superior spatial resolution makes TEM the appropriate technique to estimate the size and size distribution of the precipitates, while APT provides the chemical composition. Similarly, SANS analysis incorporates both the size and the compositional information thus derived independently and provides statiscally averaged quantitative analysis overcoming the field-of-view limitations of both TEM and APT. This combinatorial approach improves the accuracy of quantification and provides the true representation of the microstructure.