1. Introduction

In the domain of melting, a phenomenon known as close-contact melting (CCM) stands out. Unlike conventional convection-driven melting with expanding molten liquid spaces, CCM involves a distinct process where the surface of an unmelted solid and a heating element are pressed together under external force. This results in the formation of a thin molten film flow between the solid and heating surfaces, facilitating solid–liquid phase change heat transfer at a low-Reynolds-number flow of the liquid. Close-contact melting can be observed in two primary modes: heat source-driven (constant pressure) and unmelted solid-driven (gravity-driven) (Hu et al. Reference Hu, Li, Xu and Fan2022), depending on the external force applied to the object. The former mode refers to the scenario where the heated surface penetrates into an unmelted solid, which includes glacier drilling by heating (Schuller, Kowalski & Raback Reference Schuller, Kowalski and Raback2016), subtractive machining (Mayer & Moaveni Reference Mayer and Moaveni2008) and the ‘melt down’ of nuclear fuel (Emerman & Turcotte Reference Emerman and Turcotte1983). The latter mode can be observed readily in daily life, such as when ice, butter or chocolate melts on a heated substrate. Also, it is found in latent heat thermal energy storage (Kozak, Rozenfeld & Ziskind Reference Kozak, Rozenfeld and Ziskind2014) and thermal management systems (Fu et al. Reference Fu, Yan, Gurumukhi, Garimella, King and Miljkovic2022), where a considerable heat flux can be achieved easily. In the area of thermal energy storage, the melting rate is equivalent to the charging rate.

Given the widespread applications of CCM, it has been studied extensively for decades (Hu et al. Reference Hu, Li, Xu and Fan2022). These studies explore the effects of geometry (Moore & Bayazitoglu Reference Moore and Bayazitoglu1982; Sparrow & Geiger Reference Sparrow and Geiger1986; Dong et al. Reference Dong, Chen, Wang and Ebadian1991; Fomin, Wei & Chugunov Reference Fomin, Wei and Chugunov1995) and boundary conditions for heating (Moallemi & Viskanta Reference Moallemi and Viskanta1985; Saito et al. Reference Saito, Utaka, Akiyoshi and Katayama1985a

,Reference Saito, Utaka, Akiyoshi and Katayama

b

; Bejan Reference Bejan1992; Fomin, Saitoh & Chugunov Reference Fomin, Saitoh and Chugunov1997; Groulx & Lacroix Reference Groulx and Lacroix2007; Schueller & Kowalski Reference Schueller and Kowalski2017), with a primary focus on heat transfer characteristics. Recently, attention has shifted towards understanding the mechanisms of flow and heat transfer within the liquid film. Hu et al. measured the thickness variation of the thin film for the first time, confirming a magnitude of

![]() $O(10^2)$

$O(10^2)$

![]() $\unicode{x03BC}$

m (Hu et al. Reference Hu, Zhang, Zhang, Liu and Fan2019). Non-Newtonian features, including Bingham (Kozak et al. Reference Kozak, Zeng, Ghossein, Rabih, Khodadadi and Ziskind2019), power-law (Kozak Reference Kozak2023) and Carreau properties for the viscosity variations (Hu & Fan Reference Hu and Fan2023), as well as temperature-dependent properties (Cregan, Williams & Myers Reference Cregan, Williams and Myers2020), have been considered to study their impact on film thickness variation and flow behaviour. Strategies such as the use of permeable surfaces (Turkyilmazoglu Reference Turkyilmazoglu2019), slip surfaces (Aljaghtham, Premnath & Alsulami Reference Aljaghtham, Premnath and Alsulami2021; Kozak Reference Kozak2022) and pressure-enhanced conditions (Chen et al. Reference Chen, Liu, Gao and Wang2022; Fu et al. Reference Fu, Yan, Gurumukhi, Garimella, King and Miljkovic2022) have been proposed to accelerate melting.

$\unicode{x03BC}$

m (Hu et al. Reference Hu, Zhang, Zhang, Liu and Fan2019). Non-Newtonian features, including Bingham (Kozak et al. Reference Kozak, Zeng, Ghossein, Rabih, Khodadadi and Ziskind2019), power-law (Kozak Reference Kozak2023) and Carreau properties for the viscosity variations (Hu & Fan Reference Hu and Fan2023), as well as temperature-dependent properties (Cregan, Williams & Myers Reference Cregan, Williams and Myers2020), have been considered to study their impact on film thickness variation and flow behaviour. Strategies such as the use of permeable surfaces (Turkyilmazoglu Reference Turkyilmazoglu2019), slip surfaces (Aljaghtham, Premnath & Alsulami Reference Aljaghtham, Premnath and Alsulami2021; Kozak Reference Kozak2022) and pressure-enhanced conditions (Chen et al. Reference Chen, Liu, Gao and Wang2022; Fu et al. Reference Fu, Yan, Gurumukhi, Garimella, King and Miljkovic2022) have been proposed to accelerate melting.

In addition, hydrophobic or superhydrophobic surfaces with microscale-trapped air can provide an effective slip length, of the order of

![]() $O(10^2)$

$O(10^2)$

![]() $\unicode{x03BC}$

m, for liquid transport (Lee, Choi & Kim Reference Lee, Choi and Kim2008; Quéré Reference Quéré2008). This characteristic is considered a promising strategy for reducing liquid film thickness, thereby potentially enhancing heat transfer of CCM. Recently, Kozak theoretically studied postpatterned hydrophobic surfaces and showed that a temperature slip length

$\unicode{x03BC}$

m, for liquid transport (Lee, Choi & Kim Reference Lee, Choi and Kim2008; Quéré Reference Quéré2008). This characteristic is considered a promising strategy for reducing liquid film thickness, thereby potentially enhancing heat transfer of CCM. Recently, Kozak theoretically studied postpatterned hydrophobic surfaces and showed that a temperature slip length

![]() $\lambda ^{*}_{t}$

(the definition is given in § 2.2.1) greater than velocity slip length

$\lambda ^{*}_{t}$

(the definition is given in § 2.2.1) greater than velocity slip length

![]() $\lambda ^{*}$

(Kozak Reference Kozak2022) leads to a reduced heat transfer; the calculation utilised the formulae

$\lambda ^{*}$

(Kozak Reference Kozak2022) leads to a reduced heat transfer; the calculation utilised the formulae

![]() $ \lambda ^{*} / l^{*}=3 \sqrt {\pi /(1-\phi )}/16-3\ln (1+\sqrt {2})/(2 \pi )$

(Davis & Lauga Reference Davis and Lauga2010) and

$ \lambda ^{*} / l^{*}=3 \sqrt {\pi /(1-\phi )}/16-3\ln (1+\sqrt {2})/(2 \pi )$

(Davis & Lauga Reference Davis and Lauga2010) and

![]() $\lambda ^{*}=3\lambda ^{*}_t/4$

(Enright et al. Reference Enright, Hodes, Salamon and Muzychka2014), where

$\lambda ^{*}=3\lambda ^{*}_t/4$

(Enright et al. Reference Enright, Hodes, Salamon and Muzychka2014), where

![]() $^{*}$

represents dimensional quantities,

$^{*}$

represents dimensional quantities,

![]() $l^{*}$

is the period of a post pattern and

$l^{*}$

is the period of a post pattern and

![]() $\phi$

is the liquid–gas area fraction. Although this work established a framework for analysing velocity and temperature slip effects on CCM, the expressions for

$\phi$

is the liquid–gas area fraction. Although this work established a framework for analysing velocity and temperature slip effects on CCM, the expressions for

![]() $\lambda ^*$

rely on three assumptions: (i) shear flow in the liquid above the surface; (ii) a flat gas–liquid interface; (iii) perfect slip on the gas–liquid interface. Assumption (iii) is satisfied when

$\lambda ^*$

rely on three assumptions: (i) shear flow in the liquid above the surface; (ii) a flat gas–liquid interface; (iii) perfect slip on the gas–liquid interface. Assumption (iii) is satisfied when

![]() $ h_s^{*} {\mu _l^{*}}/{\mu _g^{*}} \gg l^{*}$

(Belyaev & Vinogradova Reference Belyaev and Vinogradova2010; Asmolov & Vinogradova Reference Asmolov and Vinogradova2012), where

$ h_s^{*} {\mu _l^{*}}/{\mu _g^{*}} \gg l^{*}$

(Belyaev & Vinogradova Reference Belyaev and Vinogradova2010; Asmolov & Vinogradova Reference Asmolov and Vinogradova2012), where

![]() $h_s^{*}$

,

$h_s^{*}$

,

![]() $ {\mu _l^{*}}$

and

$ {\mu _l^{*}}$

and

![]() $\mu _g^{*}$

denote microstructure height, liquid viscosity and gas viscosity, respectively. However, assumptions (i) and (ii) may not apply to CCM due to the features of Poiseuille flow and deformation of the meniscus, leading to a complicated effective slip. The assumption of a constant ratio

$\mu _g^{*}$

denote microstructure height, liquid viscosity and gas viscosity, respectively. However, assumptions (i) and (ii) may not apply to CCM due to the features of Poiseuille flow and deformation of the meniscus, leading to a complicated effective slip. The assumption of a constant ratio

![]() $\lambda _t^*/ \lambda ^*$

is valid for large aspect ratios

$\lambda _t^*/ \lambda ^*$

is valid for large aspect ratios

![]() $\Lambda \equiv h^*/l^*$

(Enright et al. Reference Enright, Hodes, Salamon and Muzychka2014), where

$\Lambda \equiv h^*/l^*$

(Enright et al. Reference Enright, Hodes, Salamon and Muzychka2014), where

![]() $h^*$

is the liquid film thickness. Furthermore, the slip lengths are governed by the geometrical patterns of the microstructure, which should be evaluated and compared.

$h^*$

is the liquid film thickness. Furthermore, the slip lengths are governed by the geometrical patterns of the microstructure, which should be evaluated and compared.

In the literature on slip, since the early works by Philip (Reference Philip1972a

,Reference Philip

b

), it has been shown that the velocity slip length

![]() $\lambda ^{*}$

is influenced by confinement effects (Lauga & Stone Reference Lauga and Stone2003; Sbragaglia & Prosperetti Reference Sbragaglia and Prosperetti2007; Teo & Khoo Reference Teo and Khoo2008; Feuillebois, Bazant & Vinogradova Reference Feuillebois, Bazant and Vinogradova2009; Schnitzer & Yariv Reference Schnitzer and Yariv2017; Landel et al. Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020). The asymptotic limit of slip length for flow past transverse slip regions inside a tube (radius

$\lambda ^{*}$

is influenced by confinement effects (Lauga & Stone Reference Lauga and Stone2003; Sbragaglia & Prosperetti Reference Sbragaglia and Prosperetti2007; Teo & Khoo Reference Teo and Khoo2008; Feuillebois, Bazant & Vinogradova Reference Feuillebois, Bazant and Vinogradova2009; Schnitzer & Yariv Reference Schnitzer and Yariv2017; Landel et al. Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020). The asymptotic limit of slip length for flow past transverse slip regions inside a tube (radius

![]() $R^*$

) has been determined (Lauga & Stone Reference Lauga and Stone2003), specifically

$R^*$

) has been determined (Lauga & Stone Reference Lauga and Stone2003), specifically

![]() $\lambda ^{*}_{\perp } / l^{*} \sim \ln (\sec (\phi \pi /2 ) )/(2\pi )$

when

$\lambda ^{*}_{\perp } / l^{*} \sim \ln (\sec (\phi \pi /2 ) )/(2\pi )$

when

![]() $l^{*}/R^{*} \ll 1$

, while

$l^{*}/R^{*} \ll 1$

, while

![]() $\lambda ^{*}_{ \perp }/R^{*} \sim \phi /(4-4\phi )$

when

$\lambda ^{*}_{ \perp }/R^{*} \sim \phi /(4-4\phi )$

when

![]() $l^{*}/R^{*} \gg 1$

; this result indicates that the velocity slip length can depend on the tube radius

$l^{*}/R^{*} \gg 1$

; this result indicates that the velocity slip length can depend on the tube radius

![]() $R^{*}$

instead of the pattern period

$R^{*}$

instead of the pattern period

![]() $l^{*}$

. Sbragaglia & Prosperetti (Reference Sbragaglia and Prosperetti2007) numerically obtained for longitudinal grooves a variation of velocity slip length

$l^{*}$

. Sbragaglia & Prosperetti (Reference Sbragaglia and Prosperetti2007) numerically obtained for longitudinal grooves a variation of velocity slip length

![]() $\lambda _{\parallel } = \lambda _{\parallel }^{*}/l^{*}$

for various aspect ratios

$\lambda _{\parallel } = \lambda _{\parallel }^{*}/l^{*}$

for various aspect ratios

![]() $\Lambda = h^{*} / l^{*}$

, where longitudinal means grooves oriented parallel to the flow, demonstrating that

$\Lambda = h^{*} / l^{*}$

, where longitudinal means grooves oriented parallel to the flow, demonstrating that

![]() $\lambda _{\parallel }$

remains constant when

$\lambda _{\parallel }$

remains constant when

![]() $\Lambda \geqslant 10$

, but shows a scaling law

$\Lambda \geqslant 10$

, but shows a scaling law

![]() $\lambda _{\parallel } \sim \Lambda$

when

$\lambda _{\parallel } \sim \Lambda$

when

![]() $\Lambda \lt 10$

. Similar confinement effects on the effective slip length can be found for either longitudinal or transverse grooves with symmetrical or asymmetrical boundary conditions (Teo & Khoo Reference Teo and Khoo2008; Schnitzer & Yariv Reference Schnitzer and Yariv2017) or on interfacial velocity at the liquid–gas interface (Landel et al. Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020). An interesting fact related to confinement effects is that longitudinal grooves provide the largest slip lengths while transverse grooves yield the smallest ones in the limit of

$\Lambda \lt 10$

. Similar confinement effects on the effective slip length can be found for either longitudinal or transverse grooves with symmetrical or asymmetrical boundary conditions (Teo & Khoo Reference Teo and Khoo2008; Schnitzer & Yariv Reference Schnitzer and Yariv2017) or on interfacial velocity at the liquid–gas interface (Landel et al. Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020). An interesting fact related to confinement effects is that longitudinal grooves provide the largest slip lengths while transverse grooves yield the smallest ones in the limit of

![]() $\Lambda \ll 1$

(Feuillebois et al. Reference Feuillebois, Bazant and Vinogradova2009). This contrasts with predictions for

$\Lambda \ll 1$

(Feuillebois et al. Reference Feuillebois, Bazant and Vinogradova2009). This contrasts with predictions for

![]() $\Lambda \gg 1$

, where arrays of posts have a larger slip length than grooves. Given the special feature of CCM that film thickness

$\Lambda \gg 1$

, where arrays of posts have a larger slip length than grooves. Given the special feature of CCM that film thickness

![]() $h^{*}$

(also the channel height) is variable and sensitive to conditions, we can consider the examples from Kozak (Reference Kozak2022), where

$h^{*}$

(also the channel height) is variable and sensitive to conditions, we can consider the examples from Kozak (Reference Kozak2022), where

![]() $l^{*} \sim 50 \ \unicode{x03BC}$

m and

$l^{*} \sim 50 \ \unicode{x03BC}$

m and

![]() $h^{*} \sim 50 \ \unicode{x03BC}$

m (

$h^{*} \sim 50 \ \unicode{x03BC}$

m (

![]() $\phi =0.99$

), as well as

$\phi =0.99$

), as well as

![]() $l^{*} \sim 16 \ \unicode{x03BC}$

m and

$l^{*} \sim 16 \ \unicode{x03BC}$

m and

![]() $h^{*} \sim 80 \ \unicode{x03BC}$

m (

$h^{*} \sim 80 \ \unicode{x03BC}$

m (

![]() $\phi =0.84$

). In this case, confinement effects may be non-negligible due to

$\phi =0.84$

). In this case, confinement effects may be non-negligible due to

![]() $1 \leqslant \Lambda \leqslant 5$

.

$1 \leqslant \Lambda \leqslant 5$

.

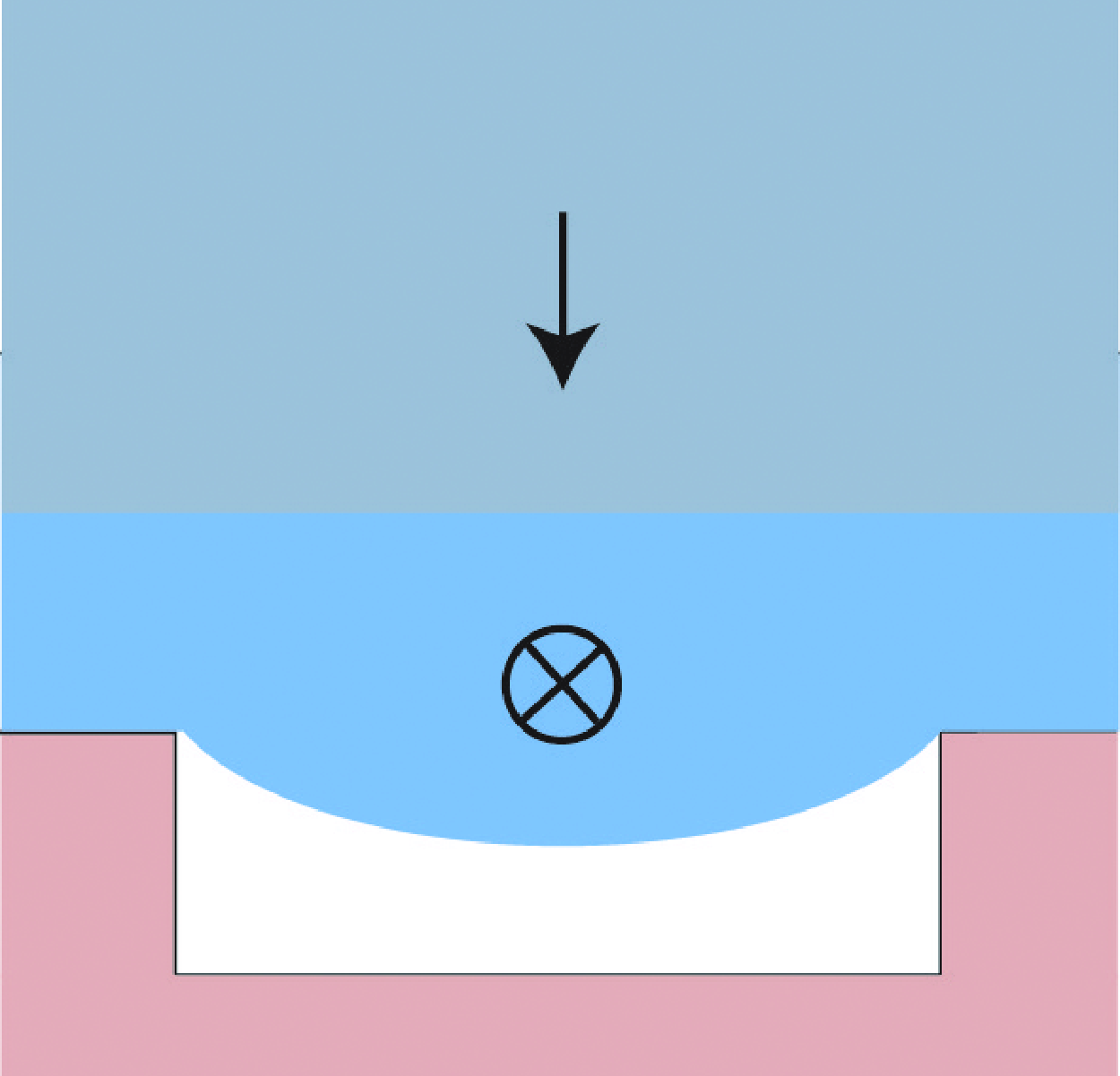

At the same time, another issue arises concerning the curved gas–liquid interface due to the wide variation of pressure exerted on the liquid film in CCM. It has been demonstrated that meniscus protrusion into cavities will either increase or decrease the slip length

![]() $\lambda ^{*}$

depending on the aspect ratio

$\lambda ^{*}$

depending on the aspect ratio

![]() $\Lambda$

(Sbragaglia & Prosperetti Reference Sbragaglia and Prosperetti2007; Teo & Khoo Reference Teo and Khoo2010; Crowdy Reference Crowdy2016; Game et al. Reference Game, Hodes, Keaveny and Papageorgiou2017; Kirk, Hodes & Papageorgiou Reference Kirk, Hodes and Papageorgiou2017). When

$\Lambda$

(Sbragaglia & Prosperetti Reference Sbragaglia and Prosperetti2007; Teo & Khoo Reference Teo and Khoo2010; Crowdy Reference Crowdy2016; Game et al. Reference Game, Hodes, Keaveny and Papageorgiou2017; Kirk, Hodes & Papageorgiou Reference Kirk, Hodes and Papageorgiou2017). When

![]() $\Lambda \gg 1$

, both slip lengths

$\Lambda \gg 1$

, both slip lengths

![]() $\lambda ^{*}_{\perp }$

and

$\lambda ^{*}_{\perp }$

and

![]() $\lambda ^{*}_{\parallel }$

decrease along with a larger meniscus angle

$\lambda ^{*}_{\parallel }$

decrease along with a larger meniscus angle

![]() $\theta$

that protrudes into grooves (Teo & Khoo Reference Teo and Khoo2010). However, for

$\theta$

that protrudes into grooves (Teo & Khoo Reference Teo and Khoo2010). However, for

![]() $ \Lambda \ll 1$

, the slip length

$ \Lambda \ll 1$

, the slip length

![]() $\lambda ^{*}$

can be increased by a meniscus for symmetrical boundaries (Sbragaglia & Prosperetti Reference Sbragaglia and Prosperetti2007; Kirk et al. Reference Kirk, Hodes and Papageorgiou2017). Besides the velocity slip length

$\lambda ^{*}$

can be increased by a meniscus for symmetrical boundaries (Sbragaglia & Prosperetti Reference Sbragaglia and Prosperetti2007; Kirk et al. Reference Kirk, Hodes and Papageorgiou2017). Besides the velocity slip length

![]() $\lambda ^{*}$

, confinement and meniscus effects also play an important role in the temperature slip length

$\lambda ^{*}$

, confinement and meniscus effects also play an important role in the temperature slip length

![]() $\lambda ^{*}_{t}$

(Enright et al. Reference Enright, Hodes, Salamon and Muzychka2014; Kirk et al. Reference Kirk, Hodes and Papageorgiou2017; Hodes et al. Reference Hodes, Kane, Bazant and Kirk2023; Tomlinson et al. Reference Tomlinson, Mayer, Kirk, Hodes and Papageorgiou2024). The primary conclusions drawn are that the confinement effect results in a larger temperature slip length, while meniscus influences tend to reduce it. However, for CCM studies, the latter has not been considered (Kozak Reference Kozak2022).

$\lambda ^{*}_{t}$

(Enright et al. Reference Enright, Hodes, Salamon and Muzychka2014; Kirk et al. Reference Kirk, Hodes and Papageorgiou2017; Hodes et al. Reference Hodes, Kane, Bazant and Kirk2023; Tomlinson et al. Reference Tomlinson, Mayer, Kirk, Hodes and Papageorgiou2024). The primary conclusions drawn are that the confinement effect results in a larger temperature slip length, while meniscus influences tend to reduce it. However, for CCM studies, the latter has not been considered (Kozak Reference Kozak2022).

1.1. Scope and structure of this work

Since constant-pressure and gravity-driven CCM are characterised by constant and growing liquid film thicknesses, respectively, as well as also corresponding to two different application scenarios, melt drilling and thermal energy storage, respectively, we focus on parallel-groove textured surfaces as a promising candidate for both modes of CCM, owing to the theoretical limit of a significant slip length for a given gas–liquid contact ratio (Feuillebois et al. Reference Feuillebois, Bazant and Vinogradova2009). Furthermore, by incorporating double re-entrant structures, these surfaces can readily maintain the Cassie state for a wide range of liquids (Liu & Kim Reference Liu and Kim2014; Wilke et al. Reference Wilke, Lu, Song and Wang2022). In § 2, we introduce the theoretical framework for CCM, considering the influences of the velocity slip length

![]() $\lambda$

and the temperature slip length

$\lambda$

and the temperature slip length

![]() $\lambda _t$

(noting that quantities without a

$\lambda _t$

(noting that quantities without a

![]() $^*$

are dimensionless), where the subscript

$^*$

are dimensionless), where the subscript

![]() $\parallel$

represents longitudinal grooves; also,

$\parallel$

represents longitudinal grooves; also,

![]() $f$

and

$f$

and

![]() $c$

denote flat interfaces and curved interfaces (menisci), respectively. Specifically, dimensional analysis of the problem is presented in § 2.1, followed by the derivation of the effective thermal slip length

$c$

denote flat interfaces and curved interfaces (menisci), respectively. Specifically, dimensional analysis of the problem is presented in § 2.1, followed by the derivation of the effective thermal slip length

![]() $\lambda _{t,f}$

and

$\lambda _{t,f}$

and

![]() $\lambda _{t,c}$

, corresponding to a flat gas–liquid interface (§ 2.2.1) and a curved surface (§ 2.2.2), respectively. The effective velocity slip lengths

$\lambda _{t,c}$

, corresponding to a flat gas–liquid interface (§ 2.2.1) and a curved surface (§ 2.2.2), respectively. The effective velocity slip lengths

![]() $\lambda _{\parallel, f}$

and

$\lambda _{\parallel, f}$

and

![]() $\lambda _{\parallel, c}$

are derived for flat (§ 2.3.1) and the curved (§ 2.3.2) liquid–gas interface, respectively. Slip lengths for all cases are solved by the standard dual-series method, whose details are introduced in the appendices. Based on the obtained effective slip lengths, a generalised one-dimensional description is developed for both constant-pressure and gravity-driven CCM in § 2.4.

$\lambda _{\parallel, c}$

are derived for flat (§ 2.3.1) and the curved (§ 2.3.2) liquid–gas interface, respectively. Slip lengths for all cases are solved by the standard dual-series method, whose details are introduced in the appendices. Based on the obtained effective slip lengths, a generalised one-dimensional description is developed for both constant-pressure and gravity-driven CCM in § 2.4.

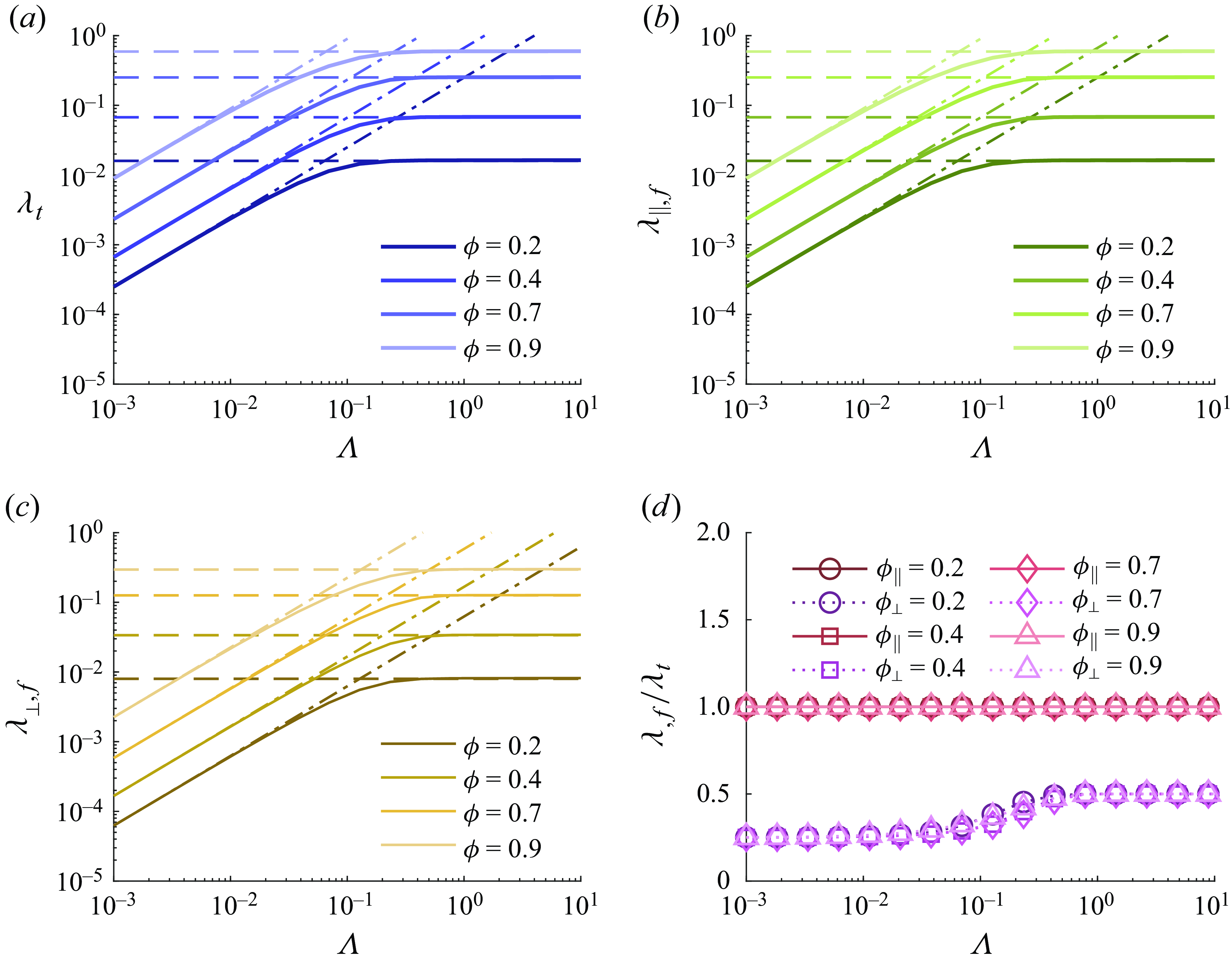

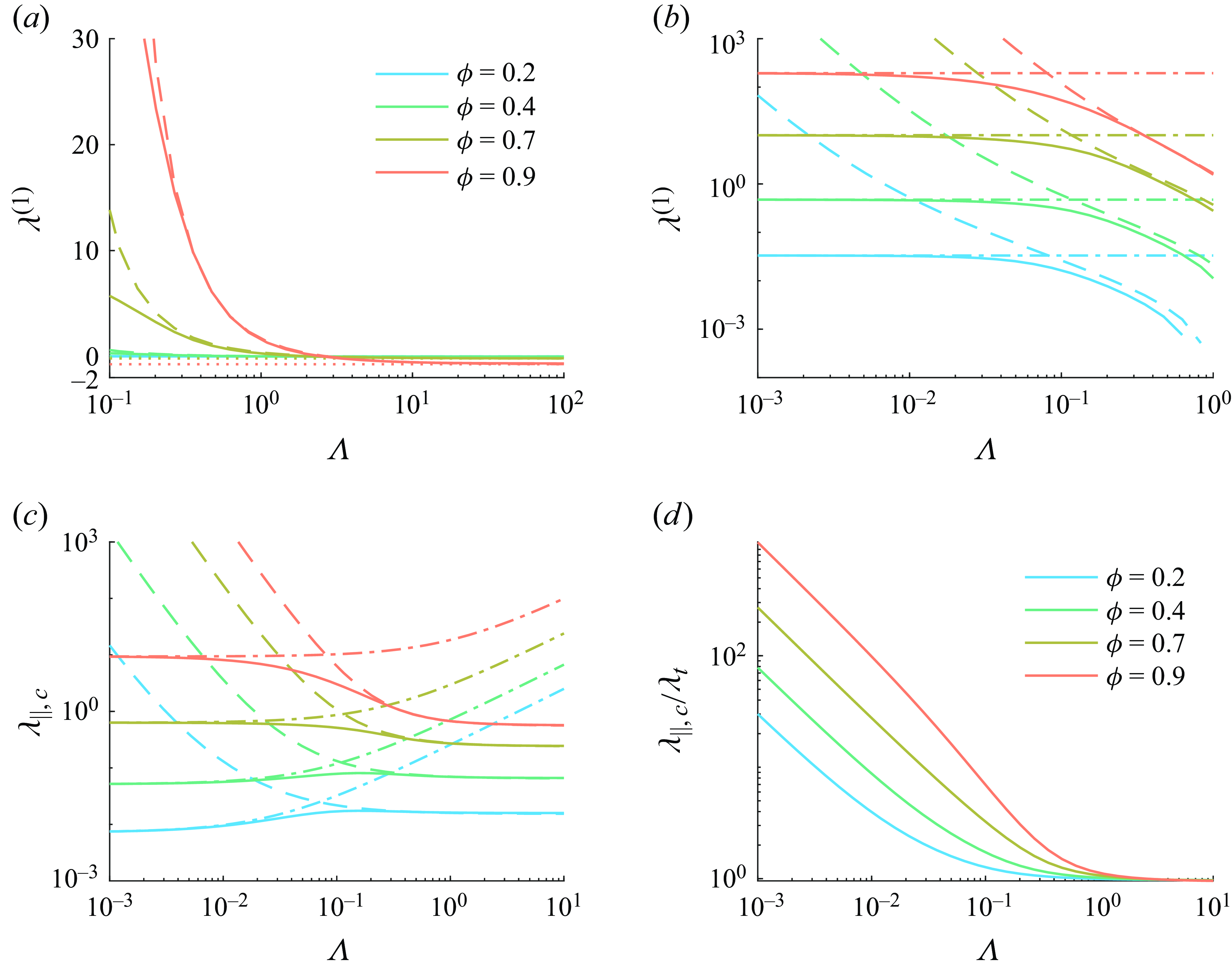

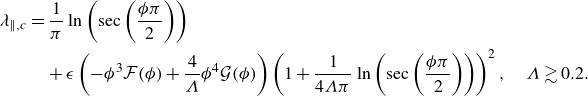

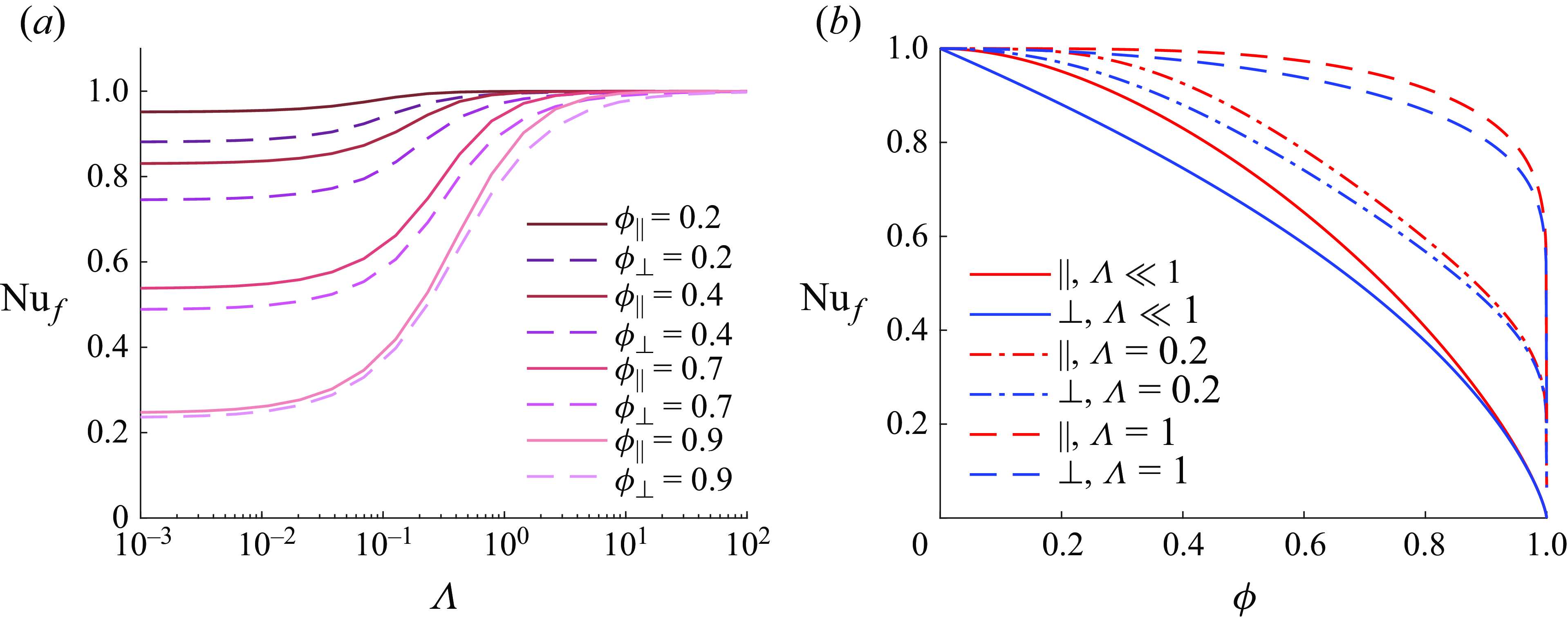

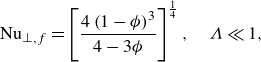

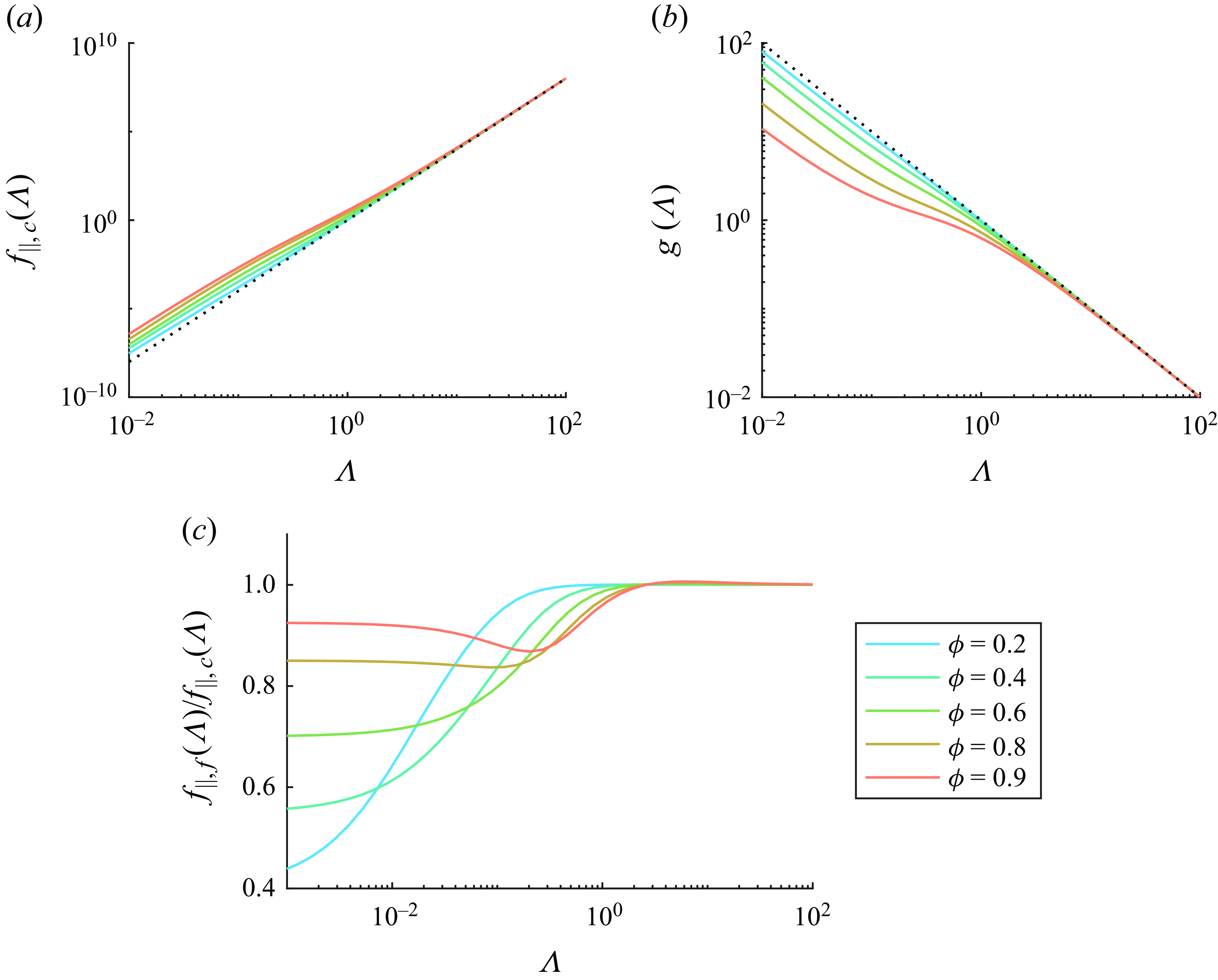

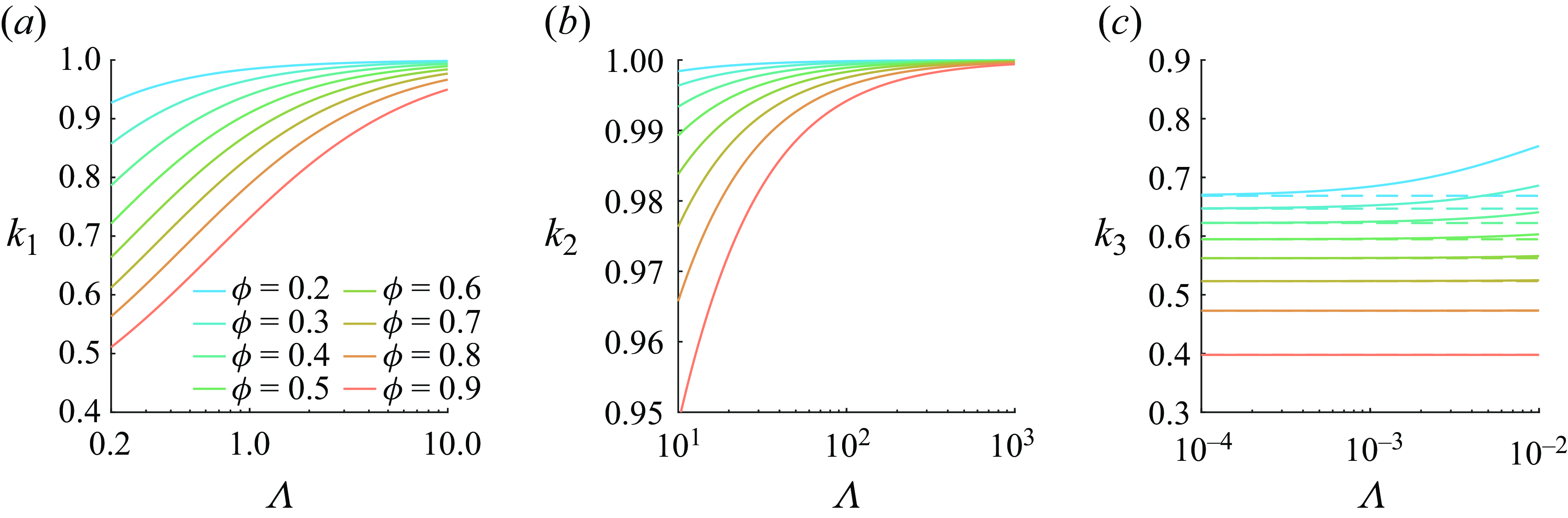

In § 3.1, we discuss the influences of the dimensionless film height

![]() $\Lambda$

on the slip lengths for the flat (§ 3.1.1) and curved (§ 3.1.2) gas–liquid interfaces. Asymptotic solutions of

$\Lambda$

on the slip lengths for the flat (§ 3.1.1) and curved (§ 3.1.2) gas–liquid interfaces. Asymptotic solutions of

![]() $\lambda$

and

$\lambda$

and

![]() $\lambda _t$

for

$\lambda _t$

for

![]() $\Lambda \gg 1$

and

$\Lambda \gg 1$

and

![]() $\Lambda \ll 1$

are summarised in table 1. In addition, a modified asymptotic solution for

$\Lambda \ll 1$

are summarised in table 1. In addition, a modified asymptotic solution for

![]() $\lambda _{\parallel, c}$

is proposed for a wide range of

$\lambda _{\parallel, c}$

is proposed for a wide range of

![]() $\Lambda \gtrsim 0.2$

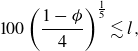

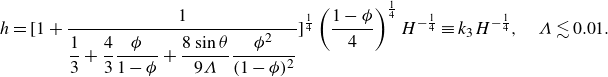

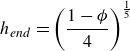

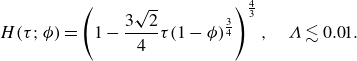

. We then discuss the slip effects on constant-pressure CCM in § 3.2, revealing the critical conditions of

$\Lambda \gtrsim 0.2$

. We then discuss the slip effects on constant-pressure CCM in § 3.2, revealing the critical conditions of

![]() $\Lambda$

and

$\Lambda$

and

![]() $\phi$

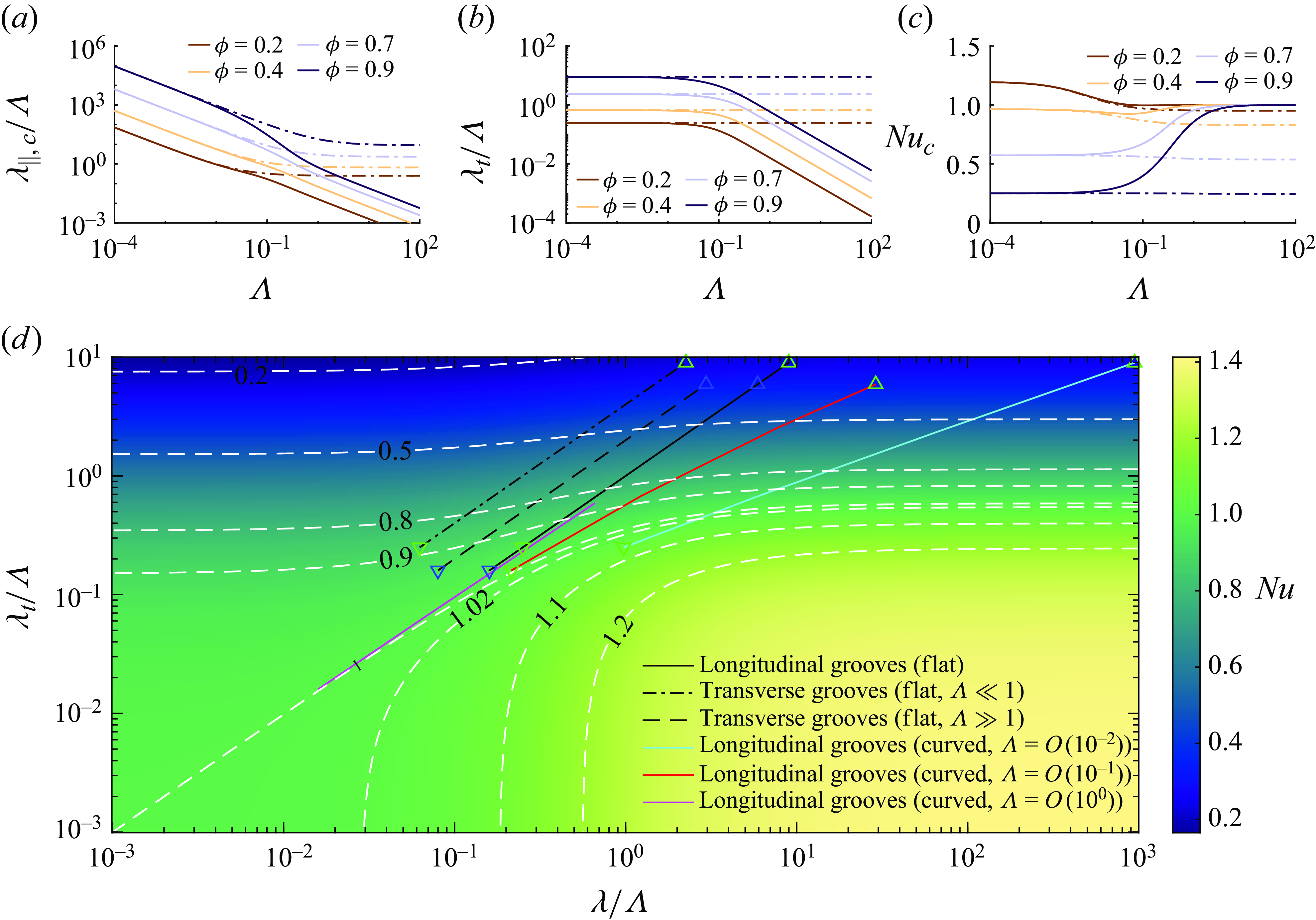

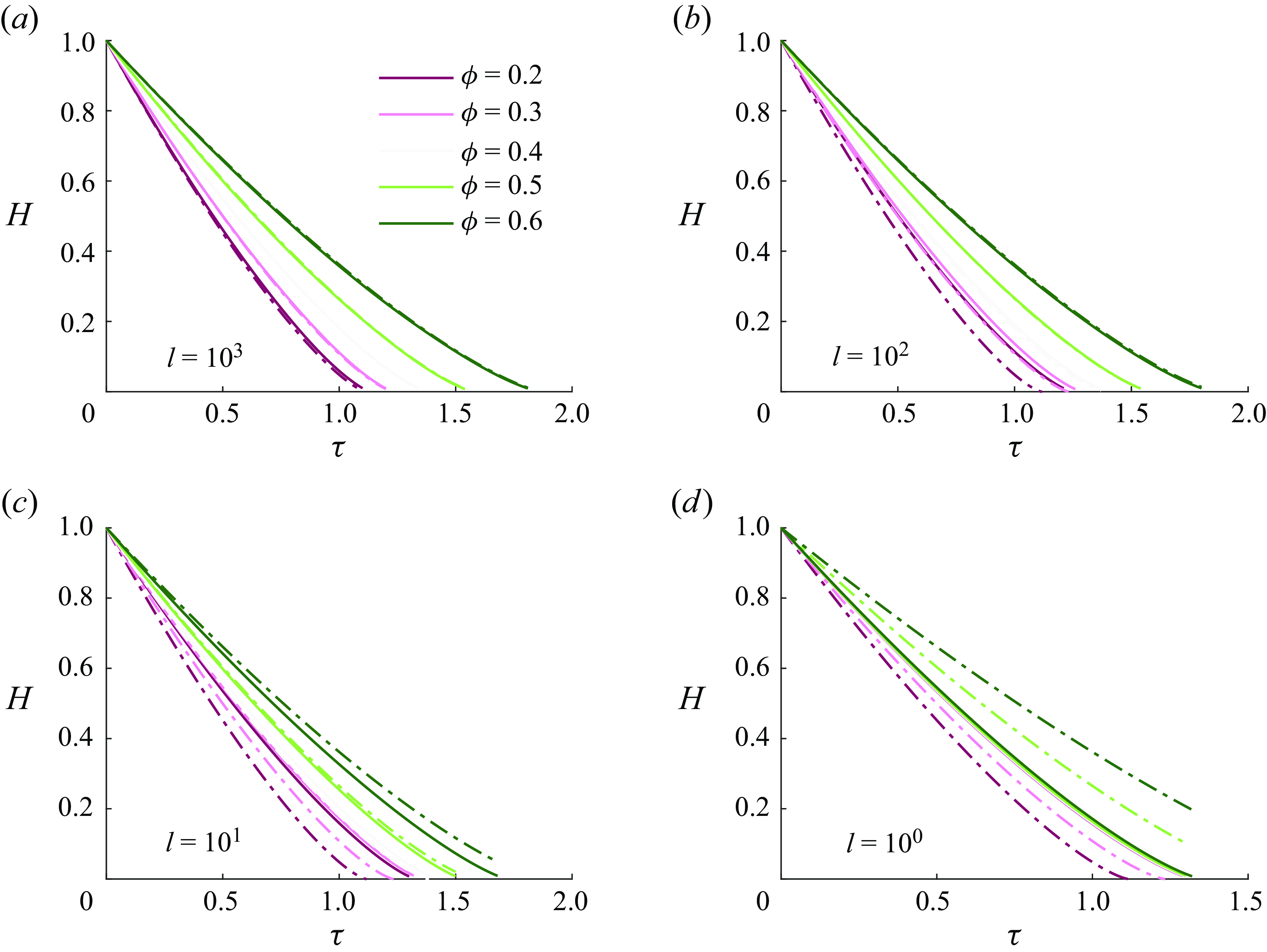

to achieve a faster melting rate. On the other hand, we analyse gravity-driven CCM in § 3.3, under limiting conditions derived from the dimensionless periodic length

$\phi$

to achieve a faster melting rate. On the other hand, we analyse gravity-driven CCM in § 3.3, under limiting conditions derived from the dimensionless periodic length

![]() $l$

, and construct a

$l$

, and construct a

![]() $l$

-

$l$

-

![]() $\phi$

phase diagram to illustrate the influences of slip.

$\phi$

phase diagram to illustrate the influences of slip.

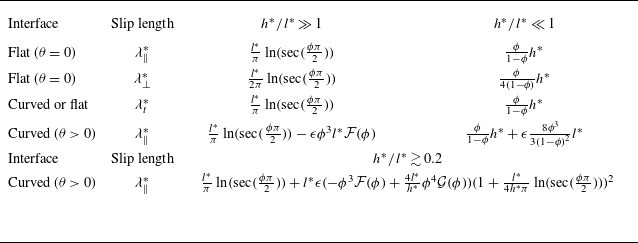

Table 1. Dimensional asymptotic formula of velocity (

![]() $\lambda _{\parallel }^{*}$

or

$\lambda _{\parallel }^{*}$

or

![]() $\lambda _{\perp }^{*}$

) and thermal (

$\lambda _{\perp }^{*}$

) and thermal (

![]() $\lambda _{t}^{*}$

) slip lengths for various confinement and meniscus effects.

$\lambda _{t}^{*}$

) slip lengths for various confinement and meniscus effects.

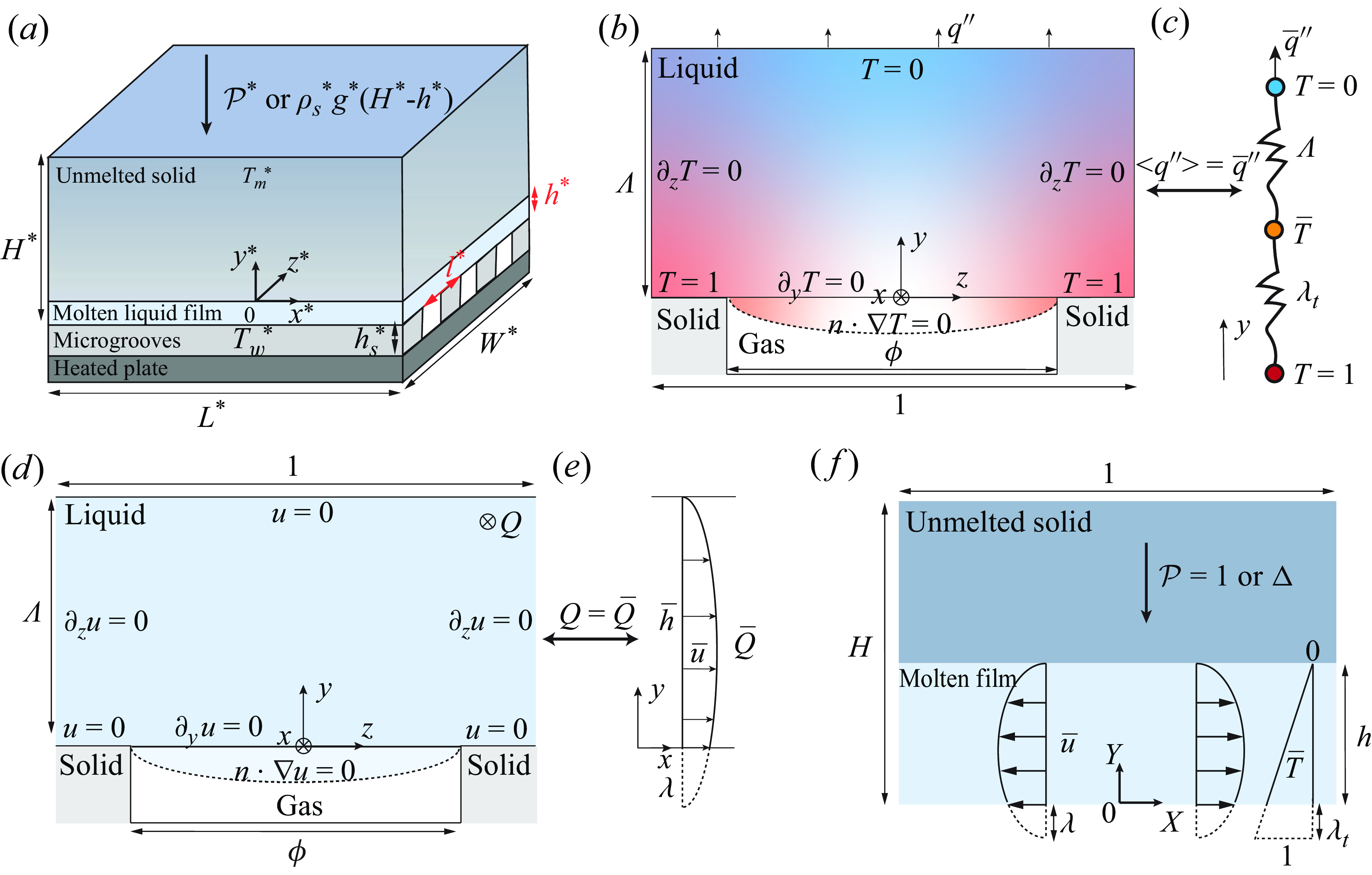

2. Physical model and theoretical framework

A typical CCM process on a microtextured hydrophobic surface is sketched in figure 1(a). Here and in the following, the notation

![]() $^{*}$

represents a dimensional quantity. A cuboid-shaped solid phase change material (PCM) with length

$^{*}$

represents a dimensional quantity. A cuboid-shaped solid phase change material (PCM) with length

![]() $L^{*}$

, width

$L^{*}$

, width

![]() $W^{*}$

and initial height

$W^{*}$

and initial height

![]() $H_{0}^{*}$

is heated from below by a textured (microgrooved) surface maintained at wall temperature

$H_{0}^{*}$

is heated from below by a textured (microgrooved) surface maintained at wall temperature

![]() $T_{w}^{*}$

and characterised by a periodic length

$T_{w}^{*}$

and characterised by a periodic length

![]() $l^{*}$

. The solid PCM, initially at its melting point

$l^{*}$

. The solid PCM, initially at its melting point

![]() $T_{m}^{*}\lt T_{w}^{*}$

, will continuously melt from the bottom under a certain pressure, which could be either a specific constant value

$T_{m}^{*}\lt T_{w}^{*}$

, will continuously melt from the bottom under a certain pressure, which could be either a specific constant value

![]() $\mathcal{P}^{*}$

or the self-weight pressure of the PCM,

$\mathcal{P}^{*}$

or the self-weight pressure of the PCM,

![]() $\rho _s^{*} g^{*} (H^{*}-h^{*})$

, depending on the mode of CCM. Given the microgrooved structure (periodic length

$\rho _s^{*} g^{*} (H^{*}-h^{*})$

, depending on the mode of CCM. Given the microgrooved structure (periodic length

![]() $l^*$

and gas fraction

$l^*$

and gas fraction

![]() $\phi$

), the mixed interface, composed of solid–liquid and gas–liquid contacts, when approximated with a one-dimensional description, introduces effective coefficients of temperature slip

$\phi$

), the mixed interface, composed of solid–liquid and gas–liquid contacts, when approximated with a one-dimensional description, introduces effective coefficients of temperature slip

![]() $\lambda _{t}^{*}$

and velocity slip

$\lambda _{t}^{*}$

and velocity slip

![]() $\lambda ^{*}$

, which are described below and significantly affect the fluid flow and heat transfer in the CCM process.

$\lambda ^{*}$

, which are described below and significantly affect the fluid flow and heat transfer in the CCM process.

Figure 1. (a) Close-contact melting of a cuboid-shaped unmelted solid with initial height

![]() $H_{0}^{*}$

, length

$H_{0}^{*}$

, length

![]() $L^{*}$

and width

$L^{*}$

and width

![]() $W^{*}$

pressed downwards by constant pressure

$W^{*}$

pressed downwards by constant pressure

![]() $\mathcal{P}^{*}$

or self-weight

$\mathcal{P}^{*}$

or self-weight

![]() $\rho _s^*g^*(H^*-h^*)$

on a heated microgrooved hydrophobic surface with characteristic periodic length

$\rho _s^*g^*(H^*-h^*)$

on a heated microgrooved hydrophobic surface with characteristic periodic length

![]() $l^{*}$

, where

$l^{*}$

, where

![]() $h^*$

is the liquid film thickness; quantities with

$h^*$

is the liquid film thickness; quantities with

![]() $^{*}$

are dimensional. Schematic diagrams of boundary conditions for (b) two-dimensional descriptions, or (c) a one-dimensional description, for the temperature distribution and temperature slip length

$^{*}$

are dimensional. Schematic diagrams of boundary conditions for (b) two-dimensional descriptions, or (c) a one-dimensional description, for the temperature distribution and temperature slip length

![]() $\lambda _{t}$

; similarly, (d)–(e) characterise the velocity boundary conditions and velocity slip length

$\lambda _{t}$

; similarly, (d)–(e) characterise the velocity boundary conditions and velocity slip length

![]() $\lambda$

on the longitudinal grooves. It is noted that length is scaled by

$\lambda$

on the longitudinal grooves. It is noted that length is scaled by

![]() $l^{*}$

for convenience. (f) The dimensionless schematic diagram (

$l^{*}$

for convenience. (f) The dimensionless schematic diagram (

![]() $L^* \ll W^*$

) by scaling as

$L^* \ll W^*$

) by scaling as

![]() $X = x^*/L^*$

,

$X = x^*/L^*$

,

![]() $Y = y^*/h_0^*$

and

$Y = y^*/h_0^*$

and

![]() $T = (T^*-T_m^*)/(T_w^*-T_m^*)$

, showing the remaining solid height

$T = (T^*-T_m^*)/(T_w^*-T_m^*)$

, showing the remaining solid height

![]() $H$

and film thickness

$H$

and film thickness

![]() $h$

is influenced by the effective velocity slip length

$h$

is influenced by the effective velocity slip length

![]() $\lambda$

and temperature slip length

$\lambda$

and temperature slip length

![]() $\lambda _{t}$

.

$\lambda _{t}$

.

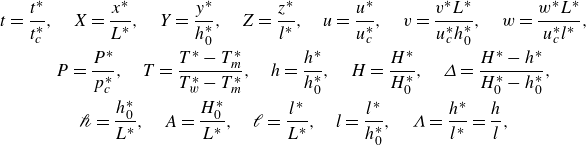

2.1. Scaling analysis and non-dimensionalization

Typically, a thin melted film of liquid separates the substrate from the solid PCM. Hence, a lubrication-style analysis is suggested. The relevant physical parameters are the gravitational acceleration

![]() $g^{*}$

, viscosity

$g^{*}$

, viscosity

![]() $\mu ^{*}$

, solid density

$\mu ^{*}$

, solid density

![]() $\rho _s^{*}$

, liquid density

$\rho _s^{*}$

, liquid density

![]() $\rho _l^{*}$

, liquid specific heat capacity

$\rho _l^{*}$

, liquid specific heat capacity

![]() $c_{p,l}^{*}$

, thermal conductivity of liquid

$c_{p,l}^{*}$

, thermal conductivity of liquid

![]() $k_l^{*}$

and latent heat of fusion

$k_l^{*}$

and latent heat of fusion

![]() $\mathcal{H}^*$

. By scaling pressure and stresses with

$\mathcal{H}^*$

. By scaling pressure and stresses with

![]() $p_c^* = \rho _s^*g^*(H_0^*-h_0^*)$

for the gravity-driven mode or

$p_c^* = \rho _s^*g^*(H_0^*-h_0^*)$

for the gravity-driven mode or

![]() $p_c^* = \mathcal{P}^*$

for the constant-pressure mode, velocity with

$p_c^* = \mathcal{P}^*$

for the constant-pressure mode, velocity with

![]() $u_c^* = {h_0^*}^2p_c^*/(\mu ^*L^*)$

, time with

$u_c^* = {h_0^*}^2p_c^*/(\mu ^*L^*)$

, time with

![]() $t_c^* = L^*/u_c^*$

and temperature with

$t_c^* = L^*/u_c^*$

and temperature with

![]() $T_w^{*}-T_m^{*}$

, we can define dimensionless variables as

$T_w^{*}-T_m^{*}$

, we can define dimensionless variables as

\begin{equation} \begin{gathered} t =\frac {t^*}{t_c^*}, \quad X=\frac {x^*}{L^*}, \quad Y=\frac {y^*}{h_0^*}, \quad Z=\frac {z^*}{l^*}, \quad u = \frac {u^*}{u_c^*}, \quad v = \frac {v^*L^*}{u_c^*h_0^*}, \quad w = \frac {w^*L^*}{u_c^*l^*},\\ \quad P = \frac {P^*}{p_c^*}, \quad T=\frac {T^*-T_m^*}{T_w^*-T_m^*},\quad h = \frac {h^*}{h_0^*}, \quad H =\frac {H^*}{H_0^*}, \quad \varDelta = \frac {H^*-h^*}{H_0^*-h_0^*}, \\ \mathscr{h} = \frac {h_0^*}{L^*}, \quad A = \frac {H_0^*}{L^*}, \quad \mathscr{l}=\frac {l^*}{L^*}, \quad l =\frac {l^*}{h_0^*},\quad \Lambda =\frac {h^*}{l^*}=\frac {h}{l}, \end{gathered} \end{equation}

\begin{equation} \begin{gathered} t =\frac {t^*}{t_c^*}, \quad X=\frac {x^*}{L^*}, \quad Y=\frac {y^*}{h_0^*}, \quad Z=\frac {z^*}{l^*}, \quad u = \frac {u^*}{u_c^*}, \quad v = \frac {v^*L^*}{u_c^*h_0^*}, \quad w = \frac {w^*L^*}{u_c^*l^*},\\ \quad P = \frac {P^*}{p_c^*}, \quad T=\frac {T^*-T_m^*}{T_w^*-T_m^*},\quad h = \frac {h^*}{h_0^*}, \quad H =\frac {H^*}{H_0^*}, \quad \varDelta = \frac {H^*-h^*}{H_0^*-h_0^*}, \\ \mathscr{h} = \frac {h_0^*}{L^*}, \quad A = \frac {H_0^*}{L^*}, \quad \mathscr{l}=\frac {l^*}{L^*}, \quad l =\frac {l^*}{h_0^*},\quad \Lambda =\frac {h^*}{l^*}=\frac {h}{l}, \end{gathered} \end{equation}

where

![]() $h_0^*$

is the initial film thickness identified below as (2.51) in § 2.4. The aspect ratio

$h_0^*$

is the initial film thickness identified below as (2.51) in § 2.4. The aspect ratio

![]() $\Lambda$

is a key parameter related to the confinement effect in the following discussion. Hence, the dimensionless variables are denoted as the velocity vector

$\Lambda$

is a key parameter related to the confinement effect in the following discussion. Hence, the dimensionless variables are denoted as the velocity vector

![]() $\boldsymbol{V}\equiv u\boldsymbol{e}_X+v\boldsymbol{e}_Y+w\boldsymbol{e}_Z$

, temperature

$\boldsymbol{V}\equiv u\boldsymbol{e}_X+v\boldsymbol{e}_Y+w\boldsymbol{e}_Z$

, temperature

![]() $T$

, pressure

$T$

, pressure

![]() $P$

, spatial gradient operator

$P$

, spatial gradient operator

![]() $\boldsymbol{\nabla }\equiv \boldsymbol{e}_X\partial _X+\boldsymbol{e}_Y\partial _Y +\boldsymbol{e}_Z\partial _Z$

and

$\boldsymbol{\nabla }\equiv \boldsymbol{e}_X\partial _X+\boldsymbol{e}_Y\partial _Y +\boldsymbol{e}_Z\partial _Z$

and

![]() $\partial _t$

is the time derivative. The Reynolds number

$\partial _t$

is the time derivative. The Reynolds number

![]() $\textrm{Re}$

, Péclet number

$\textrm{Re}$

, Péclet number

![]() $\textrm{Pe}$

, Prandtl number

$\textrm{Pe}$

, Prandtl number

![]() $\textrm{Pr}$

, Eckert number

$\textrm{Pr}$

, Eckert number

![]() $\textrm{Ec}$

, Stefan number

$\textrm{Ec}$

, Stefan number

![]() $\textrm{St}$

, density ratio

$\textrm{St}$

, density ratio

![]() $\rho$

and hydrostatic pressure ratio

$\rho$

and hydrostatic pressure ratio

![]() $p_h$

are, respectively, defined as

$p_h$

are, respectively, defined as

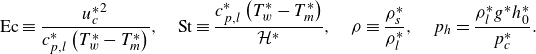

\begin{align}&\textrm{Ec} \equiv \frac {{u_c^*}^2}{ c_{p,l}^{*} \left (T_w^{*}-T_m^{*}\right )}, \quad \textrm{St} \equiv \frac {c_{p,l}^{*} \left (T_w^{*}-T_m^{*}\right )}{\mathcal{H}^*}, \quad \rho \equiv \frac {\rho _s^{*}}{\rho _l^{*}}, \quad p_h = \frac {\rho _l^*g^*h_0^*}{p_c^*}. \end{align}

\begin{align}&\textrm{Ec} \equiv \frac {{u_c^*}^2}{ c_{p,l}^{*} \left (T_w^{*}-T_m^{*}\right )}, \quad \textrm{St} \equiv \frac {c_{p,l}^{*} \left (T_w^{*}-T_m^{*}\right )}{\mathcal{H}^*}, \quad \rho \equiv \frac {\rho _s^{*}}{\rho _l^{*}}, \quad p_h = \frac {\rho _l^*g^*h_0^*}{p_c^*}. \end{align}

In this case, the equations of continuity, momentum (in the

![]() $X$

,

$X$

,

![]() $Y$

-and

$Y$

-and

![]() $Z$

directions), and energy, including the dissipation of mechanical to thermal energy in the bulk liquid and an energy balance at the melting front, are, respectively,

$Z$

directions), and energy, including the dissipation of mechanical to thermal energy in the bulk liquid and an energy balance at the melting front, are, respectively,

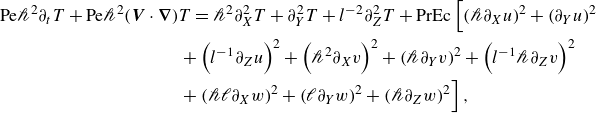

\begin{align}& \textrm{Pe}\mathscr{h}^2\partial _t T + \textrm{Pe}\mathscr{h}^2 ({\boldsymbol{V}} \cdot \boldsymbol{\nabla }) {T} = \mathscr{h}^2 \partial _X^2 T + \partial _Y^2 T + l^{-2} \partial _Z^2 T + \textrm{PrEc} \left [ \left ( \mathscr{h} \partial _X u \right )^2 + \left ( \partial _Y u \right )^2 \right . \nonumber\\ &\qquad\qquad\qquad\qquad\qquad \left . + \left ( l^{-1} \partial _Z u \right )^2 + \left ( \mathscr{h}^2 \partial _X v \right )^2 + \left ( \mathscr{h} \partial _Y v \right )^2 + \left ( l^{-1} \mathscr{h} \partial _Z v \right )^2 \right . \nonumber\\ &\qquad\qquad\qquad\qquad\qquad \left . + \left ( \mathscr{h} \mathscr{l} \partial _X w \right )^2 + \left ( \mathscr{l} \partial _Y w \right )^2 + \left ( \mathscr{h} \partial _Z w \right )^2 \right ], \end{align}

\begin{align}& \textrm{Pe}\mathscr{h}^2\partial _t T + \textrm{Pe}\mathscr{h}^2 ({\boldsymbol{V}} \cdot \boldsymbol{\nabla }) {T} = \mathscr{h}^2 \partial _X^2 T + \partial _Y^2 T + l^{-2} \partial _Z^2 T + \textrm{PrEc} \left [ \left ( \mathscr{h} \partial _X u \right )^2 + \left ( \partial _Y u \right )^2 \right . \nonumber\\ &\qquad\qquad\qquad\qquad\qquad \left . + \left ( l^{-1} \partial _Z u \right )^2 + \left ( \mathscr{h}^2 \partial _X v \right )^2 + \left ( \mathscr{h} \partial _Y v \right )^2 + \left ( l^{-1} \mathscr{h} \partial _Z v \right )^2 \right . \nonumber\\ &\qquad\qquad\qquad\qquad\qquad \left . + \left ( \mathscr{h} \mathscr{l} \partial _X w \right )^2 + \left ( \mathscr{l} \partial _Y w \right )^2 + \left ( \mathscr{h} \partial _Z w \right )^2 \right ], \end{align}

where

![]() $\varDelta$

is the remaining height of the solid to be melted and

$\varDelta$

is the remaining height of the solid to be melted and

![]() $\partial _t\varDelta$

represents the melting rate.

$\partial _t\varDelta$

represents the melting rate.

In accordance with previous experimental and theoretical results (Moallemi, Webb & Viskanta Reference Moallemi, Webb and Viskanta1986; Hu & Fan Reference Hu and Fan2023), the following well-validated assumptions are adopted: (i) the lubrication approximation is valid due to

![]() $ \mathscr{h}^2 \ll 1$

; (ii) the flow is quasisteady,

$ \mathscr{h}^2 \ll 1$

; (ii) the flow is quasisteady,

![]() $\partial /\partial {t}=0$

, as a consequence of a low effective Reynolds number,

$\partial /\partial {t}=0$

, as a consequence of a low effective Reynolds number,

![]() $\textrm{Re}\mathscr{h}^2 \ll 1$

; (iii) thermophysical properties are constant; (iv) the solid–liquid interface is flat, i.e.

$\textrm{Re}\mathscr{h}^2 \ll 1$

; (iii) thermophysical properties are constant; (iv) the solid–liquid interface is flat, i.e.

![]() $ h=h(t)$

; (v) the hydrostatic pressure in the liquid film is neglected (

$ h=h(t)$

; (v) the hydrostatic pressure in the liquid film is neglected (

![]() $p_h \ll 1$

); (vi) heat convection is negligible

$p_h \ll 1$

); (vi) heat convection is negligible

![]() $\textrm{Pe}\mathscr{h}^2 \ll 1$

when

$\textrm{Pe}\mathscr{h}^2 \ll 1$

when

![]() $\textrm{St} \leqslant 0.1$

for CCM (Hu & Fan Reference Hu and Fan2023; Ezra & Kozak Reference Ezra and Kozak2024); (vii) viscous dissipation is negligible due to

$\textrm{St} \leqslant 0.1$

for CCM (Hu & Fan Reference Hu and Fan2023; Ezra & Kozak Reference Ezra and Kozak2024); (vii) viscous dissipation is negligible due to

![]() $ \textrm{PrEc} \ll 1$

for most PCMs and thermal conditions; (viii) the initial temperature of the PCM solid remains

$ \textrm{PrEc} \ll 1$

for most PCMs and thermal conditions; (viii) the initial temperature of the PCM solid remains

![]() $T_m$

; (ix) the heat flux across the gas–liquid interface is negligible due to the much low thermal conductivity of the gas compared with the liquid. Additionally, we consider (x) the initial geometrical conditions

$T_m$

; (ix) the heat flux across the gas–liquid interface is negligible due to the much low thermal conductivity of the gas compared with the liquid. Additionally, we consider (x) the initial geometrical conditions

![]() $ \mathscr{l}^2 \ll 1$

and

$ \mathscr{l}^2 \ll 1$

and

![]() $\mathscr{h} \ll A$

. Consequently, with

$\mathscr{h} \ll A$

. Consequently, with

![]() $l =l^*/h_0^*$

providing the corresponding transverse dimensions of the liquid flow channel, the governing equations can be simplified considerably to

$l =l^*/h_0^*$

providing the corresponding transverse dimensions of the liquid flow channel, the governing equations can be simplified considerably to

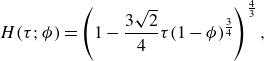

where

![]() $\tau \equiv t\textrm{St}/ [\rho \textrm{Pe}\mathscr{h}(A-\mathscr{h}) ]$

is a rescaled time, which recognises that a balance of heat conduction and the heat of fusion control the dynamics. Additionally, the force balance on the remaining solid is satisfied as

$\tau \equiv t\textrm{St}/ [\rho \textrm{Pe}\mathscr{h}(A-\mathscr{h}) ]$

is a rescaled time, which recognises that a balance of heat conduction and the heat of fusion control the dynamics. Additionally, the force balance on the remaining solid is satisfied as

where

![]() $\mathscr{c} = 0$

represents the constant-pressure CCM mode and

$\mathscr{c} = 0$

represents the constant-pressure CCM mode and

![]() $\mathscr{c} = 1$

represents a gravity-driven configuration. Then, the boundary conditions for the velocity and temperature fields within a single periodic unit cell are given as

$\mathscr{c} = 1$

represents a gravity-driven configuration. Then, the boundary conditions for the velocity and temperature fields within a single periodic unit cell are given as

The goal of the subsequent parts of § 2 is to determine the flow and temperature fields so as to find how the PCM height changes with time, i.e.

![]() $\varDelta (\tau )$

or

$\varDelta (\tau )$

or

![]() $H(\tau )$

. A significant computational difficulty is to do this calculation for different groove configurations, i.e. gas–liquid fractions

$H(\tau )$

. A significant computational difficulty is to do this calculation for different groove configurations, i.e. gas–liquid fractions

![]() $\phi$

and dimensionless periodic lengths

$\phi$

and dimensionless periodic lengths

![]() $l$

and liquid film thicknesses

$l$

and liquid film thicknesses

![]() $\Lambda$

. The specific results are given in § 3.

$\Lambda$

. The specific results are given in § 3.

2.2. Average heat flux and effective thermal slip length

In this section, a dual-series approach similar to previous work (Lauga & Stone Reference Lauga and Stone2003; Sbragaglia & Prosperetti Reference Sbragaglia and Prosperetti2007; Kirk et al. Reference Kirk, Hodes and Papageorgiou2017) was adopted to give exact solutions for an effective thermal slip length

![]() $\lambda _{t}^{*}$

in the two-dimensional configuration. For convenience and consistency with previous work, the characteristic length

$\lambda _{t}^{*}$

in the two-dimensional configuration. For convenience and consistency with previous work, the characteristic length

![]() $l^{*}$

of the periodic topography of the substrate is used for the length scale throughout this section, leading to dimensionless coordinates

$l^{*}$

of the periodic topography of the substrate is used for the length scale throughout this section, leading to dimensionless coordinates

![]() $(x,y,z)\equiv (x^*,y^*,z^*)/l^*$

and channel height

$(x,y,z)\equiv (x^*,y^*,z^*)/l^*$

and channel height

![]() $\Lambda \equiv h^*/l^*$

. Consequently, the schematic diagram of the configuration is depicted in figure 1(b). The dimensionless variables

$\Lambda \equiv h^*/l^*$

. Consequently, the schematic diagram of the configuration is depicted in figure 1(b). The dimensionless variables

![]() $X$

and

$X$

and

![]() $Y$

introduced in the previous subsection will return when we obtain a one-dimensional model of the problem in § 2.4.

$Y$

introduced in the previous subsection will return when we obtain a one-dimensional model of the problem in § 2.4.

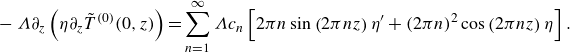

In addition to the temperature distribution, our primary interest lies in the average heat flux

![]() $\left \langle q^{\prime \prime }\right \rangle \equiv \int _{-1/2}^{1/2} -\partial _yT(\Lambda, z) dz$

through the upper boundary of the liquid film, as this parameter determines the melting rate as indicated by (2.4f

). Consequently, the introduction of an effective thermal slip length

$\left \langle q^{\prime \prime }\right \rangle \equiv \int _{-1/2}^{1/2} -\partial _yT(\Lambda, z) dz$

through the upper boundary of the liquid film, as this parameter determines the melting rate as indicated by (2.4f

). Consequently, the introduction of an effective thermal slip length

![]() $\lambda _t \equiv \lambda _t^*/l^*$

can reduce the two-dimensional problem

$\lambda _t \equiv \lambda _t^*/l^*$

can reduce the two-dimensional problem

![]() $T(y,z)$

in the

$T(y,z)$

in the

![]() $y-z$

plane to a one-dimensional problem

$y-z$

plane to a one-dimensional problem

![]() $\bar T(y)$

in the

$\bar T(y)$

in the

![]() $y$

direction, as illustrated in the schematic of the thermal transport in figure 1(b). In the following,

$y$

direction, as illustrated in the schematic of the thermal transport in figure 1(b). In the following,

![]() $\lambda _{t,f}$

and

$\lambda _{t,f}$

and

![]() $\lambda _{t,c}$

represent, respectively, the thermal slip lengths of a flat and curved gas–liquid interface.

$\lambda _{t,c}$

represent, respectively, the thermal slip lengths of a flat and curved gas–liquid interface.

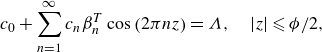

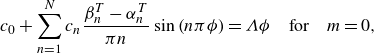

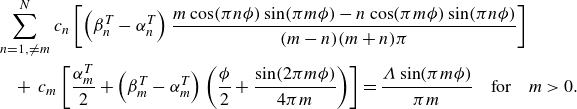

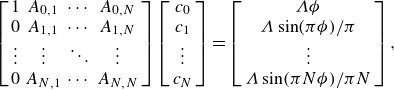

2.2.1. On the flat interface,

$\lambda _{t,f}$

$\lambda _{t,f}$

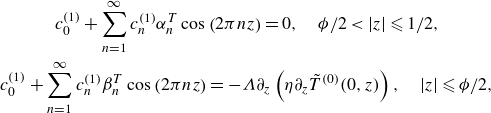

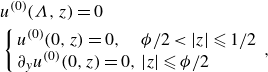

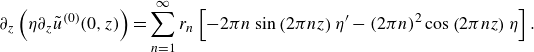

Based on (2.4e ), the dimensionless form of the energy equation is rewritten as

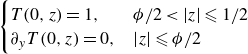

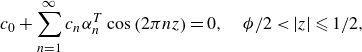

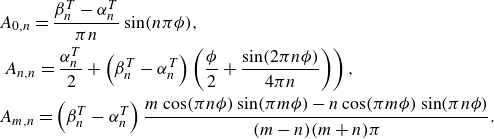

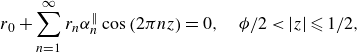

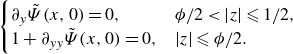

As depicted in figure 1(b), the boundary conditions are

\begin{align}& \begin{cases} {T}(0,z)=1, & \phi /2 \lt |z| \leqslant 1/2 \\ \partial _y {T}(0,z)= 0, & |z| \leqslant \phi /2 \end{cases} \end{align}

\begin{align}& \begin{cases} {T}(0,z)=1, & \phi /2 \lt |z| \leqslant 1/2 \\ \partial _y {T}(0,z)= 0, & |z| \leqslant \phi /2 \end{cases} \end{align}

we assume that the heat flux vanishes at the gas–liquid boundary owing to the smallness of the ratio of the gas and liquid thermal conductivities. We can observe that the boundary conditions for this two-dimensional problem introduce the fraction of the boundary that involves the gas–liquid fraction

![]() $\phi$

. Due to the linearity of the boundary-value problem, the temperature

$\phi$

. Due to the linearity of the boundary-value problem, the temperature

![]() $T$

can be divided into two components

$T$

can be divided into two components

![]() $T_b$

and

$T_b$

and

![]() $T_s$

, namely

$T_s$

, namely

![]() $T(y,z)=T_b(y)+T_s(y,z)$

, where

$T(y,z)=T_b(y)+T_s(y,z)$

, where

![]() $T_b(y) = 1 - y/\Lambda$

satisfies the boundary conditions on temperature in the

$T_b(y) = 1 - y/\Lambda$

satisfies the boundary conditions on temperature in the

![]() $y$

direction, and

$y$

direction, and

![]() $T_s(y,z)=\tilde {T}(y,z)/\Lambda$

accounts for the influence of the hydrophobic surface. Hence,

$T_s(y,z)=\tilde {T}(y,z)/\Lambda$

accounts for the influence of the hydrophobic surface. Hence,

![]() $\tilde {T}$

also satisfies the Laplace equation as

$\tilde {T}$

also satisfies the Laplace equation as

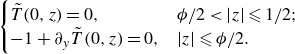

The boundary conditions for

![]() $\tilde {T}$

are

$\tilde {T}$

are

\begin{align}& \begin{cases} \tilde {T}(0,z)=0, & \phi /2 \lt |z| \leqslant 1/2; \\ -1 + \partial _y\tilde {T}(0,z) = 0, & |z| \leqslant \phi /2. \end{cases} \end{align}

\begin{align}& \begin{cases} \tilde {T}(0,z)=0, & \phi /2 \lt |z| \leqslant 1/2; \\ -1 + \partial _y\tilde {T}(0,z) = 0, & |z| \leqslant \phi /2. \end{cases} \end{align}

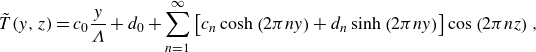

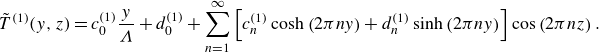

The general solution

![]() $\tilde {T}$

, accounting for condition (2.8c

), is

$\tilde {T}$

, accounting for condition (2.8c

), is

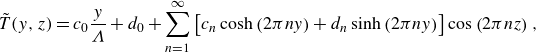

\begin{equation} \begin{aligned} \tilde {T} (y, z) = c_0 \frac {y}{\Lambda } + d_0 + \sum _{n=1}^\infty \left [c_n \cosh \left (2\pi n y\right ) + d_n \sinh \left (2\pi n y\right )\right ] \cos \left (2\pi n z\right ), \end{aligned} \end{equation}

\begin{equation} \begin{aligned} \tilde {T} (y, z) = c_0 \frac {y}{\Lambda } + d_0 + \sum _{n=1}^\infty \left [c_n \cosh \left (2\pi n y\right ) + d_n \sinh \left (2\pi n y\right )\right ] \cos \left (2\pi n z\right ), \end{aligned} \end{equation}

where

![]() $c_n$

and

$c_n$

and

![]() $d_n$

for

$d_n$

for

![]() $n \in [0, \infty )$

are constants to be determined for given

$n \in [0, \infty )$

are constants to be determined for given

![]() $\phi$

and

$\phi$

and

![]() $\Lambda$

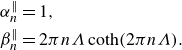

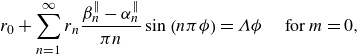

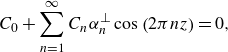

. Following the standard procedure of a dual-series method to numerically solve (2.12) as detailed in Appendix A,

$\Lambda$

. Following the standard procedure of a dual-series method to numerically solve (2.12) as detailed in Appendix A,

![]() $c_n$

and

$c_n$

and

![]() $d_n$

for

$d_n$

for

![]() $n \in [0, N-1]$

can be obtained with a numerical truncation for large enough

$n \in [0, N-1]$

can be obtained with a numerical truncation for large enough

![]() $N$

. The choice of

$N$

. The choice of

![]() $N$

should be chosen to ensure convergence of the numerical results (Teo & Khoo Reference Teo and Khoo2008). Here, we adopt

$N$

should be chosen to ensure convergence of the numerical results (Teo & Khoo Reference Teo and Khoo2008). Here, we adopt

![]() $N=500$

as there is no significant deviation with

$N=500$

as there is no significant deviation with

![]() $N=1000$

, which is also consistent with Landel et al. (Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020). Therefore, the average heat flux

$N=1000$

, which is also consistent with Landel et al. (Reference Landel, Peaudecerf, Temprano-Coleto, Gibou, Goldstein and Luzzatto-Fegiz2020). Therefore, the average heat flux

![]() $\left \langle q^{\prime \prime }\right \rangle$

can be calculated by substituting

$\left \langle q^{\prime \prime }\right \rangle$

can be calculated by substituting

![]() $c_0$

as

$c_0$

as

The definition of an effective thermal slip length

![]() $ \lambda _{t}$

representative of the composite flat liquid–gas surface and solid–liquid surface (Enright et al. Reference Enright, Hodes, Salamon and Muzychka2014) is

$ \lambda _{t}$

representative of the composite flat liquid–gas surface and solid–liquid surface (Enright et al. Reference Enright, Hodes, Salamon and Muzychka2014) is

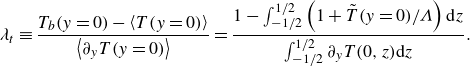

\begin{equation} \lambda _{t} \equiv \frac {T_b(y=0)- \left \langle T(y=0)\right \rangle }{\left \langle \partial _y T(y=0)\right \rangle } = \frac {1-\int _{-1/2}^{1/2}\left (1+\tilde {T}(y=0)/\Lambda \right ){\textrm d} z}{\int _{-1/2}^{1/2} \partial _yT(0, z) {\textrm d}z}. \end{equation}

\begin{equation} \lambda _{t} \equiv \frac {T_b(y=0)- \left \langle T(y=0)\right \rangle }{\left \langle \partial _y T(y=0)\right \rangle } = \frac {1-\int _{-1/2}^{1/2}\left (1+\tilde {T}(y=0)/\Lambda \right ){\textrm d} z}{\int _{-1/2}^{1/2} \partial _yT(0, z) {\textrm d}z}. \end{equation}

With the results of

![]() $1-\int _{-1/2}^{1/2}(1+\tilde {T}(y=0)/\Lambda ) {\textrm d}z= c_0/\Lambda$

due to

$1-\int _{-1/2}^{1/2}(1+\tilde {T}(y=0)/\Lambda ) {\textrm d}z= c_0/\Lambda$

due to

![]() $c_0 = -d_0$

from Appendix A and

$c_0 = -d_0$

from Appendix A and

![]() $\int _{-1/2}^{1/2} \partial _yT(0, z) {\textrm d}z= \left \langle q^{\prime \prime }\right \rangle$

, we find the effective thermal slip length

$\int _{-1/2}^{1/2} \partial _yT(0, z) {\textrm d}z= \left \langle q^{\prime \prime }\right \rangle$

, we find the effective thermal slip length

![]() $ \lambda _{t,f}$

for a flat, composite gas–liquid interface:

$ \lambda _{t,f}$

for a flat, composite gas–liquid interface:

2.2.2. On the curved interface,

$\lambda _{t,c}$

$\lambda _{t,c}$

We next consider how the deformation of the gas–liquid interface affects the thermal slip length. A curved liquid–air interface is formed by the pressure difference between liquid

![]() $ P_l^{*}$

and gas

$ P_l^{*}$

and gas

![]() $ P_g^{*}$

, and described approximately by the radius of curvature

$ P_g^{*}$

, and described approximately by the radius of curvature

![]() $ R^{*} = \sigma ^{*}/(P_l^{*} - P_g^{*})$

, where

$ R^{*} = \sigma ^{*}/(P_l^{*} - P_g^{*})$

, where

![]() $\sigma ^{*}$

is the surface tension. Hence, the shape of the meniscus can be described by the geometric relationship

$\sigma ^{*}$

is the surface tension. Hence, the shape of the meniscus can be described by the geometric relationship

where

![]() $R = R^{*} / l^{*}$

. For

$R = R^{*} / l^{*}$

. For

![]() $R \gg \phi / 2$

, this expression simplifies to

$R \gg \phi / 2$

, this expression simplifies to

after defining

![]() $\epsilon = 1 / (8R)$

, which will be assumed

$\epsilon = 1 / (8R)$

, which will be assumed

![]() $\ll 1$

, and

$\ll 1$

, and

![]() $\eta (z) = \phi ^2 - 4z^2$

. It should be noted that the protrusion angle

$\eta (z) = \phi ^2 - 4z^2$

. It should be noted that the protrusion angle

![]() $\theta$

satisfies

$\theta$

satisfies

![]() $R \sin \theta = \phi / 2$

, which leads to a maximum

$R \sin \theta = \phi / 2$

, which leads to a maximum

![]() $\epsilon = \sin \theta /4\phi = 0.217$

for

$\epsilon = \sin \theta /4\phi = 0.217$

for

![]() $\phi = 0.2$

and

$\phi = 0.2$

and

![]() $\theta = 10^{\circ }$

. Again, neglecting the influence of the conductivity of the gas phase, then we have the condition of no heat flux across the meniscus, and the temperature field should satisfy

$\theta = 10^{\circ }$

. Again, neglecting the influence of the conductivity of the gas phase, then we have the condition of no heat flux across the meniscus, and the temperature field should satisfy

which is equivalent to

where

![]() $\eta ^{\prime } \equiv \textrm{d} \eta /\textrm{d}z =-8z$

. Since

$\eta ^{\prime } \equiv \textrm{d} \eta /\textrm{d}z =-8z$

. Since

![]() $\epsilon \ll 1$

,

$\epsilon \ll 1$

,

![]() $T(-\epsilon \eta, z)$

can be obtained from

$T(-\epsilon \eta, z)$

can be obtained from

![]() $T(0, z)$

by Taylor expansion as

$T(0, z)$

by Taylor expansion as

![]() $T(-\epsilon \eta, z)=T(0, z)-\epsilon \eta \partial _y T(0, z)+O (\epsilon ^2 )$

, leading to

$T(-\epsilon \eta, z)=T(0, z)-\epsilon \eta \partial _y T(0, z)+O (\epsilon ^2 )$

, leading to

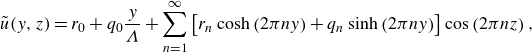

Then, substitution of (2.20) into (2.19) yields

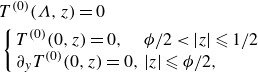

Hence, the boundary conditions are

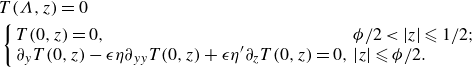

\begin{equation} \begin{aligned} & T(\Lambda, z)=0 \\ & \left \{\begin{array}{ll} T(0, z)=0, & \phi /2\lt |z| \leqslant 1 / 2; \\ \partial _y T(0, z)-\epsilon \eta \partial _{y y} T(0, z)+\epsilon \eta ^{\prime } \partial _z T(0, z)=0, & |z| \leqslant \phi /2. \end{array} \right . \end{aligned} \end{equation}

\begin{equation} \begin{aligned} & T(\Lambda, z)=0 \\ & \left \{\begin{array}{ll} T(0, z)=0, & \phi /2\lt |z| \leqslant 1 / 2; \\ \partial _y T(0, z)-\epsilon \eta \partial _{y y} T(0, z)+\epsilon \eta ^{\prime } \partial _z T(0, z)=0, & |z| \leqslant \phi /2. \end{array} \right . \end{aligned} \end{equation}

After a perturbation analysis by substituting

![]() $T=T^{(0)}+\epsilon T^{(1)}+O (\epsilon ^2 )$

(details provided in Appendix B), we find that the presence of a curved gas–liquid interface has no influence on the average heat flux and thermal slip length, which means

$T=T^{(0)}+\epsilon T^{(1)}+O (\epsilon ^2 )$

(details provided in Appendix B), we find that the presence of a curved gas–liquid interface has no influence on the average heat flux and thermal slip length, which means

We have now completed the necessary aspects of the thermal problem inside the thin film to estimate the time variations of the PCM, which will be described in § 2.4.

2.3. Flow rate – pressure gradient relationship and velocity slip length

We now consider the flow in the thin film since we need the pressure distribution to complete the force balance on the PCM. Based on (2.4b

)–(2.4d

), the main liquid flow is along the

![]() $x$

direction as indicated in figure 1(d). Similar to § 2.2, in addition to obtaining the velocity field

$x$

direction as indicated in figure 1(d). Similar to § 2.2, in addition to obtaining the velocity field

![]() $u$

, we also focus on the variation of the flow rate-pressure gradient relationship

$u$

, we also focus on the variation of the flow rate-pressure gradient relationship

![]() $Q-\partial _x P$

due to the presence of trapped gas, which will influence the pressure distribution within the liquid film and the liquid film thickness during the CCM process. By introducing the velocity slip length

$Q-\partial _x P$

due to the presence of trapped gas, which will influence the pressure distribution within the liquid film and the liquid film thickness during the CCM process. By introducing the velocity slip length

![]() $\lambda \equiv \lambda ^*/l^*$

to enable an equivalent flow rate

$\lambda \equiv \lambda ^*/l^*$

to enable an equivalent flow rate

![]() $\bar Q = Q$

as demonstrated in figure 1(e), these steps allow a dimensional reduction from

$\bar Q = Q$

as demonstrated in figure 1(e), these steps allow a dimensional reduction from

![]() $u(y,z)$

to

$u(y,z)$

to

![]() $\bar u(y)$

. In the following,

$\bar u(y)$

. In the following,

![]() $\lambda _{\parallel, f}$

and

$\lambda _{\parallel, f}$

and

![]() $\lambda _{\parallel, c}$

represent the velocity slip lengths by flat and curved gas–liquid interfaces, respectively, while the main liquid flow is parallel to the orientation of the grooves.

$\lambda _{\parallel, c}$

represent the velocity slip lengths by flat and curved gas–liquid interfaces, respectively, while the main liquid flow is parallel to the orientation of the grooves.

2.3.1. Velocity slip length on the flat interface,

$\lambda _{\parallel, f}$

$\lambda _{\parallel, f}$

With the definition of variables introduced in the previous section, the dimensionless form of the momentum equation is

where

![]() $u={u}^{*} \mu ^{*} L^{*}/({{l}^{*}}^2p_c^{*})$

. Due to linearity, the velocity

$u={u}^{*} \mu ^{*} L^{*}/({{l}^{*}}^2p_c^{*})$

. Due to linearity, the velocity

![]() $u(y,z)$

can be divided into two components

$u(y,z)$

can be divided into two components

![]() $u_b(y)$

and

$u_b(y)$

and

![]() $u_{s}(y,z)$

, where

$u_{s}(y,z)$

, where

![]() $u_b(y) = -\partial _xP (\Lambda y-y^2 )/2$

accounts for the flow without slip and

$u_b(y) = -\partial _xP (\Lambda y-y^2 )/2$

accounts for the flow without slip and

![]() $u_s(y,z)=-\partial _xP\Lambda \tilde {u}/2$

accounts for slip along the hydrophobic surface. Hence, substituting

$u_s(y,z)=-\partial _xP\Lambda \tilde {u}/2$

accounts for slip along the hydrophobic surface. Hence, substituting

![]() $u(y,z)= -\partial _xP (\Lambda y-y^2+\Lambda \tilde {u}(y,z) )/2$

leads to a boundary-value problem

$u(y,z)= -\partial _xP (\Lambda y-y^2+\Lambda \tilde {u}(y,z) )/2$

leads to a boundary-value problem

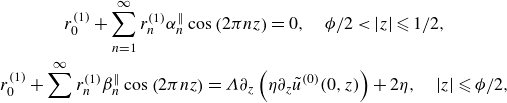

with corresponding homogeneous boundary conditions

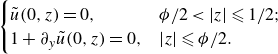

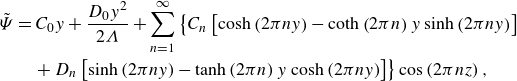

\begin{align}& \begin{cases}\tilde {u}(0, z)=0, & \phi /2 \lt |z| \leqslant 1/2; \\ 1+\partial _{y} \tilde {u}(0, z)=0, & |z|\leqslant \phi /2.\end{cases} \end{align}

\begin{align}& \begin{cases}\tilde {u}(0, z)=0, & \phi /2 \lt |z| \leqslant 1/2; \\ 1+\partial _{y} \tilde {u}(0, z)=0, & |z|\leqslant \phi /2.\end{cases} \end{align}

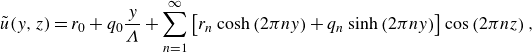

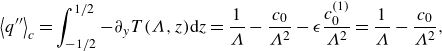

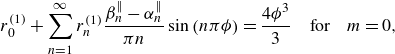

This problem is effectively identical to the thermal problem in § 2.2.1. The general solution of

![]() $\tilde {u}(y,z)$

with periodic boundary conditions at

$\tilde {u}(y,z)$

with periodic boundary conditions at

![]() $z = \pm 1/2$

is

$z = \pm 1/2$

is

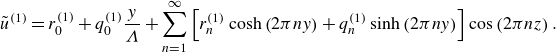

\begin{equation} \begin{aligned} \tilde {u} (y,z) = r_0 +q_{0}\frac {y}{\Lambda }+\sum _{n=1}^\infty \left [r_n\cosh \left (2\pi n y\right )+q_n \sinh \left (2\pi n y\right )\right ] \cos \left (2\pi n z\right ), \end{aligned} \end{equation}

\begin{equation} \begin{aligned} \tilde {u} (y,z) = r_0 +q_{0}\frac {y}{\Lambda }+\sum _{n=1}^\infty \left [r_n\cosh \left (2\pi n y\right )+q_n \sinh \left (2\pi n y\right )\right ] \cos \left (2\pi n z\right ), \end{aligned} \end{equation}

where constants

![]() $r_n$

and

$r_n$

and

![]() $q_n$

(

$q_n$

(

![]() $n \in [0, N-1]$

), dependent on

$n \in [0, N-1]$

), dependent on

![]() $\phi$

and

$\phi$

and

![]() $\Lambda$

, also can be numerically determined similar to the dual-series approach in Appendix C. Consequently, the increased flow rate

$\Lambda$

, also can be numerically determined similar to the dual-series approach in Appendix C. Consequently, the increased flow rate

![]() $Q_d$

due to the presence of slip can be obtained via

$Q_d$

due to the presence of slip can be obtained via

On the other hand, for a model pressure-driven channel flow with one boundary of slip length

![]() $\lambda$

, the increased flow rate

$\lambda$

, the increased flow rate

![]() $Q_d$

can be written as

$Q_d$

can be written as

Comparing the last two expressions, the effective velocity slip length

![]() $\lambda _{\parallel, f}$

on the longitudinal grooves for a flat liquid–gas interface is

$\lambda _{\parallel, f}$

on the longitudinal grooves for a flat liquid–gas interface is

A reader should notice that the detailed boundary value problems for the thermal and velocity fields, and corresponding dual integral equations solutions, show that the two problems are identical,

![]() $r_n=-c_n$

and

$r_n=-c_n$

and

![]() $r_0=c_0$

. Thus,

$r_0=c_0$

. Thus,

![]() $\lambda _{\parallel, f}=\lambda _{t,f}$

as evident from (2.31) and (2.15).

$\lambda _{\parallel, f}=\lambda _{t,f}$

as evident from (2.31) and (2.15).

2.3.2. Velocity slip length on the curved interface,

$\lambda _{\parallel, c}$

$\lambda _{\parallel, c}$

To account for a curved gas–liquid interface, we consider the configuration similar to § 2.2.2. In order to satisfy the condition of zero shear stress at the steady-state gas–liquid interface, the velocity should satisfy

which is equivalent to

Since

![]() $\epsilon \ll 1$

,

$\epsilon \ll 1$

,

![]() $u(-\epsilon \eta, z)$

can be obtained from

$u(-\epsilon \eta, z)$

can be obtained from

![]() $u(y, z)$

by Taylor expansion as

$u(y, z)$

by Taylor expansion as

![]() $u(-\epsilon \eta, z)=u(0, z)-\epsilon \eta \partial _y u(0, z)+O (\epsilon ^2 )$

as

$u(-\epsilon \eta, z)=u(0, z)-\epsilon \eta \partial _y u(0, z)+O (\epsilon ^2 )$

as

Then, substitution of (2.34a ) and (2.34b ) into (2.33) yields

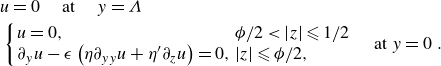

Hence, the boundary conditions are

\begin{equation} \begin{aligned} & u=0 \quad \text{ at } \quad y=\Lambda \\ & \left \{\begin{array}{ll} u=0, & \phi /2\lt |z| \leqslant 1 / 2 \\ \partial _y u-\epsilon \left ( \eta \partial _{y y} u+ \eta ^{\prime } \partial _z u\right )=0, & |z| \leqslant \phi /2, \end{array} \quad\text{ at } y=0\right . . \end{aligned} \end{equation}

\begin{equation} \begin{aligned} & u=0 \quad \text{ at } \quad y=\Lambda \\ & \left \{\begin{array}{ll} u=0, & \phi /2\lt |z| \leqslant 1 / 2 \\ \partial _y u-\epsilon \left ( \eta \partial _{y y} u+ \eta ^{\prime } \partial _z u\right )=0, & |z| \leqslant \phi /2, \end{array} \quad\text{ at } y=0\right . . \end{aligned} \end{equation}

After substituting the perturbation expansion for the velocity field,

![]() $u=u^{(0)}+\epsilon u^{(1)}+O (\epsilon ^2 )$

, we solve for the first-order velocity

$u=u^{(0)}+\epsilon u^{(1)}+O (\epsilon ^2 )$

, we solve for the first-order velocity

![]() $\tilde {u}^{(1)}$

(see Appendix D) as

$\tilde {u}^{(1)}$

(see Appendix D) as

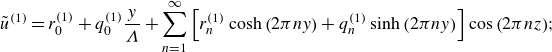

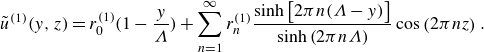

\begin{equation} \tilde {u}^{(1)}=r_0^{(1)} +q_0^{(1)}\frac {y}{\Lambda }+\sum _{n=1}^{\infty }\left [r_n^{(1)} \cosh \left (2\pi n y\right )+q_n^{(1)} \sinh \left (2\pi n y\right )\right ] \cos \left (2\pi n z\right )\!; \end{equation}

\begin{equation} \tilde {u}^{(1)}=r_0^{(1)} +q_0^{(1)}\frac {y}{\Lambda }+\sum _{n=1}^{\infty }\left [r_n^{(1)} \cosh \left (2\pi n y\right )+q_n^{(1)} \sinh \left (2\pi n y\right )\right ] \cos \left (2\pi n z\right )\!; \end{equation}

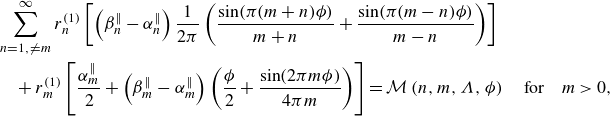

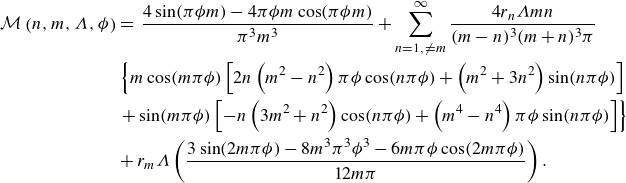

the coefficients

![]() $r_0^{(0)}$

,

$r_0^{(0)}$

,

![]() $r_n^{(0)}$

,

$r_n^{(0)}$

,

![]() $r_0^{(1)}$

, and

$r_0^{(1)}$

, and

![]() $r_n^{(1)}$

can be obtained numerically. Consequently, the total flow rate

$r_n^{(1)}$

can be obtained numerically. Consequently, the total flow rate

![]() $Q$

can be calculated as

$Q$

can be calculated as

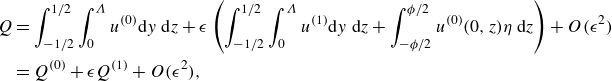

\begin{equation} \begin{aligned} Q & =\int _{-1/2}^{ 1/2} \int _{0}^{\Lambda } u^{(0)} \textrm{d} y \textrm{\ d} z+\epsilon \left (\int _{-1/2}^{ 1/2} \int _{0}^{\Lambda } u^{(1)} \textrm{d} y \textrm{\ d} z+\int _{-\phi /2}^{\phi /2} u^{(0)}(0, z) \eta \textrm{\ d} z\right )+O(\epsilon ^2) \\ &=Q^{(0)}+\epsilon Q^{(1)}+O(\epsilon ^2), \end{aligned} \end{equation}

\begin{equation} \begin{aligned} Q & =\int _{-1/2}^{ 1/2} \int _{0}^{\Lambda } u^{(0)} \textrm{d} y \textrm{\ d} z+\epsilon \left (\int _{-1/2}^{ 1/2} \int _{0}^{\Lambda } u^{(1)} \textrm{d} y \textrm{\ d} z+\int _{-\phi /2}^{\phi /2} u^{(0)}(0, z) \eta \textrm{\ d} z\right )+O(\epsilon ^2) \\ &=Q^{(0)}+\epsilon Q^{(1)}+O(\epsilon ^2), \end{aligned} \end{equation}

where

\begin{align}&\qquad\qquad\qquad\qquad\quad Q^{(0)} = -\frac {dP}{dx}\left [\frac {{\Lambda }^3}{12}+\frac {{\Lambda }^2r_0^{(0)}}{4}\right ], \end{align}

\begin{align}&\qquad\qquad\qquad\qquad\quad Q^{(0)} = -\frac {dP}{dx}\left [\frac {{\Lambda }^3}{12}+\frac {{\Lambda }^2r_0^{(0)}}{4}\right ], \end{align}

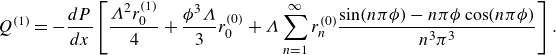

\begin{align}& Q^{(1)} = -\frac {dP}{dx}\left [\frac {{\Lambda }^2r_0^{(1)}}{4}+ \frac {\phi ^3\Lambda }{3}r_0^{(0)}+\Lambda \sum _{n=1}^{\infty } r_n^{(0)} \frac {\sin (n\pi \phi )-n\pi \phi \cos (n\pi \phi )}{n^3\pi ^3} \right ]. \end{align}

\begin{align}& Q^{(1)} = -\frac {dP}{dx}\left [\frac {{\Lambda }^2r_0^{(1)}}{4}+ \frac {\phi ^3\Lambda }{3}r_0^{(0)}+\Lambda \sum _{n=1}^{\infty } r_n^{(0)} \frac {\sin (n\pi \phi )-n\pi \phi \cos (n\pi \phi )}{n^3\pi ^3} \right ]. \end{align}

Based on

![]() $Q=-\partial _xP\Lambda ^3/12+Q_d = -\partial _xP\Lambda ^3/12 -\partial _xP\Lambda ^3\lambda /(4\Lambda +4\lambda )$

, the slip length

$Q=-\partial _xP\Lambda ^3/12+Q_d = -\partial _xP\Lambda ^3/12 -\partial _xP\Lambda ^3\lambda /(4\Lambda +4\lambda )$

, the slip length

![]() $\lambda _{\parallel, c}$

along the curved interface is

$\lambda _{\parallel, c}$

along the curved interface is

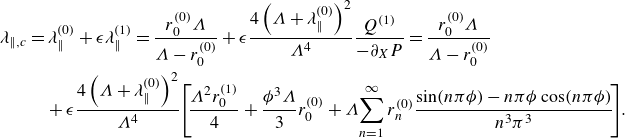

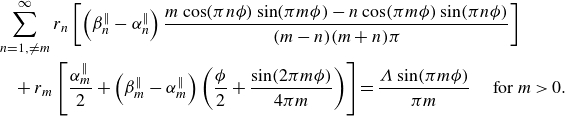

\begin{equation} \begin{aligned} \lambda _{\parallel, c} &= \lambda _{\parallel }^{(0)} + \epsilon \lambda _{\parallel }^{(1)} = \frac {r_0^{(0)}\Lambda }{\Lambda - r_0^{(0)}} + \epsilon \frac {4\left (\Lambda + \lambda _{\parallel }^{(0)}\right )^2}{{\Lambda }^4}\frac {Q^{(1)}}{-\partial _X P} = \frac {r_0^{(0)}\Lambda }{\Lambda - r_0^{(0)}} \\ & \quad + \epsilon \frac {4\left (\Lambda + \lambda _{\parallel }^{(0)}\right )^2}{{\Lambda }^4}\!\left [ \! \frac {{\Lambda }^2 r_0^{(1)}}{4} + \frac {\phi ^3 \Lambda }{3} r_0^{(0)} + \Lambda \! \sum _{n=1}^{\infty } r_n^{(0)} \frac {\sin (n\pi \phi )-n\pi \phi \cos (n\pi \phi )}{n^3\pi ^3} \! \right ]\!. \end{aligned} \end{equation}

\begin{equation} \begin{aligned} \lambda _{\parallel, c} &= \lambda _{\parallel }^{(0)} + \epsilon \lambda _{\parallel }^{(1)} = \frac {r_0^{(0)}\Lambda }{\Lambda - r_0^{(0)}} + \epsilon \frac {4\left (\Lambda + \lambda _{\parallel }^{(0)}\right )^2}{{\Lambda }^4}\frac {Q^{(1)}}{-\partial _X P} = \frac {r_0^{(0)}\Lambda }{\Lambda - r_0^{(0)}} \\ & \quad + \epsilon \frac {4\left (\Lambda + \lambda _{\parallel }^{(0)}\right )^2}{{\Lambda }^4}\!\left [ \! \frac {{\Lambda }^2 r_0^{(1)}}{4} + \frac {\phi ^3 \Lambda }{3} r_0^{(0)} + \Lambda \! \sum _{n=1}^{\infty } r_n^{(0)} \frac {\sin (n\pi \phi )-n\pi \phi \cos (n\pi \phi )}{n^3\pi ^3} \! \right ]\!. \end{aligned} \end{equation}

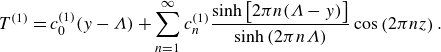

2.4. A one-dimensional description of CCM with slip

The velocity slip length

![]() $\lambda \equiv \lambda ^*/l^*$

and temperature slip length

$\lambda \equiv \lambda ^*/l^*$

and temperature slip length

![]() $\lambda _{t}\equiv \lambda _t^*/l^*$

, describing average effects from the mixed boundary conditions of the two-dimensional problem, enable us to simplify the CCM problem into an effective one-dimensional problem describing flow and heat exchange along the direction of liquid flow, shown in the schematic diagram in figure 1(f), where the notation

$\lambda _{t}\equiv \lambda _t^*/l^*$

, describing average effects from the mixed boundary conditions of the two-dimensional problem, enable us to simplify the CCM problem into an effective one-dimensional problem describing flow and heat exchange along the direction of liquid flow, shown in the schematic diagram in figure 1(f), where the notation

![]() $ \bar {()}$

implies that the variables are averaged in the

$ \bar {()}$

implies that the variables are averaged in the

![]() $z$

direction. The corresponding governing equations (2.4a

), (2.4b

), (2.4e

) and (2.4f

) can be replaced, respectively, by

$z$

direction. The corresponding governing equations (2.4a

), (2.4b

), (2.4e

) and (2.4f

) can be replaced, respectively, by

Hence, the corresponding boundary conditions in figure 1(f) are

It is worth noting that the upper velocity boundary

![]() $\bar v(X,h)$

is derived from

$\bar v(X,h)$

is derived from

![]() $\bar v^*(x^*,h^*) = \rho \partial _{t^*} H^* - \partial _{ t^*} h^*$

based on mass conservation at the melting front.

$\bar v^*(x^*,h^*) = \rho \partial _{t^*} H^* - \partial _{ t^*} h^*$

based on mass conservation at the melting front.

The velocity profile

![]() $\bar u(X,Y)$

can be obtained by integrating (2.41b

) twice with respect to

$\bar u(X,Y)$

can be obtained by integrating (2.41b

) twice with respect to

![]() $Y$

and applying boundary conditions (2.42a

), yielding

$Y$

and applying boundary conditions (2.42a

), yielding

where

![]() $ h/l = \Lambda$

. Then, substituting (2.43) into the continuity equation (2.41a

) and integrating along

$ h/l = \Lambda$

. Then, substituting (2.43) into the continuity equation (2.41a

) and integrating along

![]() $y$

from 0 to

$y$

from 0 to

![]() $h$

leads to

$h$

leads to

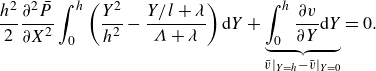

\begin{equation} \frac {h^2}{2}\frac {\partial ^2 \bar P}{\partial X^2}\int _{0}^{h}\left (\frac {Y^2}{h^2}-\frac {Y/l+\lambda }{\Lambda +\lambda }\right ) {\textrm d}Y+ \underbrace {\int _{0}^{h}\frac {\partial v}{\partial Y} {\textrm d}Y}_{\bar v|_{Y=h}-\bar v|_{Y=0}}=0. \end{equation}

\begin{equation} \frac {h^2}{2}\frac {\partial ^2 \bar P}{\partial X^2}\int _{0}^{h}\left (\frac {Y^2}{h^2}-\frac {Y/l+\lambda }{\Lambda +\lambda }\right ) {\textrm d}Y+ \underbrace {\int _{0}^{h}\frac {\partial v}{\partial Y} {\textrm d}Y}_{\bar v|_{Y=h}-\bar v|_{Y=0}}=0. \end{equation}

Noting that

![]() $\bar v(X,h) \approx \textrm{St} \partial _\tau \varDelta /(\textrm{Pe}\mathscr{h}^2)$

due to the typical property

$\bar v(X,h) \approx \textrm{St} \partial _\tau \varDelta /(\textrm{Pe}\mathscr{h}^2)$

due to the typical property

![]() $\rho -1 \lt {O}(10^{-1})$

, then substituting (2.42c

) into (2.44) leads to

$\rho -1 \lt {O}(10^{-1})$

, then substituting (2.42c

) into (2.44) leads to

The pressure distribution can be obtained by integrating (2.45) twice with respect to

![]() $x$

, and using conditions (2.42d

), to obtain

$x$

, and using conditions (2.42d

), to obtain

Then, we can substitute (2.46) into the force balance (2.5) to obtain a relationship between

![]() $\varDelta$

and

$\varDelta$

and

![]() $h$

:

$h$

:

The temperature profile can be obtained by substituting (2.42b ) into (2.41c ), yielding

Substitution of (2.48) into (2.41d ) gives

The combination of (2.47) and (2.49) leads to

Equations (2.49) and (2.50) are coupled expressions between the solid height

![]() $\varDelta (\tau )$

that remains and the film thickness

$\varDelta (\tau )$

that remains and the film thickness

![]() $h$

. Note that because of the definition

$h$

. Note that because of the definition

![]() $\Lambda =h/l$

where

$\Lambda =h/l$

where

![]() $l$

is fixed,

$l$

is fixed,

![]() $h$

varies with

$h$

varies with

![]() $\tau$

.

$\tau$

.

Recalling

![]() $\mathscr{h}=h_0^*/L^*$

and

$\mathscr{h}=h_0^*/L^*$

and

![]() $h=h^*/h_0^*$

in (2.1) indicates that

$h=h^*/h_0^*$

in (2.1) indicates that

![]() $h_0^*$

has not been specified. Usually, the initial height satisfies

$h_0^*$

has not been specified. Usually, the initial height satisfies

![]() $ H_0^* \gg h^*$

(i.e.

$ H_0^* \gg h^*$

(i.e.

![]() $\varDelta \approx H$

) and we can further find a characteristic initial film thickness

$\varDelta \approx H$

) and we can further find a characteristic initial film thickness

![]() $h_0^*$

that satisfies the

$h_0^*$

that satisfies the

![]() $\textrm{St}/\textrm{Pe}\mathscr{h}^2=1$

, corresponding to the initial solid height

$\textrm{St}/\textrm{Pe}\mathscr{h}^2=1$

, corresponding to the initial solid height

![]() $H=1$

and no-slip surface

$H=1$

and no-slip surface

![]() $\lambda =\lambda _t=0$

. This enables us to define

$\lambda =\lambda _t=0$

. This enables us to define

![]() $h_0^*$

as

$h_0^*$

as

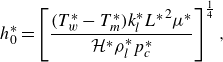

\begin{equation} h_0^* = \left [\frac {(T_w^*-T_m^*)k_l^*{L^*}^2\mu ^*}{\mathcal{H}^*\rho _l^*p_c^*}\right ]^{\frac {1}{4}}, \end{equation}

\begin{equation} h_0^* = \left [\frac {(T_w^*-T_m^*)k_l^*{L^*}^2\mu ^*}{\mathcal{H}^*\rho _l^*p_c^*}\right ]^{\frac {1}{4}}, \end{equation}

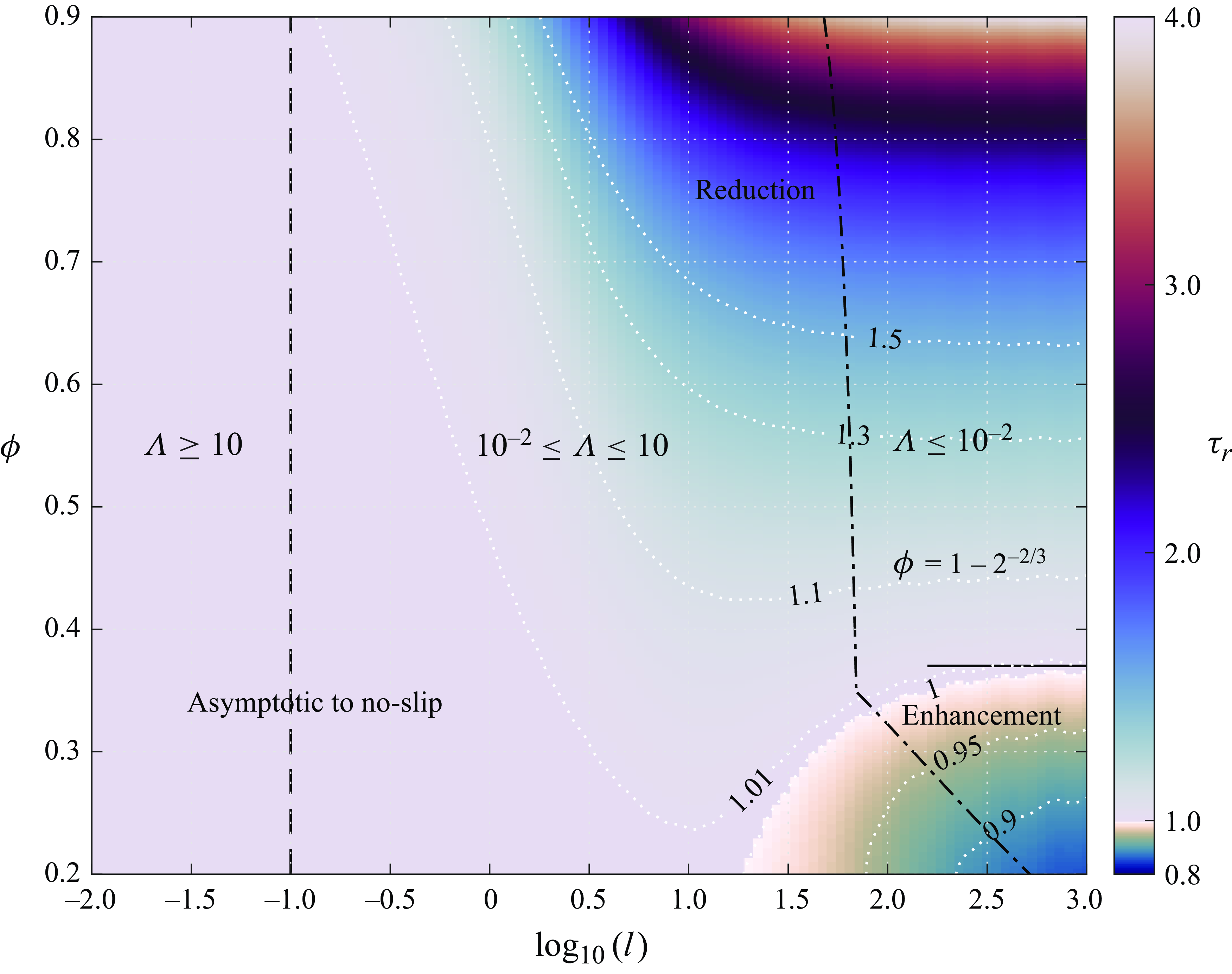

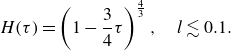

from which (2.50) and (2.49) are transformed into the equations (

![]() $\Lambda =h/l$

)

$\Lambda =h/l$

)

Based on (2.52a

), we can conclude that a constant film thickness

![]() $h$

is maintained for the constant-pressure mode (

$h$

is maintained for the constant-pressure mode (

![]() $\mathscr{c}=0$

) though

$\mathscr{c}=0$

) though

![]() $\lambda$

and

$\lambda$

and

![]() $\lambda _t$

are dependent on

$\lambda _t$

are dependent on

![]() $h$

. On the other hand, for the gravity-driven mode (

$h$

. On the other hand, for the gravity-driven mode (

![]() $\mathscr{c}=1$

) there is a coupling between

$\mathscr{c}=1$

) there is a coupling between

![]() $h$

and

$h$

and

![]() $H$

, making the solutions of

$H$

, making the solutions of

![]() $H(\tau )$

and

$H(\tau )$

and

![]() $h(\tau )$

complicated.

$h(\tau )$

complicated.

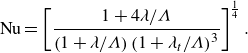

Furthermore, we introduce the Nusselt number,

![]() $\textrm{Nu}$

, based on the instantaneous height of the liquid film

$\textrm{Nu}$

, based on the instantaneous height of the liquid film

![]() $h^*(t^*)$

, to demonstrate the heat transfer capability under different conditions.

$h^*(t^*)$

, to demonstrate the heat transfer capability under different conditions.

![]() $\textrm{Nu}$

is defined as

$\textrm{Nu}$

is defined as

At this stage, we have completed all of the analysis of the thin-film flow and heat transfer necessary for modelling CCM processes, which may be enhanced using a corrugated substrate. The main variables that dictate performance are the slip lengths

![]() $\lambda$

and

$\lambda$

and

![]() $\lambda _t$

, geometric ratios

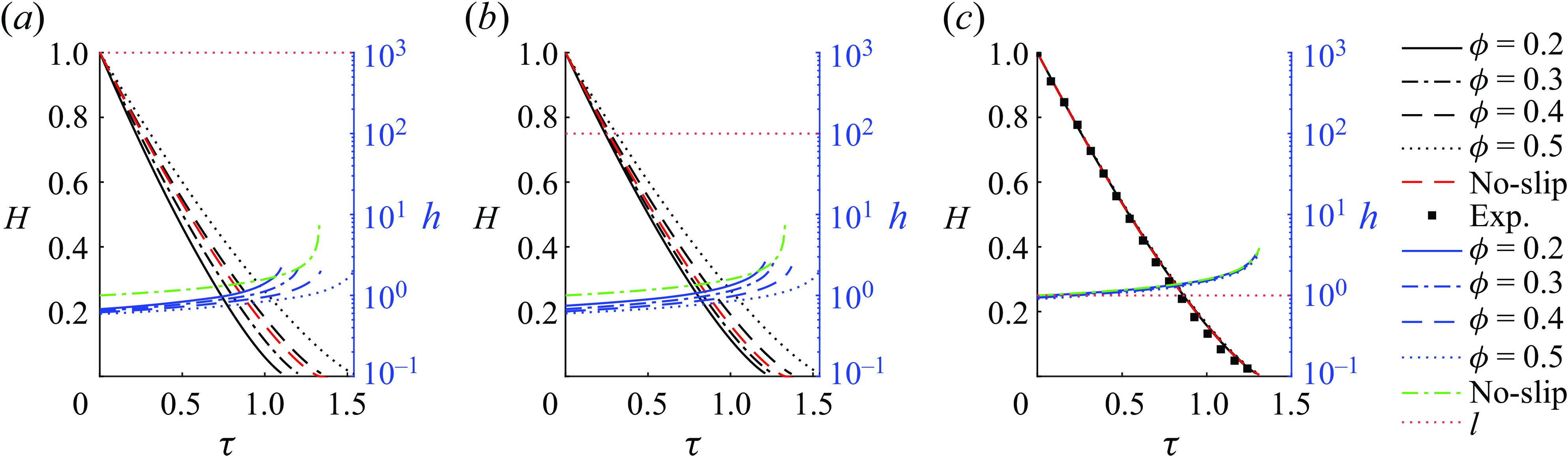

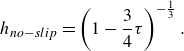

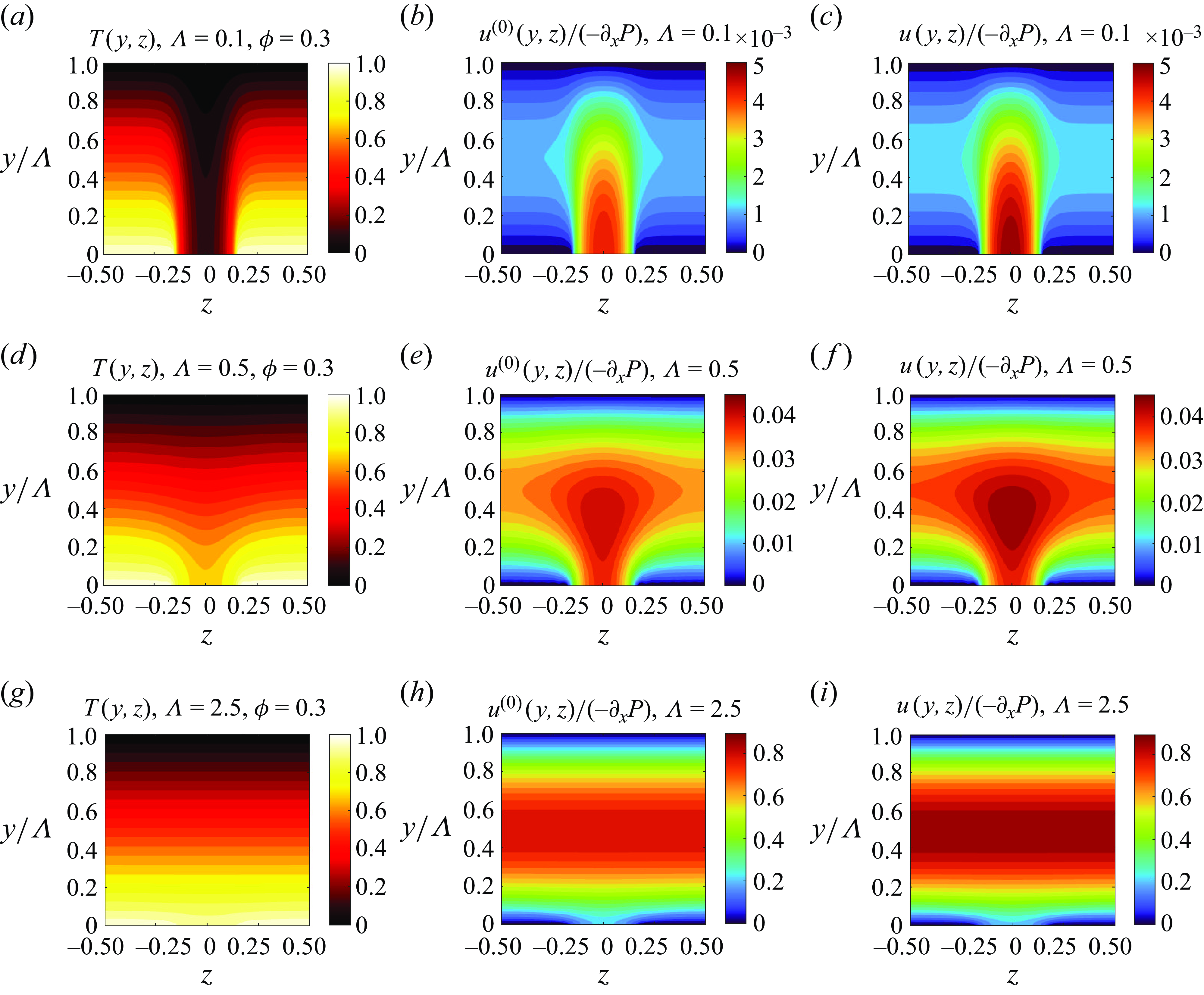

$\lambda _t$