The scarcity of “off-the-shelf” soft electronic components has curtailed the development of wearable devices, essential for biomechanical studies and even for patient rehabilitation applications. Addressing this challenge, a team led by Jennifer Lewis and Conor Walsh at Harvard University has now harnessed additive manufacturing (also known as three-dimensional printing) to make soft capacitive strain sensors composed of multicore–shell fibers.

As reported in the April 17 issue of Advanced Materials (DOI: 10.1002/adma.201500072), the two materials are deposited to form a multicore–shell architecture using a specialized print head. The material in the central channel is conductive, and is separated from an annular conductive channel by an elastomeric dielectric, so the multicore–shell fiber functions as a stretch-responsive capacitor. “The ability to make functional, high-performance devices with additive manufacturing opens a lot of doors,” says Joseph Muth, one of the lead researchers on the project.

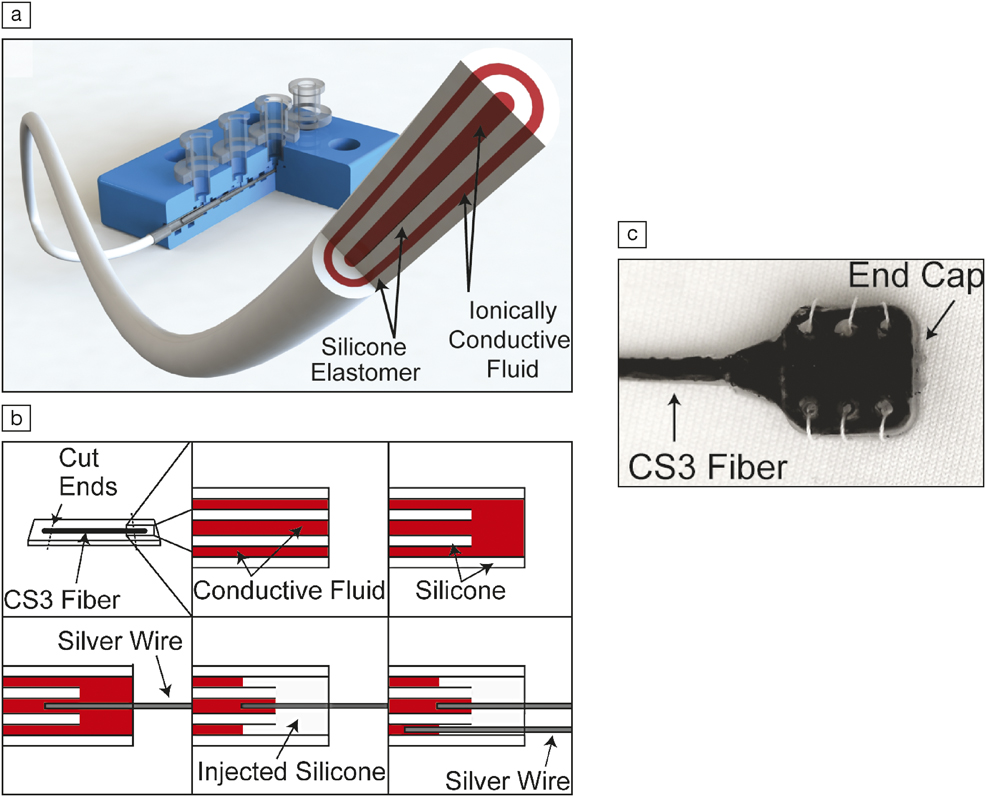

(a) Schematic of the multicore–shell printing process; (b) schematic of the sensor assembly process; and (c) sensor integration with textiles through sewing. Reprinted with permission from Adv. Mater. 27 (2015), DOI: 10.1002/adma.201500072. © 2015 Wiley.

Conventional electronics manufacturing requires costly equipment and is adapted for fabrication of rigid, two-dimensional components. Tingrui Pan, a professor of biomedical engineering at the University of California–Davis, who was not involved in the research, says, “The multi-material printing platform used to achieve a brand new type of stretchable linear capacitive sensors, which cannot be easily achieved by any existing technology,” is the key breakthrough.

This technique was enabled by the development of a specially designed, cylindrical four-channel, coaxial print- head (Figure a) to simultaneously deliver the alternating conductive and dielectric layers. A modified commercial silicone elastomer was used as both the dielectric and the encapsulant, while the conductive layers were comprised of a poly(ethylene glycol) glycerol gel electrolyte. Both of these materials are widely available and nontoxic, so they can easily and safely be used in human-device interfaces.

As important as the technology is its integration. “This design considered the integration from the outset,” says Muth. “The end cap design protects the electrical connections,” he notes, referring to the hard elastomer end piece acting as a buffer between the elastomer sensor and its silver leads, as shown in Figure b. Additionally, “the end cap has holes, so the device can be sewn in or it can be woven into the clothing” (see Figure c).

Other practical challenges of existing soft strain sensors include hysteresis and detrimental water sensitivity. These were overcome by this sensor’s cylindrical capacitor design: changes in conductance due to water absorption do not impact the capacitive signal. The sensors also needed to perform under high strain to be truly “wearable.” Because of the high extensibility of the silicone elastomer, the devices were operable up to strains of 700%.

A particularly exciting application is in next-generation wearable robots made of soft materials to unobtrusively interface to the human body. Walsh says, “These robots will augment the capabilities of healthy individuals (e.g., improved walking efficiency, increased grip strength) in addition to assisting patients who suffer from physical or neurological disorders.” Development of such devices will require novel and easily customizable fabrication methodologies for soft electronic components. Muth’s hope is that “if a researcher has know-how but lacks access to conventional sensing techniques, he/she could actually have a way to make a viable soft sensor with typical tools.”