Nomenclature

Nomenclature

-

$G_{I,C}$

$G_{I,C}$

Fracture toughness/energy in mode-I crack initiation/onset

-

$G_{II,C}$

$G_{II,C}$

-

Fracture toughness/energy in mode-II crack initiation/onset

-

$G_{I,R}$

$G_{I,R}$

-

Fracture toughness/energy in mode-I crack propagation

-

$G_{II,R}$

$G_{II,R}$

-

Fracture toughness/energy in mode-II crack propagation

-

$\overline{G_{I,C}}$

$\overline{G_{I,C}}$

-

The averaged value of fracture toughness/energy in mode-I fracture

-

$\overline{G_{II,C}}$

$\overline{G_{II,C}}$

-

The averaged value of fracture toughness/energy in mode-II fracture

Abbreviations

Abbreviations

- FRP

-

Fibre-reinforced polymer

- RTM

-

Resin transfer moulding

- VARI

Vacuum-assisted resin infusion

- CNF

Carbon nanofibre

- CNT

Carbon nanotube

- PPS

Polyphenylene sulfide

- GNP

Graphene nanoplatelet

- PSF

Polysulfone

- PA

Polyamide

- P(St-co-GMA)

Polystyrene-co-glycidyl methacrylate

- PAN

Polyacrylonitrile

- PP

Polypropylene

- PET

Polyethylene terephthalate

1.0 Introduction

Advanced fibre-reinforced polymer composite laminates are increasingly finding use in various industrial applications that demand superior mechanical properties together with weight-saving and long-term durability (e.g. aerospace and automotive structural components). However, composite laminates are generally susceptible to interlaminar cracking or delamination, which may initiate from various sources such as joints, ply drop-offs, skin-core interaction in sandwich structures, notches and in-service impact events [Reference Richardson and Wisheart1–Reference Katnam, Da Silva and Young5]. Delamination can significantly reduce laminate strength and stiffness and can subsequently lead to premature catastrophic failure if undetected. Therefore, a significant amount of research has been conducted over the years to suppress and/or delay delamination initiation and propagation by improving the interlaminar fracture toughness of composite laminates.

The majority of composite laminates used in aerospace structures are currently thermoset based because of their high specific stiffness, high specific strength, durability and processability. But thermoset resins suffer from low fracture toughness because of inherent brittleness caused by high crosslinking density. Improving the fracture toughness and ductility of thermoset matrix composites is thus of paramount importance to enhance damage tolerance, extend service life, decrease knockdown factors in design, reduce maintenance and repair costs. However, the improvement in fracture toughness is often a trade-off between toughness and strength and/or manufacturability [Reference Ritchie6]. In this regard, various methods are explored to enhance delamination resistance in recent years. Extrinsic approaches such as Z-pins, stitching and 3D interlocking have been successfully applied [Reference Mouritz and Cox7–Reference Jain, Dransfield and Mai9]. None of these approaches seems to alter the inherent fracture toughness of composite laminates but rather inhibit crack growth via through-thickness reinforcement (i.e. pins or fibres). As a result, the in-plane fibres may be displaced (creating resin-rich areas) or even be damaged during the through-thickness insertion process, which may adversely affect strength and stiffness. Moreover, specialised equipment and additional fabrication steps are required to insert such through-thickness reinforcement. In contrast, third-phase materials such as particle fillers and non-woven veils (and their combinations), i.e. for multiscale toughening, are explored as an intrinsic approach to enhance toughness by introducing energy absorbing/dissipating phenomena (i.e. toughening mechanisms), at the same time avoiding in-plane fibre distortion and damage [Reference Sela and Ishai10–Reference Tang, Ye, Zhang and Friedrich13]. While the utilisation of non-woven veils is straightforward (by inserting between laminae during layup), particle tougheners are versatile and can be used in the form of particle blended resins, coatings, dissolvable interleaves, non-dissolvable particle interleaves or directly-growing/grafting on fibre surfaces—depending on the type of particles and process used.

A toughening system should ideally be cost-effective, easy-to-process without considerably degrading engineering properties such as mechanical, electrical and thermal properties. In addition, toughening routes compatible with out-of-autoclave processing methods, e.g. resin transfer moulding (RTM) and vacuum-assisted resin infusion (VARI), play a major role in cost-effective composite manufacturing [Reference Nash, Young, McGrail and Stanley12, Reference Soutis14]. In this context, this review aims to highlight and discuss particle and non-woven veil based toughening routes by focusing on the experimental studies published in recent years. The aspects of manufacturability and pros/cons of particle and non-woven veil toughening routes are presented and compared. Multi-scale toughening routes with various combinations of nano and micro-particles and non-woven veils are also discussed. The advantages, limitations and potential of both toughening routes are reviewed, while aiming to provide an overview of the current understanding and challenges in designing and manufacturing safe and reliable composite structures.

2.0 Particle fillers for interlaminar toughening

A wide variety of nano- and micro-scale particle fillers has been employed to improve the fracture behaviour of inherently brittle thermoset resins and their composite laminates [Reference Tang, Ye, Zhang and Friedrich13, Reference Carolan, Ivankovic, Kinloch, Sprenger and Taylor15–Reference Fu, Feng, Lauke and Mai23]. In this review, the term ‘particle’ refers to the toughening phase. These particles can either be introduced (predetermined size and shape) or be formed via phase-separation of dissolvable toughener materials. The manufacturing of particle toughened composite laminates are broadly divided into three types: (a) particle blended/dissolved resins to directly infuse or impregnate fibre preforms to produce a particle-dispersed matrix phase; (b) particle interleaving to introduce particles between neighbouring laminae by sifting, particle filtering, spraying or inserting dissolvable interleaves to form particulate morphology upon phase-separation; and (c) sizing/coating or particle-growing/grafting on reinforcement fibres. These approaches are presented by referring to the particles of rubber, nano-silica, thermoplastics, and carbon-based nanomaterials, i.e. graphene, carbon nanofibres (CNF) and carbon nanotubes (CNT).

Rubber particles, which can be either introduced via phase-separation during cure (i.e. reactive liquid rubber) or resin blend of predetermined size and morphology (e.g. core-shell rubber), have been employed for toughening thermoset matrix composites for several decades [Reference Scott and Phillips24, Reference Dadfar and Ghadami25]. Although rubber particles enhance toughness, it is observed that rubber particle content could adversely affect matrix stiffness, strength and glass transition temperature (T g). An additional rigid phase may thus be introduced to compensate for the property loss caused by rubber particle tougheners. For example, hybrid rubber and nano-silica particles have been explored and shown that the stiffness, strength and T g of composites can be retained [Reference Tsai, Huang and Cheng26–Reference Sprenger29]. The particle modified resin viscosity levels have been observed to be suitable for liquid resin processing and offer enhanced fracture toughness without significant loss in other desired mechanical properties [Reference Kinloch, Mohammed, Taylor, Sprenger and Egan16, Reference Kinloch, Masania, Taylor, Sprenger and Egan30–Reference Hsieh, Kinloch, Masania, Lee, Taylor and Sprenger34]. Moreover, the fracture toughness enhancement has been observed to be synergistic with hybrid particle blends [Reference Kinloch, Masania, Taylor, Sprenger and Egan30]. But it should be taken into account that several studies have shown that high toughening often comes with relatively high particle content. Furthermore, high particle content often leads to high resin viscosity and subsequently results in non-uniform particle dispersion and agglomeration. However, the particle blended resin can be heated and transferred into a pre-heated tool to achieve low viscosity levels to overcome processing difficulties. When a particle-blended resin is infused without particle agglomeration into a fibre preform, the toughening effect is often established not only in interlaminar regions but also in intralaminar regions (i.e. within laminae) if the particle size is sufficiently small compared to the inter-fibre distance. These particles do not increase laminate thickness as in interleaving methods. As an alternative to the particle blended resins, some of the manufacturing difficulties can be mitigated with particle coated/sized fibre preforms. For instance, nano-silica particles can be used to coat/size primary fibres to enhance fibre-matrix adhesion and, subsequently, fracture properties. With this approach, significant fracture energy improvements can be obtained using low particle content (i.e. below 1%wt). In contrast, matrix toughening requires an order of magnitude of particle content to achieve the same effect (i.e. about 10%wt) [Reference Tsai, Carolan, Sprenger and Taylor35]. However, maintaining the even distribution of the particles during the fibre coating process can be a major factor.

Thermoplastic tougheners (e.g. particles, coatings, films or dissolvable non-woven veils) can dissolve in thermoset resins, or soften and partially dissolve, or remain intact during manufacturing, depending on the compatibility between the thermoplastic and thermoset combined and the cure conditions employed [Reference Nash, Young, McGrail and Stanley12, Reference Hodgkin, Simon and Varley18, Reference van der Heijden, Daelemans, Meireman, De Baere, Rahier, Van Paepegem and De Clerck36]. Depending on the content of the thermoplastic phase, the dissolved thermoplastic can lead to phase-separation, co-continuous morphology or phase-inversion upon curing the thermoset [Reference Del Saz-Orozco, Ray, Kervennic, McGrail and Stanley37, Reference Yun, Won and Kim38]. Undissolved thermoplastics remain as a discrete phase in the interlaminar regions [Reference Huang, Liu, Jiang, Wei and Qiu39]. Thermoplastic particles, in particular, are employed for toughening prepreg systems, which are successfully commercialised and used in aerospace structures [Reference Zhang and Fox40–Reference Hojo, Matsuda, Tanaka, Ochiai and Murakami42]. Thermoplastic particles can be deposited on prepreg surfaces by sifting [Reference Del Saz-Orozco, Ray, Kervennic, McGrail and Stanley37, Reference Huang, Liu, Jiang, Wei and Qiu39] or filtration during impregnation [Reference Liu, Li, Li, Luan, Ling and Yang43]. Uniform particle distribution and particle-matrix compatibility are of crucial importance for both dispersed particles and phase-separated particles [Reference Turmel and Partridge44, Reference Hillermeier and Seferis45]. Thermoplastic coating on primary fibres can provide adequate toughener distribution in the interlaminar region but can lead to reduced compressibility and poor laminate consolidation. Additional external pressure should thus be required to achieve desired laminate compaction and fibre volume fractions [Reference Wu, Yi and Wilkinson46]. Alternatively, dissolvable thermoplastic films can be used for interlaminar toughening. This method can be challenging with the liquid resin processing methods as the continuous film may barricade the resin flow in the through-the-thickness direction [Reference Nash, Young, McGrail and Stanley12]. Film interleaving can be applied for prepregs as resin flow distances are small compared to resin infusion. The melted thermoplastic film may diffuse through reinforcement fibres of neighbouring fibre preform or prepreg laminae upon the application of heat and pressure, which could partially toughen the intralaminar regions in addition to the interlaminar region [Reference Hojo, Matsuda, Tanaka, Ochiai and Murakami42, Reference Bahrami, Cordenier, Van Velthem, Ballout, Pardoen, Nysten and Bailly47]. Furthermore, thermoplastic non-woven veils can be used for interlaminar toughening (i.e. interleaves made of either dissolvable or undissolvable thermoplastic fibres), which are discussed in Section 3. For all the types of thermoplastic tougheners, the processing/manufacturing parameters and the thermoplastic precursor employed to produce the toughener can have a significant influence on the final particle morphology and resulting fracture properties [Reference Nash, Young, McGrail and Stanley12, Reference Zhang and Fox40–Reference Hojo, Matsuda, Tanaka, Ochiai and Murakami42, Reference Wang, Yu, Potter and Kim48].

Another category of particles that are considered for enhancing crack resistance and tolerance is carbon-based nanomaterials such as carbon black particles [Reference Zhang, Ye, Deng, Zhang, Tang and Chen49], carbon nanotubes (CNT) [Reference Quan, Urdániz and Ivanković50–Reference Wang, Soutis and Gresil52], carbon nanofibres (CNF) [Reference Quaresimin and Varley53], and graphene-derivatives [Reference Wang, Soutis and Gresil52, Reference Ahmadi-Moghadam and Taheri54–Reference Zeng, Liu, Chen and Soutis57], which have received increasing attention for a variety of engineering applications [Reference Domun, Hadavinia, Zhang, Sainsbury, Liaghat and Vahid58]. The superior mechanical properties of such novel materials are particularly attractive to enhance the mechanical properties and the interlaminar fracture toughness of composite laminates [Reference Godara, Mezzo, Luizi, Warrier, Lomov, Van Vuure, Gorbatikh, Moldenaers and Verpoest59]. A low particle content (1–2%) of carbon nano-materials often results in significant enhancements; in contrast, with higher particle content (>5%wt), the particles tend to agglomerate and significantly increase the resin viscosity. Thus, it becomes practically challenging to utilise liquid resin processing methods to infuse carbon nano-modified resins [Reference Seyhan, Tanoglu and Schulte60, Reference Jiménez-Suárez, Campo, Sánchez, Romón and Ureña61]. Agglomeration of particles in the laminate, uneven particle distribution, and particle filtering by manufacturing consumables or fibres can lead to varying fracture toughness values at the interlaminar regions or even degrade fracture properties [Reference Quaresimin and Varley53, Reference Seyhan, Tanoglu and Schulte60, Reference Karapappas, Vavouliotis, Tsotra, Kostopoulos and Paipetis62]. Thus, alternative techniques are needed to apply carbon nano-fillers for interlaminar toughening. For example, techniques such as manual brushing and rolling can be used to adequately wet all the layers [Reference Quan, Urdániz and Ivanković50, Reference Domun, Paton, Blackman, Kaboglu, Vahid, Zhang, Dear, Kinloch and Hadavinia63, Reference Zhu, Bakis and Adair64], although such manual methods may not be feasible for manufacturing large scale composite structural components. In addition, spraying a carbon nano-modified solution to coat individual lamina can aid the even particle distribution. The solvent in the spray solution must be evaporated before curing to prevent solvent entrapment, which could cause void formation [Reference Mujika, Vargas, Ibarretxe, De Gracia and Arrese65]. CNT and CNF can be directly grown on the primary fibres [Reference Kepple, Sanborn, Lacasse, Gruenberg and Ready66, Reference Storck, Malecki, Shah and Zupan67]. Grown-on or coated particles may reduce the laminate compressibility and compaction levels, requiring additional external pressure to achieve desired fibre volume fractions and laminate thickness [Reference Lomov, Gorbatikh, Kotanjac, Koissin, Houlle, Rochez, Karahan, Mezzo and Verpoest68, Reference Patel, Potluri, Yousaf and Wilkinson69]. Alternatively, carbon-nanomaterials can be deposited on/in carriers such as resin films [Reference Mirjalili, Ramachandramoorthy and Hubert70] or non-woven veils [Reference Quan, Mischo, Binsfeld, Ivankovic and Murphy71, Reference Quan, Mischo, Li, Scarselli, Ivanković and Murphy72], then later be introduced at the interlaminar regions. Similarly, vertically aligned CNT arrays (forests) [Reference Ni, Furtado, Fritz, Kopp, Camanho and Wardle73, Reference Garcia, Wardle and Hart74], CNT sheets (synthesised with floating-catalyst chemical vapour deposition method) [Reference Xin, Sarasini, Tirillò, Bavasso, Sbardella, Lampani and De Rosa75, Reference Ou, González and Vilatela76], and bucky papers (made of CNFs or CNTs) [Reference Khan and Kim77, Reference Liu, Shen and Zhou78] can be interleaved at the interlaminar regions. Depending on the method used to manufacture carbon nano-toughened composite laminates, the toughening effect can exist not only at the interlaminar regions but also at the intralaminar regions (i.e. when primary fibres are successfully impregnated/coated with carbon nano-modified matrix, rather than depositing carbon nano-fillers at the interlaminar region).

3.0 Non-woven veils for interlaminar toughening

Non-woven veils, which are also referred to as mats, membranes or tissues, are fibrous networks (webs) composed of continuous or discontinuous (i.e. short/chopped) fibres, see Fig. 1(a). When introduced (i.e. interleaved) between neighbouring laminae during laminate stacking, interleaving fibres are located parallel to the laminate plane in the interlaminar regions. It can be thought of as sandwiching a discrete layer of fibres between primary laminae. Although non-woven veil interleaving is not a new idea [Reference Browning and Schwartz79, Reference Green, Bashford and Bowyer80], this concept is reawakened lately due to several reasons: the properties of resin matrix (i.e. viscosity, glass transition temperature, strength and stiffness) are largely preserved [Reference Nash, Ray, Young and Stanley81–Reference Li, Li, Zhang, Yu, Liu, Zhang, Jia, Yang, Xue and Ryu85], non-woven veils allow resin flow between neighbouring laminae because of their highly porous/permeable nature [Reference Shin, Anders, Kim, Jin and Nutt86] (i.e. high compatibility with both prepreg and liquid resin processing methods [Reference Nash, Young, McGrail and Stanley12, Reference Girardy and Beraud87]). Additionally, non-woven veil interleaving significantly improves interlaminar fracture toughness without requiring considerable modifications to the manufacturing process, equipment or steps.

Figure 1. (a) SEM micrograph of a PPS (polyphenylene sulfide) microfibre non-woven veil, (b) cross-sectional optical and (c) SEM micrographs of carbon fibre-epoxy laminate interleaved with PPS non-woven microfibre veils (the x, y and z-axes represent fibre, transverse and through-thickness directions, respectively).

Non-woven veils can be broadly categorised into two groups: microfibre veils and nanofibre veils. Non-woven microfibre veils are made of randomly distributed short microfibres (i.e. a few microns in diameter), providing a high aspect ratio and high specific surface area. Microfibre veils are mass-producible [Reference Albrecht, Fuchs and Kittelmann88], and a wide variety of areal weights are commercially available, which ranges from as light as a few grams to a couple of hundreds of grams per square meter (i.e. 2–400gsm) [89]. Various microfibres including thermoplastic fibres [Reference Fitzmaurice, Ray and Mccarthy83, Reference Quan, Bologna, Scarselli, Ivankovic and Murphy90–Reference Kuwata and Hogg95], carbon [Reference Lee, Lee, Cheong and Noguchi96], glass [Reference Arouche, de Freitas and de Barros97], aramid/Kevlar fibres [Reference Beylergil, Tanoglu and Aktas98, Reference Sohn and Hu99], and mixed blends of different fibres [Reference Kuwata and Hogg95, Reference Kuwata and Hogg100] can be used for manufacturing veils. Microfibre veils have received particular attention for significant enhancements in mode-I [Reference O’Donovan, Ray and McCarthy82, Reference Quan, Bologna, Scarselli, Ivankovic and Murphy90–Reference Ramirez, Hogg and Sampson92, Reference Kuwata and Hogg95, Reference Del Saz-Orozco, Ray and Stanley101], mode-II [Reference Ramirez, Hogg and Sampson92, Reference Kuwata and Hogg100, Reference Quan, Bologna, Scarselli, Ivanković and Murphy102] fracture toughness and the impact and post-impact performance of laminates [Reference Walker, Sohn and Hu103, Reference Hogg104], together with cost-effectiveness and processability. But one of the drawbacks of microfibre veil interleaving is the inevitable increase in laminate thickness, especially when every interlaminar region is interleaved (see Fig. 1(b) and (c)). The thickness of the veil interleaved interlaminar region increases with the increased areal weight [Reference Quan, Bologna, Scarselli, Ivankovic and Murphy90, Reference İnal, Akbolat, Soutis and Katnam91, Reference Beylergil, Tanoğlu and Aktaş93]. Although such an increase in thickness is observed to be beneficial for resisting impact loading [Reference Greenhalgh and Hiley11, Reference Nash, Young and Stanley105, Reference Davies and Zhang106], it reduces the overall fibre volume fraction of the reinforcement fibres considerably in the laminate, affecting in-plane laminate strength and stiffness [Reference Beylergil, Tanoğlu and Aktaş93]. When non-woven veils with low areal weight are interleaved, laminate thickness (i.e. using constant thickness closed moulds) can be controlled for maintaining the in-plane properties [Reference García-Rodríguez, Costa, Rankin, Boardman, Singery and Mayugo94]. Moreover, when pre-pregs are interleaved with microfibre veils, the resin contained by the prepreg layers may not be sufficient to fully wet/impregnate relatively thick veils (i.e. high areal weight), which can lead to void generation and affect the laminate properties [Reference Lee, Lee, Cheong and Noguchi96]. Such a problem is unlikely to occur for laminates manufactured via resin infusion/transfer methods. However, non-woven microfibre veils may act as flow distribution media because of their highly permeable nature and could create a non-uniform flow front during infusion, leading to porosity in the interleaved regions [Reference Nash, Young and Stanley105]. A post-infusion dwelling step before the final cure can be carried out to reduce the porosity levels caused by such non-uniform flow phenomenon [Reference Shin, Anders, Kim, Jin and Nutt86].

Alternatively, non-woven veils composed of predominantly continuous nanofibres manufactured with electro-spinning technology have received attention over the last decades [Reference van der Heijden, Daelemans, Meireman, De Baere, Rahier, Van Paepegem and De Clerck36, Reference Jiang, Chen, Duan, Mei, Greiner and Agarwal107–Reference Palazzetti and Zucchelli112]. Electrospun nanofibre veils have an ultra-high aspect ratio and specific surface area (much higher than that of micro-fibre veils) due to their nanofibres (i.e. with a diameter less than a micron). Nanofibres, which can be manufactured with a wide range of thermoplastic polymer and other material alternatives, have higher mechanical properties than their bulk phase with aligned molecular orientation along the fibre direction and with a reduced amount of defects/flaws. Electrospun nanofibre veils are highly compatible with composite laminate manufacturing techniques and can significantly reduce the interleave thickness (compared to microfiber veils). Nanofibre veils can be introduced as interlaminar tougheners in two ways: (a) directly spinning/depositing on the base fibre preforms [Reference Bilge, Ozden-Yenigun, Simsek, Menceloglu and Papila113–Reference De Schoenmaker, Van der Heijden, De Baere, Van Paepegem and De Clerck117], and (b) spinning/collecting on a collector as a stand-alone non-woven veil and later interleaving during the laminate stacking [Reference van der Heijden, Daelemans, De Schoenmaker, De Baere, Rahier, Van Paepegem and De Clerck116–Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck118]. The direct deposition can be beneficial as nanofibres are in direct contact with reinforcement fibres but may cause interaction between fabric/prepreg and electrospinning solvents/chemicals. In addition, environmental conditions (i.e. temperature, humidity, out-of-freezer time) must be carefully monitored while electrospinning on prepreg materials to maintain the properties of prepreg layers. The transfer from the collector to the interlaminar region needs to be handled carefully to prevent surface contamination and veil damage. By interleaving the nanofibre veils, the strength and stiffness of composite laminates can be maintained or even slightly be increased [Reference Li, Li, Zhang, Yu, Liu, Zhang, Jia, Yang, Xue and Ryu85, Reference Bilge, Ozden-Yenigun, Simsek, Menceloglu and Papila113, Reference Bilge, Venkataraman, Menceloglu and Papila114, Reference van der Heijden, Daelemans, De Schoenmaker, De Baere, Rahier, Van Paepegem and De Clerck116, Reference De Schoenmaker, Van der Heijden, De Baere, Van Paepegem and De Clerck117, Reference Beylergil, Tanoğlu and Aktaş119, Reference Beylergil, Tanoğlu and Aktaş120] up to a critical veil thickness [Reference Zhang, Lin and Wang84, Reference Liu, Huang, He and Han121, Reference Chen, Zhao, Zhou, Rahman, Wu, Wu, Xu and Fong122]. Electro-spinning can be used to produce different forms of nanofibre veils such as core-shell nanofibre veils (i.e. with co-axial electro-spinning) and blending of mixed fibres from different materials (i.e. dissolvable and undissolvable fibres) [Reference Saghafi, Zucchelli, Palazzetti and Minak123, Reference Daelemans, Kizildag, Van Paepegem, D’hooge and De Clerck124]. By selecting the proportion of different materials, novel electrospun nanofibre veils can be produced for a given set of design requirements and the targeted balance between fracture energy levels (i.e.

![]() ${G_{II,C}}$

/

${G_{II,C}}$

/

![]() ${G_{I,C}}$

ratio). It is also possible to achieve electrospun nanofibre veils with a preferential alignment [Reference Li, Liu, Zhu, Li, Jia, Wang, Li and Yang125]; however, random distribution/entanglement is shown to be more beneficial for enhancing fracture toughness [Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck126]. Besides, the random fibre distribution, which is convenient to manufacture, is favourable as the delamination in practical applications may propagate in different directions, unlike the pre-determined direction of propagation in fracture test specimens. Non-woven veils can also provide an approximately constant interlaminar thickness which may aid to maintain the adhesive thickness between bonded substrates, which can benefit composite patch repairs and bonded joints [Reference Arouche, de Freitas and de Barros97, Reference Tzetzis, Hogg and Jogia127, Reference Tzetzis and Hogg128]. Finally, although non-woven veils (both microfibre and electrospun nanofibre veils) are lightweight materials, it is worth noting that the toughener veils may introduce additional weight at the structural scale [Reference Sela and Ishai10, Reference Greenhalgh and Hiley11].

${G_{I,C}}$

ratio). It is also possible to achieve electrospun nanofibre veils with a preferential alignment [Reference Li, Liu, Zhu, Li, Jia, Wang, Li and Yang125]; however, random distribution/entanglement is shown to be more beneficial for enhancing fracture toughness [Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck126]. Besides, the random fibre distribution, which is convenient to manufacture, is favourable as the delamination in practical applications may propagate in different directions, unlike the pre-determined direction of propagation in fracture test specimens. Non-woven veils can also provide an approximately constant interlaminar thickness which may aid to maintain the adhesive thickness between bonded substrates, which can benefit composite patch repairs and bonded joints [Reference Arouche, de Freitas and de Barros97, Reference Tzetzis, Hogg and Jogia127, Reference Tzetzis and Hogg128]. Finally, although non-woven veils (both microfibre and electrospun nanofibre veils) are lightweight materials, it is worth noting that the toughener veils may introduce additional weight at the structural scale [Reference Sela and Ishai10, Reference Greenhalgh and Hiley11].

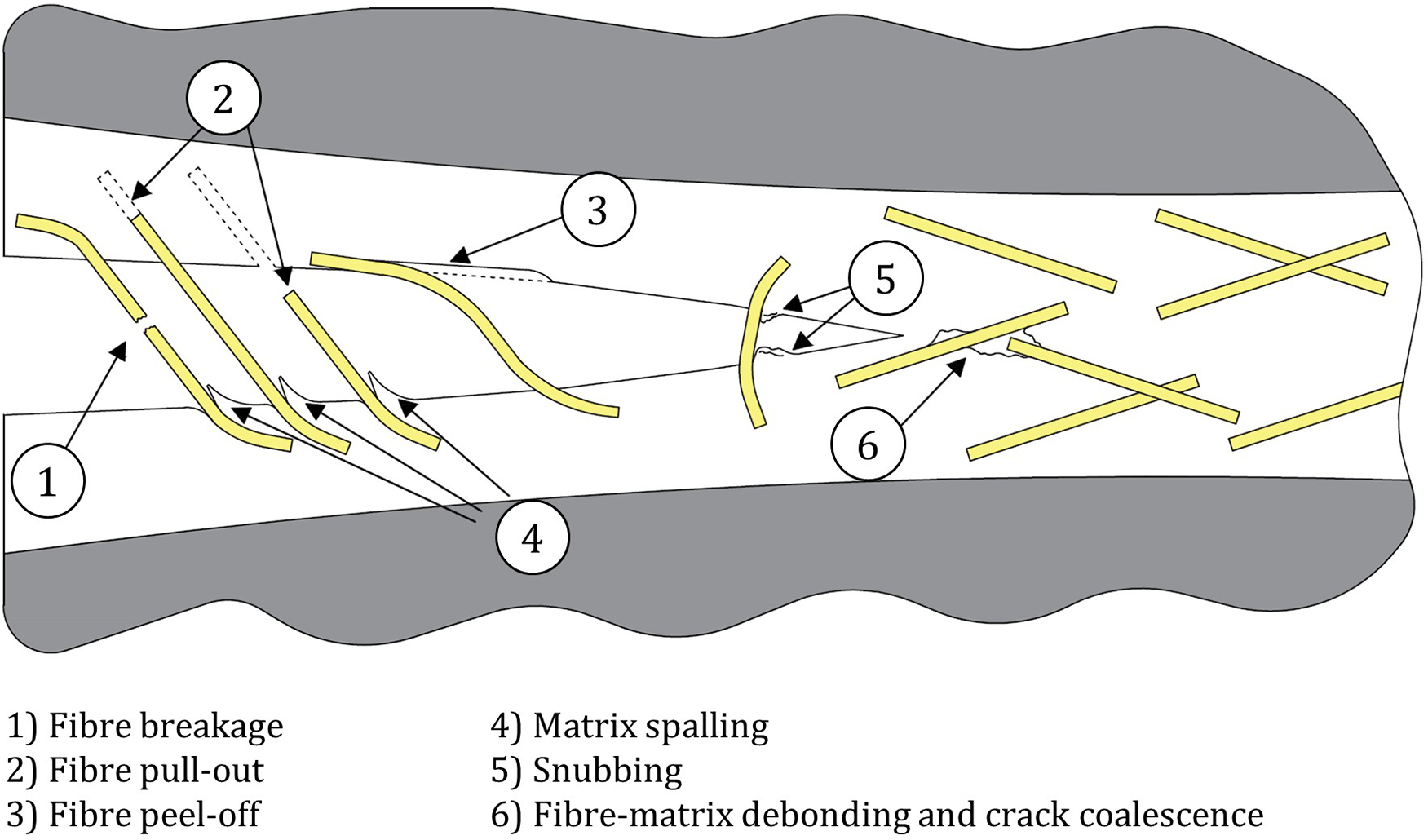

4.0 Non-woven veils: toughening mechanisms

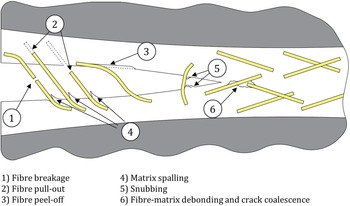

The effectiveness of toughening mechanisms of non-woven veils strongly depends on the interaction of fibres with the surrounding matrix (i.e. fibre-matrix adhesion) and the veil fibres’ mechanical behaviour. In the case of undissolvable veils (i.e. in which the veil fibres maintain their fibrous form during and after the manufacturing process), the fibre-matrix debonding, matrix yielding and crack coalescence in the resin essentially occur ahead of the crack front and absorb the fracture energy (as intrinsic mechanisms). As an extrinsic mechanism (i.e. a phenomenon that occurs at the crack wake), fibre bridging contributes to the resistance to crack opening. The fibre bridging mechanism can be recognised in the fracture energy vs crack length curves (i.e. R-curves) as a gradual increase in the fracture energy [Reference Sela and Ishai10] (i.e. rising R-curve). A plateau might be reached at a certain crack length when the fibre bridging is eventually saturated. However, if a reduction/decline in the fracture energy is observed with the increased crack length (i.e. falling R-curve), it may indicate that less fibre bridging is taking place as the crack grows, in comparison to the early levels of crack growth [Reference İnal, Akbolat, Soutis and Katnam91]. This is often caused by crack deflection from the interlaminar region into the intralaminar regions or veil/lamina interface, which is discussed in Section 5.2. Eventually, the bridged veil fibres break and are pulled out or peeled off from the matrix. During crack propagation, the surrounding matrix can experience spalling, snubbing or void growth [Reference Ravindran, Ladani, Wu, Kinloch, Wang and Mouritz129–Reference Huang and Zhao132]. These toughening mechanisms in non-woven veil interleaved laminates are illustrated in Fig. 2.

Figure 2. An illustration of extrinsic and intrinsic toughening mechanisms in non-woven veil interleaved laminates.

Fibre breakage occurs in the case of sufficient bonding and long fibre length. Sufficiently strong bonding prevents the fibres from debonding, being pulled out or peeled off easily, and leads to fibre breakage at the end of the fibre bridging [Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck118, Reference Teklal, Djebbar, Allaoui, Hivet, Joliff and Kacimi133]. In nanofibre veils, the fibres are long and continuous, and almost no free fibre ends exist due to the continuous spinning process. Hence, numerous fibres form bridges between the crack faces and break. During fibre breakage, ductile (tough) fibres can absorb energy by stretching and eventually yielding before breaking. In contrast, brittle fibres exhibit a lower energy absorption capability due to their low failure strain. As a result, broken fibres can exhibit fibrillations or necking depending on the fibre type. For example, interleaves made of Kevlar microfibres show extensive fibrillation upon breakage under mode-I and mode-II fracture [Reference Sohn and Hu99, Reference Sohn and Hu134]. In contrast, ductile fibre fracture with yielding/necking can be seen in thermoplastic nanofibres due to their high strain to failure [Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck118, Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck135].

Fibre pull-out may occur due to fibre bridging because of weak fibre-matrix bonding and short fibre lengths. The fibres progressively debond from the surrounding matrix, start sliding and are finally pulled out from the surrounding matrix. Fibre-matrix friction can contribute to energy dissipation during sliding (i.e. frictional pull-out). When a fibre is completely pulled out, one end of the fibre is embedded in the matrix, and the other end is free of any physical constraint. As no load can thus be transferred over the fibre length, the fibre no longer contributes to energy dissipation. The pull-out mechanism often occurs in non-woven microfibre veils having chopped/short fibres. Furthermore, the veil fibres are peeled off from the surrounding matrix (i.e. crack growth at the fibre-matrix interface). With matrix cracks in the interleaved region, fibres and matrix may debond and partially expose the fibre surfaces along the fibre axis. Subsequently, the fibres gradually debond/peel-off from the surrounding matrix with a limited contribution to energy dissipation as damage/crack propagates [Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck135]. The fibre-matrix interaction is a governing factor in fibre bridging mechanisms. A weak fibre-matrix adhesion could be favourable for dissipating energy [Reference Soutis14, Reference Nash, Ray, Young and Stanley81, Reference İnal, Akbolat, Soutis and Katnam91, Reference Hogg104, Reference Nash, Young and Stanley136, Reference Nash, Young and Stanley137] in the case of microfibre veils to trigger the abovementioned toughening mechanisms. In contrast, an enhanced fibre-matrix bonding may delay the crack accumulation and improves the fracture energy [Reference Tsai, Carolan, Sprenger and Taylor35, Reference Wang, Ma, Chen and Dai138]. As a result, fewer fibres debond from the surrounding matrix and participate in fibre bridging, which results in relatively low fracture energy enhancement from crack onset to crack propagation [Reference Tsai, Carolan, Sprenger and Taylor35, Reference Wang, Ma, Chen and Dai138, Reference Quan, Deegan, Alderliesten, Dransfeld, Murphy, Ivanković and Benedictus139]. However, if the adhesion between veil fibres and the resin is excessively strong or the veil/lamina interface is weak, no crack can accumulate and propagate in the interleaved region. Instead, the crack deviates and predominantly propagates into the untoughened laminae as an intralaminar crack, or crack grows at the veil/lamina interface [Reference İnal, Akbolat, Soutis and Katnam91, Reference Del Saz-Orozco, Ray and Stanley101, Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck118] (i.e. crack propagation via energetically favourable path). Thus, the damage/toughening mechanisms cannot be initiated and absorb energy. In such a case, the areal weight is less prominent on the obtained fracture energy enhancements [Reference van der Heijden, Daelemans, De Schoenmaker, De Baere, Rahier, Van Paepegem and De Clerck116]. The surface properties of interleaving fibres can be altered by different approaches (i.e. ultraviolet irradiation [Reference Quan, Deegan, Alderliesten, Dransfeld, Murphy, Ivanković and Benedictus139, Reference Quan, Deegan, Binsfeld, Li, Atkinson, Ivanković and Murphy140], hygrothermal conditioning [Reference Nash, Ray, Young and Stanley81, Reference Nash, Young and Stanley136], different fibre sizing or particle deposition [Reference Wang, Ma, Chen and Dai138]) to introduce the aforementioned toughening mechanisms. The extrinsic mechanisms (i.e. fibre breakage, pull-out and peel-off) as well as the intrinsic mechanisms, can simultaneously occur during crack growth in veil toughened interfaces due to the randomness associated with the fibre distribution in veils, yet the contribution of each mechanism in enhancing fracture toughness may differ depending on the interactions between the veil fibres and the neighbouring matrix.

The morphology of the veil interleaved region obtained after curing the resin is an important factor. Although the veils are produced in a fibrous form, veil fibres made of materials with lower melting temperatures than the resin cure temperature (i.e. usually, thermoplastic with low melting point such as polycaprolactone with

![]() ${T_{melt}} \approx 60^\circ {\textrm{C}}$

) cannot maintain their initial fibrous network. Fibres can melt during resin cure and dissolve [Reference Quan, Alderliesten, Dransfeld, Murphy, Ivanković and Benedictus141], phase-separate [Reference Li, Li, Zhang, Yu, Liu, Zhang, Jia, Yang, Xue and Ryu85, Reference Saghafi, Zucchelli, Palazzetti and Minak123], phase-invert [Reference Wong, Lin, McGrail, Peijs and Hogg142] or create bead-like structures in the fibrous network [Reference Bilge, Ozden-Yenigun, Simsek, Menceloglu and Papila113]. If the resin or mould is preheated to an elevated temperature for resin infusion/transfer, the dissolvable veil may melt before/during infusion and migrate with the resin flow. This results in an uneven toughener distribution in the interlaminar region and, consequently, lead to varying fracture toughness [Reference Wong, Lin, McGrail, Peijs and Hogg142, Reference Zhang, Bharti, Li, Du, Bilotti and Peijs143]. The veil fibres may also melt during resin post-cure and re-solidify into their fibrous form upon cooldown (i.e.

${T_{melt}} \approx 60^\circ {\textrm{C}}$

) cannot maintain their initial fibrous network. Fibres can melt during resin cure and dissolve [Reference Quan, Alderliesten, Dransfeld, Murphy, Ivanković and Benedictus141], phase-separate [Reference Li, Li, Zhang, Yu, Liu, Zhang, Jia, Yang, Xue and Ryu85, Reference Saghafi, Zucchelli, Palazzetti and Minak123], phase-invert [Reference Wong, Lin, McGrail, Peijs and Hogg142] or create bead-like structures in the fibrous network [Reference Bilge, Ozden-Yenigun, Simsek, Menceloglu and Papila113]. If the resin or mould is preheated to an elevated temperature for resin infusion/transfer, the dissolvable veil may melt before/during infusion and migrate with the resin flow. This results in an uneven toughener distribution in the interlaminar region and, consequently, lead to varying fracture toughness [Reference Wong, Lin, McGrail, Peijs and Hogg142, Reference Zhang, Bharti, Li, Du, Bilotti and Peijs143]. The veil fibres may also melt during resin post-cure and re-solidify into their fibrous form upon cooldown (i.e.

![]() $T_{\textit{cure}}<T_{\textit{melt}}<T_{\textit{post-cure}}$

) [Reference van der Heijden, Daelemans, Meireman, De Baere, Rahier, Van Paepegem and De Clerck36, Reference van der Heijden, Daelemans, De Schoenmaker, De Baere, Rahier, Van Paepegem and De Clerck116]. In the case of dissolved fibres, the extrinsic toughening mechanisms such as fibre bridging and the associated toughening mechanisms cannot be introduced. But dissolvable veils can alter matrix ductility and improve energy dissipation via plastic deformations. Moreover, phase-separated or phase-inverted particles contribute to energy dissipation via particle debonding, cavitation, shear yielding, void growth and crack deflection, and thus help to enhance interlaminar fracture toughness [Reference Zheng, Huang, Liu, Gao and Mai144]. A blend of dissolved and undissolved veil can lead to higher interlaminar fracture toughness because of the toughening mechanisms induced by both morphologies [Reference Saghafi, Zucchelli, Palazzetti and Minak123, Reference Daelemans, Kizildag, Van Paepegem, D’hooge and De Clerck124, Reference Quan, Alderliesten, Dransfeld, Murphy, Ivanković and Benedictus141], which is discussed Section 6.2.

$T_{\textit{cure}}<T_{\textit{melt}}<T_{\textit{post-cure}}$

) [Reference van der Heijden, Daelemans, Meireman, De Baere, Rahier, Van Paepegem and De Clerck36, Reference van der Heijden, Daelemans, De Schoenmaker, De Baere, Rahier, Van Paepegem and De Clerck116]. In the case of dissolved fibres, the extrinsic toughening mechanisms such as fibre bridging and the associated toughening mechanisms cannot be introduced. But dissolvable veils can alter matrix ductility and improve energy dissipation via plastic deformations. Moreover, phase-separated or phase-inverted particles contribute to energy dissipation via particle debonding, cavitation, shear yielding, void growth and crack deflection, and thus help to enhance interlaminar fracture toughness [Reference Zheng, Huang, Liu, Gao and Mai144]. A blend of dissolved and undissolved veil can lead to higher interlaminar fracture toughness because of the toughening mechanisms induced by both morphologies [Reference Saghafi, Zucchelli, Palazzetti and Minak123, Reference Daelemans, Kizildag, Van Paepegem, D’hooge and De Clerck124, Reference Quan, Alderliesten, Dransfeld, Murphy, Ivanković and Benedictus141], which is discussed Section 6.2.

5.0 Particle and non-woven veil toughening: limitations

5.1 Interlaminar thickness: effect on fracture toughness

In the case of particle toughening, even though the trade-off between manufacturability and desired properties is somewhat balanced by adjusting the particle type, content and manufacturing process, it is important to note that the enhanced fracture toughness of the particle toughened bulk matrix may not fully be attained in situ (i.e. in composite laminates) to improve intralaminar and interlaminar toughness [Reference Liu and Macosko19]. This phenomenon of limited fracture toughness translation is mainly attributed to the restriction of the fracture process zone size at the crack front due to the presence of reinforcement fibres [Reference Scott and Phillips24, Reference Zeng, Liu, Mai and Du31, Reference Domun, Paton, Blackman, Kaboglu, Vahid, Zhang, Dear, Kinloch and Hadavinia63, Reference Bradley145]. Relatively rigid reinforcement fibres and limited thickness of the interlaminar region suppress the formation of the fracture process zone required and thus alter the damage and toughening mechanisms. Nevertheless, the in situ composite fracture energy may well match with corresponding bulk matrix fracture toughness (i.e.

![]() $G_{I,C}^{composite} \approx G_{I,C}^{matrix}$

) up to certain level of fracture toughness [Reference Carolan, Ivankovic, Kinloch, Sprenger and Taylor15, Reference Sprenger32, Reference Bradley145–Reference Klingler, Bajpai and Wetzel147]. Although there are different limits suggested in the literature, it is hard to specify a generalised threshold below which the bulk matrix toughness can be fully translated to in situ fracture toughness. This uncertainty arises as various particle tougheners in different material systems are used, leading to dissimilar toughening effects for each toughened material system. When the interlaminar region is relatively thick and larger than the bulk matrix fracture process zone size, the fibre restriction is relieved and the in situ fracture toughness (i.e. interlaminar fracture toughness) can match the bulk matrix fracture toughness up to 1,000 to 2,000J/m2 [Reference Hsieh, Kinloch, Masania, Lee, Taylor and Sprenger34, Reference Ngah and Taylor148, Reference Stevanovic, Kalyanasundaram, Lowe and Jar149].

$G_{I,C}^{composite} \approx G_{I,C}^{matrix}$

) up to certain level of fracture toughness [Reference Carolan, Ivankovic, Kinloch, Sprenger and Taylor15, Reference Sprenger32, Reference Bradley145–Reference Klingler, Bajpai and Wetzel147]. Although there are different limits suggested in the literature, it is hard to specify a generalised threshold below which the bulk matrix toughness can be fully translated to in situ fracture toughness. This uncertainty arises as various particle tougheners in different material systems are used, leading to dissimilar toughening effects for each toughened material system. When the interlaminar region is relatively thick and larger than the bulk matrix fracture process zone size, the fibre restriction is relieved and the in situ fracture toughness (i.e. interlaminar fracture toughness) can match the bulk matrix fracture toughness up to 1,000 to 2,000J/m2 [Reference Hsieh, Kinloch, Masania, Lee, Taylor and Sprenger34, Reference Ngah and Taylor148, Reference Stevanovic, Kalyanasundaram, Lowe and Jar149].

In the case of non-woven veil interleaving, it is observed that the higher the number of fibres involved in the fracture, the higher the interlaminar fracture energy [Reference Ramirez, Hogg and Sampson92, Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck115]. This can be achieved by using veils with high areal weights or by reducing the veil fibre diameter for the same areal weight (e.g. using nanofibres instead of microfibres [Reference van der Heijden, Daelemans, Meireman, De Baere, Rahier, Van Paepegem and De Clerck36]). As highlighted in Section 3, increasing the areal weight of veils results in an increased interleave thickness (i.e. thicker interlaminar region), which is more pronounced in microfibre veils, see Fig. 1(b) and (c). The thicker interleave contains an increased number of fibres and a thicker matrix region (i.e. larger volume of resin). This region may be considered as a resin-rich region as the volume fraction of veil fibres is low, see Fig. 1(c). As the fracture process zone is confined to a thin matrix region between neighbouring laminae in an untoughened (i.e. without interleaving) interlaminar region, increasing the interlaminar thickness up to a critical value results in higher fracture toughness due to the increased size of the unconstrained fracture process zone [Reference Cooper, Ivankovic, Karac, McAuliffe and Murphy150–Reference Aksoy and Carlsson152]. The fracture energy enhancement that arises from the increased areal weight of non-woven veils may not thus be solely attributed to the increased number of veil fibres, and the increased interlaminar resin thickness could also contribute to the fracture toughness enhancement. In fact, the above discussion applies to all forms of interleaving, including particle and film interleaves, as they increase the interlaminar thickness. However, only a limited amount of work has been done to uncouple and fully understand the individual contributions of the interlaminar matrix region and the toughener phase [Reference Stevanovic, Kalyanasundaram, Lowe and Jar149, Reference Groleau, Shi, Yee, Bertram, Sue and Yang153, Reference Shen, Liu, Zhou and Wu154].

5.2 Crack path deviation: energetically favourable paths

With toughened interlaminar regions via various types of interleaving materials (i.e. non-woven veils, films, particles, bucky papers or CNT forests), the crack front may deviate and propagate into the energetically favourable path [Reference Wang, Takao, Matsubara and Kim21, Reference Hojo, Matsuda, Tanaka, Ochiai and Murakami42, Reference Ni, Furtado, Fritz, Kopp, Camanho and Wardle73, Reference İnal, Akbolat, Soutis and Katnam91, Reference Del Saz-Orozco, Ray and Stanley101, Reference van der Heijden, Daelemans, De Schoenmaker, De Baere, Rahier, Van Paepegem and De Clerck116, Reference Quan, Deegan, Alderliesten, Dransfeld, Murphy, Ivanković and Benedictus139, Reference Beckermann and Pickering155–Reference Beylergil, Tanoğlu and Aktaş157], see Fig. 3. The type of loading (i.e. quasi-static or cyclic) can also affect the crack length at which the crack deviated [Reference Hojo, Matsuda, Tanaka, Ochiai and Murakami42, Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck135]. The energetically favourable path is either the intralaminar regions next to the interleaved region or the interleave/lamina interface when the interleave/lamina bonding is relatively weak. Once the crack is diverted into a lower toughness region, it is improbable that further crack growth occurs in the interleaved region. However, when the crack front encounters some resin-rich regions (i.e. in the wavy surface of woven laminates or stitching induced resin pockets of non-crimp fabric laminates), some contribution to the fracture energy absorption from the interleave can be obtained [Reference İnal, Akbolat, Soutis and Katnam91, Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck118, Reference Brugo and Palazzetti158]. Discontinuous interleave patches (i.e. strips) perpendicular to the crack growth direction can be employed to ‘lure’ the crack back to interleaved regions [Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck118, Reference Yasaee, Bond, Trask and Greenhalgh159, Reference Yasaee, Bond, Trask and Greenhalgh160]. Hence, the crack can be arrested in the discontinuous interleaved regions, following a certain length of intralaminar growth. Although this method introduces fluctuations in the R-curves (i.e. varying fracture toughness along the crack path), the average fracture energy of the toughened interlaminar regions can be considerably higher than that of the untoughened interlaminar regions. The width and spacing of the veil strips can be optimised, or specially designed interleave structures [Reference Arnold, Henne, Bender and Drechsler161] can be used to obtain an optimum outcome in terms of interlaminar fracture toughness. Another solution proposed to maintain the crack growth in the interleave is via introducing stress concentrations in the interlaminar region such that the increased local stresses initiate toughening mechanisms further away from the crack tip [Reference Chen, Zhang, Liu, Chen and Guo162]. Introducing tough interphase between the interleave and the neighbouring laminae could also be effective to maintain interlaminar crack growth [Reference Hojo, Matsuda, Tanaka, Ochiai and Murakami42]. Furthermore, increasing the fracture toughness of intralaminar regions can be considered to control the crack path. In this case, a particle toughened resin can be infused/impregnated to the intralaminar regions. Nano-particles (i.e. rubber, nano-silica or carbon nanomaterials) can penetrate the neighbouring laminae due to their smaller size than the inter-fibre spacing of the reinforcement fibres. The fracture enhancement of interleaving methods is relatively more reliable for the crack onset [Reference Beylergil, Tanoğlu and Aktaş157] due to crack deviation, thus a localised/selective toughening can be applied in the vicinity of the regions of stress concentrations such as holes and free-edges [Reference Bilge, Venkataraman, Menceloglu and Papila114]. Likewise, non-woven veils can be introduced to pre-determined machining/drilling sites to suppress the peel-up and push-out delaminations caused by the machining tool [Reference Sun, Hu, Shi, Guo, Zhang and Chen163].

Figure 3. An illustration of crack path deviation from interleaved region to energetically favourable path, i.e. interleave/lamina interface or intralaminar region (the x and z axes represent fibre direction and through-the-thickness directions, respectively).

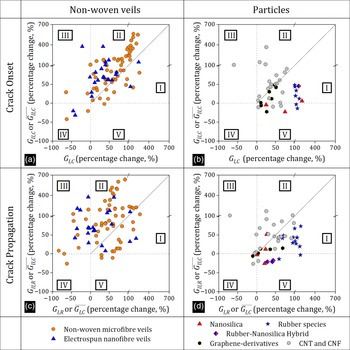

Figure 4. A comparison of percentage changes in crack onset and crack propagation fracture energies in mode-I and mode-II fracture as compared to the respective baseline values for glass or carbon fibre reinforced epoxy composite laminates toughened with non-woven microfibre and electrospun nanofibre veils in (a) and (c) (data extracted from Refs Reference van der Heijden, Daelemans, Meireman, De Baere, Rahier, Van Paepegem and De Clerck36, Reference Quan, Bologna, Scarselli, Ivankovic and Murphy90, Reference Ramirez, Hogg and Sampson92, Reference Kuwata and Hogg95, Reference Kuwata and Hogg100, Reference Quan, Bologna, Scarselli, Ivanković and Murphy102, Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck115, Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck118, Reference Saghafi, Zucchelli, Palazzetti and Minak123, Reference Daelemans, Kizildag, Van Paepegem, D’hooge and De Clerck124, Reference Quan, Deegan, Alderliesten, Dransfeld, Murphy, Ivanković and Benedictus139, Reference Beckermann and Pickering155, Reference Brugo and Palazzetti158, Reference Arnold, Henne, Bender and Drechsler161, Reference Zheng, Liu, Gao and Mai165–Reference Lee, Kim, Hang and Cheong172); and toughened with rubber, nano-silica, CNT, CNF and graphene-derivatives in (b) and (d) (data extracted from Refs Reference Tang, Ye, Zhang and Deng27, Reference Kinloch, Masania, Taylor, Sprenger and Egan30, Reference Quan, Urdániz and Ivanković50, Reference Quaresimin and Varley53, Reference Ahmadi-Moghadam and Taheri54, Reference Körbelin, Kötter, Voormann, Brandenburg, Selz and Fiedler56, Reference Karapappas, Vavouliotis, Tsotra, Kostopoulos and Paipetis62–Reference Zhu, Bakis and Adair64, Reference Patel, Potluri, Yousaf and Wilkinson69, Reference Mirjalili, Ramachandramoorthy and Hubert70, Reference Liu, Shen and Zhou78, Reference Gouda, Chatterjee, Barhai, Jawali, Rahatekar and Wisnom173–Reference Arai, Noro, Sugimoto and Endo180). Note that dissolvable non-woven veils and multiscale toughened composites are not included in the plots, and both axes in all the plots are bi-linearly scaled for convenience.

6.0 Trends and research opportunities

6.1 Mode-I and II fracture: effect of particles and non-woven veils

It has been reviewed in the previous sections that various tougheners can be used for improving the interlaminar and intralaminar fracture toughness of composite laminates. Depending on the toughener type, process parameters and conditions explored, a varying level of success has been observed in enhancing the fracture properties. Thus, a straightforward evaluation is presented in Fig. 4 by using the data published in the literature to compare the enhancements achieved in interlaminar fracture toughness with different toughener materials. A comparison of the percentage change in the interlaminar fracture energies of mode-I vs mode-II obtained by non-woven veils and particle tougheners is shown (see Fig. 4). The fracture energies at crack onset (i.e.

![]() ${G_{I,C}}$

and

${G_{I,C}}$

and

![]() ${G_{II,C}}$

) and during crack propagation (i.e.

${G_{II,C}}$

) and during crack propagation (i.e.

![]() ${G_{I,R}}$

and

${G_{I,R}}$

and

![]() ${G_{II,R}}$

) are evaluated for non-woven veils and particle tougheners separately. The plots in Fig. 4 are divided into five regions as follows: region-I, the toughener is more beneficial to mode-I as compared to mode-II; region-II, the toughener is more beneficial to mode-II as compared to mode-I; region-III, the toughener is beneficial to mode-II but detrimental to mode-I; region-IV, the toughener is detrimental for both mode-I and mode-II; and region-V, the toughener is beneficial for mode-I but detrimental for mode-II. Figure 4(a) and (c) compare the percentage changes in fracture energies at the crack onset (i.e.

${G_{II,R}}$

) are evaluated for non-woven veils and particle tougheners separately. The plots in Fig. 4 are divided into five regions as follows: region-I, the toughener is more beneficial to mode-I as compared to mode-II; region-II, the toughener is more beneficial to mode-II as compared to mode-I; region-III, the toughener is beneficial to mode-II but detrimental to mode-I; region-IV, the toughener is detrimental for both mode-I and mode-II; and region-V, the toughener is beneficial for mode-I but detrimental for mode-II. Figure 4(a) and (c) compare the percentage changes in fracture energies at the crack onset (i.e.

![]() ${G_{I,C}}$

and

${G_{I,C}}$

and

![]() ${G_{II,C}}$

) for non-woven veils and particles, respectively. Similarly, Fig. 4(b) and d compare the percentage change in fracture energies during crack propagation (i.e.

${G_{II,C}}$

) for non-woven veils and particles, respectively. Similarly, Fig. 4(b) and d compare the percentage change in fracture energies during crack propagation (i.e.

![]() ${G_{I,R}}$

and

${G_{I,R}}$

and

![]() ${G_{II,R}}$

).

${G_{II,R}}$

).

Numerous research articles show that various toughening routes can modify interlaminar fracture toughness. In some publications, the data for both mode-I and mode-II fracture energies are not available for the material system explored, while most of the fracture studies are focused on mode-I fracture properties. It is understandable that the mode-I fracture requires less energy compared to mode-II, hence considered to be more critical. Additionally, mode-I fracture energies provide a basis for direct comparison between fracture energies of unreinforced matrix and composite laminates. However, mode-II fracture energy is also an important property as it can play a significant role in the case of in-plane shear dominant loading conditions [Reference Greenhalgh and Hiley11, Reference Nettles and Scharber164]. In addition to that, the interpretation of resulting fracture energies varies in the literature. For example, only

![]() ${G_{I,R}}$

and

${G_{I,R}}$

and

![]() ${G_{II,R}}$

are reported in some publications whereas some other publications only publish

${G_{II,R}}$

are reported in some publications whereas some other publications only publish

![]() ${G_{I,C}}$

and

${G_{I,C}}$

and

![]() ${G_{II,C}}$

before any R-curve behaviour is observed. Thus, some of the data points in the crack onset graphs (Fig. 4(a) and (c)) may not have the corresponding values in crack propagation (Fig. 4(b) and (d)) or vice versa. Besides, a number of publications feature average fracture energies for mode-I and mode-II (i.e.

${G_{II,C}}$

before any R-curve behaviour is observed. Thus, some of the data points in the crack onset graphs (Fig. 4(a) and (c)) may not have the corresponding values in crack propagation (Fig. 4(b) and (d)) or vice versa. Besides, a number of publications feature average fracture energies for mode-I and mode-II (i.e.

![]() $\overline {{G_{I,C}}} $

and

$\overline {{G_{I,C}}} $

and

![]() $\overline {{G_{II,C}}} $

), which is to represent

$\overline {{G_{II,C}}} $

), which is to represent

![]() ${G_{I,R}}$

and

${G_{I,R}}$

and

![]() ${G_{II,R}}$

, respectively. In fact, the crack onset and crack propagation are easy to distinguish in mode-I fracture tests due to the predominantly stable crack growth. However, mode-II fracture tests may result in early unstable crack growth and clear identification of

${G_{II,R}}$

, respectively. In fact, the crack onset and crack propagation are easy to distinguish in mode-I fracture tests due to the predominantly stable crack growth. However, mode-II fracture tests may result in early unstable crack growth and clear identification of

![]() ${G_{II,C}}$

and

${G_{II,C}}$

and

![]() ${G_{II,R}}$

is not always straightforward. In such cases, when mode-II fracture energy is disclosed in the form of a single value (such as

${G_{II,R}}$

is not always straightforward. In such cases, when mode-II fracture energy is disclosed in the form of a single value (such as

![]() $\overline {{G_{II,C}}} $

or

$\overline {{G_{II,C}}} $

or

![]() ${G_{II,C}}$

), it is assumed that the given value represents both

${G_{II,C}}$

), it is assumed that the given value represents both

![]() ${G_{II,C}}$

and

${G_{II,C}}$

and

![]() ${G_{II,R}}$

, for the sake of completeness of Fig. 4. As a result, the number of data used for the current evaluation is limited to some extent, especially for particle tougheners.

${G_{II,R}}$

, for the sake of completeness of Fig. 4. As a result, the number of data used for the current evaluation is limited to some extent, especially for particle tougheners.

It can be seen in Fig. 4(a) that non-woven veils are generally more beneficial for

![]() ${G_{II,C}}$

compared to

${G_{II,C}}$

compared to

![]() ${G_{I,C}}$

. The majority of the data points are in region-II. The same applies to Fig. 4(c), but the data points are more scattered. This observation is consistent with some published literature, where mode-II fracture toughness is enhanced more than mode-I fracture toughness in the case of non-woven veil interleaves [Reference van der Heijden, Daelemans, Meireman, De Baere, Rahier, Van Paepegem and De Clerck36, Reference Arouche, de Freitas and de Barros97, Reference Daelemans, Kizildag, Van Paepegem, D’hooge and De Clerck124]. The data points in regions III, IV and V of Fig. 4(c) indicates that the crack propagation energies are lower than the baseline values. It may indicate that both extrinsic and intrinsic toughening mechanisms of non-woven veils have not effectively contributed to the energy dissipation in crack growth, which could be related to the crack path deviation, as discussed in Section 5.2. Similarly, high aspect ratio particles (i.e. CNT, CNF and graphene-derivatives) are not only beneficial for

${G_{I,C}}$

. The majority of the data points are in region-II. The same applies to Fig. 4(c), but the data points are more scattered. This observation is consistent with some published literature, where mode-II fracture toughness is enhanced more than mode-I fracture toughness in the case of non-woven veil interleaves [Reference van der Heijden, Daelemans, Meireman, De Baere, Rahier, Van Paepegem and De Clerck36, Reference Arouche, de Freitas and de Barros97, Reference Daelemans, Kizildag, Van Paepegem, D’hooge and De Clerck124]. The data points in regions III, IV and V of Fig. 4(c) indicates that the crack propagation energies are lower than the baseline values. It may indicate that both extrinsic and intrinsic toughening mechanisms of non-woven veils have not effectively contributed to the energy dissipation in crack growth, which could be related to the crack path deviation, as discussed in Section 5.2. Similarly, high aspect ratio particles (i.e. CNT, CNF and graphene-derivatives) are not only beneficial for

![]() ${G_{I,C}}$

but also for

${G_{I,C}}$

but also for

![]() ${G_{II,C}}$

(see Fig. 4(b)). CNT and CNF particles maintain such trend in crack propagation (see Fig. 4(d)), while graphene-derivatives tend to be relatively more beneficial for

${G_{II,C}}$

(see Fig. 4(b)). CNT and CNF particles maintain such trend in crack propagation (see Fig. 4(d)), while graphene-derivatives tend to be relatively more beneficial for

![]() ${G_{I,R}}$

. This may be attributed to tubular/fibrous morphology of CNT and CNF particles similar to non-woven veils, which can bridge the crack faces [Reference Khan and Kim77, Reference Liu, Shen and Zhou78]. Near-spherical particle tougheners of rubber, nano-silica and their hybrids are mainly beneficial for

${G_{I,R}}$

. This may be attributed to tubular/fibrous morphology of CNT and CNF particles similar to non-woven veils, which can bridge the crack faces [Reference Khan and Kim77, Reference Liu, Shen and Zhou78]. Near-spherical particle tougheners of rubber, nano-silica and their hybrids are mainly beneficial for

![]() ${G_{I,C}}$

(see Fig. 4(b)). During crack propagation, the contribution of nano-silica is comparatively limited while rubber particles maintain their trend being relatively more beneficial to mode-I fracture (see Fig. 4(d)). Thermoplastic particles are not included in Fig. 4 as the particle formation depends on several aspects, as discussed in Section 2. Nonetheless, it should be noted that the majority of the data in Fig. 4(a) and (c) are obtained from undissolvable thermoplastic non-woven veils.

${G_{I,C}}$

(see Fig. 4(b)). During crack propagation, the contribution of nano-silica is comparatively limited while rubber particles maintain their trend being relatively more beneficial to mode-I fracture (see Fig. 4(d)). Thermoplastic particles are not included in Fig. 4 as the particle formation depends on several aspects, as discussed in Section 2. Nonetheless, it should be noted that the majority of the data in Fig. 4(a) and (c) are obtained from undissolvable thermoplastic non-woven veils.

6.2 Multi-scale toughening and multi-functionality

The multiscale toughening methods refer to the processing routes that utilise two or more tougheners, which could be of different scales and different morphologies, to improve the fracture properties of composite laminates. In comparison, multifunctionality in composites offers superior material properties for engineering design requirements typically including, but not limited to, electrical, mechanical and thermal properties. Additional particle phases can be incorporated together with non-woven veils to induce multifunctionality while enhancing fracture resistance and tolerance. It can be achieved by ensuring the co-existence of the non-woven veil and the additional phase in the interlaminar region.

Non-woven veils can be used as a carrier of additional phases such as carbon nanotubes (CNT) [Reference Quan, Mischo, Binsfeld, Ivankovic and Murphy71, Reference Quan, Mischo, Li, Scarselli, Ivanković and Murphy72, Reference Zheng, Huang, Liu, Gao and Mai144, Reference Lee, Kim, Hang and Cheong172], graphene nanoplatelets (GNP) [Reference Quan, Mischo, Binsfeld, Ivankovic and Murphy71], carbon black [Reference Wang, Ma, Chen and Dai138] and silver nanowires [Reference Guo, Yi, Liu and Liu170]. The additional phase can be deposited onto the veil fibres by vacuum filtering [Reference Zheng, Huang, Liu, Gao and Mai144], hand brushing [Reference Wang, Ma, Chen and Dai138], spray coating [Reference Quan, Mischo, Binsfeld, Ivankovic and Murphy71, Reference Quan, Mischo, Li, Scarselli, Ivanković and Murphy72] or immersion coating [Reference Guo, Yi, Liu and Liu170]. The deposited additional phase directly affects the veil fibre/matrix adhesion and accordingly results in a change in the fracture properties. It may lead to an increase or decrease in fracture toughness, which depends on many aspects such as the veil fibre, additional phase-resin compatibility, distribution of the additional phase and final morphology of the veil. In particular, the distribution of the additional phase is vital as an uneven distribution could lead to varying interlaminar fracture toughness. This approach is likely to minimise the particle content used to achieve enhanced fracture properties, similar to coating reinforcement fibres with particle tougheners [Reference Tsai, Carolan, Sprenger and Taylor35]. This approach can also be explored to easily transfer multi-functional particles that tend to agglomerate when mixed into the resin (e.g. carbon-based nano-fillers), as discussed in Section 2.

Another way to achieve multiscale toughening using non-woven veils is via blending the nano-scale particles into the electrospinning solution, then electrospinning nanofibre veils [Reference Bilge, Ozden-Yenigun, Simsek, Menceloglu and Papila113, Reference Li, Liu, Zhu, Li, Jia, Wang, Li and Yang125, Reference Hamer, Leibovich, Green, Avrahami, Zussman, Siegmann and Sherman166, Reference Eskizeybek, Yar and Avcı181]. In this approach, the additional phase is not deposited on the surface of the veil but embedded in the veil fibres and a particle-modified fibre is obtained. Depending on the type and amount of the additional phase, the mechanical properties (i.e. stiffness and strength) and the morphology of electrospun nanofibre can be altered. This can lead to enhanced energy absorption during fibre bridging and results in enhanced fracture toughness, in comparison to the neat veils [Reference Hamer, Leibovich, Green, Avrahami, Zussman, Siegmann and Sherman166, Reference Eskizeybek, Yar and Avcı181]. When electrospun nanofibres are produced using a thermoplastic with a low melting point, the additional phase is dispersed at the interlaminar region as nanofibres melt and phase separate [Reference Li, Liu, Zhu, Li, Jia, Wang, Li and Yang125].

Another approach to obtain a multiscale toughened composite laminate with non-woven veils is either by using a particle blended resin as the matrix phase or by obtaining additional particulate phase at the interlaminar region as a result of phase separation after dissolving [Reference Saghafi, Zucchelli, Palazzetti and Minak123, Reference Daelemans, Kizildag, Van Paepegem, D’hooge and De Clerck124, Reference Quan, Alderliesten, Dransfeld, Murphy, Ivanković and Benedictus141, Reference Zheng, Liu, Gao and Mai165]. This approach causes no direct changes in either the fibre properties or the fibre-matrix interface of the veil fibres. Instead, the additional phase toughens the matrix that surrounds the non-woven veil. When a particle blended matrix is infused into non-woven veil interleaved fibre preforms, intralaminar regions (i.e. within lamina) are toughened with particles, while interlaminar regions are multiscale toughened with the non-woven veil and the particles. Moreover, as highlighted in Section 5.1, the thickness of interlaminar region can affect the fracture process zone at the crack tip and influence the fracture toughness enhancement. Therefore, this multi-scale toughening approach can lead to a larger fracture process zone due to the increased interlaminar thickness, which can aid to obtain a higher contribution to the fracture toughness from the particle blended matrix.

A list of some multi-scale toughened composites is given in Table 1 with non-woven veil toughening and multiscale toughening. It can be seen that multiscale toughening offers higher fracture toughness enhancements when compared to non-woven veil interleaving. These enhancements can be additive or even synergistic. However, additional tougheners cannot contribute to fracture toughness or even become detrimental above a specific limit [Reference Quan, Mischo, Binsfeld, Ivankovic and Murphy71, Reference Li, Liu, Zhu, Li, Jia, Wang, Li and Yang125]. Nevertheless, by adjusting the proportions of both toughener phases, multiscale toughened systems could be tailored to obtain desired fracture toughness enhancement in mode-I and mode-II.

Table 1. A comparison of fracture energy enhancement via multiscale toughening in composite laminates with non-woven veils and particles

aPolysulfone

bPolyphenylene sulfide

cPolyamide

dPolystyrene-co-glycidyl methacrylate

ePolyacrylonitrile

In addition to the fracture toughness enhancement, multifunctionality is desirable in composite laminates to combine various material properties. For example, non-woven veils can be selected such that, following damage events, the veil fibres melt upon the application of heat and bond the fracture surfaces together. Therefore, the fracture toughness and other mechanical properties can be recovered [Reference Varley and Parn182, Reference Gao, Liu, Wu and Zhong183]. Vibration damping is another important capability of thermoplastic-based interleaving due to their viscoelastic behaviour [Reference Kishi, Kuwata, Matsuda, Asami and Murakami184], which applies to thermoplastic non-woven veils [Reference Nash, Ray, Young and Stanley81, Reference Beylergil, Tanoğlu and Aktaş93, Reference Ni, Wen, He, Yi, Zhao and Xu185]. However, thermoplastic non-woven veils significantly reduce the electrical conductivity of composite laminates. Electrical conductivity is of importance to improve an aircraft’s ability to withstand lightning strikes. The conventional way to provide lightning strike protection is using a mesh of conductive material (i.e. metallic mesh), which adds to the overall weight. Hence, improving the electrical conductivity (i.e. decreasing the electrical resistivity) with various conductive particles carried by non-woven veils could lead to significant weight savings while improving the fracture toughness [Reference Quan, Mischo, Li, Scarselli, Ivanković and Murphy72, Reference Guo, Yi, Liu and Liu170, Reference Guo, Yi, Rudd and Liu171, Reference Brown, Robert, Koutsos and Ray186, Reference Barjasteh, Sutanto, Reddy and Vinh187]. Furthermore, enhanced electrical conductivity could be explored for structural health monitoring [Reference Brown, Robert, Koutsos and Ray186]. Even though the additional phases may not be particularly beneficial for the fracture properties, the resulting fracture toughness can still be higher than that of the untoughened composite laminate. A list of some of the published literature on multiscale toughened multifunctional composite laminates with enhanced electrical properties in addition to enhanced fracture energy is given in Table 2.

Table 2. A comparison of enhanced electrical properties and fracture toughness in multiscale toughened multifunctional composite laminates with non-woven veils and particles

aPolypropylene

bPolyethylene terephthalate

The X, Y and Z represent the fibre, transverse and through-the-thickness directions in a unidirectional composite laminate, respectively

6.3 Mechanical properties: effect of particles and non-woven veils

In the previous sections, the focus was mainly on the quasi-static fracture conditions. But various service conditions such as fatigue, low-velocity impact, post-impact in-plane loading, high strain loading and environmental ageing conditions must be considered to understand the role of third-phase toughening materials on the mechanical behaviour under such loading conditions. With various tougheners, the accumulation and propagation of matrix cracks can be suppressed—leading to lower crack density and delaying final failure (e.g. increasing fatigue life) [Reference Knoll, Riecken, Kosmann, Chandrasekaran, Schulte and Fiedler188–Reference Zhou, Pervin, Jeelani and Mallick192]. Interlaminar fatigue crack growth rates can be significantly reduced as tougheners enhance interlaminar fracture energy and suppress the growth of delamination [Reference Hojo, Matsuda, Tanaka, Ochiai and Murakami42, Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck135, Reference Fenner and Daniel193, Reference Brugo, Minak, Zucchelli, Yan, Belcari, Saghafi and Palazzetti194]. Similarly, high-strain response can be improved by using third-phase tougheners [Reference Özden-Yenigün, Bilge, Sünbüloğlu, Bozdağ and Papila195]. The enhanced laminate fracture properties because of the addition of tougheners are also beneficial to improve the damage resistance and tolerance of laminates to low-velocity impact loading. By reducing the extent of impact-induced delamination and damage (i.e. size, depth and area) near the impacted region, the residual compressive strength of laminates can be improved [Reference Xin, Sarasini, Tirillò, Bavasso, Sbardella, Lampani and De Rosa75, Reference Walker, Sohn and Hu103, Reference Hogg104, Reference Daelemans, van der Heijden, De Baere, Rahier, Van Paepegem and De Clerck115, Reference Ni, Wen, He, Yi, Zhao and Xu185, Reference Landowski, Strugała, Budzik and Imielińska196, Reference McGrail and Jenkins197]. However, the selection of tougheners for composite laminates should consider the fracture properties and also take into account in-service environmental conditions. Evaluating the effectiveness of the toughener phases under hygro-thermal conditions, such as cryogenic or elevated temperatures [Reference Carolan, Ivankovic, Kinloch, Sprenger and Taylor15, Reference Xu, Du, Liu, Guo and Mai198, Reference Khan, Iqbal, Munir and Kim199], hot-wet conditions [Reference Nash, Ray, Young and Stanley81, Reference Nash, Young and Stanley136, Reference Nash, Young and Stanley137, Reference Tsotsis200], thermal ageing [Reference Kwon, Shin, Kim, Baek, Park, DeVries and Park201], is of importance to explore the merits of third-phase tougheners in engineering applications. For example, the properties of tougheners and matrix change with temperature, directly affecting toughening mechanisms [Reference Xu, Du, Liu, Guo and Mai198, Reference Khan, Iqbal, Munir and Kim199]. Similarly, moisture absorption can affect fracture toughness and post-impact properties when laminates are exposed to hot-wet conditions [Reference Nash, Ray, Young and Stanley81, Reference Nash, Young and Stanley136, Reference Nash, Young and Stanley137, Reference Arnold, Henne, Bender and Drechsler161, Reference Tsotsis200].

In addition to experimental studies, understanding the structure-property relationships via analytical and computational modelling is essential. Identifying intralaminar and interlaminar toughening mechanisms, and their contribution, at multiple length scales is necessary to fully understand the sequence and interaction of various mechanisms and toughener types. Models that can accommodate multiple material length scales can play a significant role to determine the contribution of individual toughening mechanisms to the fracture toughness of laminates at macroscale [Reference Hsieh, Kinloch, Masania, Lee, Taylor and Sprenger34, Reference Huang, Hu and Liu131, Reference Huang and Zhao132, Reference Hsieh, Kinloch, Taylor and Kinloch191, Reference Bray, Dittanet, Guild, Kinloch, Masania, Pearson and Taylor202]. Moreover, statistical and probabilistic models are necessary to understand the influence of material variability on fracture properties [Reference Ramirez, Hogg and Sampson92, Reference Jones, Kinloch, Michopoulos, Brunner and Phan203]. By identifying the critical factors contributing to the enhancement of fracture properties, composite laminates with various tougheners could be tailored to specific design requirements.

7.0 Concluding remarks

This article reviewed the interlaminar fracture toughness of composite laminates with particle fillers and non-woven fibre veils. The benefits and limitations of both toughening approaches are discussed. The fracture toughness enhancements due to various tougheners are evaluated, and recent research on multiscale toughened multifunctional composite laminates is also compared. The following key points are drawn:

-

• Although resin infusion/impregnation methods can effectively be used to introduce particle tougheners (e.g. nano-scale particles) into interlaminar and intralaminar regions, an optimum particle content should be determined not only to obtain enhanced fracture toughness but also to prevent particle agglomeration and maintain the resin properties (e.g. viscosity and glass transition temperature) for processability. For example, low aspect ratio particles such as nano-silica and rubber are particularly promising for low-cost processing methods. In contrast, high aspect ratio particles (e.g. CNTs, CNFs and graphene derivatives) offer significant improvements in fracture toughness, see Fig. 4, but can considerably alter the resin viscosity and lead to particle agglomeration.

-