1. Introduction

The business model of passenger vehicles has undergone a significant transformation, evolving from a purely functional mode of transportation to a highly networked vehicle with a passenger interior design that can be dynamically adapted to meet the evolving needs of customers, as evidenced by the emergence of on-demand features (Padberg Reference Padberg, Stadelmann, Pufahl and Laux2020; Möller et al. Reference Möller, Schneiderbauer, Garms, Gläfke, Köster, Stegmüller and Bobka2021). In addition to price, public infrastructure and government subsidies for electric vehicles (Kang et al. Reference Kang, Ren, Feinberg and Papalambros2016), the decisive purchase criterion for customers has changed from driving performance, acceleration behaviour and driving comfort to holistic customer experience and the functions offered in the vehicle that mainly influence the driving experience, such as highly assisted driving, comfort functions, connectivity and so on (Padberg Reference Padberg, Stadelmann, Pufahl and Laux2020). Consequently, the value perceived by the customer is increasingly derived from mobility services and customer features enabled by the vehicle, rather than by the vehicle itself (Padberg Reference Padberg, Stadelmann, Pufahl and Laux2020). Furthermore, the interaction and integration within the broader mobility system are becoming increasingly crucial for the passenger experience (Al Maghraoui et al. Reference Al Maghraoui, Vallet, Puchinger and Yannou2019). Furthermore, the advent of new technologies, such as autonomous driving and (battery) electric driving, implies an increasing importance of software, cloud services and a growing variety of sensors (Hofacker Reference Hofacker2015; Goppelt Reference Goppelt2020).

This shift in the automotive industry is also reflected in the entry of new competitors from the software industry. For instance, Google developed enabling technologies for autonomous vehicles for several years and launched their first own vehicle called Waymo (Clausen & Olteanu Reference Clausen and Olteanu2021). Other electronic- or software-driven companies are also increasingly active in the automotive market. Examples of such companies include Uber, Apple and BYD (Viereckl et al. Reference Viereckl, Ahlemann, Koster and Jursch2015; Dudley, Banister, & Schwanen Reference Dudley, Banister and Schwanen2017; Clausen & Olteanu Reference Clausen and Olteanu2021). In addition, start-ups are entering the market with disruptive technologies, such as on-vehicle solar modules or extreme-fast charging batteries, and business models designed to gain market importance, as exemplified by Lightyear Technologies B.V. or StoreDot Ltd. While Tesla, Inc. is the most prominent example of a disruptive player, further Asian manufacturers entering the international market, such as SAIC Motor and Geely (Clausen & Olteanu Reference Clausen and Olteanu2021; Boewe Reference Boewe2023). Increased competition and market pressure mean that customers expect innovation and time-to-market at an ever-faster pace (Eversheim & Schulten Reference Eversheim, Schulten, Kals and van Houten1999). At the same time, there are demands for safe and reliable products with reduced programme costs (Hofacker Reference Hofacker2015; Tutt Reference Tutt2023). Past engineering problems and launch delays at German car manufacturers have demonstrated that existing, conventional, component- and function-orientated engineering approaches are no longer sufficient to cope with the engineering complexity of software-intensive, highly networked vehicles (Dudenhöffer & Krüger Reference Dudenhöffer and Krüger2004; Handelsblatt 2020). One example of this is the implementation of over-the-air updates, which has recently led to the first waves of lawsuits against Porsche Inc. (Bigelow & Leipold, Reference Bigelow and Leipold2023).

Systems engineering (SE) offers a promising solution for managing the interdisciplinary engineering of complex technical systems (Papalambros Reference Papalambros, Maier, Oehmen and Vermaas2020; Gräßler & Oleff Reference Gräßler and Oleff2022) and combines the component and function perspective of former approaches (Albers et al. Reference Albers, Haug, Heitger, Fahl, Hirschter, Binz, Bertsche, Bauer, Riedel, Spath and Roth2019). In the past, SE was used particularly in areas with a very high level of technical complexity, such as aerospace and defence industries. Currently, SE is becoming increasingly significant in automotive industry (Denger & Tschirner Reference Denger and Tschirner2014; Gräßler & Oleff Reference Gräßler and Oleff2022; Pertschy Reference Pertschy2021; Volkswagen AG 2022), which is reflected, among other factors, in the INCOSE Automotive Vision 2025 (Davey Reference Davey2020).

From an abstracted view, SE refers to the overarching application of engineering methodologies to achieve defined engineering goals, including the fulfilment of stakeholder needs (HoHossain & Jaradat Reference Hossain, Jaradat, Ng, Nepal, Schott and Keathley2018). Therefore, different approaches and schools of SE are developed and applied in practice (Department of Defense 2022; Gräßler & Oleff Reference Gräßler and Oleff2022; Haberfellner et al. Reference Haberfellner, Weck, Fricke and Vössner2019; INCOSE 2015; NASA 2007). The diversity of different approaches leads to a lack of clarity in the definition of “Systems Engineering” or difficulty in standardising a “Systems Engineering approach.” Based on the synthesis of established SE definitions by (Hossain & Jaradat Reference Hossain, Jaradat, Ng, Nepal, Schott and Keathley2018) and in accordance with Graessler and Oleff (Reference Gräßler and Oleff2022), SE can be classified as follows: SE refers to an interdisciplinary and holistic engineering approach based on the collaborative application of methodologies to develop systems from a holistic lifecycle perspective. The focus here is on structured and continuous requirements engineering, system design and the integration of subsystems into the overall system, which operates within a system of systems. The implementation of defined processes is managed by the systems engineer, who is responsible for different process areas and thus establishes different key roles in organisations (Gräßler & Oleff Reference Gräßler and Oleff2022).

The introduction of SE represents a significant transformation of established engineering organisations, encompassing a shift in processes, methods, tools and structures (PMTS). The established processes, ways of thinking and engineering methods are subjected to critical examination and adapted to align with the SE. This results in the restructuring of systems and the optimisation of organisational structures and processes. As The Open Group (TOGAF) notes, it is crucial to oversee the transformation process, even in limited areas, to ensure a successful implementation of SE (The Open Group 2018). Furthermore, numerous authors have highlighted the necessity for change management when introducing SE (Bretz Reference Bretz2021a; Bretz, Kaiser, & Dumitrescu Reference Bretz, Kaiser and Dumitrescu2019; Gräßler & Oleff Reference Gräßler and Oleff2022; The Open Group 2018). To control and guide a transformation, different approaches to organisational change are employed in change and transformation management (Graessler Reference Graessler2001a, Reference Graessler2001b, Reference Graessler2004a; Reference Graessler, Tichkiewitch and Brissaud2004b; By Reference By2005). According to Kwiecinski, a transformation can be defined as “the evolution or revolution of an operating paradigm to one that is more encompassing of realities not […] considered […] in the previous frame of reference. It generally occurs when we bump up against the limitations of our current frame of reference.” (Kwiecinski Reference Kwiecinski and Neal2018).

In many cases, the terms change and transformation are used synonymously. In this context, transformation is understood as the development from an actual state to a target state through a planned organisational engineering process that is initiated top-down (Bittner-Fesseler, Krutzke, & Hermann Reference Bittner-Fesseler, Krutzke and Hermann2023). Change in return describes the resulting bottom-up development and modification of the organisation (Bittner-Fesseler, Krutzke, & Hermann Reference Bittner-Fesseler, Krutzke and Hermann2023). The particular challenge of a transformation is that both the old and the new worlds are present and exist in the company at the same time. Hartwich describes this as the conversion of a ship on the high seas (Hartwich Reference Hartwich2014).

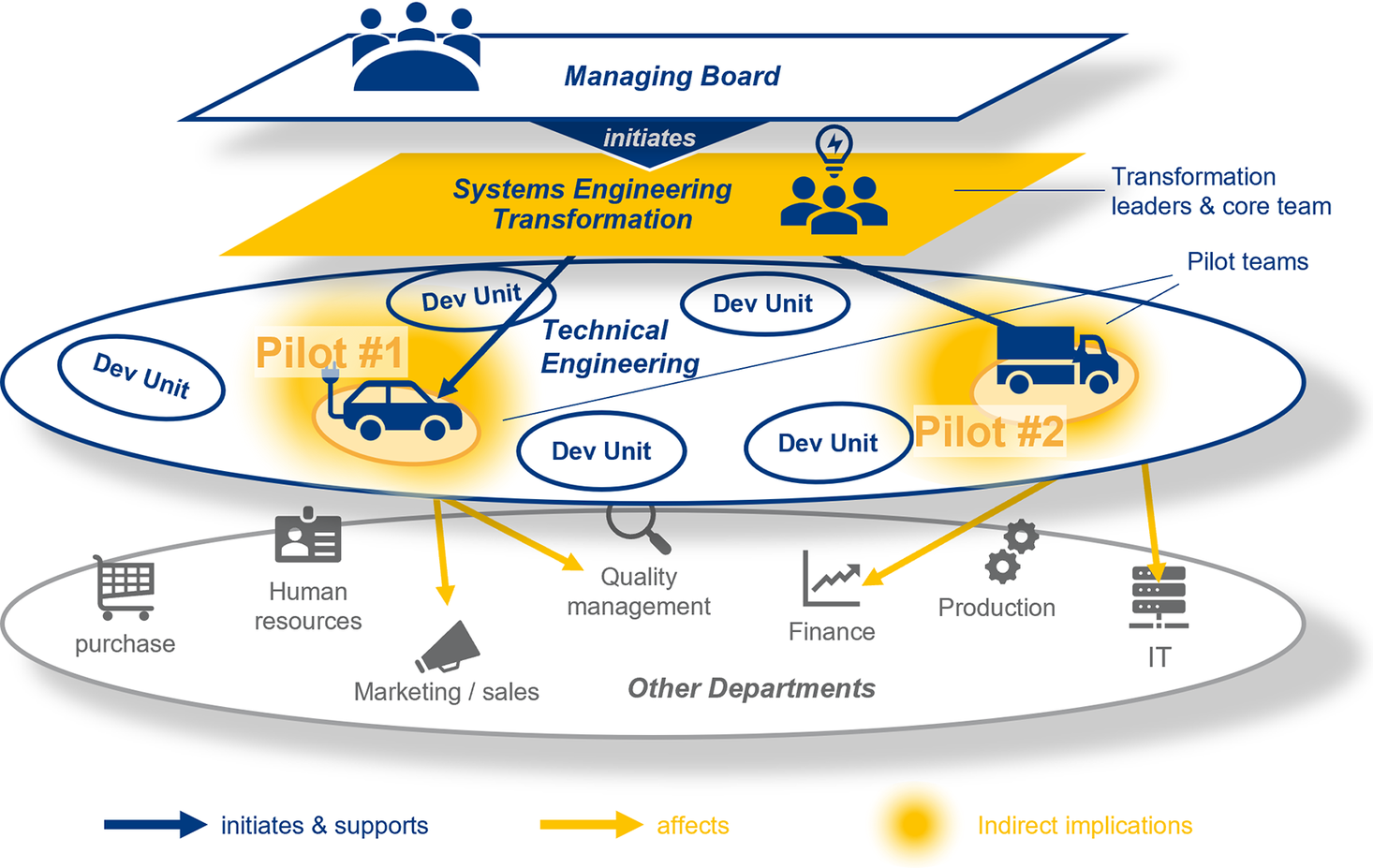

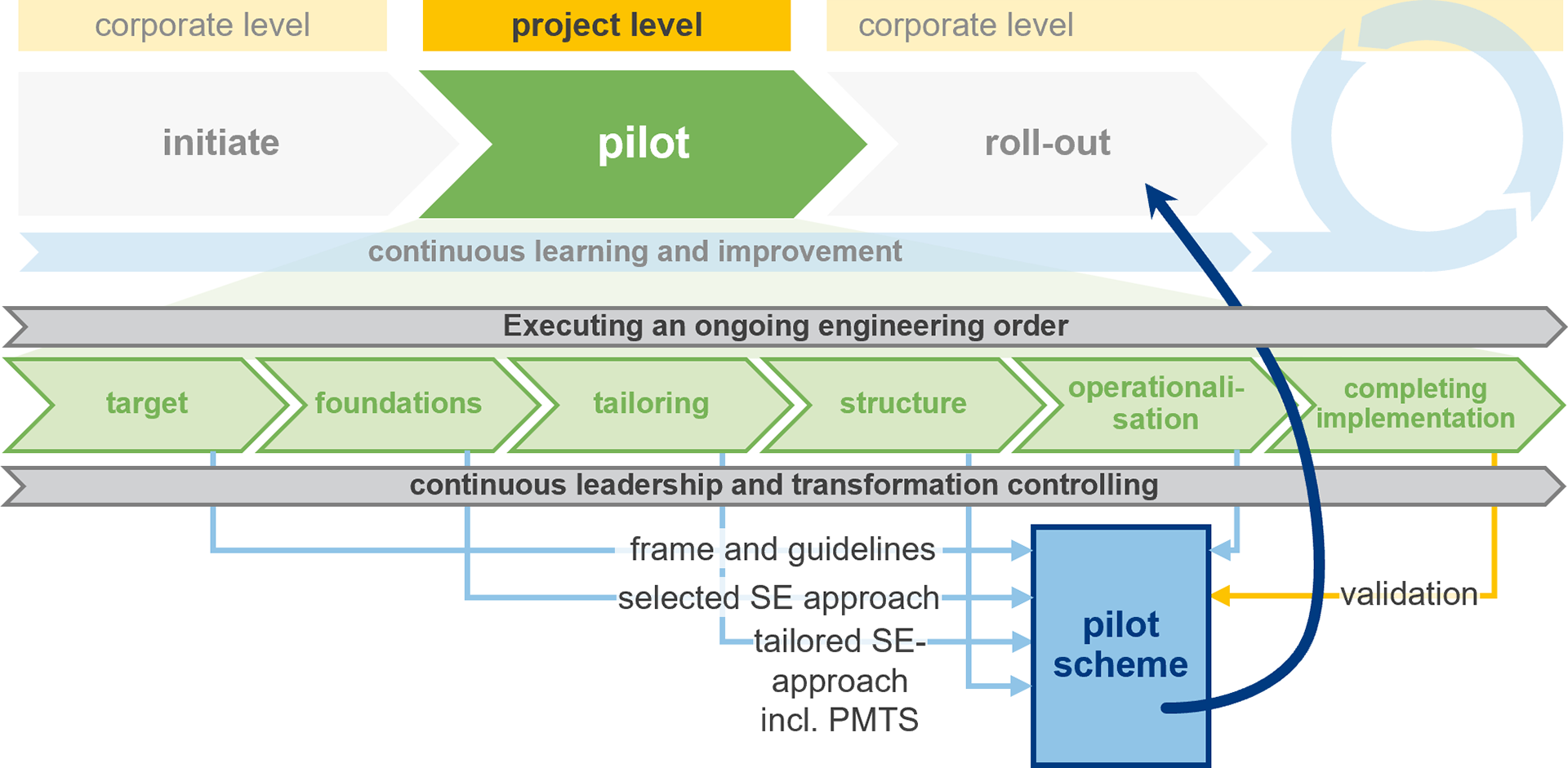

In accordance with this definition, an SE transformation may be defined as the transformation of an engineering organisation from a design space-centred engineering approach towards interdisciplinary systems thinking. While the majority of SE transformation occurs within the technical engineering division, it is important to consider the impact on other departments, such as production, sales, marketing, finance and so forth Consequently, existing interrelations must be evaluated and modified to align with the new required PMTS of the organisation. This is achieved through the implementation of new processes, methods, tools and design principles, which address the evolving technical challenges, e.g., bionic-based approaches (Bartz, Uttich, & Bender Reference Bartz, Uttich and Bender2019). SE transformation requires a top-level decision initiated by the managing board. In the context of this overarching SE transformation, pilot projects are initiated to introduce SE while other engineering orders are handled conventionally (see Figure 1).

Figure 1. Pilot projects within an overarching SE transformation.

The SETup automotive method (Systems Engineering Transformation under piloting in automotive industry) is presented to support large car manufacturers with large engineering department structures in the introduction of SE. The method is derived from established change management and SE approaches and validated in the automotive industrial practice of the automotive industry. A systematic literature review is conducted to identify relevant existing approaches. The practicability of the method is ensured by continuous parallel validation in industrial practice. In addition, the authors’ experiences from transformation projects of large automotive manufacturers and suppliers are considered. Due to its specialisation on the needs of large companies, the method was applied during the SE transformation of a large German car manufacturer and was approved by top-level managers. The proposed research results focus on piloting with further roll-out waves as a key enabler for SE transformation, as it is addressed as key enabler for different other transformation initiatives (Dombrowski & Hanke Reference Dombrowski and Hanke2007; SOPHISTen 2019). Piloting as part of a transformation project refers to the strategic implementation of new ideas, processes or technologies through a test run in a limited setting, such as a department or project, before the changes are rolled out to the entire organisation (Heidenberg et al. Reference Heidenberg, Matinlassi, Pikkarainen, Hirkman, Partanen, Hutchison, Kanade, Kittler, Kleinberg, Mattern, Mitchell and Oivo2010). Piloting allows the potential impact, risks and success of changes to be tested before they are implemented on a large scale (Heidenberg et al. Reference Heidenberg, Matinlassi, Pikkarainen, Hirkman, Partanen, Hutchison, Kanade, Kittler, Kleinberg, Mattern, Mitchell and Oivo2010).

The SETup automotive method contains a transformation process model that incorporates core activities, ensuring transparency and structure in SE transformation implementation. The method provides engineering organisations structure and a basis for SE transformation through piloting. It therefore provides key points of orientation that need to be taken into account during the transformation. The piloting aspect is concretised by core activities for generating a tailor-made and validated pilot scheme for the organisational embedding of SE.

2. Research method

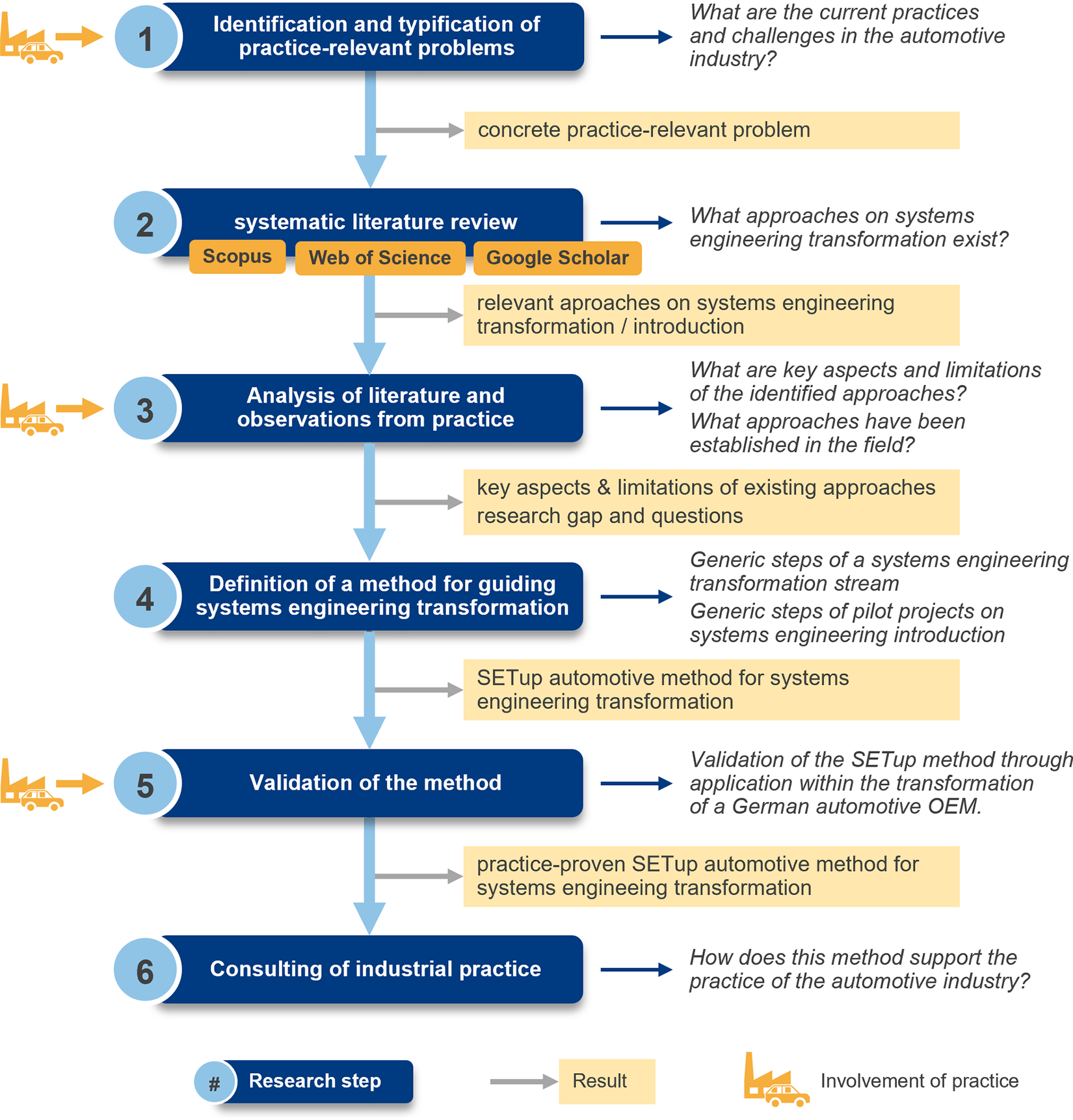

The applied research method, as outlined by Ulrich (Reference Ulrich1981)), comprises six distinct steps (see Figure 2). The identification and typification of practice-relevant problems, which form the basis of this work, are derived from the practice and current challenges of the automotive industry. In general, this research project intensively involves practice across all stages. To identify problem-relevant theories and procedures, a systematic literature review (Machi & McEvoy Reference Machi and McEvoy2016) is conducted. In the context of this literature review, existing approaches supporting the introduction of SE with a particular focus on established change management approaches are identified. The scientific search libraries Scopus and Web of Science are used for the systematic literature review, in accordance with the suggestion by Gusenbauer & Haddaway (Reference Gusenbauer and Haddaway2020)). Subsequently, Google Scholar is employed to ensure the breadth and completeness of the identified research results. In the subsequent phase of the research, a comprehensive analysis of the literature is conducted to identify the key aspects and limitations of existing approaches to the introduction of SE. Based on the findings from the literature review and observations from practice in the automotive industry, the research gap is defined, and the central research questions of this paper are formulated.

Figure 2. Scientific approach of this research according to Ulrich (Reference Ulrich1981).

The identified key aspects serve as the foundation for defining the SETup automotive method for SE Transformation under piloting. In the fourth research step, the context of application is examined, and generic steps of the method are derived on the basis of established change management approaches. In addition, the pilot phase is concretised with sub-phases and activities, which were reflected and refined in expert discussions with industrial transformation managers as well as experienced consultants. In several workshops held in the context of an ongoing SE transformation at a German car manufacturer, key hurdles and relevant steps in the practical introduction of SE were discussed and derived for the method. In addition, the content of the method is supplemented by the authors’ extensive experience in transformation projects with various companies in the automotive industry. In the fifth research step, the SETup automotive method is validated in terms of applicability, effectiveness and fulfilment of derived requirements within SE transformation of a large German car manufacturer. In the course of workshops with industrial transformation experts, managers and systems engineers, the strategic and operative aspects of managing and guiding the ongoing SE transformation were discussed and reflected upon. Finally, the practical impact of the developed SETup automotive method is derived, and recommendations for practical application are given.

3. Foundations for systems engineering transformation

As outlined in the introduction to this paper and explained using examples, the transformation of an organisation that successfully and efficiently practices SE requires not only technical knowledge but also far-reaching changes in the organisational structure and culture. To fully understand the development of a method for carrying out SE transformations, the following state of the art focuses on three central points. First, the fundamentals of SE are presented with fundamental principles, methods and published approaches in the introduction of SE in organisations. The SE fundamentals introduced provide the theoretical foundation for the requirements for the necessary organisational change. Subsequently, the principle of organisational engineering is introduced, with piloting placed in this context. Building on this, fundamental approaches to organisational change and change management are presented. These provide established tools and methods for translating the requirements of organisational change into concrete measures, which form the basis for the method developed in this research work.

3.1. Systems engineering

SE comprises an approach to the interdisciplinary engineering of complex technical systems, such as cyber-physical systems (INCOSE 2015; Gräßler & Oleff Reference Gräßler and Oleff2022). There are different views on the scope and core elements of SE. Gräßler and Oleff take up a variety of views and derive three core elements: systems thinking (“SE mindset”) (Haberfellner et al. Reference Haberfellner, Weck, Fricke and Vössner2019), an engineering methodology supported by models such as the V-model (Iris Graessler & Hentze Reference Graessler and Hentze2020; Gräßler Reference Gräßler2017; VDI 2021) and a role model (Iris Graessler, Wiechel, & Pottebaum Reference Graessler, Wiechel and Pottebaum2021; Sheard Reference Sheard1996). To describe the roles of SE, competence models can be employed (NASA 2007; Papalambros Reference Papalambros, Maier, Oehmen and Vermaas2020). As Papalambros points out, SE roles, especially the role of a modern engineering systems designer, require a comprehensive combination of technical expertise and human skills that can be accessed through practice and experience (Papalambros Reference Papalambros, Maier, Oehmen and Vermaas2020).

Systems thinking is predicated on the consideration of the entire system throughout its entire life cycle. This encompasses the definition of requirements, the development of an end-to-end architecture, the system design, the implementation, the verification and validation, and the systems operation and maintenance (INCOSE 2015). The fundamental principle of systems thinking is the decomposition of a complex overall system into numerous smaller subsystems down to the smallest subsystem size under consideration (INCOSE 2015; Haberfellner et al. Reference Haberfellner, Weck, Fricke and Vössner2019). Systems thinking necessitates the cognitive ability to recognise and manage the system not only as a whole but also interactions between physical components and between individuals, groups and supplier organisations (Papalambros Reference Papalambros, Maier, Oehmen and Vermaas2020). In this context, Greenne and Papalambros propose a pragmatic approach to establishing an understanding and applying systems thinking in practice (Greene & Papalambros Reference Greene and Papalambros2016), which can be seen as one essential aspect of SE transformation. Through modelling (model-based SE) engineering potential can be identified, for example, in the context of modular kits in the automotive industry (Albers et al. Reference Albers, Bursac, Scherer, Birk, Powelske and Muschik2019).

The engineering methodology of SE is based on SE processes, which define procedures for the holistic engineering of systems and help to structure relevant steps throughout the entire engineering process, from requirements elicitation to release. In addition, SE methods are comprised of different approaches, which are proven solution patterns for systematically solving engineering problems and tasks. Tools support the implementation of processes and methods in SE (e.g. for modelling, simulation or project management). The structures of teams, departments and information flows serve as the foundation for a seamless process and engineering success. Consequently, they must be tailored to the PMT of the selected SE approach (NASA 2007; INCOSE 2015; Gräßler & Oleff Reference Gräßler and Oleff2022).

There is a variety of approaches and handbooks on SE, but they lack in-depth practical guidance on its implementation. Examples for approaches and handbooks are INCOSE Handbook, the NASA SE Handbook and the DoD SE Handbook (NASA 2007; INCOSE 2015; Haberfellner et al. Reference Haberfellner, Weck, Fricke and Vössner2019; Department of Defense 2022). The authors of the INCOSE Handbook v5 identify three distinct types of SE transformation and underline the necessity of organisational and cultural change: (1) the transition from a state of zero SE to a fully operational SE, (2) the shift from a traditional SE approach to an agile SE methodology and (3) the evolution from a document-centric SE paradigm to a model-based SE framework (INCOSE 2023). Moreover, the majority of existing approaches define a target image or vision of the implementation of SE without specifying the necessary steps. Furthermore, other approaches focus on the third type of SE transformation, which is the implementation of model-based SE (Brusa, Calà, & Ferretto Reference Brusa, Calà and Ferretto2018).

3.2. Organisational engineering and piloting

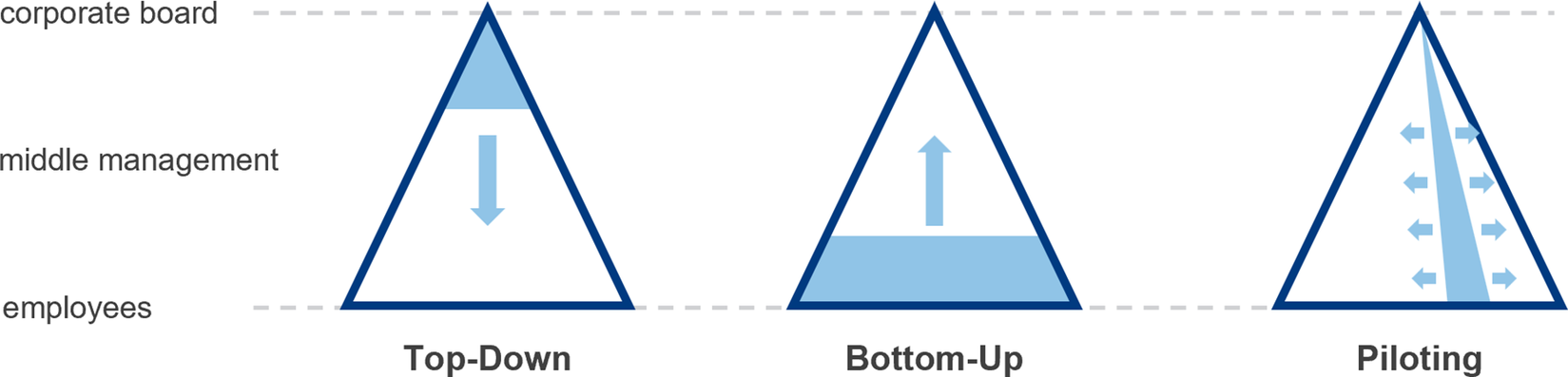

Barnard defines an organisation as a system of cooperative activities that are carried out by human beings (Barnard Reference Barnard1968). The increasing size of organisations leads to challenges in executing organisational changes (Scherm & Pietsch Reference Scherm and Pietsch2007). Therefore, strategies and preferred starting points of change initiatives are discussed in the theory of organisational engineering. In addition to several types of strategies, the top-down approach and the bottom-up approach are very popular and widespread in other fields. “Top-Down” means that changes are decided at the highest management level of the company and then carried “down” through organisational levels. On the one hand, this allows the change to be exemplified at management level as a good example to strive for; on the other hand, there is a risk of resistance due to the low level of involvement of lower hierarchical levels and a danger that changes will not be fully anchored in the organisation. Following the bottom-up approach, changes are started at lower hierarchical levels and scaled upwards in the organisation. This avoids time-consuming organisational decision-making processes but often lacks the resources and freedom to change higher-level structures (Scherm & Pietsch Reference Scherm and Pietsch2007).

Piloting can be seen as a synergetic combination of the top-down and bottom-up approaches (Kempster, Higgs, & Wuerz Reference Kempster, Higgs and Wuerz2014). Change initiatives and pilot projects are decided at management level (Dombrowski & Hanke Reference Dombrowski and Hanke2007; Scherm & Pietsch Reference Scherm and Pietsch2007). A pilot project is a plan for the exemplary implementation of a previously defined target state within a protected and delimited test area (Dombrowski & Hanke Reference Dombrowski and Hanke2007). The implementation is carried out through involvement of all hierarchical levels and thus leads to less resistance (see Figure 3). At the same time, all necessary resources and competences are made available to the project by the company’s management and external protection of the project is ensured. As Dombrowski and Hanke have shown, a pilot project can be the optimum way to initiate a change process (Dombrowski & Hanke Reference Dombrowski and Hanke2007).

Figure 3. Schematic visualisation of three different starting points of organisational change [in accordance to (Scherm & Pietsch Reference Scherm and Pietsch2007; Krapf Reference Krapf2019)].

3.3. Fundamental approaches for organisational change (change management)

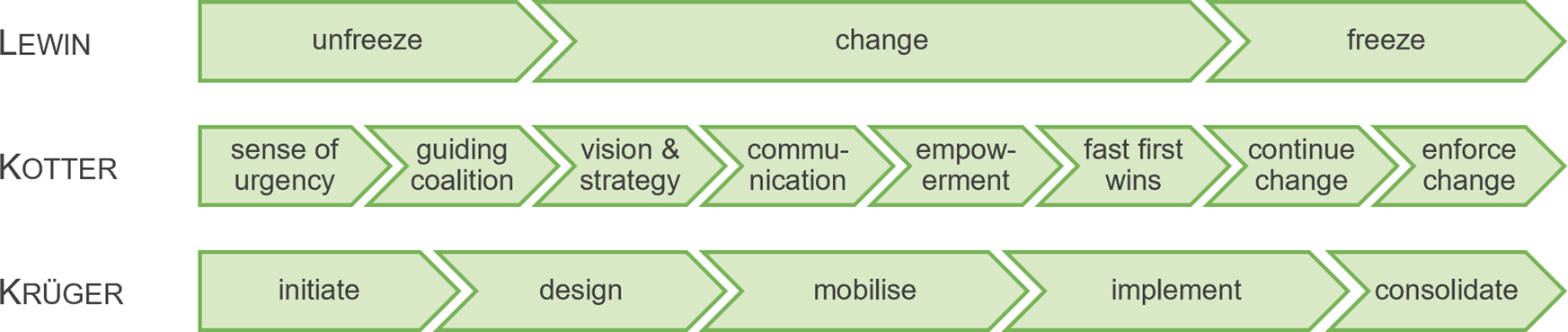

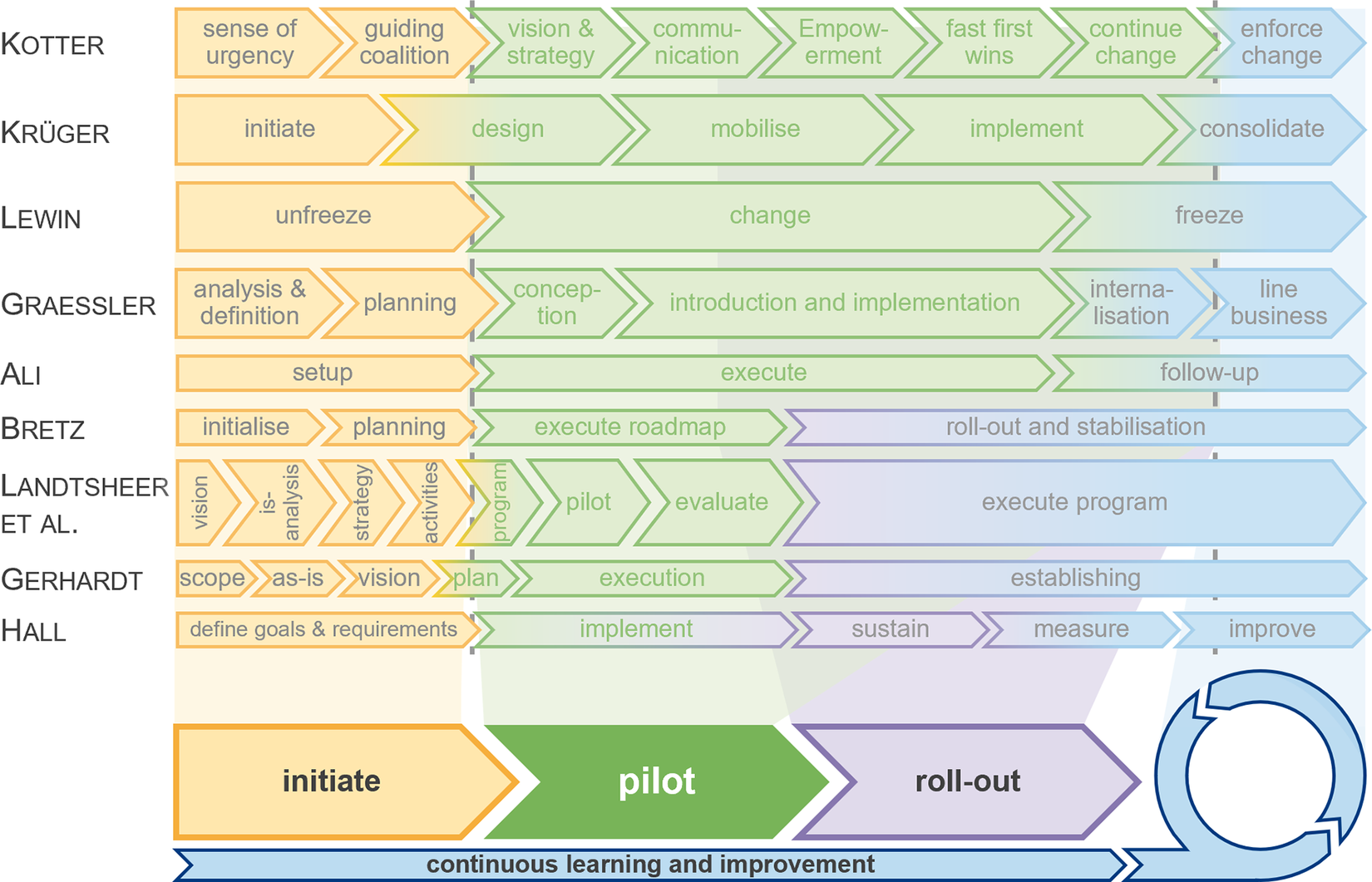

A transformation process can be understood as organisational learning (Büchel & Probst Reference Büchel, Probst, Sulzberger and Zaugg2018). Within this process of organisational learning, four stages are reached: unconscious incompetence, conscious incompetence, conscious competence and unconscious competence (Gräßler Reference Gräßler2004; O’Connor & Seymour Reference O’Connor and Seymour1996). In the theory of change management, there are different approaches with different emphases. Based on the selection and recommendation of Bellantuono et al., the scientific models by Lewin and Kotter are used as the basis for this research (see Figure 4) (Bellantuono et al. Reference Bellantuono, Nuzzi, Pontrandolfo and Scozzi2021). In addition, the approach by Krüger and Bach is examined in more detail, as it has already been analysed in works with a comparable focus (Bretz Reference Bretz2021b). Further common approaches, which are not considered in detail are, for example, the McKinsey 7-S Model, the ADKAR-Model and the General Electric’s Change Acceleration Process Model (Joseph Galli Reference Joseph Galli2018). Next to this, multiple discipline specific approaches exist, as for example the four steps of agile transformation by Bergius et al. (Reference Bergius, Rosenke, Frosch, Ludwig and Vollmer2018). In addition to the wide range of well-known approaches, there are many unpublished company-specific approaches, which cannot be considered for this research.

Figure 4. Comparison of the change approaches by Lewin, Kotter and Krüger. [in accordance with Bellantuono et al. (Reference Bellantuono, Nuzzi, Pontrandolfo and Scozzi2021)].

The three-phase model proposed by Lewin (Reference Lewin1951) outlines the stages essential for organisational transformation: unfreeze, change and refreeze. The unfreeze phase involves recognising the need for change, breaking existing cultural patterns and fostering awareness through communication. Employee involvement and addressing concerns are crucial for gaining support. The subsequent change phase introduces and implements new ideas, processes or structures, which are actively visible within the organisation. The refreeze phase stabilises changes, integrating them into daily work, ensuring sustainability and employee acceptance. The model emphasises gradual change and active employee involvement, providing a structured approach for successful implementation and overcoming resistance. Due to its generic nature, the model can be applied as a foundation for various change processes. (Lewin Reference Lewin1951).

Kotter’s eight-step process for leading change is based on previously identified transformation errors (Kotter Reference Kotter1995, Reference Kotter2012) and offers detailed stages that surpass Lewin’s model. The approach begins with creating a sense of urgency, presenting opportunities for understanding and supporting change. Subsequent steps include building a leadership coalition, developing a vision and strategy and widely communicating them to gain stakeholder support. The successful implementation of a transformation initiative necessitates the removal of obstacles, the provision of resources, and the celebration of early successes to boost confidence and motivation. The seventh step of the Kotter model utilises improvements as a catalyst for continuous change, while the final step focuses on embedding change deeply into the organisational culture for sustainability. The model underscores the significance of leadership, communication and continuous employee involvement throughout the entire change process. (Kotter Reference Kotter2012).

The five-phase model by Krüger and Bach represents a process-oriented approach to change management. It focuses on changing processes and procedures within organisations. In the first phase, an in-depth analysis of existing processes and their weaknesses is conducted. This analysis identifies the main causes of inefficiency. Based on this analysis, a change concept is developed. Goals and solutions are defined to address the identified weaknesses and improve the processes. The implementation of change is focused on actively involving the staff and preparing them for the new processes. The control phase is concerned with monitoring and evaluating the implemented changes. The success of the changes is measured using appropriate metrics, and the objectives are ensured to be met. The phase model ends with the stabilisation of the implemented changes in processes and the assurance of sustainability (Krüger & Bach Reference Krüger and Bach2014).

4. Identification of research gap based on systematic literature review

In addition to the above-outlined state of the art, a systematic literature analysis is conducted to identify published research findings on piloting an SE transformation. As a preliminary step, synonyms for the terms “Systems Engineering introduction” or “Systems Engineering transformation” are searched for. Synonyms are searched in both academic and popular online libraries and search engines, and their relevance is assessed based on the number of hits. The following terms are identified as relevant for the purposes of this study: SE introduction, SE implementation, SE transformation, SE transition and SE application. In addition, some of the terms were also used in reverse order and in conjunction with “of,” such as “Systems Engineering introduction” and “introduction of Systems Engineering.” The search terms were linked to a second-level search term using boolean search operators to identify relevant methods, approaches, frameworks and guidelines. As proposed by Gusenbauer & Haddaway (Reference Gusenbauer and Haddaway2020), the search is conducted in the libraries of Scopus and Web of Science to identify valid scientific approaches. Furthermore, Google Scholar is employed to ensure the breadth and completeness of industrial practice.

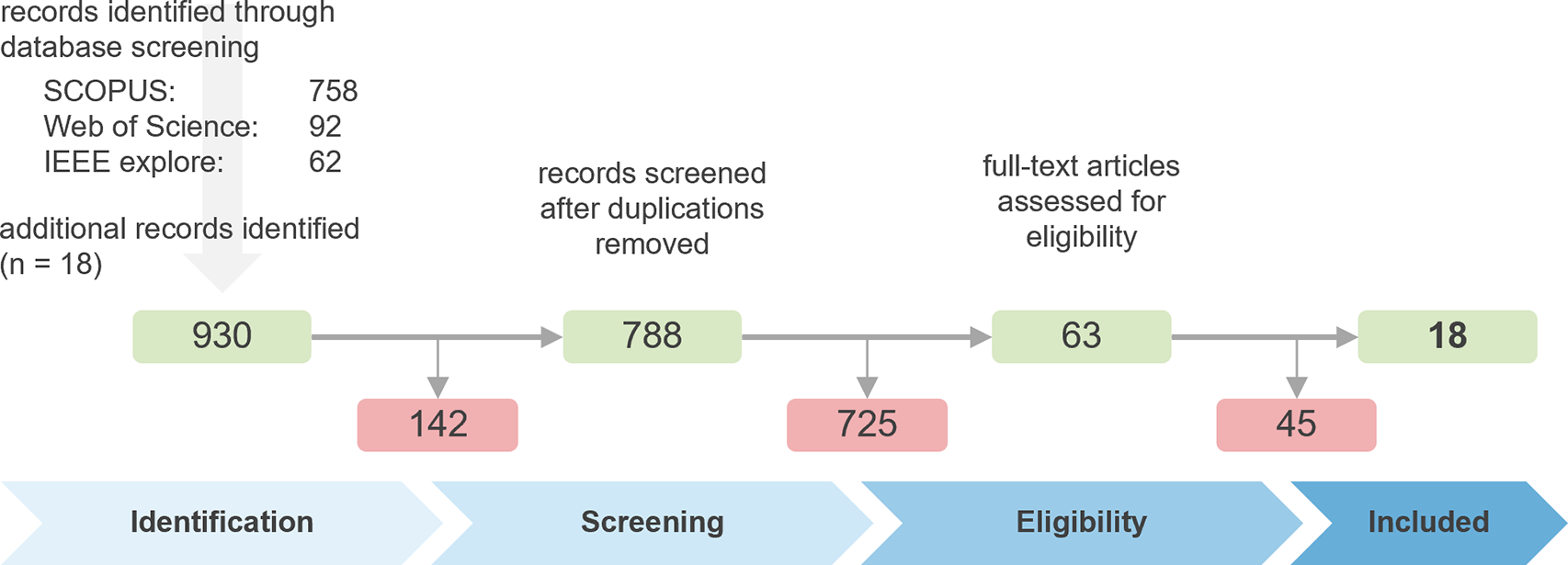

More than 16 search sequences with 930 results are carried out. In the first step, the search results are evaluated individually based on the title, abstract and keywords used, thereby reducing the number of relevant publications to 63 (see Figure 5). The central decision criterion is the reference to change or transformation management in direct or indirect connection with SE implementation. In the next step, duplicates are removed, and approaches are selected that fulfil at least one of the following defined evaluation criteria:

-

1. The approach offers a procedure with defined steps for the introduction of SE.

-

2. The approach proposes success criteria for the introduction of SE.

-

3. The approach is based on fundamentals of organisational change respectively change management.

-

4. The approach is not specified on special kinds of implementation (e.g. model-based SE – MBSE) or can be at least generically applied to fundamental SE.

-

5. The approach is generic without focus on a specific branch of industry despite the automotive industry.

Figure 5. Number of search results along the review steps based on PRISMA.

The literature review, as outlined above, reveals a variety of approaches to the introduction of SE, with different focal points and strategies. Various authors derive a concept for the introduction of SE based on the achievement of maturity levels and concretise this, for example, through action requirements, timelines and dependency models (Steffen et al. Reference Steffen, Enge, Schulze, Czaja, Schulze, Tschirner, Kaffenberger and Ackva2017; Bretz Reference Bretz2021b; Wilke et al. Reference Wilke, Pfeifer, Heitmann, Anacker, Dumitrescu and Franke2022). Ali presents the introduction of SE as a change model based on Lewin’s three steps, without providing detailed concretisations and recommendations for practice (Ali Reference Ali1999). Various approaches focus on the introduction of model-based SE. Some of these approaches assume that the SE structures already exist within companies, or derive the implementation from a modelling perspective (Kleiner Reference Kleinern.d.; Pregitzer et al. Reference Pregitzer, Blumör, Kleiner, Krastel and Neubert2014; Kößler & Paetzold Reference Kößler and Paetzold2017; Bajzek et al. Reference Bajzek, Fritz, Hick, Maletz, Faustmann, Stieglbauer, Hick, Küpper and Sorger2020). This may involve a focus on tools, the generation of a system model or modelling languages (Gerhardt Reference Gerhardt2016). Other approaches set individual focal points without considering organisational changes in detail (Davis, Mazzuchi, & Sarkani Reference Davis, Mazzuchi and Sarkani2011; Kolossváry, Feszty, & Dőry Reference Kolossváry, Feszty and Dőry2023). The approaches described in detail below are identified as most relevant for this research work and are therefore assessed individually:

Aslaksen et al. from the INCOSE Infrastructure working group concretise the SE introduction in the field of large infrastructure projects of construction industry (Aslaksen et al. Reference Aslaksen, deLamare, Fehon, Godau, Knott, Kouassi and de Liefde2012). Benefits and process enablers are described, but a model with concrete procedural steps is missing (Aslaksen et al. Reference Aslaksen, deLamare, Fehon, Godau, Knott, Kouassi and de Liefde2012). Although the INCOSE SE Handbook is probably the best-known SE manual, the description of introducing SE is not covered.

Alt’s work focuses on the introduction and implementation of model-based SE, but the conclusions he draws refer to SE rather than model-based engineering. Consequently, he addresses the non-technical aspects of SE and defines six key factors. These are management support, the “right” role staffing, training and qualification and continuously tool chain. While the work provides some guidance on the steps to be taken towards introducing SE, it lacks a concrete method with defined activities (Alt Reference Alt2012).

Landtsheer et al. present an eight-step guide to implementing SE. The first four steps involve analysing the situation and identifying methods. The next step is to define the change/design programme. Subsequently, pilot projects are initiated and evaluated. During the pilot phase, adaptation of the design programme is considered. The final phase is the broad implementation of the programme. The guide provides detailed descriptions of each step and is underpinned by an insight into the practical application of this guideline. However, the implementation of new organisational structures is less focused. The approach does not provide concrete support and guidance for the implementation of these steps. Overarching change management and technical activities are mentioned but not described in detail. The author points out the importance for a successful pilot project, as it is the foundation for further change projects. (de Landtsheer et al. Reference de Landtsheer, Aartman, Jamar, de Liefde, Malotaux, Reinhoudt and Schreinemakers2006).

Heihoff-Schwede et al. address the lack of methods and models that concretise the implementation of SE. In their research, they provide an explanatory metamodel that focuses on the elements and relationships of a SE implementation (Heihoff-Schwede et al. Reference Heihoff-Schwede, Bretz, Kaiser and Dumitrescu2019). Bretz builds upon this research, developing a generic, high-level approach with four steps aligned with Krüger’s change management approach (Bretz Reference Bretz2021b). He focuses on a maturity model for SE implementation (Bretz Reference Bretz2021b).

Graessler presents an approach of introducing SE that follows the principles of change management based on Iris Gräßler (Reference Gräßler2004)). A reference process is presented based on a generic approach to organisational learning and change management. Five phases of change are defined. In addition, six fields of action are described and detailed with relevant activities for introducing SE. The activities are divided into three categories: top management, middle management and systems engineer/operational. Pilot initiatives are also highlighted as a means of achieving and communicating early success stories to gain employee involvement. However, there is a lack of detail on the implementation of pilot projects. In addition, an SE role model is presented as one of the key enablers for a successful SE implementation (Graessler, Oleff, & Hentze Reference Graessler, Oleff and Hentze2019; Gräßler & Oleff Reference Gräßler and Oleff2022). (Gräßler & Oleff Reference Gräßler and Oleff2022).

The conducted review of literature reveals that the approaches presented above, in addition to other specific approaches (Kempster, Higgs, & Wuerz Reference Kempster, Higgs and Wuerz2014; Lines et al. Reference Lines, Sullivan, Smithwick and Mischung2015), emphasise the pivotal role of pilot initiatives in facilitating transformation in general or the introduction of SE. Through pilot projects, it is possible to achieve rapid wins (compare to Gräßler & Oleff Reference Gräßler and Oleff2022; Kotter Reference Kotter2012) and disseminate these successes across the entire company. However, existing approaches do not situate their relevance within the context of a comprehensive SE transformation. Furthermore, the concretisation of pilot projects and the further dissemination of a proven approach to other projects and units has not yet been published. Nevertheless, there may already exist company-specific solutions and good practices, but these are not accessible yet. Due to time restrictions, existing good practices are often hardly documented within the company itself – especially not put into a higher context and being published. Furthermore, projects overseen by the authors in the automotive industry have demonstrated that change management skills, in general, and knowledge of fundamental change management approaches (in particular Kotter), are available in certain segments of middle management, while this group is expected to play a pivotal role in driving transformation. However, there is a lack of concrete implementation of these approaches and classification in the context of SE. The following research questions are therefore derived from the practical findings and this systematic literature research:

-

RQ1: Which core elements of change management are essential for guiding SE transformation?

-

RQ2: Which pilots are required for SE transformation in automotive industry?

-

RQ3: How shall the roll-out to whole product creation be conducted?

5. Method for SE transformation under piloting in automotive industry (SETup automotive)

The challenges outlined necessitate a reorientation in vehicle engineering, demanding technical innovations and effective collaboration among diverse organisational units, each with its individual goals. Traditional car manufacturer structures are organised around components like bodywork and powertrain. To support SE with its new processes, ways of thinking, methods and tools, organisational structures must be aligned accordingly. Therefore, models and methods to ensure transparency, comprehensibility and structure are required.

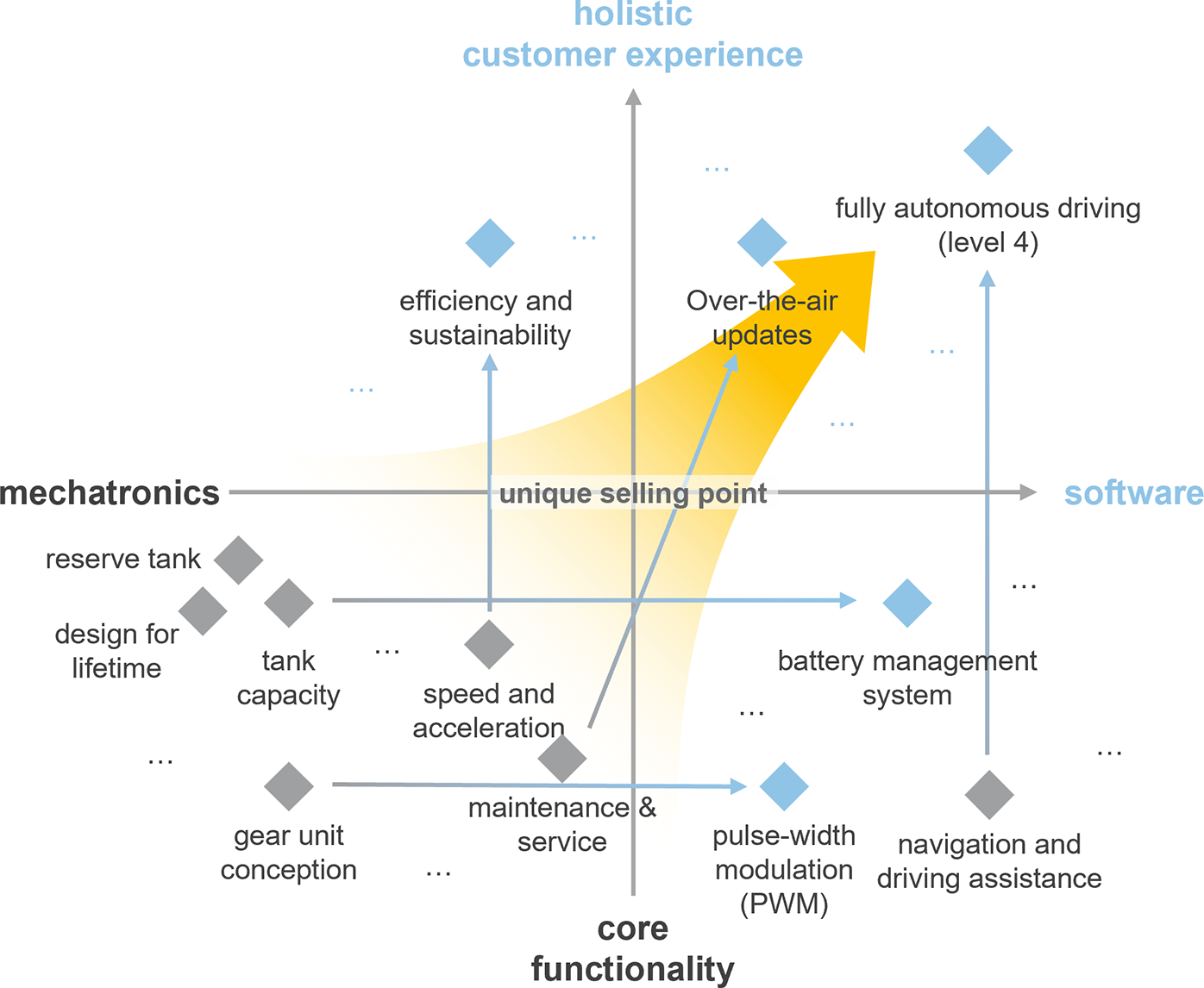

A unique feature of automotive engineering and production is the high number of units paired with a large number of product variants. The prevailing high safety criticality is emphasised by strict regulatory requirements. The engineering complexity in the automotive industry is fuelled by a shift in importance from mechatronics to software on the one hand and from core functionality to holistic customer experiences that enable situation-specific adaptability to passenger needs on the other (see Figure 6). This can be attributed to the automotive technology that has matured over decades, which no longer allows for sufficient differentiation based purely on performance features.

Figure 6. Shift of unique selling points in automotive industry.

Furthermore, from a human resources perspective, new challenges emerge. In large automotive companies, tasks, responsibilities and authorisations of specific roles are clearly defined. Established role structures serve as the foundation for individual career paths. In addition, competency and expertise are typically concentrated in central departments, such as group-wide process engineering or in-house consulting. These central departments are employed to train and retain experts, for example, for change projects (Graessler Reference Graessler2001b). Consequently, a substantial number of car manufacturers have established central SE departments in recent years.

The challenges faced by major car manufacturers in guiding SE transformation are analysed. Consequently, the results of the literature research conducted and the fundamental works on SE presented in the state of the art were used to identify the success factors for introducing SE and to derive the requirements for a method for SE introduction in major automotive companies. Furthermore, the authors’ experience of several years of transformation processes with car manufacturers and suppliers has been incorporated into the study. Finally, the identified success factors and needs were discussed and concretised with practical insights by industry experts with over 15 years of industry experience. The identified needs are summarised by the following requirements:

-

R-1 The method shall support automotive industry in guiding a SE transformation.

-

R-2 The engineering organisation must not be overloaded by means of capacity.

-

R-3 Current engineering goals and ongoing orders must be maintained.

-

R-4 SE must be tailored to the individual company and project.

-

R-5 Existing structures must be considered, assessed and migrated comprehensibly into a new structural organisation if necessary.

-

R-6 Employees’ fears must be considered to avoid resistance.

-

R-7 Basic and expert knowledge regarding SE and its effectiveness must be established and provided within the company.

-

R-8 The effectiveness of the SE approach must be proven and communicated to create multipliers through the organisation.

Pilot projects, as evidenced in literature and industrial practice (Dombrowski & Hanke Reference Dombrowski and Hanke2007; Alt Reference Alt2012), offer invaluable insights into a company’s specific challenges. Experts execute selected methods and strategies in these projects, gradually refining them, minimising risks and allowing regular business operations elsewhere to continue undisturbed. This established foundation serves as the basis for subsequent adaptation in further units. In the context of SE transformation, engaging employees in pilot projects enables them to develop a profound understanding of SE across all hierarchical levels and build up a competence team. This facilitates the customisation of generic SE principles to address specific company or project needs, resulting in a tailored template for broader implementation. Successful pilot project participants become motivated multipliers, laying the groundwork for widespread company-wide change.

To develop a method for SE transformation, existing change management approaches are analysed and compared (see 3. State of the art – Approaches for organisational change). Furthermore, the model of the practical implementation of SE by Graessler (Graessler Reference Graessler, Tichkiewitch and Brissaud2004b; Gräßler & Oleff Reference Gräßler and Oleff2022) as well as process models identified in literature review are reflected. The models are compared by their phase descriptions and included activities (see Figures 4 and 7).

A comparison of the existing process models for the introduction of SE shows clear parallels between the approaches (see Figure 7). As can be seen, all approaches begin with an initiation phase, which is further concretised depending on the approach. Across all approaches, the focus of this phase is essentially on analysing the current situation, raising awareness of the need for change and preparing for change by defining goals and visions. All approaches conclude with some form of institutionalisation of the change within the organisation, through the perpetuation of operationalisation or continuous improvement processes. The aspect of piloting is only explicitly presented by Landtsheer et al., while the other approaches do not specify the extent of implementation within the organisation. The presented model for SE transformation under piloting therefore represents an abstracted view of the established approaches, in which piloting with subsequent successive roll-out is explicitly emphasised and concretised. Based on the roll-out concept by Graessler (Graessler Reference Graessler, Tichkiewitch and Brissaud2004b), as a result of practical observations from change and transformation projects, taking into account and clustering the established approaches and in accordance with (Bergius et al. Reference Bergius, Rosenke, Frosch, Ludwig and Vollmer2018), the four essential steps of the SETup automotive method are thus derived: initiate, piloting, roll-out and parallel continuous learning and improvement. In the following figure, these four phases are schematically related to the phases of the previously analysed models (see Figures 4 and 7) and further described in detail in the following section.

Figure 7. Phases of the method for SE Transformation under piloting in automotive industry (SETup automotive).

The initial phase, “initiate,” corresponds to the initial stages of the established approaches. Those involved become aware of the necessity for change. The decision to alter the status quo is made, and the requisite activities are initiated to establish the change project. In particular, a team is entrusted with the task and an initial overarching vision of change is established. The transformation core team should comprise both a C-level patron of the transformation project, who will assume ownership and remove obstacles, and experienced transformation experts, who will manage, lead and support the implementation of the transformation. This is where the second phase, “pilot,” begins: In a pilot project, the transformation is carried out in a delimited area of the company. Unlike top-down or bottom-up approaches, a pilot project involves all levels of company. The goal is to create motivation and conviction at all levels of the company and spreads it through these multipliers (see Figure 5). In essence, each pilot project itself follows the three phases of Lewin. Expertise and ways of working are achieved in the pilot area within the pilot project. In the third phase, “roll-out,” these gains are transferred and implemented in further parts of the company. The fourth phase of the model comprises overarching “continuous learning and improvement,” which is particularly intense during the pilot phase but remains important even after the transformation has been successfully completed.

Following the chosen research approach based on the derived phases, the necessary activities of introducing SE are collected from literature. To complete and concretise the activities, discussions were held with experts from various projects on the introduction of SE in automotive industry in the period of 2021–2024. Of particular note are projects at two different companies: (a) the introduction of model-based SE at a German automotive supplier; (b) different projects to support the SE transformation of a German car manufacturer

-

a) Over the course of a 9-month project period, the foundations for a transformation were laid, a pilot project was initiated, and the employees were enabled to model, resulting in the initialisation of visible successes within the company. An expansion to other units of the company is currently being planned. Within the project, 11 engineers were included and nine workshops were conducted. In terms of this research, the proposed model was discussed with three engineers in individual interviews.

-

b) Furthermore, the findings from supporting the SE transformation of a major German automotive manufacturer over a period of 3 years were reflected upon. In the course of this research work, experts involved in this project were interviewed who had already accompanied the transformation since its initiation. The first pilot project is currently in the operationalisation phase based on specific vehicle engineering. Further pilot projects are currently in the initialisation phase. In this context, more than 10 workshops with more than 20 experts, with each having more than 10 years of experience in the management and implementation of process change programmes , from different hierarchical levels and work areas, transformation stakeholders and R&D consultants were evaluated. Furthermore, activities were explicitly discussed with three transformation managers and five consultants, involved in the project, in individual interviews. Each interview participant has contributed to at least one transformation project but is currently focused exclusively on the pilot project under consideration. In addition, results and experiences from documenting the transformation process and status, involving more than 500 working hours, are evaluated. Within this documentation, activities are defined and recorded with a focus on programme management, organisational structure, SE principles and processes, employee empowerment and interfaces with other units.

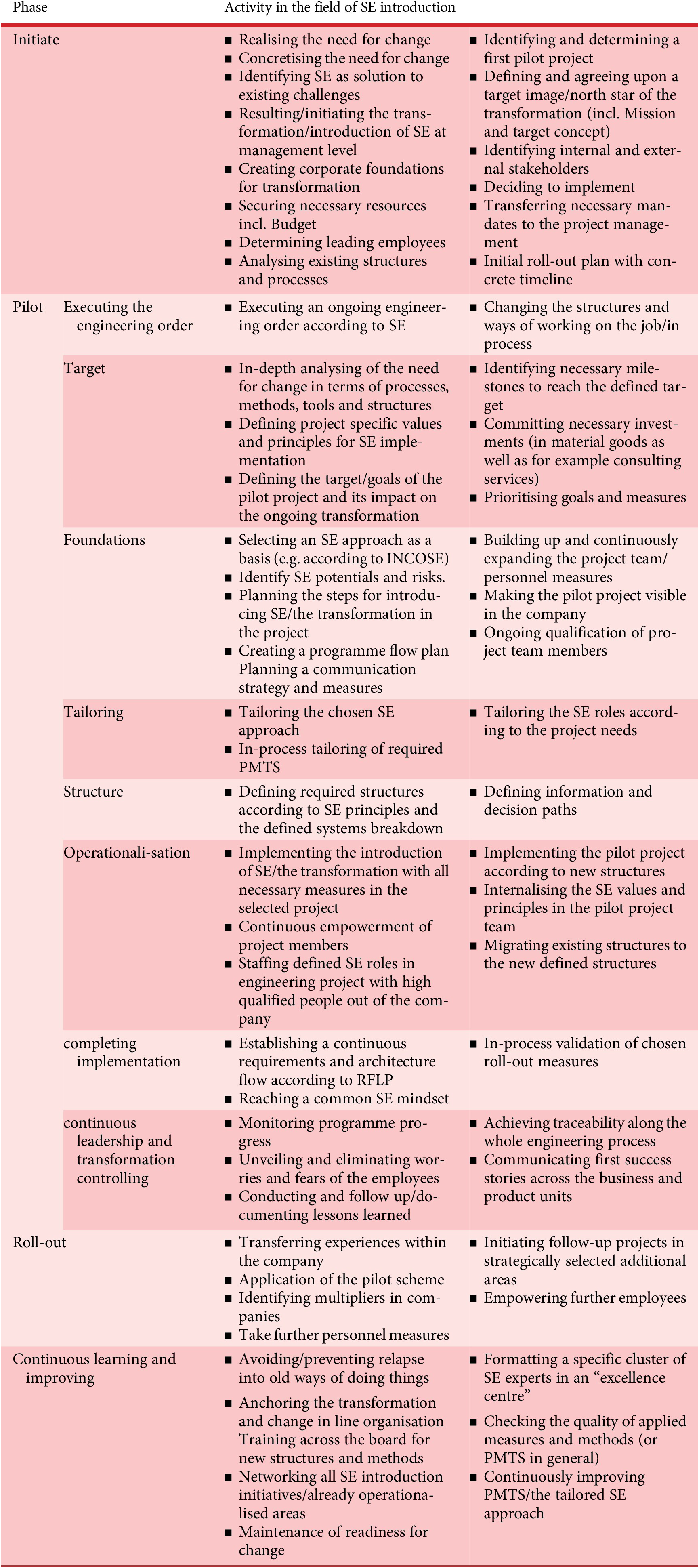

Based on the insights of the authors and the conducted interviews, the initial identified activities are supplemented. Furthermore, based on the discussions held and the activities analysis, the “pilot” phase is broken down in subphases. The derived activities and their allocation to the four SETup phases are described in Table 1.

Table 1. Core activities within the four phases of the SETup automotive method

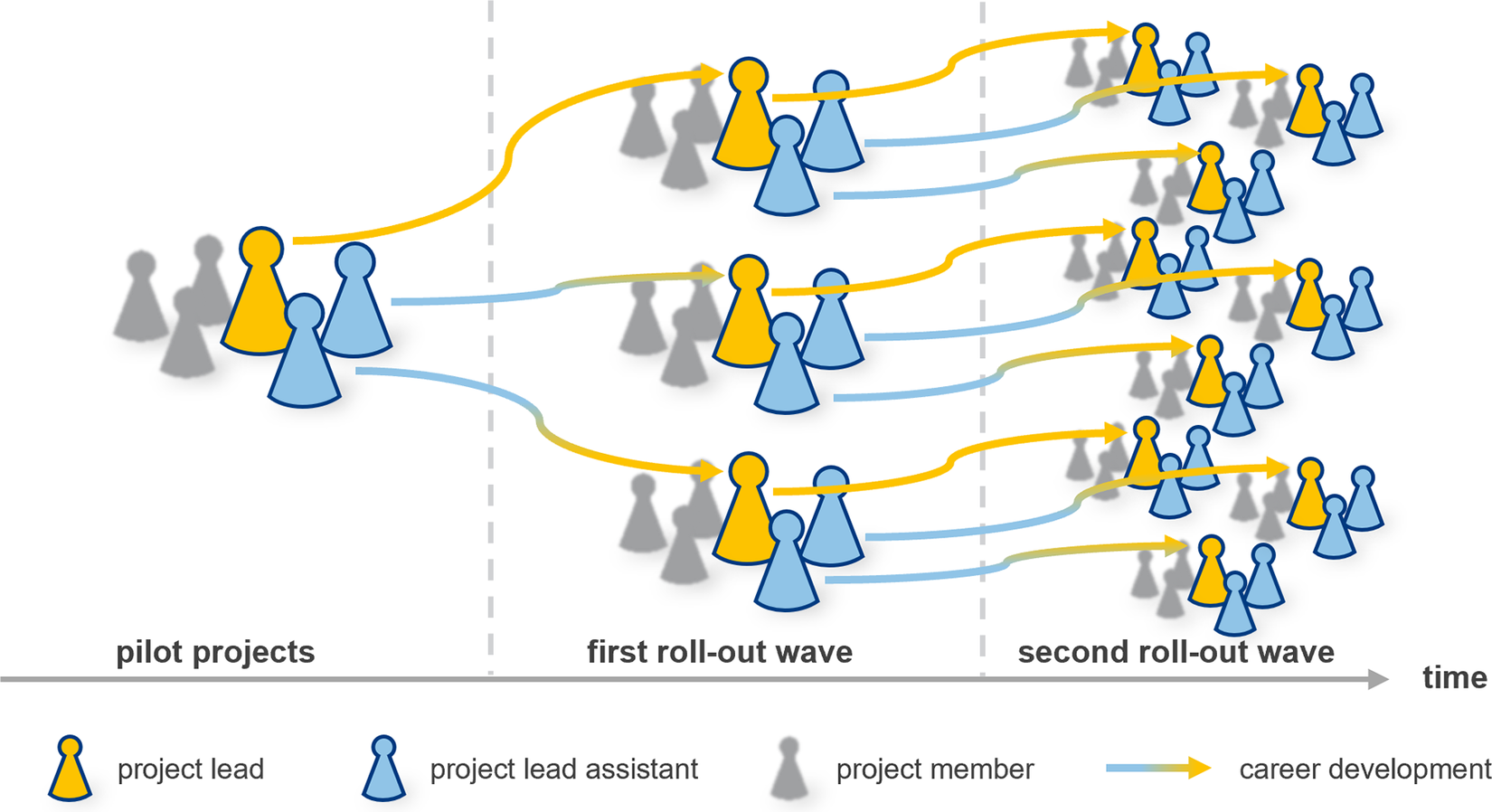

The overall four-phase model of SE transformation is understood as an overall transformation initiative linked to the highest corporate level. Within this transformation, pilot projects are project-specific initiatives that form the basis for company-wide roll-out of SE (compare Figure 1). A pilot project represents the initial phase of an initial roll-out plan for transformation (see Figure 8). It is typically followed by a further pilot project, as exemplary suggested by Alt (Reference Alt2012), and two cascading roll-out waves. Following the conclusion of a first pilot project, its success and results are validated. This process allows for the improvement of a transformation strategy, tailored approaches and PMTS for further piloting. Furthermore, a time-delayed parallel run of pilot projects is possible. The first and second roll-out waves are conducted on the basis of the SE transformation pilot scheme, which was elaborated and validated in the pilot projects. The typical or ideal duration of pilot projects and roll-out phases is not considered within the scope of this research. Rather, these should be determined on a project-specific basis according to the circumstances.

Figure 8. Typical abstracted roll-out plan of a transformation conducting two pilot projects and two roll-out waves (schematic visualisation).

The concretisation of the pilot phase in subphases is referenced in Table 1 and illustrated in Figure 9. In essence, a pilot project is established on an ongoing engineering order, which implies that organisational change is conducted in-process. The pilot phase begins with the definition of the target of the specific pilot project. This can be based on challenges in existing engineering processes (e.g., “with SE we can handle the increased complexity of our product”) or it can be focused on a specific expression of SE in the project (e.g., “we are building a continuous RFLP architecture from scratch”). In addition, relevant foundations for the pilot project are defined: The pilot project core team is expanded with experts from the organisation; a basic SE approach is selected, and further SE potentials are identified and selected. The steps of the SE implementation are defined in the form of a programme flow chart with meaningful milestones. In addition, a communication strategy is created, and the project becomes visible within the organisation. Furthermore, the project team members are continuously qualified and trained.

Figure 9. Detailed dissection of the pilot phase with focus on the elaboration of a company-specific pilot scheme for SE roll-out.

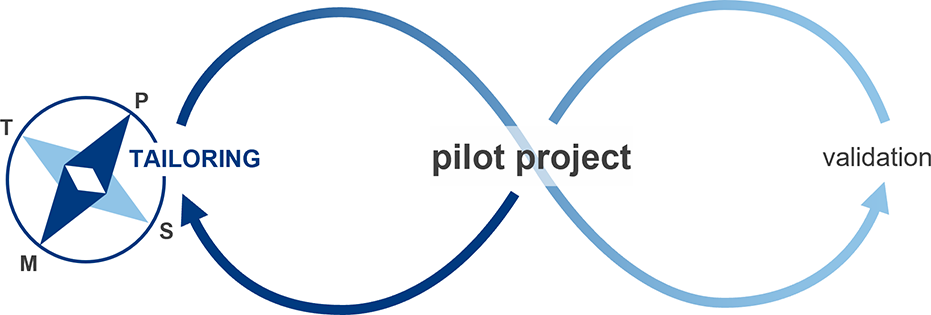

With the enlarged and empowered pilot project core team, the selected generic SE approach and relevant PMTS must be tailored to the company and project-specific needs. For example, based on the INCOSE handbook (INCOSE 2015), relevant processes are identified and adapted to the project needs. The INCOSE handbook comprises a process for tailoring itself is defined, which can be applied to project-specific PMTS tailoring (INCOSE 2023). A logical engineering sequence, for example, according to the V-model (VDI 2021), and relevant SE artefacts are also selected. Another important part is the tailoring of roles, for example, based on a role model, such as Iris Graessler, Oleff, & Hentze (Reference Graessler, Oleff and Hentze2019) and Sheard (Reference Sheard1996)). This process of tailoring is an ongoing one that persists throughout the pilot project. Through continuous tailoring and validation of its results within the pilot project (see Figure 10), the most suitable solutions for the company and the specific project can be achieved. In PMTS, tailoring defined SE processes (INCOSE 2015) are tailored and concretised for application in the company and project. The methods employed by the company, as well as those required for the implementation of SE (Gräßler & Oleff, Gräßler & Oleff Reference Gräßler and Oleff2022; Haberfellner et al. Reference Haberfellner, Weck, Fricke and Vössner2019) or for sustainable product engineering (Stark et al. Reference Stark, Buchert, Neugebauer, Bonvoisin and Finkbeiner2017), are prepared for company-compliant application. It has been demonstrated that the challenges associated with future vehicle technologies, such as Level 4 autonomous driving, necessitate the utilisation of specialised methods (e.g. scenario technology, wizard of oz) in conjunction with one another (Strömberg et al. Reference Strömberg, Pettersson, Andersson, Rydström, Dey, Klingegård and Forlizzi2018). Furthermore, the application of specific tools must be considered, such as design steps in the context of topology optimisation through to modelling in a CAE tool (Walbrun, Witzgall, & Wartzack Reference Walbrun, Witzgall and Wartzack2019). Furthermore, additional tools are identified and established throughout the course of the project. In light of the processes and engineering focus, it may be necessary to adapt organisational structures in terms of roles, hierarchies, decision-making instances and information flows.

Figure 10. Dimensions of PMTS Tailoring and its continuous validation in a pilot project.

Furthermore, a first draft of a reference architecture for the structural breakdown of the developed system is created with the participation of interdisciplinary experts. Based on the logical system structure and the tailored SE role model, the organisational structure is defined in two ways. The structural organisation is defined on the basis of the system overview and the defined roles. The process organisation is defined with role- and system-based information and decision paths. Finally, the organisation with its defined roles and teams, needs to be filled with content-specific qualified people from the organisation who are motivated to drive the transformation forward.

On this basis, the operationalisation of SE in the pilot engineering project is conducted. This includes a continuous requirements and architecture flow according to RFLP (requirements, functions, logics, physics) as well as systematic, traceable integration, verification and validation (testing). The entire collaboration and information flow through all system levels have to be internalised, and operational challenges have to be solved by the team. The migration of previous structures and responsibilities is also focused and compiled during operationalisation. The migration of existing structures and responsibilities is also focused and compiled during operationalisation. Existing role models and responsibilities have to be compared with the tailored SE role model and processes, and a mapping of the roles is carried out. Care must be taken to ensure that no responsibilities are unconsidered and therefore are not covered by a role in the future. In some cases, this may require further development of the role model and the addition of specialist roles.

Two aspects of the SETup automotive method are essential for a successful SE transformation. On the one hand, continuous learning and improvement is required in all phases, that is, constant questioning and checking of decisions taken, as well as measurement and adjustment of these decisions. On the other hand, continuous leadership with transformation controlling is required. This includes, for example, removing barriers and risks of the transformation or pilot project and motivating the team. This is why early success stories are communicated throughout the company. The programme process is also monitored and reported to the transformation leaders and the management board. To spread SE throughout the organisation, the experiences of the pilot projects are summarised in a company-specific pilot scheme for further SE roll-out. This includes all the key aspects of SE implementation that regularly emerge from the different focus areas of the pilot phase, such as an overall frame with guidelines for the SE implementation; the selected SE approach with its specific tailoring and a tailored PMTS; a reference architecture and a pattern of an organisational structure with specific role and team characteristics and guidelines for the transformation and migration of existing structures. The completed SE implementation of a pilot project can be seen as a validation of the SE pilot scheme.

5.1. Competence development in SE transformation

Selecting the “right” people to lead the transformation is critical to its success. Therefore, an initial pilot project core team is set up with experienced engineers, supported by a central transformation core team. Industrial practice has shown that commitment and willingness to change, as well as practical leadership and project management experience in specific required areas, are key selection criteria. In industry, people who are expected to lead future projects often take part in early projects to acquire specialised expertise. Through this type of competence multiplication (see Figure 11), transformation leaders are trained on the job and can use the good and bad experiences directly in subsequent projects.

Figure 11. Principle of a competence multiplication.

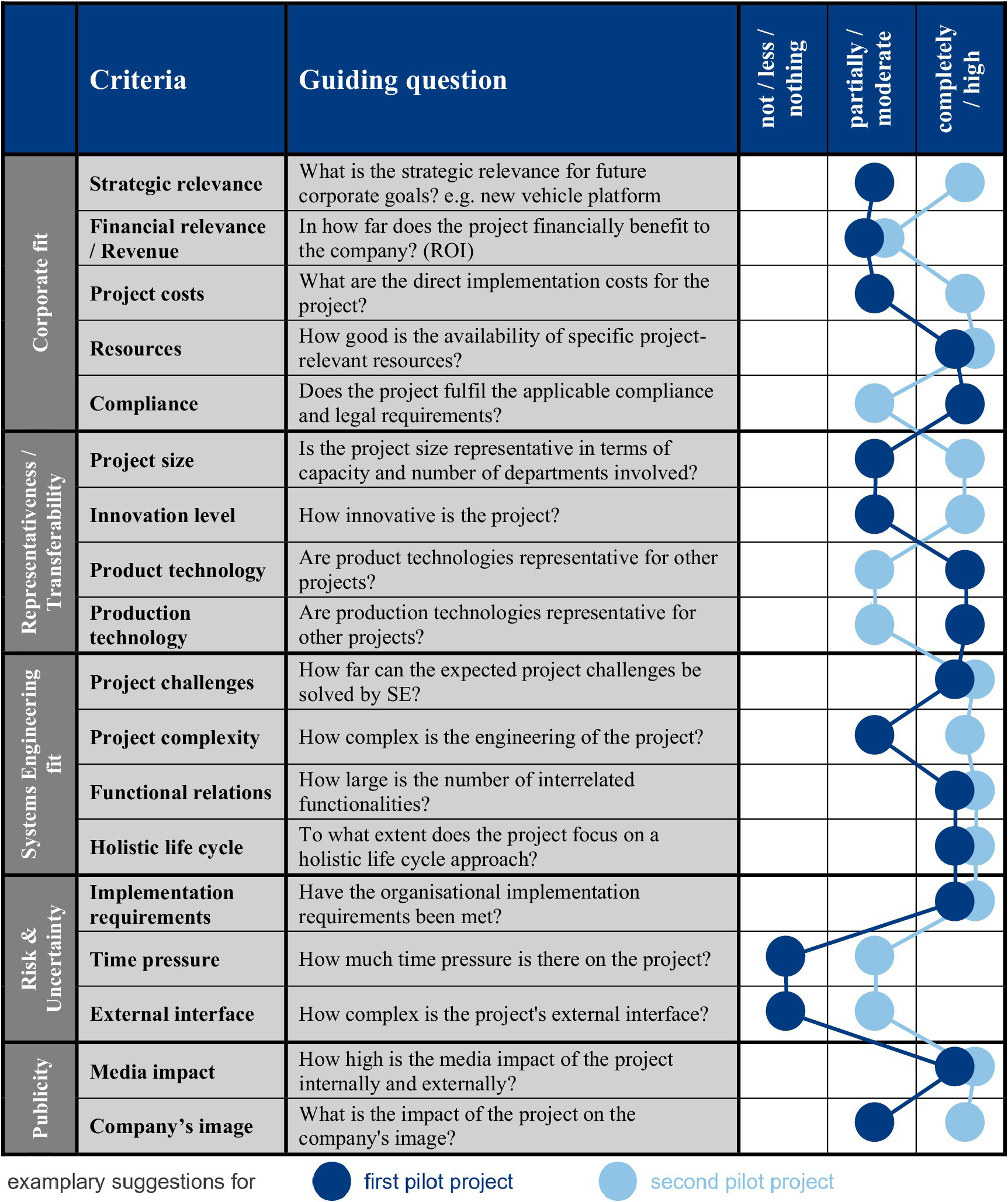

5.2. Identification of suitable pilot projects

As mentioned by authors (de Landtsheer et al. Reference de Landtsheer, Aartman, Jamar, de Liefde, Malotaux, Reinhoudt and Schreinemakers2006; Heidenberg et al. Reference Heidenberg, Matinlassi, Pikkarainen, Hirkman, Partanen, Hutchison, Kanade, Kittler, Kleinberg, Mattern, Mitchell and Oivo2010), the success of a pilot project is essential for further commitment and roll-out of a transformation. Therefore, it is crucial to carefully select a pilot project based on specific criteria that are aligned with the goals and capabilities of the SE approach itself, as well as with the individual company’s transformation goals and messages to the wider community. Choosing a balanced level of complexity can allow the organisation to test the adaptability of SE methods in a safe environment. In the following several criteria for selecting a suitable pilot project are derived from industrial practice, in terms of:

-

- Corporate fit – How well does the project fit in with the company’s overall direction?

-

- Representativeness/transferability – How representative is the project for regular projects and thus the transferability of the results?

-

- Systems Engineering fit – How well do the challenges of the project fit in with the benefits of SE?

-

- Risk & Uncertainty – How secure is the realisation of the project?

-

- Publicity – How high is the visibility of the project internally and externally?

The following literature-based criteria were discussed with experts with decades of experience in organisational change projects and adapted with insights from industrial practice. In one-on-one discussions with four experts, the objectives for a first and a second pilot project are defined and, as an example, drawn as a profile line in the following matrix (see Table 2). During these discussions, each criterion was considered and assessed individually. In a second step, all the experts’ assessments were compared, and divergences discussed to reach a consensual commitment.

Table 2. Decision scheme for selecting a fitting pilot project

6. Applying the method in industrial context

The SETup automotive method is validated in terms of its applicability and fulfilment of requirements as part of an ongoing SE transformation at a large German car manufacturer. The application of the method is presented below, along with a description of the method’s steps. To categorise the starting position, the current situation and the company’s motivation for introducing SE are first briefly classified. The activities carried out in the first phase, “initiate,” are then described. The “pilot” phase is explained in detail, with the activities carried out along the underlying sub-steps. This is followed by an outlook and status quo of the planning of further pilot projects and the roll-out across the board, which has not yet commenced. Finally, the application and the requirements placed on the method are reflected and evaluated based on the project findings.

The increasing complexity due to functional interrelations and the increasing number of regulatory requirements for vehicle authorisation are reasons for introducing SE within the automotive company under consideration. The company’s starting point is to invest more heavily in terms of engineering effort in the early phase (frontloading) to reduce complexity in later phases of product creation in a manageable way. In addition, standardised architectures should accelerate engineering and harmonise interfaces. Moreover, the objective is to establish a foundation for A-SPICE certification-compliant engineering in accordance with legal regulations. By implementing a holistic systems approach within the company, the intention is also to actively consider the integration of the product within a higher-level ecosystem during the engineering process.

In accordance with the “initiate” phase of the SETup automotive method, a central department has been established with the objective of developing the requisite skills, PMTS and framework to facilitate the introduction of SE throughout the company. In addition to SE skills, the contract also encompasses the consideration of A-SPICE process maturity at a defined level. The SE transformation has been initiated by the company’s board of directors, a budget has been defined, and the central department is directly linked to a senior management role. The central department is responsible for defining the fields of action required to prepare the corporate foundations for the transformation. These include analysing existing structures and defining a target image. In particular, the fields of action include corporate tailoring of PMTS, the needs of other corporate departments indirectly affected by the transformation and the ability to manage a change process. Consequently, an initial roll-out plan is formulated, delineating initial staggered pilot and reflection phases, as well as further parallel roll-out waves. The inaugural pilot project for the introduction of SE is selected within the central department and with the guidance of the executive board, independently of the authors of this research. The pilot project was selected in part due to its high strategic importance as a new generation of vehicles with high technical challenges, such as fully autonomous driving according to level 4 and a long battery-electric range. Furthermore, the project was widely communicated in advance as a groundbreaking milestone for the brand, thereby affording an elevated level of visibility for the engineering according to SE principles. An initial pilot project core team of three systems engineers was commissioned and provided with a secure budget.

In the next step, “pilot” weekly working sessions were held at the beginning, to set up the pilot project. An initial approach to the pilot project was discussed with the systems engineers and adopted as the basis for the subsequent conception of the sub-steps of the pilot phase within the SETup automotive method. As part of the first step (target), a target image for the vehicle project was developed in collaboration with all relevant parties. This image serves as the foundation for the pilot project and its eventual success. The premises established in this phase include the joint development of SE PMTS with the central department and its application in the pilot project, as well as the development of platform engineering-specific scopes and scaling principles. A project vision was defined, which encompasses both product specifications, such as the intention to enable highly networked and autonomous driving, and the implementation of SE, for instance, the objective to build a 100% RFLP architecture. According to the following step of the method (foundations), the INCOSE SE approach (INCOSE 2015) and the V-model (VDI 2206:2021 2021) are selected as engineering logic, and project-specific premises are defined. With regard to the project-specific adaptation of the selected approach (tailoring), an organisational structure is defined in the next step (structure) on the basis of a reference architecture for automotive system decomposition defined at the corporate level. Individual logical system elements are combined in a manner that results in organisational units having similar levels of responsibility. SE teams are defined on the basis of an SE role model (Graessler, Oleff, & Hentze Reference Graessler, Oleff and Hentze2019). Even if the organisational model is based on vertical and horizontal uniformity of the team composition, the diversity of the staffing of the defined roles may vary according to the scope of responsibility at the specific system level. Therefore, in the next step (operationalisation), the roles are staffed with engineers out of the engineering departments. The process structure of the organisation is also defined on the basis of different types of information flow. Owners of leadership roles communicate and inform from the bottom up, while owners of technical roles communicate with peers at different system levels. To operationalise the tailored SE principles, the defined SE roles at all system levels are filled with people from different engineering departments. To facilitate the transition from the old responsibilities to the new roles, migration concepts are prepared and communicated. This includes role descriptions mapped to INCOSE processes and SE artefacts (Graessler et al. Reference Graessler, Thiele, Grewe and Hieb2022). Throughout the whole change process, employees are trained in the principles of SE in broad qualification initiatives. In line with the principle of competence multiplication, the managers of the subsequent pilot projects in other locations are involved in the pilot project at an early stage.

In over 50 expert discussions with more than 10 transformation managers, systems engineers and experienced consultants involved in the project, core activities were concretised for implementation in the project. Based on the feedback, the concept of the method has been refined and translated into a project-specific project plan for further operational application. The project plan and pilot scheme were communicated in the form of the project documentation, which is confirmed and approved by 14 top-level managers.

With a time delay of 2 years, two further pilot projects are initiated on the basis of the knowledge gained so far. The following pilot projects have been initiated in a direct relation to the first pilot project but with limited engineering scope and in different markets. The programme documentation is therefore further abstracted and used as a fundamental pilot scheme for SE implementation in these departments. A “roll-out” across the organisation is not yet planned, as the first pilot projects are to be completed and validated first. In terms of “continuous learning and improvement,” a continuous acceleration has been supported by the central department for transformation. This has involved the further adaptation of the role model to the projects’ needs and under consideration of earlier implemented roles. Furthermore, further processes have been improved based on continuous learnings, such as the configuration and risk management.

6.1. Evaluation

The SE transformation of a large automotive company has shown that the method proposed meets the needs of the industry for a structured approach to the introduction of SE (R-1). The step-by-step procedure with an initial pilot project makes it possible to gain experience in a small environment, to visualise the initial successes and effects of SE and thus to gain advocates within the company (R-3, R-8). In this way, existing organisations are not overloaded and employee fears and resistance to change are reduced (R-2, R-6). As part of the method, a multi-level tailoring of the INCOSE SE approach is anchored, which was also demonstrably implemented in the use case at company level and subsequently at project level. The multi-level tailoring reduces the complexity of the PMTS and can therefore be applied more quickly in the pilot project (R-4). As part of a transparent migration concept, existing roles in engineering are mapped to the SE roles based on existing tasks, authorisations and responsibilities (R-5). This enabled organisation-specific gaps and requirements to be identified and filled with additional roles. A basic understanding of the SE approach is essential to fulfil the SE roles. This was ensured for the core roles through on-the-job coaching and through a comprehensive training campaign and strategy (R-7).

6.2. Discussion

As this pilot project demonstrates, the introduction of SE represents a profound transformation within existing organisational structures. A crucial aspect is that the company’s engineering operations must continue uninterrupted, and that all previously defined engineering orders and goals must be maintained. This ensures the company’s competitiveness. An essential aspect of introducing SE is the achievement of a common “mindset,” which is the foundation for SE within the organisation. In this context, mindset is understood as a uniform understanding of and commitment to the SE principles. Consequently, a comprehensive system perspective and a unified understanding of the system, including a baseline to ensure uniform information accessibility for all project participants, must be pursued. The comprehensive implementation of SE in a project is fundamental to enable individuals to fully internalise the SE approach and discard their previous ways of thinking. This implies that in a tangible project setting with a clearly delineated team, work is conducted in accordance with the SE approach from inception to completion, and adverse external factors are mitigated wherever feasible.

In essence, the implementation of change must ultimately lead to a change in corporate culture, away from obsolete structures towards the new SE structures. Only when obsolete ways of working are discarded and a unified commitment to SE is achieved, for example, when people are convinced of the approach and intrinsically motivated to implement and develop it, will a sustainable transformation of an engineering organisation towards SE succeed.

7. Conclusion

Recent events in the automotive industry and studies indicate that current engineering approaches are inadequate to address the complexity of future product generations. Consequently, SE is becoming an increasingly crucial approach to resolve interdisciplinary issues in the automotive industry. Introducing a novel engineering approach necessitates an organisational transformation, which presents a number of challenges. As various approaches address the necessity for change management and pilot initiatives to introduce SE, this research develops the SETup automotive method as a change management approach for SE transformation under piloting in the automotive industry.

Common change management and SE transformation approaches are reviewed and lay the foundation for the SETup automotive method for SE transformation. The SETup automotive method brings together established change management fundamentals in the context of SE and provides guidance for SE transformation. Therefore, a step-by-step roll-out concept with two or more pilot projects and followed by two roll-out waves is recommended. To identify a suitable pilot project, this research provides criteria and guiding questions, which are derived from literature and reflected with industrial experts. In addition, essential phases are described and detailed with relevant activities. The key results of the phases taken are identified and used as a basis for a pilot scheme for the roll-out of SE in further units. The pilot scheme is continuously improved by learning from pilot initiatives in different units. The step-by-step procedure, which involves initiating single pilot projects rather than a broad top-down or bottom-up change, ensures that the organisation is not overloaded and that current engineering goals can be maintained. The accompanying phase of continuous learning and improvement ensures that the state of SE implementation is continuously inspected and adapted to the organisation’s needs. Another key aspect of the presented method and its activities is the migration of existing structures and responsibilities into the organisation. To achieve this, workshops are held with the objective of identifying the most appropriate solutions for the organisation.

The SETup automotive method was developed and continuously adapted based on practical insights gained from the implementation of SE in the automotive industry. During the course of these projects, several workshops and working sessions were conducted to provide guidance for a pilot project within the transformation. In excess of 500 working hours were invested in the documentation of the results of the project in the form of a pilot scheme, which serves as the basis for the further roll-out of SE to other units and brands. Furthermore, numerous discussions were held with experts, transformation stakeholders and R&D consultants, which enabled the method to be further tailored to the actual needs of industrial application. The procedure applied according to the SETup method was documented in project documentation and approved by top-level managers. Although the method is derived from the automotive industry context, many aspects of the method offer opportunities in other industries. Therefore, further tailoring to sector-specific needs will be required. The outcomes of the application in industrial fields should be reflected to further optimise the method.

The SETup automotive method presented here responds to the research call (Alt Reference Alt2012) for a method to support management in SE transformation. Therefore, the method represents a step-by-step procedure with core activities to guide the transformation. In particular, PMTS tailoring is emphasised as an important activity but is not described in detail here. To facilitate further application in practice, guidelines on PMTS tailoring must be developed. These should focus on role model tailoring and adapting organisational structures. In addition, the components of a SE pilot scheme can be further explored and detailed in a practical way. Another aspect of future research is the determination and measurability of the SE transformation in a company. To this end, existing maturity models should be analysed in detail and compared with the engineering method. In addition, it is necessary to identify the measurement parameters and performance indicators for the process assessment of SE transformation.