Book contents

- Frontmatter

- Dedication

- Contents

- List of Illustrations

- List of Tables

- Acknowledgements

- Abbreviations

- A Note on Money, Weights and Measures, and Places

- Maps

- Introduction

- 1 Making Cloth

- 2 Marketing Cloth

- 3 Identifying Clothiers

- 4 Clothiers and Government

- 5 Clothiers in Society

- 6 Famous Clothiers

- Conclusion

- Appendices

- Gazetteer of Surviving Buildings

- Glossary

- Bibliography

- Index

- Frontmatter

- Dedication

- Contents

- List of Illustrations

- List of Tables

- Acknowledgements

- Abbreviations

- A Note on Money, Weights and Measures, and Places

- Maps

- Introduction

- 1 Making Cloth

- 2 Marketing Cloth

- 3 Identifying Clothiers

- 4 Clothiers and Government

- 5 Clothiers in Society

- 6 Famous Clothiers

- Conclusion

- Appendices

- Gazetteer of Surviving Buildings

- Glossary

- Bibliography

- Index

Summary

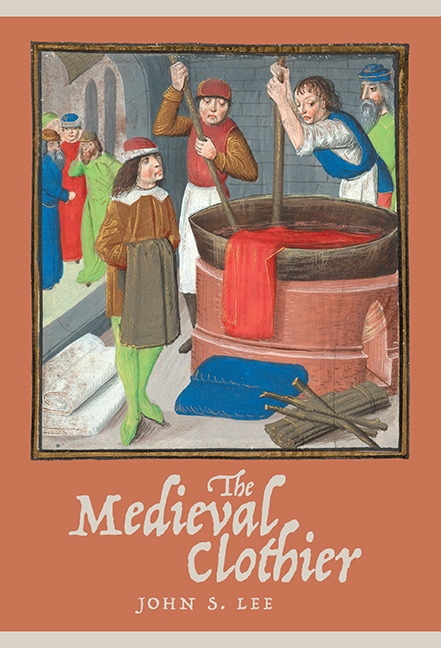

Anyone producing a piece of cloth from raw wool needs to undertake several different activities (Figure 3). Specialised cloth-workers including carders, combers, spinners, weavers, fullers and dyers emerged during the Middle Ages, skilled in specific aspects of cloth-making. We still use terms from cloth-making processes in our everyday speech, when we talk of being ‘dyed in the wool’ or ‘on tenterhooks’. Spinster originally denoted someone who practised spinning, but from the seventeenth century, unmarried women have been designated in legal terms as spinsters. Common surnames reflect the processes carried out by various textile workers, including Weaver, Webb, Webber, and Webster (weavers), Fuller and Walker (fullers), and Dyer and Lister (dyers). This chapter explores these activities, taking a step-by-step approach from the buying of wool to the finishing of the fabric. Clothiers coordinated these processes, and in some cases carried out stages of production themselves.

PROCESSES IN THE MAKING OF CLOTH

The main product of the medieval textile industry was broadcloth, made from short staple wool, which was densely woven and heavily fulled. By the later Middle Ages this had been standardised at 26 to 28 yards long and 1¾ yards wide, produced by two weavers working on a broadloom. The type and price varied according to the quality of the wool used, the dye and the degree of finish. Some cloths were woven on a narrower loom, requiring only one person to weave. These were half the width of a standard broadcloth and known as straits. Worsted, made from long staple wool, was made mainly for the home market and was far less heavily legislated. Linen was produced from flax, and harden cloth from hemp or flax.

The clothier's first task was to obtain wool. Its quality, its source and the frequency with which clothiers bought it varied according to the resources at their disposal. A document of 1615 shows how clothiers procured their wool in different ways according to the money they had available. The wealthiest bought from wool producers in wool counties, made their provision for the whole year beforehand, and had the wool spun, woven and fulled by their own employees. Less affluent clothiers travelled little to wool-producing counties but borrowed money to buy wool, mostly at the market, had it made into cloth to sell, and then borrowed more money.

- Type

- Chapter

- Information

- The Medieval Clothier , pp. 39 - 76Publisher: Boydell & BrewerPrint publication year: 2018