Published online by Cambridge University Press: 15 February 2021

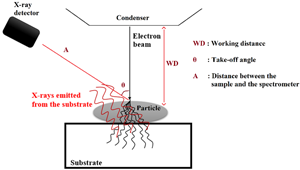

A simple and fast method for thickness measurements using electron probe microanalysis (EPMA) is described. The method is applicable on samples with a thickness smaller than the electron depth range and does not require any knowledge of instrumental parameters. The thickness is determined by means of the distance that electrons travel inside the sample before crossing through it. Samples are first deposited on a substrate that, when reached by the transmitted electrons, produces an X-ray signal. The measured characteristic X-ray line intensity of the substrate is later used to determine the energy of transmitted electrons, which is proportional to the distance that electrons travel inside the sample. The study was performed on spherical K411 glass particles and cylindrical particles of U–Ce oxide with a size ranging from 0.2 to 4 μm. The measured thicknesses of all the studied particles showed good agreements with the real values. Although the method is only validated on particles with usual shapes, it can be applied to determine a local thickness of thin samples with irregular morphologies. This can help solving multiple issues in analysis with EPMA of non-bulk samples exhibiting complex geometries. Three dimensional microscopic imaging could also find a good utility in the described method.