Article contents

Focused Ion Beam Preparation of Low Melting Point Metals: Lessons Learned From Indium

Published online by Cambridge University Press: 22 March 2022

Abstract

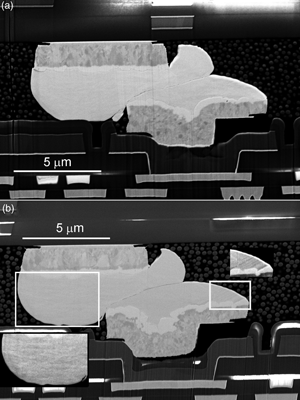

Indium (In) and other low melting point metals are used as interconnects in a variety of hybridized circuits and a full understanding of the metallurgy of these interconnects is important to the reliability and performance of the devices. This paper shows that room temperature focused ion beam (FIB) preparation of cross-sections, using Ga+ or Xe+ can result in artifacts that obscure the true In microbump structure. The use of modified milling strategies to minimize the increased local sample temperature are shown to produce cross-sections that are representative of the In bump microstructure in some sample configurations. Furthermore, cooling of the sample to cryogenic temperatures is shown to reliably eliminate artifacts in FIB prepared cross-sections of In bumps allowing the true bump microstructure to be observed.

- Type

- Materials Science Applications

- Information

- Copyright

- Copyright © The Author(s), 2022. Published by Cambridge University Press on behalf of the Microscopy Society of America

References

- 7

- Cited by