Article contents

Effect of Reheating and Quenching on the Cathodoluminescence Intensity of Free Lime in Steelmaking Slag

Published online by Cambridge University Press: 17 May 2021

Abstract

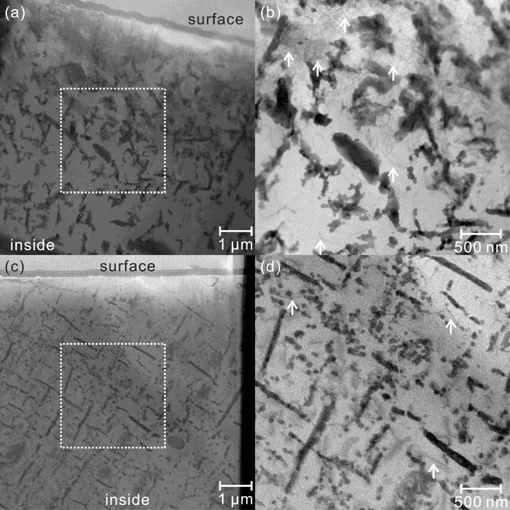

Determining free lime content in steelmaking slag is crucial for its safe reuse in road construction. A simple method has been recently developed to rapidly derive this value via cathodoluminescence (CL) imaging of steelmaking slag, previously quenched from 1,000°C to room temperature, according to the illuminated areas corresponding to free lime (luminescence peak at 600 nm). This quenching is required to obtain intense CL from free lime, but the mechanism of such signal enhancement is still unknown. Therefore, the present study investigated the mechanism by comparing the microstructures, CL images, and CL spectra of free lime in quenched and unquenched steelmaking slag. Large amounts of defects, including dislocations, were observed in the free lime emitting intense luminescence at 600 nm, whereas the samples without clear CL exhibited only a few defects. These results and previous studies suggest that the luminescence at 600 nm from free lime is enhanced by the CL originating from oxygen vacancies (380 nm); therefore, the enhancement of the intensity of the free lime CL peak could be attributed to the increase in the oxygen vacancies via quenching from 1,000°C to room temperature.

Keywords

- Type

- Materials Science Applications

- Information

- Copyright

- Copyright © The Author(s), 2021. Published by Cambridge University Press on behalf of the Microscopy Society of America

References

- 5

- Cited by