1. Introduction

As a granular material constituted of an interconnected network of ice grains, snow has a complex mechanical behaviour influenced both by the material properties of ice and by its intrinsic microstructure. As a homogeneous material, ice can show both brittle and ductile behaviour, depending on the external conditions as strain rate for instance (Schulson, Reference Schulson1990). It also exhibits temperature-dependant creep behaviour (Barnes and others, Reference Barnes, Tabor and Walker1971). From a microscopic perspective, snow exhibits diverse microstructures initially dictated by the meteorological conditions at snowfall but evolving over time under the influence of the environmental constraints. This so-called snow metamorphism is mostly driven by the temperature and its gradient within the snow layer. Under specific climatic conditions, snow metamorphism leads to the transformation of snowflakes into bonded spherical ice grains (Fierz, Reference Fierz2009; Calonne and others, Reference Calonne, Flin, Geindreau, Lesaffre and du Roscoat2014) which normally goes along with a snow densification (Kojima, Reference Kojima1967).

Modelling the mechanical behaviour of snow is of great interest in various fields, from avalanche prediction and mitigation (Nicot, Reference Nicot2004; Gaume and others, Reference Gaume, Chambon, Eckert, Naaim and Schweizer2015), winter sports equipment (Fauve and others, Reference Fauve, Rhyner, Lüthi, Schneebeli and Lehning2008), to snow tire design (Shoop and others, Reference Shoop, Kestler and Haehnel2006; Lee, Reference Lee2013; Hjort and others, Reference Hjort, Eriksson and Bruzelius2017). Two kinds of approaches are widely adopted for snow modelling, namely continuum-based and particle-based methods. Particle-based methods have the advantage of explicitly accounting for the characteristics of snow microstructure. They are based on an individual representation of grains, mostly through the discrete element method (DEM) (Cundall and Strack, Reference Cundall and Strack1979; Radjai and others, Reference Radjai, Wolf, Jean and Moreau1998; Luding, Reference Luding2008; Smilauer, Reference Smilauer2010). DEM has already been used for snow by modelling the ice grains as discrete particles connected by ice bonds (Johnson and Hopkins, Reference Johnson and Hopkins2005; Mede and others, Reference Mede, Chambon, Hagenmuller and Nicot2018; Mulak and Gaume, Reference Mulak and Gaume2019; Willibald and others, Reference Willibald, Scheuber, Löwe, Dual and Schneebeli2019; Bobillier and others, Reference Bobillier, Bergfeld, Dual, Gaume, van Herwijnen and Schweizer2021; Kabore and others, Reference Kabore, Peters, Michael and Nicot2021; Peters and others, Reference Peters, Kabore, Michael and Nicot2021) or to represent snow elements (Gaume and others, Reference Gaume, van Herwijnen, Chambon, Birkeland and Schweizer2015). In return for taking effective account of the effect of the microstructure, DEM is computationally costly, which limits its ability to model large scale systems. As an alternative to discrete numerical methods, continuum-based approaches of snow include the finite element method (Meschke and others, Reference Meschke, Liu and Mang1996; Podolskiy and others, Reference Podolskiy, Chambon, Naaim and Gaume2013; Fourteau and others, Reference Fourteau, Freitag, Malinen and Löwe2024), the finite difference method (Dent and Lang, Reference Dent and Lang1980), the material point method (Gaume and others, Reference Gaume, Gast, Teran, van Herwijnen and Jiang2018, Reference Gaume, van Herwijnen, Gast, Teran and Jiang2019; Trottet, Reference Trottet2022) and the smooth particles hydrodynamics (El-Sayegh and El-Gindy, Reference El-Sayegh and El-Gindy2019) among others. In these methods, snow is modelled as a continuous medium and its material behaviour is accounted for by a constitutive relation. For example, a Drucker-Prager (Haehnel and Shoop, Reference Haehnel and Shoop2004; Lee, Reference Lee2009; Gaume and others, Reference Gaume, Chambon, Naaim, Eckert, Bonelli, Dascalu and Nicot2011; Blatny and others, Reference Blatny, Löwe and Gaume2023) or a modified Cam-Clay (Gaume and others, Reference Gaume, Gast, Teran, van Herwijnen and Jiang2018; Guillet and others, Reference Guillet, Blatny, Trottet, Steffen and Gaume2023) constitutive material laws are widely used in the field of snow avalanche modelling. Such approaches are usually significantly less time-consuming than DEM, meaning that they can address large scale systems. However, the constitutive relations implemented are generally phenomenological and therefore do not explicitly account for the snow microstructure, which makes them harder to calibrate. However, recent works have highlighted the importance of incorporating snow microstructure into constitutive models to more accurately capture its mechanical behaviour (Blatny and others, Reference Blatny, Löwe, Wang and Gaume2021, Reference Blatny, Löwe and Gaume2023).

In this paper, we propose a continuum approach based on a constitutive material model that incorporates explicitly the discrete microstructure of snow, thus combining the advantages of both modelling strategies. To this end, the 3-D H-model (Nicot and Darve, Reference Nicot and Darve2011; Xiong and others, Reference Xiong, Nicot and Yin2017) is extended to snow, considered as an assembly of spherical ice particles connected by ice bonds. This model was originally introduced for soil modelling in dry (Wautier, Reference Wautier2021) and partially saturated conditions (Xiong, Reference Xiong2021). The ability of the H-model to be used at large scale has been demonstrated by Xiong and others (Reference Xiong, Yin and Nicot2019), where the 3-D H-model is used to model geotechnical problems. In this approach, a granular material is described as a distribution of mesostructures formed by a few grains. The collection of these mesostructures (denoted H-cells in the following) in various configurations provides a statistical description of the microstructure. From the individual mechanical response of each mesostructure, the material constitutive relation can be formulated in a continuum framework by statistical homogenization. In the hereafter presented extension of the 3-D H-model, the particles forming the H-cells represent ice grains with an interparticle contact law specifically suited to ice. The latter was developed to capture the ice bond evolution as well as the ice grain contact and is partly based on a previous work (Kabore and others, Reference Kabore, Peters, Michael and Nicot2021). As many engineering applications (vehicles moving on snow, winter sports, …) imply short-term time scales and fast loading, only the brittle behaviour of ice will be considered in the following. Since density is one of the most important parameters in snow behaviour, special attention is brought to the relationship between the geometry of the mesostructures in the H-model and the macroscopic density. The influence of the aging of snow before the mechanical loading and its impact on the calibration of the numerical parameter are also investigated. Finally, the capacity of the model to account for varying conditions such as the temperature and the loading rate is demonstrated.

2. Multi-scale model for snow

The H-model was initially developed for granular soils, first in two dimensions (Nicot and Darve, Reference Nicot and Darve2011; Veylon and others, Reference Veylon, Nicot, Zhu and Darve2018) before being extended to three dimensions (Xiong and others, Reference Xiong, Nicot and Yin2017). It has been progressively extended to capture additional physical phenomena, such as the existence of capillary forces in unsaturated soils (Wautier, Reference Wautier2021; Xiong, Reference Xiong2021), or erosion by suffusion (Ma and others, Reference Ma, Wautier and Nicot2022). Here, further extension of the 3-D H-model to snow modelling relies on implementing a specific customized contact law for ice bonds, restricting the scope of the study to fast loading conditions (strain rate above ![]() ${10^{ - 4}}{{\text{s}}^{ - 1}}{ }$), so that the ice behaviour can be assumed to be exclusively brittle (Schulson, Reference Schulson1990).

${10^{ - 4}}{{\text{s}}^{ - 1}}{ }$), so that the ice behaviour can be assumed to be exclusively brittle (Schulson, Reference Schulson1990).

2.1. A multi-scale constitutive model for granular materials: the 3-D H-model

Contrary to phenomenological approaches, multi-scale models introduce a statistical homogenization process, which consists in inferring the mechanical behaviour of a given material from the constitutive properties taking place at a smaller microscopic scale (Wautier, Reference Wautier2021). More precisely, the material constitutive law is obtained from the weighted averaged behaviours of several mesostructures, which are each constituted by a set of grains. First conceptualized by Satake (Reference Satake1992) and later explored by Kruyt and Rothenburg (Reference Kruyt and Rothenburg1996), grain loops are an example of such mesostructures in a 2-D granular assembly. In principle, these loops enable a geometrical description through a particle graph paving the space and have been shown to be a powerful tool to explain the behaviour of granular materials based on local physics. Namely, it has been observed that grain loops containing more than six grains within a granular material can serve as a meaningful descriptor for the material scale behaviour (Zhu and others, Reference Zhu, Veylon, Nicot and Darve2016, Reference Zhu, Nicot and Darve2016a, Reference Zhu, Nicot and Darve2016b; Liu and others, Reference Liu, Nicot and Zhou2018). These results support the physical suitability of the H-model in which the microstructure is described as a collection of either hexagonal grain assemblies in the 2-D H-model (Nicot and Darve, Reference Nicot and Darve2011) or bi-hexagonal grain assemblies in the 3-D H-model (Xiong and others, Reference Xiong, Nicot and Yin2017).

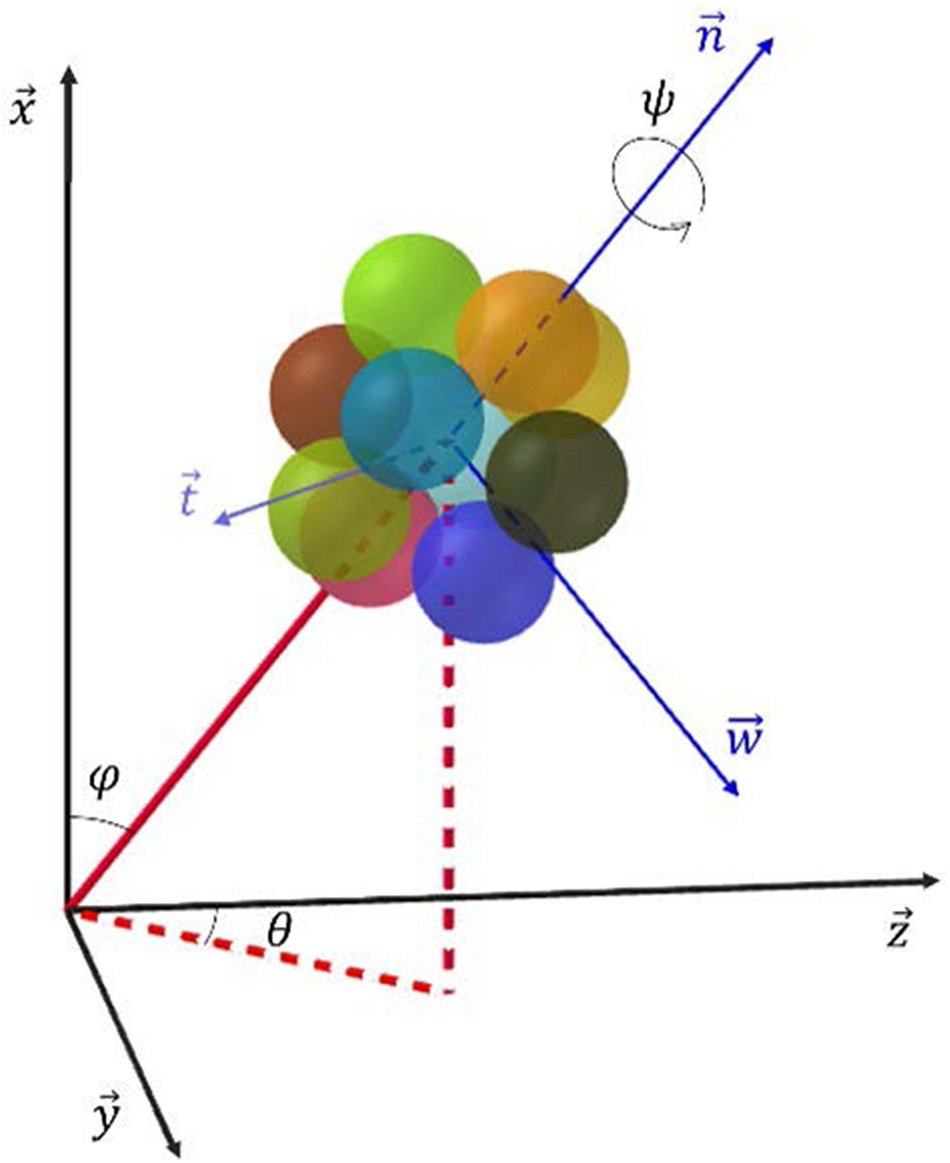

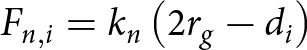

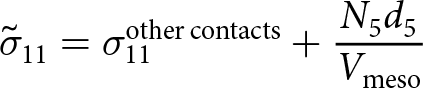

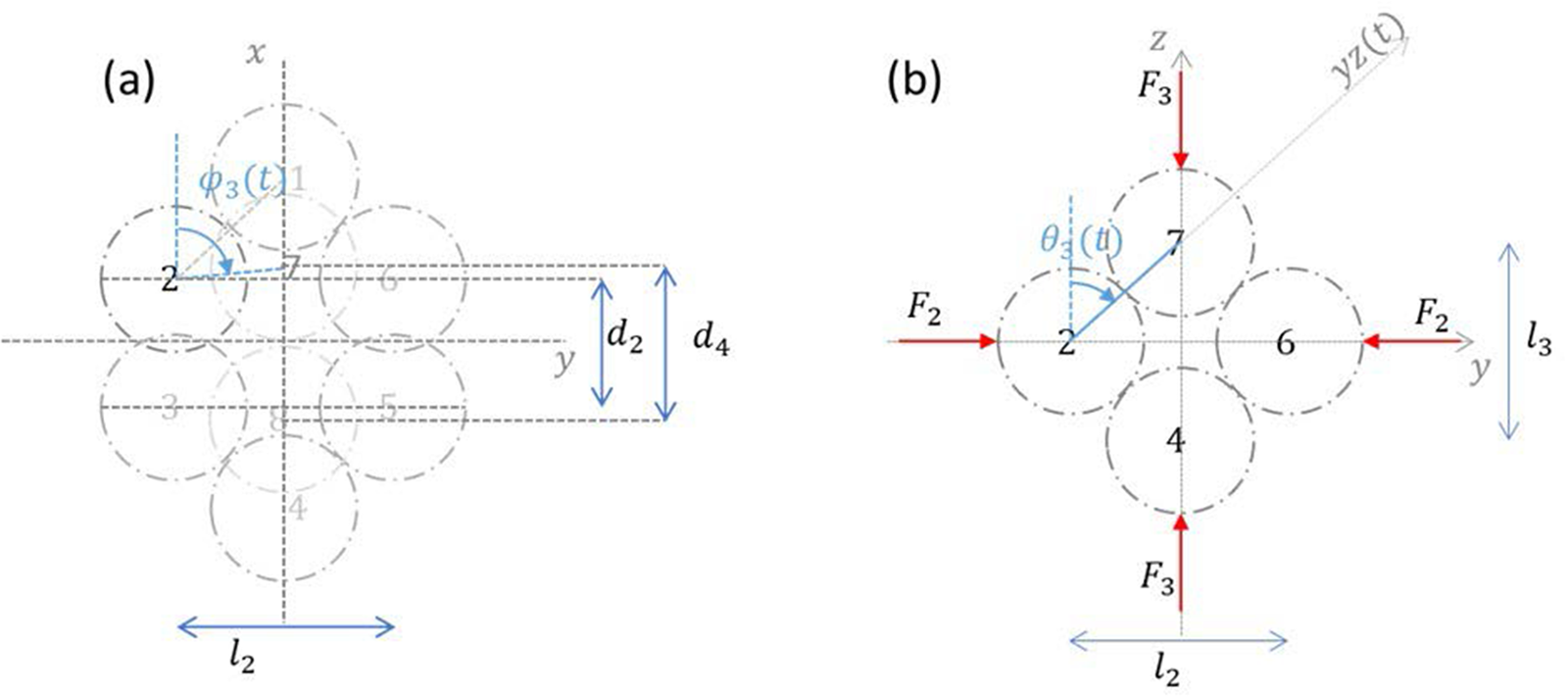

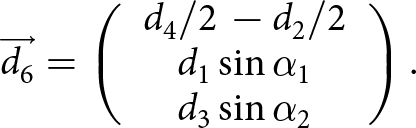

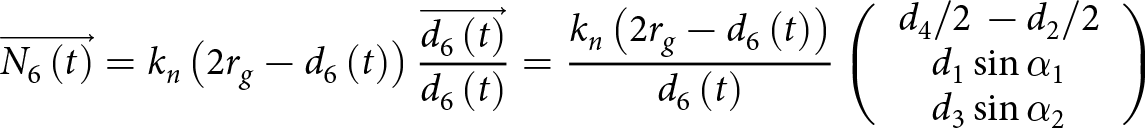

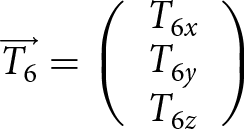

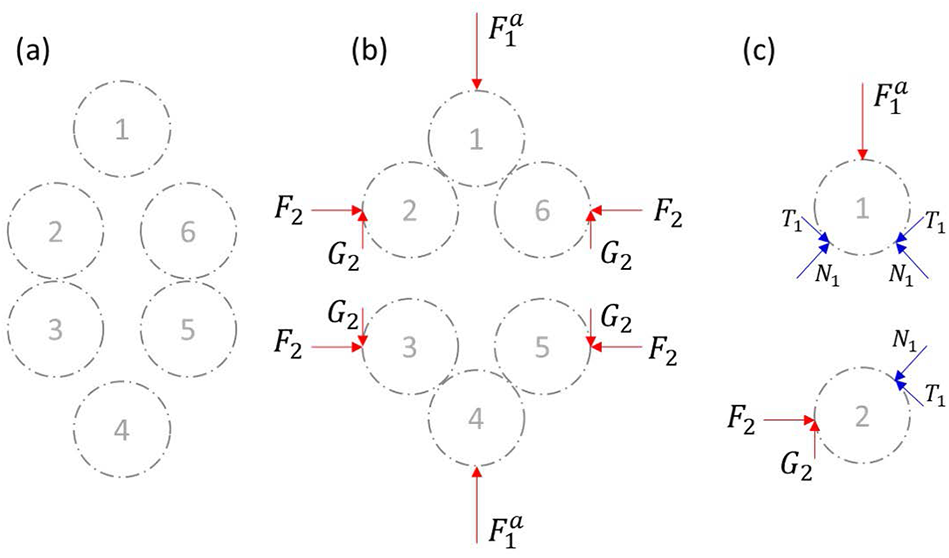

The tridimensional bi-hexagonal mesostructure is formed of two perpendicular hexagons as represented in Fig. 1. Each H-cell has an orientation in space, characterized by the three Euler angles ![]() $\varphi $,

$\varphi $, ![]() $\theta $ and

$\theta $ and ![]() $\psi $ with respect to the global reference frame. The distribution of this orientation

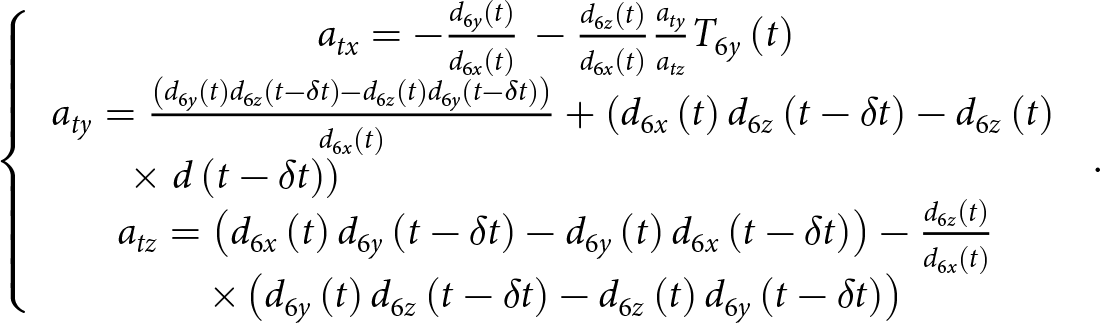

$\psi $ with respect to the global reference frame. The distribution of this orientation ![]() $\omega \left( {\theta ,\varphi ,\psi } \right){ }$ describes the initial anisotropy of the microstructure. The two hexagons of the mesostructure are supposed to remain in orthogonal planes over any loading. The planar geometry of the two hexagons is shown in Fig. 2. By adopting symmetry assumptions in the cell geometry, each hexagon can be parameterized by only two intergranular distances (

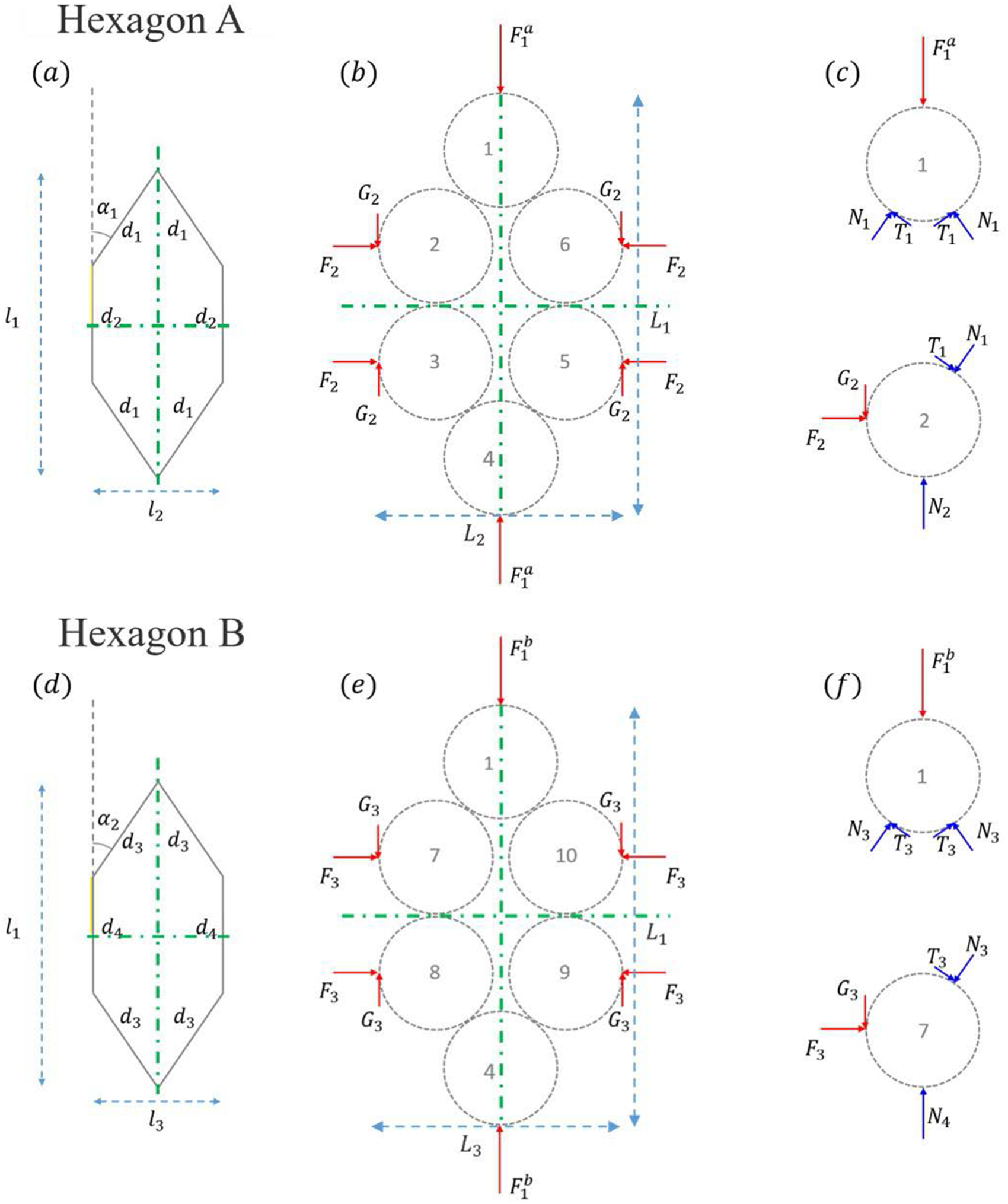

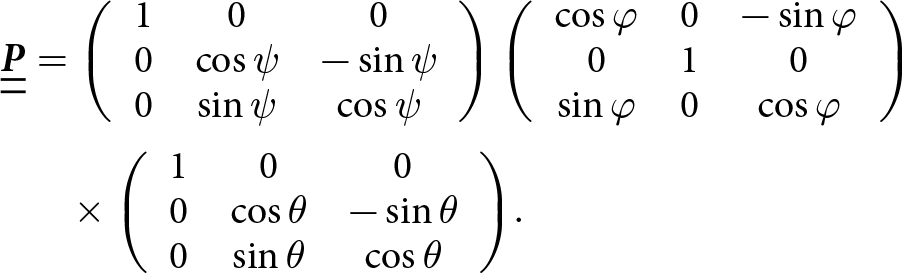

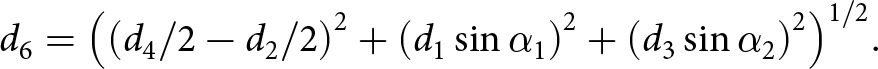

$\omega \left( {\theta ,\varphi ,\psi } \right){ }$ describes the initial anisotropy of the microstructure. The two hexagons of the mesostructure are supposed to remain in orthogonal planes over any loading. The planar geometry of the two hexagons is shown in Fig. 2. By adopting symmetry assumptions in the cell geometry, each hexagon can be parameterized by only two intergranular distances (![]() ${d_1}$ and

${d_1}$ and ![]() ${d_2}$ in hexagon A, and

${d_2}$ in hexagon A, and ![]() ${d_3}$ and

${d_3}$ and ![]() ${d_4}$ in hexagon B) and an opening angle (

${d_4}$ in hexagon B) and an opening angle (![]() ${\alpha _1}$ in hexagon A and

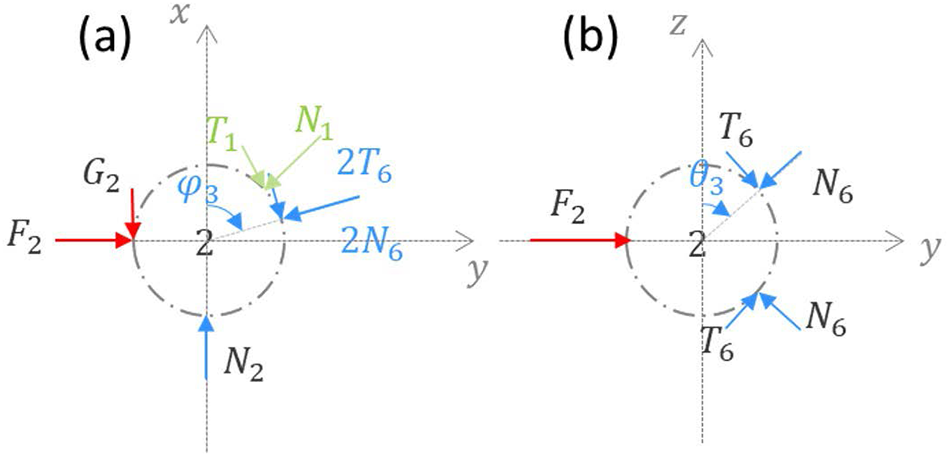

${\alpha _1}$ in hexagon A and ![]() ${\alpha _2}$ in hexagon B). The symmetries in the cell allow to consider only four different contact points, between grains 1–2, 2–3, 1–7 and 7–8. To maintain the overall symmetry assumption in the cell geometry, equality is also imposed between the various forces within the cell:

${\alpha _2}$ in hexagon B). The symmetries in the cell allow to consider only four different contact points, between grains 1–2, 2–3, 1–7 and 7–8. To maintain the overall symmetry assumption in the cell geometry, equality is also imposed between the various forces within the cell: ![]() ${F_{\text{i}}}$ and

${F_{\text{i}}}$ and ![]() ${G_{\text{i}}}$, representing the normal and tangential external forces in the three directions of the space, and

${G_{\text{i}}}$, representing the normal and tangential external forces in the three directions of the space, and ![]() ${N_{\text{i}}}$ and

${N_{\text{i}}}$ and ![]() ${T_{\text{i}}}$, representing the normal and tangential contact forces at the four different contact points between the grains, as described in Fig. 2. The external vertical force on grain 1 can be decomposed into two terms

${T_{\text{i}}}$, representing the normal and tangential contact forces at the four different contact points between the grains, as described in Fig. 2. The external vertical force on grain 1 can be decomposed into two terms ![]() $F_1^a$ and

$F_1^a$ and ![]() $F_1^b$, which respectively insure the equilibrium of hexagons A and B.

$F_1^b$, which respectively insure the equilibrium of hexagons A and B.

Figure 1. 3-D bi-hexagonal mesostructure in the global reference frame with the definition of the Euler angles.

Figure 2. Schematic representation of the two hexagonal grain configurations constituting the 3-D H-cell showing: (a, d) geometry of the hexagons, (b, e) external forces on the hexagons and (c, f) equilibrium of forces on the grains. The dashed-dotted green lines represent the symmetry axis in the considered plane.

Depending on the loading of the cells, some contacts between grains can appear or be lost. Appendices C and D describe these potential cases in detail.

The overall homogenization scheme used for the H-model, as summarized in Fig. 3, allows connecting continuum/macroscale and particle/microscale descriptions of the material. An incremental constitutive relation linking the global incremental strain tensor ![]() ${{\delta }}\underline {\underline {\boldsymbol{\varepsilon }} } $ to the global incremental stress

${{\delta }}\underline {\underline {\boldsymbol{\varepsilon }} } $ to the global incremental stress ![]() ${{\delta }}\underline {\underline {\boldsymbol{\sigma }} } $ is thus implicitly derived. In the following, we briefly review the main steps of this homogenization scheme.

${{\delta }}\underline {\underline {\boldsymbol{\sigma }} } $ is thus implicitly derived. In the following, we briefly review the main steps of this homogenization scheme.

Figure 3. Schematic representation of overall sequence of the 3-D H-model methodology.

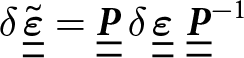

The model assumes strain homogeneity such that the same macroscopic strain is applied in all H-cells. Consequently, the local incremental strain tensor ![]() ${{\delta }}\underline {\underline {\widetilde {\boldsymbol{\varepsilon }}} } $ in each H-cell is expressed in the local frame as

${{\delta }}\underline {\underline {\widetilde {\boldsymbol{\varepsilon }}} } $ in each H-cell is expressed in the local frame as

\begin{equation}{{\delta }}\,\underline {\underline {\widetilde {\boldsymbol{\varepsilon }}} } = \underline {\underline {\boldsymbol{P}} }\,{{\delta }}\,\underline {\underline {\boldsymbol{\varepsilon }} } \,\,{ }{\underline {\underline {\boldsymbol{P}} } ^{ - 1}}\end{equation}

\begin{equation}{{\delta }}\,\underline {\underline {\widetilde {\boldsymbol{\varepsilon }}} } = \underline {\underline {\boldsymbol{P}} }\,{{\delta }}\,\underline {\underline {\boldsymbol{\varepsilon }} } \,\,{ }{\underline {\underline {\boldsymbol{P}} } ^{ - 1}}\end{equation} with ![]() $\underline {P}$ being the rotation matrix between the global and local frames:

$\underline {P}$ being the rotation matrix between the global and local frames:

\begin{align}\underline {\underline {\boldsymbol{P}} }& = \left( {\begin{array}{*{20}{c}}

1&0&0 \\

0&{\cos \psi }&{ - \sin \psi } \\

0&{\sin \psi }&{\cos \psi }

\end{array}} \right)\left( {\begin{array}{*{20}{c}}

{\cos \varphi }&0&{ - \sin \varphi } \\

0&1&0 \\

{\sin \varphi }&0&{\cos \varphi }

\end{array}} \right)\nonumber\\ &\quad{}\times\left( {\begin{array}{*{20}{c}}

1&0&0 \\

0&{\cos \theta }&{ - \sin \theta } \\

0&{\sin \theta }&{\cos \theta }

\end{array}} \right)\!.\end{align}

\begin{align}\underline {\underline {\boldsymbol{P}} }& = \left( {\begin{array}{*{20}{c}}

1&0&0 \\

0&{\cos \psi }&{ - \sin \psi } \\

0&{\sin \psi }&{\cos \psi }

\end{array}} \right)\left( {\begin{array}{*{20}{c}}

{\cos \varphi }&0&{ - \sin \varphi } \\

0&1&0 \\

{\sin \varphi }&0&{\cos \varphi }

\end{array}} \right)\nonumber\\ &\quad{}\times\left( {\begin{array}{*{20}{c}}

1&0&0 \\

0&{\cos \theta }&{ - \sin \theta } \\

0&{\sin \theta }&{\cos \theta }

\end{array}} \right)\!.\end{align} The changes in the H-cell lengths ![]() ${{\delta }}{L_{\text{i}}}$ can be deduced from the diagonal coefficients of the local incremental strain tensor and the external length of the H-cell

${{\delta }}{L_{\text{i}}}$ can be deduced from the diagonal coefficients of the local incremental strain tensor and the external length of the H-cell ![]() ${L_{\text{i}}}$, as defined in Fig. 2:

${L_{\text{i}}}$, as defined in Fig. 2:

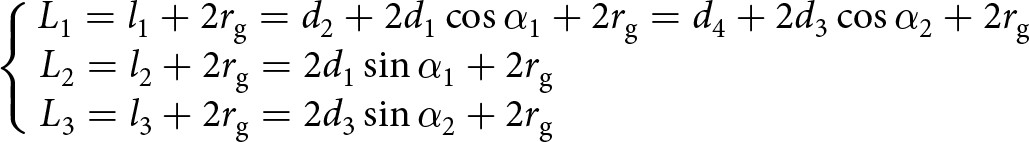

The evolution of the H-cell geometry depends directly on the variations of the H-cell lengths and on the force balance applied to the mesostructure. The geometrical compatibility equations read:

\begin{align}\left\{ \!\!{\begin{array}{*{20}{c}}

{{L_1} = {l_1} + 2{r_{\text{g}}} = {d_2} + 2{d_1}\cos {\alpha _1} + 2{r_{\text{g}}} = {d_4} + 2{d_3}\cos {\alpha _2} + 2{r_{\text{g}}}} \\

\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!{{L_2} = {l_2} + 2{r_{\text{g}}} = 2{d_1}\sin {\alpha _1} + 2{r_{\text{g}}}{ }} \\

\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!{{L_3} = {l_3} + 2{r_{\text{g}}} = 2{d_3}\sin {\alpha _2} + 2{r_{\text{g}}}{ }}

\end{array}} \right.\nonumber\\ \end{align}

\begin{align}\left\{ \!\!{\begin{array}{*{20}{c}}

{{L_1} = {l_1} + 2{r_{\text{g}}} = {d_2} + 2{d_1}\cos {\alpha _1} + 2{r_{\text{g}}} = {d_4} + 2{d_3}\cos {\alpha _2} + 2{r_{\text{g}}}} \\

\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!{{L_2} = {l_2} + 2{r_{\text{g}}} = 2{d_1}\sin {\alpha _1} + 2{r_{\text{g}}}{ }} \\

\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!{{L_3} = {l_3} + 2{r_{\text{g}}} = 2{d_3}\sin {\alpha _2} + 2{r_{\text{g}}}{ }}

\end{array}} \right.\nonumber\\ \end{align} with ![]() ${L_{\text{i}}}$ the lengths of the smallest peripheral parallelepiped volume,

${L_{\text{i}}}$ the lengths of the smallest peripheral parallelepiped volume, ![]() ${l_{\text{i}}}$ the lengths of the hexagons defined by the centres of the grains and

${l_{\text{i}}}$ the lengths of the hexagons defined by the centres of the grains and ![]() ${r_{\text{g}}}$ the grain radius.

${r_{\text{g}}}$ the grain radius.

Differential variation of Eqn (4) provides three equations relating the variations of the H-cell lengths ![]() ${{\delta }}{L_{\text{i}}}$ to the variations of both the intergranular distances

${{\delta }}{L_{\text{i}}}$ to the variations of both the intergranular distances ![]() ${{\delta }}{d_{\text{i}}}$ and the opening angles

${{\delta }}{d_{\text{i}}}$ and the opening angles ![]() ${{\delta }}{\alpha _{\text{i}}}:$

${{\delta }}{\alpha _{\text{i}}}:$

\begin{equation}\left\{\kern-8pt\begin{array}{c}\;\;\delta L_2=\delta d_2+2\delta d_1\cos\alpha_1+d_1\sin\alpha_1\,\delta\alpha_1\\\;\;\;\;\;\;\;\;=\delta d_4+2\delta d_3\cos\alpha_2+d_3\sin\alpha_2\,\delta\alpha_2\\\delta L_2=2\delta d_1\sin\alpha_1+d_1\cos\alpha_1\,\delta\alpha_1\;\;\;\;\;\;\;\\\delta L_3=2\delta d_3\sin\alpha_2+d_3\cos\alpha_2\,\delta\alpha_2\;\;\;\;\;\;\;\end{array}\right..\!\\\end{equation}

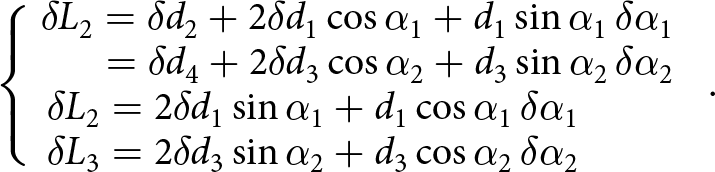

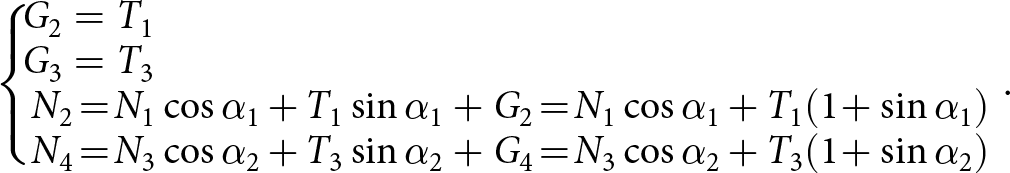

\begin{equation}\left\{\kern-8pt\begin{array}{c}\;\;\delta L_2=\delta d_2+2\delta d_1\cos\alpha_1+d_1\sin\alpha_1\,\delta\alpha_1\\\;\;\;\;\;\;\;\;=\delta d_4+2\delta d_3\cos\alpha_2+d_3\sin\alpha_2\,\delta\alpha_2\\\delta L_2=2\delta d_1\sin\alpha_1+d_1\cos\alpha_1\,\delta\alpha_1\;\;\;\;\;\;\;\\\delta L_3=2\delta d_3\sin\alpha_2+d_3\cos\alpha_2\,\delta\alpha_2\;\;\;\;\;\;\;\end{array}\right..\!\\\end{equation}Considering the balance of forces and momentum for the grains 2 and 7 provides:

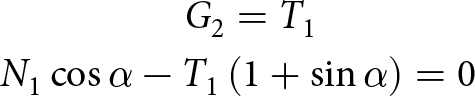

\begin{align}\left\{ \!\!{\begin{array}{c}

\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!{{G_2} = {T_1}\,} \\

\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!{{G_3} = {T_3}\,} \\

\!{{N_2} \!=\! {N_1}\cos {\alpha _1} \,{+}\, {T_1}\sin {\alpha _1} + {G_2} \!=\! {N_1}\cos {\alpha _1} \,{+}\, {T_1}( {1 \!+ \sin {\alpha _1}} )} \\

\!{{N_4} \!=\! {N_3}\cos {\alpha _2} \,{+}\, {T_3}\sin {\alpha _2} + {G_4} \!=\! {N_3}\cos {\alpha _2} \,{+}\, {T_3}( {1 \!+ \sin {\alpha _2}} )}

\end{array}} \right.\!\!\!.\!\!\!\nonumber\\ \end{align}

\begin{align}\left\{ \!\!{\begin{array}{c}

\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!{{G_2} = {T_1}\,} \\

\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!\!{{G_3} = {T_3}\,} \\

\!{{N_2} \!=\! {N_1}\cos {\alpha _1} \,{+}\, {T_1}\sin {\alpha _1} + {G_2} \!=\! {N_1}\cos {\alpha _1} \,{+}\, {T_1}( {1 \!+ \sin {\alpha _1}} )} \\

\!{{N_4} \!=\! {N_3}\cos {\alpha _2} \,{+}\, {T_3}\sin {\alpha _2} + {G_4} \!=\! {N_3}\cos {\alpha _2} \,{+}\, {T_3}( {1 \!+ \sin {\alpha _2}} )}

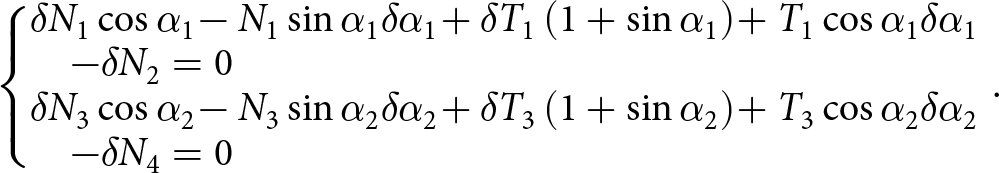

\end{array}} \right.\!\!\!.\!\!\!\nonumber\\ \end{align}Differentiating these last two equilibrium equations yields:

\begin{align}\left\{\kern-5pt {\begin{array}{l}

\delta {N_1}\cos {\alpha _1} \!- {N_1}\sin {\alpha _1}\delta {\alpha _1} \!+ \delta {T_1}\left( {1 + \sin {\alpha _1}} \right) \!+ {T_1}\cos {\alpha _1}\delta {\alpha _1} \\ \quad - \delta {N_2} = 0 \\

\delta {N_3}\cos {\alpha _2} \!- {N_3}\sin {\alpha _2}\delta {\alpha _2} \!+ \delta {T_3}\left( {1 + \sin {\alpha _2}} \right) \!+ {T_3}\cos {\alpha _2}\delta {\alpha _2}\\ \quad- \delta {N_4} = 0

\end{array}} \right.\!\!\!.\!\!\!\nonumber\\ \end{align}

\begin{align}\left\{\kern-5pt {\begin{array}{l}

\delta {N_1}\cos {\alpha _1} \!- {N_1}\sin {\alpha _1}\delta {\alpha _1} \!+ \delta {T_1}\left( {1 + \sin {\alpha _1}} \right) \!+ {T_1}\cos {\alpha _1}\delta {\alpha _1} \\ \quad - \delta {N_2} = 0 \\

\delta {N_3}\cos {\alpha _2} \!- {N_3}\sin {\alpha _2}\delta {\alpha _2} \!+ \delta {T_3}\left( {1 + \sin {\alpha _2}} \right) \!+ {T_3}\cos {\alpha _2}\delta {\alpha _2}\\ \quad- \delta {N_4} = 0

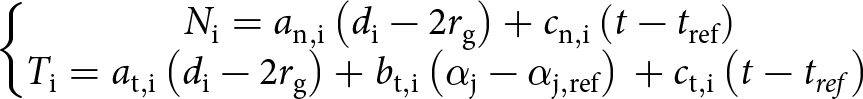

\end{array}} \right.\!\!\!.\!\!\!\nonumber\\ \end{align} The contact forces are related to the H-cell geometrical parameters through a contact law. In the general case of a visco-elastic contact, a generic form of the contact law at a given contact ![]() ${\text{i}}$ reads:

${\text{i}}$ reads:

\begin{equation}\left\{\kern-5pt {\begin{array}{l}

\qquad\qquad{{N_{\text{i}}} = {a_{{\text{n}},{\text{i}}}}\left( {{d_{\text{i}}} - 2{r_{\text{g}}}} \right) + {c_{{\text{n}},{\text{i}}}}\left( {t - {t_{{\text{ref}}}}} \right)\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,} \\

{{T_{\text{i}}} = {a_{{\text{t}},{\text{i}}}}\left( {{d_{\text{i}}} - 2{r_{\text{g}}}} \right) + {b_{{\text{t}},{\text{i}}}}\left( {{\alpha _{\text{j}}} - {\alpha _{{\text{j}},{\text{ref}}}}} \right)\, + {c_{{\text{t}},{\text{i}}}}\left( {t - {t_{ref}}} \right)}

\end{array}} \right.\end{equation}

\begin{equation}\left\{\kern-5pt {\begin{array}{l}

\qquad\qquad{{N_{\text{i}}} = {a_{{\text{n}},{\text{i}}}}\left( {{d_{\text{i}}} - 2{r_{\text{g}}}} \right) + {c_{{\text{n}},{\text{i}}}}\left( {t - {t_{{\text{ref}}}}} \right)\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,} \\

{{T_{\text{i}}} = {a_{{\text{t}},{\text{i}}}}\left( {{d_{\text{i}}} - 2{r_{\text{g}}}} \right) + {b_{{\text{t}},{\text{i}}}}\left( {{\alpha _{\text{j}}} - {\alpha _{{\text{j}},{\text{ref}}}}} \right)\, + {c_{{\text{t}},{\text{i}}}}\left( {t - {t_{ref}}} \right)}

\end{array}} \right.\end{equation} with ![]() ${a_{{\text{n}},{\text{i}}}}$,

${a_{{\text{n}},{\text{i}}}}$, ![]() ${c_{{\text{n}},{\text{i}}}},$

${c_{{\text{n}},{\text{i}}}},$ ![]() ${a_{{\text{t}},{\text{i}}}}$,

${a_{{\text{t}},{\text{i}}}}$, ![]() ${b_{{\text{t}},{\text{i}}}}$ and

${b_{{\text{t}},{\text{i}}}}$ and ![]() ${c_{{\text{t}},{\text{i}}}}$ being independent of the geometry. The

${c_{{\text{t}},{\text{i}}}}$ being independent of the geometry. The ![]() ${a_{{\text{n}},{\text{i}}}}$ and the

${a_{{\text{n}},{\text{i}}}}$ and the ![]() ${a_{{\text{t}},{\text{i}}}}$ coefficients are stiffness terms expressing the evolution of the intergranular distance in terms of the incremental contact forces (normal and tangential respectively). The coefficients

${a_{{\text{t}},{\text{i}}}}$ coefficients are stiffness terms expressing the evolution of the intergranular distance in terms of the incremental contact forces (normal and tangential respectively). The coefficients ![]() ${b_{{\text{t}},{\text{i}}}}$ link the tangential contact force to the evolution of the opening angle. The coefficients

${b_{{\text{t}},{\text{i}}}}$ link the tangential contact force to the evolution of the opening angle. The coefficients ![]() ${c_{{\text{n}},{\text{i}}}}$ and

${c_{{\text{n}},{\text{i}}}}$ and ![]() ${c_{{\text{t}},{\text{i}}}}$ are viscosity terms, which depend on the contact loading. Note that

${c_{{\text{t}},{\text{i}}}}$ are viscosity terms, which depend on the contact loading. Note that ![]() ${\alpha _{{\text{i}},{\text{ref}}}}$ denotes the opening angle at the beginning of the loading at time

${\alpha _{{\text{i}},{\text{ref}}}}$ denotes the opening angle at the beginning of the loading at time ![]() ${t_{{\text{ref}}}}$. The contact law specifically developed for snow will be detailed in the next section.

${t_{{\text{ref}}}}$. The contact law specifically developed for snow will be detailed in the next section.

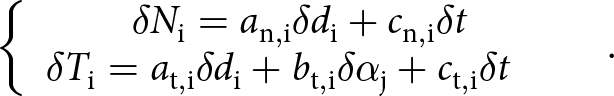

Differentiation of Eqn (8) provides a generic incremental form of the contact law:

\begin{equation}\left\{ {\begin{array}{l}

\quad\,\,\,\,\,\,\,{\delta {N_{\text{i}}} = {a_{{\text{n}},{\text{i}}}}\delta {d_{\text{i}}} + {c_{{\text{n}},{\text{i}}}}\delta t\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,} \\

{\delta {T_{\text{i}}} = {a_{{\text{t}},{\text{i}}}}\delta {d_{\text{i}}} + {b_{{\text{t}},{\text{i}}}}\delta {\alpha _{\text{j}}} + {c_{{\text{t}},{\text{i}}}}\delta t}

\end{array}} \right..\end{equation}

\begin{equation}\left\{ {\begin{array}{l}

\quad\,\,\,\,\,\,\,{\delta {N_{\text{i}}} = {a_{{\text{n}},{\text{i}}}}\delta {d_{\text{i}}} + {c_{{\text{n}},{\text{i}}}}\delta t\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,} \\

{\delta {T_{\text{i}}} = {a_{{\text{t}},{\text{i}}}}\delta {d_{\text{i}}} + {b_{{\text{t}},{\text{i}}}}\delta {\alpha _{\text{j}}} + {c_{{\text{t}},{\text{i}}}}\delta t}

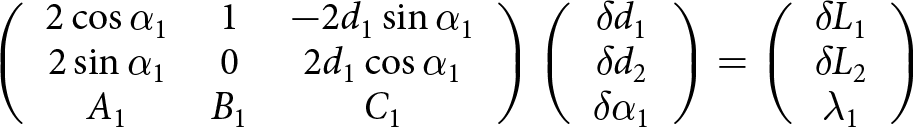

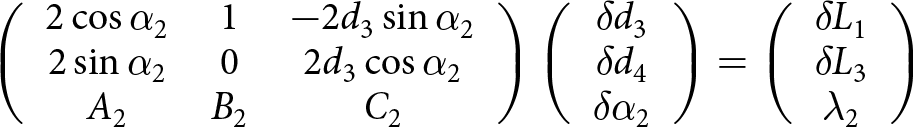

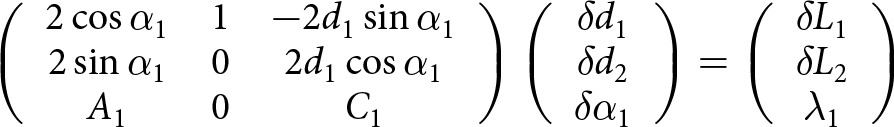

\end{array}} \right..\end{equation}Combining Eqns (5), (7) and (9) results in two sets of equations that provide the changes in the intergranular distances and in the opening angles as a function of the changes in the H-cell lengths:

\begin{equation}\left( {\begin{array}{*{20}{c}}

{2\cos {\alpha _1}}&1&{ - 2{d_1}\sin {\alpha _1}} \\

{2\sin {\alpha _1}}&0&{2{d_1}\cos {\alpha _1}} \\

{{A_1}}&{{B_1}}&{{C_1}}

\end{array}} \right)\left( {\begin{array}{*{20}{c}}

{\delta {d_1}} \\

{\delta {d_2}} \\

{\delta {\alpha _1}}

\end{array}} \right) = \left( {\begin{array}{*{20}{c}}

{\delta {L_1}} \\

{\delta {L_2}} \\

{{\lambda _1}}

\end{array}} \right)\end{equation}

\begin{equation}\left( {\begin{array}{*{20}{c}}

{2\cos {\alpha _1}}&1&{ - 2{d_1}\sin {\alpha _1}} \\

{2\sin {\alpha _1}}&0&{2{d_1}\cos {\alpha _1}} \\

{{A_1}}&{{B_1}}&{{C_1}}

\end{array}} \right)\left( {\begin{array}{*{20}{c}}

{\delta {d_1}} \\

{\delta {d_2}} \\

{\delta {\alpha _1}}

\end{array}} \right) = \left( {\begin{array}{*{20}{c}}

{\delta {L_1}} \\

{\delta {L_2}} \\

{{\lambda _1}}

\end{array}} \right)\end{equation}and

\begin{equation}\left( {\begin{array}{*{20}{c}}

{2\cos {\alpha _2}}&1&{ - 2{d_3}\sin {\alpha _2}} \\

{2\sin {\alpha _2}}&0&{2{d_3}\cos {\alpha _2}} \\

{{A_2}}&{{B_2}}&{{C_2}}

\end{array}} \right)\left( {\begin{array}{*{20}{c}}

{\delta {d_3}} \\

{\delta {d_4}} \\

{\delta {\alpha _2}}

\end{array}} \right) = \left( {\begin{array}{*{20}{c}}

{\delta {L_1}} \\

{\delta {L_3}} \\

{{\lambda _2}}

\end{array}} \right)\end{equation}

\begin{equation}\left( {\begin{array}{*{20}{c}}

{2\cos {\alpha _2}}&1&{ - 2{d_3}\sin {\alpha _2}} \\

{2\sin {\alpha _2}}&0&{2{d_3}\cos {\alpha _2}} \\

{{A_2}}&{{B_2}}&{{C_2}}

\end{array}} \right)\left( {\begin{array}{*{20}{c}}

{\delta {d_3}} \\

{\delta {d_4}} \\

{\delta {\alpha _2}}

\end{array}} \right) = \left( {\begin{array}{*{20}{c}}

{\delta {L_1}} \\

{\delta {L_3}} \\

{{\lambda _2}}

\end{array}} \right)\end{equation}with

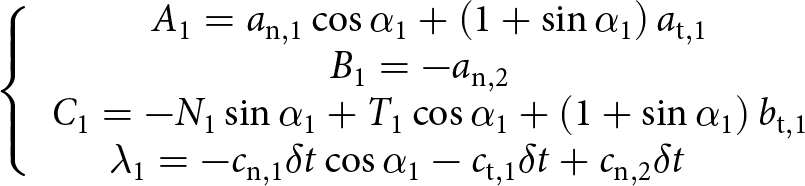

\begin{equation}\left\{ {\begin{array}{*{20}{c}}

{{A_1} = {a_{{\text{n}},1}}\cos {\alpha _1} + \left( {1 + \sin {\alpha _1}} \right){a_{{\text{t}},1}}} \\

\!\!\!{{B_1} = - {a_{{\text{n}},2}}} \\

{{C_1} = - {N_1}\sin {\alpha _1} + {T_1}\cos {\alpha _1} + \left( {1 + \sin {\alpha _1}} \right){b_{{\text{t}},1}}} \\

\!\!\!\!\!\!\!\!\!\!{{\lambda _1} = - {c_{{\text{n}},1}}\delta t\cos {\alpha _1} - {c_{{\text{t}},1}}\delta t + {c_{{\text{n}},2}}\delta t}

\end{array}} \right.\end{equation}

\begin{equation}\left\{ {\begin{array}{*{20}{c}}

{{A_1} = {a_{{\text{n}},1}}\cos {\alpha _1} + \left( {1 + \sin {\alpha _1}} \right){a_{{\text{t}},1}}} \\

\!\!\!{{B_1} = - {a_{{\text{n}},2}}} \\

{{C_1} = - {N_1}\sin {\alpha _1} + {T_1}\cos {\alpha _1} + \left( {1 + \sin {\alpha _1}} \right){b_{{\text{t}},1}}} \\

\!\!\!\!\!\!\!\!\!\!{{\lambda _1} = - {c_{{\text{n}},1}}\delta t\cos {\alpha _1} - {c_{{\text{t}},1}}\delta t + {c_{{\text{n}},2}}\delta t}

\end{array}} \right.\end{equation}and

\begin{equation}\left\{ {\begin{array}{*{20}{c}}

{\,{A_2} = {a_{{\text{n}},3}}\cos {\alpha _2} + \left( {1 + \sin {\alpha _2}} \right){a_{{\text{t}},3}}} \\

\!\!{{B_2} = - {a_{{\text{n}},4}}} \\

{{C_2} = - {N_3}\sin {\alpha _2} + {T_3}\cos {\alpha _2} + \left( {1 + \sin {\alpha _2}} \right){b_{{\text{t}},2}}} \\

\!\!\!\!\!\!\!\!\!\!\!\!{{\lambda _2} = - {c_{{\text{n}},3}}\delta t\cos {\alpha _2} - {c_{{\text{t}},3}}\delta t + {c_{{\text{n}},4}}\delta t}

\end{array}} \right..\end{equation}

\begin{equation}\left\{ {\begin{array}{*{20}{c}}

{\,{A_2} = {a_{{\text{n}},3}}\cos {\alpha _2} + \left( {1 + \sin {\alpha _2}} \right){a_{{\text{t}},3}}} \\

\!\!{{B_2} = - {a_{{\text{n}},4}}} \\

{{C_2} = - {N_3}\sin {\alpha _2} + {T_3}\cos {\alpha _2} + \left( {1 + \sin {\alpha _2}} \right){b_{{\text{t}},2}}} \\

\!\!\!\!\!\!\!\!\!\!\!\!{{\lambda _2} = - {c_{{\text{n}},3}}\delta t\cos {\alpha _2} - {c_{{\text{t}},3}}\delta t + {c_{{\text{n}},4}}\delta t}

\end{array}} \right..\end{equation}The incremental contact forces can be obtained from the incremental intergranular distances and opening angles according to the incremental contact law (9).

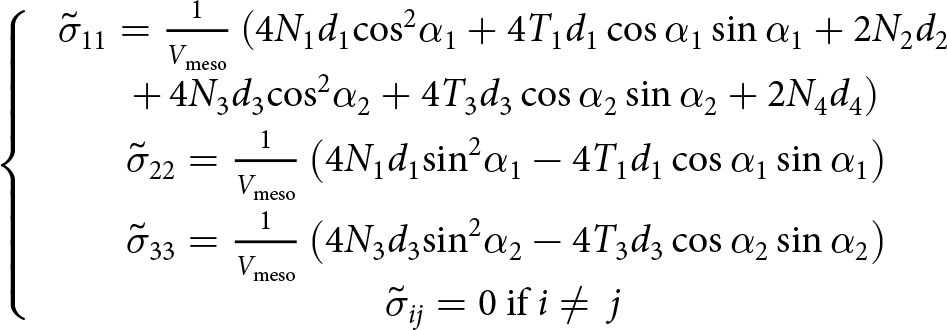

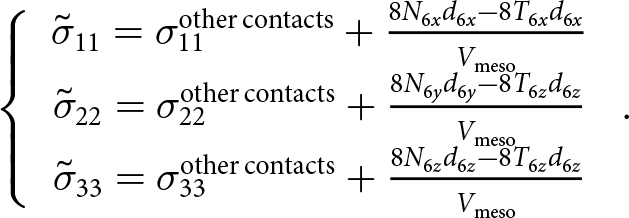

Continuing with the continuum formulation, the Love–Weber formula (Love, Reference Love1892) expresses the local stresses ![]() $\underline {\underline {\widetilde {\boldsymbol{\sigma }}} } $ at the scale of the H-cell from the updated contact forces

$\underline {\underline {\widetilde {\boldsymbol{\sigma }}} } $ at the scale of the H-cell from the updated contact forces ![]() ${N_{\text{i}}}\left( t \right) = {N_{\text{i}}}\left( {t - {{\delta }}t} \right) + {{\delta }}{N_{\text{i}}}$ and

${N_{\text{i}}}\left( t \right) = {N_{\text{i}}}\left( {t - {{\delta }}t} \right) + {{\delta }}{N_{\text{i}}}$ and ![]() ${T_{\text{i}}}\left( t \right) = {T_{\text{i}}}\left( {t - {{\delta }}t} \right) + {{\delta }}{T_{\text{i}}}$

${T_{\text{i}}}\left( t \right) = {T_{\text{i}}}\left( {t - {{\delta }}t} \right) + {{\delta }}{T_{\text{i}}}$

\begin{align}\left\{ {\begin{array}{*{20}{c}}

{\,{{\tilde \sigma }_{11}} = \frac{1}{{{V_{{\text{meso}}}}}}\left( {4{N_{\text{1}}}{d_1}{{\cos }^2}{\alpha _1} + 4{T_1}{d_1}\cos {\alpha _1}\sin {\alpha _1} + 2{N_2}{d_2}} \right.} \\[5pt]

{\left. {+\,4{N_{\text{3}}}{d_3}{{\cos }^2}{\alpha _2} + 4{T_3}{d_3}\cos {\alpha _2}\sin {\alpha _2} + 2{N_4}{d_4}} \right)} \\[3pt]

{\,{{\tilde \sigma }_{22}} = \frac{1}{{{V_{{\text{meso}}}}}}\left( {4{N_{\text{1}}}{d_1}{{\sin }^2}{\alpha _1} - 4{T_1}{d_1}\cos {\alpha _1}\sin \alpha_1} \right)} \\[7pt]

{\,{{\tilde \sigma }_{33}} = \frac{1}{{{V_{{\text{meso}}}}}}\left( {4{N_{\text{3}}}{d_3}{{\sin }^2}{\alpha _2} - 4{T_3}{d_3}\cos {\alpha _2}\sin \alpha_2} \right)}\\

{\tilde \sigma}_{ij}=0\ {\text{if}}\ i\neq\ j\\

\end{array}} \right.\nonumber\\ \end{align}

\begin{align}\left\{ {\begin{array}{*{20}{c}}

{\,{{\tilde \sigma }_{11}} = \frac{1}{{{V_{{\text{meso}}}}}}\left( {4{N_{\text{1}}}{d_1}{{\cos }^2}{\alpha _1} + 4{T_1}{d_1}\cos {\alpha _1}\sin {\alpha _1} + 2{N_2}{d_2}} \right.} \\[5pt]

{\left. {+\,4{N_{\text{3}}}{d_3}{{\cos }^2}{\alpha _2} + 4{T_3}{d_3}\cos {\alpha _2}\sin {\alpha _2} + 2{N_4}{d_4}} \right)} \\[3pt]

{\,{{\tilde \sigma }_{22}} = \frac{1}{{{V_{{\text{meso}}}}}}\left( {4{N_{\text{1}}}{d_1}{{\sin }^2}{\alpha _1} - 4{T_1}{d_1}\cos {\alpha _1}\sin \alpha_1} \right)} \\[7pt]

{\,{{\tilde \sigma }_{33}} = \frac{1}{{{V_{{\text{meso}}}}}}\left( {4{N_{\text{3}}}{d_3}{{\sin }^2}{\alpha _2} - 4{T_3}{d_3}\cos {\alpha _2}\sin \alpha_2} \right)}\\

{\tilde \sigma}_{ij}=0\ {\text{if}}\ i\neq\ j\\

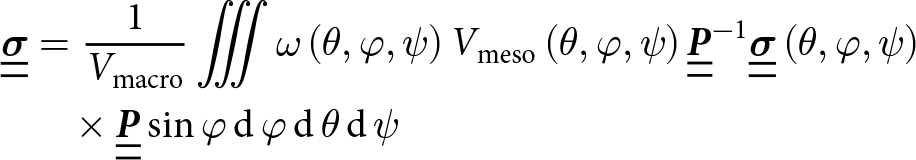

\end{array}} \right.\nonumber\\ \end{align} where ![]() ${V_{{\text{meso}}}}$ is the external volume of the mesostructure (Wautier, Reference Wautier2021). Finally, a statistical homogenization of the stresses over the complete H-cell collection provides the stress tensor

${V_{{\text{meso}}}}$ is the external volume of the mesostructure (Wautier, Reference Wautier2021). Finally, a statistical homogenization of the stresses over the complete H-cell collection provides the stress tensor ![]() $\underline {\underline {\boldsymbol{\sigma }} } $ in the global frame:

$\underline {\underline {\boldsymbol{\sigma }} } $ in the global frame:

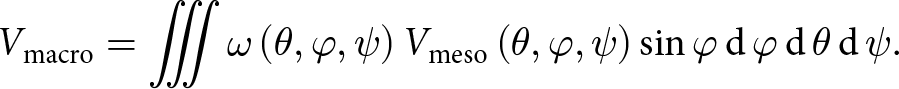

\begin{align}\underline {\underline {\boldsymbol{\sigma }} } &= \frac{1}{{{V_{{\text{macro}}}}}}\iiint \omega \left( {\theta ,\varphi ,\psi } \right){V_{{\text{meso}}}}\left( {\theta ,\varphi ,\psi } \right){{\underline {\underline {\boldsymbol{P}} } }^{ - 1}}{ }\underline {\underline {\boldsymbol{\sigma }} } \left( {\theta ,\varphi ,\psi } \right){ } \nonumber\\ &\quad\times\underline {\underline {\boldsymbol{P}} } \sin \varphi\,{\text{d}}\,\varphi\,{\text{d}}\,\theta\,{\text{d}}\,\psi \end{align}

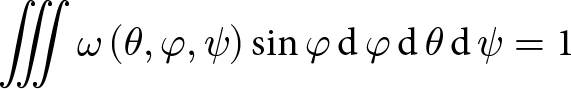

\begin{align}\underline {\underline {\boldsymbol{\sigma }} } &= \frac{1}{{{V_{{\text{macro}}}}}}\iiint \omega \left( {\theta ,\varphi ,\psi } \right){V_{{\text{meso}}}}\left( {\theta ,\varphi ,\psi } \right){{\underline {\underline {\boldsymbol{P}} } }^{ - 1}}{ }\underline {\underline {\boldsymbol{\sigma }} } \left( {\theta ,\varphi ,\psi } \right){ } \nonumber\\ &\quad\times\underline {\underline {\boldsymbol{P}} } \sin \varphi\,{\text{d}}\,\varphi\,{\text{d}}\,\theta\,{\text{d}}\,\psi \end{align} where ![]() $\omega \left( {\theta ,\varphi ,\psi } \right)$ is the probability density function of the H-cell distribution, which satisfies:

$\omega \left( {\theta ,\varphi ,\psi } \right)$ is the probability density function of the H-cell distribution, which satisfies:

\begin{equation}\iiint {\omega \left( {\theta ,\varphi ,\psi } \right)\sin \varphi\,{\text{d}}\,\varphi\,{\text{d}}\,\theta\,{\text{d}}\,\psi } = 1\end{equation}

\begin{equation}\iiint {\omega \left( {\theta ,\varphi ,\psi } \right)\sin \varphi\,{\text{d}}\,\varphi\,{\text{d}}\,\theta\,{\text{d}}\,\psi } = 1\end{equation} and ![]() ${V_{{\text{macro}}}}$ is the total volume of the distribution of H-cells given by:

${V_{{\text{macro}}}}$ is the total volume of the distribution of H-cells given by:

\begin{equation}{V_{{\text{macro}}}} = \iiint {\omega \left( {\theta ,\varphi ,\psi } \right){V_{{\text{meso}}}}\left( {\theta ,\varphi ,\psi } \right)\sin \varphi\,{\text{d}}\,\varphi\,{\text{d}}\,\theta\,{\text{d}}\,\psi}.\end{equation}

\begin{equation}{V_{{\text{macro}}}} = \iiint {\omega \left( {\theta ,\varphi ,\psi } \right){V_{{\text{meso}}}}\left( {\theta ,\varphi ,\psi } \right)\sin \varphi\,{\text{d}}\,\varphi\,{\text{d}}\,\theta\,{\text{d}}\,\psi}.\end{equation}Eventually, we obtain a multi-scale constitutive model that relates the total stress to the global strain under an incremental formalism (Fig. 3). The hypothesis of non-correlated mesostructures inferred by the statistical homogenization, and the hypothesis on the geometry of the mesostructure could lead to an error, but previous works on the H-model (Nicot and Darve, Reference Nicot and Darve2011; Xiong and others, Reference Xiong, Nicot and Yin2017; Veylon and others, Reference Veylon, Nicot, Zhu and Darve2018; Wautier, Reference Wautier2021; Xiong, Reference Xiong2021; Deng, Reference Deng2022; Liu and others, Reference Liu, Nicot, Wautier and Darve2024) have proven that this error is not significant.

2.2. Contact law between ice grains

In the extended version of the 3-D H-model proposed hereafter, the snow constitutive features are accounted for by introducing a specific contact law between the ice grains of each hexagon of a H-cell. In the context of the snow-H-model, the history of a contact is supposed to be the following:

(i) The ice grains have undergone metamorphism processes which progressively round their shape (Fierz, Reference Fierz2009). Ice grains are thus assumed to be spherical.

(ii) Thermodynamic sintering has created viscous ice bonds at all contacts between ice grains (Kabore and others, Reference Kabore, Peters, Michael and Nicot2021) (Peters and others, Reference Peters, Kabore, Michael and Nicot2021). Each ice bond is assumed to be incompressible (Lipovsky, Reference Lipovsky2022), meaning that its volume originates only from the prior sintering conditions, such as temperature and sintering time (Szabo and Schneebeli, Reference Szabo and Schneebeli2007).

(iii) Bond creation processes are supposed to be slow compared to the loading rates considered in the targeted applications (

$\dot \varepsilon { } \geqslant {10^{ - 4}}{ }{{\text{s}}^{ - 1}}$). Consequently, if an ice bond fails during the stress loading, it has no time to reform, and the contact becomes cohesionless until the end of the loading.

$\dot \varepsilon { } \geqslant {10^{ - 4}}{ }{{\text{s}}^{ - 1}}$). Consequently, if an ice bond fails during the stress loading, it has no time to reform, and the contact becomes cohesionless until the end of the loading.

Based on these assumptions, the contact law to be developed in the snow-H-model must account for both bonded and unbonded contacts between spherical ice grains.

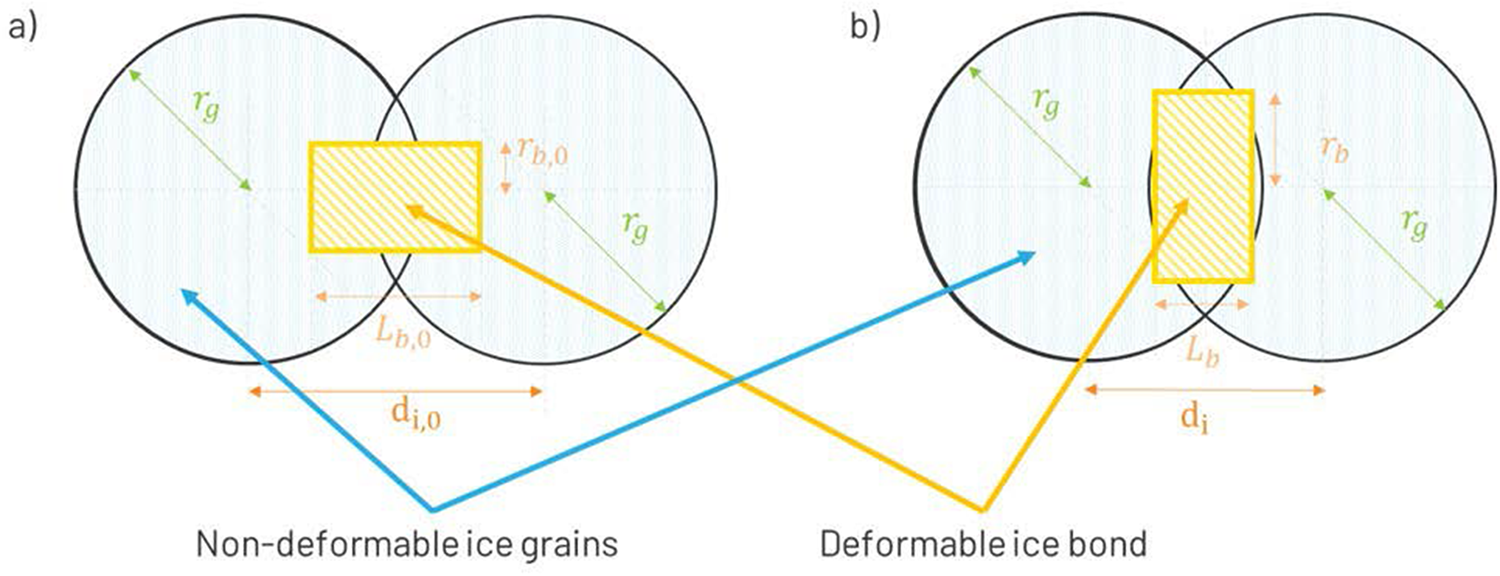

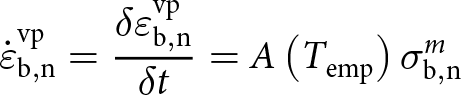

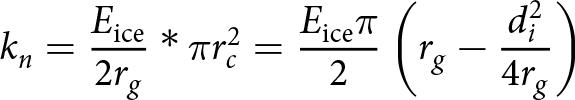

Grains in contact are assumed to be initially bonded by a cylindrical ice bridge resulting from prior snow metamorphism (Fig. 4). The bridge is characterized by its radius ![]() ${r_{\text{b}}}$ and its length

${r_{\text{b}}}$ and its length ![]() ${L_{\text{b}}}$, with

${L_{\text{b}}}$, with ![]() ${r_{{\text{b}},0}}$ and

${r_{{\text{b}},0}}$ and ![]() ${L_{{\text{b}},0}}$ their respective values at the initial time step. Note that the initial bond geometry before loading created by prior thermodynamic sintering can be changed through its initial radius, enabling the modelling of different snow types (Szabo and Schneebeli, Reference Szabo and Schneebeli2007). During mechanical loading, the strain is assumed to be localized into the cylindrical ice bonds while the spherical ice grains are assumed perfectly rigid so that the strain is fully concentrated within the bond.

${L_{{\text{b}},0}}$ their respective values at the initial time step. Note that the initial bond geometry before loading created by prior thermodynamic sintering can be changed through its initial radius, enabling the modelling of different snow types (Szabo and Schneebeli, Reference Szabo and Schneebeli2007). During mechanical loading, the strain is assumed to be localized into the cylindrical ice bonds while the spherical ice grains are assumed perfectly rigid so that the strain is fully concentrated within the bond.

Figure 4. Schematic representation of a bonded contact: (a) initially after snow metamorphism and before loading; (b) during the loading. The yellow hatched zones represent the deformable ice bond, and the blue dotted zones represent the non-deformable parts of the ice grains.

The deformable bond between two ice grains is modelled by a Maxwell elasto-viscoplastic beam on the basis of the work of Kabore and others (Reference Kabore, Peters, Michael and Nicot2021) and Peters and others (Reference Peters, Kabore, Michael and Nicot2021). The main discrepancy with this model lies in the absence of grain rotation in the H-model which leads to the lack of torsion and bending in the ice beam. The creep behaviour of ice, which can be dominant during loading, is accounted for by introducing viscoplasticity in the bond.

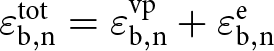

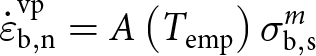

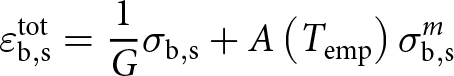

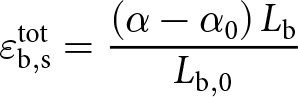

The total normal bond strain ![]() $\varepsilon_{{\text{b}},{\text{n}}}^{{\text{tot}}}$ can be split into an elastic part

$\varepsilon_{{\text{b}},{\text{n}}}^{{\text{tot}}}$ can be split into an elastic part ![]() $\varepsilon_{{\text{b}},{\text{n}}}^{\text{e}}$ and a viscoplastic part

$\varepsilon_{{\text{b}},{\text{n}}}^{\text{e}}$ and a viscoplastic part  $\varepsilon _{{\text{b}},{\text{n}}}^{{\text{vp}}}$:

$\varepsilon _{{\text{b}},{\text{n}}}^{{\text{vp}}}$:

\begin{equation}\varepsilon _{{\text{b}},{\text{n}}}^{{\text{tot}}} = \varepsilon _{{\text{b}},{\text{n}}}^{{\text{vp}}} + \varepsilon _{{\text{b}},{\text{n}}}^{\text{e}}\end{equation}

\begin{equation}\varepsilon _{{\text{b}},{\text{n}}}^{{\text{tot}}} = \varepsilon _{{\text{b}},{\text{n}}}^{{\text{vp}}} + \varepsilon _{{\text{b}},{\text{n}}}^{\text{e}}\end{equation} The viscoplastic deformation accounts for the well-known creep behaviour of ice since the creep rate  $\dot \varepsilon _{{\text{b}},{\text{n}}}^{{\text{vp}}}$ in the bond direction is related to the normal stress

$\dot \varepsilon _{{\text{b}},{\text{n}}}^{{\text{vp}}}$ in the bond direction is related to the normal stress ![]() ${\sigma _{{\text{b}},{\text{n}}}}$ by Glen’s law (Barnes and others, Reference Barnes, Tabor and Walker1971):

${\sigma _{{\text{b}},{\text{n}}}}$ by Glen’s law (Barnes and others, Reference Barnes, Tabor and Walker1971):

\begin{equation}\dot \varepsilon _{{\text{b}},{\text{n}}}^{{\text{vp}}} = \frac{{{{\delta }}\varepsilon _{{\text{b}},{\text{n}}}^{{\text{vp}}}}}{{{{\delta }}t}} = A\left( {{T_{{\text{emp}}}}} \right)\sigma _{{\text{b}},{\text{n}}}^m\end{equation}

\begin{equation}\dot \varepsilon _{{\text{b}},{\text{n}}}^{{\text{vp}}} = \frac{{{{\delta }}\varepsilon _{{\text{b}},{\text{n}}}^{{\text{vp}}}}}{{{{\delta }}t}} = A\left( {{T_{{\text{emp}}}}} \right)\sigma _{{\text{b}},{\text{n}}}^m\end{equation} where  $A\left( {{T_{{\text{emp}}}}} \right)$ is a temperature dependent coefficient, and

$A\left( {{T_{{\text{emp}}}}} \right)$ is a temperature dependent coefficient, and ![]() $m$ is an exponent generally close to 3 (Barnes and others, Reference Barnes, Tabor and Walker1971).

$m$ is an exponent generally close to 3 (Barnes and others, Reference Barnes, Tabor and Walker1971).

Finally, the elastic normal deformation is simply proportional to the normal stress. Due to the adhesion of the bond on the ice grains (which prevents the bond from expanding laterally around the contact points), using Young’s modulus ![]() $E\,$ would underestimate the stiffness of the bond/grains assembly. Thus, the oedometer coefficient of ice

$E\,$ would underestimate the stiffness of the bond/grains assembly. Thus, the oedometer coefficient of ice ![]() ${E_{{\text{oedo}}}}$ is used instead to better reflect the lateral geometrical constraints:

${E_{{\text{oedo}}}}$ is used instead to better reflect the lateral geometrical constraints:

\begin{equation}{\sigma _{{\text{b}},{\text{n}}}} = \frac{{E\left( {1 - \nu } \right)}}{{\left( {1 + \nu } \right)\left( {1 - 2\nu } \right)}}\varepsilon _{{\text{b}},{\text{n}}}^{\text{e}} = {E_{{\text{oedo}}}}\varepsilon _{{\text{b}},{\text{n}}}^{\text{e}}\end{equation}

\begin{equation}{\sigma _{{\text{b}},{\text{n}}}} = \frac{{E\left( {1 - \nu } \right)}}{{\left( {1 + \nu } \right)\left( {1 - 2\nu } \right)}}\varepsilon _{{\text{b}},{\text{n}}}^{\text{e}} = {E_{{\text{oedo}}}}\varepsilon _{{\text{b}},{\text{n}}}^{\text{e}}\end{equation} with ![]() $\nu $ the Poisson’s ratio of ice.

$\nu $ the Poisson’s ratio of ice.

The normal strain in the bond can be expressed as a function of the bond length, thanks to the strain localization assumption:

\begin{equation}\varepsilon _{{\text{b}},{\text{n}}}^{{\text{tot}}} = - \frac{{{L_{\text{b}}} - {L_{{\text{b}},0}}}}{{{L_{{\text{b}},0}}}}\end{equation}

\begin{equation}\varepsilon _{{\text{b}},{\text{n}}}^{{\text{tot}}} = - \frac{{{L_{\text{b}}} - {L_{{\text{b}},0}}}}{{{L_{{\text{b}},0}}}}\end{equation} with ![]() ${L_{\text{b}}}$ and

${L_{\text{b}}}$ and ![]() ${L_{{\text{b}},0}}$ being the bond length, respectively, at the current time and at the beginning of the loading. It should be noted that compression and contraction are counted positive.

${L_{{\text{b}},0}}$ being the bond length, respectively, at the current time and at the beginning of the loading. It should be noted that compression and contraction are counted positive.

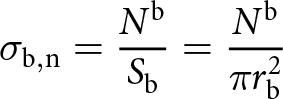

The normal stress can be related to the normal contact force ![]() ${N^{\text{b}}}$ as follows:

${N^{\text{b}}}$ as follows:

\begin{equation}{\sigma _{{\text{b}},{\text{n}}}} = \frac{{{N^{\text{b}}}}}{{{S_{\text{b}}}}} = \frac{{{N^{\text{b}}}}}{{{{\pi }}r_{\text{b}}^2}}\end{equation}

\begin{equation}{\sigma _{{\text{b}},{\text{n}}}} = \frac{{{N^{\text{b}}}}}{{{S_{\text{b}}}}} = \frac{{{N^{\text{b}}}}}{{{{\pi }}r_{\text{b}}^2}}\end{equation} where ![]() ${r_{\text{b}}}$ is the radius of the cylindrical bond and

${r_{\text{b}}}$ is the radius of the cylindrical bond and ![]() ${S_{\text{b}}}$ its section.

${S_{\text{b}}}$ its section.

As the bond is the only deformable element in the bonded ice grain model, the incremental bond length ![]() ${{\delta }}{L_{\text{b}}}$ is directly equal to the incremental intergranular distance

${{\delta }}{L_{\text{b}}}$ is directly equal to the incremental intergranular distance ![]() ${{\delta }}d$:

${{\delta }}d$:

Eventually, the incompressibility condition, together with the volume conservation of the ice bond, read:

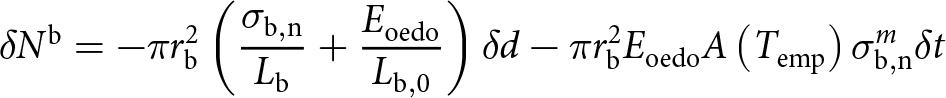

By combining Eqns (18)–(24), the contact law relating the incremental normal contact force ![]() ${{\delta }}{N^{\text{b}}}$ to the incremental intergranular distance

${{\delta }}{N^{\text{b}}}$ to the incremental intergranular distance ![]() ${{\delta }}d$ can be obtained:

${{\delta }}d$ can be obtained:

\begin{align}{{\delta }}{N^{\text{b}}} = - {{\pi }}r_{\text{b}}^2\left( {\frac{{{\sigma _{{\text{b}},{\text{n}}}}}}{{{L_{\text{b}}}}} + \frac{{{E_{{\text{oedo}}}}}}{{{L_{{\text{b}},0}}}}} \right){{\delta }}d - {{\pi }}r_{\text{b}}^2{E_{{\text{oedo}}}}A\left( {{T_{{\text{emp}}}}} \right)\sigma _{{\text{b}},{\text{n}}}^m{{\delta }}t\nonumber\\ \end{align}

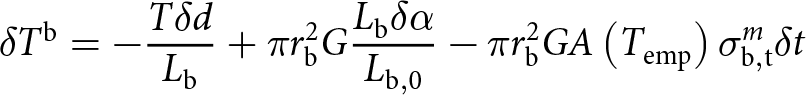

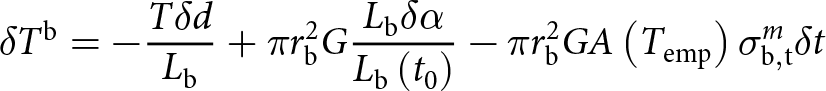

\begin{align}{{\delta }}{N^{\text{b}}} = - {{\pi }}r_{\text{b}}^2\left( {\frac{{{\sigma _{{\text{b}},{\text{n}}}}}}{{{L_{\text{b}}}}} + \frac{{{E_{{\text{oedo}}}}}}{{{L_{{\text{b}},0}}}}} \right){{\delta }}d - {{\pi }}r_{\text{b}}^2{E_{{\text{oedo}}}}A\left( {{T_{{\text{emp}}}}} \right)\sigma _{{\text{b}},{\text{n}}}^m{{\delta }}t\nonumber\\ \end{align} Likewise, the incremental tangential contact force can be expressed as a function of the incremental intergranular distance and of the variation of the bond direction, characterized by ![]() ${{\delta }}\alpha $:

${{\delta }}\alpha $:

\begin{equation}{{\delta }}{T^{\text{b}}} = - \frac{{T{{\delta }}d}}{{{L_{\text{b}}}}} + {{\pi }}r_{\text{b}}^2G\frac{{{L_{\text{b}}}{{\delta }}\alpha }}{{{L_{{\text{b}},0}}}} - {{\pi }}r_{\text{b}}^2GA\left( {{T_{{\text{emp}}}}} \right)\sigma _{{\text{b}},{\text{t}}}^m{{\delta }}t\end{equation}

\begin{equation}{{\delta }}{T^{\text{b}}} = - \frac{{T{{\delta }}d}}{{{L_{\text{b}}}}} + {{\pi }}r_{\text{b}}^2G\frac{{{L_{\text{b}}}{{\delta }}\alpha }}{{{L_{{\text{b}},0}}}} - {{\pi }}r_{\text{b}}^2GA\left( {{T_{{\text{emp}}}}} \right)\sigma _{{\text{b}},{\text{t}}}^m{{\delta }}t\end{equation} with  $G = \frac{E}{{2\left( {1 + \nu } \right)}}$ the shear modulus of ice. The way to obtain this expression using Glen’s law is detailed in Appendix A.

$G = \frac{E}{{2\left( {1 + \nu } \right)}}$ the shear modulus of ice. The way to obtain this expression using Glen’s law is detailed in Appendix A.

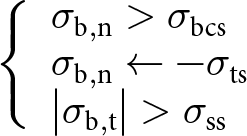

During the loading, stresses increase in the bond, which can lead to its failure. In our approach, only brittle failure is accounted for as the strain rate in the targeted engineering applications is supposed to be high enough (![]() $\dot \varepsilon \geqslant {10^{ - 4}}{{\text{s}}^{ - 1}}$). Brittle bond failure occurs as soon as one of the following conditions is met:

$\dot \varepsilon \geqslant {10^{ - 4}}{{\text{s}}^{ - 1}}$). Brittle bond failure occurs as soon as one of the following conditions is met:

\begin{equation}\left\{ {\begin{array}{l}

{{\sigma _{{\text{b}},{\text{n}}}} \gt {\sigma _{{\text{bcs}}}}} \\

{{\sigma _{{\text{b}},{\text{n}}}} \leftarrow - {\sigma _{{\text{ts}}}}} \\

{\left| {{\sigma _{{\text{b}},{\text{t}}}}} \right| \gt {\sigma _{{\text{ss}}}}}

\end{array}} \right.\end{equation}

\begin{equation}\left\{ {\begin{array}{l}

{{\sigma _{{\text{b}},{\text{n}}}} \gt {\sigma _{{\text{bcs}}}}} \\

{{\sigma _{{\text{b}},{\text{n}}}} \leftarrow - {\sigma _{{\text{ts}}}}} \\

{\left| {{\sigma _{{\text{b}},{\text{t}}}}} \right| \gt {\sigma _{{\text{ss}}}}}

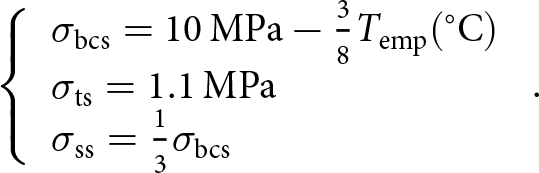

\end{array}} \right.\end{equation} where ![]() ${\sigma _{{\text{b}},{\text{n}}}}$ is the normal stress in the bond, which is positive in compression,

${\sigma _{{\text{b}},{\text{n}}}}$ is the normal stress in the bond, which is positive in compression, ![]() ${\sigma _{{\text{b}},{\text{t}}}}$ is the shear stress in the bond.

${\sigma _{{\text{b}},{\text{t}}}}$ is the shear stress in the bond. ![]() ${\sigma _{{\text{bcs}}}}$,

${\sigma _{{\text{bcs}}}}$, ![]() ${\sigma _{{\text{ts}}}}$ and

${\sigma _{{\text{ts}}}}$ and ![]() ${\sigma _{{\text{ss}}}}$ are respectively the compression, tensile and shear strength of ice (see Figure 5). The expression of the brittle strengths of the ice bonds is given by Michael (Reference Michael2014) and Kabore and others (Reference Kabore, Peters, Michael and Nicot2021):

${\sigma _{{\text{ss}}}}$ are respectively the compression, tensile and shear strength of ice (see Figure 5). The expression of the brittle strengths of the ice bonds is given by Michael (Reference Michael2014) and Kabore and others (Reference Kabore, Peters, Michael and Nicot2021):

\begin{equation}\left\{ {\begin{array}{l}

{{\sigma _{{\text{bcs}}}} = 10\,\text{MPa} - \frac{3}{8}{T_{{\text{emp}}}}{(^ \circ }\text{C})} \\

{{\sigma _{{\text{ts}}}} = 1.1\,\text{MPa}\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,} \\

{{\sigma _{{\text{ss}}}} = \frac{1}{3}{\sigma _{{\text{bcs}}}}\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,}

\end{array}} \right..\end{equation}

\begin{equation}\left\{ {\begin{array}{l}

{{\sigma _{{\text{bcs}}}} = 10\,\text{MPa} - \frac{3}{8}{T_{{\text{emp}}}}{(^ \circ }\text{C})} \\

{{\sigma _{{\text{ts}}}} = 1.1\,\text{MPa}\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,} \\

{{\sigma _{{\text{ss}}}} = \frac{1}{3}{\sigma _{{\text{bcs}}}}\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,}

\end{array}} \right..\end{equation}

Figure 5. Different modes of bond failure (tensile, compression and shear). Note that potential additional failure modes by bending and torsion are not accounted for as rotation of the grains is not possible in the H-model.

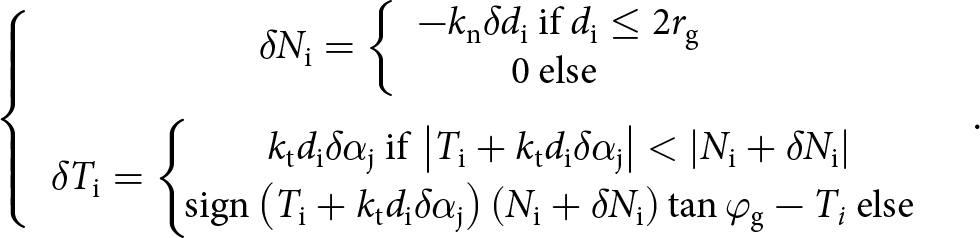

When bond failure occurs, the contact law between the ice grains is reduced to a simple elasto-plastic law:

\begin{align}\left\{ {\begin{array}{c}

{\delta {N_{\text{i}}} = \left\{ {\begin{array}{*{20}{c}}

{- {k_{\text{n}}}{{\delta }}{d_{\text{i}}}{\text{ if }}{d_{\text{i}}} \leq 2{r_{\text{g}}}} \\

{0{\text{ else }}}

\end{array}} \right.\,} \\[12pt]

{\delta {T_{\text{i}}} = \left\{ {\begin{array}{*{20}{c}}

{{k_{\text{t}}}{d_{\text{i}}}{{\delta }}{\alpha _{\text{j}}}{\text{ if }}\left| {{T_{\text{i}}} + {k_{\text{t}}}{d_{\text{i}}}{{\delta }}{\alpha _{\text{j}}}} \right| \lt \left| {{N_{\text{i}}} + {{\delta }}{N_{\text{i}}}} \right|{ }} \\[3pt]

{\!\!\!\!{\text{sign}}\left( {{T_{\text{i}}} + {k_{\text{t}}}{d_{\text{i}}}{{\delta }}{\alpha _{\text{j}}}} \right)\left( {{N_{\text{i}}} + {{\delta }}{N_{\text{i}}}} \right)\tan {\varphi _{\text{g}}} - {T_i}{\text{ else}}}

\end{array}} \right.}

\end{array}} \right..\nonumber\\ \end{align}

\begin{align}\left\{ {\begin{array}{c}

{\delta {N_{\text{i}}} = \left\{ {\begin{array}{*{20}{c}}

{- {k_{\text{n}}}{{\delta }}{d_{\text{i}}}{\text{ if }}{d_{\text{i}}} \leq 2{r_{\text{g}}}} \\

{0{\text{ else }}}

\end{array}} \right.\,} \\[12pt]

{\delta {T_{\text{i}}} = \left\{ {\begin{array}{*{20}{c}}

{{k_{\text{t}}}{d_{\text{i}}}{{\delta }}{\alpha _{\text{j}}}{\text{ if }}\left| {{T_{\text{i}}} + {k_{\text{t}}}{d_{\text{i}}}{{\delta }}{\alpha _{\text{j}}}} \right| \lt \left| {{N_{\text{i}}} + {{\delta }}{N_{\text{i}}}} \right|{ }} \\[3pt]

{\!\!\!\!{\text{sign}}\left( {{T_{\text{i}}} + {k_{\text{t}}}{d_{\text{i}}}{{\delta }}{\alpha _{\text{j}}}} \right)\left( {{N_{\text{i}}} + {{\delta }}{N_{\text{i}}}} \right)\tan {\varphi _{\text{g}}} - {T_i}{\text{ else}}}

\end{array}} \right.}

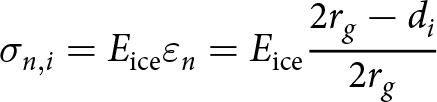

\end{array}} \right..\nonumber\\ \end{align} In the absence of ice bond, the normal stiffness ![]() ${k_{{\text{n}},{\text{i}}}}$ between ice grains at contact

${k_{{\text{n}},{\text{i}}}}$ between ice grains at contact ![]() $i\,$ evolves with grain interpenetration (see justification in Appendix B):

$i\,$ evolves with grain interpenetration (see justification in Appendix B):

\begin{equation}{k_{{\text{n}},{\text{i}}}} = {E_{{\text{ice}}}}\frac{{{\pi }}}{2}\left( {{r_{\text{g}}} - \frac{{d_{\text{i}}^2}}{{4{r_{\text{g}}}}}} \right).\end{equation}

\begin{equation}{k_{{\text{n}},{\text{i}}}} = {E_{{\text{ice}}}}\frac{{{\pi }}}{2}\left( {{r_{\text{g}}} - \frac{{d_{\text{i}}^2}}{{4{r_{\text{g}}}}}} \right).\end{equation}2.3. Extension of the 3-D H-model to snow

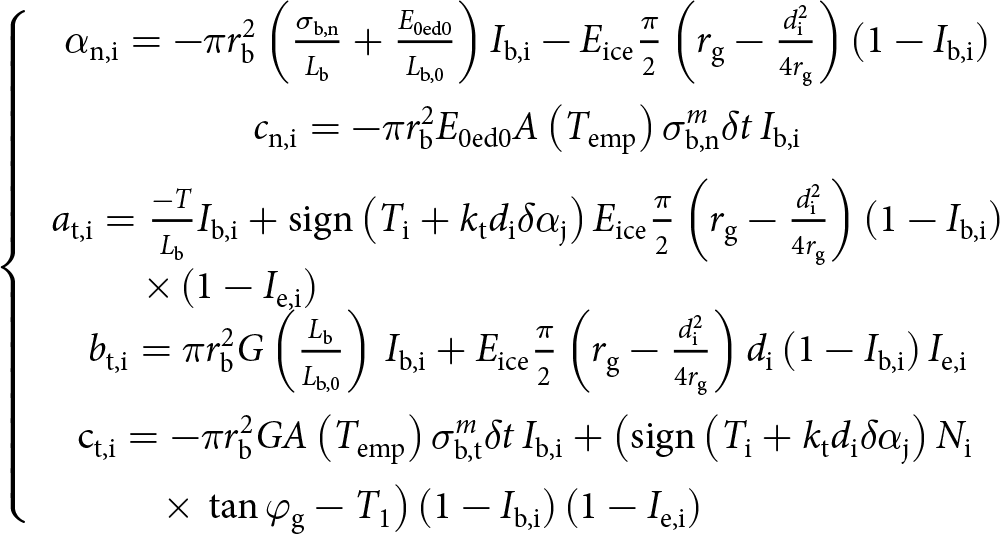

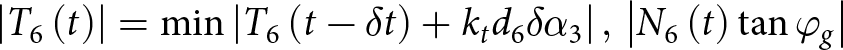

The relationship between the incremental contact forces and the changes in the local kinematics (including the intergranular distances between two ice grains and the contact direction) has been previously established in Section 2.2, both for a bonded contact (Eqns (25) and (26)) and after failure of the ice bond (Eqn (29)). The incremental normal contact force in Eqns (25) and (29) and the incremental tangential force in Eqns (26) and (29) can be written generically as in Eqn (9), with the corresponding coefficients:

\begin{align}\left\{ {\begin{array}{*{20}{c}}

{\alpha _{{\text{n,i}}}} = - {{\pi }}r_{\text{b}}^2\left( {\frac{{{\sigma _{{\text{b,n}}}}}}{{{L_{\text{b}}}}} + \frac{{{E_{{\text{0ed0}}}}}}{{{L_{{\text{b,0}}}}}}} \right){I_{{\text{b,i}}}} - {E_{{\text{ice}}}}\frac{{{\pi }}}{2}\left( {{r_{\text{g}}} - \frac{{d_{\text{i}}^2}}{{4{r_{\text{g}}}}}} \right) \left( {1 - {I_{{\text{b,i}}}}} \right) \\[10pt]

{{c_{{\text{n,i}}}} = - {{\pi }}r_{\text{b}}^2{E_{{\text{0ed0}}}}A\left( {{T_{{\text{emp}}}}} \right)\sigma _{{\text{b,n}}}^m\delta t\,{I_{{\text{b,i}}}}} \\[7pt]

{a_{{\text{t,i}}}} = \frac{-T}{{{L_{\text{b}}}}}{I_{{\text{b,i}}}} + {\text{sign}}\left( {{T_{\text{i}}} + {k_{\text{t}}}{d_{\text{i}}}\delta {\alpha _{\text{j}}}} \right){E_{{\text{ice}}}}\frac{{{\pi }}}{2}\left( {{r_{\text{g}}} - \frac{{d_{\text{i}}^2}}{{4{r_{\text{g}}}}}} \right)\left( {1 - {I_{{\text{b,i}}}}} \right)\\ \times\left( {1 - {I_{{\text{e,i}}}}} \right)\quad\qquad\qquad\qquad\qquad\qquad\qquad\qquad\quad \\

{b_{{\text{t,i}}}} = {{\pi }}r_{\text{b}}^2G\left( {\frac{{{L_{\text{b}}}}}{{{L_{{\text{b,0}}}}}}} \right)\,{I_{{\text{b,i}}}} + {E_{{\text{ice}}}}\frac{{{\pi }}}{2}\left( {{r_{\text{g}}} - \frac{{d_{\text{i}}^2}}{{4{r_{\text{g}}}}}} \right){d_{\text{i}}}\left( {1 - {I_{{\text{b,i}}}}} \right){I_{{\text{e,i}}}} \\[10pt]

{{\text{c}}_{{\text{t,i}}}} = - {{\pi }}r_{\text{b}}^2GA\left( {{T_{{\text{emp}}}}} \right)\sigma _{{\text{b,t}}}^m\delta t\,{I_{{\text{b,i}}}} + \left( {\text{sign}}\left( {{T_{\text{i}}} + {k_{\text{t}}}{d_{\text{i}}}\delta {\alpha _{\text{j}}}} \right){N_{\text{i}}} \right.\\[6pt] \quad{} \times\left.{\text{tan}}\,{\varphi _{\text{g}}} - {T_{\text{1}}} \right)\left( {1 - {I_{{\text{b,i}}}}} \right)\left( {1 - {I_{{\text{e,i}}}}} \right)\qquad\qquad\quad\quad\quad

\end{array}} \right.\nonumber\\ \end{align}

\begin{align}\left\{ {\begin{array}{*{20}{c}}

{\alpha _{{\text{n,i}}}} = - {{\pi }}r_{\text{b}}^2\left( {\frac{{{\sigma _{{\text{b,n}}}}}}{{{L_{\text{b}}}}} + \frac{{{E_{{\text{0ed0}}}}}}{{{L_{{\text{b,0}}}}}}} \right){I_{{\text{b,i}}}} - {E_{{\text{ice}}}}\frac{{{\pi }}}{2}\left( {{r_{\text{g}}} - \frac{{d_{\text{i}}^2}}{{4{r_{\text{g}}}}}} \right) \left( {1 - {I_{{\text{b,i}}}}} \right) \\[10pt]

{{c_{{\text{n,i}}}} = - {{\pi }}r_{\text{b}}^2{E_{{\text{0ed0}}}}A\left( {{T_{{\text{emp}}}}} \right)\sigma _{{\text{b,n}}}^m\delta t\,{I_{{\text{b,i}}}}} \\[7pt]

{a_{{\text{t,i}}}} = \frac{-T}{{{L_{\text{b}}}}}{I_{{\text{b,i}}}} + {\text{sign}}\left( {{T_{\text{i}}} + {k_{\text{t}}}{d_{\text{i}}}\delta {\alpha _{\text{j}}}} \right){E_{{\text{ice}}}}\frac{{{\pi }}}{2}\left( {{r_{\text{g}}} - \frac{{d_{\text{i}}^2}}{{4{r_{\text{g}}}}}} \right)\left( {1 - {I_{{\text{b,i}}}}} \right)\\ \times\left( {1 - {I_{{\text{e,i}}}}} \right)\quad\qquad\qquad\qquad\qquad\qquad\qquad\qquad\quad \\

{b_{{\text{t,i}}}} = {{\pi }}r_{\text{b}}^2G\left( {\frac{{{L_{\text{b}}}}}{{{L_{{\text{b,0}}}}}}} \right)\,{I_{{\text{b,i}}}} + {E_{{\text{ice}}}}\frac{{{\pi }}}{2}\left( {{r_{\text{g}}} - \frac{{d_{\text{i}}^2}}{{4{r_{\text{g}}}}}} \right){d_{\text{i}}}\left( {1 - {I_{{\text{b,i}}}}} \right){I_{{\text{e,i}}}} \\[10pt]

{{\text{c}}_{{\text{t,i}}}} = - {{\pi }}r_{\text{b}}^2GA\left( {{T_{{\text{emp}}}}} \right)\sigma _{{\text{b,t}}}^m\delta t\,{I_{{\text{b,i}}}} + \left( {\text{sign}}\left( {{T_{\text{i}}} + {k_{\text{t}}}{d_{\text{i}}}\delta {\alpha _{\text{j}}}} \right){N_{\text{i}}} \right.\\[6pt] \quad{} \times\left.{\text{tan}}\,{\varphi _{\text{g}}} - {T_{\text{1}}} \right)\left( {1 - {I_{{\text{b,i}}}}} \right)\left( {1 - {I_{{\text{e,i}}}}} \right)\qquad\qquad\quad\quad\quad

\end{array}} \right.\nonumber\\ \end{align} where ![]() ${\text{i}}$ stands for the number of the considered contact, as defined in Fig. 2.

${\text{i}}$ stands for the number of the considered contact, as defined in Fig. 2. ![]() ${I_{{\text{b}},{\text{i}}}}$ is a bond indicator equal to one when the ice bond at contact

${I_{{\text{b}},{\text{i}}}}$ is a bond indicator equal to one when the ice bond at contact ![]() ${\text{i}}$ exists, and zero otherwise.

${\text{i}}$ exists, and zero otherwise. ![]() ${I_{{\text{e}},{\text{i}}}}$ is a similar indicator which is equal to one in a nonbonded elastic contact, and zero otherwise. The ice contact law defined by these coefficients can be implemented readily within the standard computation scheme of the H-model. Some additional improvements of the model in relation with the creation and the loss of contacts in the H-cell are described in Appendix C and D.

${I_{{\text{e}},{\text{i}}}}$ is a similar indicator which is equal to one in a nonbonded elastic contact, and zero otherwise. The ice contact law defined by these coefficients can be implemented readily within the standard computation scheme of the H-model. Some additional improvements of the model in relation with the creation and the loss of contacts in the H-cell are described in Appendix C and D.

3. Homogeneous compression test simulations

In this section, the snow-H-model is validated at the representative elementary volume (REV) scale against experimental tests by (Abele and Gow, Reference Abele and Gow1976) conducted for different snow types. The numerical parameters are tuned to match the experimental stress/strain curves as closely as possible. This calibration procedure enables to identify the snow density range over which the model can capture the mechanical response of snow.

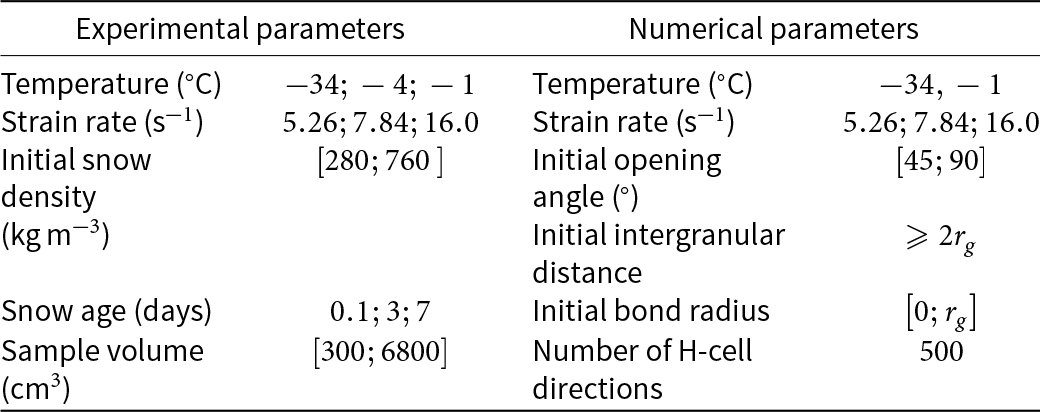

3.1. Confined compression test

In Abele and Gow (Reference Abele and Gow1976), several confined compression tests were performed on different snow samples. In practice, natural snow was collected in cylindrical containers and compacted at temperatures ranging between ![]() $ - 7^\circ {\text{C}}$ and

$ - 7^\circ {\text{C}}$ and ![]() $ - 1^\circ {\text{C}}$. The snow samples were then stored for 0.1–7 days before being tested under oedometer conditions at a constant temperature between

$ - 1^\circ {\text{C}}$. The snow samples were then stored for 0.1–7 days before being tested under oedometer conditions at a constant temperature between ![]() $ - 34^\circ {\text{C}}$ and

$ - 34^\circ {\text{C}}$ and ![]() $ - 1^\circ {\text{C}}$. The storage duration prior to testing is referred to as the snow age in the following. During the compression test, a vertical velocity of

$ - 1^\circ {\text{C}}$. The storage duration prior to testing is referred to as the snow age in the following. During the compression test, a vertical velocity of ![]() $40{\text{ cm}}/{\text{s}}$ was applied to the top of the sample, while lateral deformations were kept constant. The experimental parameters are summarized in the first two columns of Table 1. The initial snow density of each sample was determined from the original volume and after measurement of the final sample weight.

$40{\text{ cm}}/{\text{s}}$ was applied to the top of the sample, while lateral deformations were kept constant. The experimental parameters are summarized in the first two columns of Table 1. The initial snow density of each sample was determined from the original volume and after measurement of the final sample weight.

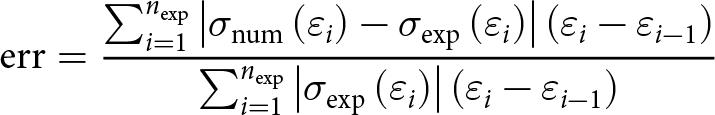

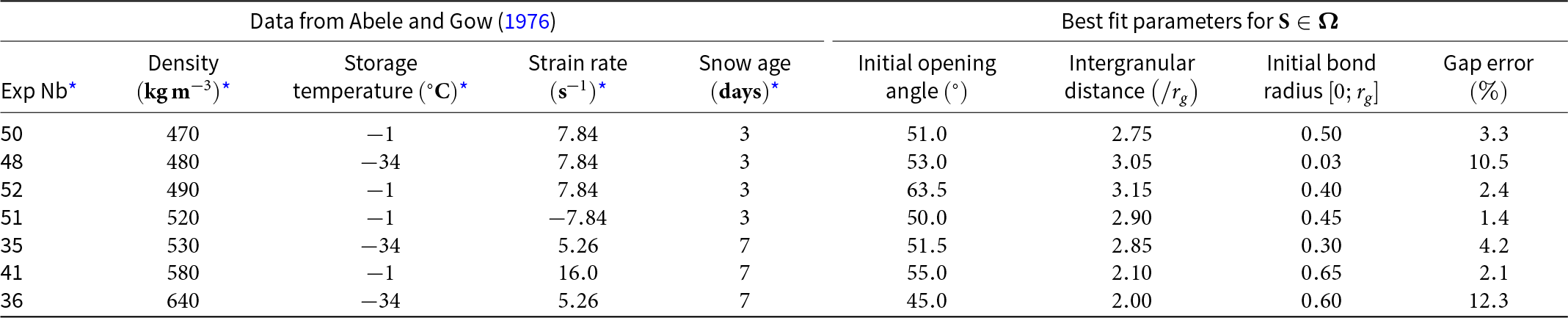

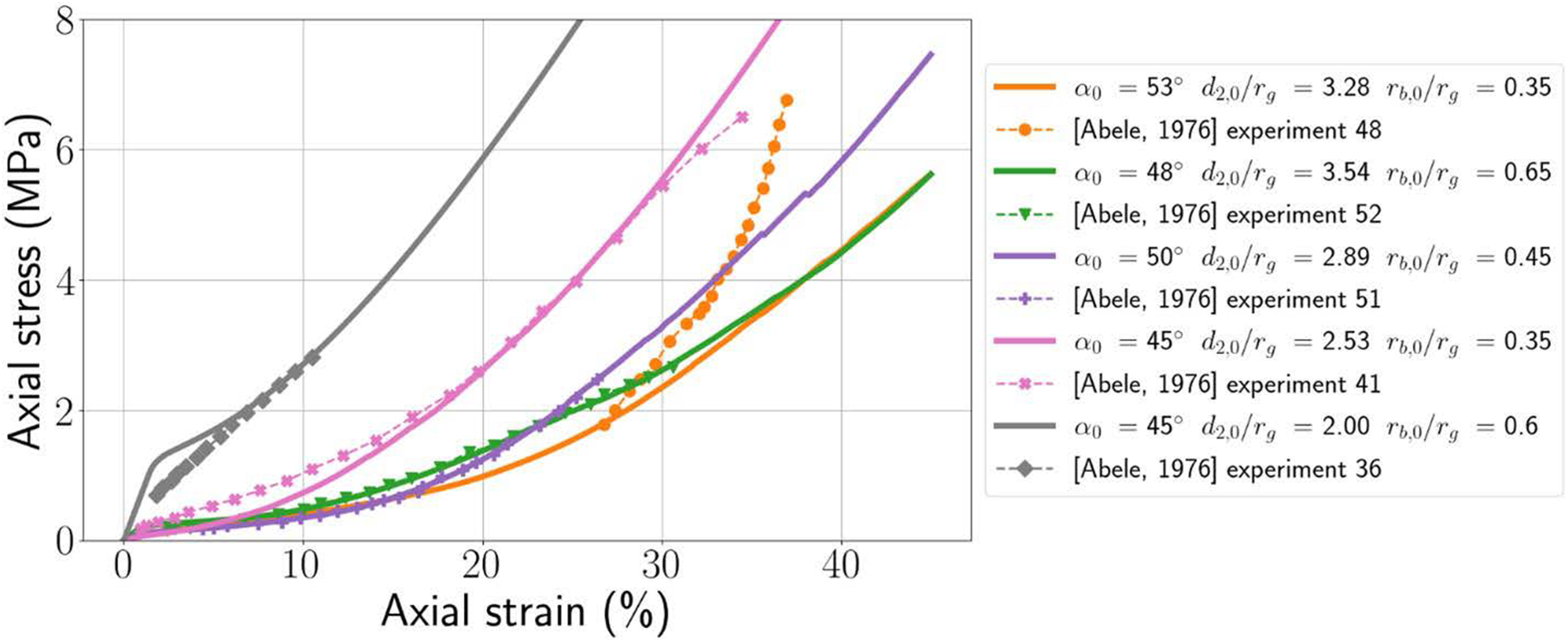

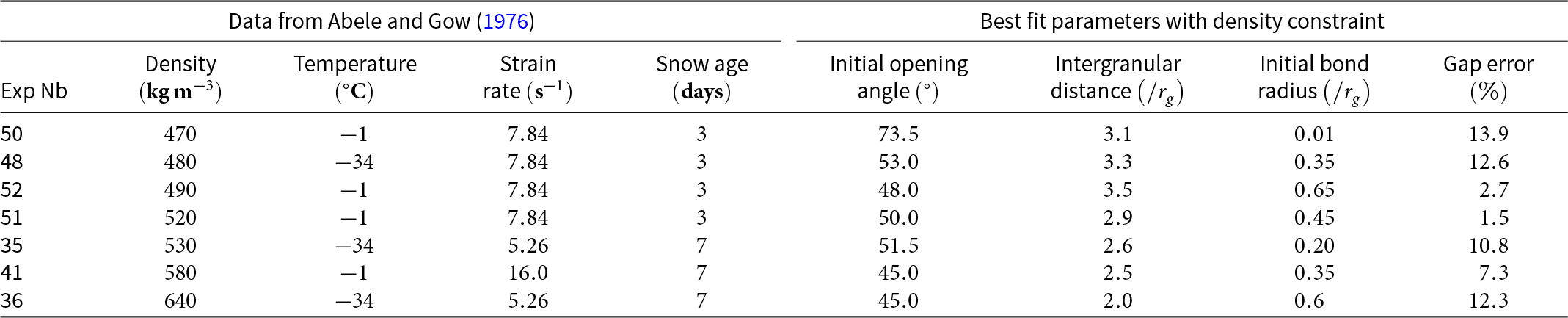

Table 1. Experimental (left) and numerical parameters (right) for confined compression tests on snow (Abele and Gow, Reference Abele and Gow1976)

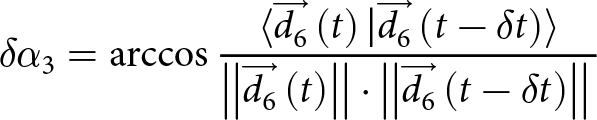

3.2. Calibration against experimental results

The extension of the 3-D H-model to snow is implemented in a stand-alone Python code which is used to run REV scale tests under strain-controlled conditions. The compression tests under lateral confining from Abele and Gow (Reference Abele and Gow1976) are reproduced with this code.

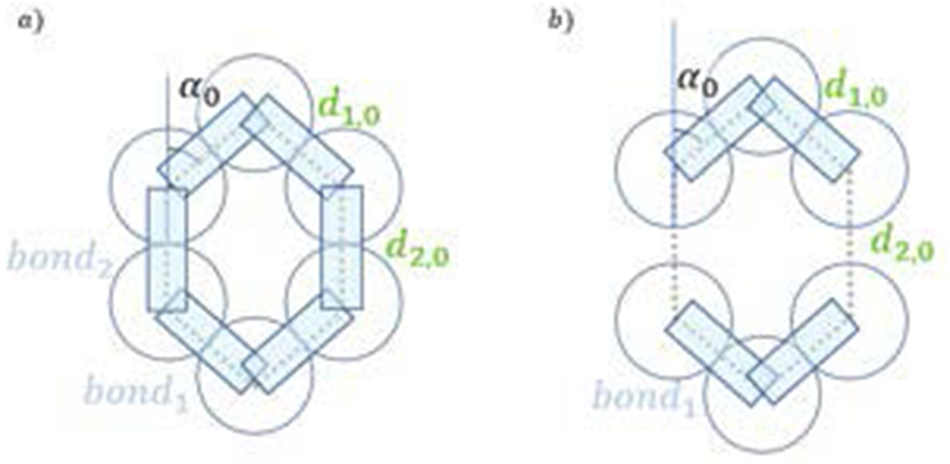

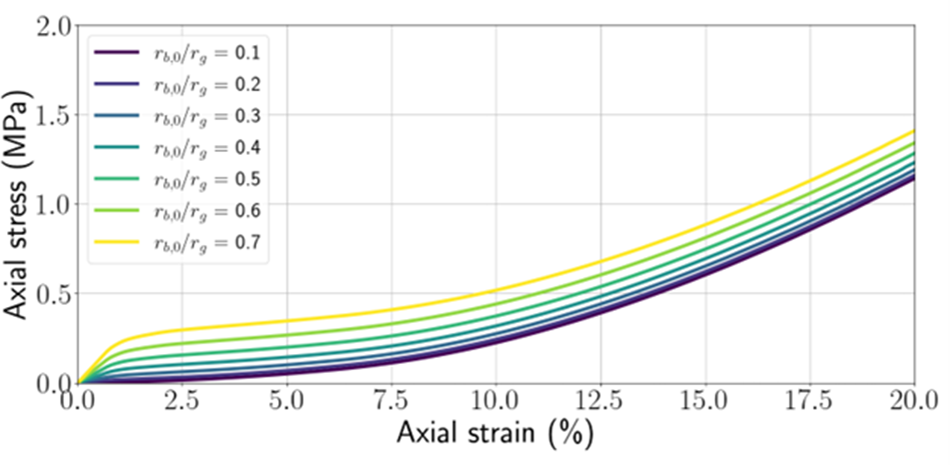

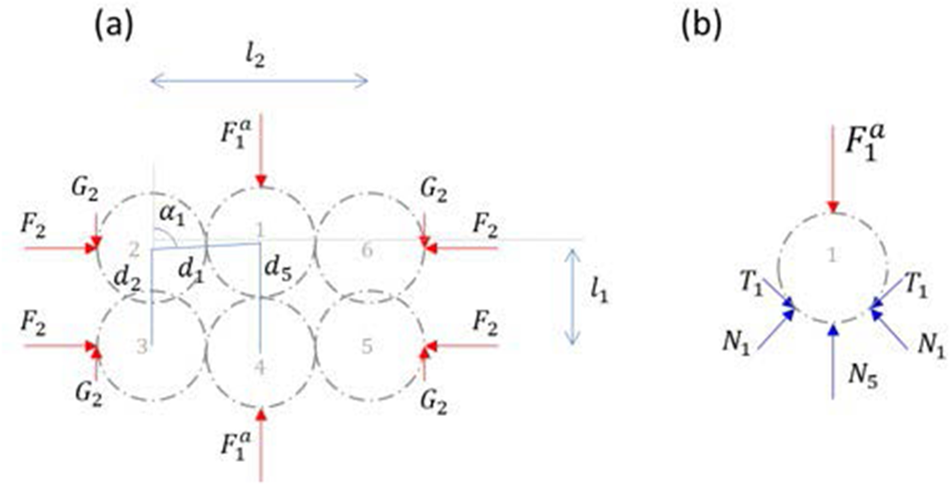

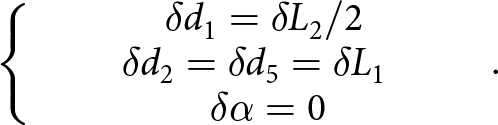

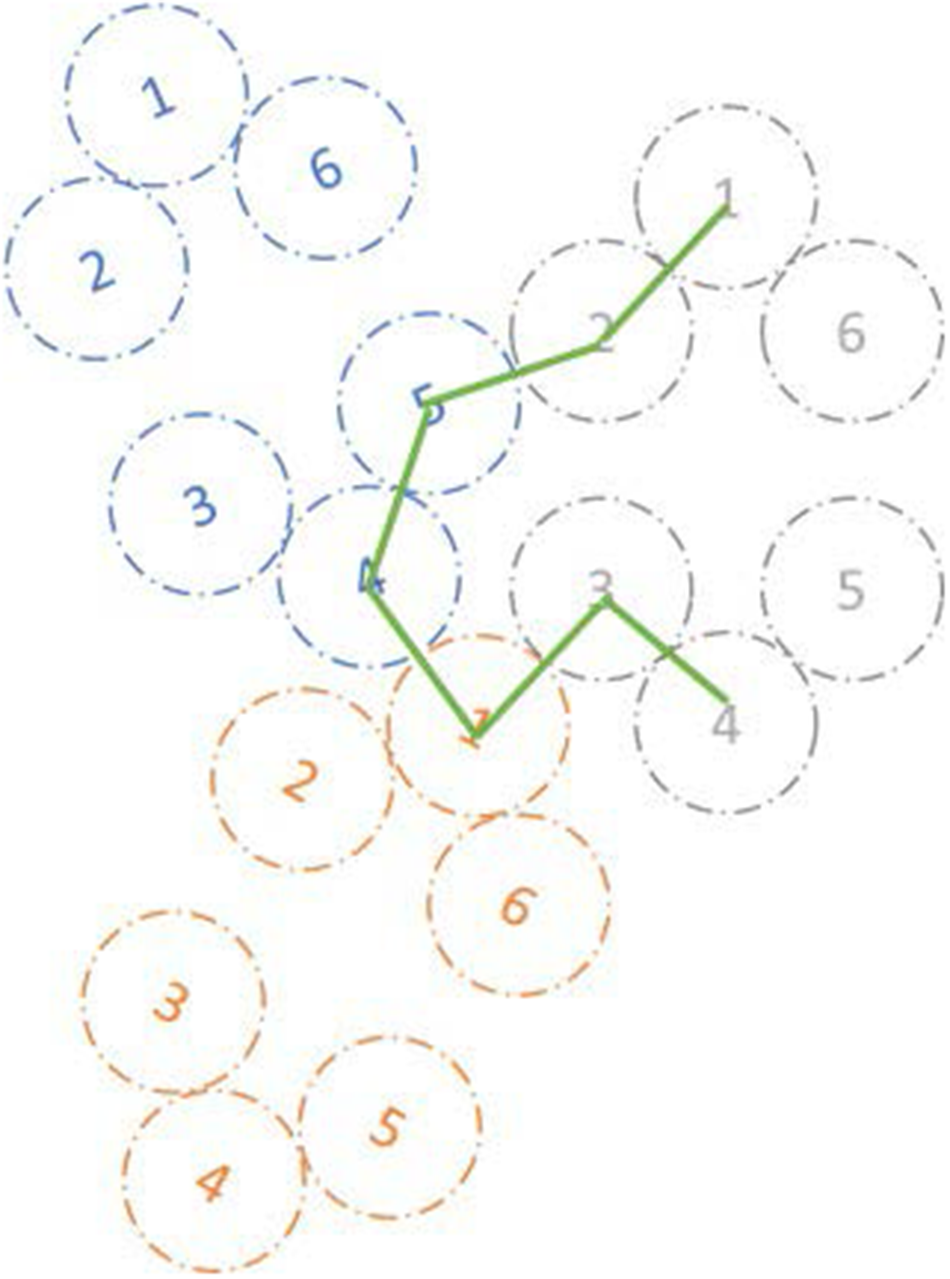

Some of the experimental parameters of the experiments such as the snow temperature and the strain rate can be directly used in the simulations. However, the initial snow density and the snow age are not explicit input parameters for the 3-D H-model. The experimental snow age is only indirectly related to the initial bond radius ![]() ${{\text{r}}_{{\text{b}},0}}$ (Szabo and Schneebeli, Reference Szabo and Schneebeli2007) and the initial density derives from the initial geometry of the H-cells. The latter is determined by the initial opening angle

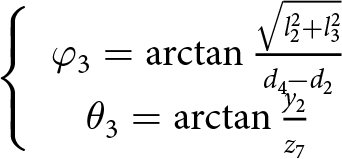

${{\text{r}}_{{\text{b}},0}}$ (Szabo and Schneebeli, Reference Szabo and Schneebeli2007) and the initial density derives from the initial geometry of the H-cells. The latter is determined by the initial opening angle ![]() ${\alpha _{1,0}} = {\alpha _{2,0}} = {\alpha _0}$ which can be varied to modify the initial density. Unlike the original H-model for sand, some grains may not necessarily be in contact in the snow-H-model (see Fig. 6), to account for large porosity values in snow. A new parameter is then introduced: the initial inter-granular distance

${\alpha _{1,0}} = {\alpha _{2,0}} = {\alpha _0}$ which can be varied to modify the initial density. Unlike the original H-model for sand, some grains may not necessarily be in contact in the snow-H-model (see Fig. 6), to account for large porosity values in snow. A new parameter is then introduced: the initial inter-granular distance ![]() ${d_{2,0}}$ (see Fig. 6 where

${d_{2,0}}$ (see Fig. 6 where ![]() ${d_{2,0}} = {d_{4,0}} \geq 2{r_{\text{g}}}$ and Appendix D). In the case where

${d_{2,0}} = {d_{4,0}} \geq 2{r_{\text{g}}}$ and Appendix D). In the case where ![]() ${d_{2,0}} = {d_{4,0}} \geq 2{r_{\text{g}}}$, the connectivity of forces within the cell is maintained through contact with neighbouring cells. This is reflected by the external force

${d_{2,0}} = {d_{4,0}} \geq 2{r_{\text{g}}}$, the connectivity of forces within the cell is maintained through contact with neighbouring cells. This is reflected by the external force ![]() $F_1^a$ being balanced by the tangential external force

$F_1^a$ being balanced by the tangential external force ![]() ${G_2}$ (see Fig. 2), resulting in the equilibrium of the two half cells (see Appendix D). As a result, the initial density in the experiments can be accounted for by calibrating the two numerical parameters

${G_2}$ (see Fig. 2), resulting in the equilibrium of the two half cells (see Appendix D). As a result, the initial density in the experiments can be accounted for by calibrating the two numerical parameters ![]() ${d_{2,0}}$ and

${d_{2,0}}$ and ![]() ${\alpha _0}$. The sintering time before loading is included in the snow-H-model from the initial bond radius

${\alpha _0}$. The sintering time before loading is included in the snow-H-model from the initial bond radius ![]() ${r_{{\text{b}},0}}$, which is capped by the grain radius. The numerical parameters and their range of variation are summarized in the last two columns of Table 1.

${r_{{\text{b}},0}}$, which is capped by the grain radius. The numerical parameters and their range of variation are summarized in the last two columns of Table 1.

Figure 6. Initial configurations of a hexagonal mesostructure: (a) 2-D representation of a ten-grain H-cell with ![]() ${d_{2,0}} = {d_{1,0}} = 2{r_{\text{g}}}$ and initial ice bonds

${d_{2,0}} = {d_{1,0}} = 2{r_{\text{g}}}$ and initial ice bonds ![]() ${\text{bon}}{{\text{d}}_1}$ and

${\text{bon}}{{\text{d}}_1}$ and ![]() ${\text{bon}}{{\text{d}}_2}$; (b) 2-D representation of two separated five-grain mesostructure with

${\text{bon}}{{\text{d}}_2}$; (b) 2-D representation of two separated five-grain mesostructure with ![]() ${d_{1,0}} = 2{r_{\text{g}}}$,

${d_{1,0}} = 2{r_{\text{g}}}$, ![]() ${d_{2,0}} \gt 2{r_{\text{g}}}$ and initial bonds

${d_{2,0}} \gt 2{r_{\text{g}}}$ and initial bonds ![]() ${\text{bon}}{{\text{d}}_1}$.

${\text{bon}}{{\text{d}}_1}$.

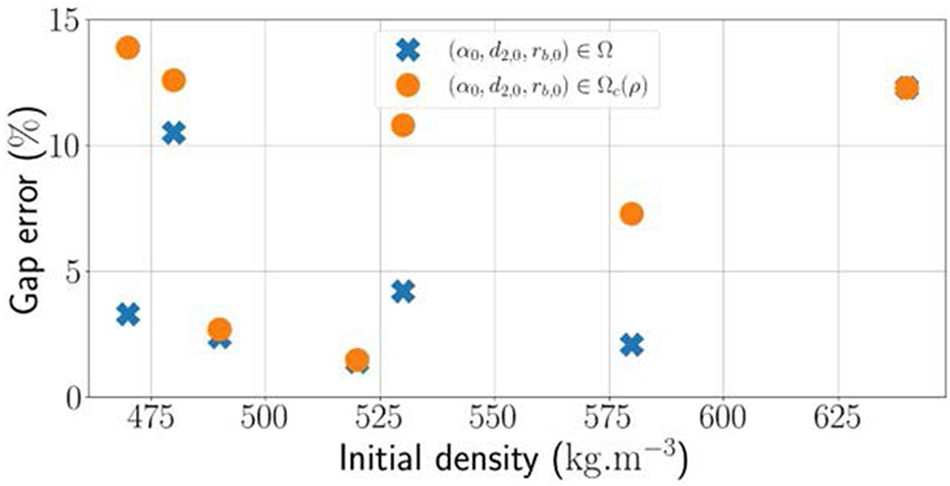

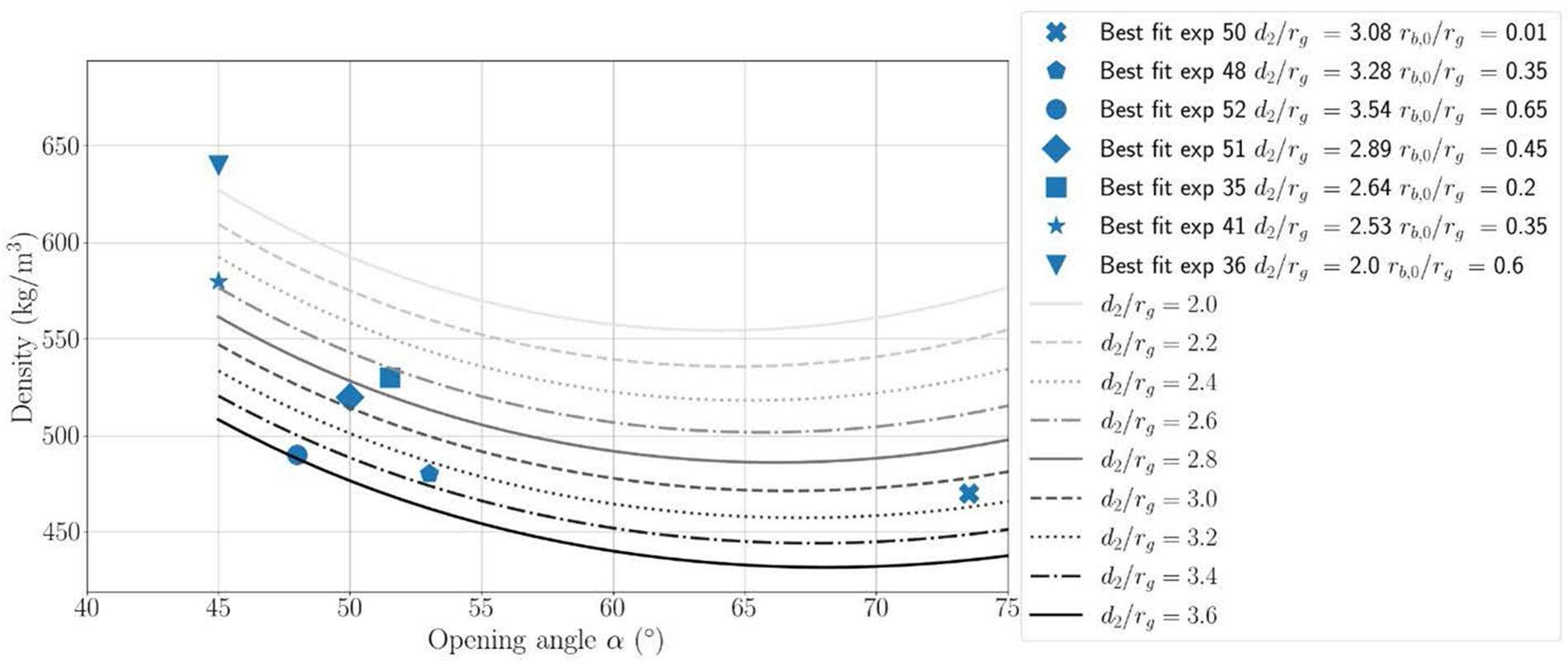

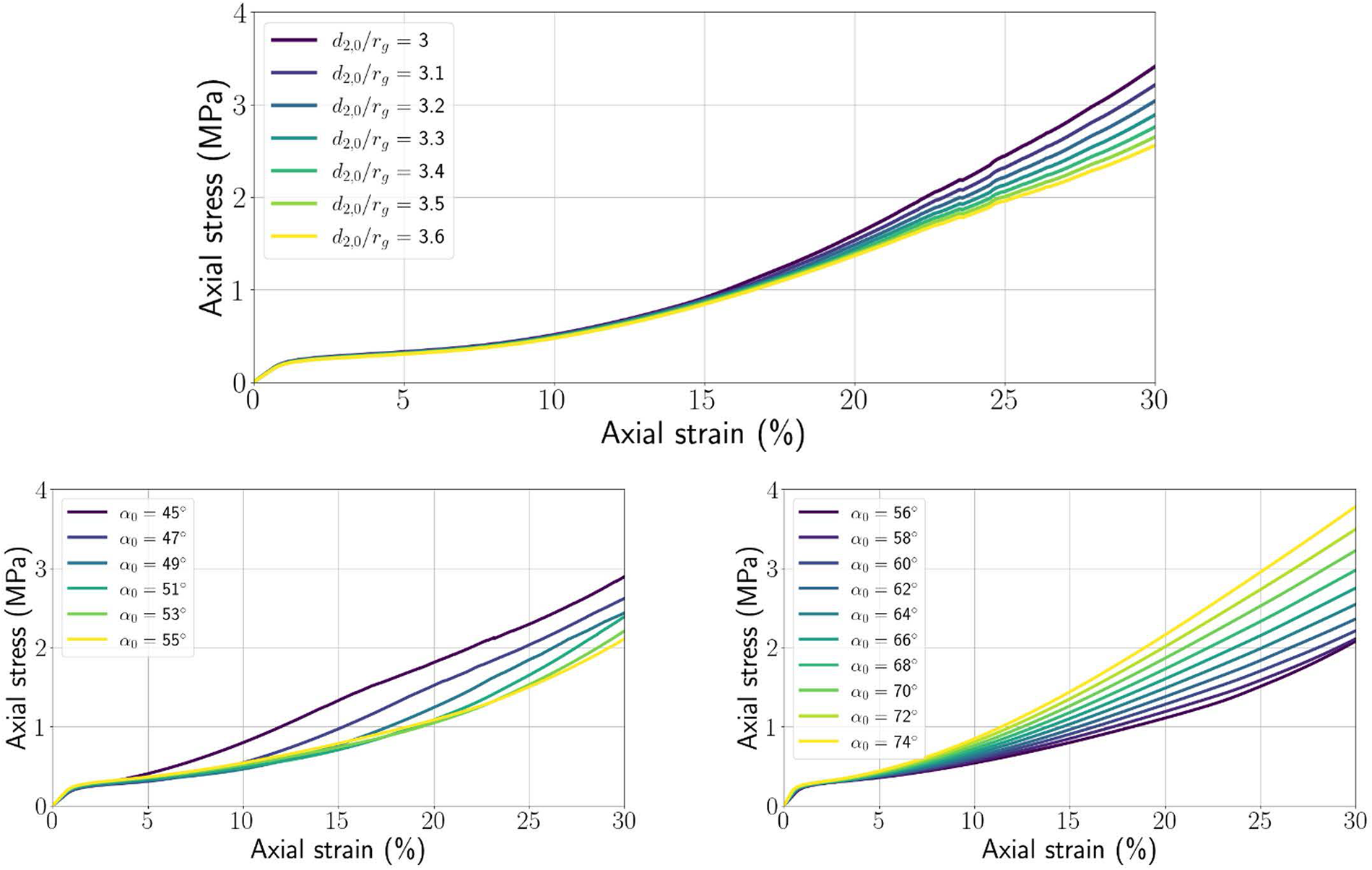

The first objective of the calibration step is to determine the initial value of the three numerical parameters describing both the geometry and the sintering state of the H-cell, namely the opening angle ![]() ${\alpha _0}$, the intergranular distance

${\alpha _0}$, the intergranular distance ![]() ${d_{2,0}}$ and the bond radius

${d_{2,0}}$ and the bond radius ![]() ${r_{{\text{b}},0}}$. To this end, stress–strain curves for different initial parameters are systematically compared to the experimental curves by Abele and Gow (Reference Abele and Gow1976). The best fitting triplet

${r_{{\text{b}},0}}$. To this end, stress–strain curves for different initial parameters are systematically compared to the experimental curves by Abele and Gow (Reference Abele and Gow1976). The best fitting triplet ![]() $\left( {{\text{denoted by the index bf}}} \right)$ in the parameter set

$\left( {{\text{denoted by the index bf}}} \right)$ in the parameter set ![]() ${{\Omega }}$ given in Table 1 corresponds to the triplet

${{\Omega }}$ given in Table 1 corresponds to the triplet  ${\left( {{\alpha _0},{d_{2,0}},{r_{{\text{b}},0}}} \right)_{{\text{bf}}}}$ which verifies:

${\left( {{\alpha _0},{d_{2,0}},{r_{{\text{b}},0}}} \right)_{{\text{bf}}}}$ which verifies:

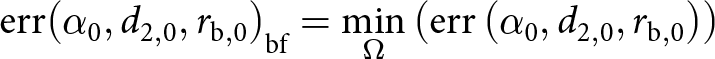

\begin{equation}{\text{err}}{\left( {{\alpha _0},{d_{2,0}},{r_{{\text{b}},0}}} \right)_{{\text{bf}}}} = \mathop {\min }\limits_{{\Omega }} \left( {{\text{err}}\left( {{\alpha _0},{d_{2,0}},{r_{{\text{b}},0}}} \right)} \right)\end{equation}

\begin{equation}{\text{err}}{\left( {{\alpha _0},{d_{2,0}},{r_{{\text{b}},0}}} \right)_{{\text{bf}}}} = \mathop {\min }\limits_{{\Omega }} \left( {{\text{err}}\left( {{\alpha _0},{d_{2,0}},{r_{{\text{b}},0}}} \right)} \right)\end{equation} with ![]() ${\text{err}}$ being a relative error gap function defined by:

${\text{err}}$ being a relative error gap function defined by:

\begin{equation}{\text{err}} = \frac{{{{\mathop \sum}}_{i = 1}^{{n_{{\text{exp}}}}}\left| {{\sigma _{{\text{num}}}}\left( {{\varepsilon _i}} \right) - {\sigma _{{\text{exp}}}}\left( {{\varepsilon _i}} \right)} \right|\left( {{\varepsilon _i} - {\varepsilon _{i - 1}}} \right)}}{{{{\mathop \sum }}_{i = 1}^{{n_{{\text{exp}}}}}\left| {{\sigma _{{\text{exp}}}}\left( {{\varepsilon _i}} \right)} \right|\left( {{\varepsilon _i} - {\varepsilon _{i - 1}}} \right)}}\end{equation}

\begin{equation}{\text{err}} = \frac{{{{\mathop \sum}}_{i = 1}^{{n_{{\text{exp}}}}}\left| {{\sigma _{{\text{num}}}}\left( {{\varepsilon _i}} \right) - {\sigma _{{\text{exp}}}}\left( {{\varepsilon _i}} \right)} \right|\left( {{\varepsilon _i} - {\varepsilon _{i - 1}}} \right)}}{{{{\mathop \sum }}_{i = 1}^{{n_{{\text{exp}}}}}\left| {{\sigma _{{\text{exp}}}}\left( {{\varepsilon _i}} \right)} \right|\left( {{\varepsilon _i} - {\varepsilon _{i - 1}}} \right)}}\end{equation} In Eqn (33), the numerator corresponds to the cumulated area between the numerical and experimental curves in the axial stress–strain space ![]() $\left( {\sigma ,\varepsilon } \right)$, whereas the denominator corresponds to the area below the experimental curve.

$\left( {\sigma ,\varepsilon } \right)$, whereas the denominator corresponds to the area below the experimental curve. ![]() ${n_{{\text{exp}}}}$ is the number of points taken from the experimental stress–strain curve,

${n_{{\text{exp}}}}$ is the number of points taken from the experimental stress–strain curve, ![]() ${\varepsilon _i}$ is the strain at the ith point of the experimental curve,

${\varepsilon _i}$ is the strain at the ith point of the experimental curve, ![]() ${\sigma _{{\text{num}}}}$ is the stress obtained with the 3-D H-model and

${\sigma _{{\text{num}}}}$ is the stress obtained with the 3-D H-model and ![]() ${\sigma _{{\text{exp}}}}$ is the experimental one.

${\sigma _{{\text{exp}}}}$ is the experimental one.

The parameter set in ![]() ${{\Omega }} = \{ {( {{\alpha _0},{d_{2,0}},{r_{{\text{b}}0}}} ) \in [ {{{45}^ \circ };{{90}^ \circ }} ] \times }$

${{\Omega }} = \{ {( {{\alpha _0},{d_{2,0}},{r_{{\text{b}}0}}} ) \in [ {{{45}^ \circ };{{90}^ \circ }} ] \times }$ ![]() ${[ {2{ }{r_{\text{g}}};{ }3.6{ }{r_{\text{g}}}} ] \times [ {0.05{ }{r_{\text{g}}};0.9{ }{r_{\text{g}}}} ]} \}$ has been explored for experimental curves corresponding to a density between

${[ {2{ }{r_{\text{g}}};{ }3.6{ }{r_{\text{g}}}} ] \times [ {0.05{ }{r_{\text{g}}};0.9{ }{r_{\text{g}}}} ]} \}$ has been explored for experimental curves corresponding to a density between ![]() $470{\text{ kg}}/{{\text{m}}^3}$ and

$470{\text{ kg}}/{{\text{m}}^3}$ and ![]() $640{\text{ kg}}/{{\text{m}}^3}$. The stress–strain curves of the experimental data and the corresponding best fitting numerical curves in

$640{\text{ kg}}/{{\text{m}}^3}$. The stress–strain curves of the experimental data and the corresponding best fitting numerical curves in ![]() ${{\Omega }}$ are reported in Fig. 7.

${{\Omega }}$ are reported in Fig. 7.

Figure 7. Stress–strain curves for confined compression test: experimental results from Abele and Gow (Reference Abele and Gow1976) and best fitting numerical curves obtained with the 3-D H-model.

Table 2 reports the best fit parameters with the initial density of the experimental specimens increasing from ![]() $470{\text{ kg}}/{{\text{m}}^3}$ to

$470{\text{ kg}}/{{\text{m}}^3}$ to ![]() $640{\text{ kg}}/{{\text{m}}^3}$. The relative error gap, as defined in Eqn (33), ranges between

$640{\text{ kg}}/{{\text{m}}^3}$. The relative error gap, as defined in Eqn (33), ranges between ![]() $1.4{ }$% and

$1.4{ }$% and ![]() $12.3{\text{\% }}$.

$12.3{\text{\% }}$.

Table 2. Parameters giving the best fit for each experimental curve in  $\boldsymbol{\Omega} = \left[ {{{45}^ \circ };{{90}^ \circ }} \right] \times \left[ {2\,{r_g};\,3.6\,{r_g}} \right] \times \left[ {0.05\,{r_g};0.9\,{r_g}} \right].$

$\boldsymbol{\Omega} = \left[ {{{45}^ \circ };{{90}^ \circ }} \right] \times \left[ {2\,{r_g};\,3.6\,{r_g}} \right] \times \left[ {0.05\,{r_g};0.9\,{r_g}} \right].$

* Data from Abele and Gow (Reference Abele and Gow1976) experiments.

When plotted as a function of the initial snow density in Fig. 7, the error is found smaller in the middle of the density range. In any case, the value of the relative error between experimental and numerical curves remains relatively small, which confirms the ability of the 3-D H-model to be used as a constitutive model for snow, at least within the density range ![]() $\left[ {470;{ }640} \right]{\text{ kg}}/{{\text{m}}^3}$. Higher densities are impossible to reach with the 3-D H-model, as the condition

$\left[ {470;{ }640} \right]{\text{ kg}}/{{\text{m}}^3}$. Higher densities are impossible to reach with the 3-D H-model, as the condition ![]() ${\alpha _0} = 45^\circ $ and

${\alpha _0} = 45^\circ $ and ![]() ${d_{2,0}}/{r_{\text{g}}} = 2$ corresponds to the limit case where a contact between the two hexagons within a cell is created. For lower densities, the mismatch between experimental and numerical curves becomes too large to include these densities in the range of validity of the snow-H-model.

${d_{2,0}}/{r_{\text{g}}} = 2$ corresponds to the limit case where a contact between the two hexagons within a cell is created. For lower densities, the mismatch between experimental and numerical curves becomes too large to include these densities in the range of validity of the snow-H-model.

This first calibration was carried out blindly, in the sense that only the minimization of the gap between measured and predicted data was targeted, without considering the agreement between experimental density and model density, the latter being controlled by the two geometric parameters of the H-cell. This is the purpose of the next section, to achieve a much more versatile model.

4. Discussion on the model versatility

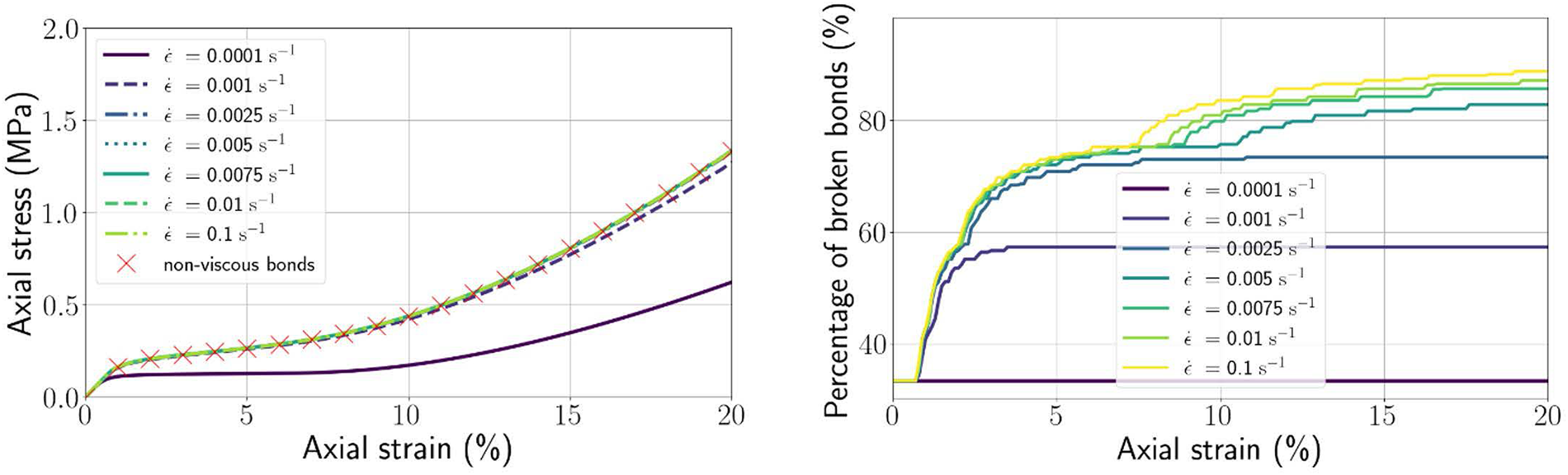

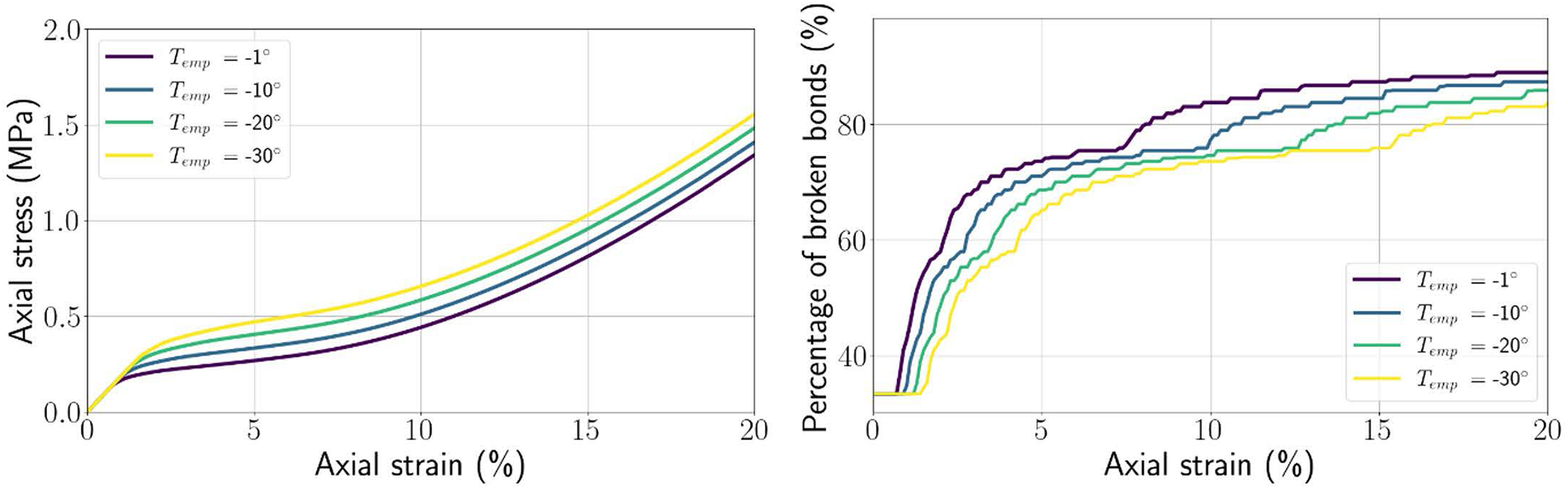

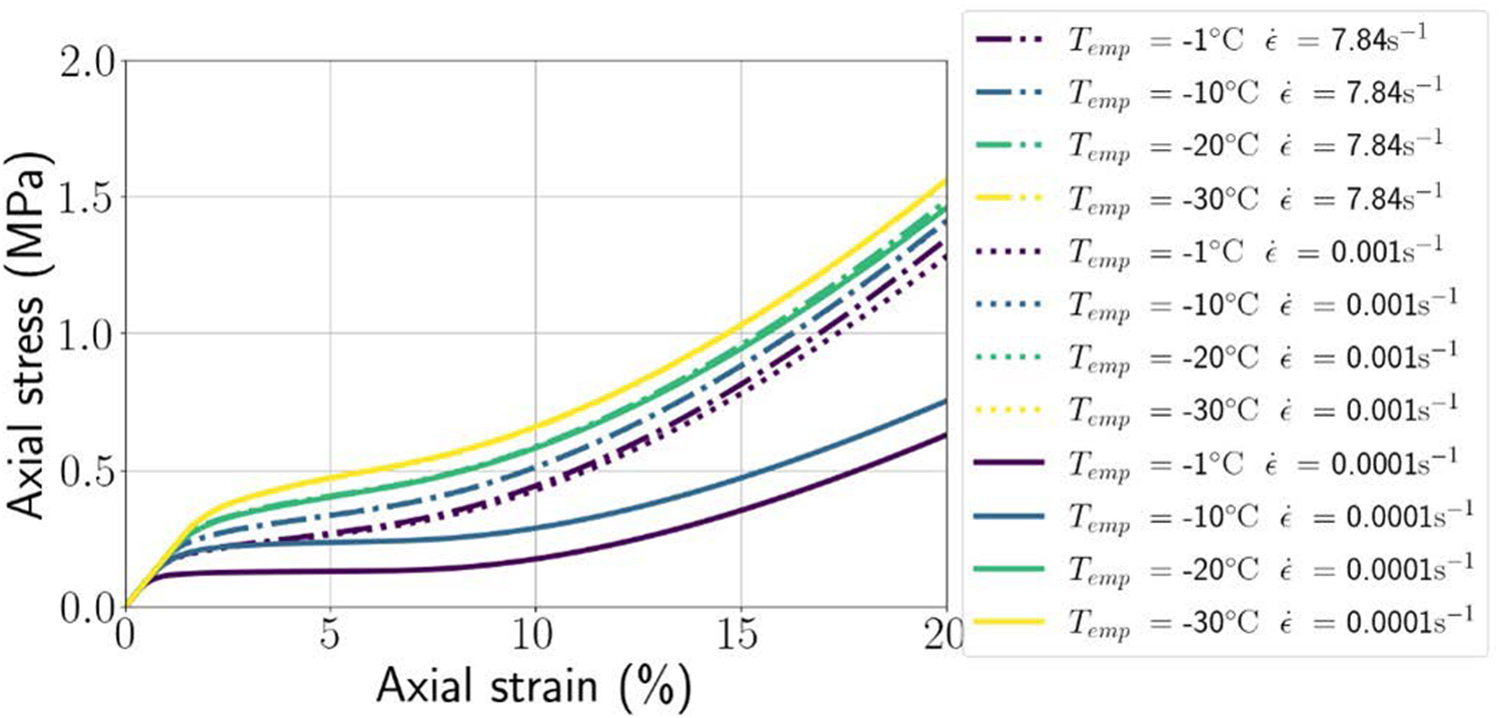

As the snow-H-model has demonstrated its ability to reproduce experimental results through parameter adjustment, the next step is to assess its predictive capability for snow behaviour under varying conditions of density, temperature and strain rate.

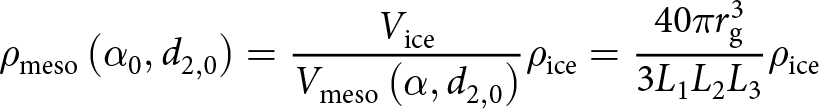

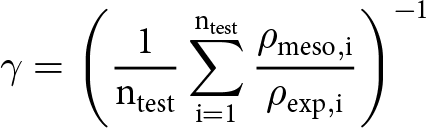

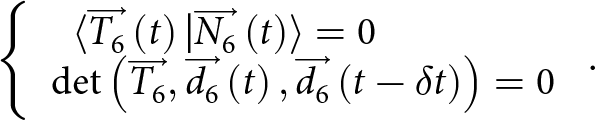

4.1. Relation between mesoscopic geometry and macroscopic density

Calculating the density in multi-scale models is challenging as its mesostructure only includes those elements which are actively participating in the force transmission. For instance, in the present model, the bi-hexagonal pattern is designed as the minimal structure to depict only snow grains which are part of force chains. The surrounding space includes both void and snow grains not participating to force transmission. This is the reason why we cannot and should not calibrate the H-cell geometry to match directly the macroscopic density. Therefore, we have chosen first to calibrate the initial geometrical parameters of the cells to match the experimental stress–strain curves from Abele and Gow (Reference Abele and Gow1976). The objective of this section is to provide an estimation of the proportion of ice grains participating to force transmission by comparing the macroscopic snow density ![]() ${\rho _{{\text{snow}}}}$ and the mesoscopic density

${\rho _{{\text{snow}}}}$ and the mesoscopic density ![]() ${\rho _{{\text{meso}}}}$.

${\rho _{{\text{meso}}}}$.

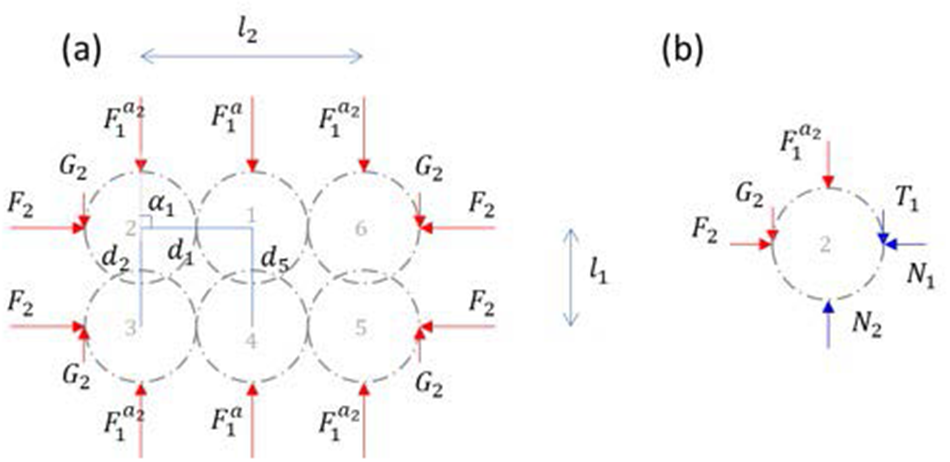

In the snow-H-model, we selected the smallest peripheral parallelepiped volume as the H-cell volume ![]() ${V_{{\text{meso}}}}$ (see Fig. 9). Under this assumption, the mesoscopic density can be expressed as follows:

${V_{{\text{meso}}}}$ (see Fig. 9). Under this assumption, the mesoscopic density can be expressed as follows:

\begin{equation}{\rho _{{\text{meso}}}}\left( {{\alpha _0},{d_{2,0}}} \right) = \frac{{{V_{{\text{ice}}}}}}{{{V_{{\text{meso}}}}\left( {\alpha ,{d_{2,0}}} \right)}}{\rho _{{\text{ice}}}} = \frac{{40{{\pi }}r_{\text{g}}^3}}{{3{L_1}{L_2}{L_3}}}{\rho _{{\text{ice}}}}\end{equation}

\begin{equation}{\rho _{{\text{meso}}}}\left( {{\alpha _0},{d_{2,0}}} \right) = \frac{{{V_{{\text{ice}}}}}}{{{V_{{\text{meso}}}}\left( {\alpha ,{d_{2,0}}} \right)}}{\rho _{{\text{ice}}}} = \frac{{40{{\pi }}r_{\text{g}}^3}}{{3{L_1}{L_2}{L_3}}}{\rho _{{\text{ice}}}}\end{equation} where ![]() ${V_{{\text{ice}}}}$ is the volume of solid ice, which corresponds to the volume of the ten spherical grains (we neglect the ice bond volumes), and