Article contents

Mechanism of FIB-Induced Phase Transformation in Austenitic Steel

Published online by Cambridge University Press: 29 November 2021

Abstract

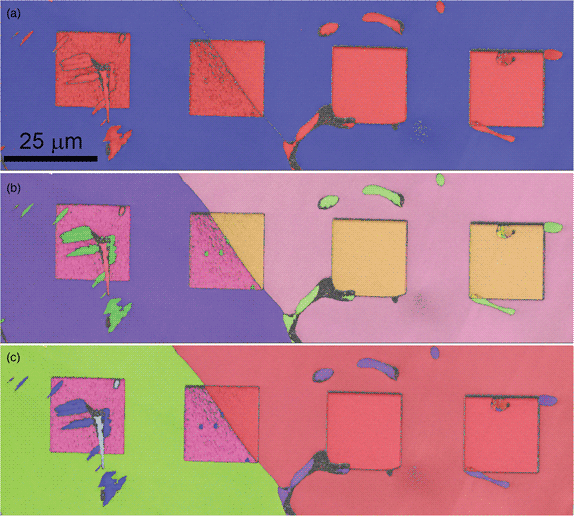

The transformation of unstable austenite to ferrite or α′ martensite as a result of exposure to Xe+ or Ga+ ions at room temperature was studied in a 304 stainless steel casting alloy. Controlled Xe+ and Ga+ ion beam exposures of the 304 were carried out at a variety of beam/sample geometries. It was found that both Ga+ and Xe+ ion irradiation resulted in the transformation of the austenite to either ferrite or α′ martensite. In this paper, we will refer to the transformation product as a BCC phase. The crystallographic orientation of the transformed area was controlled by the orientation of the austenite grain and was consistent with either the Nishiyama–Wasserman or the Kurdjumov–Sachs orientation relationships. On the basis of the Xe+ and Ga+ ion beam exposures, the transformation is not controlled by the chemical stabilization of the BCC phase by the ion species, but is a result of the disorder caused by the ion-induced recoil motion and subsequent return of the disordered region to a more energetically favorable phase.

- Type

- Materials Science Applications

- Information

- Copyright

- Copyright © The Author(s), 2021. Published by Cambridge University Press on behalf of the Microscopy Society of America

References

- 5

- Cited by