1. Introduction

A favourite Italian dessert is the panna cotta, similar to thick custard or blancmange. It resists the force of gravity, to stand up in the shape in which it was set, but wobbles like jelly after being lightly disturbed, quickly returning to its original configuration. Then, when the spoon is pushed in, the panna cotta smoothly and irrevocably flows apart along a seam. The material therefore combines the properties of a deformable or soft, viscoelastic solid, with those of a viscous fluid, depending on the strength of the imposed stress. In other words, panna cotta has properties one usually associates with a yield-stress fluid. A great many other materials share these properties, from mud and lava in geophysical contexts, to mucus in biology and to creams, gels and slurries in industrial processes. The flows associated with these materials have application in a wide and colourful variety of settings, ranging from geological hazards, to locomotion and to transport, mixing and optimisation problems.

Solid mechanicians typically view the yield stress from below, considering the recoverable displacements arising before flow, and determining when yield occurs as a mode of failure. Fluid mechanicians often consider the yield stress as a nuisance, complicating the effective viscosity of the material and rendering it singular as yield is approached from above. Plasticity theory applies in between, with classical approaches sometimes ignoring any solid-like deformation below the yield point or viscous effects above it. Unsurprisingly, however, the true nature of a material like panna cotta can only by appreciated by fully understanding the transition from the viscoelastic solid below the yield stress to the viscoplastic fluid above it. We refer the reader to recent reviews for a fuller discussion on such issues and more (Balmforth, Frigaard & Ovarlez Reference Balmforth, Frigaard and Ovarlez2014; Bonn et al. Reference Bonn, Denn, Berthier, Divoux and Manneville2017; Coussot Reference Coussot2018; Frigaard Reference Frigaard2019a ; Larson & Wei Reference Larson and Wei2019).

Notwithstanding this last point, here, we adopt the historical perspective of the fluid mechanician, and explore how the simple presence of a yield stress can fundamentally impact viscous flow behaviour. Throughout this work we focus on the idealised setting of relatively slow, steady flows in two spatial dimensions; this is the setting of the classical Stokes problem in viscous fluid mechanics, for which we have over a century’s worth of analysis and understanding to exploit. With a yield stress and its fundamentally nonlinear nature, however, many of the tools and much of the intuition built for Stokes flows no longer apply. Indeed, the yield stress introduces a range of new features into slow, steady flows. Our purpose here is to illustrate how the yield stress impacts flow problems, and identify the novelties. Our overarching goal is to re-establish some of the intuition lost from the Stokes problem by the incorporation of the yield stress.

For that reason, we focus most of our discussion on one of the simplest kinds of viscoplastic fluid: an incompressible material described by the Herschel–Bulkley constitutive law (which contains within it, as a limiting case, the famous Bingham plastic constitutive law; Hohenemser & Prager (Reference Hohenemser and Prager1932); Oldroyd (Reference Oldroyd1947a )). Such a material is characterised by a scalar yield stress, above which it flows in a viscous manner and below which it is rigid. Because our goal is chiefly to consider the impact of the yield stress, our interest is well away from the Newtonian limit. Indeed, we focus on situations where the yield stress is relatively strong, or equivalently, when the flow is very slow. Both translate to the ‘plastic limit’ of the problem, where the yield stress dominates the internal stresses, except over the narrow boundary layers wherein length scales are sufficiently small that viscous effects survive (Oldroyd Reference Oldroyd1947b ; Balmforth et al. Reference Balmforth, Craster, Hewitt, Hormozi and Maleki2017).

We begin in § 2 with an illustrative overview of various common dynamical features that occur in slow, steady viscoplastic flows in this plastic limit. This discussion sets the scene for the remainder of the article by conceptually introducing much of the interesting phenomenology of viscoplastic flows, the analysis and interpretation of which occupies the subsequent sections. After this opening overview section, we proceed to outline the mathematical foundations, including some details of plasticity theory, in § 3, before presenting three extended ‘case studies’ of viscoplastic problems in §§ 4, 5 and 6. These illustrate many of the features already introduced in § 2, but are considered in somewhat more detail. Conceptual issues, points of interest and open research questions are discussed throughout these sections as they arise; these ideas are all then brought together in a final discussion and perspectives section (§ 7).

2. Canonical viscoplastic behaviour: an overview

The defining feature of a viscoplastic material is the presence of a threshold yield stress; if the stress exceeds this value, the material yields and flows. The simplest models assume that the threshold value is a material constant, that the material is rigid and undeformed below the threshold, and that the rheological response of the material is always an instantaneous function of the local strain rate (thus precluding any elastic effects). Given a flow field

![]() $\boldsymbol{u}$

, the associated deviatoric stress

$\boldsymbol{u}$

, the associated deviatoric stress

![]() $\boldsymbol{\tau }$

and strain rate

$\boldsymbol{\tau }$

and strain rate

![]() $\boldsymbol{{\dot \gamma }} = \boldsymbol{\nabla u} +\boldsymbol{\nabla u}^T$

are then related by

$\boldsymbol{{\dot \gamma }} = \boldsymbol{\nabla u} +\boldsymbol{\nabla u}^T$

are then related by

where the symbols

![]() $\dot {\gamma }$

and

$\dot {\gamma }$

and

![]() $\tau$

refer to the scalar second invariants of the respective tensors,

$\tau$

refer to the scalar second invariants of the respective tensors,

![]() ${\dot {\gamma }} = \sqrt { (1/2){\dot \gamma }_{ij}{\dot \gamma }_{ij}}$

and

${\dot {\gamma }} = \sqrt { (1/2){\dot \gamma }_{ij}{\dot \gamma }_{ij}}$

and

![]() $\tau = \sqrt { (1/2)\tau _{ij}\tau _{ij}}$

. The yield stress is

$\tau = \sqrt { (1/2)\tau _{ij}\tau _{ij}}$

. The yield stress is

![]() $\tau _{_{_P}}$

and the function

$\tau _{_{_P}}$

and the function

![]() ${\mu }({\dot \gamma })$

here is the generalised ‘plastic’ viscosity. It is immediately clear that the stress state of the material is determined by contributions from both plastic and viscous stresses (the first and second terms in (2.2), respectively) when the yield threshold is exceeded. The relative importance of these contributions is typically measured by the ‘Bingham number’

${\mu }({\dot \gamma })$

here is the generalised ‘plastic’ viscosity. It is immediately clear that the stress state of the material is determined by contributions from both plastic and viscous stresses (the first and second terms in (2.2), respectively) when the yield threshold is exceeded. The relative importance of these contributions is typically measured by the ‘Bingham number’

![]() $\textit{Bi}$

, which, given a flow problem with length and velocity scales

$\textit{Bi}$

, which, given a flow problem with length and velocity scales

![]() $\mathcal{L}$

and

$\mathcal{L}$

and

![]() $\mathcal{U}$

, respectively, and thus strain-rate scale

$\mathcal{U}$

, respectively, and thus strain-rate scale

![]() $\mathcal{U}/\mathcal{L}$

, is

$\mathcal{U}/\mathcal{L}$

, is

We refer to the limit

![]() $\textit{Bi} \gg 1$

as the ‘plastic limit’ of the problem: in this limit the yield stress plays a dominant role in the dynamics of the flow, and, as we shall see, flow solutions can look remarkably unlike their Newtonian counterparts. Note that this limit is achieved both when the yield stress itself is large, but also for arbitrary non-zero yield stress when the strain rate is sufficiently small (at the initiation of motion, for example).

$\textit{Bi} \gg 1$

as the ‘plastic limit’ of the problem: in this limit the yield stress plays a dominant role in the dynamics of the flow, and, as we shall see, flow solutions can look remarkably unlike their Newtonian counterparts. Note that this limit is achieved both when the yield stress itself is large, but also for arbitrary non-zero yield stress when the strain rate is sufficiently small (at the initiation of motion, for example).

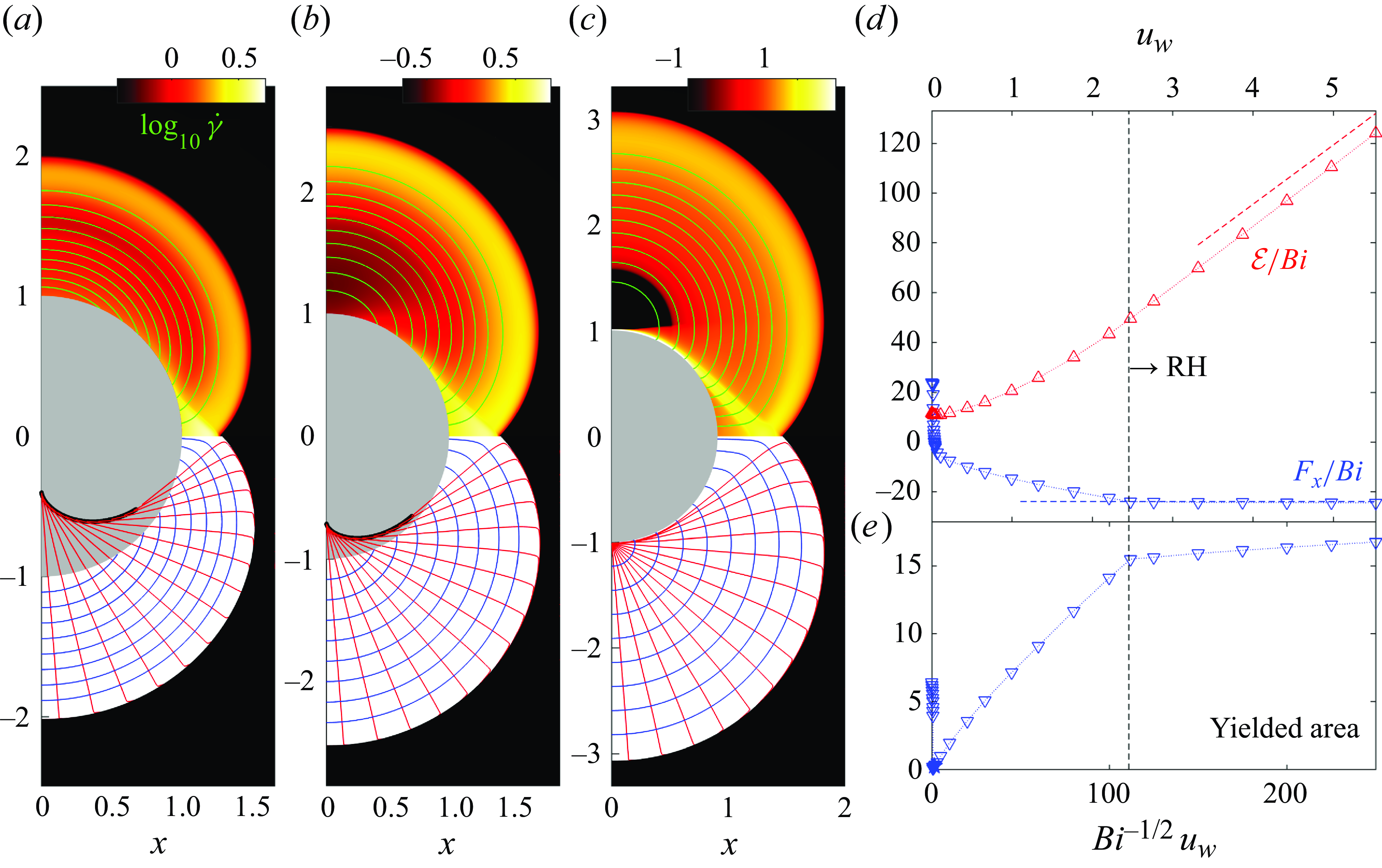

Before delving into the mathematical and numerical details associated with manipulating and analysing constitutive laws of the kind outlined above, we first provide a brief overview of the different sorts of behaviour that such a model can produce. There are various hallmarks of viscoplastic flows when

![]() $\textit{Bi} \gg 1$

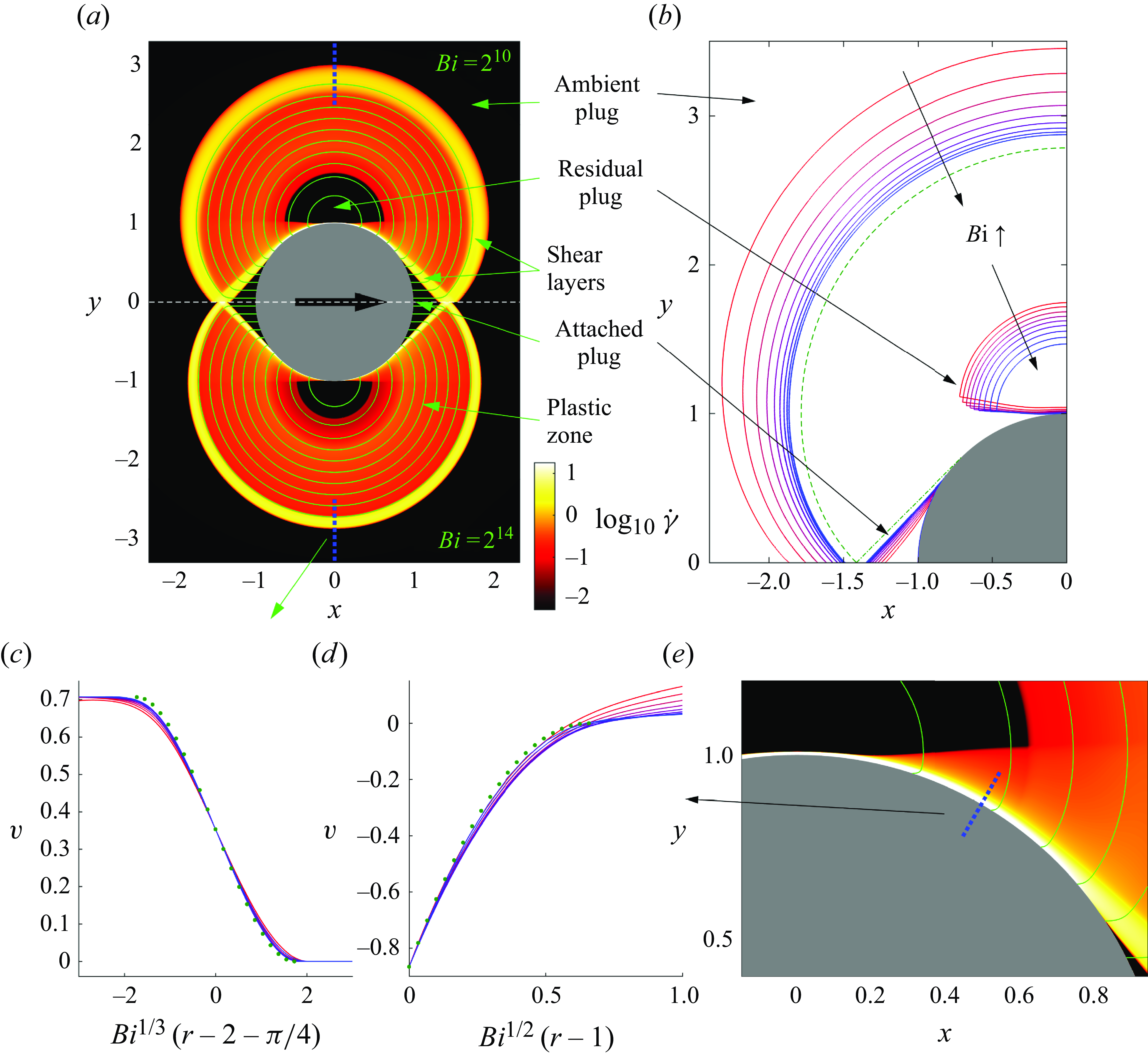

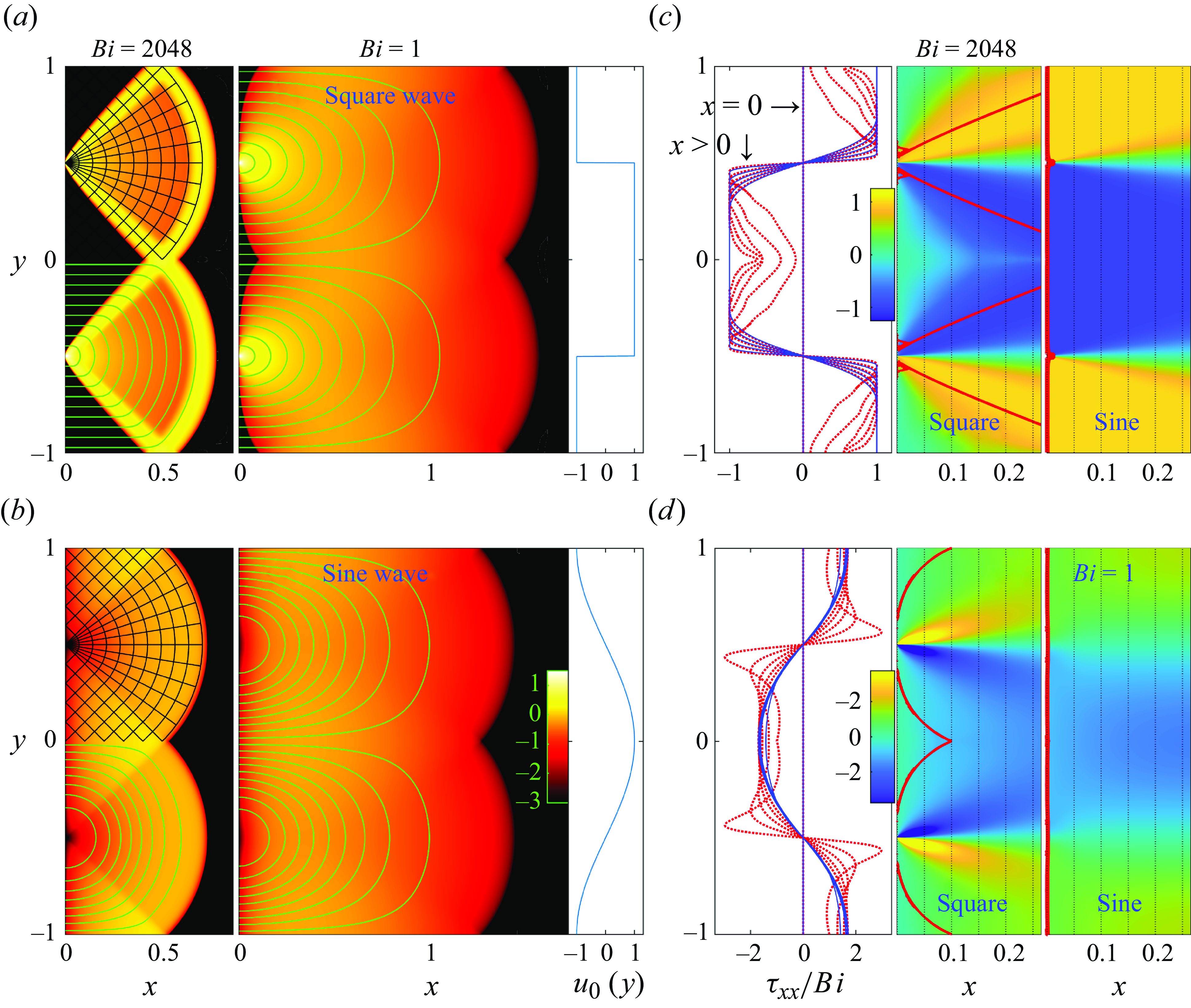

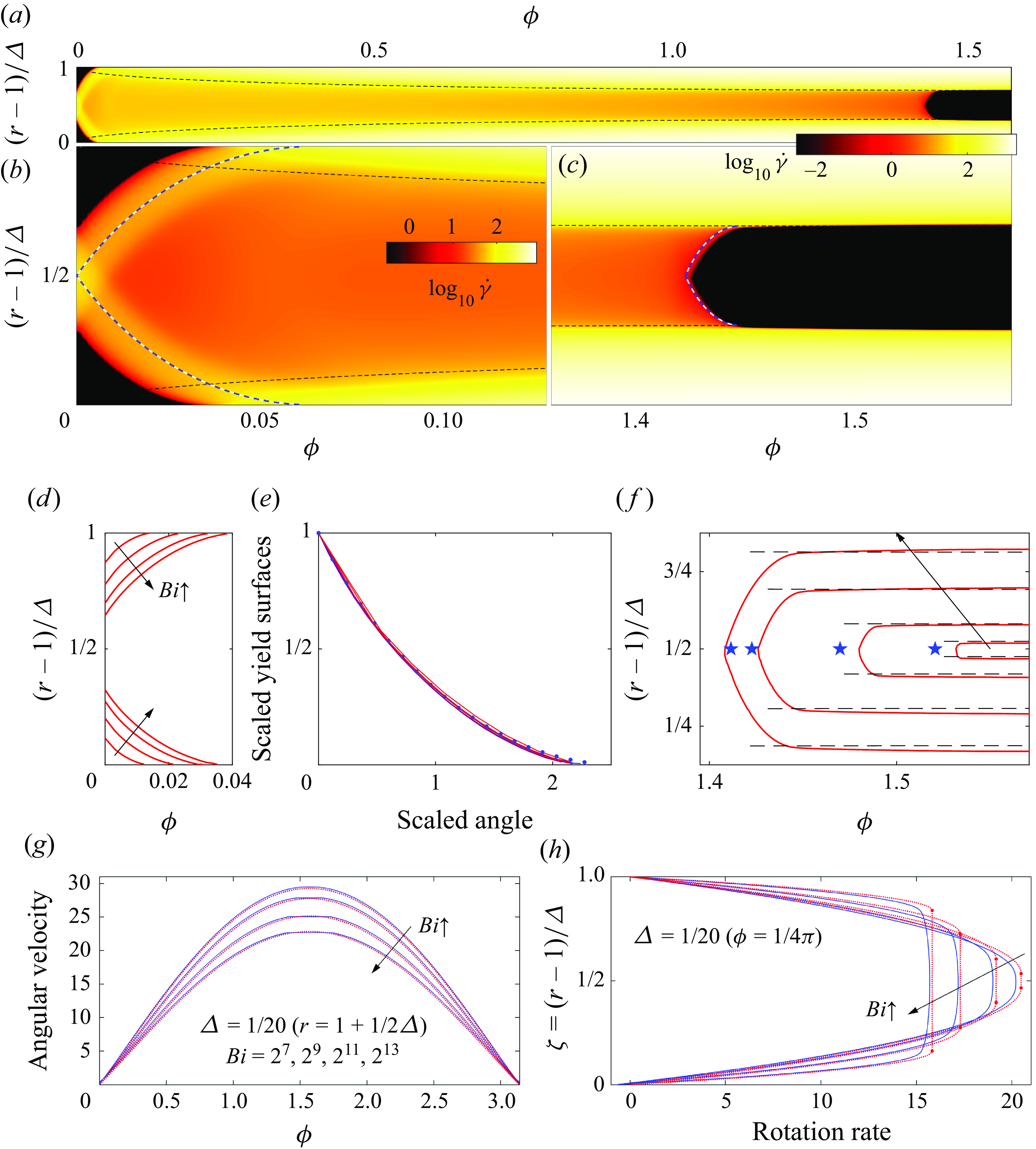

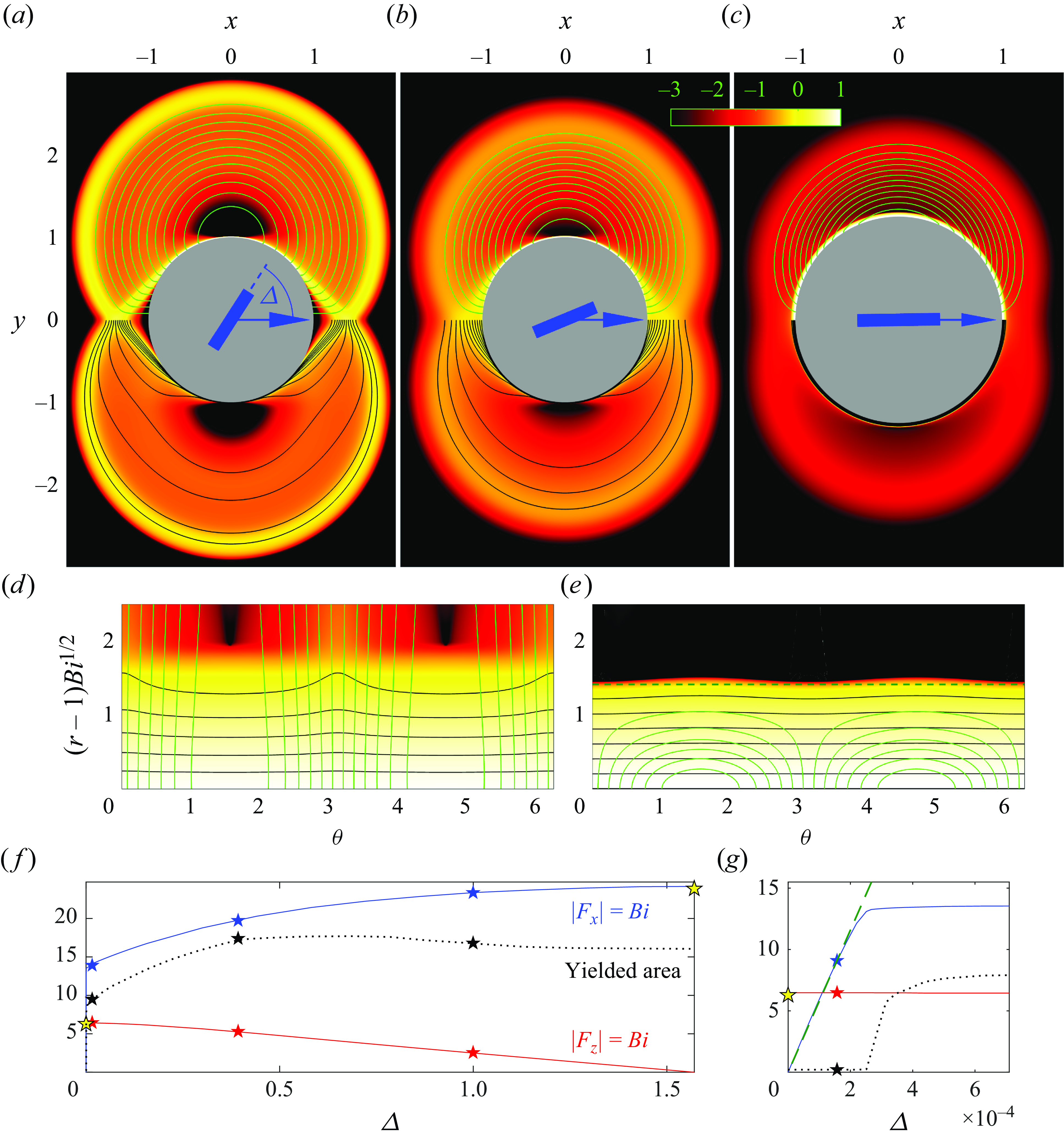

that will recur throughout this work, and these are perhaps best introduced by means of an example flow solution. Figure 1 shows sample numerical solutions of two-dimensional, inertialess flow of a Bingham fluid (

$\textit{Bi} \gg 1$

that will recur throughout this work, and these are perhaps best introduced by means of an example flow solution. Figure 1 shows sample numerical solutions of two-dimensional, inertialess flow of a Bingham fluid (

![]() ${\mu } = \text{constant}$

in (2.2)) around a translating disk (e.g. Roquet & Saramito (Reference Roquet and Saramito2003); Tokpavi, Magnin & Jay (Reference Tokpavi, Magnin and Jay2008); Chaparian & Frigaard (Reference Chaparian and Frigaard2017b

); Supekar, Hewitt & Balmforth (Reference Supekar, Hewitt and Balmforth2020)). This problem is well known in viscous fluid mechanics as a setting for the famous Stokes paradox: there is no purely viscous solution for flow around a translating disk; inertial effects inevitably impact the flow sufficiently far from the disk. Viscoplastic fluids have no such problem: the stress must decay away from the translating disk and, for any Bingham number, will eventually ‘plug up’ the material as it falls below the yield stress (see, e.g. Hewitt & Balmforth (Reference Hewitt and Balmforth2018)). That feature is a generic one for viscoplastic problems: stresses decay away from the point(s) of disturbance, causing the material to plug up sufficiently far away. As the influence of the yield stress (i.e.

${\mu } = \text{constant}$

in (2.2)) around a translating disk (e.g. Roquet & Saramito (Reference Roquet and Saramito2003); Tokpavi, Magnin & Jay (Reference Tokpavi, Magnin and Jay2008); Chaparian & Frigaard (Reference Chaparian and Frigaard2017b

); Supekar, Hewitt & Balmforth (Reference Supekar, Hewitt and Balmforth2020)). This problem is well known in viscous fluid mechanics as a setting for the famous Stokes paradox: there is no purely viscous solution for flow around a translating disk; inertial effects inevitably impact the flow sufficiently far from the disk. Viscoplastic fluids have no such problem: the stress must decay away from the translating disk and, for any Bingham number, will eventually ‘plug up’ the material as it falls below the yield stress (see, e.g. Hewitt & Balmforth (Reference Hewitt and Balmforth2018)). That feature is a generic one for viscoplastic problems: stresses decay away from the point(s) of disturbance, causing the material to plug up sufficiently far away. As the influence of the yield stress (i.e.

![]() $\textit{Bi}$

) is increased, the yielded region of deformation typically becomes increasingly localised to the source of the disturbance.

$\textit{Bi}$

) is increased, the yielded region of deformation typically becomes increasingly localised to the source of the disturbance.

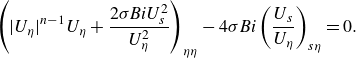

Figure 1. (a) Numerical solution for the nearly plastic flow of a Bingham fluid around a disk translating to the right. Shown is the logarithmic shear rate

![]() $\log _{10}{\dot \gamma }$

as a density map over the

$\log _{10}{\dot \gamma }$

as a density map over the

![]() $(x,y)$

-plane, for two solutions with different values for the dimensionless yield stress (

$(x,y)$

-plane, for two solutions with different values for the dimensionless yield stress (

![]() $\textit{Bi}=2^{10}$

, top;

$\textit{Bi}=2^{10}$

, top;

![]() $2^{14}$

, bottom; each full solution is symmetric about

$2^{14}$

, bottom; each full solution is symmetric about

![]() $y=0$

). The green lines show a selection of streamlines. In (b) the borders of the plugs are shown for a wider suite of computed solutions with

$y=0$

). The green lines show a selection of streamlines. In (b) the borders of the plugs are shown for a wider suite of computed solutions with

![]() $\textit{Bi}=2^j$

,

$\textit{Bi}=2^j$

,

![]() $j=6,7,\ldots, 16$

, with yield stress increasing as indicated (and colour coded from red to blue). The (green) dashed and dot-dashed lines indicate the outer yield surface and border of the serendipitous plug of the perfectly plastic solution (Randolph & Houlsby Reference Randolph and Houlsby1984). The wall boundary layer along the top side of the disk for

$j=6,7,\ldots, 16$

, with yield stress increasing as indicated (and colour coded from red to blue). The (green) dashed and dot-dashed lines indicate the outer yield surface and border of the serendipitous plug of the perfectly plastic solution (Randolph & Houlsby Reference Randolph and Houlsby1984). The wall boundary layer along the top side of the disk for

![]() $\textit{Bi}=2^{10}=1024$

is shown in more detail in (d). Angular velocity

$\textit{Bi}=2^{10}=1024$

is shown in more detail in (d). Angular velocity

![]() $v$

profiles are plotted in (c,d) along the cuts indicated by dotted blue lines in (a) and (e), for the suite of computations in (b). These profiles are collapsed by plotting

$v$

profiles are plotted in (c,d) along the cuts indicated by dotted blue lines in (a) and (e), for the suite of computations in (b). These profiles are collapsed by plotting

![]() $v$

against the scaled coordinates indicated, and compared with the predictions of boundary-layer theory (green dots; §§ C.1.1 and C.1.2).

$v$

against the scaled coordinates indicated, and compared with the predictions of boundary-layer theory (green dots; §§ C.1.1 and C.1.2).

That said, as seen in figure 1(a), which shows the deformation-rate field for two different values of

![]() $\textit{Bi} \gg 1$

separated by roughly an order of magnitude, the flow pattern is richer than just a simple localisation of viscous motion. Moreover, flow does not become confined to narrow regions around the disk. In fact, the region of yielded material in the two cases is almost identical, indicating that the flow field converges towards a non-trivial plastic limit as

$\textit{Bi} \gg 1$

separated by roughly an order of magnitude, the flow pattern is richer than just a simple localisation of viscous motion. Moreover, flow does not become confined to narrow regions around the disk. In fact, the region of yielded material in the two cases is almost identical, indicating that the flow field converges towards a non-trivial plastic limit as

![]() $\textit{Bi} \to \infty$

. The colour map and logarithmic scale used here helpfully illustrate both the location of the rigid plugs (black) and the relative contributions of plastic deformations (small, but non-zero strain rates; orange) and residual viscous motion (larger strain rates; yellow). The anatomy of these solutions reflects an interplay between the extended plastic regions, thin viscous layers and unyielded plugs.

$\textit{Bi} \to \infty$

. The colour map and logarithmic scale used here helpfully illustrate both the location of the rigid plugs (black) and the relative contributions of plastic deformations (small, but non-zero strain rates; orange) and residual viscous motion (larger strain rates; yellow). The anatomy of these solutions reflects an interplay between the extended plastic regions, thin viscous layers and unyielded plugs.

The extended regions of nearly plastic deformation dominate the flow pattern when

![]() $\textit{Bi} \gg 1$

. In figure 1(a), these regions extend out to circular arcs beginning from a point ahead of the disk to a (symmetric) point at the back; fluid circulates from fore to aft within them. Small, rigidly rotating plugs occupy the centres of the circulating flows, while narrow shear layers act as buffers from both the outer unyielded plug and from the moving disk. Two other, rigidly translating plugs with triangular yield surfaces are attached to the disk at the front and back. The stress and deformation fields in the extended regions of nearly plastic deformation approach those for a disk moving in a perfectly plastic material (Randolph & Houlsby Reference Randolph and Houlsby1984); the clean, geometrical nature of these regions reflects an underlying map of characteristics, the so-called slipline field (Hill Reference Hill1950; Prager & Hodge Reference Prager and Hodge1951), that solve the hyperbolic plastic problem, as discussed in more detail in § 3.4 below.

$\textit{Bi} \gg 1$

. In figure 1(a), these regions extend out to circular arcs beginning from a point ahead of the disk to a (symmetric) point at the back; fluid circulates from fore to aft within them. Small, rigidly rotating plugs occupy the centres of the circulating flows, while narrow shear layers act as buffers from both the outer unyielded plug and from the moving disk. Two other, rigidly translating plugs with triangular yield surfaces are attached to the disk at the front and back. The stress and deformation fields in the extended regions of nearly plastic deformation approach those for a disk moving in a perfectly plastic material (Randolph & Houlsby Reference Randolph and Houlsby1984); the clean, geometrical nature of these regions reflects an underlying map of characteristics, the so-called slipline field (Hill Reference Hill1950; Prager & Hodge Reference Prager and Hodge1951), that solve the hyperbolic plastic problem, as discussed in more detail in § 3.4 below.

Over the shear layers that buffer the extended nearly plastic regions, viscous stresses become important, and their interplay with the plastic stresses controls the dynamics (see Oldroyd (Reference Oldroyd1947b

); Balmforth et al. (Reference Balmforth, Craster, Hewitt, Hormozi and Maleki2017)). It turns out, however, that the nature of this control depends on whether one boundary is a rigid wall or not (in essence, there is a fixed constraint on the magnitude of the stress at the edge of a plug region that is absent if the layer borders a rigid wall). As demonstrated in detail in Appendix C, wall-bounded layers are generically thinner, with higher shear rates, than ‘free’ shear layers bordering a plug. In figure 1, panels (c) and (d) show how the widths of these two types of boundary layers scale with

![]() $\textit{Bi}^{-1/2}$

and

$\textit{Bi}^{-1/2}$

and

![]() $\textit{Bi}^{-1/3}$

, respectively. Those scalings, in each case, follow from consideration of the size of the pressure drop across the layers. These viscoplastic layers have vanishing thickness for

$\textit{Bi}^{-1/3}$

, respectively. Those scalings, in each case, follow from consideration of the size of the pressure drop across the layers. These viscoplastic layers have vanishing thickness for

![]() $\textit{Bi}\to \infty$

, becoming lines of slip in the perfectly plastic limit.

$\textit{Bi}\to \infty$

, becoming lines of slip in the perfectly plastic limit.

Finally, the plugs also come in different varieties. The outer, ‘ambient’ plug of figure 1 is one variety, corresponding to a permanent feature of the plastic limit. This permanence is visible in panel (b), which plots the yield surfaces for computations with varying

![]() $\textit{Bi}$

. The outermost yield surface, the border of the ambient plug, converges to a finite curve for

$\textit{Bi}$

. The outermost yield surface, the border of the ambient plug, converges to a finite curve for

![]() $\textit{Bi}\to \infty$

which corresponds to the yield surface of the perfectly plastic slipline solution (Randolph & Houlsby Reference Randolph and Houlsby1984). In addition to appearing in the perfectly plastic solution, these ‘permanent’ plugs are characterised by stress fields that certainly fall below the yield value.

$\textit{Bi}\to \infty$

which corresponds to the yield surface of the perfectly plastic slipline solution (Randolph & Houlsby Reference Randolph and Houlsby1984). In addition to appearing in the perfectly plastic solution, these ‘permanent’ plugs are characterised by stress fields that certainly fall below the yield value.

A second plug variety is illustrated by the rotating plugs at the cores of the recirculation zones. Unlike the permanent plugs, these regions of rigid rotation steadily shrink as

![]() $\textit{Bi}$

is increased, and vanish completely in the limit

$\textit{Bi}$

is increased, and vanish completely in the limit

![]() $\textit{Bi} \to \infty$

(although their decay is extremely weak; Supekar et al. (Reference Supekar, Hewitt and Balmforth2020) argue that the plug radius decays like

$\textit{Bi} \to \infty$

(although their decay is extremely weak; Supekar et al. (Reference Supekar, Hewitt and Balmforth2020) argue that the plug radius decays like

![]() $\textit{Bi}^{-3/28}$

). The rotating plugs also do not feature in the perfectly plastic slipline solution. In other words, these ‘residual plugs’ constitute a second variety of plugs that have their origin in viscous effects (which are evidently sufficient to reduce stresses below the yield value for finite

$\textit{Bi}^{-3/28}$

). The rotating plugs also do not feature in the perfectly plastic slipline solution. In other words, these ‘residual plugs’ constitute a second variety of plugs that have their origin in viscous effects (which are evidently sufficient to reduce stresses below the yield value for finite

![]() $\textit{Bi}$

if the local strain rate remains relatively small).

$\textit{Bi}$

if the local strain rate remains relatively small).

Last, the rigid plugs attached to the front and back of the disk are examples of a third plug variety. In the numerical solutions, these plugs have yield surfaces that again converge to finite curves (figure 1 b), as for the permanent plugs. However, unlike the latter, the whole interior of the triangular plugs are held close to the yield threshold. Moreover, these regions are identified as part of the deforming region in the perfectly plastic solution (which we illustrate more fully below in § 5). By pure coincidence, it turns out that the velocity field over the triangular regions is simultaneously consistent with rigid-body motion, being simply an extension of the disk’s velocity. Those regions thereby become identified numerically as plugs. In fact, when we consider some other disk-flow problems in § 5, we uncover different examples in which triangular regions at the front and back truly yield and deform plastically, owing to the imposition of different velocity boundary conditions on the disk surface that lead to a conflict with rigid-body motion. The attached plugs in figure 1 are therefore examples of what one might call ‘serendipitous’ plugs.

A summary of all these features, amounting to a list of expectations for the flow patterns in the plastic limit, is given in table 1. A number of principles underlie these features. These principles, and some of their consequences, will be identified and discussed in the remainder of this article, and are summarised in table 2.

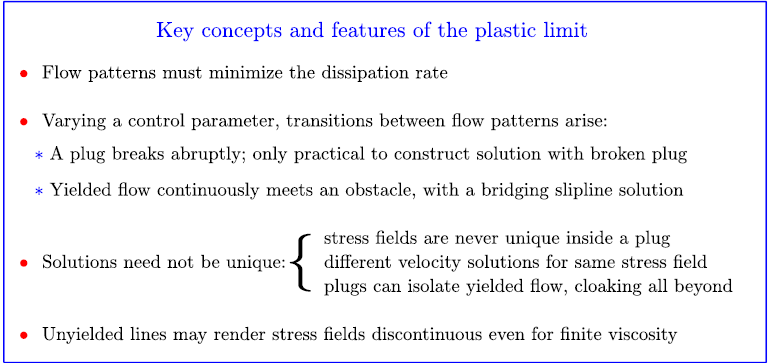

Table 1. Typical flow features in the plastic limit.

Table 2. Key guiding principles underlying the typical flow features listed in table 1.

3. Mathematical foundations

3.1. Conservation laws; prototypical viscoplastic rheology

Consider the flow of a two-dimensional, incompressible, complex fluid, describing the geometry by a Cartesian coordinate system

![]() $({\hat {x}},{\hat {y}})$

. The fluid velocity is

$({\hat {x}},{\hat {y}})$

. The fluid velocity is

![]() $\boldsymbol{{\hat {u}}} = ({\hat {u}},{\hat {v}})$

. Conservation of mass and momentum demand that

$\boldsymbol{{\hat {u}}} = ({\hat {u}},{\hat {v}})$

. Conservation of mass and momentum demand that

and

where

![]() $\hat {p}$

is the pressure and

$\hat {p}$

is the pressure and

![]() $\hat {\boldsymbol{f}}$

represents any body force like gravity (we use the hat notation to denote dimensional variables; this decoration is removed using suitable scalings, to arrive at a dimensionless formulation, as outlined presently).

$\hat {\boldsymbol{f}}$

represents any body force like gravity (we use the hat notation to denote dimensional variables; this decoration is removed using suitable scalings, to arrive at a dimensionless formulation, as outlined presently).

One of the simplest and most popular constitutive models for a yield-stress fluid of the form of (2.2) is the Herschel-Bulkley law, with tensorial formulation

The plastic viscosity,

![]() ${\mu }(\hat {{\dot \gamma }})=K\hat {{\dot \gamma }}^{n-1}$

takes the same form as the power-law fluid, with a consistency

${\mu }(\hat {{\dot \gamma }})=K\hat {{\dot \gamma }}^{n-1}$

takes the same form as the power-law fluid, with a consistency

![]() $K$

and power-law index

$K$

and power-law index

![]() $n$

. The yield stress is

$n$

. The yield stress is

![]() $\tau _{_{_P}}$

; if

$\tau _{_{_P}}$

; if

![]() $\hat \tau \lt {\tau _{_{_P}}}$

, this threshold for yield is not breached and the deformation rates must all vanish, translating to

$\hat \tau \lt {\tau _{_{_P}}}$

, this threshold for yield is not breached and the deformation rates must all vanish, translating to

![]() $\hat {\dot \gamma }_{ij}=0$

. An important special case of (3.3) is when

$\hat {\dot \gamma }_{ij}=0$

. An important special case of (3.3) is when

![]() $n=1$

and the rate-dependent part of the stress takes the form of a constant viscous stress. This is the Bingham fluid, which is popular because of its simplicity, not its realism. Fits to data obtained in rheometers more typically generate power-law exponents

$n=1$

and the rate-dependent part of the stress takes the form of a constant viscous stress. This is the Bingham fluid, which is popular because of its simplicity, not its realism. Fits to data obtained in rheometers more typically generate power-law exponents

![]() $n\lt 1$

, although the power-law form itself is usually only a rougher representation of real fluid behaviour (Balmforth et al. Reference Balmforth, Frigaard and Ovarlez2014; Bonn et al. Reference Bonn, Denn, Berthier, Divoux and Manneville2017; Coussot Reference Coussot2018; Frigaard Reference Frigaard2019a

).

$n\lt 1$

, although the power-law form itself is usually only a rougher representation of real fluid behaviour (Balmforth et al. Reference Balmforth, Frigaard and Ovarlez2014; Bonn et al. Reference Bonn, Denn, Berthier, Divoux and Manneville2017; Coussot Reference Coussot2018; Frigaard Reference Frigaard2019a

).

Importantly, when

![]() ${\hat {\tau }}\lt {\tau _{_{_P}}}$

, no relation is imposed between the stresses and strain rates. In two dimensions, the two force-balance equations (3.2) are then insufficient to determine the two independent components of

${\hat {\tau }}\lt {\tau _{_{_P}}}$

, no relation is imposed between the stresses and strain rates. In two dimensions, the two force-balance equations (3.2) are then insufficient to determine the two independent components of

![]() $\hat {\boldsymbol \tau }$

and the pressure

$\hat {\boldsymbol \tau }$

and the pressure

![]() $\hat {p}$

. That is, the stress state is formally indeterminate over any plugged region, which is an awkward feature of the problem that will recur often in our discussion.

$\hat {p}$

. That is, the stress state is formally indeterminate over any plugged region, which is an awkward feature of the problem that will recur often in our discussion.

3.2. Scaling and dimensionless formulation

It is helpful to reformulate the equations in dimensionless form and identify key dimensionless groups. We have already identified the Bingham number (2.3) as the ratio of viscous and yield-stress scales; for the Herschel–Bulkley law, given length and velocity scales

![]() $\mathcal{L}$

and

$\mathcal{L}$

and

![]() $\mathcal{U}$

, the Bingham number is

$\mathcal{U}$

, the Bingham number is

with

![]() $\textit{Bi} \gg 1$

denoting the plastic limit of the problem. Alternatively, when the velocity scale is not imposed, but a body force like gravity is present, a stress scale

$\textit{Bi} \gg 1$

denoting the plastic limit of the problem. Alternatively, when the velocity scale is not imposed, but a body force like gravity is present, a stress scale

![]() $\mathcal{P}$

can be defined (such as

$\mathcal{P}$

can be defined (such as

![]() $\mathcal{P} = \rho g \mathcal{L}$

). In this circumstance, one can define a velocity scale

$\mathcal{P} = \rho g \mathcal{L}$

). In this circumstance, one can define a velocity scale

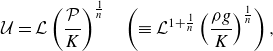

\begin{equation} \mathcal{U} = \mathcal{L} \left ( \frac {\mathcal{P}}{K} \right )^{\frac 1n} \quad \left (\equiv \mathcal{L}^{1+\frac 1n} \left ( \frac {\rho g}{K} \right )^{\frac 1n} \right ), \end{equation}

\begin{equation} \mathcal{U} = \mathcal{L} \left ( \frac {\mathcal{P}}{K} \right )^{\frac 1n} \quad \left (\equiv \mathcal{L}^{1+\frac 1n} \left ( \frac {\rho g}{K} \right )^{\frac 1n} \right ), \end{equation}

where

![]() $\rho$

and

$\rho$

and

![]() $g$

denote density and gravitational acceleration and the Bingham number in (3.4) becomes

$g$

denote density and gravitational acceleration and the Bingham number in (3.4) becomes

![]() $\textit{Bi}={\tau _{_{_P}}}/\mathcal{P}$

(or

$\textit{Bi}={\tau _{_{_P}}}/\mathcal{P}$

(or

![]() ${\tau _{_{_P}}}/(\rho g \mathcal{L})$

). This parameter must remain order one if the applied stresses are to exceed the yield stress and force motion. Strictly speaking,

${\tau _{_{_P}}}/(\rho g \mathcal{L})$

). This parameter must remain order one if the applied stresses are to exceed the yield stress and force motion. Strictly speaking,

![]() $\textit{Bi}$

now represents the ratio of yield stress to the imposed stress, and (for gravity) is sometimes referred to as the ‘Oldroyd number’ instead. The plastic limit is then characterised by the special value of

$\textit{Bi}$

now represents the ratio of yield stress to the imposed stress, and (for gravity) is sometimes referred to as the ‘Oldroyd number’ instead. The plastic limit is then characterised by the special value of

![]() $\textit{Bi}$

for which the fluid speed approaches zero. That is, the plastic limit corresponds to the threshold for motion.

$\textit{Bi}$

for which the fluid speed approaches zero. That is, the plastic limit corresponds to the threshold for motion.

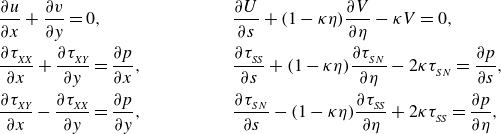

For two-dimensional flow without body forces, we write the dimensionless governing equations using either a Cartesian coordinate system

![]() $(x,y)$

or general curvilinear coordinates

$(x,y)$

or general curvilinear coordinates

![]() $(s,\eta )$

built from the arc length along some prescribed curve and its normal:

$(s,\eta )$

built from the arc length along some prescribed curve and its normal:

\begin{equation} \begin{aligned} &\frac {\partial {u}}{\partial {x}}+\frac {\partial {v}}{\partial {y}} = 0, \cr &\frac {\partial {{\tau _{_{\textit{XX}}}}}}{\partial {x}} + \frac {\partial {{\tau _{_{\textit{XY}}}}}}{\partial {y}} = \frac {\partial {p}}{\partial {x}},\cr &\frac {\partial {{\tau _{_{\textit{XY}}}}}}{\partial {x}} - \frac {\partial {{\tau _{_{\textit{XX}}}}}}{\partial {y}} = \frac {\partial {p}}{\partial {y}}, \end{aligned} \qquad \qquad \begin{aligned} &\frac {\partial {U}}{\partial {s}} + (1-\kappa \eta )\frac {\partial {V}}{\partial {\eta }} - \kappa V = 0, \cr &\frac {\partial {{\tau _{_{\textit{SS}}}}}}{\partial {s}} + (1-\kappa \eta )\frac {\partial {{\tau _{_{SN}}}}}{\partial {\eta }} - 2\kappa {\tau _{_{SN}}} = \frac {\partial {p}}{\partial {s}},\cr &\frac {\partial {{\tau _{_{SN}}}}}{\partial {s}} - (1-\kappa \eta )\frac {\partial {{\tau _{_{\textit{SS}}}}}}{\partial {\eta }} + 2\kappa {\tau _{_{\textit{SS}}}} = \frac {\partial {p}}{\partial {\eta }}, \end{aligned} \end{equation}

\begin{equation} \begin{aligned} &\frac {\partial {u}}{\partial {x}}+\frac {\partial {v}}{\partial {y}} = 0, \cr &\frac {\partial {{\tau _{_{\textit{XX}}}}}}{\partial {x}} + \frac {\partial {{\tau _{_{\textit{XY}}}}}}{\partial {y}} = \frac {\partial {p}}{\partial {x}},\cr &\frac {\partial {{\tau _{_{\textit{XY}}}}}}{\partial {x}} - \frac {\partial {{\tau _{_{\textit{XX}}}}}}{\partial {y}} = \frac {\partial {p}}{\partial {y}}, \end{aligned} \qquad \qquad \begin{aligned} &\frac {\partial {U}}{\partial {s}} + (1-\kappa \eta )\frac {\partial {V}}{\partial {\eta }} - \kappa V = 0, \cr &\frac {\partial {{\tau _{_{\textit{SS}}}}}}{\partial {s}} + (1-\kappa \eta )\frac {\partial {{\tau _{_{SN}}}}}{\partial {\eta }} - 2\kappa {\tau _{_{SN}}} = \frac {\partial {p}}{\partial {s}},\cr &\frac {\partial {{\tau _{_{SN}}}}}{\partial {s}} - (1-\kappa \eta )\frac {\partial {{\tau _{_{\textit{SS}}}}}}{\partial {\eta }} + 2\kappa {\tau _{_{\textit{SS}}}} = \frac {\partial {p}}{\partial {\eta }}, \end{aligned} \end{equation}

where

is the curvature of the prescribed curve. Here and throughout this work, capital-letter subscripts are used to identify tensor components. The velocity field in Cartesian coordinates is

![]() $(u,v)$

; the curvilinear relative is

$(u,v)$

; the curvilinear relative is

![]() $(U,V)$

. The strain-rate components are given by

$(U,V)$

. The strain-rate components are given by

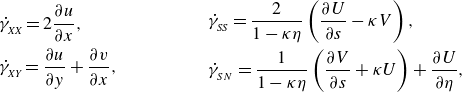

\begin{equation} \begin{aligned} &{\dot \gamma _{_{\textit{XX}}}} = 2\frac {\partial {u}}{\partial {x}},\cr &{\dot \gamma _{_{\textit{XY}}}} = \frac {\partial {u}}{\partial {y}}+\frac {\partial {v}}{\partial {x}}, \end{aligned} \qquad \qquad \begin{aligned} &{\dot \gamma _{_{\textit{SS}}}} = \frac {2}{1-\kappa \eta }\left (\frac {\partial {U}}{\partial {s}}-\kappa V\right ),\cr &{\dot \gamma _{_{SN}}} = \frac {1}{1-\kappa \eta }\left (\frac {\partial {V}}{\partial {s}}+\kappa U\right )+ \frac {\partial {U}}{\partial {\eta }}, \end{aligned} \end{equation}

\begin{equation} \begin{aligned} &{\dot \gamma _{_{\textit{XX}}}} = 2\frac {\partial {u}}{\partial {x}},\cr &{\dot \gamma _{_{\textit{XY}}}} = \frac {\partial {u}}{\partial {y}}+\frac {\partial {v}}{\partial {x}}, \end{aligned} \qquad \qquad \begin{aligned} &{\dot \gamma _{_{\textit{SS}}}} = \frac {2}{1-\kappa \eta }\left (\frac {\partial {U}}{\partial {s}}-\kappa V\right ),\cr &{\dot \gamma _{_{SN}}} = \frac {1}{1-\kappa \eta }\left (\frac {\partial {V}}{\partial {s}}+\kappa U\right )+ \frac {\partial {U}}{\partial {\eta }}, \end{aligned} \end{equation}

and the Herschel–Bulkley constitutive law is

The nonlinear rheology in (3.9) presents some challenges for computing numerical solutions to (3.6)–(3.9), primarily because of the yield condition. A convenient, alternative approach that circumvents such challenges is provided by ‘regularising’ the constitutive law: (3.9) is replaced by a smoothed version with a well-defined and finite relationship between stress and strain rate everywhere. More precise techniques also exist, most notably the augmented Lagrangian approach, which provides an iterative solution to the exact rheology directly. Some details of both of these schemes, along with other numerical considerations and observations, are presented in Appendix A.

Alternatively, as in any fluid mechanical problem, asymptotic approaches based on an extreme difference in length scales provide a useful tool for interrogating viscoplastic flows (Balmforth Reference Balmforth2019). Shallow flows can be attacked with a generalisation of viscous lubrication theory, although the approach has been incorrectly denigrated in the past because of the fallacy of the so-called lubrication paradox (Balmforth & Craster Reference Balmforth and Craster1999; Hewitt & Balmforth Reference Hewitt and Balmforth2012). More generally, and as illustrated earlier, viscous deformation becomes restricted to narrow boundary layers in the plastic limit, which are amenable to boundary-layer analysis (Oldroyd Reference Oldroyd1947b ; Balmforth et al. Reference Balmforth, Craster, Hewitt, Hormozi and Maleki2017). Such asymptotic approaches can become technically involved; the interested reader can find further details in Appendix C.

3.3. Extremum principles and minimum dissipation

The (dimensionless) governing equations can be cast into a variational form that identifies extremum principles satisfied by the velocity and stress fields (see Prager (Reference Prager1954) and, for example, Frigaard (Reference Frigaard2019b )). We quote these principles in settings for which we ignore any body forces (i.e. gravity) and the velocity field is prescribed on all the boundaries. The principles therefore apply to the steady flow problems considered in § 4 and § 5, and provide a useful constraint associated with the net dissipation rate on the solutions in the plastic limit.

The first principle is that, of all the divergence-free velocity fields

![]() $\boldsymbol{v}$

that match up with the velocities along the boundaries, the actual velocity field

$\boldsymbol{v}$

that match up with the velocities along the boundaries, the actual velocity field

![]() $\boldsymbol{u}$

minimises the functional

$\boldsymbol{u}$

minimises the functional

where

![]() $\mathcal{D}$

denotes the domain occupied by the fluid and

$\mathcal{D}$

denotes the domain occupied by the fluid and

![]() ${\dot \gamma }(\boldsymbol{v})$

denotes the strain-rate invariant built from

${\dot \gamma }(\boldsymbol{v})$

denotes the strain-rate invariant built from

![]() $\boldsymbol{v}$

. In this minimisation, the trial velocity fields are not linked through the constitutive law to any stress field.

$\boldsymbol{v}$

. In this minimisation, the trial velocity fields are not linked through the constitutive law to any stress field.

The second principle is that, of all the possible stress fields

![]() $\tilde {\boldsymbol{\sigma }}$

that satisfy the force-balance equations, independently of the constitutive law, the actual stress

$\tilde {\boldsymbol{\sigma }}$

that satisfy the force-balance equations, independently of the constitutive law, the actual stress

![]() $\boldsymbol{\sigma }$

maximises

$\boldsymbol{\sigma }$

maximises

where

![]() $\partial \mathcal{D}$

denotes the boundary of the fluid domain, with unit outward normal

$\partial \mathcal{D}$

denotes the boundary of the fluid domain, with unit outward normal

![]() $\boldsymbol{\hat {n}}$

and infinitesimal arc length

$\boldsymbol{\hat {n}}$

and infinitesimal arc length

![]() $\textrm {d} s$

, and

$\textrm {d} s$

, and

![]() $\tau (\tilde {\boldsymbol{\sigma }})$

denotes the second invariant of the trial stress field.

$\tau (\tilde {\boldsymbol{\sigma }})$

denotes the second invariant of the trial stress field.

Necessarily, when the extrema are achieved, we also have that

![]() $\Phi [\boldsymbol{u}]=\Psi [ \boldsymbol{\sigma }]$

, which corresponds to the integral constraint

$\Phi [\boldsymbol{u}]=\Psi [ \boldsymbol{\sigma }]$

, which corresponds to the integral constraint

and is simply an expression of the fact that the power supplied through boundaries (the left-hand side) must balance the net dissipation rate (

![]() $\mathcal{E}$

, the second integral). Importantly, in the plastic limit,

$\mathcal{E}$

, the second integral). Importantly, in the plastic limit,

![]() $\tau {\dot \gamma } \to \textit{Bi}{\dot \gamma }$

and the velocity minimisation corresponds to selecting the trial velocity field that has the least net rate of dissipation. In addition, if a body force is present (cf. § 6), the work performed by that force must also be added to the variational problems and to (3.12) (Prager Reference Prager1954; Frigaard Reference Frigaard2019b

).

$\tau {\dot \gamma } \to \textit{Bi}{\dot \gamma }$

and the velocity minimisation corresponds to selecting the trial velocity field that has the least net rate of dissipation. In addition, if a body force is present (cf. § 6), the work performed by that force must also be added to the variational problems and to (3.12) (Prager Reference Prager1954; Frigaard Reference Frigaard2019b

).

3.4. Plasticity theory

For

![]() $\textit{Bi}\gg 1$

, the theory of perfect plasticity applies (Hill Reference Hill1950; Prager & Hodge Reference Prager and Hodge1951); key concepts for generating solutions in this limit are provided below. Additional details of slipline analysis, and a sample construction of a relevant slipline pattern, can be found in Appendix B.

$\textit{Bi}\gg 1$

, the theory of perfect plasticity applies (Hill Reference Hill1950; Prager & Hodge Reference Prager and Hodge1951); key concepts for generating solutions in this limit are provided below. Additional details of slipline analysis, and a sample construction of a relevant slipline pattern, can be found in Appendix B.

3.4.1. Sliplines

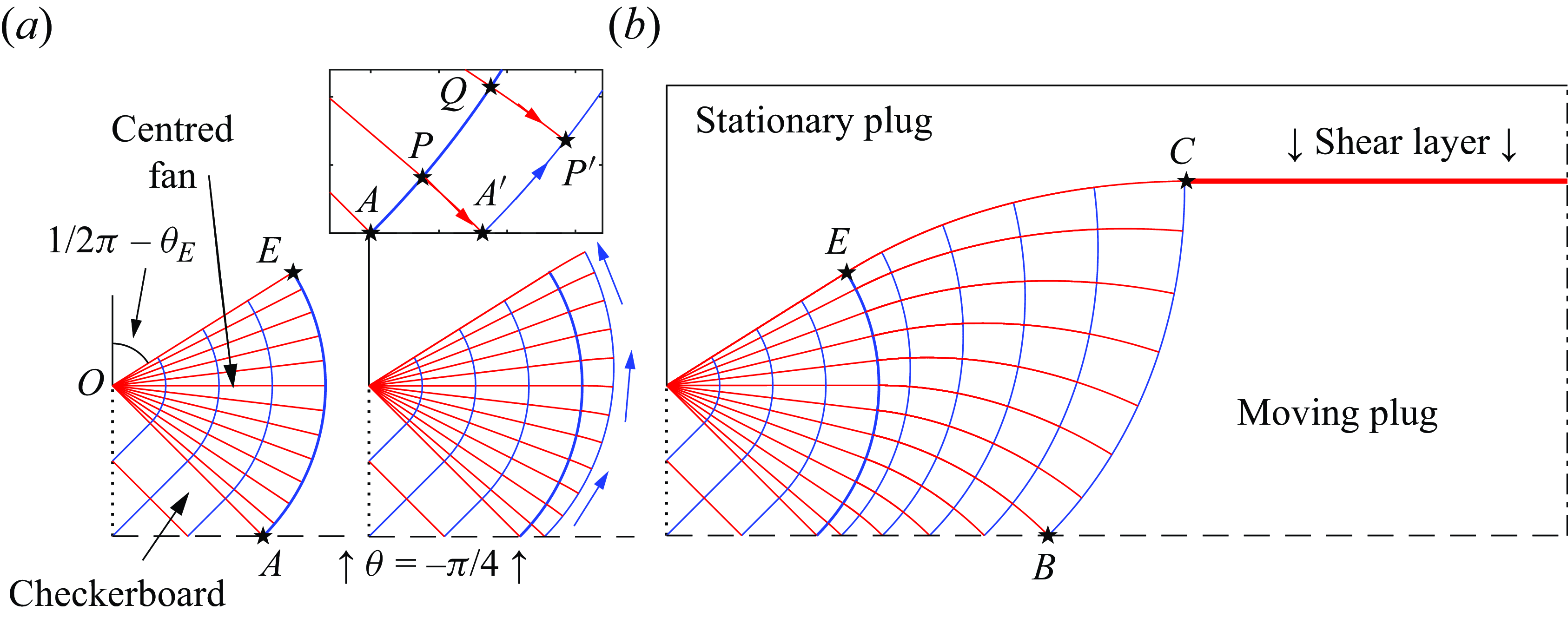

In terms of our two-dimensional Cartesian coordinate system, the constitutive law in the ideal plastic limit reduces to

which motivates the definition of the new variable

![]() $\theta$

in

$\theta$

in

We may then manipulate the force-balance equations (3.2) into the hyperbolic pairing

That is, we have the Riemann invariant

![]() $p+2\textit{Bi}\theta$

along the curves with

$p+2\textit{Bi}\theta$

along the curves with

![]() $\textrm {d} y/\textrm {d} x = \tan \theta$

; the curves with

$\textrm {d} y/\textrm {d} x = \tan \theta$

; the curves with

![]() $\textrm {d} y/\textrm {d} x = -\cot \theta$

have

$\textrm {d} y/\textrm {d} x = -\cot \theta$

have

![]() $p-2\textit{Bi}\theta = \textrm{constant}$

. These characteristic curves are the ‘sliplines’ of classical plasticity theory (Hill Reference Hill1950; Prager & Hodge Reference Prager and Hodge1951). Evidently, the two sets of curves are orthogonal to one another, and are commonly referred to as the

$p-2\textit{Bi}\theta = \textrm{constant}$

. These characteristic curves are the ‘sliplines’ of classical plasticity theory (Hill Reference Hill1950; Prager & Hodge Reference Prager and Hodge1951). Evidently, the two sets of curves are orthogonal to one another, and are commonly referred to as the

![]() $\alpha$

and

$\alpha$

and

![]() $\beta $

-lines. Convention takes the two sliplines to form a local right-handed coordinate system.

$\beta $

-lines. Convention takes the two sliplines to form a local right-handed coordinate system.

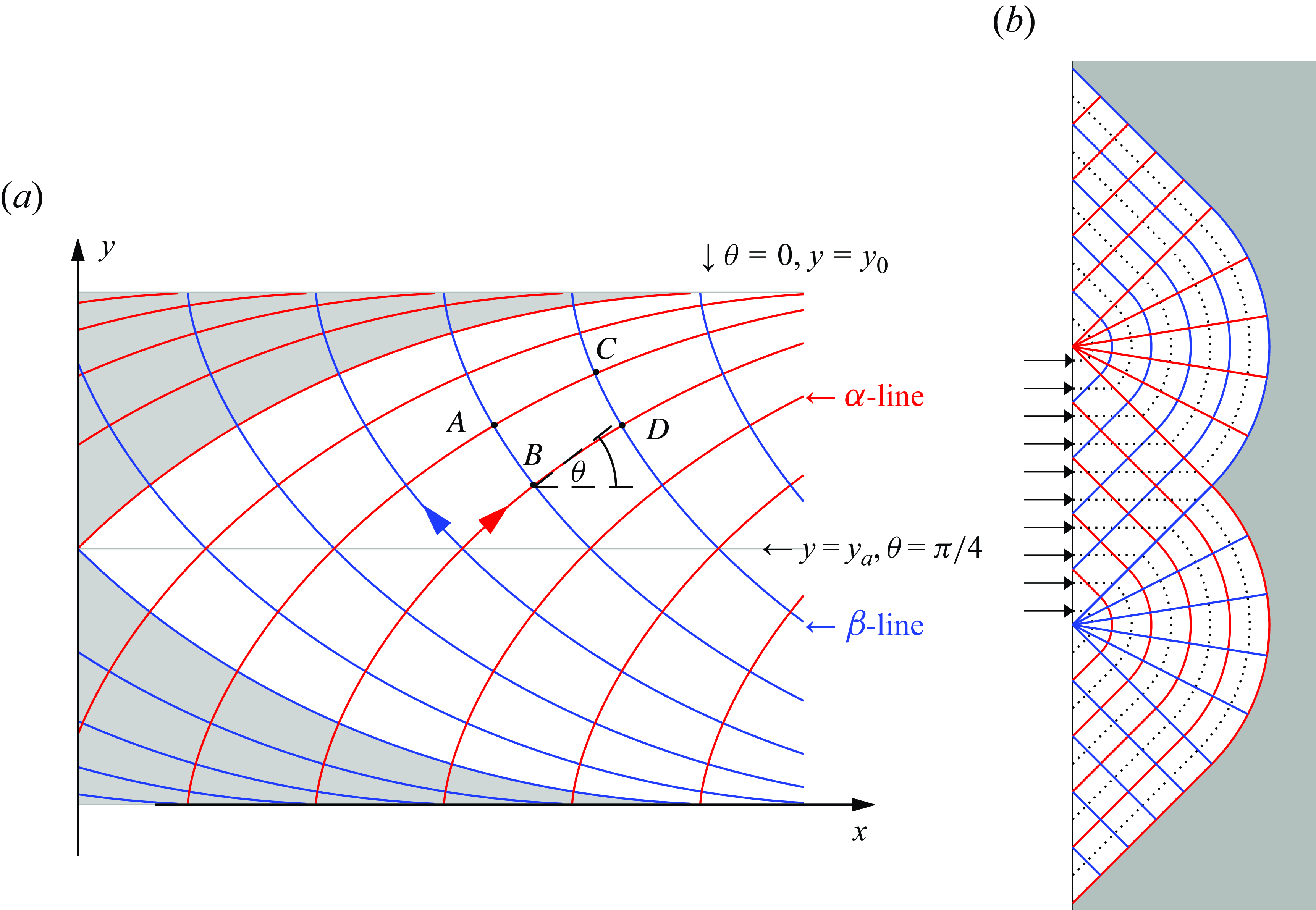

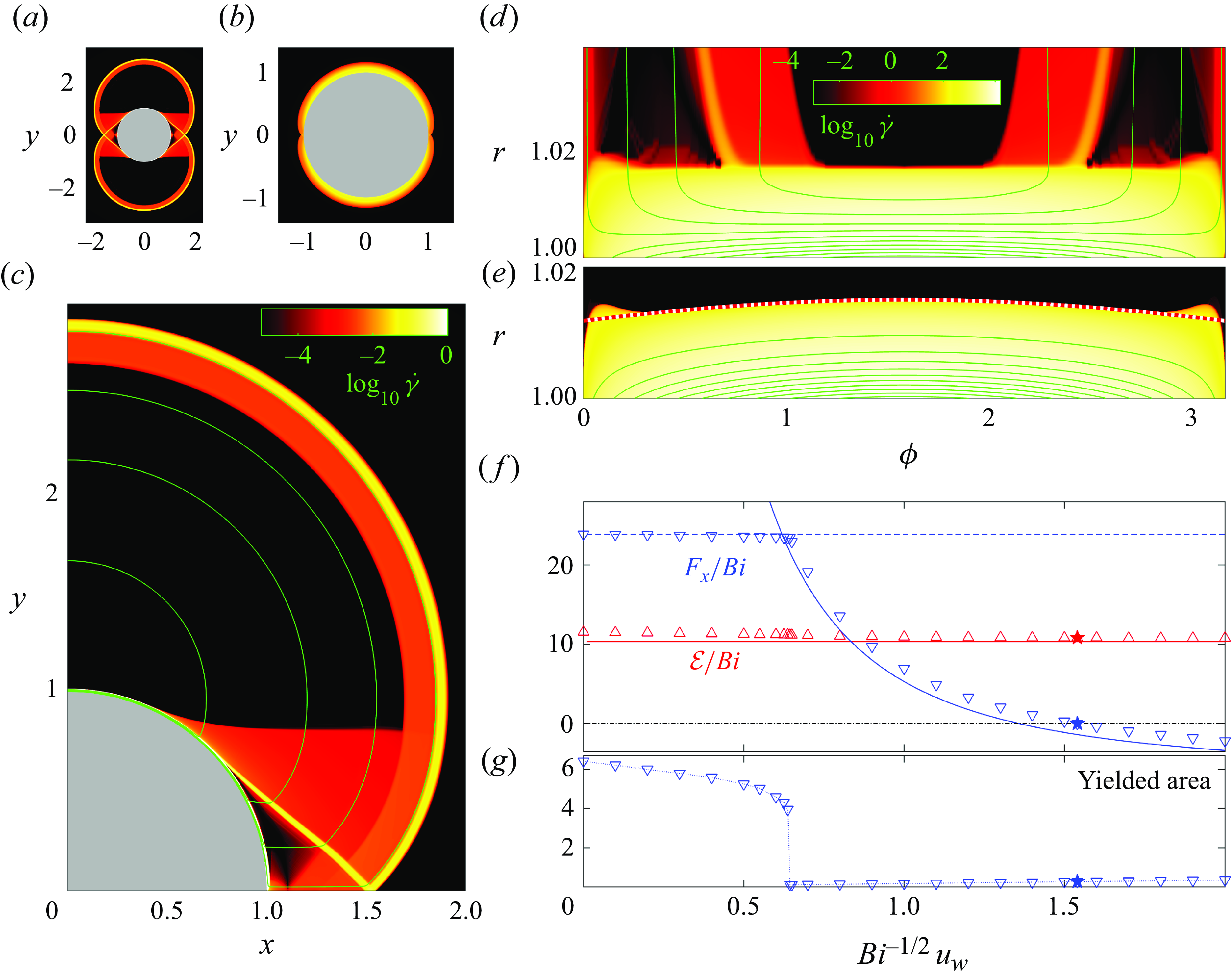

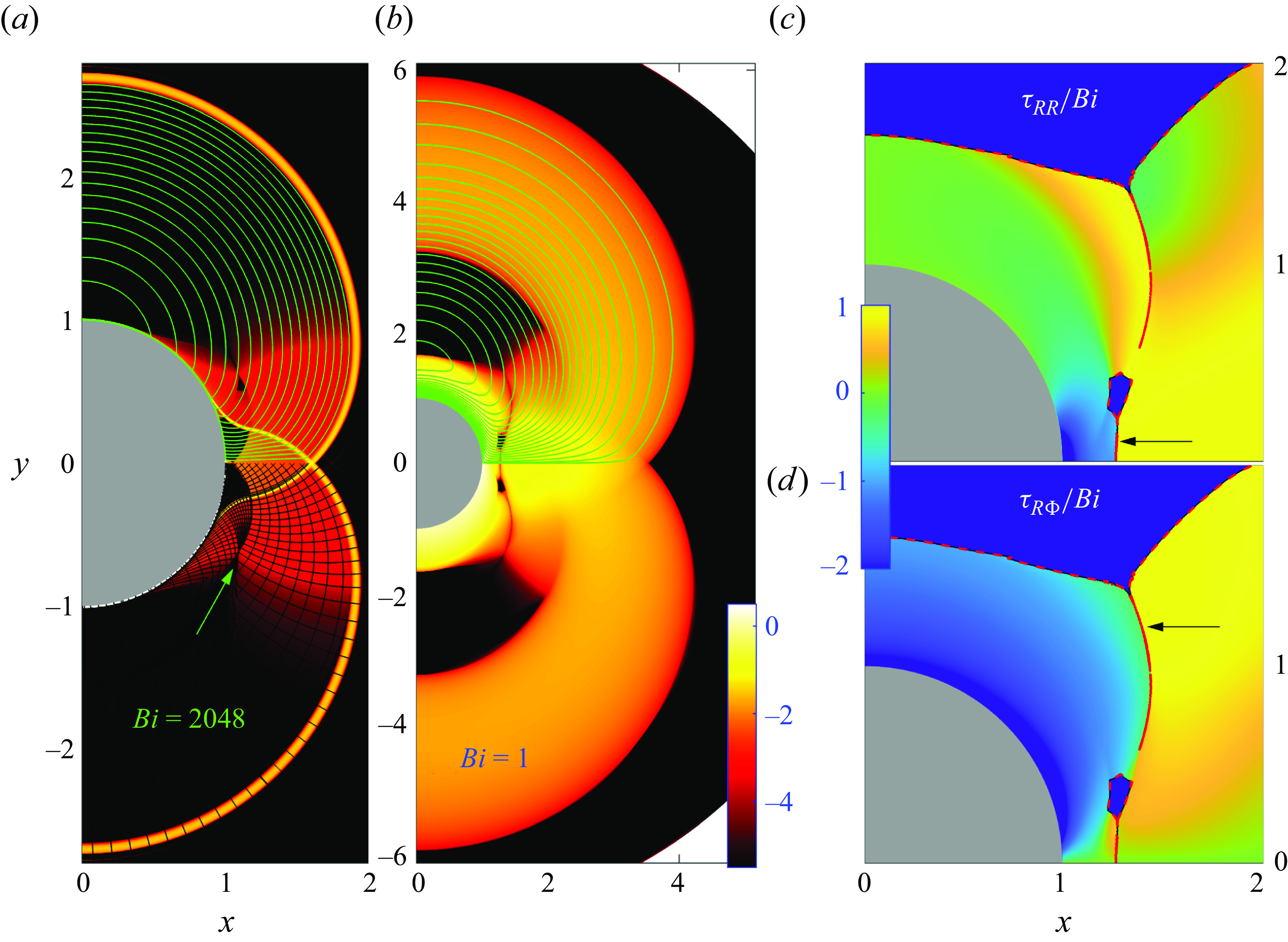

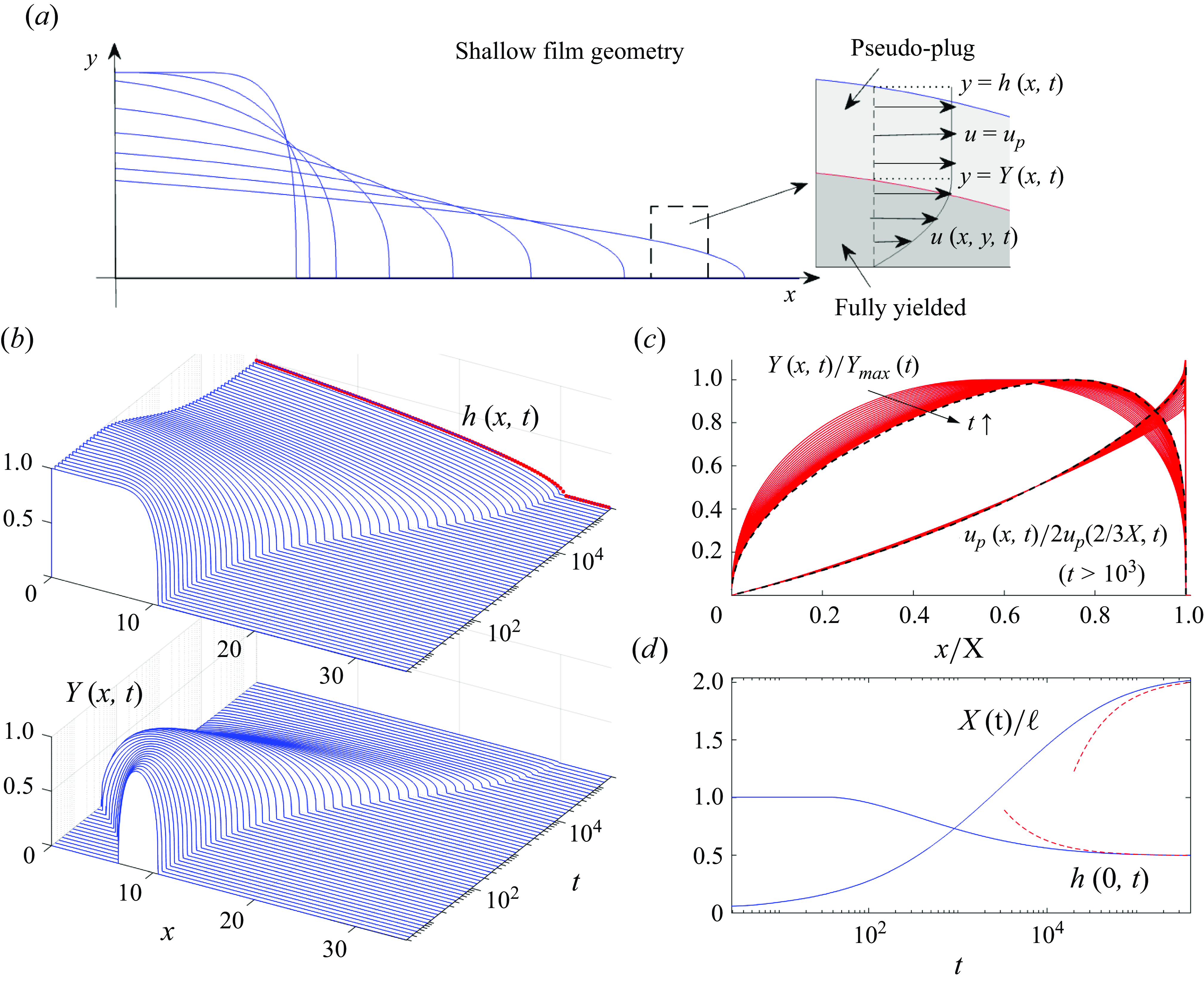

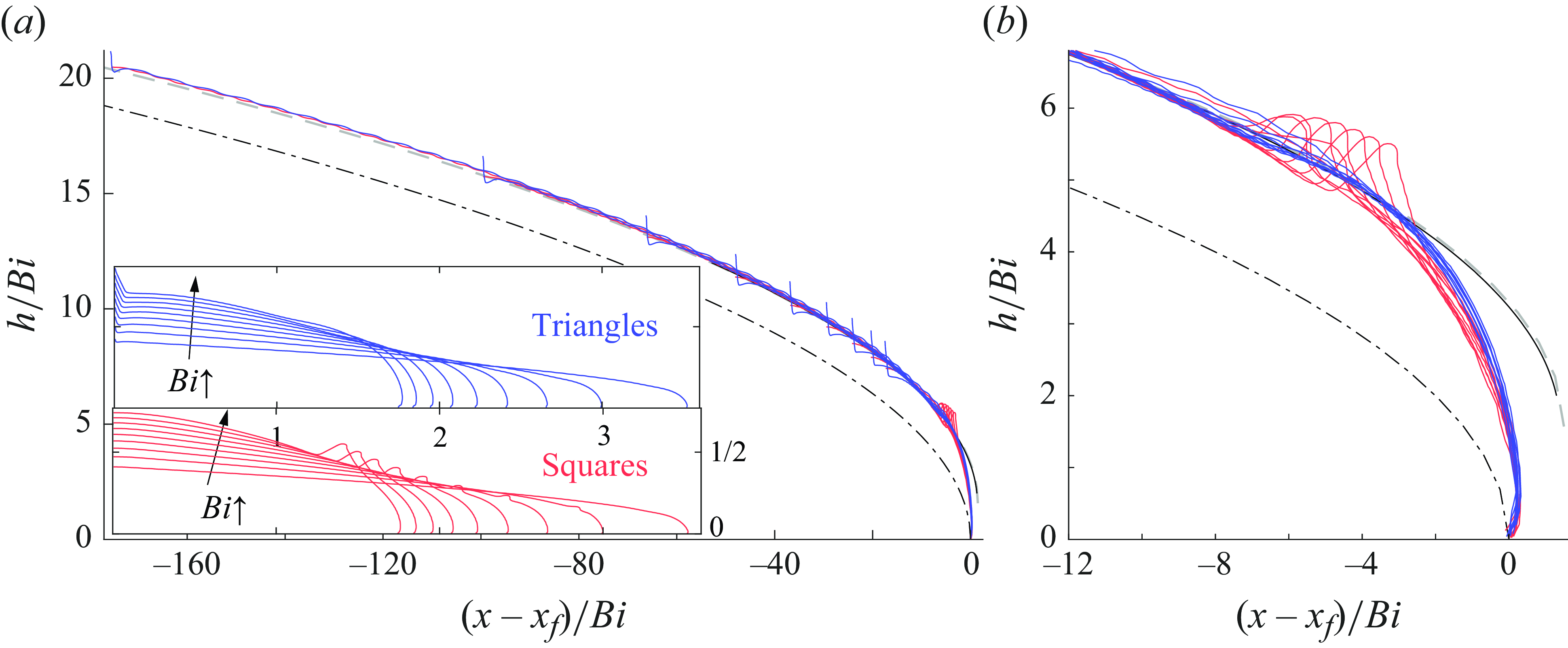

The sliplines form a net that spans all the yielded regions (two examples are shown in figure 2). A number of properties of the network follow from (3.15). Two, in particular, are often quoted and termed ‘Hencky’s rules’; we describe these more thoroughly in Appendix B.1. One important consequence of them is that when a slipline of one family (i.e.

![]() $\alpha$

or

$\alpha$

or

![]() $\beta$

) is straight, then all the other lines of the same family must also be straight if sliplines from the other slipline family connect them together. This relatively strong geometrical constraint impacts the structure of the yielded regions and provides a pathway to solving the slipline equations analytically in some problems. In particular, it implies that when one slipline is straight, the acceptable slipline fields include square checkerboards and centred circular fans, as illustrated in figure 2(b), or a set of involutes to a curve such as a circle (as we encounter later).

$\beta$

) is straight, then all the other lines of the same family must also be straight if sliplines from the other slipline family connect them together. This relatively strong geometrical constraint impacts the structure of the yielded regions and provides a pathway to solving the slipline equations analytically in some problems. In particular, it implies that when one slipline is straight, the acceptable slipline fields include square checkerboards and centred circular fans, as illustrated in figure 2(b), or a set of involutes to a curve such as a circle (as we encounter later).

In general, however, the utility of sliplines is limited because rigid plugs can be present, over which (3.13) no longer holds, and any slipline can be taken to be a yield surface bounding these plugs (Hill (Reference Hill1950); Prager & Hodge (Reference Prager and Hodge1951); see also figure 2). Worse, discontinuities can also appear in the stress field. The sliplines do not remain continuous across these features, implying scars can disfigure the slipline pattern. The (total) normal and shear stresses remain continuous across any such discontinuity, but there can be a jump in the tangential normal stress (i.e.

![]() ${\sigma _{_{\textit{SS}}}}={\tau _{_{\textit{SS}}}}-p$

, if the curvilinear coordinate system is aligned with the discontinuity). These conditions translate to the requirement that the sliplines meet the discontinuity at equal angles.

${\sigma _{_{\textit{SS}}}}={\tau _{_{\textit{SS}}}}-p$

, if the curvilinear coordinate system is aligned with the discontinuity). These conditions translate to the requirement that the sliplines meet the discontinuity at equal angles.

Figure 2. Illustrations of the slipline field, and Prandtl’s (a) cycloid and (b) punch solutions. The shaded regions indicate plugs. In (b), the dotted lines show sample streamlines.

Complicating matters further is that, in many problems, boundary conditions are provided on the velocity, not the stress. One cannot then construct the slipline field without a consideration of the velocity field. The components of the velocity field along the sliplines,

![]() $(v_\alpha, v_\beta )$

, satisfy the so-called Geiringer equations

$(v_\alpha, v_\beta )$

, satisfy the so-called Geiringer equations

which follow from the constraint of incompressibility (3.1). These equations imply that the plastic flow lines (i.e. the characteristics of the velocity field) coincide with the sliplines. Therefore, if the velocity field is directed along one set of sliplines, these curves also correspond to streamlines and the velocity along them remains fixed. Again, a complication is that the ideal plastic velocity field need not remain continuous. In fact, as implied by the name, a slipline can be taken as the locus of a jump in tangential velocity. In other words, velocity discontinuities can be present, but they are aligned with sliplines. Figure 2(b) also plots a selection of streamlines, corresponding to the slipline field shown. Here, fluid enters the domain at an angle to the

![]() $45^\circ$

checkerboard of sliplines. Once fluid reaches the fan, however, slip occurs, allowing the velocity to re-align with the circular arcs of the fan. Thereafter, one of the slipline families corresponds to streamlines.

$45^\circ$

checkerboard of sliplines. Once fluid reaches the fan, however, slip occurs, allowing the velocity to re-align with the circular arcs of the fan. Thereafter, one of the slipline families corresponds to streamlines.

Although the slipline field can be used to directly construct a range of perfectly plastic solutions, the difficulties implicit in the construction can make such an approach unwieldy and it is often not possible to proceed analytically. While techniques have been developed to ease numerical constructions of the slipline field (Collins Reference Collins1982), our perspective here is different. With the advent of augmented Lagrangian numerical techniques, one can solve two-dimensional problems of viscoplastic steady flow with relative ease, even close to the plastic limit. This circumvents any need to construct numerical slipline fields directly. Instead, with a numerical viscoplastic solution in hand, the slipline analysis provides a convenient tool to diagnose the solution structure, pointing to the existence of any analytical special cases and providing a means to verify the fidelity of computations. We illustrate these ideas later, using some specific flow configurations.

3.4.2. Exact solutions and constructions

Two classical exact solutions to the slipline problem date back to Prandtl and are illustrated in figure 2. The solution illustrated in figure 2(b) consists of a patchwork of circular fans and triangular checkerboards. The rightmost sliplines (a

![]() $\beta $

-line for the bottom half, and an

$\beta $

-line for the bottom half, and an

![]() $\alpha $

-line for the top) provide a yield surface. This construction was offered by Prandtl as a slipline solution for plastic indentation, following along the lines of traditional developments for the indentation of a punch in linear elasticity. Prandtl’s solution (rotated by ninety degrees) is commonly used in soil mechanics for the failure of a foundation above a cohesive soil.

$\alpha $

-line for the top) provide a yield surface. This construction was offered by Prandtl as a slipline solution for plastic indentation, following along the lines of traditional developments for the indentation of a punch in linear elasticity. Prandtl’s solution (rotated by ninety degrees) is commonly used in soil mechanics for the failure of a foundation above a cohesive soil.

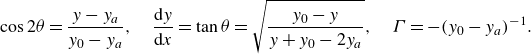

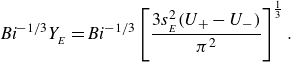

A second solution offered by Prandtl applies to the compression of a plastic layer, or a squeeze flow. In this case the sliplines are cycloids: if

![]() $\theta =\theta (y)$

and

$\theta =\theta (y)$

and

![]() $p=\textit{Bi}[ -\Gamma x + \Phi (y)]$

, then the force-balance equations reduce to

$p=\textit{Bi}[ -\Gamma x + \Phi (y)]$

, then the force-balance equations reduce to

If

![]() $\theta =0$

at

$\theta =0$

at

![]() $y=y_0$

and

$y=y_0$

and

![]() $\theta = (1/4)\pi$

at

$\theta = (1/4)\pi$

at

![]() $y=y_a$

, then the

$y=y_a$

, then the

![]() $\alpha $

-lines follow from

$\alpha $

-lines follow from

\begin{equation} \cos 2\theta = \frac {y-y_a}{y_0-y_a}, \quad \frac {\textrm {d} y}{\textrm {d} x} = \tan \theta = \sqrt {\frac {y_0-y}{y+y_0-2y_a}}, \quad \Gamma = -(y_0-y_a)^{-1}. \end{equation}

\begin{equation} \cos 2\theta = \frac {y-y_a}{y_0-y_a}, \quad \frac {\textrm {d} y}{\textrm {d} x} = \tan \theta = \sqrt {\frac {y_0-y}{y+y_0-2y_a}}, \quad \Gamma = -(y_0-y_a)^{-1}. \end{equation}

Hence

if

![]() $x=x_0$

for

$x=x_0$

for

![]() $y=y_a$

, which is the equation for a cycloid. Note that this curve is scale free, in the sense that any scaling of

$y=y_a$

, which is the equation for a cycloid. Note that this curve is scale free, in the sense that any scaling of

![]() $y$

and

$y$

and

![]() $x$

leaves the equation unchanged (as long as

$x$

leaves the equation unchanged (as long as

![]() $\Gamma$

can be scaled suitably too). The resulting slipline field is actually what is illustrated in figure 2(a).

$\Gamma$

can be scaled suitably too). The resulting slipline field is actually what is illustrated in figure 2(a).

Note that Prandtl’s two solutions illustrate an important feature of the plasticity problem: the squeezing walls generating the cycloid solutions in figure 2(a) are assumed to be ‘fully rough’, a condition demands that the fluid slides along the wall with a local shear stress that equals the yield stress. For a viscoplastic fluid, such slip prompts the appearance of a thin wall boundary layer over which the tangential velocity is brought back to zero. In other words, fully rough boundary conditions on the walls translate to no slip, and the slipline angle is either

![]() $\theta =0$

or

$\theta =0$

or

![]() $\theta =(1/2)\pi$

. Conversely, the surface on the left in figure 2(b) is free, implying that the shear stress must vanish, and

$\theta =(1/2)\pi$

. Conversely, the surface on the left in figure 2(b) is free, implying that the shear stress must vanish, and

![]() $\theta =\pm (1/4)\pi$

. Such a condition on the slipline angle also applies along lines of symmetry, such as the midline between the squeezing plates in figure 2(b). The

$\theta =\pm (1/4)\pi$

. Such a condition on the slipline angle also applies along lines of symmetry, such as the midline between the squeezing plates in figure 2(b). The

![]() $y$

-axis can further be taken as another line of symmetry at the centre of the squeeze flow, if the shaded region is assumed to plug up with yield surfaces along the bordering sliplines. The correspondence between no-slip or free-slip boundary conditions and the fixing of the slipline angle recurs in the examples we present below.

$y$

-axis can further be taken as another line of symmetry at the centre of the squeeze flow, if the shaded region is assumed to plug up with yield surfaces along the bordering sliplines. The correspondence between no-slip or free-slip boundary conditions and the fixing of the slipline angle recurs in the examples we present below.

More generally, the slipline equations (when expressed in terms of the two local radii of curvature, or some other geometrical variables; Appendix B.1) and Geiringer’s equations reduce to the telegraph equation under a change of independent variables (from arc length to an angle parameterisation; Hill (Reference Hill1950)). Classical solutions to that problem then allow one to write down exact solutions to the plasticity problem in terms of single integrals if information is provided along a known slipline. Even if such information is not provided, one can still use this solution as the basis of a numerical scheme (Dewhurst & Collins Reference Dewhurst and Collins1973; Collins Reference Collins1982). This strategy significantly expanded the library of slipline solutions available in the plasticity literature (e.g. Collins (Reference Collins1970, Reference Collins1982)), a resource that largely remains untapped in analyses of viscoplastic fluid flows near the plastic limit. In fact, this technique leads to semi-analytical solutions, one of which is closely related to the slipline problem discussed in § 4 (Hill Reference Hill1950; Chakrabarty Reference Chakrabarty1979). Other exact solutions or constructions follow from searching for self-similar solutions (e.g. Taylor-West & Hogg (Reference Taylor-West and Hogg2021, Reference Taylor-West and Hogg2023)).

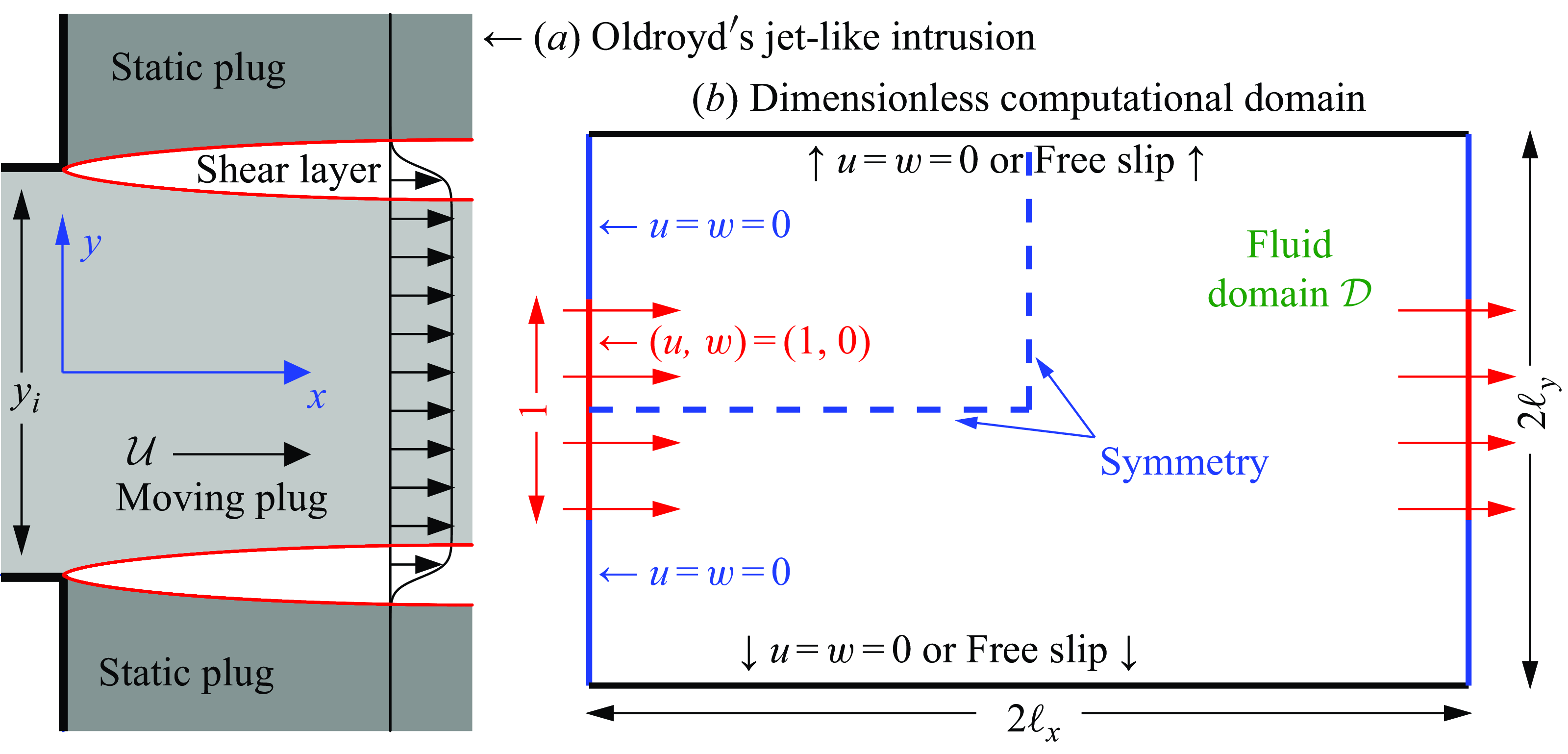

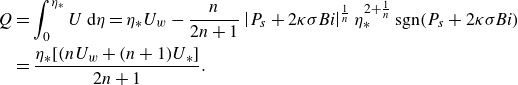

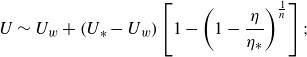

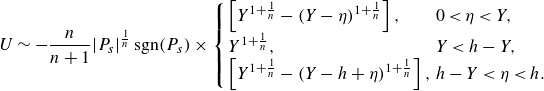

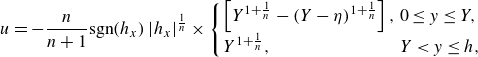

4. Jet-like intrusion

To illustrate viscoplastic flow dynamics near the plastic limit, we consider three model problems for a Bingham fluid (

![]() $n=1$

). The first, sketched in figure 3, corresponds to a modification of a problem suggested by Oldroyd (Reference Oldroyd1947b

) in which a jet-like intrusion of viscoplastic fluid flows through a rectangular channel. The fluid enters with fixed speed

$n=1$

). The first, sketched in figure 3, corresponds to a modification of a problem suggested by Oldroyd (Reference Oldroyd1947b

) in which a jet-like intrusion of viscoplastic fluid flows through a rectangular channel. The fluid enters with fixed speed

![]() $U$

over an orifice on the left wall of width

$U$

over an orifice on the left wall of width

![]() $y_i$

, then leaves through a similar exit on the right wall. We take

$y_i$

, then leaves through a similar exit on the right wall. We take

![]() $\mathcal{L}=y_i$

as the characteristic length scale, and impose symmetry conditions along the midlines of the rectangle, at

$\mathcal{L}=y_i$

as the characteristic length scale, and impose symmetry conditions along the midlines of the rectangle, at

![]() $x=\ell _x$

and

$x=\ell _x$

and

![]() $y=0$

, reducing our computational domain to the upper left quadrant. We consider two possible boundary conditions for the walls at

$y=0$

, reducing our computational domain to the upper left quadrant. We consider two possible boundary conditions for the walls at

![]() $y=\pm \ell _y$

: no slip conditions and free slip conditions. Adopting no slip simulates flow through a localised expansion. Such flows have previously been used as model problems for viscoplastic computations (Mitsoulis & Tsamopoulos Reference Mitsoulis and Tsamopoulos2017) and experiments (Coussot Reference Coussot2014), and have received attention in the classical plasticity literature (Hill Reference Hill1950). Alternatively, with free-slip conditions, we simulate an array of vertically stacked, periodic injections. It proves useful to consider both no slip and free slip at

$y=\pm \ell _y$

: no slip conditions and free slip conditions. Adopting no slip simulates flow through a localised expansion. Such flows have previously been used as model problems for viscoplastic computations (Mitsoulis & Tsamopoulos Reference Mitsoulis and Tsamopoulos2017) and experiments (Coussot Reference Coussot2014), and have received attention in the classical plasticity literature (Hill Reference Hill1950). Alternatively, with free-slip conditions, we simulate an array of vertically stacked, periodic injections. It proves useful to consider both no slip and free slip at

![]() $y=\pm \ell _y$

in order to illustrate some important repercussions of placing a plug against a wall.

$y=\pm \ell _y$

in order to illustrate some important repercussions of placing a plug against a wall.

Figure 3. Sketch of a jet-like intrusion through a rectangular domain. The characteristic scales

![]() $\mathcal{L}$

and

$\mathcal{L}$

and

![]() $\mathcal{U}$

are taken to be the inflow speed

$\mathcal{U}$

are taken to be the inflow speed

![]() $U$

and the inlet width

$U$

and the inlet width

![]() $y_i$

. Practically, the symmetries about

$y_i$

. Practically, the symmetries about

![]() $y=0$

and

$y=0$

and

![]() $x=\ell_x$

are used to consider only a quarter of the domain.

$x=\ell_x$

are used to consider only a quarter of the domain.

4.1. Narrow domains; breaking the incoming plug

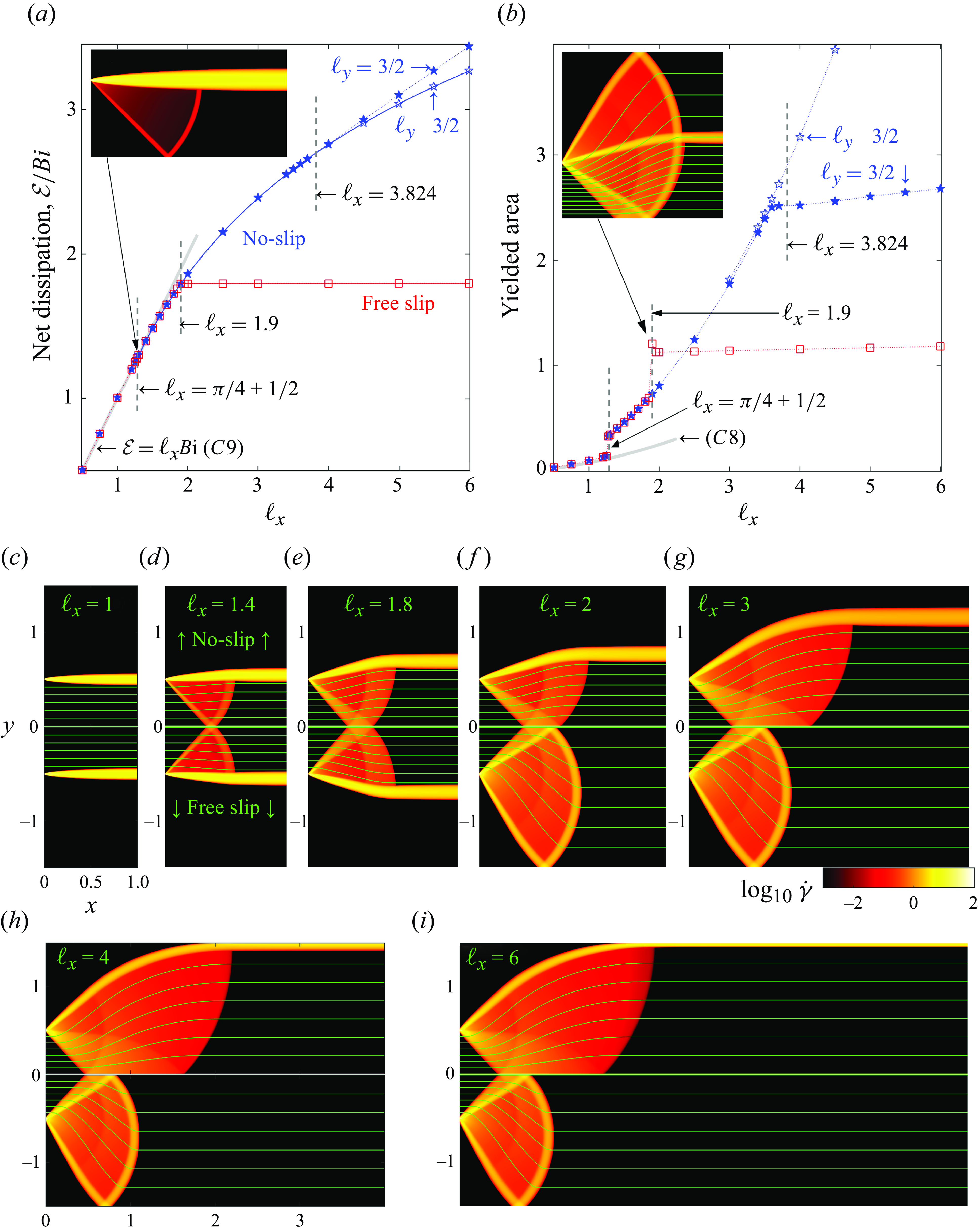

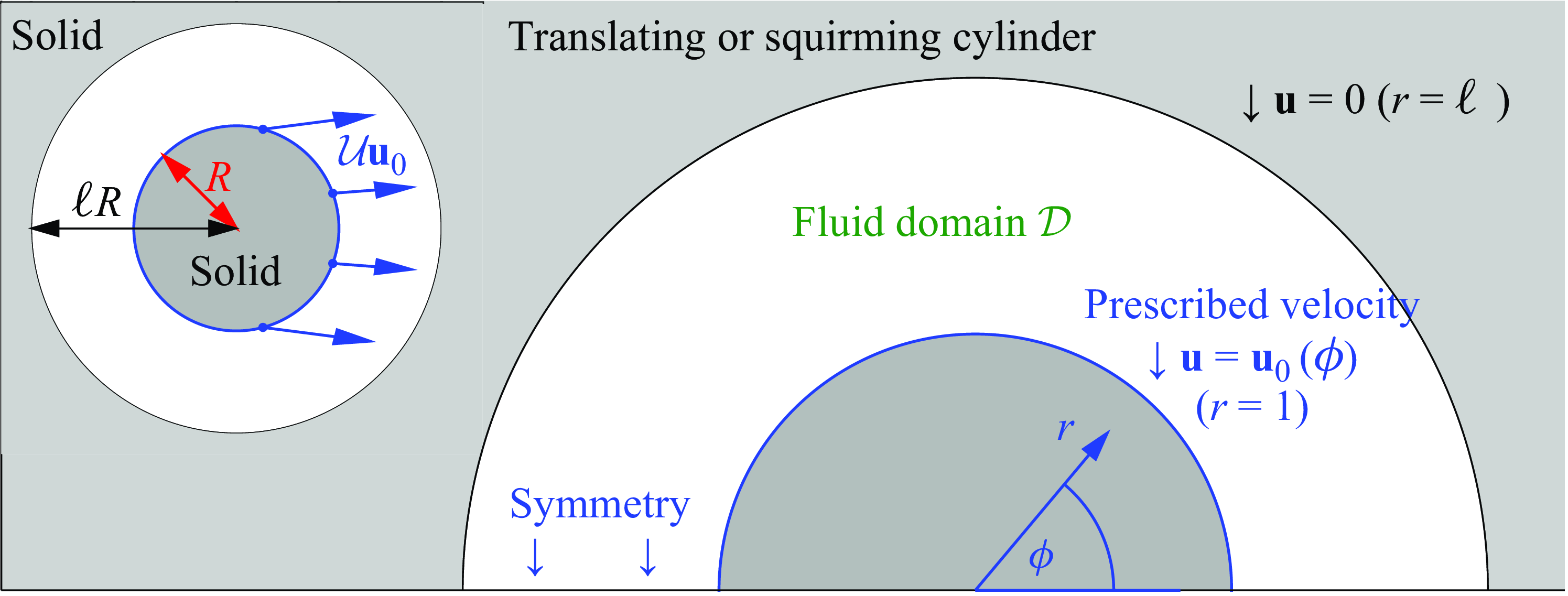

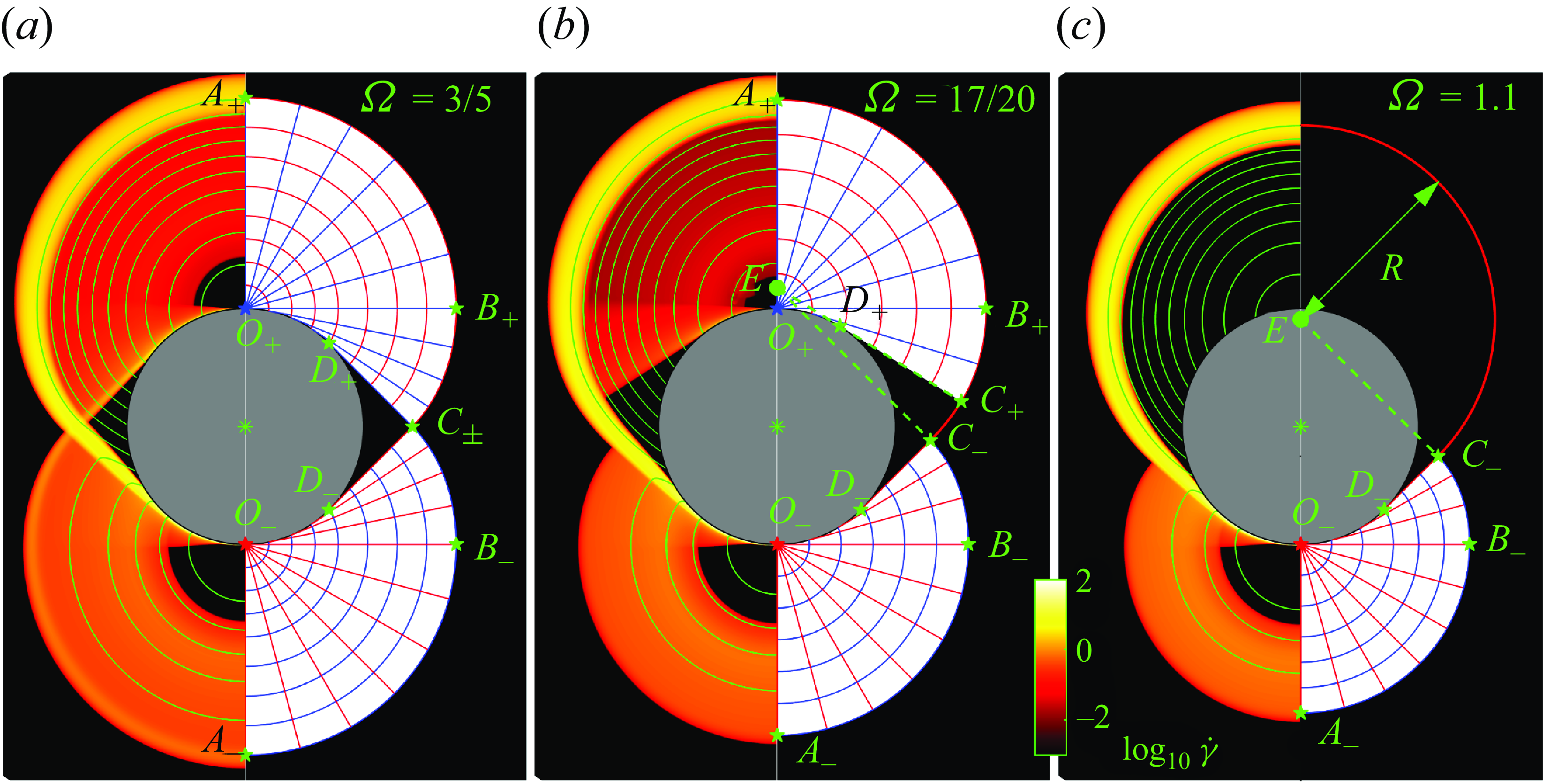

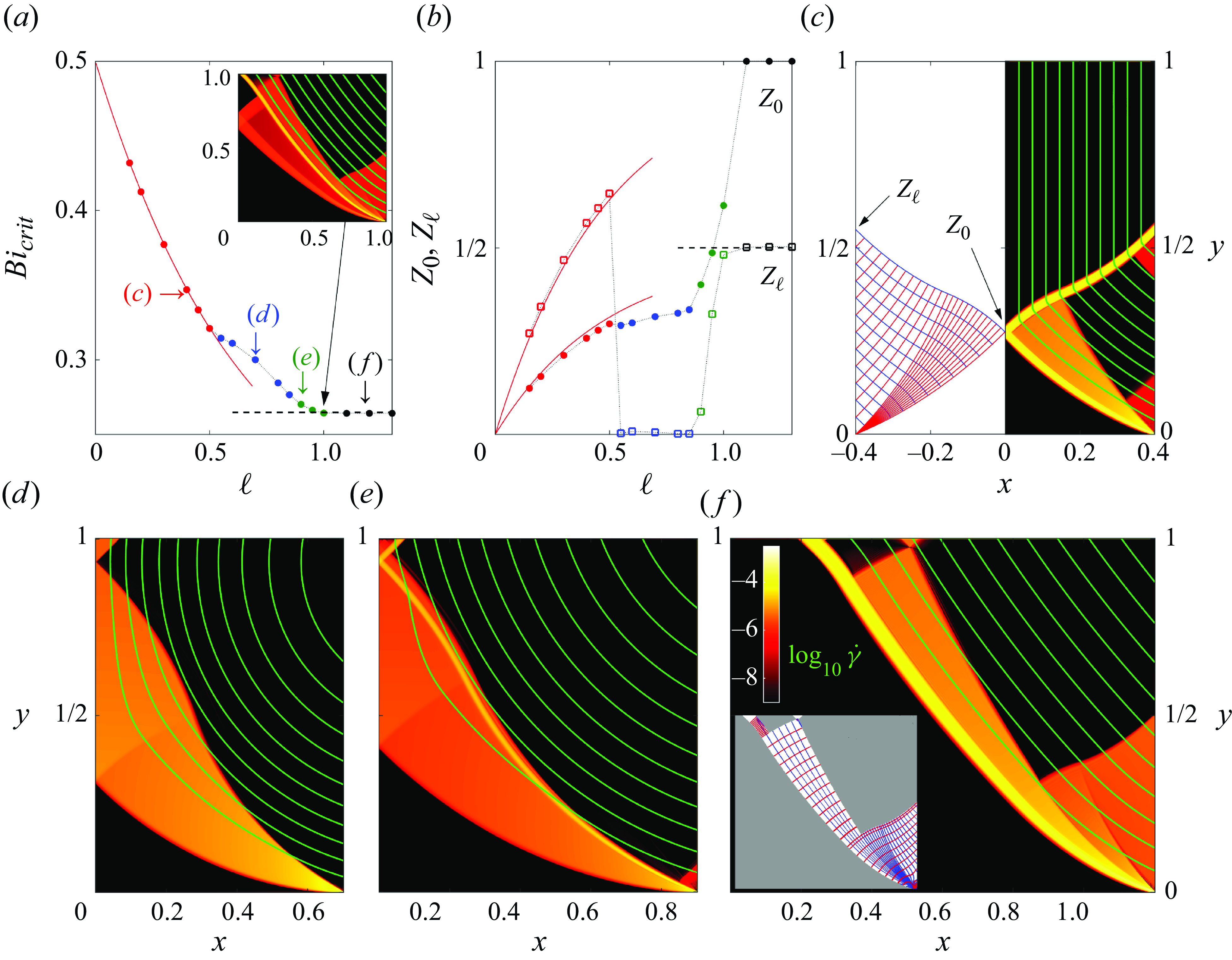

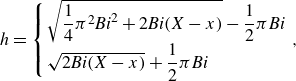

A suite of numerical solutions for the jet problem are displayed in figure 4. Here, the Bingham number is fixed close to the plastic limit (

![]() $\textit{Bi}=2048$

), the cross-stream height is set at

$\textit{Bi}=2048$

), the cross-stream height is set at

![]() $\ell _y= 3/2$

and the downstream length

$\ell _y= 3/2$

and the downstream length

![]() $\ell _x$

is varied. For small domain lengths

$\ell _x$

is varied. For small domain lengths

![]() $\ell _x$

, flow enters and exits the domain as a moving plug of almost uniform width bordered by two thin shear layers (figure 4

c). This localisation of fluid deformation by the yield stress, and the creation of extensive blockages, is rather different from traditional Stokes flow, for which fluid deforms throughout the domain (and is equivalent to the localisation of viscoplastic flow around the disk in figure 1). The shear layers have a structure that can be predicted by Oldroyd’s boundary-layer theory (see figure 5

a,c), as outlined in § C.1.1. That analysis indicates that the net dissipation

$\ell _x$

, flow enters and exits the domain as a moving plug of almost uniform width bordered by two thin shear layers (figure 4

c). This localisation of fluid deformation by the yield stress, and the creation of extensive blockages, is rather different from traditional Stokes flow, for which fluid deforms throughout the domain (and is equivalent to the localisation of viscoplastic flow around the disk in figure 1). The shear layers have a structure that can be predicted by Oldroyd’s boundary-layer theory (see figure 5

a,c), as outlined in § C.1.1. That analysis indicates that the net dissipation

![]() $\mathcal{E}$

over the upper half of the domain is approximately

$\mathcal{E}$

over the upper half of the domain is approximately

![]() $\ell _x\textit{Bi}$

(cf. (C9)) and the area of the corresponding yielded region is given by (C8); both diagnostics are plotted in figure 4(a,b) for the full series of computations.

$\ell _x\textit{Bi}$

(cf. (C9)) and the area of the corresponding yielded region is given by (C8); both diagnostics are plotted in figure 4(a,b) for the full series of computations.

Figure 4. Viscoplastic jets for

![]() $(\textit{Bi},\ell _y)=(2048, {3}/{2})$

and varying

$(\textit{Bi},\ell _y)=(2048, {3}/{2})$

and varying

![]() $\ell _x$

. (a) Net dissipation rate and (b) area of the yielded regions for

$\ell _x$

. (a) Net dissipation rate and (b) area of the yielded regions for

![]() $y\gt 0$

, plotted against

$y\gt 0$

, plotted against

![]() $\ell _x$

. (c)–(i) Density maps of

$\ell _x$

. (c)–(i) Density maps of

![]() $\log _{10}{\dot \gamma }$

on the

$\log _{10}{\dot \gamma }$

on the

![]() $(x,y)$

-plane for the values of

$(x,y)$

-plane for the values of

![]() $\ell _x$

indicated. For each

$\ell _x$

indicated. For each

![]() $\ell _x$

, two solutions are shown: for the upper (filled blue stars in (a,b)), no-slip conditions are applied at

$\ell _x$

, two solutions are shown: for the upper (filled blue stars in (a,b)), no-slip conditions are applied at

![]() $y=\pm \ell _y$

; for the lower (open red squares in (a,b)), free-slip conditions are used instead. The insets in (a,b) show transitional, free-slip solutions at

$y=\pm \ell _y$

; for the lower (open red squares in (a,b)), free-slip conditions are used instead. The insets in (a,b) show transitional, free-slip solutions at

![]() $\ell _x=1.275$

and

$\ell _x=1.275$

and

![]() $\ell _x=1.9$

. Open (blue) stars in (a)–(b) represent solutions with

$\ell _x=1.9$

. Open (blue) stars in (a)–(b) represent solutions with

![]() $\ell _y\gg 3/2$

, for which the yielded regions do not touch the top and bottom boundaries. The grey lines in (a,b) show the predictions in (C8)–(C9). The solid blue and red lines in (a) show predictions for

$\ell _y\gg 3/2$

, for which the yielded regions do not touch the top and bottom boundaries. The grey lines in (a,b) show the predictions in (C8)–(C9). The solid blue and red lines in (a) show predictions for

![]() $\mathcal{E}$

based on the slipline fields in figure 6(a). The vertical dashed lines at

$\mathcal{E}$

based on the slipline fields in figure 6(a). The vertical dashed lines at

![]() $\ell _x=({\pi }/{4})+(1/2)$

and

$\ell _x=({\pi }/{4})+(1/2)$

and

![]() $\ell _x\approx 1.9$

indicate the flow pattern transitions arising when one of the plugs breaks; that at

$\ell _x\approx 1.9$

indicate the flow pattern transitions arising when one of the plugs breaks; that at

![]() $\ell _x=3.824$

indicates where the slipline solution predicts that the yielded region collides with the walls at

$\ell _x=3.824$

indicates where the slipline solution predicts that the yielded region collides with the walls at

![]() $y=\pm \ell _y$

.

$y=\pm \ell _y$

.

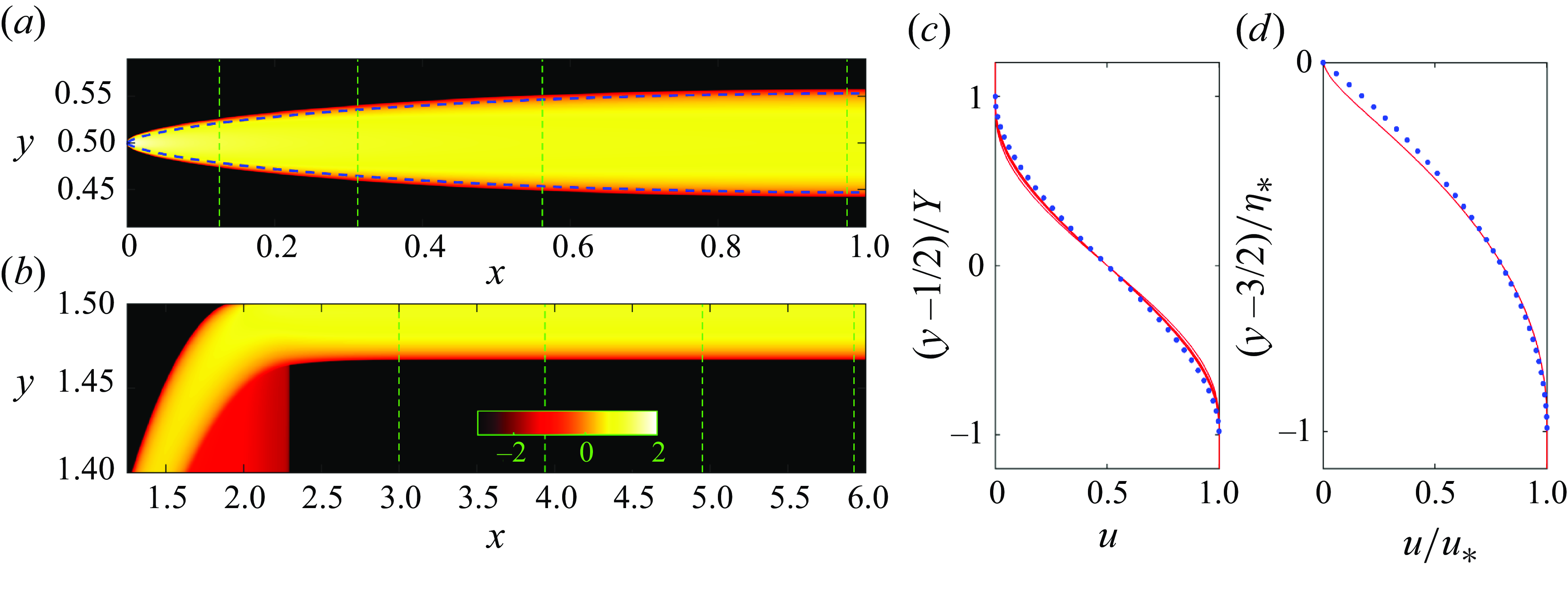

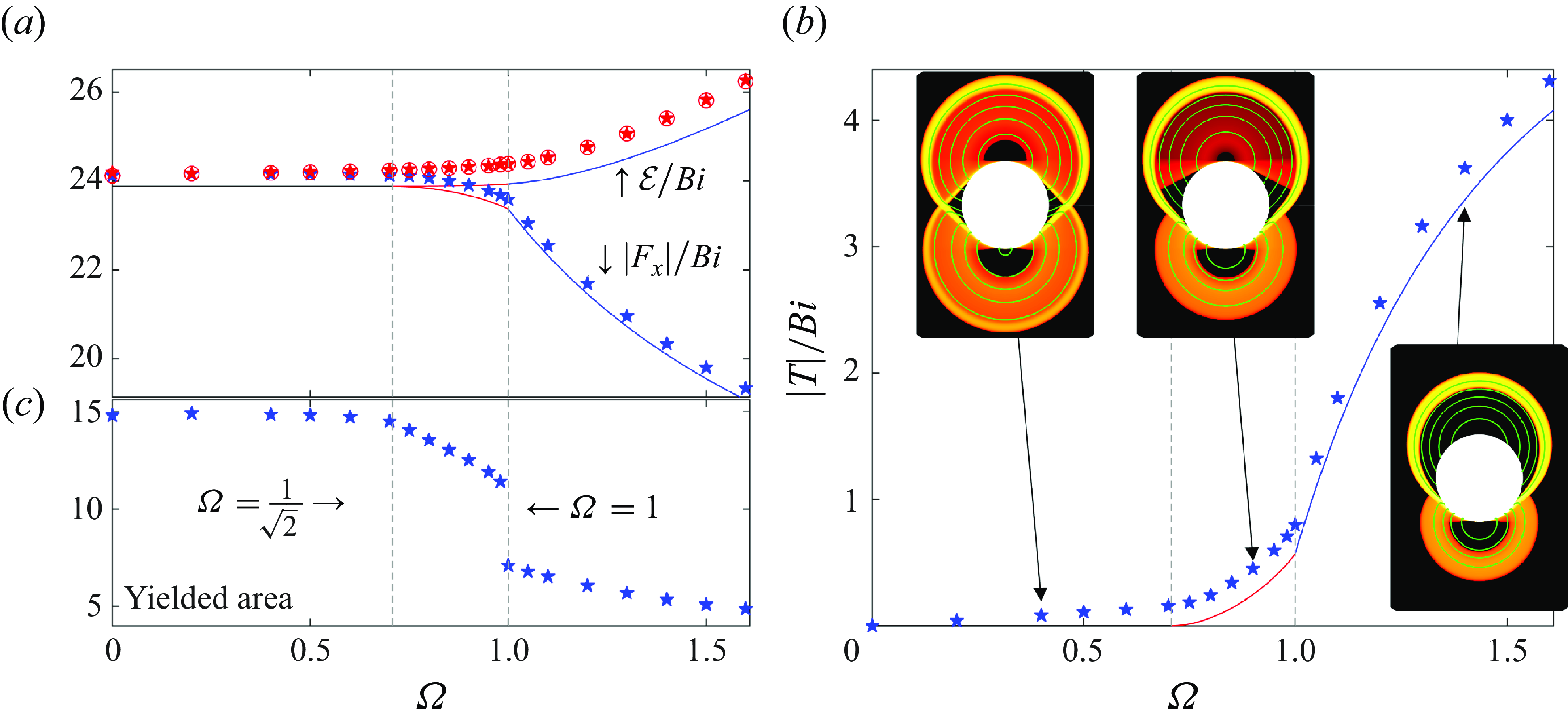

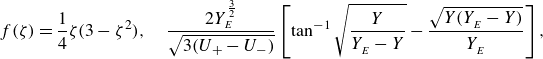

Figure 5. (a,c) The viscoplastic shear layer for

![]() $\ell _x=1$

(cf. figure 4

c), and (b,d) the wall boundary layer for

$\ell _x=1$

(cf. figure 4

c), and (b,d) the wall boundary layer for

![]() $\ell _x=6$

(cf. figure 4

i). The vertical dashed lines in (a,b) show the cuts at which the horizontal velocity profiles of (b,d) are drawn. The dashed curves in (a) shows the yield surfaces predicted by shear-layer theory (§ C.1.1). In (c), the velocity profiles (shown by red lines) are collapsed by shifting each by

$\ell _x=6$

(cf. figure 4

i). The vertical dashed lines in (a,b) show the cuts at which the horizontal velocity profiles of (b,d) are drawn. The dashed curves in (a) shows the yield surfaces predicted by shear-layer theory (§ C.1.1). In (c), the velocity profiles (shown by red lines) are collapsed by shifting each by

![]() $(1/2)$

, then plotting them against

$(1/2)$

, then plotting them against

![]() $\zeta =(y-(1/2))/Y$

, where

$\zeta =(y-(1/2))/Y$

, where

![]() $Y$

is the local half-width of the shear layer. In (d), the profiles are collapsed by scaling

$Y$

is the local half-width of the shear layer. In (d), the profiles are collapsed by scaling

![]() $u$

by the plug speed

$u$

by the plug speed

![]() $u_*$

, and then plotting the curves against

$u_*$

, and then plotting the curves against

![]() $\zeta =(y- (3/2)/\eta _*$

, where

$\zeta =(y- (3/2)/\eta _*$

, where

![]() $\eta _*$

is the local boundary-layer thickness. The blue dots in (c,d) show the predictions

$\eta _*$

is the local boundary-layer thickness. The blue dots in (c,d) show the predictions

![]() $(1/2)-(1/4)\zeta (3-\zeta ^2)$

(§§ C.1.1) and

$(1/2)-(1/4)\zeta (3-\zeta ^2)$

(§§ C.1.1) and

![]() $(2+\zeta )\zeta$

(C.1.2).

$(2+\zeta )\zeta$

(C.1.2).

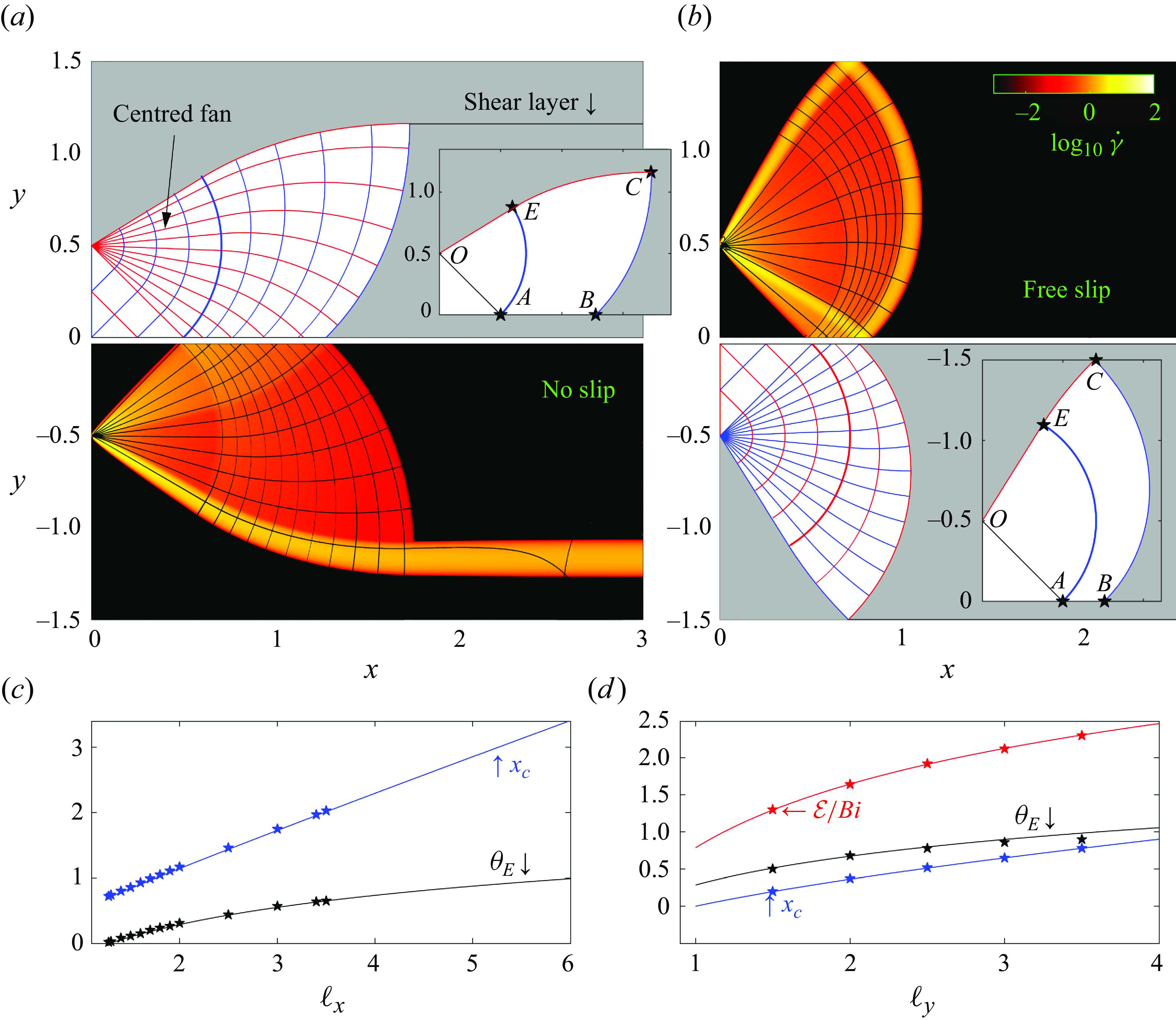

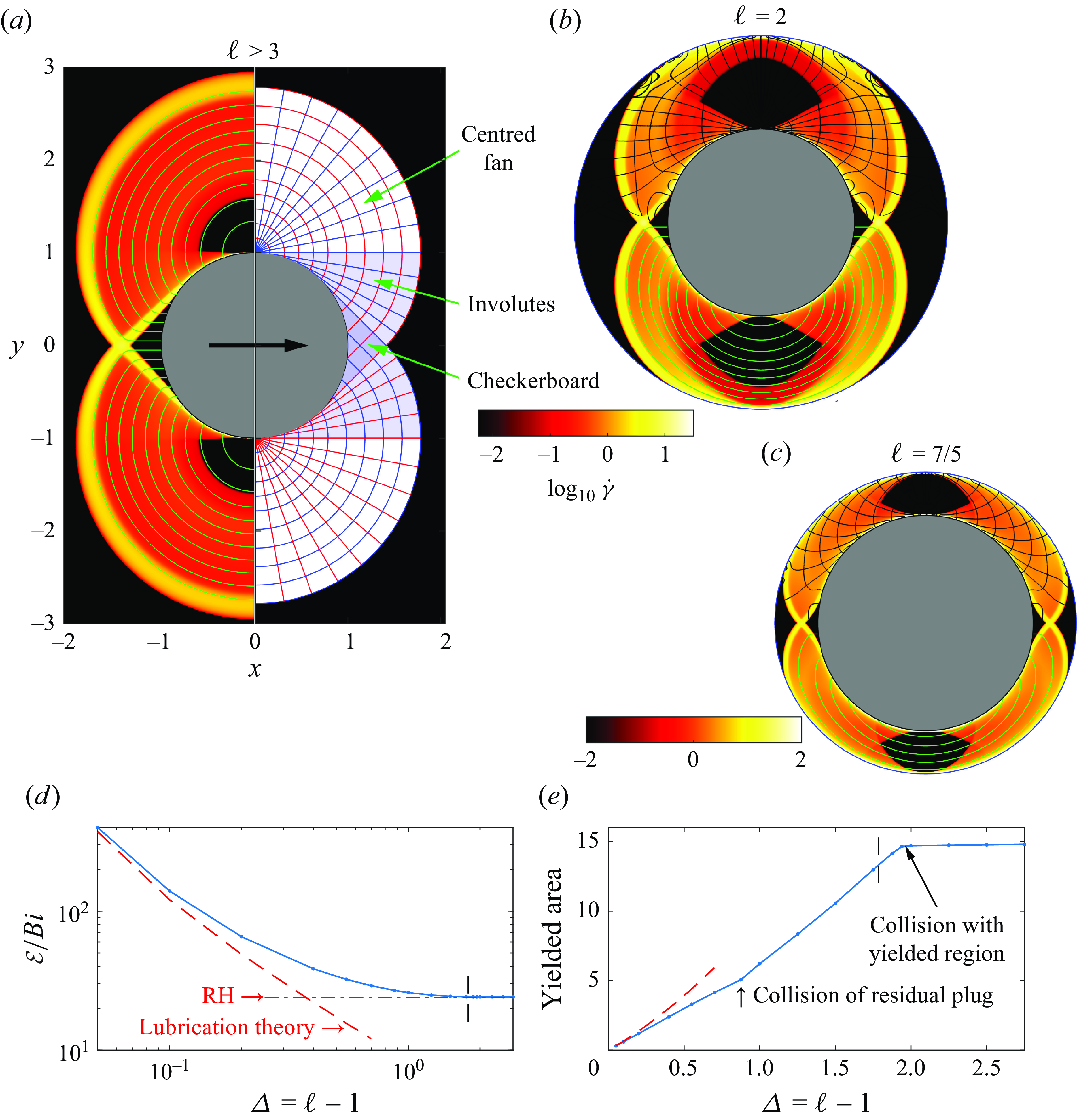

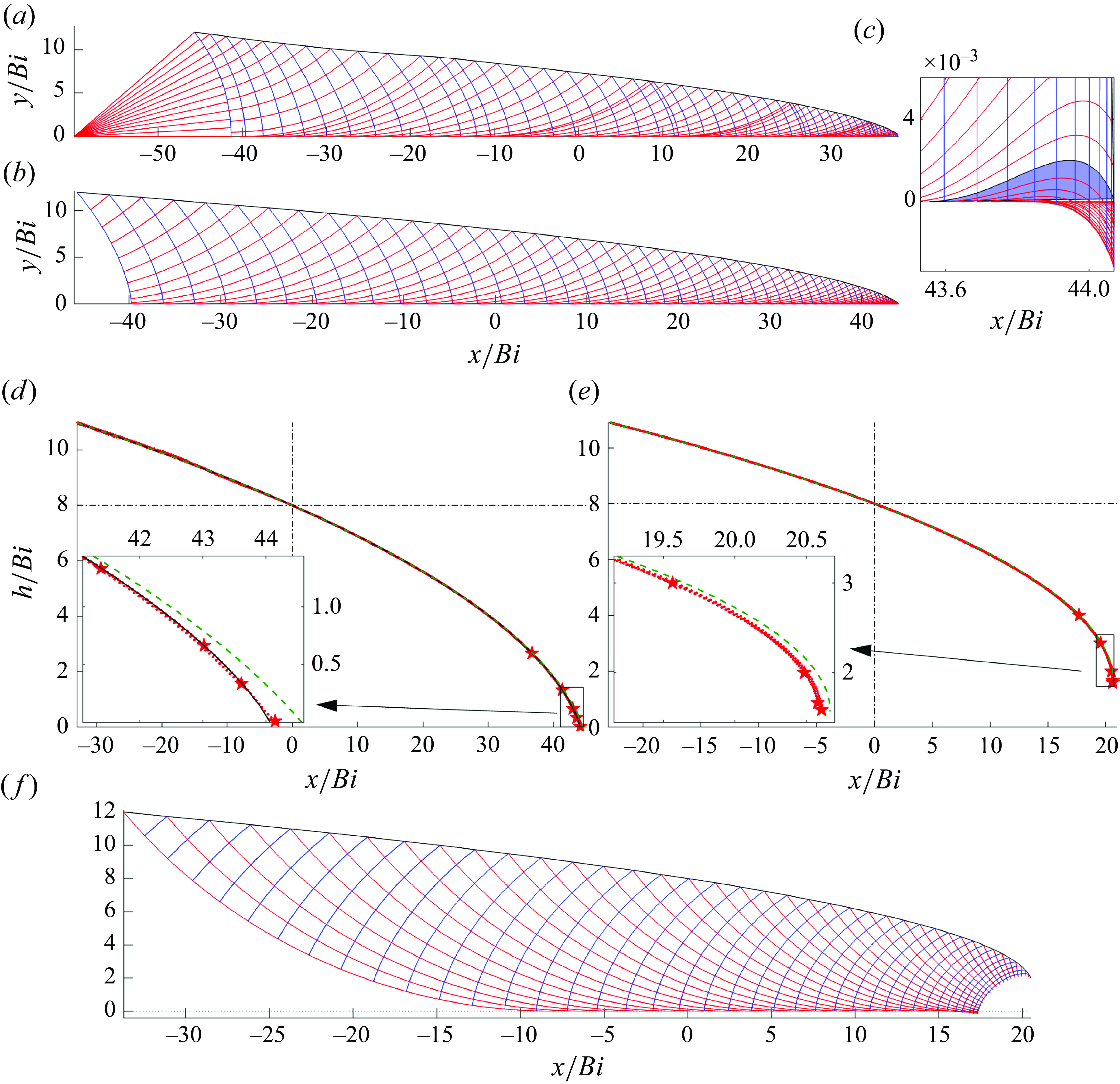

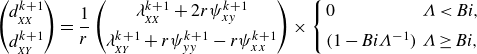

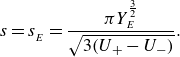

Figure 6. The two slipline fields for

![]() $\ell _x=3$

(cf. figure 4

g) for the (b) no-slip and (c) free-slip cases. Additional diagnostics are plotted in (c,d). In (a,b), half of the domain shows the numerical solution for

$\ell _x=3$

(cf. figure 4

g) for the (b) no-slip and (c) free-slip cases. Additional diagnostics are plotted in (c,d). In (a,b), half of the domain shows the numerical solution for

![]() $\log _{10}{\dot \gamma }$

along with reconstructions of the curves of constant

$\log _{10}{\dot \gamma }$

along with reconstructions of the curves of constant

![]() $p\pm 2\textit{Bi}\theta$

, and the insets display the geometry of the yielded regions and some special points of the slipline construction. For (c), we plot the

$p\pm 2\textit{Bi}\theta$

, and the insets display the geometry of the yielded regions and some special points of the slipline construction. For (c), we plot the

![]() $x-$

position of point

$x-$

position of point

![]() $C$

(

$C$

(

![]() $x_{_C}$

) and the slipline angle

$x_{_C}$

) and the slipline angle

![]() $(\theta _{_E}$

) at point

$(\theta _{_E}$

) at point

![]() $E$

against

$E$

against

![]() $\ell _x$

for no-slip solutions with

$\ell _x$

for no-slip solutions with

![]() $\ell _y=3$

. In (d), the scaled dissipation rate

$\ell _y=3$

. In (d), the scaled dissipation rate

![]() $\mathcal{E}/\textit{Bi}$

,

$\mathcal{E}/\textit{Bi}$

,

![]() $\theta _{_E}$

and

$\theta _{_E}$

and

![]() $x_{_C}$

are plotted against

$x_{_C}$

are plotted against

![]() $\ell _y$

, for free-slip solutions with

$\ell _y$

, for free-slip solutions with

![]() $\ell _y=1.5$

. The stars in (c,d) display corresponding results from the numerical solutions (with

$\ell _y=1.5$

. The stars in (c,d) display corresponding results from the numerical solutions (with

![]() $x_{_C}$

measured from the right-hand border of the plastic region in (a), then from the centre of the shear layer at

$x_{_C}$

measured from the right-hand border of the plastic region in (a), then from the centre of the shear layer at

![]() $y=\ell _y$

in (b) and

$y=\ell _y$

in (b) and

![]() $\theta _{_E}$

from the centre of the upper shear layer at

$\theta _{_E}$

from the centre of the upper shear layer at

![]() $x=(1/4)$

).

$x=(1/4)$

).

As the domain becomes longer, the stresses exerted on the moving plug increase; eventually, this increase causes the plug to break. A region of almost perfectly plastic deformation then appears near the inlet that allows the jet to adjust its width (figure 4 d,e). This widening reduces the net dissipation rate below that expected for an unbroken plug (figure 4 a), and abruptly increases the area of yielded plug (figure 4 b). Evidently, the widening of the jet is sufficient to reduce the velocity jumps across the shear layers, and the net dissipation rate within them, despite the lengthening of those layers and the additional dissipation incurred over the plastic region.

As illustrated in figure 6(a,b), the perfectly plastic flow can be described by slipline theory: much as for Prandtl’s punch, two centred fans emerge from the edges of the inlet, with a triangular wedge between them. Indeed, the intrusion can be viewed as an indentation problem, with different boundary conditions applying on the left wall. The fans extend outwards and meet along the centreline of the jet; the slipline pattern then continues out to the right, with all the sliplines becoming curved due to the symmetry condition along

![]() $y=0$

(

$y=0$

(

![]() $|\theta |=({1}/{4})\pi$

). The plastic region terminates to the right along a final slipline that fronts the widened moving plug. Shear layers continue to buffer the jet from above and below. More details of the construction of the slipline field are given in Appendix B. Note that the checkerboard of sliplines filling the wedge at the inlet, in combination with the rigid-body inflow velocity, allows that region to solidify into another example of an serendipitous plug. A different example, in which the inflow is not rigid and the checkerboard remains fully plastic, is presented below in § 4.5.

$|\theta |=({1}/{4})\pi$

). The plastic region terminates to the right along a final slipline that fronts the widened moving plug. Shear layers continue to buffer the jet from above and below. More details of the construction of the slipline field are given in Appendix B. Note that the checkerboard of sliplines filling the wedge at the inlet, in combination with the rigid-body inflow velocity, allows that region to solidify into another example of an serendipitous plug. A different example, in which the inflow is not rigid and the checkerboard remains fully plastic, is presented below in § 4.5.

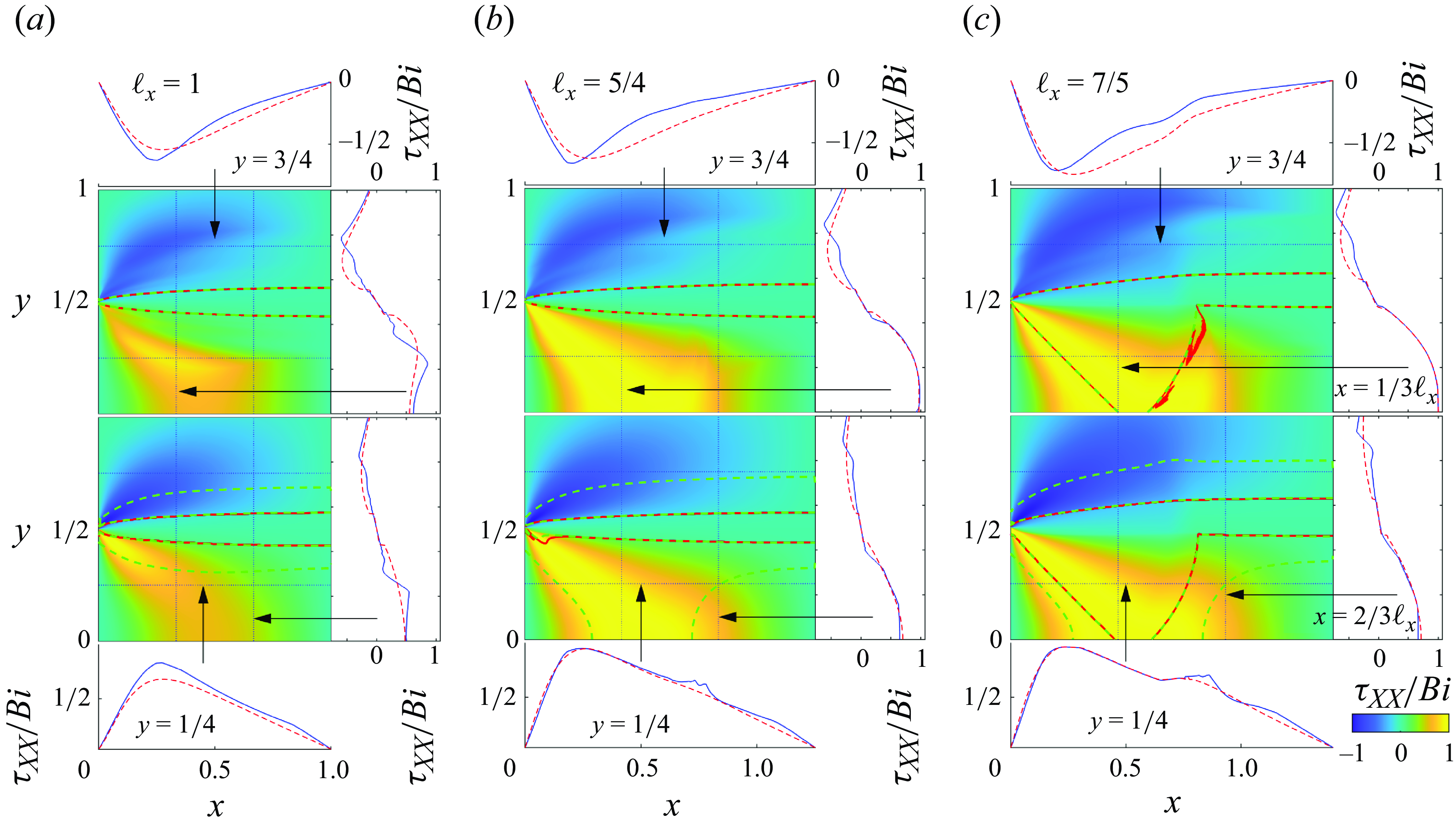

Figure 6(b,c) also illustrates the slipline field reconstructed directly from the numerical solutions, by plotting the curves of constant

![]() $p\pm \textit{Bi} \tan ^{-1}({\tau _{_{\textit{XX}}}}/{\tau _{_{\textit{XY}}}})$

(cf. equations (3.15)). This more practical strategy to determine the sliplines successfully confirms most of the details of the slipline field, but breaks down in the shear layers and plugs, and fails to trace all the sliplines in the fans. An example is which the reconstruction is even poorer will be encountered later in figure 10(b).

$p\pm \textit{Bi} \tan ^{-1}({\tau _{_{\textit{XX}}}}/{\tau _{_{\textit{XY}}}})$

(cf. equations (3.15)). This more practical strategy to determine the sliplines successfully confirms most of the details of the slipline field, but breaks down in the shear layers and plugs, and fails to trace all the sliplines in the fans. An example is which the reconstruction is even poorer will be encountered later in figure 10(b).

From the slipline solution, one can construct the force balance on the widened plug, which controls the size of the plastic region. Appendix B.2 summarises the details of this calculation, which provides predictions for a number of key characteristics of the flow pattern, as plotted in figures 4(a) and 6(b,c). For example, the net dissipation rate can be determined, either by a direct calculation using Geiringer’s equations (3.16), or by exploiting the power balance in (3.12) and calculating the power input along the borders of the slipline pattern.

The analysis of the slipline patterns also predicts the domain length at which the uninterrupted moving plug breaks: the critical value is

![]() $\ell _x\sim (1/4)\pi +(1/2)$

, as seen in figure 4(a,b). Because sudden jumps arise in the properties of the flow pattern at this transition (including the area of the yielded region), owing to the breakage of the plug, we refer to this type of bifurcation as ‘first order’, following the terminology of phase-transition theory. As we shall see below, continuous, or ‘second-order’ bifurcations are also possible, that do not involve the breakage of any plug. Note that the transition for the numerical solutions in figure 4 is slightly shifted and ‘blurred’: the finite Bingham number used for the computations adjusts the domain length at which the plug breaks and appears to lead to flow patterns with mixed character over a narrow window surrounding that transition (see the inset in figure 4

a). However, it is hard to tell whether this latter feature is genuine or an artefact of the numerical scheme, the solution having perhaps failed to properly converge (see Appendix A).

$\ell _x\sim (1/4)\pi +(1/2)$

, as seen in figure 4(a,b). Because sudden jumps arise in the properties of the flow pattern at this transition (including the area of the yielded region), owing to the breakage of the plug, we refer to this type of bifurcation as ‘first order’, following the terminology of phase-transition theory. As we shall see below, continuous, or ‘second-order’ bifurcations are also possible, that do not involve the breakage of any plug. Note that the transition for the numerical solutions in figure 4 is slightly shifted and ‘blurred’: the finite Bingham number used for the computations adjusts the domain length at which the plug breaks and appears to lead to flow patterns with mixed character over a narrow window surrounding that transition (see the inset in figure 4

a). However, it is hard to tell whether this latter feature is genuine or an artefact of the numerical scheme, the solution having perhaps failed to properly converge (see Appendix A).

In fact, there are actually two suites of computations shown in figure 4: one with no-slip walls at

![]() $y=\pm \ell _y$

, the other with free slip there. As long as

$y=\pm \ell _y$

, the other with free slip there. As long as

![]() $\ell _x$

remains less than about

$\ell _x$

remains less than about

![]() $1.9$

, the two sets of solutions are identical. In other words, two different problems have the same solution. This coincidence arises because of the cloaking effect of the plug that intervenes between the flowing region and the wall for

$1.9$

, the two sets of solutions are identical. In other words, two different problems have the same solution. This coincidence arises because of the cloaking effect of the plug that intervenes between the flowing region and the wall for

![]() $\ell _x \lesssim 1.9$

: if the wall lies inside a plug, that entire region is rigid and so the conditions applying upon the wall, and even its shape are irrelevant. This notion of cloaking dates back at least to Oldroyd (see Balmforth, Craster & Hewitt (Reference Balmforth, Craster and Hewitt2021)), and has been considered in detail for the motion of differently shaped particles encased in viscoplastic fluid (Chaparian & Frigaard Reference Chaparian and Frigaard2017a

,Reference Chaparian and Frigaard

b

). The difference between the two cases that emerges for longer domains arises because the plug breaks for free-slip walls at

$\ell _x \lesssim 1.9$

: if the wall lies inside a plug, that entire region is rigid and so the conditions applying upon the wall, and even its shape are irrelevant. This notion of cloaking dates back at least to Oldroyd (see Balmforth, Craster & Hewitt (Reference Balmforth, Craster and Hewitt2021)), and has been considered in detail for the motion of differently shaped particles encased in viscoplastic fluid (Chaparian & Frigaard Reference Chaparian and Frigaard2017a

,Reference Chaparian and Frigaard

b

). The difference between the two cases that emerges for longer domains arises because the plug breaks for free-slip walls at

![]() $\ell _x\approx 1.9$

, decloaking the wall (see below in § 4.3).

$\ell _x\approx 1.9$

, decloaking the wall (see below in § 4.3).

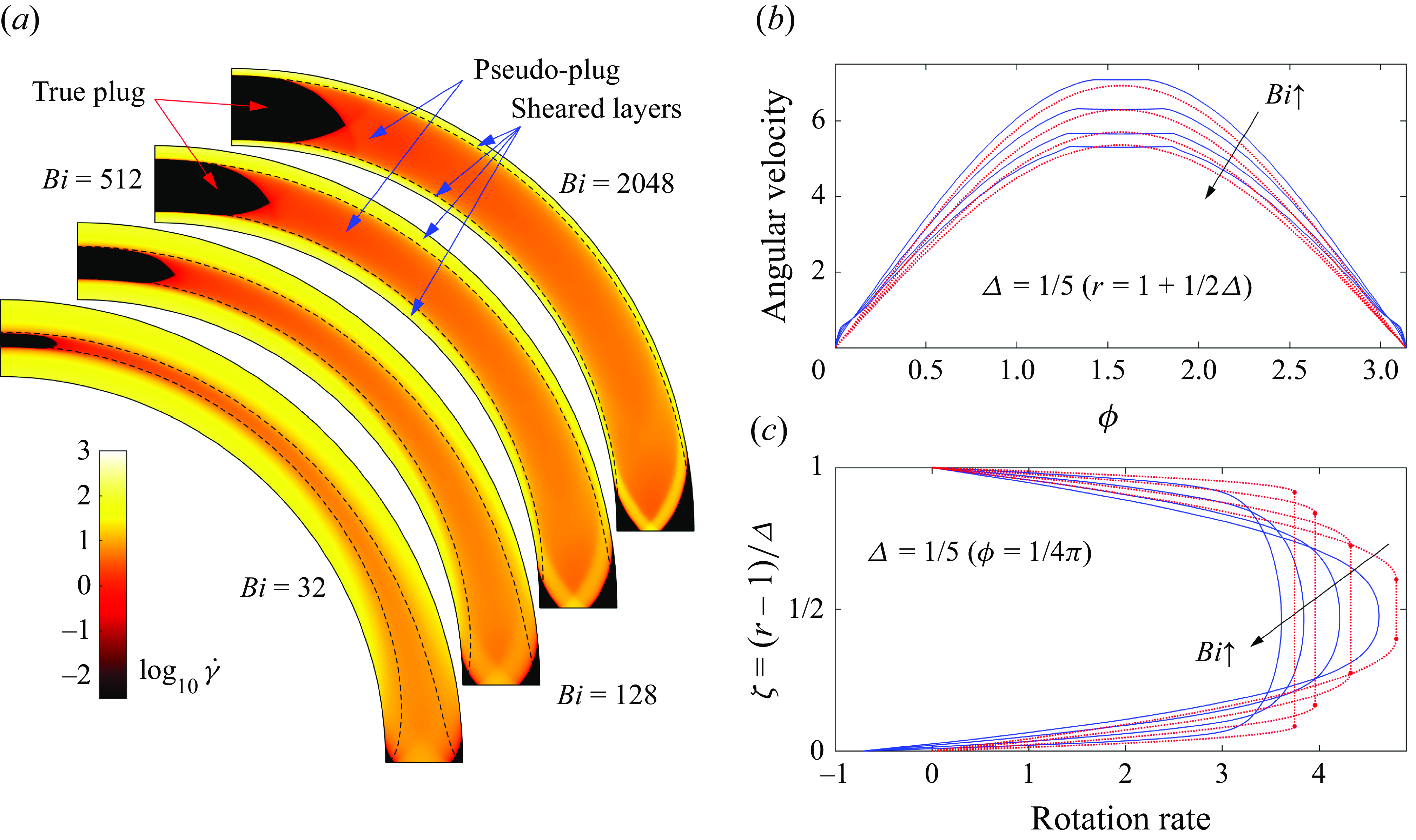

4.2. Wide domains; no-slip walls

For longer domain lengths, the solutions depend on the boundary condition applied along the top and bottom boundaries (see e.g. figure 4

a,b,f). With a no-slip condition, the jet continues to widen gradually until it meets the walls at