1. Introduction

The interaction between flexible structures and surrounding fluids is a common and well-known phenomenon in nature, as seen in the reconfiguration of plants (de Langre Reference de Langre2008), flapping of flags (Shelley & Zhang Reference Shelley and Zhang2011), swimming fish (Triantafyllou, Triantafyllou & Yue Reference Triantafyllou, Triantafyllou and Yue2000) and the flight of birds/insects (Wu Reference Wu2011). Studying the dynamics of these fluid–flexible structure systems is valuable for biologists seeking a deeper understanding of plant biology and the locomotion of aquatic and aerial animals (Nepf Reference Nepf2012; Lauder Reference Lauder2015). Moreover, the fundamental mechanisms uncovered can serve as inspiration for engineers designing high-performance biomimetic aerial/underwater vehicles or robots (Platzer et al. Reference Platzer, Jones, Young and Lai2008; Smits Reference Smits2019). The applications extend to energy extraction (Allen & Smits Reference Allen and Smits2001; Wu Reference Wu2011; Mathai et al. Reference Mathai, Tzezana, Das and Breuer2022), the paper industry (Watanabe et al. Reference Watanabe, Suzuki, Sugihara and Sueoka2002) and flow control (Shen et al. Reference Shen, Zhang, Yue and Triantafyllou2003; Sunil, Kumar & Poddar Reference Sunil, Kumar and Poddar2022). As a result, these issues have captivated human interest for several decades.

Previous studies, such as Alben, Shelley & Zhang (Reference Alben, Shelley and Zhang2002), Gao et al. (Reference Gao, Pan, Wang and Tian2020) and Sun et al. (Reference Sun, Peng, Yang, Xiong, Wang and Wang2022), have focused on drag reduction in fluid–flexible structure interactions. Classic theory for rigid bluff bodies suggests that drag (![]() $F_d$) is proportional to the square of the oncoming flow speed (

$F_d$) is proportional to the square of the oncoming flow speed (![]() $U$), i.e.

$U$), i.e. ![]() $F_d \sim U^2$ (Batchelor Reference Batchelor1967). However, flexible bodies under fluid loading undergo reconfiguration, decreasing the projected area perpendicular to the flow and adopting a more streamlined posture (Alben et al. Reference Alben, Shelley and Zhang2002; Buchak, Eloy & Reis Reference Buchak, Eloy and Reis2010; Luhar & Nepf Reference Luhar and Nepf2011; Schouveiler & Eloy Reference Schouveiler and Eloy2013). This reconfiguration results in a slower-growing form of drag, expressed as

$F_d \sim U^2$ (Batchelor Reference Batchelor1967). However, flexible bodies under fluid loading undergo reconfiguration, decreasing the projected area perpendicular to the flow and adopting a more streamlined posture (Alben et al. Reference Alben, Shelley and Zhang2002; Buchak, Eloy & Reis Reference Buchak, Eloy and Reis2010; Luhar & Nepf Reference Luhar and Nepf2011; Schouveiler & Eloy Reference Schouveiler and Eloy2013). This reconfiguration results in a slower-growing form of drag, expressed as ![]() $F_d \sim U^{2 + \mathscr {V}}$, where

$F_d \sim U^{2 + \mathscr {V}}$, where ![]() $\mathscr {V}$ is the Vogel exponent (Vogel Reference Vogel1984, Reference Vogel1989). Examples like tree leaves (Vogel Reference Vogel1989) or circular plastic sheets (Schouveiler & Boudaoud Reference Schouveiler and Boudaoud2006) demonstrate a much slower drag growth than the

$\mathscr {V}$ is the Vogel exponent (Vogel Reference Vogel1984, Reference Vogel1989). Examples like tree leaves (Vogel Reference Vogel1989) or circular plastic sheets (Schouveiler & Boudaoud Reference Schouveiler and Boudaoud2006) demonstrate a much slower drag growth than the ![]() $U^2$ law as they roll into tighter cones in the fluid. In a two-dimensional (2-D) flowing soap film, a flexible fibre tethered at the midpoint exhibits drag scaling as

$U^2$ law as they roll into tighter cones in the fluid. In a two-dimensional (2-D) flowing soap film, a flexible fibre tethered at the midpoint exhibits drag scaling as ![]() $U^{4/3}$ (i.e.

$U^{4/3}$ (i.e. ![]() $\mathscr {V}=-2/3$) at high Reynolds numbers (

$\mathscr {V}=-2/3$) at high Reynolds numbers (![]() $Re$), as observed in the experimental and theoretical study by Alben et al. (Reference Alben, Shelley and Zhang2002) and Alben, Shelley & Zhang (Reference Alben, Shelley and Zhang2004). Additionally, Zhu (Reference Zhu2008) numerically studied a compliant fibre tethered in a viscous flow at moderate

$Re$), as observed in the experimental and theoretical study by Alben et al. (Reference Alben, Shelley and Zhang2002) and Alben, Shelley & Zhang (Reference Alben, Shelley and Zhang2004). Additionally, Zhu (Reference Zhu2008) numerically studied a compliant fibre tethered in a viscous flow at moderate ![]() $Re$ (i.e.

$Re$ (i.e. ![]() $Re \in [10, 800]$) and found that the power law exponents decrease monotonically from approximately 2 towards 4/3 as

$Re \in [10, 800]$) and found that the power law exponents decrease monotonically from approximately 2 towards 4/3 as ![]() $Re$ increases. Experimental investigations by Barois & de Langre (Reference Barois and de Langre2013) on the reconfiguration of flexible ribbons with added weight at the free end revealed that drag is nearly independent of free-stream velocity at high

$Re$ increases. Experimental investigations by Barois & de Langre (Reference Barois and de Langre2013) on the reconfiguration of flexible ribbons with added weight at the free end revealed that drag is nearly independent of free-stream velocity at high ![]() $Re$. This unique phenomenon is a focal point of the present study. In nature, plants laden with fruits naturally droop and sway in the wind. Similarly, in everyday scenarios, heavy objects are often added to the trailing edge of flags to prevent violent flapping. These observations highlight the relevance of weighted flexible structures in both natural and engineered systems.

$Re$. This unique phenomenon is a focal point of the present study. In nature, plants laden with fruits naturally droop and sway in the wind. Similarly, in everyday scenarios, heavy objects are often added to the trailing edge of flags to prevent violent flapping. These observations highlight the relevance of weighted flexible structures in both natural and engineered systems.

However, the aforementioned studies do not address the flapping or vibration of bodies. When flow passes a bluff body, vortex shedding typically occurs with significant flow separation at relatively high ![]() $Re$. In such cases, a vortex wake, such as the Kármán vortex street, becomes observable. The periodic shedding of vortices results in oscillatory forces acting on the body, causing drag and lift in the streamwise and transverse directions, respectively. If the body is elastically mounted, it may undergo substantial vibration, termed vortex-induced vibration (VIV) (Williamson & Govardhan Reference Williamson and Govardhan2004). There is an extensive body of literature on VIV of rigid objects, including works by Sarpkaya (Reference Sarpkaya2004), Wu, Ge & Hong (Reference Wu, Ge and Hong2012), Raissi et al. (Reference Raissi, Wang, Triantafyllou and Karniadakis2019), Carlson, Currier & Modarres-Sadeghi (Reference Carlson, Currier and Modarres-Sadeghi2021) and Han et al. (Reference Han, de Langre, Thompson, Hourigan and Zhao2023), for interested readers to explore.

$Re$. In such cases, a vortex wake, such as the Kármán vortex street, becomes observable. The periodic shedding of vortices results in oscillatory forces acting on the body, causing drag and lift in the streamwise and transverse directions, respectively. If the body is elastically mounted, it may undergo substantial vibration, termed vortex-induced vibration (VIV) (Williamson & Govardhan Reference Williamson and Govardhan2004). There is an extensive body of literature on VIV of rigid objects, including works by Sarpkaya (Reference Sarpkaya2004), Wu, Ge & Hong (Reference Wu, Ge and Hong2012), Raissi et al. (Reference Raissi, Wang, Triantafyllou and Karniadakis2019), Carlson, Currier & Modarres-Sadeghi (Reference Carlson, Currier and Modarres-Sadeghi2021) and Han et al. (Reference Han, de Langre, Thompson, Hourigan and Zhao2023), for interested readers to explore.

In the presence of an oncoming flow, flexible structures like flags, fibres or filaments may exhibit passive flapping motions (Zhang et al. Reference Zhang, Childress, Libchaber and Shelley2000; Jia et al. Reference Jia, Li, Yin and Yin2007; Jia & Yin Reference Jia and Yin2008; Kim et al. Reference Kim, Cossé, Huertas Cerdeira and Gharib2013). Taneda (Reference Taneda1968) experimentally explored various flags and observed that flags remain motionless in slow flows, transitioning to regular and irregular flapping states as the flow speed increases. The motion of flexible filaments in a flowing soap film was investigated by Zhang et al. (Reference Zhang, Childress, Libchaber and Shelley2000), revealing two distinct dynamical states for a single filament: stretched–straight and coherent flapping states. Shelley, Vandenberghe & Zhang (Reference Shelley, Vandenberghe and Zhang2005) studied oscillations of heavy flags through experiments and theoretical analysis, identifying a critical flow velocity triggering flag flapping. The corresponding Strouhal number (![]() $St$) is consistent with that of swimming/flying animals for efficient cruising (Taylor, Nudds & Thomas Reference Taylor, Nudds and Thomas2003). Eloy et al. (Reference Eloy, Lagrange, Souilliez and Schouveiler2008) conducted experiments on the flutter of flexible plates with varying aspect ratios, highlighting the significance of three-dimensional (3-D) effects. Numerous numerical studies complement these experiments. For instance, 2-D simulations of a flag in viscous flow by Zhu & Peskin (Reference Zhu and Peskin2002) and Connell & Yue (Reference Connell and Yue2007), or inviscid flow by Alben & Shelley (Reference Alben and Shelley2008) confirmed bistable properties or hysteresis observed in experiments by Zhang et al. (Reference Zhang, Childress, Libchaber and Shelley2000) and Shelley et al. (Reference Shelley, Vandenberghe and Zhang2005). Connell & Yue (Reference Connell and Yue2007), by altering the mass ratio of 2-D flags and fluid, identified three distinct regimes: fixed-point, regular flapping and chaotic flapping regimes. The flapping of 3-D flags was simulated by Kim & Peskin (Reference Kim and Peskin2007) and Huang & Sung (Reference Huang and Sung2010), considering the effects of gravity. Additional numerical simulations of flexible flags or filaments can be found in works by Zhu & Peskin (Reference Zhu and Peskin2003), Zhu (Reference Zhu2009), Uddin, Huang & Sung (Reference Uddin, Huang and Sung2013), O'Connor & Revell (Reference O'Connor and Revell2019) and others.

$St$) is consistent with that of swimming/flying animals for efficient cruising (Taylor, Nudds & Thomas Reference Taylor, Nudds and Thomas2003). Eloy et al. (Reference Eloy, Lagrange, Souilliez and Schouveiler2008) conducted experiments on the flutter of flexible plates with varying aspect ratios, highlighting the significance of three-dimensional (3-D) effects. Numerous numerical studies complement these experiments. For instance, 2-D simulations of a flag in viscous flow by Zhu & Peskin (Reference Zhu and Peskin2002) and Connell & Yue (Reference Connell and Yue2007), or inviscid flow by Alben & Shelley (Reference Alben and Shelley2008) confirmed bistable properties or hysteresis observed in experiments by Zhang et al. (Reference Zhang, Childress, Libchaber and Shelley2000) and Shelley et al. (Reference Shelley, Vandenberghe and Zhang2005). Connell & Yue (Reference Connell and Yue2007), by altering the mass ratio of 2-D flags and fluid, identified three distinct regimes: fixed-point, regular flapping and chaotic flapping regimes. The flapping of 3-D flags was simulated by Kim & Peskin (Reference Kim and Peskin2007) and Huang & Sung (Reference Huang and Sung2010), considering the effects of gravity. Additional numerical simulations of flexible flags or filaments can be found in works by Zhu & Peskin (Reference Zhu and Peskin2003), Zhu (Reference Zhu2009), Uddin, Huang & Sung (Reference Uddin, Huang and Sung2013), O'Connor & Revell (Reference O'Connor and Revell2019) and others.

In this study, we numerically investigate the dynamics of flexible ribbons in a uniform flow, with a weight ![]() $G$ added at the trailing edges. Notably, the only existing experimental research on this specific fluid–flexible structure problem was conducted by Barois & de Langre (Reference Barois and de Langre2013). However, their study lacked comprehensive discussion, omitting crucial details such as flow fields, potentially due to experimental measurement challenges. Additionally, they did not account for the effects of aspect ratio (

$G$ added at the trailing edges. Notably, the only existing experimental research on this specific fluid–flexible structure problem was conducted by Barois & de Langre (Reference Barois and de Langre2013). However, their study lacked comprehensive discussion, omitting crucial details such as flow fields, potentially due to experimental measurement challenges. Additionally, they did not account for the effects of aspect ratio (![]() ${A{\kern-4pt}R}$) and the 2-D cases, which could yield notably different results, particularly when vibrations occur with a large aspect ratio. Furthermore, their study neglected viscous effects given the sufficiently large

${A{\kern-4pt}R}$) and the 2-D cases, which could yield notably different results, particularly when vibrations occur with a large aspect ratio. Furthermore, their study neglected viscous effects given the sufficiently large ![]() $Re$. To address these limitations, we conduct both 2-D and 3-D simulations at low Reynolds numbers (

$Re$. To address these limitations, we conduct both 2-D and 3-D simulations at low Reynolds numbers (![]() ${\sim }O(10^2)$). Our investigation involves a thorough examination of ribbon reconfiguration and forces, and we establish a simplified theoretical model based on force decomposition for accurate predictions. Force decomposition allows us to isolate tangential forces, enabling a closer examination of viscous effects. Special attention is given to ribbon vibrations and the derivation of scaling laws. Additionally, we explore 3-D effects by varying the aspect ratio, conducting a detailed analysis of both 2-D and 3-D flow fields.

${\sim }O(10^2)$). Our investigation involves a thorough examination of ribbon reconfiguration and forces, and we establish a simplified theoretical model based on force decomposition for accurate predictions. Force decomposition allows us to isolate tangential forces, enabling a closer examination of viscous effects. Special attention is given to ribbon vibrations and the derivation of scaling laws. Additionally, we explore 3-D effects by varying the aspect ratio, conducting a detailed analysis of both 2-D and 3-D flow fields.

Adding weight to the end of the flexible ribbon serves several purposes in our study. Firstly, it simulates gravity's effect on flexible structures encountered in real-world scenarios. Our goal is to understand how gravity influences their motion and deformation. Secondly, adding weight enables us to manipulate the system's dynamic behaviour. Adjusting the centre of mass affects dynamic characteristics like vibration frequency, amplitude and mode shape of the ribbon. This provides more control variables and experimental parameters, enhancing our understanding of fluid–structure interaction. Furthermore, this approach offers insights and strategies for designing and optimizing flexible structures. Optimizing weight distribution improves performance across aerospace and mechanical engineering. For example, in flexible unmanned aerial vehicles, added weights may enhance flight dynamics.

Note that both 2-D and 3-D simulations are essential in our study. Considering that achieving a much wider range of ![]() ${A{\kern-4pt}R}$ would demand significant computational resources, we selected a feasible range that still allowed us to investigate relevant 3-D effects. The 2-D simulations are valuable as they correspond to cases where

${A{\kern-4pt}R}$ would demand significant computational resources, we selected a feasible range that still allowed us to investigate relevant 3-D effects. The 2-D simulations are valuable as they correspond to cases where ![]() ${A{\kern-4pt}R}$ approaches infinity, assuming deformation in the spanwise direction can be neglected. This simplification enables us to focus on the fundamental behaviour of the ribbon and its interaction with the surrounding fluid. Besides, conducting 2-D simulations aligns with our theoretical analysis, which is inherently two-dimensional. This allows for a direct comparison between theoretical predictions and numerical simulations, facilitating a deeper understanding of the fluid–structure interaction phenomenon.

${A{\kern-4pt}R}$ approaches infinity, assuming deformation in the spanwise direction can be neglected. This simplification enables us to focus on the fundamental behaviour of the ribbon and its interaction with the surrounding fluid. Besides, conducting 2-D simulations aligns with our theoretical analysis, which is inherently two-dimensional. This allows for a direct comparison between theoretical predictions and numerical simulations, facilitating a deeper understanding of the fluid–structure interaction phenomenon.

The remainder of this paper is organized as follows. In § 2, we present the physical problem and mathematical formulation. The numerical method and validation are detailed in § 3. In § 4, we discuss comprehensive results, and concluding remarks are provided in § 5.

2. Physical problem and mathematical formulation

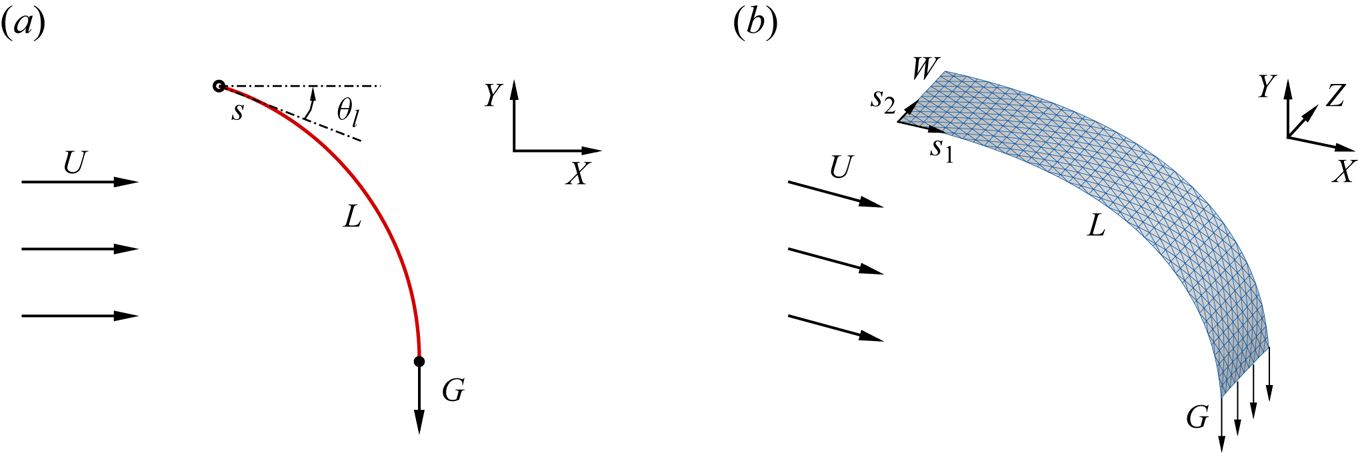

The schematic diagrams of the 2-D and 3-D flexible ribbons considered in our study are illustrated in figure 1. These flexible ribbons, characterized by a length ![]() $L$ (and width

$L$ (and width ![]() $W$ in 3-D cases), are immersed in a uniform flow with an oncoming speed

$W$ in 3-D cases), are immersed in a uniform flow with an oncoming speed ![]() $U$. The leading edge of the ribbon is stationary, while a weight

$U$. The leading edge of the ribbon is stationary, while a weight ![]() $G$ is affixed at the trailing edge, inducing a natural droop. The remaining sections of the ribbon have the freedom to move and passively deform, facilitated by fluid–structure interactions.

$G$ is affixed at the trailing edge, inducing a natural droop. The remaining sections of the ribbon have the freedom to move and passively deform, facilitated by fluid–structure interactions.

Figure 1. Schematic diagrams illustrating 2-D (a) and 3-D (b) flexible ribbons in a uniform flow. Here, ![]() $U$ represents the oncoming flow speed,

$U$ represents the oncoming flow speed, ![]() $L$ and

$L$ and ![]() $W$ denote the chord and span length of the ribbon, respectively,

$W$ denote the chord and span length of the ribbon, respectively, ![]() $G$ is the weight added at the trailing edge,

$G$ is the weight added at the trailing edge, ![]() $\theta _l$ is the angle between the tangent direction of the leading edge and the horizontal direction and

$\theta _l$ is the angle between the tangent direction of the leading edge and the horizontal direction and ![]() $s$ as well as

$s$ as well as ![]() $(s_1, s_2)$ represent the curvilinear coordinates on the ribbons.

$(s_1, s_2)$ represent the curvilinear coordinates on the ribbons.

We employ the incompressible Navier–Stokes equations to model and solve the fluid flow,

where ![]() $\boldsymbol {v}$ is the velocity,

$\boldsymbol {v}$ is the velocity, ![]() $p$ is the pressure,

$p$ is the pressure, ![]() $\rho$ is the density of the fluid,

$\rho$ is the density of the fluid, ![]() $\mu$ is the dynamic viscosity and

$\mu$ is the dynamic viscosity and ![]() $\boldsymbol {f}_{b}$ denotes the Eulerian momentum force acting on the surrounding fluid due to the immersed boundary.

$\boldsymbol {f}_{b}$ denotes the Eulerian momentum force acting on the surrounding fluid due to the immersed boundary.

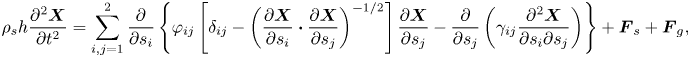

To characterize the deformation and motion of the ribbon within a Lagrangian coordinate system, we employ the structural equation. In the case of 3-D scenarios, the structural equation is formulated as follows (Huang & Sung Reference Huang and Sung2010; Hua, Zhu & Lu Reference Hua, Zhu and Lu2014):

\begin{align} \rho_s h \frac{\partial^2 \boldsymbol{X}}{\partial t^2}=\sum_{i, j=1}^2 \frac{\partial}{\partial s_i}\left\{\varphi_{i j} \left[\delta_{i j}-\left(\frac{\partial \boldsymbol{X}}{\partial s_i} \boldsymbol{\cdot} \frac{\partial \boldsymbol{X}}{\partial s_j}\right)^{-1 / 2}\right] \frac{\partial \boldsymbol{X}}{\partial s_j}-\frac{\partial}{\partial s_j} \left(\gamma_{i j} \frac{\partial^2 \boldsymbol{X}}{\partial s_i \partial s_j}\right)\right\}+ \boldsymbol{F}_s + \boldsymbol{F}_{g}, \end{align}

\begin{align} \rho_s h \frac{\partial^2 \boldsymbol{X}}{\partial t^2}=\sum_{i, j=1}^2 \frac{\partial}{\partial s_i}\left\{\varphi_{i j} \left[\delta_{i j}-\left(\frac{\partial \boldsymbol{X}}{\partial s_i} \boldsymbol{\cdot} \frac{\partial \boldsymbol{X}}{\partial s_j}\right)^{-1 / 2}\right] \frac{\partial \boldsymbol{X}}{\partial s_j}-\frac{\partial}{\partial s_j} \left(\gamma_{i j} \frac{\partial^2 \boldsymbol{X}}{\partial s_i \partial s_j}\right)\right\}+ \boldsymbol{F}_s + \boldsymbol{F}_{g}, \end{align}

where ![]() $\boldsymbol {X}(s_1, s_2, t)=(X(s_1, s_2, t), Y(s_1, s_2, t), Z(s_1, s_2, t))$ is the position vector of the ribbon,

$\boldsymbol {X}(s_1, s_2, t)=(X(s_1, s_2, t), Y(s_1, s_2, t), Z(s_1, s_2, t))$ is the position vector of the ribbon, ![]() $s_1$ and

$s_1$ and ![]() $s_2$ are the chordwise and spanwise Lagrangian coordinates, respectively,

$s_2$ are the chordwise and spanwise Lagrangian coordinates, respectively, ![]() $\rho _{s}$ is the structural mass density,

$\rho _{s}$ is the structural mass density, ![]() $h$ is the structural thickness,

$h$ is the structural thickness, ![]() $\boldsymbol {F}_{s}$ is the Lagrangian force exerted on the plate by the surrounding fluid,

$\boldsymbol {F}_{s}$ is the Lagrangian force exerted on the plate by the surrounding fluid, ![]() $\boldsymbol {F}_{g} = G \boldsymbol g / g$ is the weight added at the trailing edge (here,

$\boldsymbol {F}_{g} = G \boldsymbol g / g$ is the weight added at the trailing edge (here, ![]() $g$ is the magnitude of gravitational acceleration

$g$ is the magnitude of gravitational acceleration ![]() $\boldsymbol g$) and

$\boldsymbol g$) and ![]() $\delta _{i j}$ is the Kronecker delta function. Matrix

$\delta _{i j}$ is the Kronecker delta function. Matrix ![]() $\varphi _{i j}$ is the in-plane effect matrix, where

$\varphi _{i j}$ is the in-plane effect matrix, where ![]() $\varphi _{11}=\varphi _{22}=E h$ is the structural stretching stiffness and

$\varphi _{11}=\varphi _{22}=E h$ is the structural stretching stiffness and ![]() $\varphi _{12}$ is the structural shearing stiffness. Matrix

$\varphi _{12}$ is the structural shearing stiffness. Matrix ![]() $\gamma _{ij}$ represents the out-of-plane effect matrix associated with bending and twisting stiffness, where

$\gamma _{ij}$ represents the out-of-plane effect matrix associated with bending and twisting stiffness, where ![]() $\gamma _{11} = EI$ denotes the chordwise bending stiffness. At the leading edge (

$\gamma _{11} = EI$ denotes the chordwise bending stiffness. At the leading edge (![]() $s_1 = 0$), the simply supported condition is adopted, i.e.

$s_1 = 0$), the simply supported condition is adopted, i.e.

At the trailing edge (![]() $s_1 = L$) and two other free edges (

$s_1 = L$) and two other free edges (![]() $s_2 = 0$ or

$s_2 = 0$ or ![]() $W$), the boundary conditions are

$W$), the boundary conditions are

\begin{equation} \varphi_{i j}\left[\delta_{i j}-\left(\frac{\partial \boldsymbol{X}}{\partial s_i} \boldsymbol{\cdot} \frac{\partial \boldsymbol{X}}{\partial s_j}\right)^{-1 / 2}\right] \frac{\partial \boldsymbol X}{\partial s_j}-\frac{\partial}{\partial s_j}\left(\gamma_{i j} \frac{\partial^2 \boldsymbol X}{\partial s_i \partial s_j}\right)=0,\quad \frac{\partial^2 \boldsymbol{X}}{\partial s_i \partial s_j}=0. \end{equation}

\begin{equation} \varphi_{i j}\left[\delta_{i j}-\left(\frac{\partial \boldsymbol{X}}{\partial s_i} \boldsymbol{\cdot} \frac{\partial \boldsymbol{X}}{\partial s_j}\right)^{-1 / 2}\right] \frac{\partial \boldsymbol X}{\partial s_j}-\frac{\partial}{\partial s_j}\left(\gamma_{i j} \frac{\partial^2 \boldsymbol X}{\partial s_i \partial s_j}\right)=0,\quad \frac{\partial^2 \boldsymbol{X}}{\partial s_i \partial s_j}=0. \end{equation}

Here, the Einstein summation convention is not applied on ![]() $i$ and

$i$ and ![]() $j$ (

$j$ (![]() $i, j=1, 2$). In addition, the weight

$i, j=1, 2$). In addition, the weight ![]() $G=W m_t g$ is evenly distributed at the trailing edge (see figure 1b), where

$G=W m_t g$ is evenly distributed at the trailing edge (see figure 1b), where ![]() $m_t$ is the mass per unit length of the additional weight.

$m_t$ is the mass per unit length of the additional weight.

For the 2-D cases, the structural equation (2.3) degenerates into the following form (Zhu & Peskin Reference Zhu and Peskin2002; Connell & Yue Reference Connell and Yue2007; Hua, Zhu & Lu Reference Hua, Zhu and Lu2013):

\begin{equation} \rho_{s} h \frac{\partial^{2} \boldsymbol{X}}{\partial t^{2}}-\frac{\partial}{\partial s} \left[E h\left(1-\left|\frac{\partial \boldsymbol{X}} {\partial s}\right|^{-1}\right) \frac{\partial \boldsymbol{X}}{\partial s}\right]+E I \frac{\partial^{4} \boldsymbol{X}}{\partial s^{4}}=\boldsymbol{F}_{s} + \boldsymbol{F}_{g}, \end{equation}

\begin{equation} \rho_{s} h \frac{\partial^{2} \boldsymbol{X}}{\partial t^{2}}-\frac{\partial}{\partial s} \left[E h\left(1-\left|\frac{\partial \boldsymbol{X}} {\partial s}\right|^{-1}\right) \frac{\partial \boldsymbol{X}}{\partial s}\right]+E I \frac{\partial^{4} \boldsymbol{X}}{\partial s^{4}}=\boldsymbol{F}_{s} + \boldsymbol{F}_{g}, \end{equation}

where ![]() $s$ is the Lagrangian coordinate,

$s$ is the Lagrangian coordinate, ![]() $\boldsymbol {X}(s, t)=(X(s, t), Y(s, t))$ is the position vector of the ribbon. At the leading edge of the ribbon (

$\boldsymbol {X}(s, t)=(X(s, t), Y(s, t))$ is the position vector of the ribbon. At the leading edge of the ribbon (![]() $s=0$), the simply supported condition (2.4a,b) becomes

$s=0$), the simply supported condition (2.4a,b) becomes

At the free end (![]() $s=L$), the boundary conditions are

$s=L$), the boundary conditions are

\begin{equation} -E h\left(1-\left|\frac{\partial \boldsymbol{X}}{\partial s}\right|^{-1}\right) \frac{\partial \boldsymbol{X}}{\partial s} + E I \frac{\partial^3 \boldsymbol{X}}{\partial s^3}=0,\quad \frac{\partial^2 \boldsymbol{X}}{\partial s^2}=0. \end{equation}

\begin{equation} -E h\left(1-\left|\frac{\partial \boldsymbol{X}}{\partial s}\right|^{-1}\right) \frac{\partial \boldsymbol{X}}{\partial s} + E I \frac{\partial^3 \boldsymbol{X}}{\partial s^3}=0,\quad \frac{\partial^2 \boldsymbol{X}}{\partial s^2}=0. \end{equation}

Besides, the weight ![]() $G=1 \cdot m_t g$ (considering unit depth) is concentrated at the trailing edge (see figure 1a).

$G=1 \cdot m_t g$ (considering unit depth) is concentrated at the trailing edge (see figure 1a).

In our study, the fluid density ![]() $\rho$, the dynamic viscosity

$\rho$, the dynamic viscosity ![]() $\mu$ and the dimensional length of the ribbon

$\mu$ and the dimensional length of the ribbon ![]() $L$ are fixed. To normalize the above equations, the characteristic quantities

$L$ are fixed. To normalize the above equations, the characteristic quantities ![]() $\rho$,

$\rho$, ![]() $L$ and

$L$ and ![]() $U_{ref} = \kappa \mu / \rho L$ are chosen, where

$U_{ref} = \kappa \mu / \rho L$ are chosen, where ![]() $\kappa =200$ is a constant (note that other values of

$\kappa =200$ is a constant (note that other values of ![]() $\kappa$ are also acceptable, and would not alter the trends and findings presented in our study). Therefore, the characteristic time is

$\kappa$ are also acceptable, and would not alter the trends and findings presented in our study). Therefore, the characteristic time is ![]() $T = L / U_{ref}$, and the gravitational acceleration is

$T = L / U_{ref}$, and the gravitational acceleration is ![]() $g = U_{ref}^2 / L$. Based on dimensional analysis, the following dimensionless governing parameters are introduced: the aspect ratio

$g = U_{ref}^2 / L$. Based on dimensional analysis, the following dimensionless governing parameters are introduced: the aspect ratio ![]() ${A{\kern-4pt}R} = W/L$, the Reynolds number based on the oncoming flow speed

${A{\kern-4pt}R} = W/L$, the Reynolds number based on the oncoming flow speed ![]() $Re_u=\rho U L / \mu$, the mass ratio of the ribbon to the fluid

$Re_u=\rho U L / \mu$, the mass ratio of the ribbon to the fluid ![]() $M=\rho _{s} h/ \rho L$, the mass ratio of additional weight at the trailing edge to the fluid

$M=\rho _{s} h/ \rho L$, the mass ratio of additional weight at the trailing edge to the fluid ![]() $M_t=m_t / \rho L^2$, the stretching stiffness

$M_t=m_t / \rho L^2$, the stretching stiffness ![]() $S =E h / \rho U_{ref}^{2} L$ and the bending stiffness

$S =E h / \rho U_{ref}^{2} L$ and the bending stiffness ![]() $K =E I / \rho U_{ref}^{2} L^{3}$.

$K =E I / \rho U_{ref}^{2} L^{3}$.

3. Numerical method and validation

The lattice Boltzmann method (Chen & Doolen Reference Chen and Doolen1998) is employed for the numerical solution of the Navier–Stokes equations, while a finite element method is utilized to model the motion of the flexible plate (Doyle Reference Doyle2001). The immersed boundary method (Zhu & Peskin Reference Zhu and Peskin2002) is employed to couple the fluid and structure solvers. To enforce the no-slip boundary condition, the body force term ![]() $\boldsymbol {f}_{b}$ in (2.1) acts as an interaction force between the fluid and the immersed boundary. The deformation of the plate is addressed using the corotational scheme (Doyle Reference Doyle2001), which is adept at handling large displacements. Further details on the numerical methods can be found in our previous papers (Hua et al. Reference Hua, Zhu and Lu2013; Huang, Wei & Lu Reference Huang, Wei and Lu2018; Zhang, Huang & Lu Reference Zhang, Huang and Lu2020).

$\boldsymbol {f}_{b}$ in (2.1) acts as an interaction force between the fluid and the immersed boundary. The deformation of the plate is addressed using the corotational scheme (Doyle Reference Doyle2001), which is adept at handling large displacements. Further details on the numerical methods can be found in our previous papers (Hua et al. Reference Hua, Zhu and Lu2013; Huang, Wei & Lu Reference Huang, Wei and Lu2018; Zhang, Huang & Lu Reference Zhang, Huang and Lu2020).

The simulations are performed on a computational domain in the range ![]() $[-15, 25] \times [-15, 15]$ in the

$[-15, 25] \times [-15, 15]$ in the ![]() $x$ and

$x$ and ![]() $y$ directions for 2-D cases, and

$y$ directions for 2-D cases, and ![]() $[-10, 30] \times [-10, 10] \times [-10, 10]$ in the

$[-10, 30] \times [-10, 10] \times [-10, 10]$ in the ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ directions for 3-D cases. This domain size is sufficiently large to eliminate any boundary effects. Initially, the fluid's velocity field is

$z$ directions for 3-D cases. This domain size is sufficiently large to eliminate any boundary effects. Initially, the fluid's velocity field is ![]() $U \boldsymbol e_x$ throughout the domain, where

$U \boldsymbol e_x$ throughout the domain, where ![]() $\boldsymbol e_x$ is the unit vector in the

$\boldsymbol e_x$ is the unit vector in the ![]() $x$ direction. A uniform velocity

$x$ direction. A uniform velocity ![]() $U \boldsymbol e_x$ is imposed at the upstream boundary and the side boundaries of the fluid computational domain. At the downstream boundary, a convective boundary condition

$U \boldsymbol e_x$ is imposed at the upstream boundary and the side boundaries of the fluid computational domain. At the downstream boundary, a convective boundary condition ![]() $\partial \boldsymbol {v} / \partial t + U \partial \boldsymbol {v} / \partial x = \boldsymbol {0}$ is specified.

$\partial \boldsymbol {v} / \partial t + U \partial \boldsymbol {v} / \partial x = \boldsymbol {0}$ is specified.

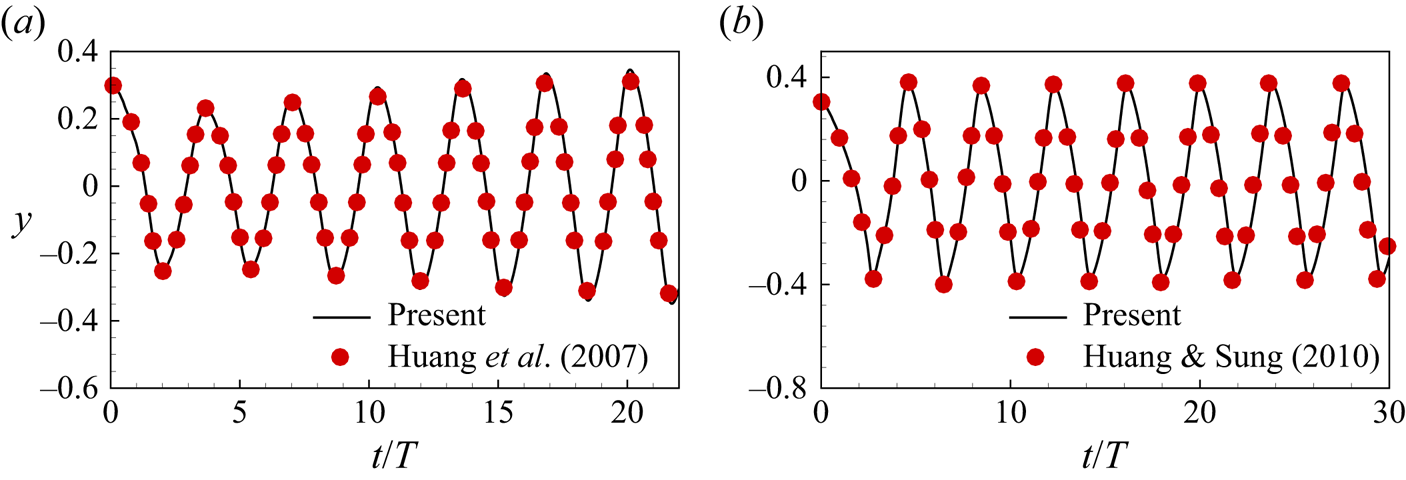

To validate the numerical method, simulations of 2-D and 3-D flags in a uniform flow are conducted. In the 2-D case, the non-dimensional parameters are ![]() $Re=200$,

$Re=200$, ![]() $K=0.0015$,

$K=0.0015$, ![]() $M=1.5$,

$M=1.5$, ![]() $S=1000$ and Froude number

$S=1000$ and Froude number ![]() $Fr=g L / U^2=0.5$ (Huang et al. Reference Huang, Shin and Sung2007). For the 3-D case, the parameters are

$Fr=g L / U^2=0.5$ (Huang et al. Reference Huang, Shin and Sung2007). For the 3-D case, the parameters are ![]() $Re=200$,

$Re=200$, ![]() $K=0.0001$,

$K=0.0001$, ![]() $M=1.0$,

$M=1.0$, ![]() $S=1000$,

$S=1000$, ![]() $Fr=0$ and

$Fr=0$ and ![]() ${A{\kern-4pt}R} =1$ (Huang & Sung Reference Huang and Sung2010). The results are depicted in figure 2, showing good agreement with results in the literature (Huang et al. Reference Huang, Shin and Sung2007; Huang & Sung Reference Huang and Sung2010).

${A{\kern-4pt}R} =1$ (Huang & Sung Reference Huang and Sung2010). The results are depicted in figure 2, showing good agreement with results in the literature (Huang et al. Reference Huang, Shin and Sung2007; Huang & Sung Reference Huang and Sung2010).

Figure 2. Validations for cases: (a) transverse displacement of the trailing edge of the 2-D flag with ![]() $Re=200$,

$Re=200$, ![]() $K=0.0015$,

$K=0.0015$, ![]() $M=1.5$,

$M=1.5$, ![]() $S=1000$ and

$S=1000$ and ![]() $Fr=0.5$ (Huang, Shin & Sung Reference Huang, Shin and Sung2007); (b) transverse displacement of the centre of the trailing edge of the 3-D flag with

$Fr=0.5$ (Huang, Shin & Sung Reference Huang, Shin and Sung2007); (b) transverse displacement of the centre of the trailing edge of the 3-D flag with ![]() $Re=200$,

$Re=200$, ![]() $K=0.0001$,

$K=0.0001$, ![]() $M=1.0$,

$M=1.0$, ![]() $S=1000$,

$S=1000$, ![]() $Fr=0$ and

$Fr=0$ and ![]() ${A{\kern-4pt}R} =1$ (Huang & Sung Reference Huang and Sung2010).

${A{\kern-4pt}R} =1$ (Huang & Sung Reference Huang and Sung2010).

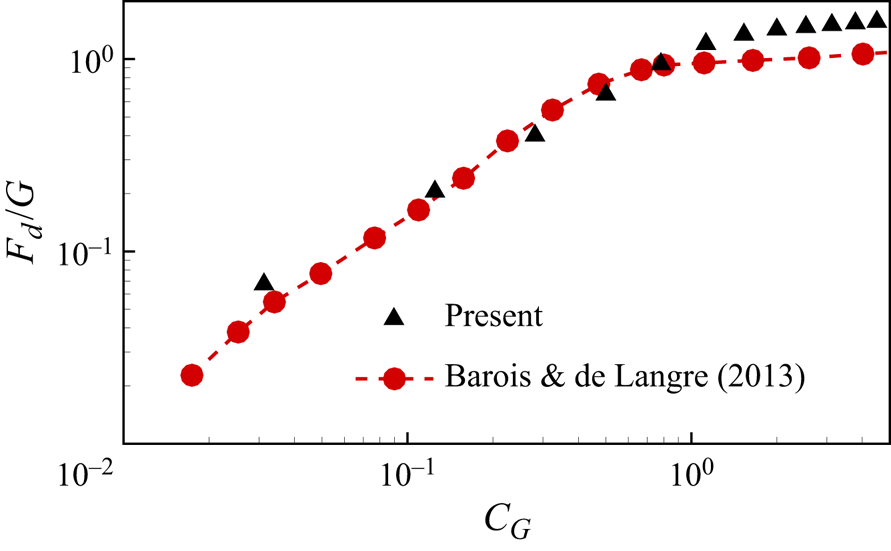

Besides, we have also made a direct comparison of our results with those of Barois & de Langre (Reference Barois and de Langre2013), as shown in figure 3. In this comparison, the ![]() $G$-normalized drag

$G$-normalized drag ![]() $F_d / G$ of the 3-D ribbon is presented as a function of

$F_d / G$ of the 3-D ribbon is presented as a function of ![]() $C_G$ with

$C_G$ with ![]() $M_t = 1$ and

$M_t = 1$ and ![]() ${A{\kern-4pt}R} = 0.5$, where the definition of

${A{\kern-4pt}R} = 0.5$, where the definition of ![]() $C_G$ in 3-D scenarios is

$C_G$ in 3-D scenarios is ![]() $C_G = {\rho U^2 L W}/{2G}$. Despite our

$C_G = {\rho U^2 L W}/{2G}$. Despite our ![]() $Re_u$ being approximately one or two orders of magnitude smaller than theirs (

$Re_u$ being approximately one or two orders of magnitude smaller than theirs (![]() ${\sim }O(10^2\unicode{x2013}10^3)$ compared with

${\sim }O(10^2\unicode{x2013}10^3)$ compared with ![]() ${\sim }O(10^3\unicode{x2013}10^5)$), our results capture the variation trend of the

${\sim }O(10^3\unicode{x2013}10^5)$), our results capture the variation trend of the ![]() $F_d/G$ curve well. Especially when

$F_d/G$ curve well. Especially when ![]() $C_G<1$, our results are consistent with their experimental findings. This indicates the significance of our study within the

$C_G<1$, our results are consistent with their experimental findings. This indicates the significance of our study within the ![]() $Re_u \sim O(10^2\unicode{x2013}10^3)$ range. However, for

$Re_u \sim O(10^2\unicode{x2013}10^3)$ range. However, for ![]() $C_G>1$, we observe that our

$C_G>1$, we observe that our ![]() $F_d/G$ values are notably larger than their corresponding values. This discrepancy may be due to the significant skin friction caused by viscous effects in our study, owing to our lower

$F_d/G$ values are notably larger than their corresponding values. This discrepancy may be due to the significant skin friction caused by viscous effects in our study, owing to our lower ![]() $Re_u$, as discussed in § 4.2.1.

$Re_u$, as discussed in § 4.2.1.

Figure 3. The ![]() $G$-normalized drag

$G$-normalized drag ![]() $F_d / G$ of the 3-D ribbon as a function of

$F_d / G$ of the 3-D ribbon as a function of ![]() $C_G$ with

$C_G$ with ![]() $M_t = 1$ and

$M_t = 1$ and ![]() ${A{\kern-4pt}R} = 0.5$. The experimental results of Barois & de Langre (Reference Barois and de Langre2013) are also presented with

${A{\kern-4pt}R} = 0.5$. The experimental results of Barois & de Langre (Reference Barois and de Langre2013) are also presented with ![]() ${A{\kern-4pt}R} \approx 0.1$.

${A{\kern-4pt}R} \approx 0.1$.

Furthermore, our numerical strategy has been successfully validated and applied to study various flow problems, including tandem flexible inverted flags in a uniform flow (Huang et al. Reference Huang, Wei and Lu2018), the impact of trailing-edge shape on the self-propulsive performance of heaving flexible plates (Zhang et al. Reference Zhang, Huang and Lu2020) and the scaling laws of the self-propulsive performance of flexible plates (Liu, Liu & Huang Reference Liu, Liu and Huang2022). Additional detailed numerical validations are available in these referenced papers.

The outcomes of the grid independence and time-step independence assessments for the 2-D and 3-D flexible ribbons are depicted in figure 4. It indicates that ![]() $\Delta x / L=0.01$ and

$\Delta x / L=0.01$ and ![]() $\Delta t / T=0.00025$ are suitable for the 2-D cases, while

$\Delta t / T=0.00025$ are suitable for the 2-D cases, while ![]() $\Delta x / L=0.025$ and

$\Delta x / L=0.025$ and ![]() $\Delta t / T=0.000625$ are sufficient for the 3-D cases to attain accurate results. Consequently, we adopt these mesh sizes and time-step sizes in our subsequent simulations.

$\Delta t / T=0.000625$ are sufficient for the 3-D cases to attain accurate results. Consequently, we adopt these mesh sizes and time-step sizes in our subsequent simulations.

Figure 4. Grid independence and time-step independence study for (a) the 2-D ribbon with ![]() $M_t = 1$ and

$M_t = 1$ and ![]() $Re_u = 200$ and (b) the 3-D ribbon with

$Re_u = 200$ and (b) the 3-D ribbon with ![]() $M_t = 1$,

$M_t = 1$, ![]() $Re_u = 200$ and

$Re_u = 200$ and ![]() ${A{\kern-4pt}R} =0.25$. The streamwise force

${A{\kern-4pt}R} =0.25$. The streamwise force ![]() $F_x$ normalized by

$F_x$ normalized by ![]() $F_{ref} = (1/2) \rho U_{ref}^2 L$ as a function of time is presented.

$F_{ref} = (1/2) \rho U_{ref}^2 L$ as a function of time is presented.

4. Results and discussion

In the present simulations, certain parameters are held constant: mass ratio of the ribbon to the fluid (![]() $M = 0.5$), bending stiffness (

$M = 0.5$), bending stiffness (![]() $K = 10^{-4}$) and stretching stiffness (

$K = 10^{-4}$) and stretching stiffness (![]() $S=10^4$). The choice of a large

$S=10^4$). The choice of a large ![]() $S$ ensures that the ribbon is nearly inextensible, while a small

$S$ ensures that the ribbon is nearly inextensible, while a small ![]() $K$ ensures that the ribbon is fully compliant with the surrounding flow, aligning with the experimental findings of Barois & de Langre (Reference Barois and de Langre2013). The selected value for

$K$ ensures that the ribbon is fully compliant with the surrounding flow, aligning with the experimental findings of Barois & de Langre (Reference Barois and de Langre2013). The selected value for ![]() $M$ also conforms to previous studies on flexible bodies in a uniform flow (Huang & Sung Reference Huang and Sung2010; Hua et al. Reference Hua, Zhu and Lu2014; Sun et al. Reference Sun, Peng, Yang, Xiong, Wang and Wang2022), where

$M$ also conforms to previous studies on flexible bodies in a uniform flow (Huang & Sung Reference Huang and Sung2010; Hua et al. Reference Hua, Zhu and Lu2014; Sun et al. Reference Sun, Peng, Yang, Xiong, Wang and Wang2022), where ![]() $M$ ranges from

$M$ ranges from ![]() $10^{-1}$ to

$10^{-1}$ to ![]() $10^0$. The remaining key parameters, namely the inflow Reynolds number

$10^0$. The remaining key parameters, namely the inflow Reynolds number ![]() $Re_u$, the mass ratio of the additional weight at the trailing edge

$Re_u$, the mass ratio of the additional weight at the trailing edge ![]() $M_t$ and the aspect ratio

$M_t$ and the aspect ratio ![]() ${A{\kern-4pt}R}$, are left variable. Both 2-D and 3-D cases are considered, and the corresponding results are presented in §§ 4.1 and 4.2, respectively.

${A{\kern-4pt}R}$, are left variable. Both 2-D and 3-D cases are considered, and the corresponding results are presented in §§ 4.1 and 4.2, respectively.

4.1. Analysis of two-dimensional results

In the 2-D scenarios, the aspect ratio ![]() ${A{\kern-4pt}R} = \infty$, and we investigate the effects of

${A{\kern-4pt}R} = \infty$, and we investigate the effects of ![]() $Re_u$ (

$Re_u$ (![]() $\in [50,800]$ with an interval of 50) and

$\in [50,800]$ with an interval of 50) and ![]() $M_t$ (

$M_t$ (![]() $=1, 2$ and

$=1, 2$ and ![]() $3$). In Appendix A, we demonstrate that the initial angle of the ribbon has no impact on the statistics of interest, such as time-averaged forces. Once released from the initial state, the system promptly reaches an equilibrium state, where the ribbon may undergo periodic oscillations.

$3$). In Appendix A, we demonstrate that the initial angle of the ribbon has no impact on the statistics of interest, such as time-averaged forces. Once released from the initial state, the system promptly reaches an equilibrium state, where the ribbon may undergo periodic oscillations.

Our initial focus is on quasi-static results (§ 4.1.1) to propose a simplified model (§ 4.1.2). In this context, quantitative results are presented as time-averaged values unless explicitly specified otherwise. For instance, the time-averaged drag and lift are defined as ![]() $F_d = f_1 \int _{t^{\prime }}^{t^{\prime }+1/f_1} F_x(t) \,\mathrm {d} t$ and

$F_d = f_1 \int _{t^{\prime }}^{t^{\prime }+1/f_1} F_x(t) \,\mathrm {d} t$ and ![]() $F_l = f_1 \int _{t^{\prime }}^{t^{\prime }+1/f_1} F_y(t) \,\mathrm {d} t$, respectively, where

$F_l = f_1 \int _{t^{\prime }}^{t^{\prime }+1/f_1} F_y(t) \,\mathrm {d} t$, respectively, where ![]() $f_1$ represents the dominant frequency or flapping frequency, and

$f_1$ represents the dominant frequency or flapping frequency, and ![]() $F_x(t)$ and

$F_x(t)$ and ![]() $F_y(t)$ denote the instantaneous streamwise and transverse forces of the ribbon. The analysis of kinematic characteristics (i.e. vibrations) and flow fields of the system will be conducted in § 4.1.4.

$F_y(t)$ denote the instantaneous streamwise and transverse forces of the ribbon. The analysis of kinematic characteristics (i.e. vibrations) and flow fields of the system will be conducted in § 4.1.4.

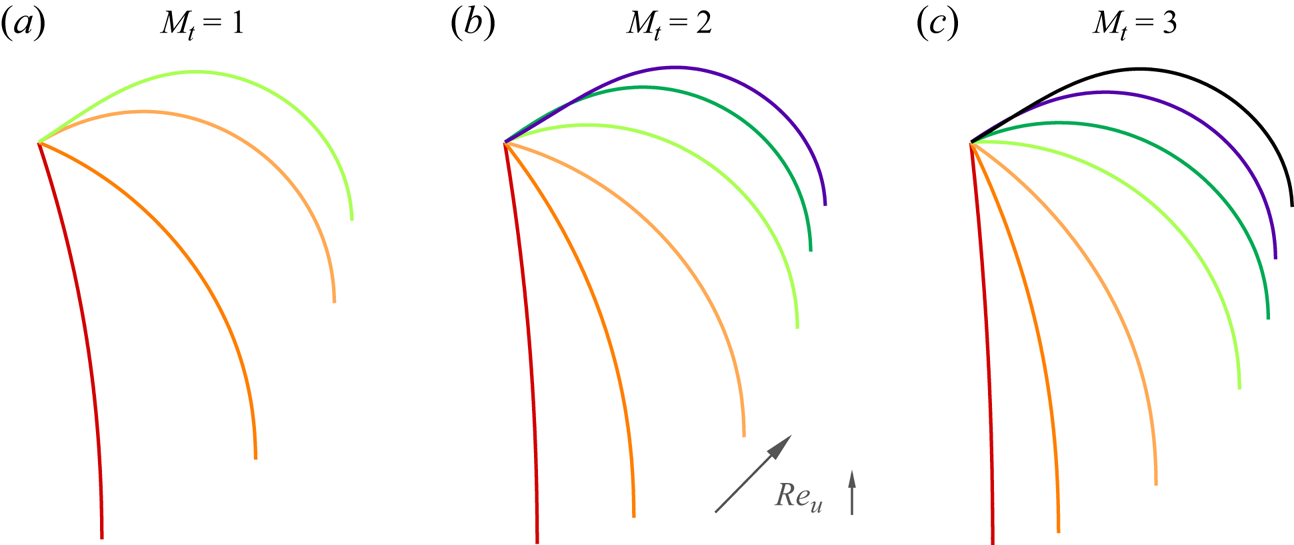

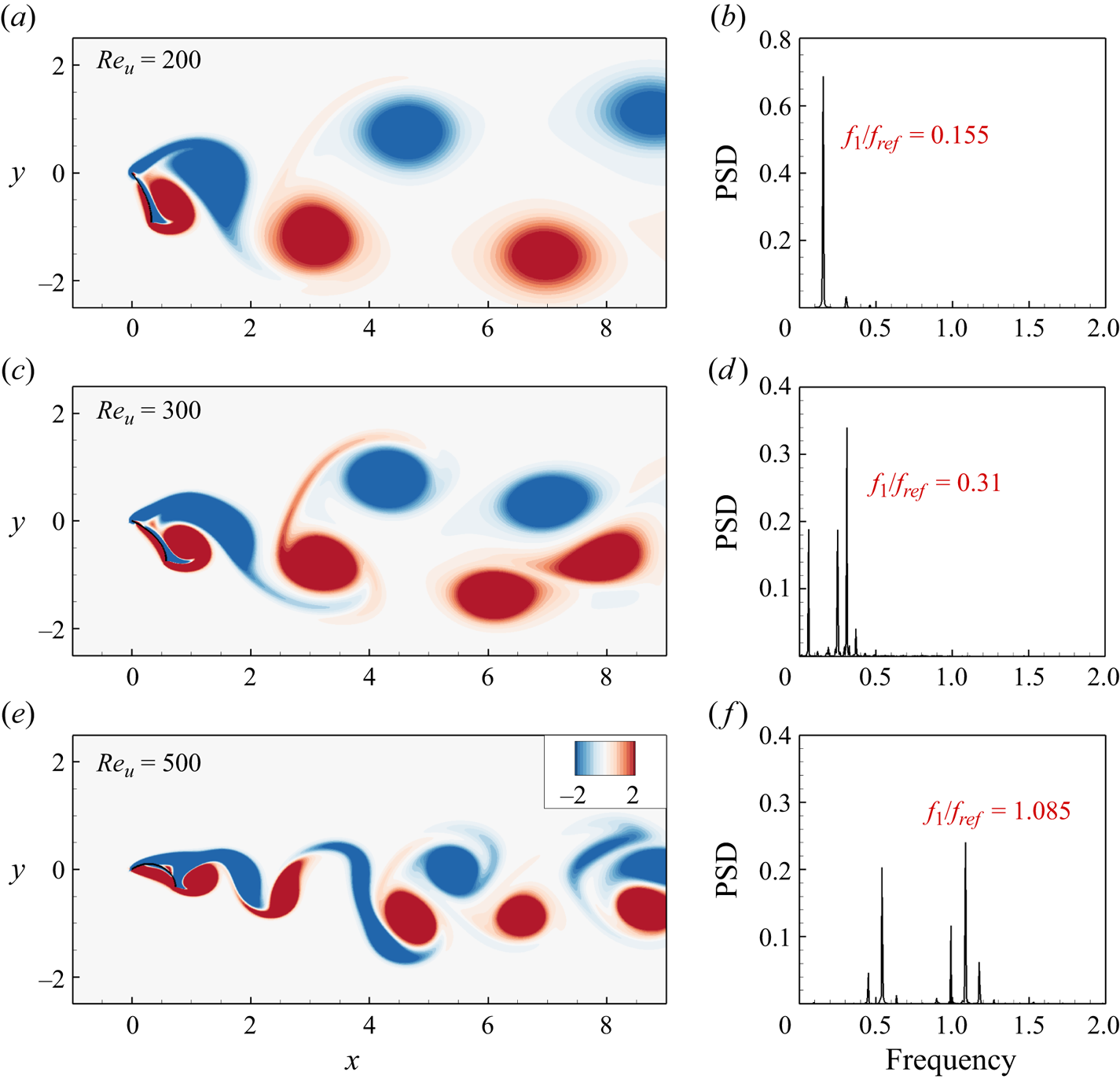

4.1.1. Reconfiguration and forces

The discussion on the reconfiguration of the ribbons is presented first, as depicted in figure 5. In slow flows (i.e. small ![]() $Re_u$), the ribbon sags downwards due to gravity acting on the trailing edge. As

$Re_u$), the ribbon sags downwards due to gravity acting on the trailing edge. As ![]() $Re_u$ increases, the ribbon gradually lifts upwards with noticeable bending deformations (figure 5), presenting a more streamlined shape. The projection length of the ribbon in the

$Re_u$ increases, the ribbon gradually lifts upwards with noticeable bending deformations (figure 5), presenting a more streamlined shape. The projection length of the ribbon in the ![]() $x$ and

$x$ and ![]() $y$ directions, denoted as

$y$ directions, denoted as ![]() $L_x$ and

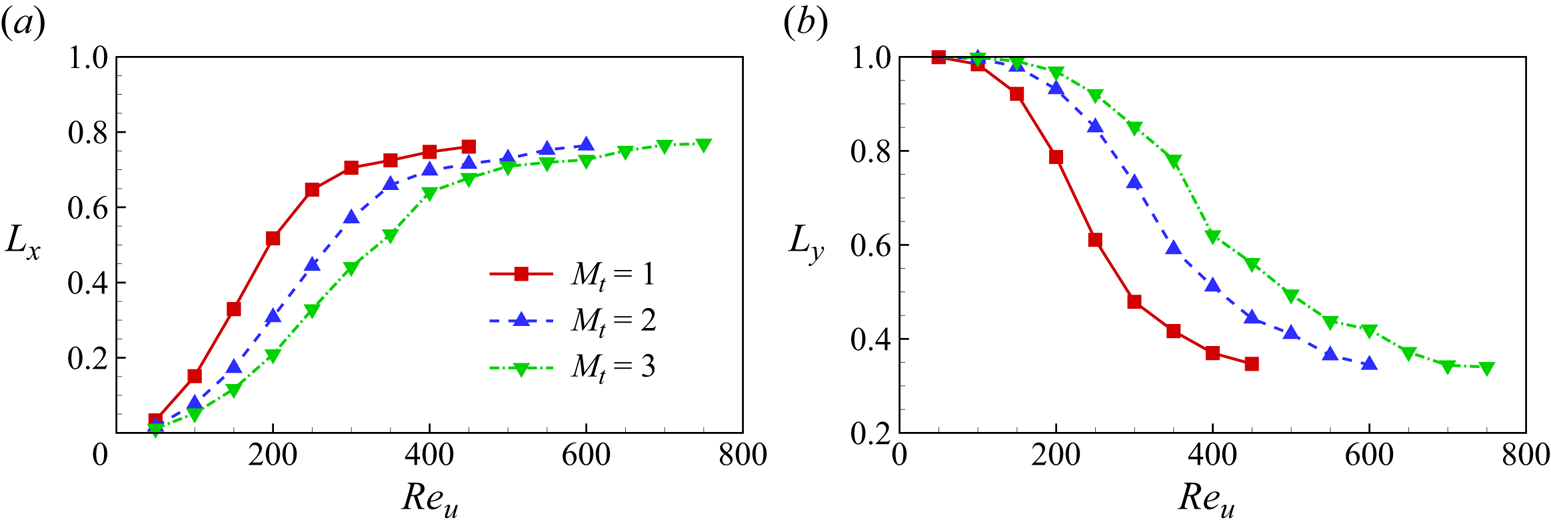

$L_x$ and ![]() $L_y$ respectively, monotonically increases and decreases with the flow speed, as illustrated in figure 6. These observations align with the fundamental characteristics of flexible body reconfiguration in flow (Alben et al. Reference Alben, Shelley and Zhang2002; Gosselin, de Langre & Machado-Almeida Reference Gosselin, de Langre and Machado-Almeida2010).

$L_y$ respectively, monotonically increases and decreases with the flow speed, as illustrated in figure 6. These observations align with the fundamental characteristics of flexible body reconfiguration in flow (Alben et al. Reference Alben, Shelley and Zhang2002; Gosselin, de Langre & Machado-Almeida Reference Gosselin, de Langre and Machado-Almeida2010).

Figure 5. The equilibrium configurations of the ribbons for (a) ![]() $M_t = 1$,

$M_t = 1$, ![]() $Re_u = 100\unicode{x2013}400$, (b)

$Re_u = 100\unicode{x2013}400$, (b) ![]() $M_t = 2$,

$M_t = 2$, ![]() $Re_u = 100\unicode{x2013}600$ and (c)

$Re_u = 100\unicode{x2013}600$ and (c) ![]() $M_t = 3$,

$M_t = 3$, ![]() $Re_u = 100\unicode{x2013}700$. Here, the curves represent time-averaged configurations, as the ribbons undergo periodic oscillation in 2-D scenarios. In each panel, the

$Re_u = 100\unicode{x2013}700$. Here, the curves represent time-averaged configurations, as the ribbons undergo periodic oscillation in 2-D scenarios. In each panel, the ![]() $Re_u$ values of the cases increase gradually from left to right, with an interval of 100.

$Re_u$ values of the cases increase gradually from left to right, with an interval of 100.

Figure 6. The normalized projected length of the ribbon in the ![]() $x$ and

$x$ and ![]() $y$ directions, i.e. (a)

$y$ directions, i.e. (a) ![]() $L_x$ and (b)

$L_x$ and (b) ![]() $L_y$.

$L_y$.

It is noteworthy that higher speeds can induce self-collision of the ribbon due to violent vibrations (see § 4.1.4). This leads to simulation failure, and the corresponding cases are discarded. Thus, there exists a critical value of ![]() $Re_u$, denoted as

$Re_u$, denoted as ![]() $Re_u^c$, beyond which the system becomes unstable. The value of

$Re_u^c$, beyond which the system becomes unstable. The value of ![]() $Re_u^c$ is dependent on the mass ratio of the weight added at the trailing edge

$Re_u^c$ is dependent on the mass ratio of the weight added at the trailing edge ![]() $M_t$. We observed that, for

$M_t$. We observed that, for ![]() $M_t = 1$, 2 and 3, the critical Reynolds number

$M_t = 1$, 2 and 3, the critical Reynolds number ![]() $Re_u^c$ is approximately 450, 600 and 750, respectively. Consequently, in figures 6 and 7, only cases with

$Re_u^c$ is approximately 450, 600 and 750, respectively. Consequently, in figures 6 and 7, only cases with ![]() $Re_u \leq Re_u^c$ are plotted. This observation of

$Re_u \leq Re_u^c$ are plotted. This observation of ![]() $Re_u^c$ increasing with

$Re_u^c$ increasing with ![]() $M_t$ agrees with expectations, as a larger

$M_t$ agrees with expectations, as a larger ![]() $M_t$ typically enhances system stability.

$M_t$ typically enhances system stability.

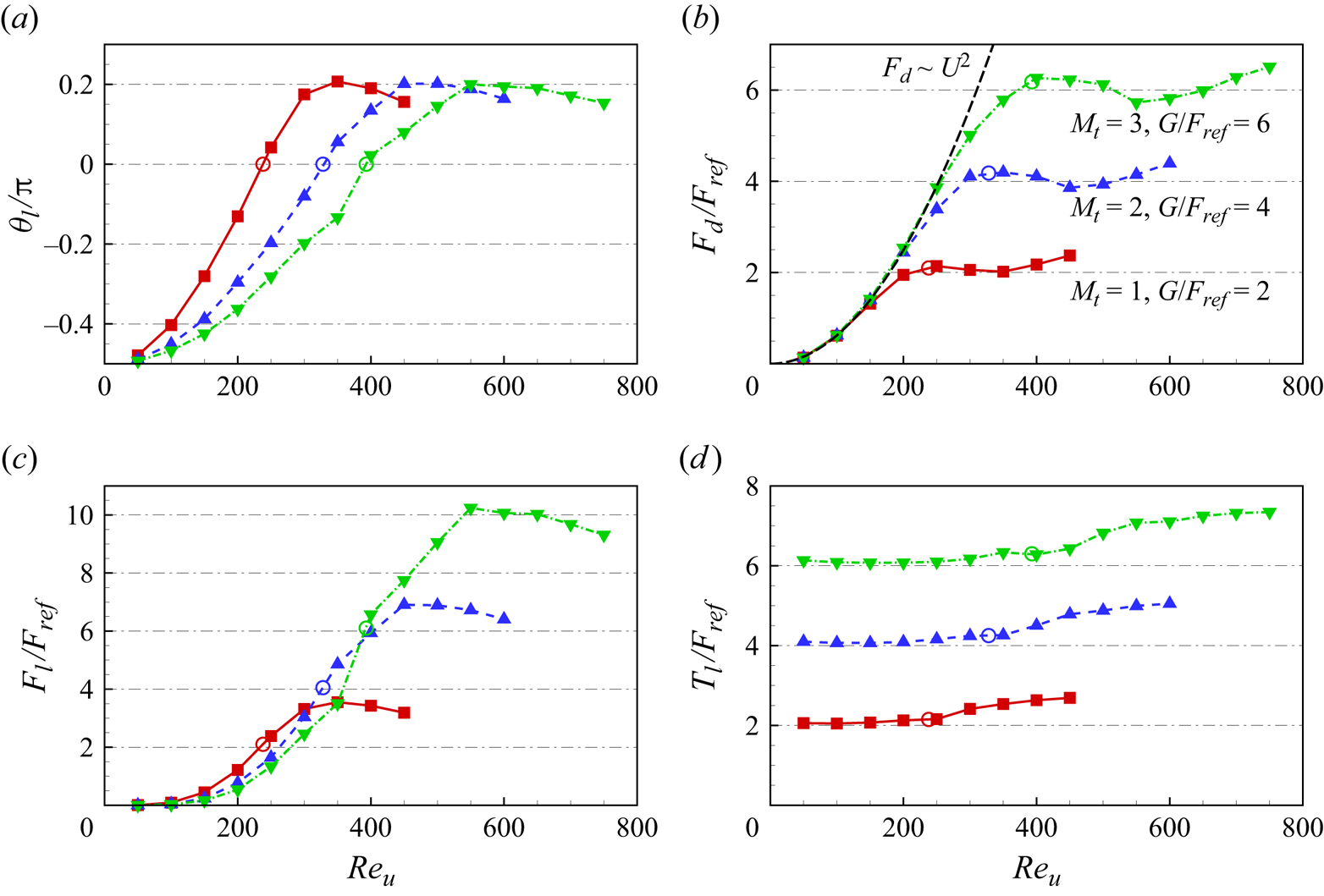

Figure 7. The normalized time-averaged (a) leading-edge inclination angle ![]() $\theta _l$, (b) drag

$\theta _l$, (b) drag ![]() $F_d$, (c) lift

$F_d$, (c) lift ![]() $F_l$ and (d) leading-edge tension

$F_l$ and (d) leading-edge tension ![]() $T_l$ of the 2-D ribbons as functions of

$T_l$ of the 2-D ribbons as functions of ![]() $Re_u$ for various

$Re_u$ for various ![]() $M_t$. The hollow circles mark the positions where

$M_t$. The hollow circles mark the positions where ![]() $\theta _l = 0$.

$\theta _l = 0$.

In addition to ![]() $L_x$ and

$L_x$ and ![]() $L_y$, the leading-edge inclination angle

$L_y$, the leading-edge inclination angle ![]() $\theta _l$ can also be employed to quantitatively describe the ribbon's reconfiguration (see figure 1a). Figure 7(a) illustrates

$\theta _l$ can also be employed to quantitatively describe the ribbon's reconfiguration (see figure 1a). Figure 7(a) illustrates ![]() $\theta _l$ as a function of

$\theta _l$ as a function of ![]() $Re_u$. It is noted that

$Re_u$. It is noted that ![]() $\theta _l$ exhibits an initial increase followed by a slight decrease with the increase of

$\theta _l$ exhibits an initial increase followed by a slight decrease with the increase of ![]() $Re_u$. The decrease in

$Re_u$. The decrease in ![]() $\theta _l$ for large

$\theta _l$ for large ![]() $Re_u$ is associated with the increase in the streamwise projection length

$Re_u$ is associated with the increase in the streamwise projection length ![]() $L_x$ of the ribbon (see figures 5 and 6(a), and note that the ribbon's total length remains constant due to its inextensibility). Its further mechanism will be discussed in figure 8. It is noteworthy that

$L_x$ of the ribbon (see figures 5 and 6(a), and note that the ribbon's total length remains constant due to its inextensibility). Its further mechanism will be discussed in figure 8. It is noteworthy that ![]() $\theta _l$ can significantly exceed 0, as evident in figure 7(a), where the maximum value of

$\theta _l$ can significantly exceed 0, as evident in figure 7(a), where the maximum value of ![]() $\theta _l$ is approximately

$\theta _l$ is approximately ![]() $36^\circ$, or in figure 5, where the ribbon conspicuously protrudes upwards for large

$36^\circ$, or in figure 5, where the ribbon conspicuously protrudes upwards for large ![]() $Re_u$. This result diverges from the experiments conducted by Barois & de Langre (Reference Barois and de Langre2013), where the maximum value of

$Re_u$. This result diverges from the experiments conducted by Barois & de Langre (Reference Barois and de Langre2013), where the maximum value of ![]() $\theta _l$ is 0. A more in-depth analysis of this disparity is provided in the subsequent sections.

$\theta _l$ is 0. A more in-depth analysis of this disparity is provided in the subsequent sections.

Figure 8. Time-averaged pressure contours around the ribbon for ![]() $Re_u = 350$ (a), 400 (b) and 450 (c) with

$Re_u = 350$ (a), 400 (b) and 450 (c) with ![]() $M_t = 1$. Solid and dashed lines denote the positive and negative normalized pressure contours, respectively.

$M_t = 1$. Solid and dashed lines denote the positive and negative normalized pressure contours, respectively.

The flow-induced reconfiguration significantly influences the forces acting on the ribbons (Schouveiler & Boudaoud Reference Schouveiler and Boudaoud2006; Luhar & Nepf Reference Luhar and Nepf2011). Figure 7(b–d) presents the time-averaged drag ![]() $F_d$, lift

$F_d$, lift ![]() $F_l$ and leading-edge tension

$F_l$ and leading-edge tension ![]() $T_l$ of the ribbon as functions of

$T_l$ of the ribbon as functions of ![]() $Re_u$ for different

$Re_u$ for different ![]() $M_t$. It is observed that, at small

$M_t$. It is observed that, at small ![]() $Re_u$, the drag of the ribbon adheres well to the classical quadratic law, i.e.

$Re_u$, the drag of the ribbon adheres well to the classical quadratic law, i.e. ![]() $F_d \sim Re_u^2 \sim U^2$ (see the dashed line in figure 7b). This behaviour is attributed to the minimal deformation of the ribbon at small

$F_d \sim Re_u^2 \sim U^2$ (see the dashed line in figure 7b). This behaviour is attributed to the minimal deformation of the ribbon at small ![]() $Re_u$. For instance, at

$Re_u$. For instance, at ![]() $Re_u \leq 250$ with

$Re_u \leq 250$ with ![]() $M_t = 3$, the ribbon exhibits

$M_t = 3$, the ribbon exhibits ![]() $L_y \geq 0.92$ (see figure 6b), resembling an upright rigid plate. Consequently, the drag of the ribbon at small

$L_y \geq 0.92$ (see figure 6b), resembling an upright rigid plate. Consequently, the drag of the ribbon at small ![]() $Re_u$ mimics that of rigid bluff bodies. The

$Re_u$ mimics that of rigid bluff bodies. The ![]() $U^2$ growth in drag also implies the predominance of form drag while skin friction can be neglected (Alben et al. Reference Alben, Shelley and Zhang2002). In the absence of skin friction, the tension of the ribbon is uniform and equivalent to the weight

$U^2$ growth in drag also implies the predominance of form drag while skin friction can be neglected (Alben et al. Reference Alben, Shelley and Zhang2002). In the absence of skin friction, the tension of the ribbon is uniform and equivalent to the weight ![]() $G$ added at the trailing edge (see § 4.1.2). Therefore, at small

$G$ added at the trailing edge (see § 4.1.2). Therefore, at small ![]() $Re_u$, the leading-edge tension

$Re_u$, the leading-edge tension ![]() $T_l$ of the ribbon remains nearly constant (see figure 7d), i.e.

$T_l$ of the ribbon remains nearly constant (see figure 7d), i.e. ![]() $T_l \approx G$ (note that the value of normalized weight

$T_l \approx G$ (note that the value of normalized weight ![]() $G/F_{ref}$ is twice that of

$G/F_{ref}$ is twice that of ![]() $M_t$ due to the factor

$M_t$ due to the factor ![]() $1/2$ in

$1/2$ in ![]() $F_{ref} = (1/2) \rho U_{ref}^2 L$).

$F_{ref} = (1/2) \rho U_{ref}^2 L$).

As ![]() $Re_u$ increases, the influence of skin friction becomes significant. The hollow circles in figure 7 mark the positions where

$Re_u$ increases, the influence of skin friction becomes significant. The hollow circles in figure 7 mark the positions where ![]() $\theta _l = 0$, signifying a point where skin friction starts to play a crucial role. Figure 7(d) indicates that, when

$\theta _l = 0$, signifying a point where skin friction starts to play a crucial role. Figure 7(d) indicates that, when ![]() $\theta _l > 0$, the leading-edge tension

$\theta _l > 0$, the leading-edge tension ![]() $T_l$ experiences a substantial increase with the rising

$T_l$ experiences a substantial increase with the rising ![]() $Re_u$. This phenomenon may be attributed to the fact that, under large

$Re_u$. This phenomenon may be attributed to the fact that, under large ![]() $Re_u$ conditions (

$Re_u$ conditions (![]() $\theta _l > 0$), the ribbon's shape tends to align more parallel to the oncoming flow (see figure 5), facilitating the generation of skin friction. Consequently, skin friction contributes to the tension in the ribbon, resulting in

$\theta _l > 0$), the ribbon's shape tends to align more parallel to the oncoming flow (see figure 5), facilitating the generation of skin friction. Consequently, skin friction contributes to the tension in the ribbon, resulting in ![]() $T_l > G$ for high

$T_l > G$ for high ![]() $Re_u$ (figure 7d).

$Re_u$ (figure 7d).

Here, we would like to estimate the magnitude of the skin friction to better elucidate whether it plays an important role. The skin friction can be approximated as viscous drag per unit width on a flat plate aligned with the flow, expressed as: ![]() $F_{vis} = 1.33\rho U^2 L_x Re_u^{-1/2}$ (Batchelor Reference Batchelor1967; Alben et al. Reference Alben, Shelley and Zhang2002) (i.e. the

$F_{vis} = 1.33\rho U^2 L_x Re_u^{-1/2}$ (Batchelor Reference Batchelor1967; Alben et al. Reference Alben, Shelley and Zhang2002) (i.e. the ![]() $U^{3/2}$ scaling), where

$U^{3/2}$ scaling), where ![]() $L_x$ is the length of the plate (in our study, it is the projected length of the ribbon in the

$L_x$ is the length of the plate (in our study, it is the projected length of the ribbon in the ![]() $x$ direction). The dimensionless skin friction is given by:

$x$ direction). The dimensionless skin friction is given by: ![]() $\hat F_{vis} = F_{vis} / F_{ref}=1.33\rho U^2 L_x Re_u^{-1/2} / (0.5 \rho U_{ref}^2 L ) = 2.66 Re_u^{3/2} L_x / ( \kappa ^2 L )$. Through calculation, when

$\hat F_{vis} = F_{vis} / F_{ref}=1.33\rho U^2 L_x Re_u^{-1/2} / (0.5 \rho U_{ref}^2 L ) = 2.66 Re_u^{3/2} L_x / ( \kappa ^2 L )$. Through calculation, when ![]() $Re_u$ is small,

$Re_u$ is small, ![]() $F_{vis}$ is at least one order of magnitude smaller than the total drag

$F_{vis}$ is at least one order of magnitude smaller than the total drag ![]() $F_d$, indicating its negligible contribution (i.e.

$F_d$, indicating its negligible contribution (i.e. ![]() $F_{vis} / F_d < 10^{-1}$). Specifically, for the case with

$F_{vis} / F_d < 10^{-1}$). Specifically, for the case with ![]() $Re_u = 400$ and

$Re_u = 400$ and ![]() $M_t = 2$,

$M_t = 2$, ![]() $F_{vis} / F_d \approx 0.09$, thus the skin friction can be ignored. However, at large

$F_{vis} / F_d \approx 0.09$, thus the skin friction can be ignored. However, at large ![]() $Re_u$,

$Re_u$, ![]() $F_{vis}$ significantly increases. For instance, for

$F_{vis}$ significantly increases. For instance, for ![]() $Re_u = 600$ and

$Re_u = 600$ and ![]() $M_t = 2$,

$M_t = 2$, ![]() $F_{vis} / F_d \approx 0.17$, which closely matches the percentage increase of

$F_{vis} / F_d \approx 0.17$, which closely matches the percentage increase of ![]() $T_l$ compared with

$T_l$ compared with ![]() $G$ in figure 7(d). Alternatively, the approximate 17 % increase can be directly observed from figure 12(a). This indicates that, at large

$G$ in figure 7(d). Alternatively, the approximate 17 % increase can be directly observed from figure 12(a). This indicates that, at large ![]() $Re_u$, the skin friction may have a significant effect on leading-edge tension increment. These conclusions are consistent with what we have found and summarized in the above analysis and § 4.1.2.

$Re_u$, the skin friction may have a significant effect on leading-edge tension increment. These conclusions are consistent with what we have found and summarized in the above analysis and § 4.1.2.

Remarkably, it is observed that, when ![]() $\theta _l > 0$, the change in

$\theta _l > 0$, the change in ![]() $F_d$ remains small, and

$F_d$ remains small, and ![]() $F_d$ approximates

$F_d$ approximates ![]() $G$ as

$G$ as ![]() $Re_u$ increases (see figure 7b). In other words, the drag appears to be independent of the oncoming flow speed, resembling the findings of Barois & de Langre (Reference Barois and de Langre2013). In the experiments by Barois & de Langre (Reference Barois and de Langre2013), skin friction was neglected as

$Re_u$ increases (see figure 7b). In other words, the drag appears to be independent of the oncoming flow speed, resembling the findings of Barois & de Langre (Reference Barois and de Langre2013). In the experiments by Barois & de Langre (Reference Barois and de Langre2013), skin friction was neglected as ![]() $Re_u \sim O(10^4)$. Consequently, the tension in the ribbon equalled the weight added at the trailing edge, i.e.

$Re_u \sim O(10^4)$. Consequently, the tension in the ribbon equalled the weight added at the trailing edge, i.e. ![]() $T_l = G$. As

$T_l = G$. As ![]() $Re_u$ increased, they observed that the leading edge of the ribbon remained horizontal (Barois & de Langre Reference Barois and de Langre2013), implying

$Re_u$ increased, they observed that the leading edge of the ribbon remained horizontal (Barois & de Langre Reference Barois and de Langre2013), implying ![]() $\theta _l = 0$. Therefore, the drag remained constant since

$\theta _l = 0$. Therefore, the drag remained constant since ![]() $F_d = T_l \cos \theta _l = G$ (see figure 25a). In contrast, in our study,

$F_d = T_l \cos \theta _l = G$ (see figure 25a). In contrast, in our study, ![]() $\theta _l$ continues to increase after reaching 0 (figure 7a), resulting in a further reduction in the transverse projection length

$\theta _l$ continues to increase after reaching 0 (figure 7a), resulting in a further reduction in the transverse projection length ![]() $L_y$ (figure 6b) and the form drag. However, the increased skin friction, as detailed in the next section, compensates for the reduced form drag, thereby maintaining the total drag substantially unchanged (figure 7b).

$L_y$ (figure 6b) and the form drag. However, the increased skin friction, as detailed in the next section, compensates for the reduced form drag, thereby maintaining the total drag substantially unchanged (figure 7b).

Concerning the lift ![]() $F_l$, it primarily relies on the transverse pressure difference across the ribbon. Notably, a larger transverse pressure difference results in a greater

$F_l$, it primarily relies on the transverse pressure difference across the ribbon. Notably, a larger transverse pressure difference results in a greater ![]() $\theta _l$. Consequently,

$\theta _l$. Consequently, ![]() $F_l$ exhibits a similar trend to

$F_l$ exhibits a similar trend to ![]() $\theta _l$ as

$\theta _l$ as ![]() $Re_u$ increases (see figure 7c). In figure 8, we present time-averaged pressure contours around the ribbon for

$Re_u$ increases (see figure 7c). In figure 8, we present time-averaged pressure contours around the ribbon for ![]() $Re_u = 350$, 400 and 450 with

$Re_u = 350$, 400 and 450 with ![]() $M_t = 1$. It is seen that, with the rise in

$M_t = 1$. It is seen that, with the rise in ![]() $Re_u$, the high-pressure region beneath the ribbon diminishes and shifts towards the trailing edge, indicating a decrease in the pressure difference across the ribbon. Hence, beyond certain thresholds (e.g.

$Re_u$, the high-pressure region beneath the ribbon diminishes and shifts towards the trailing edge, indicating a decrease in the pressure difference across the ribbon. Hence, beyond certain thresholds (e.g. ![]() $Re_u = 350$ for

$Re_u = 350$ for ![]() $M_t = 1$ and

$M_t = 1$ and ![]() $Re_u = 450$ for

$Re_u = 450$ for ![]() $M_t = 2$), both

$M_t = 2$), both ![]() $F_l$ and

$F_l$ and ![]() $\theta _l$ decline as

$\theta _l$ decline as ![]() $Re_u$ increases, as depicted in figure 7(a,c). Additionally, since

$Re_u$ increases, as depicted in figure 7(a,c). Additionally, since ![]() $F_l = T_l \sin \theta _l + G$ (see figure 25a), it becomes evident that

$F_l = T_l \sin \theta _l + G$ (see figure 25a), it becomes evident that ![]() $F_l \approx G$ when

$F_l \approx G$ when ![]() $\theta _l = 0$ (indicated by the hollow circles in figure 7c).

$\theta _l = 0$ (indicated by the hollow circles in figure 7c).

Furthermore, it is observable that an increase in ![]() $M_t$ (or the weight

$M_t$ (or the weight ![]() $G$) leads to an approximately proportional increase in

$G$) leads to an approximately proportional increase in ![]() $T_l$ (figure 7d). This, in turn, results in a proportional increase in

$T_l$ (figure 7d). This, in turn, results in a proportional increase in ![]() $F_d$ and

$F_d$ and ![]() $F_l$ when

$F_l$ when ![]() $Re_u$ is large (figure 7b,c). Therefore,

$Re_u$ is large (figure 7b,c). Therefore, ![]() $G$ emerges as a pivotal characteristic force of the system, offering insights for force rescaling in § 4.1.3.

$G$ emerges as a pivotal characteristic force of the system, offering insights for force rescaling in § 4.1.3.

4.1.2. Simplified theoretical model

To facilitate a more insightful analysis of the fluid–flexible structure problem, it is necessary to establish a simplified theoretical model. In Appendix B, we achieve this by decomposing the force acting on the ribbon. Next, we would like to check whether the model can effectively predict the equilibrium configurations and forces of the ribbons.

According to (B7), we can obtain the local inclination angle ![]() $\theta$ at different positions of the ribbon. Specifically, in (B7), let

$\theta$ at different positions of the ribbon. Specifically, in (B7), let ![]() $\hat s = 0$ (i.e. the leading edge), we can get that

$\hat s = 0$ (i.e. the leading edge), we can get that

or

Substituting (4.2) into (B7), we have

The equations (4.3) and (B7) describe the theoretical equilibrium shape of the ribbon. In practical terms, (4.3) is more useful than (B7) because it is more convenient to observe ![]() $\theta _l$ rather than

$\theta _l$ rather than ![]() $f_n$ in experiments. Figure 9 shows the local inclination angle

$f_n$ in experiments. Figure 9 shows the local inclination angle ![]() $\theta$ along the ribbon for various

$\theta$ along the ribbon for various ![]() $Re_u$ with

$Re_u$ with ![]() $M_t = 2$, where symbols and lines represent numerical and theoretical (according to (4.3)) results, respectively. It is seen that the theoretical model effectively predicts

$M_t = 2$, where symbols and lines represent numerical and theoretical (according to (4.3)) results, respectively. It is seen that the theoretical model effectively predicts ![]() $\theta$ along the ribbon when

$\theta$ along the ribbon when ![]() $Re_u$ is not too large. However, the model fails for large

$Re_u$ is not too large. However, the model fails for large ![]() $Re_u$, primarily because, under those circumstances, the large tangential force stretches the ribbon in the streamwise direction, and the shape is no longer a circular arc (see the cases with large

$Re_u$, primarily because, under those circumstances, the large tangential force stretches the ribbon in the streamwise direction, and the shape is no longer a circular arc (see the cases with large ![]() $Re_u$ in figure 5).

$Re_u$ in figure 5).

Figure 9. The local inclination angle ![]() $\theta$ along the ribbon for various

$\theta$ along the ribbon for various ![]() $Re_u$ with

$Re_u$ with ![]() $M_t = 2$. Symbols and lines represent numerical and theoretical (according to (4.3)) results, respectively.

$M_t = 2$. Symbols and lines represent numerical and theoretical (according to (4.3)) results, respectively.

This theoretical model is also applicable for predicting the drag and lift of the ribbon. Although (4.2) has provided the relationship between ![]() $f_n$ and

$f_n$ and ![]() $\theta _l$, we aim to validate the results through numerical simulations. Figure 10 illustrates the

$\theta _l$, we aim to validate the results through numerical simulations. Figure 10 illustrates the ![]() $G$-normalized total normal force

$G$-normalized total normal force ![]() $f_n L / G$ as a function of the leading-edge inclination angle

$f_n L / G$ as a function of the leading-edge inclination angle ![]() $\theta _l$. It is observed that, for all

$\theta _l$. It is observed that, for all ![]() $M_t$,

$M_t$, ![]() $f_n L / G$ well satisfies the linear relationship with respect to

$f_n L / G$ well satisfies the linear relationship with respect to ![]() $\theta _l$ with the slope

$\theta _l$ with the slope ![]() $\gamma = 1.1$, while the slope given by (4.2) is 1. This slight difference may arise from the non-uniform distribution of

$\gamma = 1.1$, while the slope given by (4.2) is 1. This slight difference may arise from the non-uniform distribution of ![]() $f_n$ near the edges (see figure 26a). The tangential force might also influence the slope as it alters the ribbon shape (i.e.

$f_n$ near the edges (see figure 26a). The tangential force might also influence the slope as it alters the ribbon shape (i.e. ![]() $\theta _l$) and local tension magnitude. Considering these factors,

$\theta _l$) and local tension magnitude. Considering these factors, ![]() $\gamma$ can be regarded as a correction parameter, and (4.2) can be modified to

$\gamma$ can be regarded as a correction parameter, and (4.2) can be modified to

According to (4.3) and (4.4), the total drag ![]() $F_d$ and lift

$F_d$ and lift ![]() $F_l$ of the ribbon can be calculated as follows:

$F_l$ of the ribbon can be calculated as follows:

\begin{align} F_d = \int_0^1-f_n \sin \theta {\cdot} L \,\mathrm{d} \hat{s} &= \int_0^1-\frac{\gamma G}{L} \left(\theta_l+\frac{\rm \pi}{2}\right) \sin \left[\theta_l-\hat{s}\left(\theta_l+\frac{\rm \pi}{2}\right)\right] {\cdot} L \,\mathrm{d} \hat{s} \nonumber\\ &= \gamma G \cos \theta_l, \end{align}

\begin{align} F_d = \int_0^1-f_n \sin \theta {\cdot} L \,\mathrm{d} \hat{s} &= \int_0^1-\frac{\gamma G}{L} \left(\theta_l+\frac{\rm \pi}{2}\right) \sin \left[\theta_l-\hat{s}\left(\theta_l+\frac{\rm \pi}{2}\right)\right] {\cdot} L \,\mathrm{d} \hat{s} \nonumber\\ &= \gamma G \cos \theta_l, \end{align} \begin{align} F_l=\int_0^1 f_n \cos \theta {\cdot} L \,\mathrm{d} \hat{s} &= \int_0^1 \frac{\gamma G}{L}\left(\theta_l+\frac{\rm \pi}{2}\right) \cos \left[\theta_l-\hat{s}\left(\theta_l+\frac{\rm \pi}{2}\right)\right] {\cdot} L \,\mathrm{d} \hat{s} \nonumber\\ &= \gamma G(1+\sin \theta_l). \end{align}

\begin{align} F_l=\int_0^1 f_n \cos \theta {\cdot} L \,\mathrm{d} \hat{s} &= \int_0^1 \frac{\gamma G}{L}\left(\theta_l+\frac{\rm \pi}{2}\right) \cos \left[\theta_l-\hat{s}\left(\theta_l+\frac{\rm \pi}{2}\right)\right] {\cdot} L \,\mathrm{d} \hat{s} \nonumber\\ &= \gamma G(1+\sin \theta_l). \end{align}

Figure 11 presents the ![]() $G$-normalized drag

$G$-normalized drag ![]() $F_d / G$ and lift

$F_d / G$ and lift ![]() $F_l / G$. The numerical results align well with the theoretical values given by (4.5) and (4.6). However, small discrepancies are noticed for cases with

$F_l / G$. The numerical results align well with the theoretical values given by (4.5) and (4.6). However, small discrepancies are noticed for cases with ![]() $\theta _l \approx 0.2{\rm \pi}$ (see figure 11a). This is not surprising as the assumptions made in the theoretical prediction,

$\theta _l \approx 0.2{\rm \pi}$ (see figure 11a). This is not surprising as the assumptions made in the theoretical prediction, ![]() $f_n \approx C$ and

$f_n \approx C$ and ![]() $f_\tau \approx 0$, are broken in these large-

$f_\tau \approx 0$, are broken in these large-![]() $Re_u$ cases.

$Re_u$ cases.

Figure 10. The ![]() $G$-normalized total normal force

$G$-normalized total normal force ![]() $f_n L / G$ as a function of the leading-edge inclination angle

$f_n L / G$ as a function of the leading-edge inclination angle ![]() $\theta _l$ for different

$\theta _l$ for different ![]() $M_t$. The dash-dotted line is the fitting curve:

$M_t$. The dash-dotted line is the fitting curve: ![]() ${f_n L}/{G} = \gamma (\theta _l + {{\rm \pi} }/{2})$, with a slope of

${f_n L}/{G} = \gamma (\theta _l + {{\rm \pi} }/{2})$, with a slope of ![]() $\gamma = 1.1$ and

$\gamma = 1.1$ and ![]() $R^2 = 0.99$.

$R^2 = 0.99$.

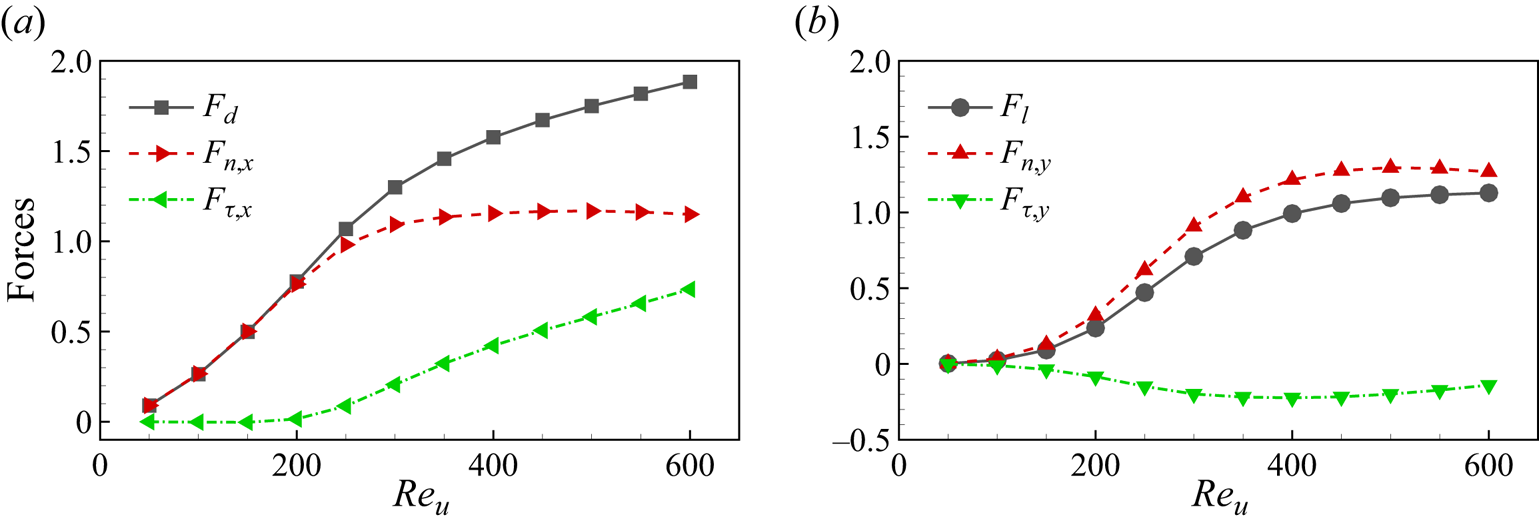

Next, we examine the contribution of normal and tangential forces to drag and lift (i.e. the ![]() $x$ and

$x$ and ![]() $y$ component forces experienced by the ribbon). Let us begin by investigating the contribution of normal and tangential forces to drag

$y$ component forces experienced by the ribbon). Let us begin by investigating the contribution of normal and tangential forces to drag

where ![]() $f_1$ is the vibration frequency of the ribbon (see § 4.1.4). The contribution of normal and tangential forces to lift

$f_1$ is the vibration frequency of the ribbon (see § 4.1.4). The contribution of normal and tangential forces to lift

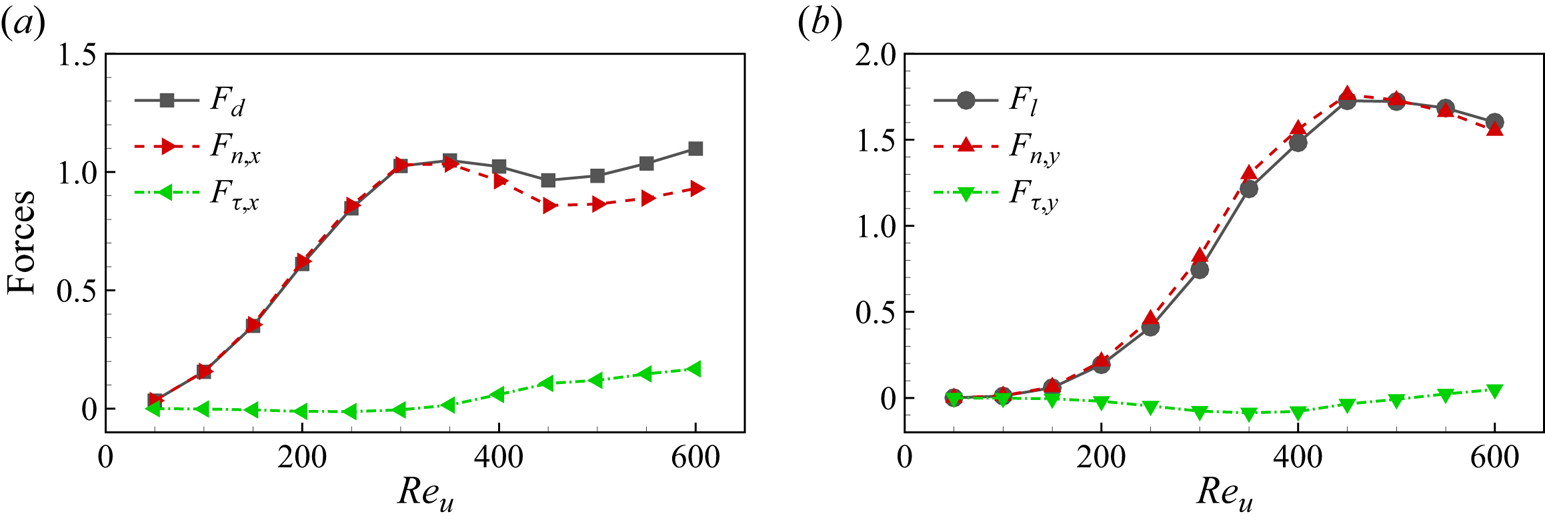

In figure 12, we present these forces as functions of ![]() $Re_u$ for cases with

$Re_u$ for cases with ![]() $M_t = 2$. It is observed that, when

$M_t = 2$. It is observed that, when ![]() $Re_u \leq 300$, the drag almost entirely comes from the normal force since

$Re_u \leq 300$, the drag almost entirely comes from the normal force since ![]() $F_d \approx F_{n, x}$ and

$F_d \approx F_{n, x}$ and ![]() $F_{\tau, x} \approx 0$ (see figure 12a). When

$F_{\tau, x} \approx 0$ (see figure 12a). When ![]() $Re_u > 300$, the tangential force begins to exert its effect in generating drag, contributing approximately 15 % of the drag for

$Re_u > 300$, the tangential force begins to exert its effect in generating drag, contributing approximately 15 % of the drag for ![]() $Re_u = 600$ (see figure 12a). These results are consistent with our estimation of skin friction or tangential force in § 4.1.1. Therefore, for high

$Re_u = 600$ (see figure 12a). These results are consistent with our estimation of skin friction or tangential force in § 4.1.1. Therefore, for high ![]() $Re_u$ (or

$Re_u$ (or ![]() $\theta _l$), the drag calculated by the theoretical model (4.5) is smaller than the actual one (see figure 11a).

$\theta _l$), the drag calculated by the theoretical model (4.5) is smaller than the actual one (see figure 11a).

Figure 12. (a) The drag ![]() $F_d$, the total

$F_d$, the total ![]() $x$-component of

$x$-component of ![]() $\boldsymbol f_n$ and

$\boldsymbol f_n$ and ![]() $\boldsymbol f_\tau$ (i.e.

$\boldsymbol f_\tau$ (i.e. ![]() $F_{n, x}$ and

$F_{n, x}$ and ![]() $F_{\tau, x}$) and (b) the lift

$F_{\tau, x}$) and (b) the lift ![]() $F_l$, the total

$F_l$, the total ![]() $y$-component of

$y$-component of ![]() $\boldsymbol f_n$ and

$\boldsymbol f_n$ and ![]() $\boldsymbol f_\tau$ (i.e.

$\boldsymbol f_\tau$ (i.e. ![]() $F_{n, y}$ and

$F_{n, y}$ and ![]() $F_{\tau, y}$) as functions of

$F_{\tau, y}$) as functions of ![]() $Re_u$ with

$Re_u$ with ![]() $M_t = 2$. The forces are rescaled using

$M_t = 2$. The forces are rescaled using ![]() $G$.

$G$.

On the other hand, as shown in figure 12(b), the tangential force contributes less to the lift, and almost all the lift is generated by the normal force, i.e. ![]() $F_l \approx F_{n, y}$. Hence, the theoretical model works well for the lift, even when

$F_l \approx F_{n, y}$. Hence, the theoretical model works well for the lift, even when ![]() $Re_u$ (or

$Re_u$ (or ![]() $\theta _l$) is large (see figure 11b).

$\theta _l$) is large (see figure 11b).

4.1.3. Normalization analysis and rescaling

In § 4.1.1, we presented key results of the ribbons vs ![]() $Re_u$, normalizing the forces by

$Re_u$, normalizing the forces by ![]() $F_{ref}= (1/2) \rho U_{ref}^2 L$. However, these data did not collapse (see figure 7). The introduction of new scaling parameters is necessary to achieve a possible uniform scaling and enhance our understanding of the underlying mechanisms of the problem.

$F_{ref}= (1/2) \rho U_{ref}^2 L$. However, these data did not collapse (see figure 7). The introduction of new scaling parameters is necessary to achieve a possible uniform scaling and enhance our understanding of the underlying mechanisms of the problem.

Note that the forces involved in the system mainly include the fluid force characterized by ![]() $\rho U^2 L$, the elastic force characterized by

$\rho U^2 L$, the elastic force characterized by ![]() $EI / L^2$ and the weight

$EI / L^2$ and the weight ![]() $G$ added at the trailing edge. Since the bending stiffness of the ribbon in our study is

$G$ added at the trailing edge. Since the bending stiffness of the ribbon in our study is ![]() $K =E I / \rho U_{ref}^{2} L^{3} = 10^{-4}$, we can see that

$K =E I / \rho U_{ref}^{2} L^{3} = 10^{-4}$, we can see that ![]() $E I / L^{2} = 10^{-4} \rho U_{ref}^{2} L \approx 10^{-4} \rho U^2 L$, i.e. the elastic force is negligible because it is much smaller than the fluid force. While

$E I / L^{2} = 10^{-4} \rho U_{ref}^{2} L \approx 10^{-4} \rho U^2 L$, i.e. the elastic force is negligible because it is much smaller than the fluid force. While ![]() $G$ and

$G$ and ![]() $\rho U^2 L$ are of the same order of magnitude. Therefore, the behaviour of the ribbon is primarily governed by the balance between

$\rho U^2 L$ are of the same order of magnitude. Therefore, the behaviour of the ribbon is primarily governed by the balance between ![]() $G$ and the characteristic fluid force

$G$ and the characteristic fluid force ![]() $\rho U^2 L$. Hence, a key non-dimensional parameter can be defined as (Barois & de Langre Reference Barois and de Langre2013)

$\rho U^2 L$. Hence, a key non-dimensional parameter can be defined as (Barois & de Langre Reference Barois and de Langre2013)

which can also be regarded as the ![]() $G$-normalized characteristic fluid force. It is inspired by the theoretical model in § 4.1.2, where

$G$-normalized characteristic fluid force. It is inspired by the theoretical model in § 4.1.2, where ![]() $f_n$,

$f_n$, ![]() $F_d$ and

$F_d$ and ![]() $F_l$ are all proportional to

$F_l$ are all proportional to ![]() $G$ (see (4.4), (4.5) and (4.6)). This suggests that

$G$ (see (4.4), (4.5) and (4.6)). This suggests that ![]() $G$ serves as the characteristic force of the system, and all forces, including the characteristic fluid force

$G$ serves as the characteristic force of the system, and all forces, including the characteristic fluid force ![]() $\rho U^2 L$, should be rescaled using

$\rho U^2 L$, should be rescaled using ![]() $G$.

$G$.

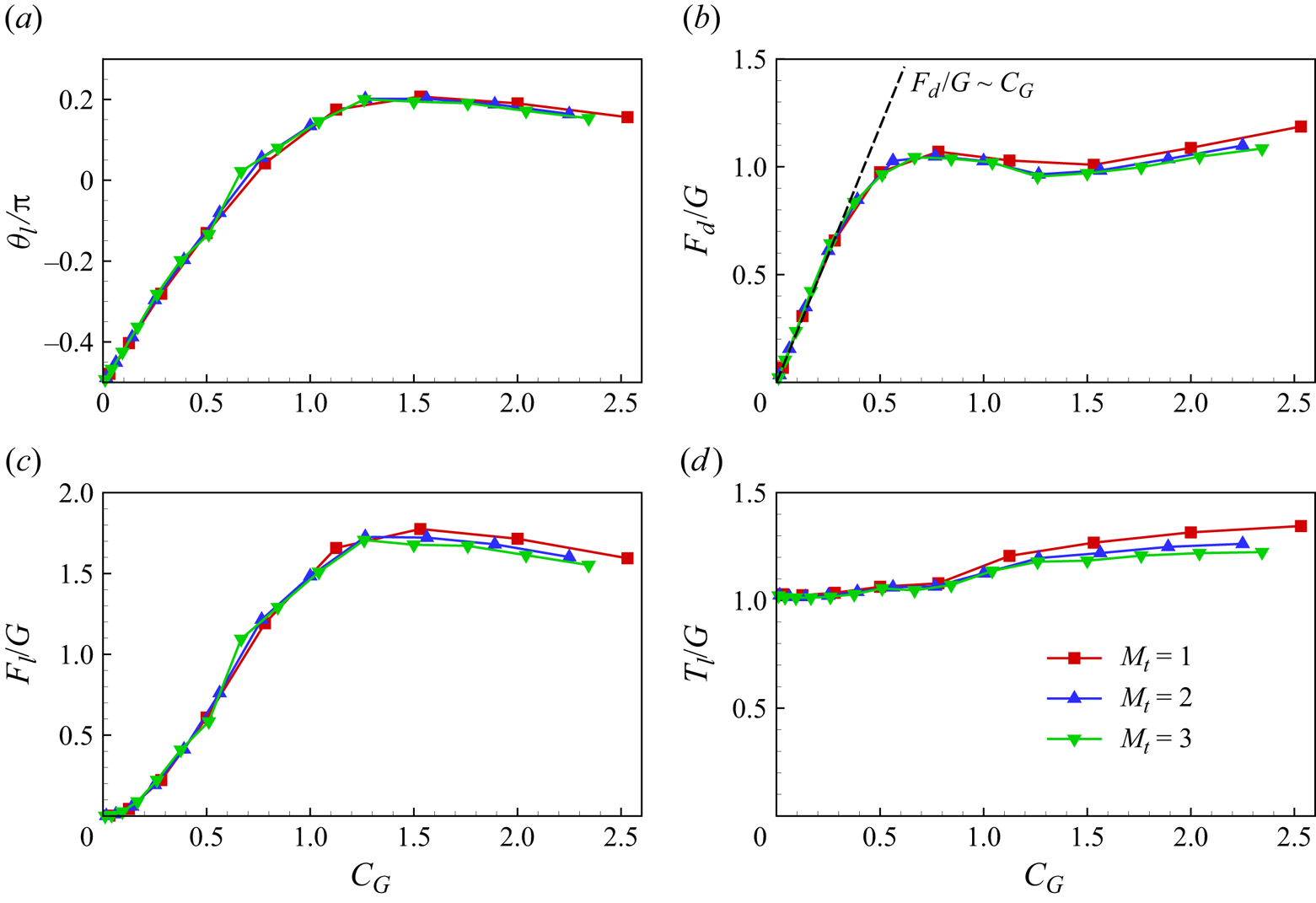

The forces and angle data in the new scaling are plotted in figure 13. Remarkably, this scaling collapses the data well for all ![]() $M_t$, compared with figure 7. Additionally, for small

$M_t$, compared with figure 7. Additionally, for small ![]() $C_G$, the

$C_G$, the ![]() $G$-normalized drag can be scaled as

$G$-normalized drag can be scaled as ![]() $F_d / G \sim C_G$, corresponding to the

$F_d / G \sim C_G$, corresponding to the ![]() $U^2$ growth of drag in figure 7(b); while

$U^2$ growth of drag in figure 7(b); while ![]() $F_d / G \approx 1$ when

$F_d / G \approx 1$ when ![]() $C_G$ is large (see figure 13b), corresponding to

$C_G$ is large (see figure 13b), corresponding to ![]() $F_d \approx G$ (figure 7b). It is also noteworthy that, similar to

$F_d \approx G$ (figure 7b). It is also noteworthy that, similar to ![]() $Re_u^c$, there is a critical

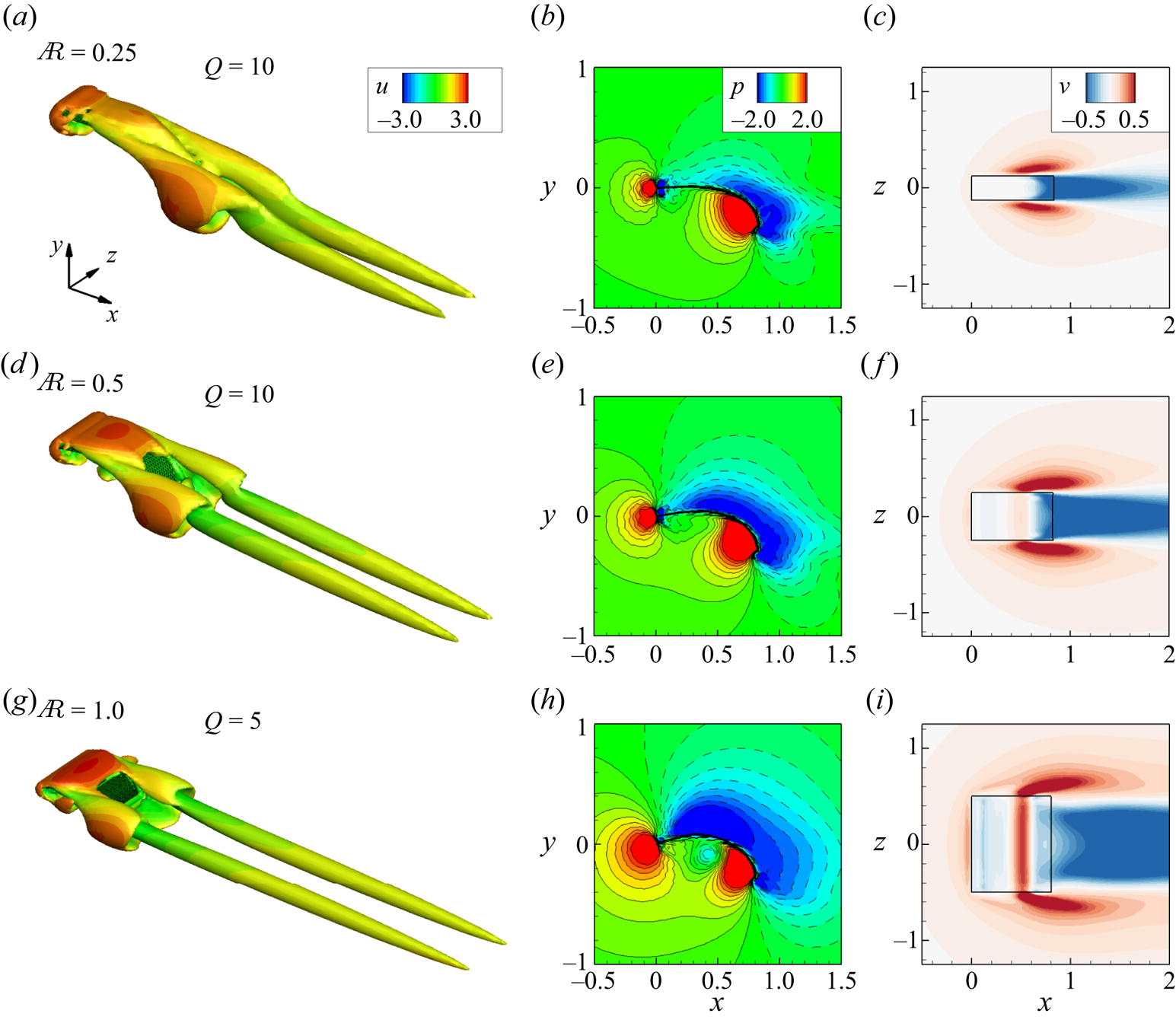

$Re_u^c$, there is a critical ![]() $C_G$, i.e.