1. Introduction

Optical fibres form a critical component of the modern interconnected world in which information must be transmitted over extremely long distances and at high speeds in a secure and reliable way. In recent years the use of microstructured optical fibres (MOFs) has become significant in a number of applications (Pal Reference Pal2010; Chen et al. Reference Chen, Stokes, Buchak, Crowdy and Ebendorff-Heidepriem2016; Liu et al. Reference Liu, Tam, Htein, Tse and Lu2017). Such MOFs are fibres that contain an array of air holes that run parallel to the axis of the fibre. The air holes modify the optical transmission properties and allow for fibres with highly customisable optical properties that are extremely valuable in a number of important applications. These include micro-electrode fabrication (Puil et al. Reference Puil, Huang, Miura and Ireland2003; Huang et al. Reference Huang, Wylie, Miura and Howell2007), microscopy fabrication (Gallacchi et al. Reference Gallacchi, Kölsch, Kneppe and Meixner2001) and high-accuracy sensing (Xue et al. Reference Xue, Liu, Lu, Xia, Wu and Fu2023). The optical properties are highly sensitive to small deviations in the hole geometry, and it is therefore extremely important to have a very carefully controlled fabrication process.

The most common method for fabricating fibres is by taking a relatively large preform with a hole structure and stretching it so as to reduce the cross-sectional area by factors of up to 10 000 times. For Newtonian materials, in the absence of surface tension, theoretical results have shown that the stretching process will precisely reduce the relative size of the thread whilst maintaining the geometry (Dewynne, Howell & Wilmott Reference Dewynne, Howell and Wilmott1994). However, in real-world applications surface tension effects are non-negligible and this can cause significant deviations in the shapes and positions of the hole structures. This is particularly critical in the production of MOFs, as the optical properties are highly sensitive to the hole geometry. In some cases, some of the holes may even close. Pressurising air channels can be used to prevent this but also causes geometry changes and may cause holes to burst (Chen et al. Reference Chen, Stokes, Buchak, Crowdy and Ebendorff-Heidepriem2016). Therefore, one needs to take into account the effects of surface tension and pressure to ensure that the desired hole structure is achieved in the extended fibre. Another important issue in the fabrication process is that the drawing of threads is subject to an oscillatory instability, known as draw resonance, which causes non-uniformities in the axial thread profiles (Denn Reference Denn1980). If severe, this will render an optical fibre not fit for purpose. Suppressing instabilities of this type is therefore a critical aspect of fibre fabrication.

In the case of MOFs, Chen et al. (Reference Chen, Stokes, Buchak, Crowdy and Ebendorff-Heidepriem2015, Reference Chen, Stokes, Buchak, Crowdy and Ebendorff-Heidepriem2016) showed that surface tension can dramatically affect the sizes and shapes of the holes and their experiments demonstrated that the hole dynamics can be extremely difficult to control. Their experiments were performed using glass materials that are well approximated as being Newtonian. In fact, most MOFs are made from glass materials, but there has been growing interest in using polymer materials for fibre production. Early experiments using polymeric materials were conducted by Demay & Agassant (Reference Demay and Agassant1985) who investigated the draw resonance phenomenon for fibres without holes under nearly isothermal conditions using four different polyesters. The experimental findings are in accordance with non-isothermal and viscoelastic computations and demonstrated that an increase in viscoelastic properties leads to enhanced stability. More recently there have been numerous experimental studies that examined various characteristics of drawing using polymeric materials (Van Eijkelenborg et al. Reference Van2001; Large et al. Reference Large, Poladian, Barton and van Eijkelenborg2008; Argyros Reference Argyros2013; Gierej et al. 2022). Polymer fibres offer advantages such as lower processing temperatures and ease of preform creation, and a wide range of polymers have been found suitable for the fabrication process. Unlike glass materials, polymer materials can exhibit significant viscoelasticity. This leads to the question of whether viscoelastic polymeric materials can be utilised to better achieve the manufacturing goals of preserving internal hole structures and controlling instabilities. Hence, a motivation of this work is to determine how elastic effects can be leveraged to improve the fabrication process for the drawing of ‘holey’ fibres and other related applications.

The drawing of threads has an extensive history dating back to Matovich & Pearson (Reference Matovich and Pearson1969) who considered the drawing of a Newtonian solid thread (with no holes) and determined the criteria for instability. Shah & Pearson (Reference Shah and Pearson1972) proposed a generalised theoretical model by considering the effects of inertia, gravity and surface tension, along with thermal effects. It turns out that the interaction between the various physical effects gives rise to complicated and very rich dynamics that has been studied by a number of authors (Geyling Reference Geyling1976; Geyling & Homsy Reference Geyling and Homsy1980; Cummings & Howell Reference Cummings and Howell1999; Forest & Zhou Reference Forest and Zhou2001; Wylie, Huang & Miura Reference Wylie, Huang and Miura2007; Suman & Kumar Reference Suman and Kumar2009; Taroni et al. Reference Taroni, Breward, Cummings and Griffiths2013; Bechert & Scheid Reference Bechert and Scheid2017; Philippi et al. Reference Philippi, Bechert, Chouffart, Waucquez and Scheid2022). All of these works considered Newtonian solid threads with no internal holes.

The dynamics of drawing solid threads composed of viscoelastic fluids has also been widely investigated. Denn, Petrie & Avenas (Reference Denn, Petrie and Avenas1975) neglected surface tension and inertia, proposed approximate equations and obtained the steady-state solutions for a thread composed of a generalised Maxwell material. Fisher & Denn (Reference Fisher and Denn1976) extended the study by including the deformation-rate dependency of polymeric materials (White–Metzner model) and performed a linear stability analysis. Jung & Hyun (Reference Jung and Hyun1999) developed a simple approximate method for determining the stability threshold for a viscoelastic solid thread, and the mechanism for draw resonance was discussed by Hyun et al. (Reference Hyun1999). Park (Reference Park1990) considered the steady drawing process of a two-phase compound fibre, in which the core is a Newtonian fluid surrounded by a sheath layer that is modelled as a weakly upper-convected Maxwell fluid. Lee & Park (Reference Lee and Park1995) studied the stability of this type of flow. Gupta & Chokshi (Reference Gupta and Chokshi2017) considered the linear stability of a compound fibre whose core is described using the extended pom-pom (XPP) model and whose sheath layer is described using the upper-convected Maxwell model. Under non-isothermal drawing, Zhou & Kumar (Reference Zhou and Kumar2010) investigated the steady state and linear stability of the non-isothermal drawing of viscoelastic fibres whose viscosity varies with temperature. Zhou et al. (Reference Zhou, Tan, Janakiraman and Kumar2011) examined the melt-blowing process of viscoelastic materials modelled under varying temperature conditions, performing linear stability and sensitivity analyses. Gupta & Chokshi (Reference Gupta and Chokshi2018) considered the stability of the drawing of a polymeric fluid described by the XPP model in the presence of thermal effects. Nevertheless, they argued that, for small-air-gap flows the role of thermal effects in stability is negligible (Demay & Agassant Reference Demay and Agassant1985; Gupta & Chokshi Reference Gupta and Chokshi2015). In fact, there are many works considering various aspects of the drawing of viscoelastic threads: Van der Walt et al. (Reference Van der Walt, Hulsen, Bogaerds, Meijer and Bulters2012) considered generalised boundary conditions and Gupta & Chokshi (Reference Gupta and Chokshi2015) performed a weakly nonlinear analysis. All of these studies involved fluid flows with no internal holes.

Early work on the drawing of Newtonian threads with holes was performed by Pearson & Petrie (Reference Pearson and Petrie1970a ,Reference Pearson and Petrie b ). Subsequently, Fitt et al. (2001, 2002) derived an asymptotic mathematical model for the drawing of axisymmetric threads with an internal hole. They showed that there are negligible leading-order pressure gradients in the radial direction and so similar mathematical techniques to those used in the case of a solid thread could be used. Griffiths & Howell (2007, 2008) and Stokes et al. (Reference Stokes, Buchak, Crowdy and Ebendorff-Heidepriem2014) developed a general mathematical framework for analysing non-axisymmetric threads. This was generalised to include internal pressurisation of holes (Chen et al. Reference Chen, Stokes, Buchak, Crowdy and Ebendorff-Heidepriem2015) and thermal effects (Stokes, Wylie & Chen Reference Stokes, Wylie and Chen2019). To our best knowledge, there are very few studies that consider the draw resonance instability of threads with internal hole structure. Only very recently, Wylie et al. (Reference Wylie, Papri, Stokes and He2023) studied the draw resonance instability of MOFs with internal holes. All of these works are for Newtonian fluids.

Despite the extensive work on the drawing of Newtonian threads with holes, there has been no systematic derivation or examination of viscoelastic threads with holes. At first sight, this seems to be perplexing until one realises that in the case of viscoelastic threads there are capillary forces acting on the inside of the holes that induce pressure gradients in the radial direction that are not present in the Newtonian case. These radial pressure gradients introduce complicated feedback mechanisms between the axial and perpendicular flows that fundamentally modify the rate at which holes close and the stability characteristics of the flow. In fact, we will show that these radial pressure gradients are crucial to understanding the role that viscoelasticity plays. From a technical viewpoint the radial pressure gradients prevent one from applying the techniques used by previous authors such as Fitt et al. (Reference Fitt, Furusawa, Monro and Please2001) and Stokes et al. (Reference Stokes, Wylie and Chen2019). Nevertheless, we adopt the Giesekus constitutive model (Giesekus Reference Giesekus1982) and derive asymptotic long-wave equations that allow us to determine how weakly viscoelastic effects modify the Newtonian flow. Elastic effects are known to hinder the surface-tension-driven pinching that occurs in threads without holes (Entov & Hinch Reference Entov and Hinch1997; Li & Fontelos Reference Li and Fontelos2003). Therefore, it seems reasonable that elastic stresses should oppose any inward radial flow generated by surface tension and hence act to reduce hole closure during the drawing process. However, surprisingly, we show that elasticity typically tends to induce more rapid hole closure. On the other hand, the opposite is true if the tube has a sufficiently thin wall at the inlet nozzle of the device or if the axial stretching is sufficiently weak. By carefully examining the expressions for the hole size at the take-up point we explain how the second normal stress difference induced by elastic effects modifies the hole evolution process. Furthermore, we consider the draw resonance instability and determine whether elastic effects stabilise or destabilise the drawing process. We show that if inertia is negligible then elastic effects always act to destabilise the flow. However, for non-zero inertia, elastic effects can be either stabilising or destabilising depending on the surface tension, inlet hole size and parameters that describe the constitutive behaviour.

The paper is structured as follows. Section 2 presents the model formulation and derives the governing equations using the assumption of a slender tube. Section 3 explores the weakly elastic limit and derives the long-wave nonlinear system that describes the drawing of an axisymmetric tube made of a viscoelastic fluid. Section 4 discusses the steady-state profiles and explains how elasticity influences hole evolution. Section 5 conducts a linear stability analysis to assess the impact of elasticity on the stability of the drawing process. Finally, § 6 provides a discussion of the results.

2. Model formulation

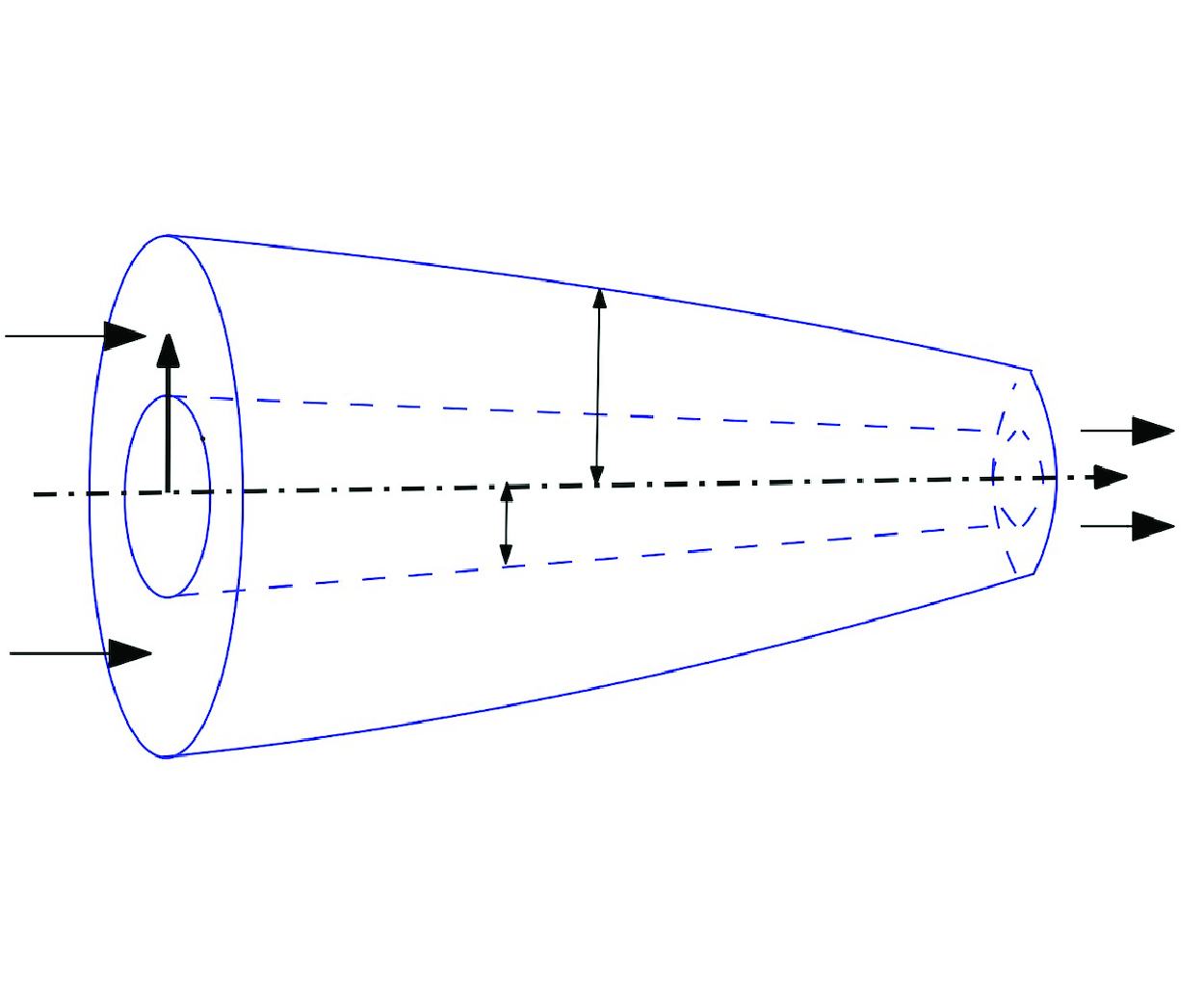

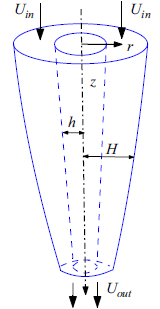

Figure 1. Schematic of the drawing process for a viscoelastic tube.

We consider a slender axisymmetric tube composed of a viscoelastic incompressible fluid. This fluid is fed through a nozzle of a drawing device with a constant velocity

![]() $U_{in}$

. At the nozzle the outer radius is denoted by

$U_{in}$

. At the nozzle the outer radius is denoted by

![]() $H_{in}$

, and the inner one by

$H_{in}$

, and the inner one by

![]() $h_{in}$

. We define

$h_{in}$

. We define

![]() $\phi =h_{in}/H_{in}$

to be the ratio of the inner to the outer radius at the input nozzle with

$\phi =h_{in}/H_{in}$

to be the ratio of the inner to the outer radius at the input nozzle with

![]() $0\lt \phi \lt 1$

. At a distance

$0\lt \phi \lt 1$

. At a distance

![]() $L$

from the nozzle, the tube is pulled by a take-up roller such that the tube has a speed

$L$

from the nozzle, the tube is pulled by a take-up roller such that the tube has a speed

![]() $U_{out}$

. Our focus in the present work is the flow from the inlet nozzle (

$U_{out}$

. Our focus in the present work is the flow from the inlet nozzle (

![]() $z=0$

) to the take-up point (

$z=0$

) to the take-up point (

![]() $z=L$

). For simplicity we do not consider pressurisation of the air channel, although it is straightforward to generalise. In what follows,

$z=L$

). For simplicity we do not consider pressurisation of the air channel, although it is straightforward to generalise. In what follows,

![]() $z$

is the distance measured along the axis of the tube,

$z$

is the distance measured along the axis of the tube,

![]() $r$

is the distance measured radially outward from the axis of the tube,

$r$

is the distance measured radially outward from the axis of the tube,

![]() $\theta$

is the azimuthal coordinate and

$\theta$

is the azimuthal coordinate and

![]() $t$

is the time. The inner and outer radii of the tube are denoted by

$t$

is the time. The inner and outer radii of the tube are denoted by

![]() $h(z, t)$

and

$h(z, t)$

and

![]() $H(z,t)$

, respectively, as shown in figure 1. The fluid has a velocity field

$H(z,t)$

, respectively, as shown in figure 1. The fluid has a velocity field

![]() $\textbf{u}=(v, 0, u)$

in cylindrical coordinates, where

$\textbf{u}=(v, 0, u)$

in cylindrical coordinates, where

![]() $v,\ 0$

and

$v,\ 0$

and

![]() $u$

are the velocity components in the

$u$

are the velocity components in the

![]() $r,\ \theta$

and

$r,\ \theta$

and

![]() $z$

directions, respectively.

$z$

directions, respectively.

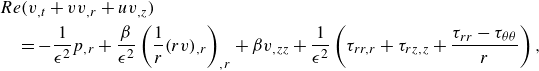

The equations for the fluid tube are given by conservation of mass and momentum:

where a comma is used to represent partial derivative with respect to the letter following the comma,

![]() $\boldsymbol{\nabla }$

is the differential operator given by

$\boldsymbol{\nabla }$

is the differential operator given by

![]() $\boldsymbol{\nabla }=(\partial _r, \partial _\theta /r, \partial _z)$

in cylindrical coordinates,

$\boldsymbol{\nabla }=(\partial _r, \partial _\theta /r, \partial _z)$

in cylindrical coordinates,

![]() $\rho$

is the density and

$\rho$

is the density and

![]() $\boldsymbol{\sigma }$

is the total stress tensor. We assume that the viscoelasticity in the fluid arises from polymers that are dissolved in a Newtonian solvent and adopt the Giesekus model (Giesekus Reference Giesekus1982). Therefore, the stress tensor

$\boldsymbol{\sigma }$

is the total stress tensor. We assume that the viscoelasticity in the fluid arises from polymers that are dissolved in a Newtonian solvent and adopt the Giesekus model (Giesekus Reference Giesekus1982). Therefore, the stress tensor

![]() $\boldsymbol{\sigma }$

satisfies the following constitutive relation:

$\boldsymbol{\sigma }$

satisfies the following constitutive relation:

where

![]() $p$

is the pressure,

$p$

is the pressure,

![]() $\textbf{I}$

is the identity matrix,

$\textbf{I}$

is the identity matrix,

![]() $\textbf{D}=(\boldsymbol{\nabla }\textbf{u}+(\boldsymbol{\nabla }\textbf{u})^\intercal)/2$

is the strain-rate tensor,

$\textbf{D}=(\boldsymbol{\nabla }\textbf{u}+(\boldsymbol{\nabla }\textbf{u})^\intercal)/2$

is the strain-rate tensor,

![]() $\eta _s$

is the viscosity of the solvent,

$\eta _s$

is the viscosity of the solvent,

![]() $\eta _p$

is the viscosity of the polymer,

$\eta _p$

is the viscosity of the polymer,

![]() $\boldsymbol{\tau }$

is the polymer stress tensor and

$\boldsymbol{\tau }$

is the polymer stress tensor and

![]() $\lambda$

is the relaxation time for the polymer. The parameter

$\lambda$

is the relaxation time for the polymer. The parameter

![]() $\alpha$

is the mobility factor which is dimensionless and represents the importance of the quadratic term in the constitutive law (2.4). In the case of

$\alpha$

is the mobility factor which is dimensionless and represents the importance of the quadratic term in the constitutive law (2.4). In the case of

![]() $\alpha =0$

, the Giesekus model reduces to the Oldroyd-B model (Oldroyd Reference Oldroyd1950). For

$\alpha =0$

, the Giesekus model reduces to the Oldroyd-B model (Oldroyd Reference Oldroyd1950). For

![]() $\alpha =0$

and

$\alpha =0$

and

![]() $\eta _s=0$

, the Giesekus model reduces to the upper-convected Maxwell model. One well-known drawback of the Oldroyd-B and upper-convected Maxwell models is that they can give rise to infinite stresses at finite elongational rates (Bird, Armstrong & Hassager Reference Bird, Armstrong and Hassager1987; Renardy Reference Renardy2000; Tanner Reference Tanner2000; Evans, Palhares Junior & Oishi Reference Evans, Palhares Junior and Oishi2017). The Giesekus model removes this unphysical feature by adding a term that is quadratic in the stress tensor into the constitutive relation. We note that

$\eta _s=0$

, the Giesekus model reduces to the upper-convected Maxwell model. One well-known drawback of the Oldroyd-B and upper-convected Maxwell models is that they can give rise to infinite stresses at finite elongational rates (Bird, Armstrong & Hassager Reference Bird, Armstrong and Hassager1987; Renardy Reference Renardy2000; Tanner Reference Tanner2000; Evans, Palhares Junior & Oishi Reference Evans, Palhares Junior and Oishi2017). The Giesekus model removes this unphysical feature by adding a term that is quadratic in the stress tensor into the constitutive relation. We note that

![]() $\alpha$

should be smaller than

$\alpha$

should be smaller than

![]() $0.5$

to avoid a non-monotonic dependence of the shear stress on the shear rate in simple shear flows (Morozov & Spagnolie Reference Morozov and Spagnolie2015). In the weakly viscoelastic regime, where the relaxation time is much shorter than the characteristic time of the flow, the Giesekus model simplifies to a type of second-order fluid model. This is achieved by expanding the polymer stress tensor in a series based on the relaxation time. In addition, for simple steady shear flow, the shear viscosity in the Giesekus model remains bounded for finite shear rates. For the simple steady extensional flow, the extensional viscosity and normal stress differences of the Giesekus model are also bounded for any finite extension rate. For further details, we refer the reader to Giesekus (Reference Giesekus1982), Barrow et al. (Reference Barrow, Brown, Cordy, Williams and Williams2004) and Minh (Reference Minh2023).

$0.5$

to avoid a non-monotonic dependence of the shear stress on the shear rate in simple shear flows (Morozov & Spagnolie Reference Morozov and Spagnolie2015). In the weakly viscoelastic regime, where the relaxation time is much shorter than the characteristic time of the flow, the Giesekus model simplifies to a type of second-order fluid model. This is achieved by expanding the polymer stress tensor in a series based on the relaxation time. In addition, for simple steady shear flow, the shear viscosity in the Giesekus model remains bounded for finite shear rates. For the simple steady extensional flow, the extensional viscosity and normal stress differences of the Giesekus model are also bounded for any finite extension rate. For further details, we refer the reader to Giesekus (Reference Giesekus1982), Barrow et al. (Reference Barrow, Brown, Cordy, Williams and Williams2004) and Minh (Reference Minh2023).

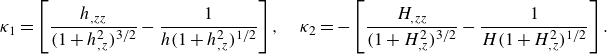

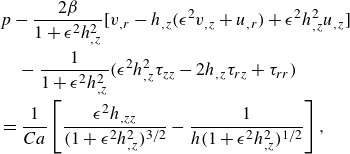

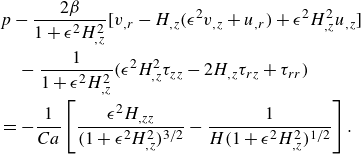

On the inner and outer surfaces of the tube, the dynamic boundary conditions are

Here,

![]() $\gamma$

is the surface tension and

$\gamma$

is the surface tension and

![]() $\kappa _1{\kern-1pt}$

and

$\kappa _1{\kern-1pt}$

and

![]() $\kappa _2$

are the mean curvatures of inner and outer surfaces, respectively, given by

$\kappa _2$

are the mean curvatures of inner and outer surfaces, respectively, given by

\begin{align} \kappa _1=\left [\frac {h_{,zz}}{(1+h_{,z}^2)^{3/2}}-\frac {1}{h(1+h_{,z}^2)^{1/2}}\right],\quad \kappa _2=-\left [\frac {H_{,zz}}{(1+H_{,z}^2)^{3/2}}-\frac {1}{H(1+H_{,z}^2)^{1/2}}\right]. \end{align}

\begin{align} \kappa _1=\left [\frac {h_{,zz}}{(1+h_{,z}^2)^{3/2}}-\frac {1}{h(1+h_{,z}^2)^{1/2}}\right],\quad \kappa _2=-\left [\frac {H_{,zz}}{(1+H_{,z}^2)^{3/2}}-\frac {1}{H(1+H_{,z}^2)^{1/2}}\right]. \end{align}

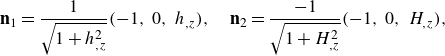

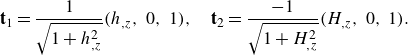

The vectors

![]() $\textbf{n}_i$

and

$\textbf{n}_i$

and

![]() $\textbf{t}_{i}$

$\textbf{t}_{i}$

![]() $(i=1,\ 2)$

are the unit vectors on the inner and outer surfaces in the normal and tangential directions, which are given by

$(i=1,\ 2)$

are the unit vectors on the inner and outer surfaces in the normal and tangential directions, which are given by

\begin{align} &\textbf{n}_1=\frac {1}{\sqrt {1+h_{,z}^2}}(-1,\ 0,\ h_{,z}),\quad \textbf{n}_2=\frac {-1}{\sqrt {1+H_{,z}^2}}(-1,\ 0,\ H_{,z}), \end{align}

\begin{align} &\textbf{n}_1=\frac {1}{\sqrt {1+h_{,z}^2}}(-1,\ 0,\ h_{,z}),\quad \textbf{n}_2=\frac {-1}{\sqrt {1+H_{,z}^2}}(-1,\ 0,\ H_{,z}), \end{align}

\begin{align} &\textbf{t}_1=\frac {1}{\sqrt {1+h_{,z}^2}}(h_{,z},\ 0,\ 1),\quad \textbf{t}_2=\frac {-1}{\sqrt {1+H_{,z}^2}}(H_{,z},\ 0,\ 1). \end{align}

\begin{align} &\textbf{t}_1=\frac {1}{\sqrt {1+h_{,z}^2}}(h_{,z},\ 0,\ 1),\quad \textbf{t}_2=\frac {-1}{\sqrt {1+H_{,z}^2}}(H_{,z},\ 0,\ 1). \end{align}

The kinematic boundary conditions are

At the inlet nozzle

![]() $z=0$

, the boundary conditions are

$z=0$

, the boundary conditions are

At the take-up point

![]() $z=L$

, the boundary condition is

$z=L$

, the boundary condition is

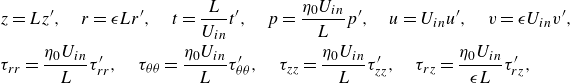

2.1. Scaling analysis and non-dimensionalisation

In this work, we consider a slender axisymmetric tube in which the typical radius is far less than the length, that is,

![]() $H_{in}\ll L$

, so that the dimensionless parameter

$H_{in}\ll L$

, so that the dimensionless parameter

![]() $\epsilon =H_{in}\sqrt {1-\phi ^2}/L$

is small. We then introduce the following scalings:

$\epsilon =H_{in}\sqrt {1-\phi ^2}/L$

is small. We then introduce the following scalings:

\begin{align} &z=Lz^\prime,\quad r=\epsilon L r^\prime,\quad t=\frac {L}{U_{in}}t^\prime,\quad p=\frac {\eta _0 U_{in}}{L}p^\prime,\quad u=U_{in} u^\prime,\quad v=\epsilon U_{in} v^\prime,\nonumber \\ &\tau _{rr}=\frac {\eta _0 U_{in}}{L}\tau ^\prime _{rr},\quad \tau _{\theta \theta }=\frac {\eta _0 U_{in}}{L}\tau ^\prime _{\theta \theta },\quad \tau _{zz}=\frac {\eta _0 U_{in}}{L}\tau ^\prime _{zz},\quad \tau _{rz}=\frac {\eta _0 U_{in}}{\epsilon L}\tau ^\prime _{rz}, \end{align}

\begin{align} &z=Lz^\prime,\quad r=\epsilon L r^\prime,\quad t=\frac {L}{U_{in}}t^\prime,\quad p=\frac {\eta _0 U_{in}}{L}p^\prime,\quad u=U_{in} u^\prime,\quad v=\epsilon U_{in} v^\prime,\nonumber \\ &\tau _{rr}=\frac {\eta _0 U_{in}}{L}\tau ^\prime _{rr},\quad \tau _{\theta \theta }=\frac {\eta _0 U_{in}}{L}\tau ^\prime _{\theta \theta },\quad \tau _{zz}=\frac {\eta _0 U_{in}}{L}\tau ^\prime _{zz},\quad \tau _{rz}=\frac {\eta _0 U_{in}}{\epsilon L}\tau ^\prime _{rz}, \end{align}

where

![]() $\eta _0=\eta _s+\eta _p$

is the bulk viscosity and

$\eta _0=\eta _s+\eta _p$

is the bulk viscosity and

![]() $\tau _{rr},\ \tau _{\theta \theta },\ \tau _{zz}$

and

$\tau _{rr},\ \tau _{\theta \theta },\ \tau _{zz}$

and

![]() $\tau _{rz}$

are the non-zero components of the polymer stress tensor

$\tau _{rz}$

are the non-zero components of the polymer stress tensor

![]() $\boldsymbol{\tau }$

. Substituting the scalings (2.14) into (2.1)–(2.7) and omitting the primes for convenience, we obtain the non-dimensional governing equations and boundary conditions, which are given in Appendix A. The non-dimensional parameters involved in the non-dimensional system are

$\boldsymbol{\tau }$

. Substituting the scalings (2.14) into (2.1)–(2.7) and omitting the primes for convenience, we obtain the non-dimensional governing equations and boundary conditions, which are given in Appendix A. The non-dimensional parameters involved in the non-dimensional system are

The parameter

![]() $\beta$

is the solvent to bulk viscosity ratio, with a range of

$\beta$

is the solvent to bulk viscosity ratio, with a range of

![]() $0\leqslant \beta \lt 1$

. For

$0\leqslant \beta \lt 1$

. For

![]() $\beta =0$

the fluid is composed entirely of polymers and there is no solvent. As

$\beta =0$

the fluid is composed entirely of polymers and there is no solvent. As

![]() $\beta$

approaches

$\beta$

approaches

![]() $1$

, the viscosity is dominated by the solvent viscosity and so the flow behaves like a purely Newtonian fluid. The Deborah number

$1$

, the viscosity is dominated by the solvent viscosity and so the flow behaves like a purely Newtonian fluid. The Deborah number

![]() $De$

is the ratio of the relaxation time to the characteristic time for fluid to flow through the device. The Reynolds number

$De$

is the ratio of the relaxation time to the characteristic time for fluid to flow through the device. The Reynolds number

![]() $Re$

quantifies the relative importance of inertial and viscous effects. In the present work, we concentrate on the weakly viscoelastic scenario in which

$Re$

quantifies the relative importance of inertial and viscous effects. In the present work, we concentrate on the weakly viscoelastic scenario in which

![]() $De\ll 1$

. We note that if

$De\ll 1$

. We note that if

![]() $De=0$

, (A1)–(A3) reduce to those for the Newtonian flow, with viscosity

$De=0$

, (A1)–(A3) reduce to those for the Newtonian flow, with viscosity

![]() $\eta _0=\eta _s+\eta _p$

. In addition,

$\eta _0=\eta _s+\eta _p$

. In addition,

![]() $Ca$

denotes the capillary number and quantifies the relative importance of viscous and surface tension forces. The draw ratio

$Ca$

denotes the capillary number and quantifies the relative importance of viscous and surface tension forces. The draw ratio

![]() $D$

represents the speed at the take-up point divided by the speed at the nozzle.

$D$

represents the speed at the take-up point divided by the speed at the nozzle.

Fibre drawing is a process that is performed using devices of very different sizes and using materials with dramatically different viscosities. This means that one typically has to consider a wide range of values for many of the parameters. The values of parameters within such flows can vary significantly based on the specific nature of the industrial process. Typically, the value of

![]() $\epsilon$

is relatively small, usually not exceeding

$\epsilon$

is relatively small, usually not exceeding

![]() $\mathcal{O}(10^{-1})$

but often much smaller. In scenarios involving drawing, the parameter

$\mathcal{O}(10^{-1})$

but often much smaller. In scenarios involving drawing, the parameter

![]() $D$

can reach values on the scale of

$D$

can reach values on the scale of

![]() $\mathcal{O}(10^3)$

or higher, whereas extrusion flows have values of

$\mathcal{O}(10^3)$

or higher, whereas extrusion flows have values of

![]() $D$

that are typically

$D$

that are typically

![]() $\mathcal{O}(1)$

(Tronnolone, Stokes & Ebendorff-Heidepriem Reference Tronnolone, Stokes and Ebendorff-Heidepriem2017). Furthermore, both small and large Reynolds and capillary numbers are important (Bechert & Scheid Reference Bechert and Scheid2017). Considering these factors, we explore a wide range of potential parameter values in this paper. Since we are interested in considering the use of polymeric fluid both with and without solvent, we consider values of

$\mathcal{O}(1)$

(Tronnolone, Stokes & Ebendorff-Heidepriem Reference Tronnolone, Stokes and Ebendorff-Heidepriem2017). Furthermore, both small and large Reynolds and capillary numbers are important (Bechert & Scheid Reference Bechert and Scheid2017). Considering these factors, we explore a wide range of potential parameter values in this paper. Since we are interested in considering the use of polymeric fluid both with and without solvent, we consider values of

![]() $\beta$

in the whole range

$\beta$

in the whole range

![]() $0\leqslant \beta \lt 1$

. In addition, there is a class of MOFs that have very large air holes and a very small amount of their cross-sectional area occupied by the fluid (Argyros & Pla Reference Argyros and Pla2007). It is important to mention that hole closure happens if

$0\leqslant \beta \lt 1$

. In addition, there is a class of MOFs that have very large air holes and a very small amount of their cross-sectional area occupied by the fluid (Argyros & Pla Reference Argyros and Pla2007). It is important to mention that hole closure happens if

![]() $\phi$

is sufficiently small and this is typically undesirable in the manufacture of MOFs. Consequently, in this paper, we focus on the range of

$\phi$

is sufficiently small and this is typically undesirable in the manufacture of MOFs. Consequently, in this paper, we focus on the range of

![]() $\phi$

as

$\phi$

as

![]() $0.5\leqslant \phi \lt 1$

.

$0.5\leqslant \phi \lt 1$

.

Due to the fact that

![]() $\epsilon$

only appears in the governing equations and boundary conditions as

$\epsilon$

only appears in the governing equations and boundary conditions as

![]() $\epsilon ^2$

, we proceed by proposing the following asymptotic expansions and assuming that

$\epsilon ^2$

, we proceed by proposing the following asymptotic expansions and assuming that

![]() $Re,\ {Ca},\ \alpha$

and

$Re,\ {Ca},\ \alpha$

and

![]() $\beta$

are

$\beta$

are

![]() $\mathcal{O}(1)$

quantities:

$\mathcal{O}(1)$

quantities:

Substituting (2.16)–(2.18) into (A1)–(A11) and equating the powers of

![]() $\epsilon$

, we obtain a set of partial differential equations and boundary conditions for each power of

$\epsilon$

, we obtain a set of partial differential equations and boundary conditions for each power of

![]() $\epsilon$

. We are interested in the leading-order asymptotic behaviour. From (A2) and (A10)–(A11), we obtain

$\epsilon$

. We are interested in the leading-order asymptotic behaviour. From (A2) and (A10)–(A11), we obtain

Hence,

![]() $u_0$

is independent of

$u_0$

is independent of

![]() $r$

, and after integrating the leading-order version of the continuity equation (A1), we obtain

$r$

, and after integrating the leading-order version of the continuity equation (A1), we obtain

where

![]() $C(z,t)$

is an integration function that is determined later using the boundary conditions. The leading-order momentum equations are given by

$C(z,t)$

is an integration function that is determined later using the boundary conditions. The leading-order momentum equations are given by

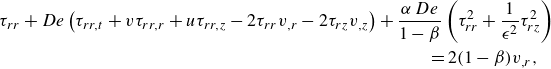

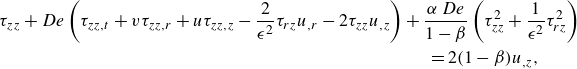

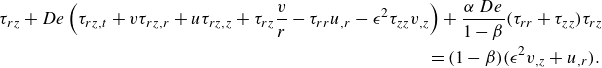

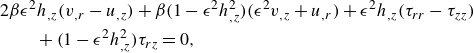

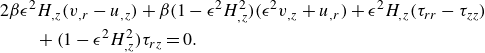

The leading-order constitutive equations are

where

![]() $\mathscr{L}(\cdot)=(\cdot)_{,t}+v_0(\cdot)_{,r}+u_0(\cdot)_{,z}$

. The leading-order normal components of the dynamic boundary conditions are

$\mathscr{L}(\cdot)=(\cdot)_{,t}+v_0(\cdot)_{,r}+u_0(\cdot)_{,z}$

. The leading-order normal components of the dynamic boundary conditions are

Considering

![]() $\mathcal{O}(\epsilon ^2)$

terms of the tangential components of the dynamic boundary conditions (A10)–(A11) gives

$\mathcal{O}(\epsilon ^2)$

terms of the tangential components of the dynamic boundary conditions (A10)–(A11) gives

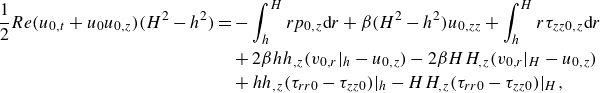

To obtain a long-wave equation, we multiply (2.21) by

![]() $r$

, integrate with respect to

$r$

, integrate with respect to

![]() $r$

and use (2.28)–(2.29) to obtain

$r$

and use (2.28)–(2.29) to obtain

\begin{align} \frac {1}{2}Re(u_{0,t}+u_0 u_{0,z})(H^2-h^2)=&-\int _{h}^{H}r p_{0,z}\text{d}r+\beta (H^2-h^2)u_{0,zz}+\int _{h}^{H}r\tau _{zz0,z}\text{d}r\nonumber \\ &+2\beta h h_{,z}(v_{0,r}|_{h}-u_{0,z})-2\beta H H_{,z}(v_{0,r}|_{H}-u_{0,z})\nonumber \\ &+hh_{,z}(\tau _{rr0}-\tau _{zz0})|_{h}-HH_{,z}(\tau _{rr0}-\tau _{zz0})|_{H}, \end{align}

\begin{align} \frac {1}{2}Re(u_{0,t}+u_0 u_{0,z})(H^2-h^2)=&-\int _{h}^{H}r p_{0,z}\text{d}r+\beta (H^2-h^2)u_{0,zz}+\int _{h}^{H}r\tau _{zz0,z}\text{d}r\nonumber \\ &+2\beta h h_{,z}(v_{0,r}|_{h}-u_{0,z})-2\beta H H_{,z}(v_{0,r}|_{H}-u_{0,z})\nonumber \\ &+hh_{,z}(\tau _{rr0}-\tau _{zz0})|_{h}-HH_{,z}(\tau _{rr0}-\tau _{zz0})|_{H}, \end{align}

where ‘

![]() $|_{h}$

’ and ‘

$|_{h}$

’ and ‘

![]() $|_{H}$

’ denote evaluation at the

$|_{H}$

’ denote evaluation at the

![]() $r=h$

and

$r=h$

and

![]() $r=H$

boundaries, respectively. Moreover, by substituting (2.20) into the kinematic boundary conditions (2.11), we obtain the equations for

$r=H$

boundaries, respectively. Moreover, by substituting (2.20) into the kinematic boundary conditions (2.11), we obtain the equations for

![]() $h$

and

$h$

and

![]() $H$

:

$H$

:

Consequently, by using (2.20) to eliminate

![]() $v_0$

we obtain a closed system, (2.22)–(2.27) and (2.30)–(2.32), for

$v_0$

we obtain a closed system, (2.22)–(2.27) and (2.30)–(2.32), for

![]() $u_0,\ h,\ H,\ p_0,\ C,\ \tau _{rr0},\ \tau _{zz0}$

and

$u_0,\ h,\ H,\ p_0,\ C,\ \tau _{rr0},\ \tau _{zz0}$

and

![]() $\tau _{\theta \theta 0}$

. In the case of a Newtonian fluid, it can be shown that the leading-order pressure

$\tau _{\theta \theta 0}$

. In the case of a Newtonian fluid, it can be shown that the leading-order pressure

![]() $p_0$

is independent of

$p_0$

is independent of

![]() $r$

(Fitt et al. Reference Fitt, Furusawa, Monro, Please and Richardson2002). This allows for a straightforward evaluation of the integrals in (2.30), resulting in a set of three equations for

$r$

(Fitt et al. Reference Fitt, Furusawa, Monro, Please and Richardson2002). This allows for a straightforward evaluation of the integrals in (2.30), resulting in a set of three equations for

![]() $u_0$

,

$u_0$

,

![]() $h$

and

$h$

and

![]() $H$

that are independent of

$H$

that are independent of

![]() $r$

. However, in the current problem the pressure is not independent of

$r$

. However, in the current problem the pressure is not independent of

![]() $r$

and it turns out that the integrals in (2.30) cannot be expressed in terms of elementary functions, so one cannot directly derive long-wave equations that are tractable. In the case of solid viscoelastic threads without internal holes, many authors have proceeded by expanding the various dynamic variables as Taylor series in powers of

$r$

and it turns out that the integrals in (2.30) cannot be expressed in terms of elementary functions, so one cannot directly derive long-wave equations that are tractable. In the case of solid viscoelastic threads without internal holes, many authors have proceeded by expanding the various dynamic variables as Taylor series in powers of

![]() $\epsilon r$

(Bechtel et al. Reference Bechtel, Forest, Holm and Lin1988; Forest & Wang Reference Forest and Wang1990; Clasen et al. Reference Clasen, Eggers, Fontelos, Li and McKinley2006; Eggers & Villermaux Reference Eggers and Villermaux2008; Li & He Reference Li and He2021). This approach is suitable because the point

$\epsilon r$

(Bechtel et al. Reference Bechtel, Forest, Holm and Lin1988; Forest & Wang Reference Forest and Wang1990; Clasen et al. Reference Clasen, Eggers, Fontelos, Li and McKinley2006; Eggers & Villermaux Reference Eggers and Villermaux2008; Li & He Reference Li and He2021). This approach is suitable because the point

![]() $r=0$

is included in the domain, so the regularity conditions at

$r=0$

is included in the domain, so the regularity conditions at

![]() $r=0$

preclude terms that are singular. However, in the current problem,

$r=0$

preclude terms that are singular. However, in the current problem,

![]() $r=0$

is not part of the domain, which means that terms arising from the

$r=0$

is not part of the domain, which means that terms arising from the

![]() $C/r$

term in (2.20) cannot be accurately described using a Taylor series expansion. In fact, if one attempts to expand in powers of

$C/r$

term in (2.20) cannot be accurately described using a Taylor series expansion. In fact, if one attempts to expand in powers of

![]() $\epsilon r$

, one immediately sees that such an expansion cannot be compatible with the normal boundary conditions (2.26)–(2.27). Therefore, an alternative method is needed to derive the long-wave equations.

$\epsilon r$

, one immediately sees that such an expansion cannot be compatible with the normal boundary conditions (2.26)–(2.27). Therefore, an alternative method is needed to derive the long-wave equations.

3. Low-Deborah-number asymptotics

In this section, we simplify our system of equations and boundary conditions, (2.22)–(2.27) and (2.30)–(2.32), using the small-Deborah-number assumption. On examination of (2.20), (2.22), (2.23) and (2.25), we observe that the elastic stresses depend on

![]() $r$

and are strongly coupled with the pressure

$r$

and are strongly coupled with the pressure

![]() $p_0$

and velocity

$p_0$

and velocity

![]() $u_0$

. This makes it challenging to deal with the integrals in (2.30). In order to overcome this challenge and obtain long-wave equations, we consider the weakly viscoelastic limit,

$u_0$

. This makes it challenging to deal with the integrals in (2.30). In order to overcome this challenge and obtain long-wave equations, we consider the weakly viscoelastic limit,

![]() ${De}\ll 1$

. Actually, many works consider the weakly viscoelastic limit for various problems and a broad range of important results have been found using such techniques (De Corato, Greco & Maffettone Reference De Corato, Greco and Maffettone2015; Zhou et al. Reference Zhou, Peng, Zhang and Zhuge2016; Datt & Elfring Reference Datt and Elfring2019; Binagia et al. Reference Binagia, Phoa, Housiadas and Shaqfeh2020; Boyko & Stone Reference Boyko and Stone2022; Boyko & Christov Reference Boyko and Christov2023). Following their methodology, we pose an expansion of the form

${De}\ll 1$

. Actually, many works consider the weakly viscoelastic limit for various problems and a broad range of important results have been found using such techniques (De Corato, Greco & Maffettone Reference De Corato, Greco and Maffettone2015; Zhou et al. Reference Zhou, Peng, Zhang and Zhuge2016; Datt & Elfring Reference Datt and Elfring2019; Binagia et al. Reference Binagia, Phoa, Housiadas and Shaqfeh2020; Boyko & Stone Reference Boyko and Stone2022; Boyko & Christov Reference Boyko and Christov2023). Following their methodology, we pose an expansion of the form

where

![]() $\psi$

represents the quantities

$\psi$

represents the quantities

![]() $\boldsymbol{\tau }_0,\ p_0,\ \boldsymbol{u}_0,\ h,\ H$

and

$\boldsymbol{\tau }_0,\ p_0,\ \boldsymbol{u}_0,\ h,\ H$

and

![]() $C$

.

$C$

.

The derivation of the leading-order long-wave equations in

![]() $De$

is presented in Appendix B. These equations (B8)–(B12) are equivalent to setting

$De$

is presented in Appendix B. These equations (B8)–(B12) are equivalent to setting

![]() $De=0$

and are therefore the same as the equations for a Newtonian fluid tube with viscosity

$De=0$

and are therefore the same as the equations for a Newtonian fluid tube with viscosity

![]() $\eta _0$

. The system is therefore essentially equivalent to that derived in Fitt et al. (Reference Fitt, Furusawa, Monro, Please and Richardson2002). To include elastic effects in our model we must consider the next-order terms in

$\eta _0$

. The system is therefore essentially equivalent to that derived in Fitt et al. (Reference Fitt, Furusawa, Monro, Please and Richardson2002). To include elastic effects in our model we must consider the next-order terms in

![]() $De$

.

$De$

.

3.1.

First-order long-wave equations in

$De$

$De$

Taking the first-order terms in

![]() $De$

of (2.20), we obtain

$De$

of (2.20), we obtain

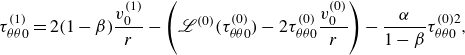

The constitutive relations (2.23)–(2.25) yield

\begin{align} &\tau ^{(1)}_{\theta \theta 0}=2(1-\beta)\frac {v^{(1)}_0}{r}-\left (\mathscr{L}^{(0)}(\tau ^{(0)}_{\theta \theta 0})-2\tau ^{(0)}_{\theta \theta 0}\frac {v^{(0)}_{0}}{r}\right)-\frac {\alpha }{1-\beta }\tau ^{(0)2}_{\theta \theta 0}, \end{align}

\begin{align} &\tau ^{(1)}_{\theta \theta 0}=2(1-\beta)\frac {v^{(1)}_0}{r}-\left (\mathscr{L}^{(0)}(\tau ^{(0)}_{\theta \theta 0})-2\tau ^{(0)}_{\theta \theta 0}\frac {v^{(0)}_{0}}{r}\right)-\frac {\alpha }{1-\beta }\tau ^{(0)2}_{\theta \theta 0}, \end{align}

where

![]() $\mathscr{L}^{(0)}(\cdot)=(\cdot)_{,t}+v^{(0)}_0(\cdot)_{,r}+u^{(0)}_0(\cdot)_{,z}$

. Using (2.22), we obtain

$\mathscr{L}^{(0)}(\cdot)=(\cdot)_{,t}+v^{(0)}_0(\cdot)_{,r}+u^{(0)}_0(\cdot)_{,z}$

. Using (2.22), we obtain

Integrating (3.6) with respect to

![]() $r$

yields

$r$

yields

where

![]() $A^{(1)}(z,t)$

is an integration function that is determined later using the first-order normal boundary conditions that are given by

$A^{(1)}(z,t)$

is an integration function that is determined later using the first-order normal boundary conditions that are given by

We note that (3.8) and (3.9) form an algebraic system for

![]() $A^{(1)}(z,t)$

and

$A^{(1)}(z,t)$

and

![]() $C^{(1)}(z,t)$

, which can be solved to give

$C^{(1)}(z,t)$

, which can be solved to give

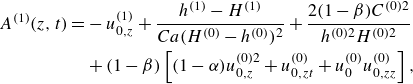

\begin{align} A^{(1)}(z,t)=&-u^{(1)}_{0,z}+\frac {h^{(1)}-H^{(1)}}{{Ca}(H^{(0)}-h^{(0)})^2}+\frac {2(1-\beta)C^{(0)2}}{h^{(0)2}H^{(0)2}} \nonumber \\ & +(1-\beta)\left [(1-\alpha)u^{(0)2}_{0,z}+u^{(0)}_{0,zt} + u^{(0)}_0u^{(0)}_{0,zz}\right], \end{align}

\begin{align} A^{(1)}(z,t)=&-u^{(1)}_{0,z}+\frac {h^{(1)}-H^{(1)}}{{Ca}(H^{(0)}-h^{(0)})^2}+\frac {2(1-\beta)C^{(0)2}}{h^{(0)2}H^{(0)2}} \nonumber \\ & +(1-\beta)\left [(1-\alpha)u^{(0)2}_{0,z}+u^{(0)}_{0,zt} + u^{(0)}_0u^{(0)}_{0,zz}\right], \end{align}

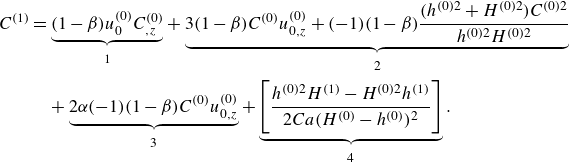

\begin{align} C^{(1)}(z,t)=&\frac {h^{(0)2}H^{(1)}-H^{(0)2}h^{(1)}}{2{Ca}(H^{(0)}-h^{(0)})^2} \nonumber \\ &\quad +(\beta -1)\left [\frac {(h^{(0)2}+H^{(0)2})C^{(0)2}}{h^{(0)2}H^{(0)2}}-(C^{(0)}_{,t}+u^{(0)}_0C^{(0)}_{,z}) +(2\alpha -3)C^{(0)}u^{(0)}_{0,z}\right]. \end{align}

\begin{align} C^{(1)}(z,t)=&\frac {h^{(0)2}H^{(1)}-H^{(0)2}h^{(1)}}{2{Ca}(H^{(0)}-h^{(0)})^2} \nonumber \\ &\quad +(\beta -1)\left [\frac {(h^{(0)2}+H^{(0)2})C^{(0)2}}{h^{(0)2}H^{(0)2}}-(C^{(0)}_{,t}+u^{(0)}_0C^{(0)}_{,z}) +(2\alpha -3)C^{(0)}u^{(0)}_{0,z}\right]. \end{align}

Hence, we can use (3.2)–(3.5) and (3.10)–(3.11) to express

![]() $v^{(1)}_0,\ \tau ^{(1)}_{rr0},\ \tau ^{(1)}_{\theta \theta 0},\ \tau ^{(1)}_{zz0},\ A^{(1)}$

and

$v^{(1)}_0,\ \tau ^{(1)}_{rr0},\ \tau ^{(1)}_{\theta \theta 0},\ \tau ^{(1)}_{zz0},\ A^{(1)}$

and

![]() $C^{(1)}$

in terms of the leading-order quantities

$C^{(1)}$

in terms of the leading-order quantities

![]() $u^{(0)}_0,\ h^{(0)},\ H^{(0)}$

and

$u^{(0)}_0,\ h^{(0)},\ H^{(0)}$

and

![]() $C^{(0)}$

. Although the physical meaning of most variables is clear, the physical interpretation of

$C^{(0)}$

. Although the physical meaning of most variables is clear, the physical interpretation of

![]() $C(z,t)=C^{(0)}(z,t)+{De}\, C^{(1)}(z,t)$

warrants some discussion. It is readily shown from (B7) and (3.11) that

$C(z,t)=C^{(0)}(z,t)+{De}\, C^{(1)}(z,t)$

warrants some discussion. It is readily shown from (B7) and (3.11) that

![]() $C$

, which first appeared in (2.20), will be identically zero in the case of zero surface tension (

$C$

, which first appeared in (2.20), will be identically zero in the case of zero surface tension (

![]() ${Ca}=\infty$

). In fact, the radial velocity

${Ca}=\infty$

). In fact, the radial velocity

![]() $v_0$

in (2.20) is composed of two parts:

$v_0$

in (2.20) is composed of two parts:

![]() $-r u_{0,z}/2$

, which arises from axial stretching and mass conservation, and

$-r u_{0,z}/2$

, which arises from axial stretching and mass conservation, and

![]() $C/r$

, which arises from surface tension acting on the inner and outer boundaries. Thus, the quantity

$C/r$

, which arises from surface tension acting on the inner and outer boundaries. Thus, the quantity

![]() $C$

represents the strength of the radial flow induced by surface tension.

$C$

represents the strength of the radial flow induced by surface tension.

Considering the terms of

![]() $\mathcal{O}(De)$

in the axial momentum equation (2.30), we get integrals that are straightforward to evaluate and obtain

$\mathcal{O}(De)$

in the axial momentum equation (2.30), we get integrals that are straightforward to evaluate and obtain

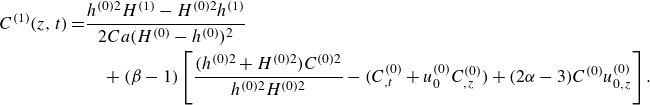

\begin{align} &\frac {1}{2}Re(u^{(1)}_{0,t}{+}u^{(1)}_0 u^{(0)}_{0,z}{+}u^{(0)}_0 u^{(1)}_{0,z})(H^{(0)2}{-}h^{(0)2}) =-Re (u^{(0)}_{0,t}{+} u^{(0)}_0u^{(0)}_{0,z})(H^{(0)}H^{(1)}{-}h^{(0)}h^{(1)})\nonumber \\ &-A^{(0)}_{,z}(H^{(0)}H^{(1)}-h^{(0)}h^{(1)})+2(2\alpha -1)(\beta -1)C^{(0)}C^{(0)}_{,z}\left (\frac {1}{H^{(0)2}}-\frac {1}{h^{(0)2}}\right)\nonumber \\ &+\left (\beta u^{(1)}_{0,zz}+\frac {1}{2}\tau ^{(1)}_{zz0,z}-\frac {1}{2}A^{(1)}_{,z}\right)(H^{(0)2}-h^{(0)2})\nonumber \\ & +\left (2\beta u^{(0)}_{0,zz}+\tau ^{(0)}_{zz0,z}\right)(H^{(0)}H^{(1)}-h^{(0)}h^{(1)})\nonumber \\ &+\left [2\beta (v^{(0)}_{0,r}-u^{(0)}_{0,z})+(\tau ^{(0)}_{rr0}-\tau ^{(0)}_{zz0})\right]\left |_{h^{(0)}}(h^{(1)}h^{(0)}_{,z}+h^{(0)}h^{(1)}_{,z})\right.\nonumber \\ &+\left.\left [2\beta (v^{(1)}_{0,r}-u^{(1)}_{0,z})+(\tau ^{(1)}_{rr0}-\tau ^{(1)}_{zz0})\right]\right |_{h^{(0)}}h^{(0)}h^{(0)}_{,z}\nonumber \\ &-\left.\left [2\beta (v^{(1)}_{0,r}-u^{(1)}_{0,z})+(\tau ^{(1)}_{rr0}-\tau ^{(1)}_{zz0})\right]\right |_{H^{(0)}}H^{(0)}H^{(0)}_{,z}\nonumber \\ &-\left.\left [2\beta (v^{(0)}_{0,r}-u^{(0)}_{0,z})+(\tau ^{(0)}_{rr0}-\tau ^{(0)}_{zz0})\right]\right |_{H^{(0)}}(H^{(1)}H^{(0)}_{,z}+H^{(0)}H^{(1)}_{,z}). \end{align}

\begin{align} &\frac {1}{2}Re(u^{(1)}_{0,t}{+}u^{(1)}_0 u^{(0)}_{0,z}{+}u^{(0)}_0 u^{(1)}_{0,z})(H^{(0)2}{-}h^{(0)2}) =-Re (u^{(0)}_{0,t}{+} u^{(0)}_0u^{(0)}_{0,z})(H^{(0)}H^{(1)}{-}h^{(0)}h^{(1)})\nonumber \\ &-A^{(0)}_{,z}(H^{(0)}H^{(1)}-h^{(0)}h^{(1)})+2(2\alpha -1)(\beta -1)C^{(0)}C^{(0)}_{,z}\left (\frac {1}{H^{(0)2}}-\frac {1}{h^{(0)2}}\right)\nonumber \\ &+\left (\beta u^{(1)}_{0,zz}+\frac {1}{2}\tau ^{(1)}_{zz0,z}-\frac {1}{2}A^{(1)}_{,z}\right)(H^{(0)2}-h^{(0)2})\nonumber \\ & +\left (2\beta u^{(0)}_{0,zz}+\tau ^{(0)}_{zz0,z}\right)(H^{(0)}H^{(1)}-h^{(0)}h^{(1)})\nonumber \\ &+\left [2\beta (v^{(0)}_{0,r}-u^{(0)}_{0,z})+(\tau ^{(0)}_{rr0}-\tau ^{(0)}_{zz0})\right]\left |_{h^{(0)}}(h^{(1)}h^{(0)}_{,z}+h^{(0)}h^{(1)}_{,z})\right.\nonumber \\ &+\left.\left [2\beta (v^{(1)}_{0,r}-u^{(1)}_{0,z})+(\tau ^{(1)}_{rr0}-\tau ^{(1)}_{zz0})\right]\right |_{h^{(0)}}h^{(0)}h^{(0)}_{,z}\nonumber \\ &-\left.\left [2\beta (v^{(1)}_{0,r}-u^{(1)}_{0,z})+(\tau ^{(1)}_{rr0}-\tau ^{(1)}_{zz0})\right]\right |_{H^{(0)}}H^{(0)}H^{(0)}_{,z}\nonumber \\ &-\left.\left [2\beta (v^{(0)}_{0,r}-u^{(0)}_{0,z})+(\tau ^{(0)}_{rr0}-\tau ^{(0)}_{zz0})\right]\right |_{H^{(0)}}(H^{(1)}H^{(0)}_{,z}+H^{(0)}H^{(1)}_{,z}). \end{align}

Considering the terms of

![]() $\mathcal{O}(De)$

in (2.31)–(2.32), we obtain

$\mathcal{O}(De)$

in (2.31)–(2.32), we obtain

Substituting (3.1) into (A12)–(A13), we obtain boundary conditions for

![]() $u^{(1)}_0$

,

$u^{(1)}_0$

,

![]() $h^{(1)}$

and

$h^{(1)}$

and

![]() $H^{(1)}$

, namely

$H^{(1)}$

, namely

As mentioned above, (B7)–(B12) represent the long-wave equations for a Newtonian fluid. We must first solve these equations to obtain

![]() $u^{(0)}_0,\ h^{(0)}$

and

$u^{(0)}_0,\ h^{(0)}$

and

![]() $H^{(0)}$

, after which we substitute these solutions into (3.2), (3.3), (3.5) and (3.10)–(3.16), which represent equations for

$H^{(0)}$

, after which we substitute these solutions into (3.2), (3.3), (3.5) and (3.10)–(3.16), which represent equations for

![]() $u^{(1)}_0,\ h^{(1)}$

and

$u^{(1)}_0,\ h^{(1)}$

and

![]() $H^{(1)}$

. The quantities

$H^{(1)}$

. The quantities

![]() $u^{(1)}_0,\ h^{(1)}$

and

$u^{(1)}_0,\ h^{(1)}$

and

![]() $H^{(1)}$

capture the leading-order effects of elastic stresses and describe the variation from the zero-Deborah-number flow. We note that in the limit

$H^{(1)}$

capture the leading-order effects of elastic stresses and describe the variation from the zero-Deborah-number flow. We note that in the limit

![]() $\beta \to 1$

, the quantities

$\beta \to 1$

, the quantities

![]() $u^{(1)}_0,\ h^{(1)}$

and

$u^{(1)}_0,\ h^{(1)}$

and

![]() $H^{(1)}$

tend to zero. This is because the limit

$H^{(1)}$

tend to zero. This is because the limit

![]() $\beta \to 1$

corresponds to the case

$\beta \to 1$

corresponds to the case

![]() $\eta _p\to 0$

that represents no polymeric effect on the flow, which is therefore purely Newtonian.

$\eta _p\to 0$

that represents no polymeric effect on the flow, which is therefore purely Newtonian.

4. Numerical method for steady-state equations

In this section, we consider the steady state by setting

![]() $\partial _{t}\equiv 0$

in (B7)–(B12) and (3.12)–(3.16). In order to numerically obtain the steady-state solutions, we note that (B8) is a second-order ordinary differential equation (ODE) for the quantity

$\partial _{t}\equiv 0$

in (B7)–(B12) and (3.12)–(3.16). In order to numerically obtain the steady-state solutions, we note that (B8) is a second-order ordinary differential equation (ODE) for the quantity

![]() $u^{(0)}_0$

, and (B9)–(B10) are two first-order ODEs for

$u^{(0)}_0$

, and (B9)–(B10) are two first-order ODEs for

![]() $h^{(0)}$

and

$h^{(0)}$

and

![]() $H^{(0)}$

. We also have three boundary conditions at

$H^{(0)}$

. We also have three boundary conditions at

![]() $z = 0$

and one boundary condition at

$z = 0$

and one boundary condition at

![]() $z = 1$

. Therefore, this system can be readily solved using a shooting method in which one starts with a guessed value of

$z = 1$

. Therefore, this system can be readily solved using a shooting method in which one starts with a guessed value of

![]() $u^{(0)}_{0,z}$

at

$u^{(0)}_{0,z}$

at

![]() $z = 0$

, then solves (B8)–(B10) numerically using a standard ODE solver (e.g. MATLAB function ‘ode45’) subject to the ‘initial’ conditions (B11), and employs a root-finding technique (e.g. MATLAB function ‘fzero’) to find

$z = 0$

, then solves (B8)–(B10) numerically using a standard ODE solver (e.g. MATLAB function ‘ode45’) subject to the ‘initial’ conditions (B11), and employs a root-finding technique (e.g. MATLAB function ‘fzero’) to find

![]() $u^{(0)}_{0,z}$

at

$u^{(0)}_{0,z}$

at

![]() $z = 0$

such that the condition (B12) is satisfied. Similarly, (3.12)–(3.14) are solved by guessing the value of

$z = 0$

such that the condition (B12) is satisfied. Similarly, (3.12)–(3.14) are solved by guessing the value of

![]() $u^{(1)}_{0,z}$

and employing a root-finding technique to achieve (3.16). Consequently, we can readily solve

$u^{(1)}_{0,z}$

and employing a root-finding technique to achieve (3.16). Consequently, we can readily solve

![]() $u_0,h$

and

$u_0,h$

and

![]() $H$

numerically up to

$H$

numerically up to

![]() $\mathcal{O}(De)$

.

$\mathcal{O}(De)$

.

4.1. Results of steady state

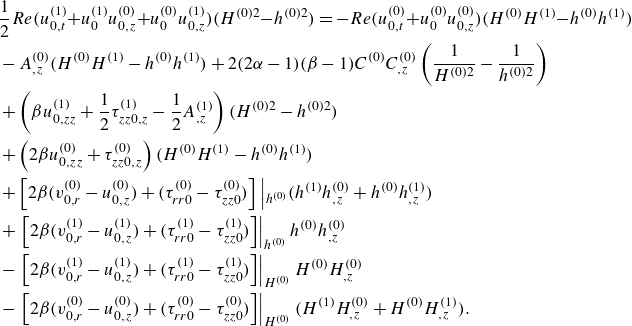

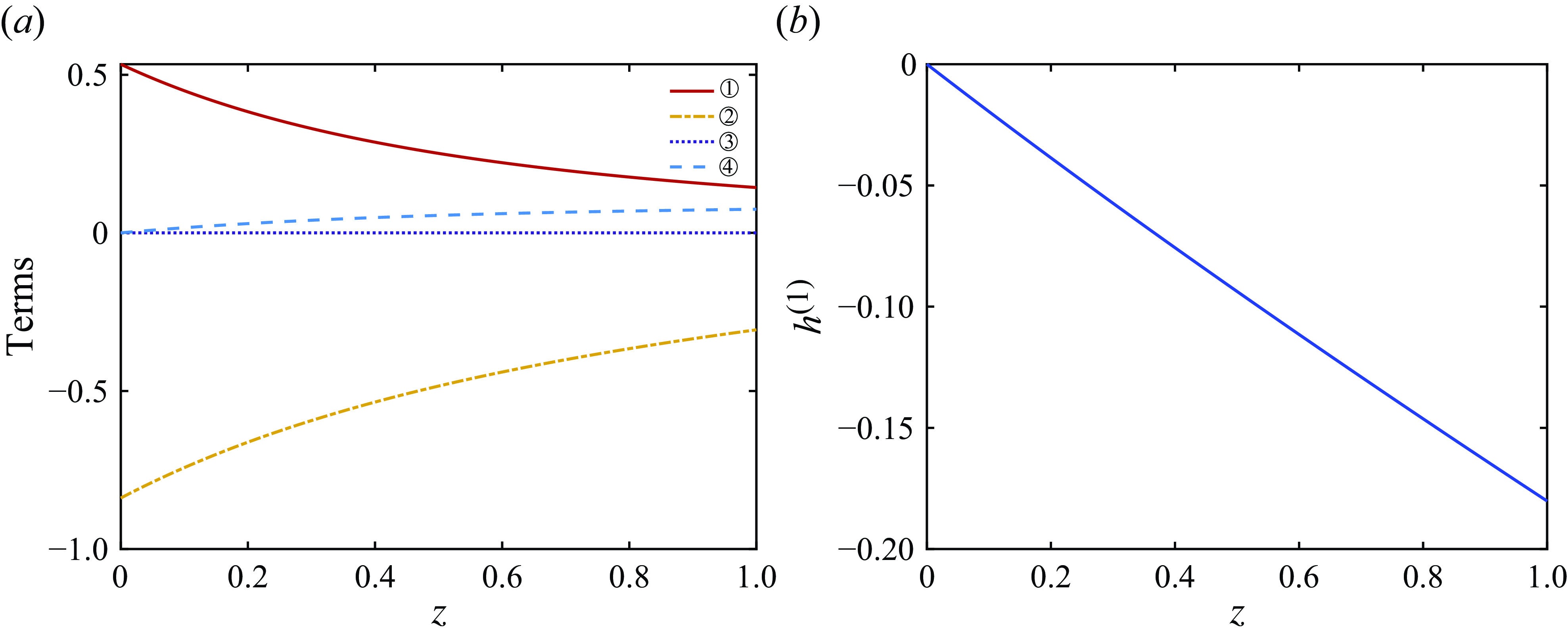

Figure 2. (a) The velocity

![]() $u^{(0)}_0$

, the hole radius

$u^{(0)}_0$

, the hole radius

![]() $h^{(0)}$

and the outer radius

$h^{(0)}$

and the outer radius

![]() $H^{(0)}$

for a Newtonian fluid versus the axial distance

$H^{(0)}$

for a Newtonian fluid versus the axial distance

![]() $z$

. (b) The corrections

$z$

. (b) The corrections

![]() $u^{(1)}_0$

,

$u^{(1)}_0$

,

![]() $h^{(1)}$

and

$h^{(1)}$

and

![]() $H^{(1)}$

to the Newtonian flow due to elastic effects. The parameters are

$H^{(1)}$

to the Newtonian flow due to elastic effects. The parameters are

![]() $D=1.5,\ Ca=1.8,\ Re=0,\ \phi =0.5,\ \alpha =0$

and

$D=1.5,\ Ca=1.8,\ Re=0,\ \phi =0.5,\ \alpha =0$

and

![]() $\beta =0.1$

.

$\beta =0.1$

.

The profiles for

![]() $u^{(0)}_0,\ h^{(0)},\ H^{(0)}$

and

$u^{(0)}_0,\ h^{(0)},\ H^{(0)}$

and

![]() $u^{(1)}_0,\ h^{(1)},\ H^{(1)}$

are plotted in figure 2 for a typical set of parameter values. Other parameters give broadly similar behaviour. Figure 2(a) is the leading-order velocity, hole size and outer radius, which are the same as those for a Newtonian fluid. As a result,

$u^{(1)}_0,\ h^{(1)},\ H^{(1)}$

are plotted in figure 2 for a typical set of parameter values. Other parameters give broadly similar behaviour. Figure 2(a) is the leading-order velocity, hole size and outer radius, which are the same as those for a Newtonian fluid. As a result,

![]() $u^{(0)},\ h^{(0)}$

and

$u^{(0)},\ h^{(0)}$

and

![]() $H^{(0)}$

are independent of the parameters

$H^{(0)}$

are independent of the parameters

![]() $\alpha$

and

$\alpha$

and

![]() $\beta$

, which characterise elasticity in the constitutive relation. Figure 2(b) represents the

$\beta$

, which characterise elasticity in the constitutive relation. Figure 2(b) represents the

![]() $\mathcal{O}(De)$

corrections to the Newtonian flow. The velocities at both inlet nozzle and take-up point are fixed, resulting in

$\mathcal{O}(De)$

corrections to the Newtonian flow. The velocities at both inlet nozzle and take-up point are fixed, resulting in

![]() $u^{(1)}_0$

being zero at both the inlet nozzle and take-up point, but

$u^{(1)}_0$

being zero at both the inlet nozzle and take-up point, but

![]() $u^{(1)}_0$

is positive in the bulk meaning that elastic effects act to increase the velocity. Figure 2 shows that the elasticity acts to reduce the hole size since

$u^{(1)}_0$

is positive in the bulk meaning that elastic effects act to increase the velocity. Figure 2 shows that the elasticity acts to reduce the hole size since

![]() $h^{(1)}$

is negative. The elasticity also contributes to a reduction of the outer radius, but this is significantly weaker than the effect on the hole size. It is worth noting that the hole size at the take-up point is one of the most important factors in the production of holey fibres, since the geometry at the take-up point represents the output of the drawing device. As we described in the introduction, the optical properties of fibres can depend very sensitively on the output geometry. Therefore, the most important quantities from a manufacturing perspective are

$h^{(1)}$

is negative. The elasticity also contributes to a reduction of the outer radius, but this is significantly weaker than the effect on the hole size. It is worth noting that the hole size at the take-up point is one of the most important factors in the production of holey fibres, since the geometry at the take-up point represents the output of the drawing device. As we described in the introduction, the optical properties of fibres can depend very sensitively on the output geometry. Therefore, the most important quantities from a manufacturing perspective are

![]() $h$

and

$h$

and

![]() $H$

at the take-up point

$H$

at the take-up point

![]() $z=1$

. Furthermore, we note from (A12) and (2.31)–(2.32) that

$z=1$

. Furthermore, we note from (A12) and (2.31)–(2.32) that

for the steady state. Expanding (4.1) with respect to

![]() $De$

and equating the terms of first order in

$De$

and equating the terms of first order in

![]() $De$

, we obtain

$De$

, we obtain

Evaluating (4.2) at

![]() $z=1$

, we obtain

$z=1$

, we obtain

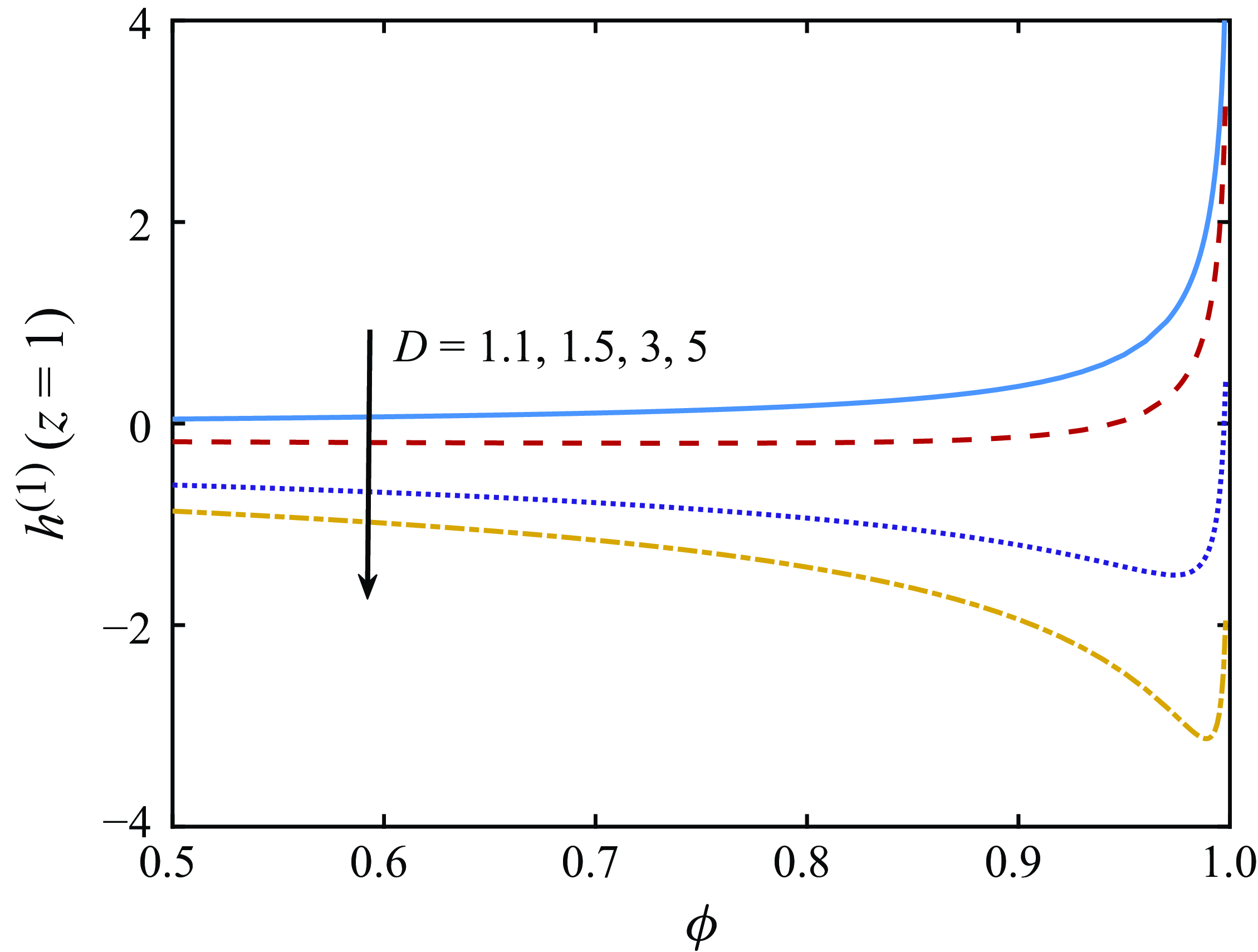

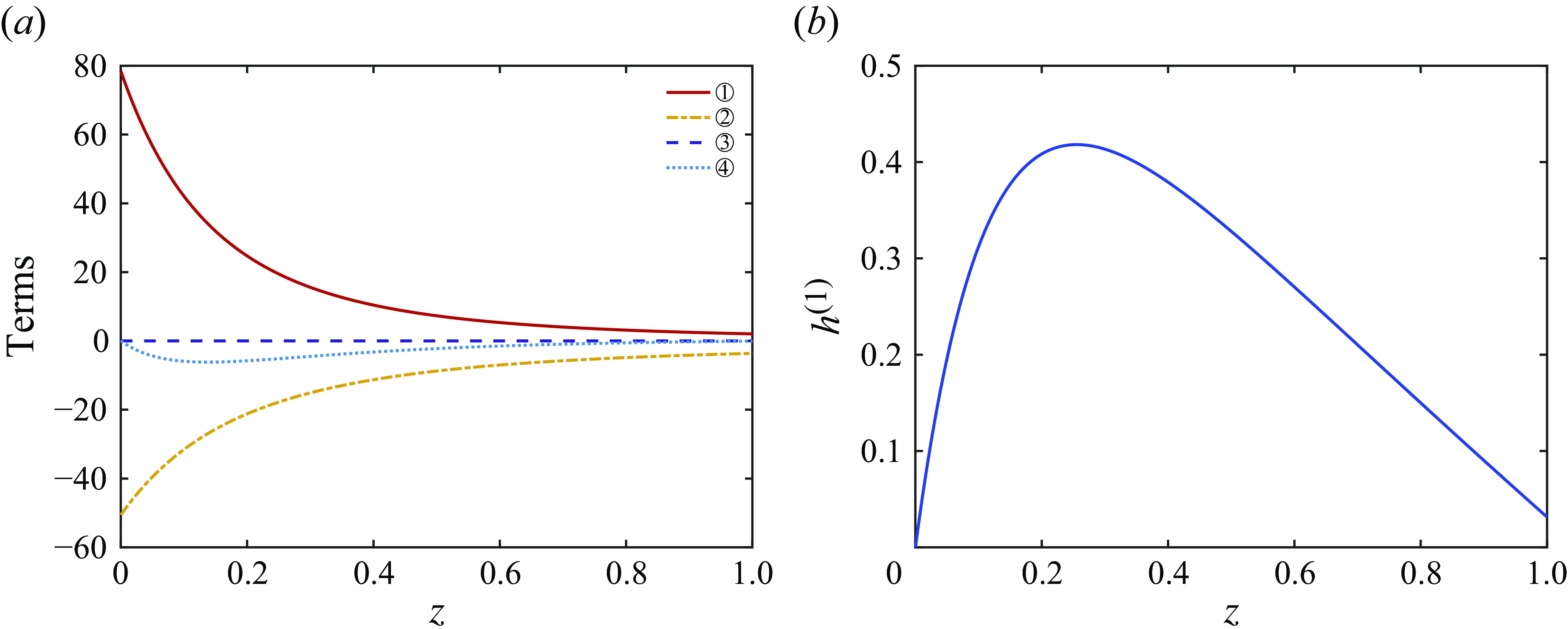

Figure 3. The effect of elasticity on the hole size at the take-up point,

![]() $h^{(1)}(z=1)$

, versus the ratio of inner to outer radius at the inlet nozzle,

$h^{(1)}(z=1)$

, versus the ratio of inner to outer radius at the inlet nozzle,

![]() $\phi$

, for different values of the draw ratio

$\phi$

, for different values of the draw ratio

![]() $D$

. Other parameters are

$D$

. Other parameters are

![]() $Ca=1.8,\ Re=0,\ \alpha =0$

and

$Ca=1.8,\ Re=0,\ \alpha =0$

and

![]() $\beta =0.1$

.

$\beta =0.1$

.

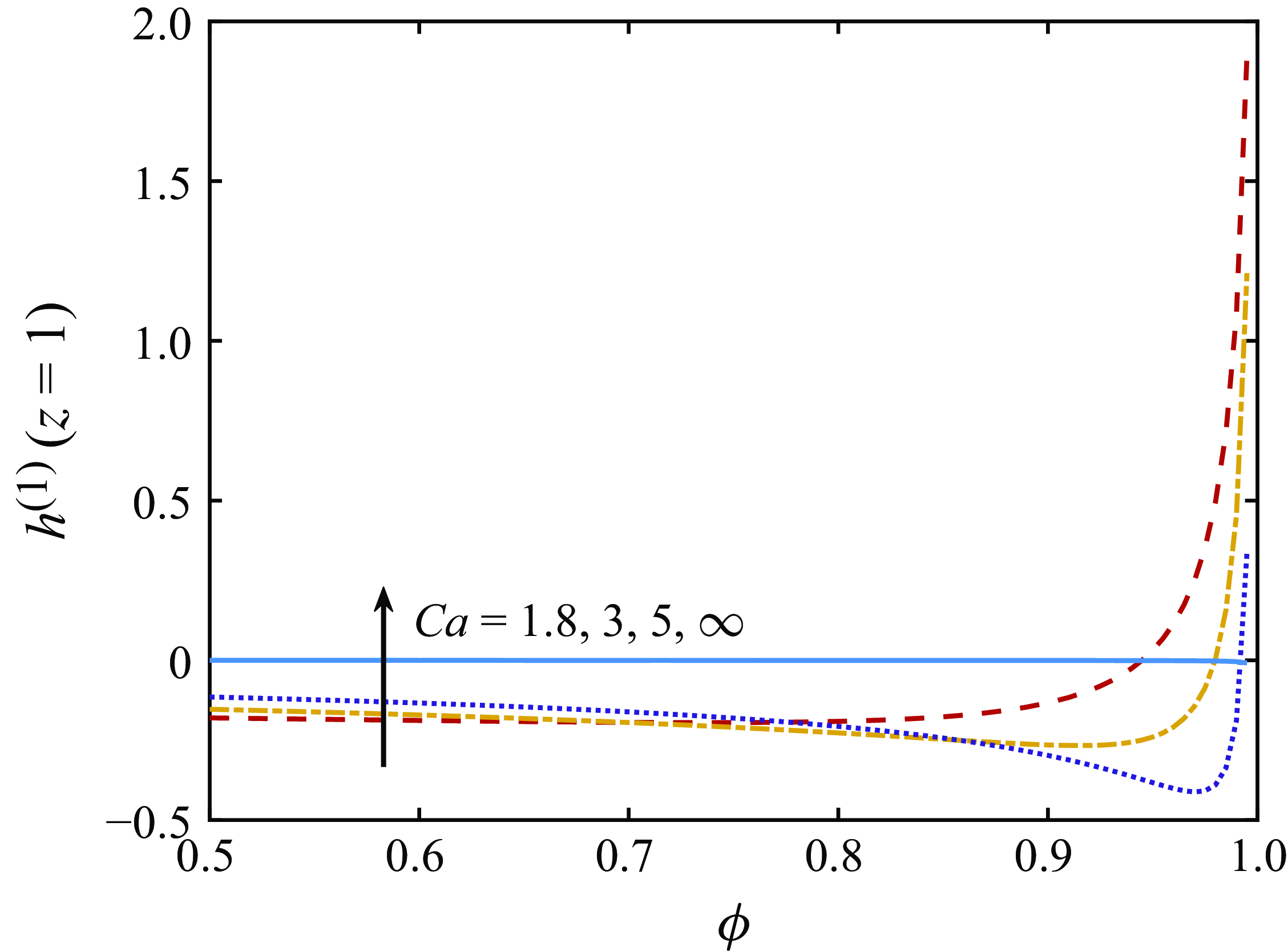

Figure 4. The effect of elasticity on the hole size at the take-up point,

![]() $h^{(1)}(z=1)$

, versus the ratio of inner to outer radius at the inlet nozzle,

$h^{(1)}(z=1)$

, versus the ratio of inner to outer radius at the inlet nozzle,

![]() $\phi$

, for different values of the capillary number

$\phi$

, for different values of the capillary number

![]() $Ca$

. Other parameters are

$Ca$

. Other parameters are

![]() $D=1.5,\ Re=0,\ \alpha =0$

and

$D=1.5,\ Re=0,\ \alpha =0$

and

![]() $\beta =0.1$

.

$\beta =0.1$

.

Thus, we can determine

![]() $H^{(1)}$

at the take-up point once

$H^{(1)}$

at the take-up point once

![]() $h^{(1)}$

is known. Therefore, we focus on

$h^{(1)}$

is known. Therefore, we focus on

![]() $h^{(1)}(z=1)$

that represents the effect that elasticity has on the hole size at the take-up point in the subsequent analysis. In figures 3 and 4 we explore how the hole size at the take-up point

$h^{(1)}(z=1)$

that represents the effect that elasticity has on the hole size at the take-up point in the subsequent analysis. In figures 3 and 4 we explore how the hole size at the take-up point

![]() $h^{(1)}(z=1)$

depends on the inlet hole size by plotting

$h^{(1)}(z=1)$

depends on the inlet hole size by plotting

![]() $h^{(1)}(z=1)$

as a function of

$h^{(1)}(z=1)$

as a function of

![]() $\phi$

, recalling that

$\phi$

, recalling that

![]() $\phi$

represents the ratio of inner radius to outer radius at the inlet nozzle. Note that these figures are for sufficiently large

$\phi$

represents the ratio of inner radius to outer radius at the inlet nozzle. Note that these figures are for sufficiently large

![]() $\phi$

(

$\phi$

(

![]() $\geqslant 0.5$

) such that hole closure (

$\geqslant 0.5$

) such that hole closure (

![]() $h^{(0)}=0$

) does not occur. Hole closure can occur for small

$h^{(0)}=0$

) does not occur. Hole closure can occur for small

![]() $\phi$

, but in fibre drawing this is, perhaps with a very few exceptions, always undesirable, since if a solid thread is desired it can be more easily obtained by using a solid thread at the inlet nozzle. Therefore, in this study, we do not consider hole closure and only focus on the dynamics for sufficiently large

$\phi$

, but in fibre drawing this is, perhaps with a very few exceptions, always undesirable, since if a solid thread is desired it can be more easily obtained by using a solid thread at the inlet nozzle. Therefore, in this study, we do not consider hole closure and only focus on the dynamics for sufficiently large

![]() $\phi$

such that hole closure does not occur. We plot the curves for different

$\phi$

such that hole closure does not occur. We plot the curves for different

![]() $D$

and

$D$

and

![]() $Ca$

in figures 3 and 4. Figure 3 shows that an increase in

$Ca$

in figures 3 and 4. Figure 3 shows that an increase in

![]() $D$

enhances the hole closure at the take-up point due to elasticity. For very weak drawing corresponding to

$D$

enhances the hole closure at the take-up point due to elasticity. For very weak drawing corresponding to

![]() $D=1.1$

,

$D=1.1$

,

![]() $h^{(1)}(z=1)$

is always positive and becomes more positive as

$h^{(1)}(z=1)$

is always positive and becomes more positive as

![]() $\phi$

increases, indicating that the elasticity always plays a role in increasing the hole size. However, for moderate drawing, with

$\phi$

increases, indicating that the elasticity always plays a role in increasing the hole size. However, for moderate drawing, with

![]() $D=1.5,\ 3$

and

$D=1.5,\ 3$

and

![]() $5$

, we observe that

$5$

, we observe that

![]() $h^{(1)}(z=1)$

is initially negative and decreases with

$h^{(1)}(z=1)$

is initially negative and decreases with

![]() $\phi$

, indicating that the effect of elasticity in decreasing the hole size at the take-up point becomes stronger as

$\phi$

, indicating that the effect of elasticity in decreasing the hole size at the take-up point becomes stronger as

![]() $\phi$

increases. However, for sufficiently large

$\phi$

increases. However, for sufficiently large

![]() $\phi$

, we see the opposite. This phenomenon can be also observed in the red curve in figure 4 for

$\phi$

, we see the opposite. This phenomenon can be also observed in the red curve in figure 4 for

![]() $Ca=1.8$

and

$Ca=1.8$

and

![]() $D=1.5$

. Therefore, roughly speaking, there are two different types of behaviour that can be observed in the plots: one where

$D=1.5$

. Therefore, roughly speaking, there are two different types of behaviour that can be observed in the plots: one where

![]() $\phi$

is close to

$\phi$

is close to

![]() $1$

, which we refer to as the ‘large hole size’ case, and another where

$1$

, which we refer to as the ‘large hole size’ case, and another where

![]() $\phi$

is not close to

$\phi$

is not close to

![]() $1$

, which we refer to as the ‘moderate hole size’ case. The subsequent sections concentrate on examining these two cases. Furthermore, figure 4 shows that for sufficiently small values of

$1$

, which we refer to as the ‘moderate hole size’ case. The subsequent sections concentrate on examining these two cases. Furthermore, figure 4 shows that for sufficiently small values of

![]() $\phi$

an increase in

$\phi$

an increase in

![]() $Ca$

will decrease the hole closure at the take-up point due to elasticity. However, the opposite trend is observed for sufficiently large values of

$Ca$

will decrease the hole closure at the take-up point due to elasticity. However, the opposite trend is observed for sufficiently large values of

![]() $\phi$

. In addition, as

$\phi$

. In addition, as

![]() $Ca\to \infty$

, (B7) and (3.11) imply that

$Ca\to \infty$

, (B7) and (3.11) imply that

![]() $C^{(0)}$

and

$C^{(0)}$

and

![]() $C^{(1)}$

will tend to zero, and one can integrate the steady version of (3.13) from

$C^{(1)}$

will tend to zero, and one can integrate the steady version of (3.13) from

![]() $z=0$

to

$z=0$

to

![]() $z=1$

to see that

$z=1$

to see that

![]() $h^{(1)}(z=1)=0$

. Hence, the hole size at the take-up point for viscoelastic fluids will tend to that for a Newtonian fluid and hence

$h^{(1)}(z=1)=0$

. Hence, the hole size at the take-up point for viscoelastic fluids will tend to that for a Newtonian fluid and hence

![]() $h^{(1)}(z=1)$

will tend to zero as

$h^{(1)}(z=1)$

will tend to zero as

![]() $Ca\to \infty$

, as shown in figure 4.

$Ca\to \infty$

, as shown in figure 4.

4.1.1. Moderate and large hole sizes

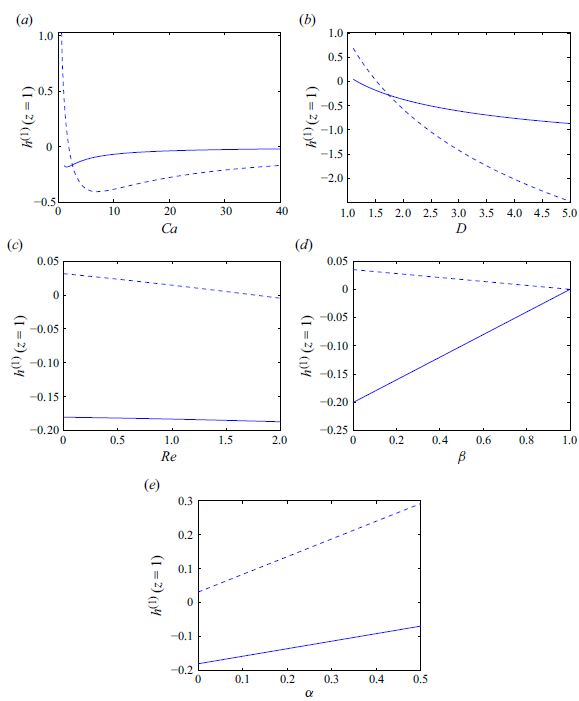

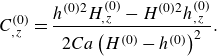

Figure 5. The effect of elasticity on the hole size at the take-up point versus (a) capillary number

![]() $Ca$

, (b) draw ratio

$Ca$

, (b) draw ratio

![]() $D$

, (c) Reynolds number

$D$

, (c) Reynolds number

![]() $Re$

, (d) solvent to bulk viscosity

$Re$

, (d) solvent to bulk viscosity

![]() $\beta$

and (e) mobility factor

$\beta$

and (e) mobility factor

![]() $\alpha$

. The solid curve is for

$\alpha$

. The solid curve is for

![]() $\phi =0.5$

, the dashed curve is for

$\phi =0.5$

, the dashed curve is for

![]() $\phi =0.95$

. In (a), other parameters are

$\phi =0.95$

. In (a), other parameters are

![]() $D=1.5,$

$D=1.5,$

![]() $Re=0$

,

$Re=0$

,

![]() $\alpha =0$

and

$\alpha =0$

and

![]() $\beta =0.1$

. In (b), other parameters are

$\beta =0.1$

. In (b), other parameters are

![]() $Re=0$

,

$Re=0$

,

![]() $Ca=1.8$

,

$Ca=1.8$

,

![]() $\alpha =0$

and

$\alpha =0$

and

![]() $\beta =0.1$

. In (c), other parameters are

$\beta =0.1$

. In (c), other parameters are

![]() $D=1.5,$

$D=1.5,$

![]() $Ca=1.8$

,

$Ca=1.8$

,

![]() $\alpha =0$

and

$\alpha =0$

and

![]() $\beta =0.1$

. In (d), other parameters are

$\beta =0.1$

. In (d), other parameters are

![]() $D=1.5$

,

$D=1.5$

,

![]() $Ca=1.8,$

$Ca=1.8,$

![]() $Re=0$

and

$Re=0$

and

![]() $\alpha =0$

. In (e), other parameters are

$\alpha =0$

. In (e), other parameters are

![]() $D=1.5$

,

$D=1.5$

,

![]() $Ca=1.8$

,

$Ca=1.8$

,

![]() $Re=0$

and

$Re=0$

and

![]() $\beta =0.1$

.

$\beta =0.1$

.

In figure 5, we compare the hole closure at the take-up point due to elasticity for moderate (

![]() $\phi =0.5$

) and large (

$\phi =0.5$

) and large (

![]() $\phi =0.95$

) inlet hole sizes. In particular, we examine how the various parameters

$\phi =0.95$

) inlet hole sizes. In particular, we examine how the various parameters

![]() $Ca,\ D,\ Re,\ \beta $

and

$Ca,\ D,\ Re,\ \beta $

and

![]() $\alpha$

affect

$\alpha$

affect

![]() $h^{(1)}(z=1)$

. In figure 5(a), we examine the effect of capillary number (Ca). Here, we start with

$h^{(1)}(z=1)$

. In figure 5(a), we examine the effect of capillary number (Ca). Here, we start with

![]() $Ca\approx 1.1$

for the case of a moderate hole size and

$Ca\approx 1.1$

for the case of a moderate hole size and

![]() $Ca\approx 0.6$

for the case of a large hole size, as the hole will close for smaller capillary numbers corresponding to very strong surface tension. For the moderate value of

$Ca\approx 0.6$

for the case of a large hole size, as the hole will close for smaller capillary numbers corresponding to very strong surface tension. For the moderate value of

![]() $\phi$

(solid curve),

$\phi$

(solid curve),

![]() $h^{(1)}(z=1)$

is always negative indicating that the hole size at the take-up point is consistently smaller than for a pure Newtonian fluid. For large

$h^{(1)}(z=1)$

is always negative indicating that the hole size at the take-up point is consistently smaller than for a pure Newtonian fluid. For large

![]() $\phi$

(dashed curve) and sufficiently small Ca,

$\phi$

(dashed curve) and sufficiently small Ca,

![]() $h^{(1)}(z=1)$

is positive indicating that the hole size at the take-up point is larger than the Newtonian one. Furthermore, we note that

$h^{(1)}(z=1)$

is positive indicating that the hole size at the take-up point is larger than the Newtonian one. Furthermore, we note that

![]() $h^{(1)}(z=1)$

is not a monotonic function of Ca. For sufficiently small Ca,

$h^{(1)}(z=1)$

is not a monotonic function of Ca. For sufficiently small Ca,

![]() $h^{(1)}(z=1)$

reduces as Ca increases. However, this trend reverses beyond a critical value of Ca. This non-monotonic behaviour can also be observed in figure 4. As shown in figure 4,

$h^{(1)}(z=1)$

reduces as Ca increases. However, this trend reverses beyond a critical value of Ca. This non-monotonic behaviour can also be observed in figure 4. As shown in figure 4,

![]() $h^{(1)}(z=1)\to 0$

when

$h^{(1)}(z=1)\to 0$

when

![]() $Ca\to \infty$

(negligible surface tension) for all

$Ca\to \infty$

(negligible surface tension) for all

![]() $\phi$

.

$\phi$

.

Figure 5(b) shows the effect of draw ratio D and that there is a critical value of D above which elastic effects decrease and below which elastic effects increase the hole size at the take-up point. For the moderate value of

![]() $\phi$

(solid curve) elastic effects only act to very weakly increase the hole size for values of D quite close to

$\phi$

(solid curve) elastic effects only act to very weakly increase the hole size for values of D quite close to

![]() $1$

. Whereas, for the large value of

$1$

. Whereas, for the large value of

![]() $\phi$

(dashed curve) the effect is much stronger and acts over a larger range of D values. An increase in the draw ratio uniformly enhances the hole closure at the take-up point due to elasticity. This phenomenon can also be observed in figure 3.

$\phi$

(dashed curve) the effect is much stronger and acts over a larger range of D values. An increase in the draw ratio uniformly enhances the hole closure at the take-up point due to elasticity. This phenomenon can also be observed in figure 3.

The effect of inertia is shown in figure 5(c). For

![]() $\phi =0.5$

(solid curve), we observe that

$\phi =0.5$

(solid curve), we observe that

![]() $h^{(1)}(z=1)$

is always negative indicating that elastic effects enhance hole closure at the take-up point. On the other hand, for

$h^{(1)}(z=1)$

is always negative indicating that elastic effects enhance hole closure at the take-up point. On the other hand, for

![]() $\phi =0.95$

(dashed curve) we observe that

$\phi =0.95$

(dashed curve) we observe that

![]() $h^{(1)}(z=1)$

is positive for

$h^{(1)}(z=1)$

is positive for

![]() $Re\lesssim 1.8$

, indicating that elastic effects suppress hole closure. However, for

$Re\lesssim 1.8$

, indicating that elastic effects suppress hole closure. However, for

![]() $Re\gtrsim 1.8$

we see that the opposite is true. Nevertheless, as Re varies the effect on

$Re\gtrsim 1.8$

we see that the opposite is true. Nevertheless, as Re varies the effect on

![]() $h^{(1)}(z=1)$

is relatively weak.

$h^{(1)}(z=1)$

is relatively weak.

Figure 5(d) shows how

![]() $\beta$

(solvent to bulk viscosity ratio) affects

$\beta$

(solvent to bulk viscosity ratio) affects

![]() $h^{(1)}(z=1)$

. We note that the maximum value that

$h^{(1)}(z=1)$

. We note that the maximum value that

![]() $\beta$

can approach is

$\beta$

can approach is

![]() $1$

, and this corresponds to a purely Newtonian fluid (only solvent). Therefore, as

$1$

, and this corresponds to a purely Newtonian fluid (only solvent). Therefore, as

![]() $\beta$

tends to unity, the elastic effects will tend to zero and we will get

$\beta$

tends to unity, the elastic effects will tend to zero and we will get

![]() $h^{(1)}(z=1)\to 0$

. For

$h^{(1)}(z=1)\to 0$

. For

![]() $\phi =0.5$

,

$\phi =0.5$

,

![]() $h^{(1)}(z=1)$

is negative, indicating that the elasticity acts to enhance hole closure. As

$h^{(1)}(z=1)$

is negative, indicating that the elasticity acts to enhance hole closure. As

![]() $\beta$

increases, the effect of elasticity becomes weaker. While for

$\beta$

increases, the effect of elasticity becomes weaker. While for

![]() $\phi =0.95$

,

$\phi =0.95$

,

![]() $h^{(1)}(z=1)$

is positive, indicating that the elasticity suppresses hole closure. As

$h^{(1)}(z=1)$

is positive, indicating that the elasticity suppresses hole closure. As

![]() $\beta$

increases towards unity the effects of elasticity on the hole closure monotonically decrease to zero.

$\beta$

increases towards unity the effects of elasticity on the hole closure monotonically decrease to zero.

In figure 5(e) we show how

![]() $\alpha$

(mobility factor) affects

$\alpha$

(mobility factor) affects

![]() $h^{(1)}(z=1)$

. We note that in the Giesekus model, physical constraints demand that

$h^{(1)}(z=1)$

. We note that in the Giesekus model, physical constraints demand that

![]() $\alpha \lt 0.5$

(Morozov & Spagnolie Reference Morozov and Spagnolie2015). For

$\alpha \lt 0.5$

(Morozov & Spagnolie Reference Morozov and Spagnolie2015). For

![]() $\phi =0.5$

elastic effects enhance hole closure, but this becomes weaker as

$\phi =0.5$

elastic effects enhance hole closure, but this becomes weaker as

![]() $\alpha$

increases. On the other hand, elastic effects suppress hole closure for

$\alpha$

increases. On the other hand, elastic effects suppress hole closure for

![]() $\phi =0.95$

and this suppression becomes stronger as

$\phi =0.95$

and this suppression becomes stronger as

![]() $\alpha$

increases. We return to this phenomenon in the next subsection.

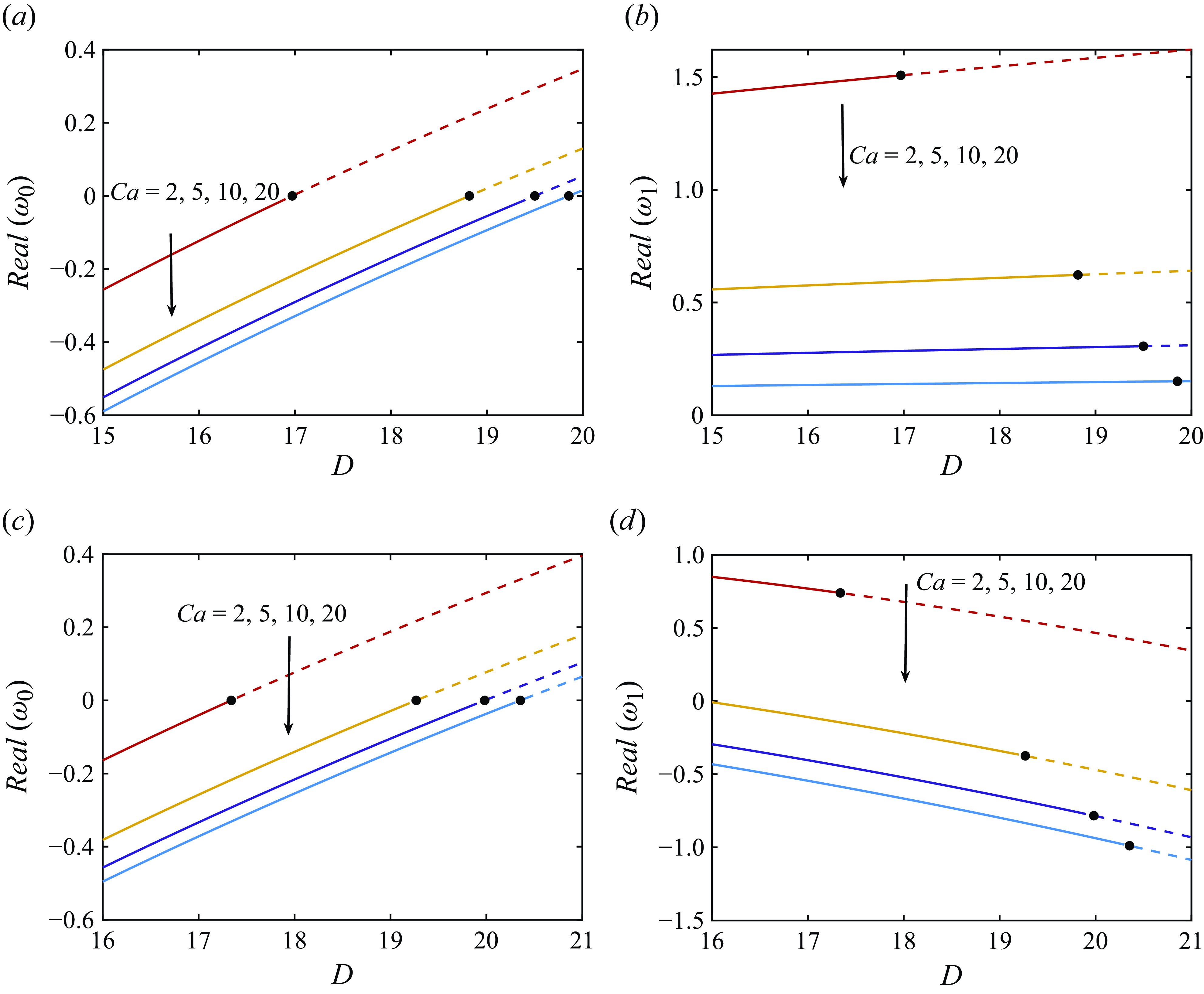

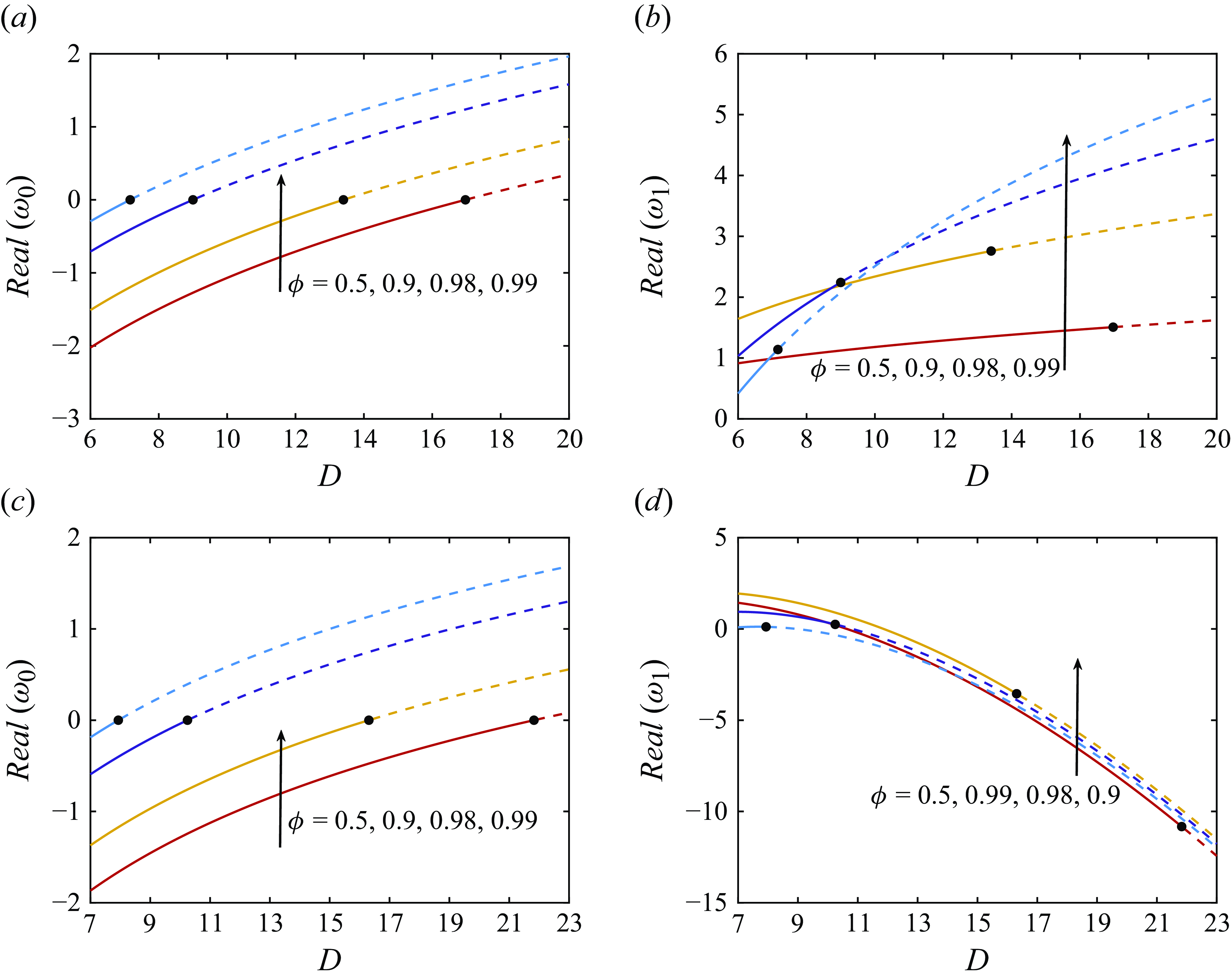

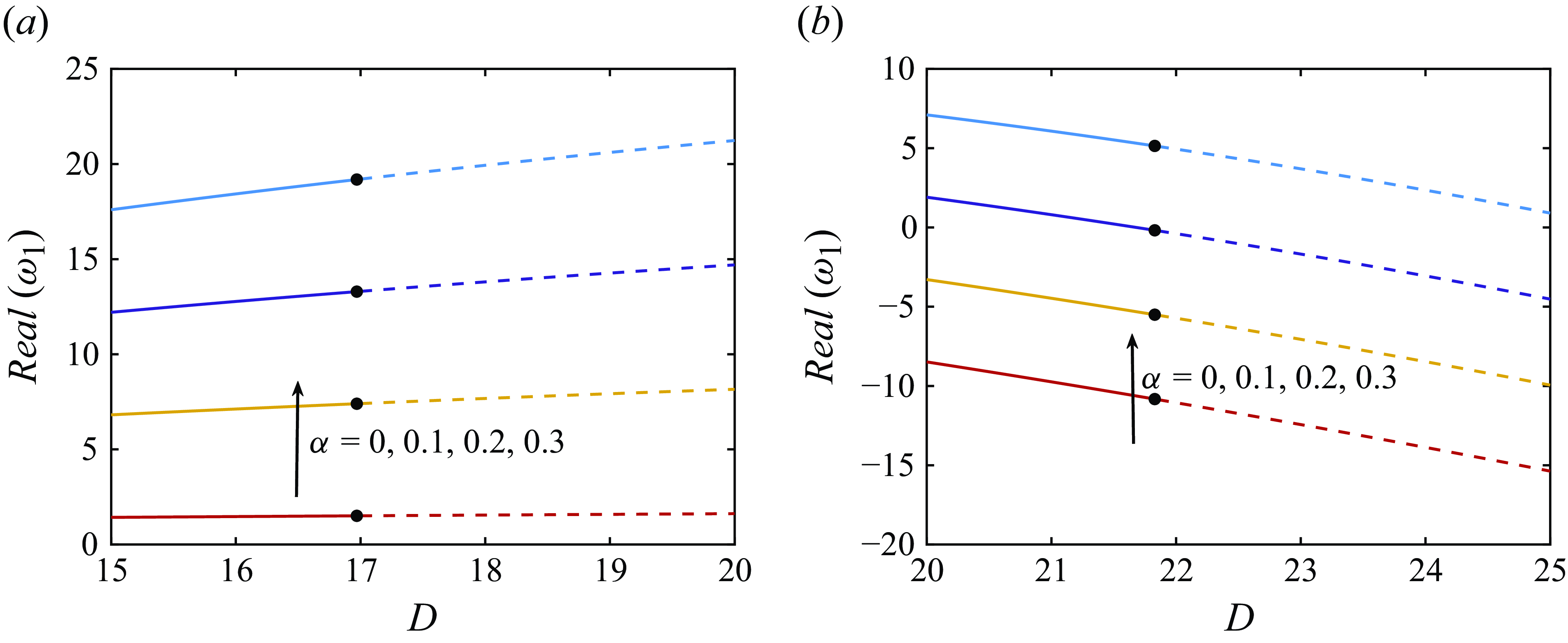

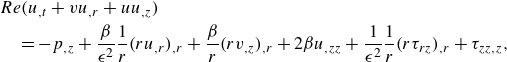

$\alpha$