Implications

The growth of human populations has increased the demand for animal proteins for human food, creating increased pressure on natural resources. Concurrently, consumers are more concerned with the environmental impact of food production. In response, animal enterprises need to develop novel and sustainable production methods to meet these increased demands. Insects, which can bioconvert organic waste (e.g. vegetable waste and manure) into a novel animal feed protein source are currently under investigation. This review will discuss the current state of mass rearing of insects as a feed source for pigs.

Introduction

The global demand for protein as food and feed is increasing as human population increases and food consumption patterns change in response to economic growth. A key example is the increased buying power of the emerging Asian middle class who are consuming more premium imported products such as meat. Furthermore, consumption of pork has increased domestically in Australia over the last decade (Allen Consulting, 2017). The Australian pork industry, with its existing strong reputation for innovation, is well placed to lead research, development and adoption of novel feed products in response to this increased global demand (Bittner et al., Reference Bittner, Ashman, Hastie, van Barneveld, Hearn, Thomson and Dunshea2017). The production of animal protein for human consumption is frequently scrutinised by the general public for the impact (both real and perceived) upon greenhouse gas (GHG) emissions, land and water use, and impacts upon biodiversity (Williams and Price, Reference Williams and Price2010). Yet, the production of meat (and fibre) continues to be important cultural and economic practices. Australian livestock agriculture industries have been increasing in size over the past two decades and currently account for an estimated 2.7% of gross domestic product, 58% of land use and 59% of water extractions (Jackson et al., Reference Jackson, Zammit and Hatfield-Dodds2018). According to the Food and Agriculture Organization of the United Nations, the goal of livestock production is to ensure that the system does not create undue pressure on ecosystems, biodiversity, land and forest resources and water quality. This view is supported by the Australian pork industry that is focused on reducing the environmental impact of the industry by improving the use of resources and managing emissions that contribute to global climate change.

The provision of feed protein sources for animal production is responsible for a large portion of the associated environmental impact of livestock industries. As the demand for animal proteins increases, the gap between supply and demand of feed protein will continue to increase. Soybean meal, the major feed plant protein source included in monogastric animal diets, has a large environmental impact due to land and water use to grow soybeans and the large-scale transportation of this commodity (Wiedemann et al., Reference Wiedemann, McGahan and Murphy2016). Soybean meal availability for animal feed can be limited due to its use in human food streams and low productivity; and in Australia most soybean meal is imported from the US and South America (M’Gee, Reference M’Gee2011). While other feed protein sources such as meat meals and tallow are balanced sources of amino acids (AAs) and are an efficient use of waste products from the animal production industries, they require processing and transport to be suitable for use in monogastric animal diets. Replacement of soybean meal with locally derived protein sources will likely lead to reductions in associated land use, energy use and emissions. A potential alternate feed protein source previously unexploited by large-scale production is insects. With feed conversion ratios approaching 2.0 (van Huis, Reference van Huis2013), the efficiency of production of insects is superior to traditional domestic animal species.

Insects are cold-blooded, rapid growing, protein and lipid rich, require minimal space and contribute to the natural diet of many species. Further, the waste produced by insect production is a valuable source of organic fertiliser that can be utilised in crop production, thus creating a closed circular economy. Insects, such as fly larvae, can bioconvert products such as vegetables and fruits, grain and grain residues, manure and animal remains into proteins (35% to 55% CP) and lipids (10% to 40%). The FAO (2011) suggests that a major initiative to reduce food waste would involve cooperation between farmers both to reduce oversupply and to find alternative streams in which waste can be efficiently used. Insects commonly examined for commercial rearing include black soldier flies (BSFs; Hermetia illucens), common houseflies (Musca domestica) and yellow mealworms (Tenebrio molitor). Black soldier flies are endemic to Australia, do not bother humans as they do not eat as adults and do not naturally carry pathogens, making them an ideal candidate for large-scale rearing. Fly larvae are found to naturally grow in manure from pigs, cattle and poultry. Fewer substrates have been explored for rearing mealworms. Several recent reviews have discussed the potential use of insects as animal feed (Rumpold and Schlüter, Reference Rumpold and Schlüter2013, Makkar et al., Reference Makkar, Tran, Heuzé and Ankers2014, Wang and Shelomi, Reference Wang and Shelomi2017). This review will discuss the potential for insect-derived protein to contribute to the protein feed sources available to the Australian pig production industry. While this review will not discuss the technical processes of rearing insects on a commercial scale, it is imperative that rearing processes are efficient in terms of output, energy/resource usage and GHG emissions to remain sustainable. For example, rearing temperature can impact the conversion efficiency of insects, and if climate control is required the energy requirements of the system would be greater (Rumpold and Schlüter, Reference Rumpold and Schlüter2013). The insect farming industry is in its infancy, with large scale-research and investment required in Australia and worldwide to confirm the safety, reliability, sustainability and potential contribution of insects as an animal feed source.

Insects as feed and food

The most commonly consumed insects globally are beetles, caterpillars and crickets (van Huis et al., Reference van Huis, Van Itterbeeck, Klunder, Mertens, Halloran, Muir and Vantomme2013). As there are more than 40 insect species that are endemic to Australia (Rumpold and Schlüter, Reference Rumpold and Schlüter2013), there is likely an appropriate insect species that can be tailored for individual production industries and types. The large-scale production of insects may contribute to filling the feed protein gap in a more efficient manner, as demonstrated by crickets (up to 80% digestible material) who are two times as efficient as chickens in converting feed to meat; four times as efficient as pigs and 12 times more efficient than cattle (van Huis et al., Reference van Huis, Van Itterbeeck, Klunder, Mertens, Halloran, Muir and Vantomme2013). Further, to produce a similar quantity of protein, pork or chicken enterprises would need 2 to 3.5 ha land, while insects would require only 1 ha of land to produce equivalent insect (mealworm) protein (van Huis et al., Reference van Huis, Van Itterbeeck, Klunder, Mertens, Halloran, Muir and Vantomme2013). In a review commissioned nearly a decade ago, the Australian poultry cooperative research centre concluded that while there is potential for insects to be used as a protein feed source for poultry production systems, further assessment of cost-benefits, investigations into feed security and growth responses to insects are required (Khusro et al., Reference Khusro, Andrew and Nicholas2012).

Life cycle assessments consider emissions throughout the production system and include the emissions from inputs such as animal feed. Replacing the soybean meal content of pig diets with larvae reared on waste is modelled (by attributing life cycle assessment) to result in reduced global warming potential and land use, though a consequential life cycle assessment demonstrated contradictory results (van Zanten et al., Reference van Zanten, Bikker, Meerburg and de Boer2018). Substitution of feed products with alternate by-products or co-products will not always result in a net reduction of the overall environmental impact, as in complex diet formulations direct substitutions are not always possible and additional ingredients may need to be included to ensure the resultant diets remain balanced. Further, the processing and transportation of insect proteins contribute to the overall emission and energy use which may not always be favourable when compared to traditional protein feeds. While water use by insect rearing processes has not been directly assessed, drought-resistant larvae exist and are predicted to have lower water, and certainly land use, compared to terrestrial animals and crops.

The Australian pork industry is dedicated to producing environmentally sustainable pork that also maintains a competitive pork industry in Australia. It is widely accepted that the feed costs associated with animal production systems can account for 60% to 70% of the cost of the entire enterprise. The high cost of feed is particularly impactful in pig production systems, with Australia having some of the highest grain prices in the world, leaving Australian producers especially vulnerable. For example, a recent downturn in pork consumption combined with increased feed costs lead to a 1.7% reduction in the number of Australian pigs slaughtered (Australian Pork Limited, 2019). Australian pork industries already contribute to reducing waste by heavily utilising agricultural and food processing by-products (such as yeast, tallow and oil seed pressings) as animal feed. Further, Australian piggeries are located in close proximity to agriculture and food processing facilities where waste is produced, and many piggeries have infrastructure in place to handle by-products. Thus, pig production systems are ideally placed to develop and adopt novel feed sources such as insects. This aligns directly with the seven main reasons for which the pork industry has developed a sustainability strategy (Australian Pork Limited, 2013).

Swill feeding pigs (such as processor and catering waste, non-processed animal products and offal) is illegal in Australia. This waste contributes to the estimated >5 million tonnes of food wasted at the production and pre-consumer stage in Australia each year, with over 75% of this waste sent to landfill (Pickin et al., Reference Pickin, Randell, Trinh and Grant2018). It is often cheaper for food producers to dispose of waste rather than to find methods to utilise non-sellable food and feed waste. However, insects can bioconvert waste into a high-protein and high-fat products potentially suitable as animal feed sources. A large variety of insects are suitable for intensive production, meaning an ideal insect candidate is available for most environmental growing conditions and feed sources worldwide. While insects may provide a viable method via which food and feed wastes can be bioconverted, it is unlikely that these waste streams would provide a sufficient volume of substrate to produce a protein source in adequate volumes to totally replace soybean meal and other common protein feed sources. Assuming a production of 5 million tonnes of food waste and a feed conversion rate of 2.0, the contribution of insects reared on feed waste in Australia would only be 2.5 million tonnes, which would be able to only partially replace protein feed imports. However, insects could contribute to the available feed and manure waste management processes of various industries, while concurrently producing a valuable feed product.

The current state of insect production and uptake

Recently, significant investments in insect rearing start-up companies have been made in Australia and worldwide. At the beginning of 2019, at least 42 European companies were involved in the production of insect meal (Mancuso et al., Reference Mancuso, Pippinato and Gasco2019), which according to the International Platform of Insects for Food and Feed (IPIFF) produced approximately 6000 tonnes of insect meal per year. In 2017, the insect rearing company Ynsect, a French company specialising in rearing insects for aquaculture with the goal of expanding into pig, poultry and pet foods in the future, raised AUD50 million from private investors (Jasper, Reference Jasper2017). To date, no data are available regarding large-scale commercial rearing of insects, though the IPIFF predicts that insect meal production will increase to 200 000 tonnes in 2020 and 1.2 million tonnes in 2025 (IPIFF, 2019). These volumes are still well below the current production levels of protein feeds and co-products produced, and this industry, which is in its infancy, requires large investment, research and development to grow into a viable competitive commodity. Research into automation processes is required to reduce the current high costs associated with production. Price thus remains a deterrent to larger adoption of insect proteins as current production levels remain low. European prices for BSF larvae range from €2 to 9/kg (approximately. AUD3 to 14) (Mancuso et al., Reference Mancuso, Pippinato and Gasco2019).

The insect protein association of Australia (IPAA) was recently established to promote the use and role of insect protein within the Australian food and feed industries. The IPAA currently has 11 Australian member companies listed as openly trading or developing insects as food or feed, though not all currently operating companies are members of IPAA. While the Australian climate is well suited, currently no Australian facilities are capable of mass rearing insects, and no best practices have been developed anywhere worldwide. Mass rearing and breeding of insects will not require complex infrastructure, though the environmental conditions need to be managed to optimise insect growth. The development and adoption of new technologies across agricultural sectors will ensure that Australia remains a world leading producer of high-quality and safe animal protein for human consumption. Australia is uniquely placed to develop a sophisticated zero waste food production system as there is both available space and access to waste products that can be distributed in a safe manner.

A significant barrier to the uptake of insects as human feed is the aversion to eating insects by Western consumers, likely driven by the association of insects with disease (Bartrim, Reference Bartrim2017). Insects have historically contributed to the diets and cultural practices of humans in a manner that is often overlooked. For example, the bogong moths (Euxoa = Agrotis infusa) which migrate to the mountains of New South Wales in populations of the millions, were feasted upon by Indigenous Australian populations for weeks to months each year (McKeown, Reference McKeown1944). Modern descriptions of culinary practices and art of Indigenous Australians underplay and, in most instances, completely overlook the role of insects (Meyer‐Rochow and Changkija, Reference Meyer‐Rochow and Changkija1997), and the modern diet consumed by Indigenous Australians has been heavily influenced by European diets. Despite a rich cultural history of entomophagy throughout Asia, Australia and Africa, consumers from Western societies are more likely to adopt insects as an animal feed rather than as a human food protein source. Marketplace acceptance of insects as food in Western societies is primarily driven by personal attitudes towards food (i.e. acceptance of novel foods), cultural and familial exposure and interest in the environmental impact and sustainability of the food (Verbeke, Reference Verbeke2015). Attitudes towards insects as an animal feed source are thought to be positive, as highlighted by a survey of agricultural stakeholders and farmers in Belgium (Verbeke et al., Reference Verbeke, Spranghers, De Clercq, De Smet, Sas and Eeckhout2015). Further, German dog-owning consumers were willing to accept insects for feeding meat- or egg-producing animals or domestic pets (Von Jeinsen and Heise, Reference Von Jeinsen and Heise2018).

It is worth considering the environmental and socio-economic benefits of this novel industry, which may surpass the current projections based solely on costs of input v. output. Quantifying the environmental benefits of insect production systems is less straightforward, as demonstrated by contrasting responses from life cycle assessments (van Zanten et al., Reference van Zanten, Bikker, Meerburg and de Boer2018). Insects can also be produced as bait for smaller mammals, for their medicinal values and for the provision of fertiliser. These properties are particularly beneficial to the production of small-scale farms in developing countries. These small-scale practices may be less viable economically as stand-alone farms; but when considered as additional income streams or to produce protein sources for use as feed or food, there would be localised economic empowerment benefits. This is particularly true for the development of food and economic security in developing nations. For example, producing insects in orphanages in the Democratic Republic of Congo can generate significant income (approximately US$300/month), while also producing a sustainable and nutritious food and feed source (Franklin et al., Reference Franklin, Brandt and Ureda2018).

The production of insects on a commercial scale will require the establishment of a new supply chain with contributions from farmers, nutritionists, biochemists, processors and marketers. As summarised by Aarts (Reference Aarts2019), the food and feed industries need to work together to promote the advancement and acceptance of the insect production industries by getting the science right, not compromising on food/feed safety, innovating, thinking outside the norm and collaborating. The ethical, legal and safety implications of insect production in Australia must be considered and framework developed as the industry progresses and grows.

Legal implications

The legalities of feeding insects to animals differ worldwide, as summarised for key regions (European Union (EU), US, China, Mexico, Australia and Canada) by Lähteenmäki-Uutela et al. (Reference Lähteenmäki-Uutela, Grmelová, Hénault-Ethier, Deschamps, Vandenberg, Ai, Yumei, Baoru and Nemane2017). In Australia, edible insects are currently classified as ‘novel food’ for human consumption. According to the Department of Agriculture and Water Resources, in Australia insects are currently fed to fish, poultry, pigs and pets. Animal feed materials in Australia are regulated by the Australian Pesticides and Veterinary Medicine Authority (AVPMA). Feed products do not require registration with the AVPMA if they (•) are fed as part of a normal diet; (•) are intended solely for nutritional purposes; (•) do not contain medications or other active ingredients and (•) do not make any health, production or performance claims. Insects are, therefore, not required to be registered. As farmed animals, however, insects are prohibited from being fed manure, catering waste or unprocessed meat products.

As a novel food source, Australian regulations (Food standards Australia New Zealand (FSANZ)) dictate that products containing insects undergo pre-market assessment (unless previously approved as are mealworms, crickets and mealworm beetles currently) and be approved by FSANZ before the product can be sold.

In Europe, the IPIFF has requested that European feed legislation be updated to allow the feeding of insects reared on vegetable substrates for pets, aquaculture, poultry and pigs. In July 2017, insect proteins (from BSF, house flies, yellow mealworms, lesser mealworms, house crickets, banded crickets and field crickets) were approved for inclusion in aquaculture diets in the EU (Boloh, Reference Boloh2018). Insect feed for ruminants is currently banned worldwide due to the perceived risk of BSE, though specific research into the transmission of prion (and other) diseases by insects is yet to be completed. China has an established regulatory framework for insect production, which has allowed for the upscaling of insect production. In Australia, regulatory hurdles exist that pose challenges for importing live insects and approval is required to import insect-derived feed products (which must be dead, and heat treated). As global research into feeding different types of livestock, infectious disease transmission, chemical accumulation and allergens are conducted regulatory frameworks are likely to be updated. These processes will, however, take time.

In the EU, it is unlikely that insects reared on animal waste or manure would be permitted to be fed to domestic production animals, as prohibited by the current classification of insects as farmed animals (which cannot consume manure, catering waste or unprocessed former foods containing meat or fish) (Boloh, Reference Boloh2018). However, advancements in understanding the processes and screening to assure product safety may provide scope to change these regulations.

Ethics is an aspect of large-scale insect production that is rarely considered. Do insects feel pain? Does it matter? Insects are comfortably reared in high-density environments likely without impacting animal welfare. However, methods of killing insects are not well researched, with current practices including freezing, cooking and boiling. Australia and other developed nations have stringent ethics regulations that apply to domestically farmed animals; and if insects are to become farm animals in the future, it is likely similar guidelines would need to be defined and adhered to by commercial industries.

Chemical composition of insects

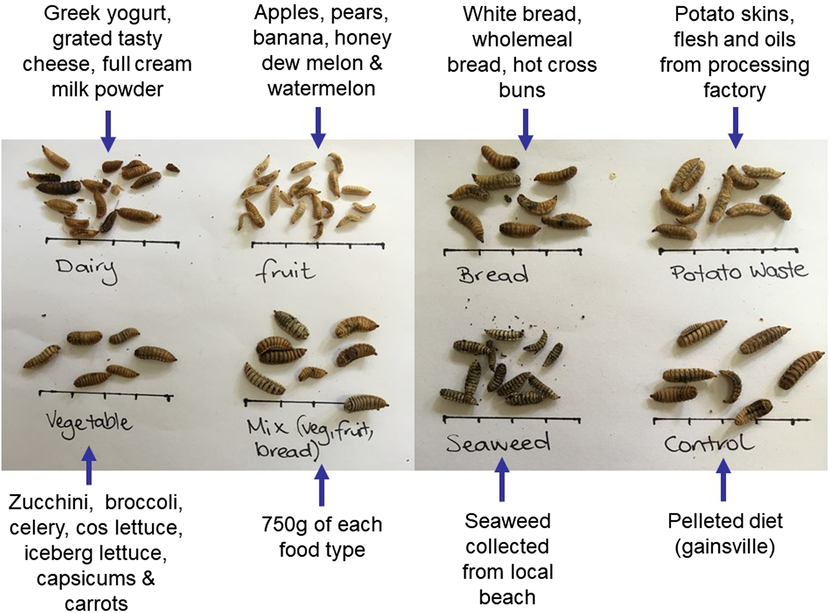

Insect chemical composition and size are determined by the insect species and the feed consumed during the rearing process. For example, one female BSF can produce 400 to 600 larvae, with each larvae estimated to consume 0.5 g organic matter per day. BSF flies do not consume feed as adults and thus accumulate protein and fat stores as growing larvae. Thus, the composition of feed provided to the growing larvae will dictate the final fat and protein content. This is promising as it allows for the manipulation of final products to meet the specific individual needs of different production systems and animal types within a production system (i.e. weaner v. grower pigs). Figure 1 demonstrates the range of sizes of larvae reared on various food waste substrates for 7 days. Conversely, Lalander et al. (Reference Lalander, Diener, Zurbrügg and Vinnerås2019) investigated a range of rearing substrates on BSF larvae growth and nutrient content, demonstrating that AA and CP content did not vary greatly, while some sewage sludge were less suitable as rearing substrate than abattoir or fruit and vegetable wastes. Insects commonly investigated as animal feed sources, such as BSF larvae, housefly larvae and mealworms, range from 40% to 60% CP and 10% to 20% fat, and are high in minerals such as calcium (approximately 10% ash). The essential AA index was found to be favourable for BSF larvae as feed for growing pigs and broiler chickens (Veldkamp and Bosch, Reference Veldkamp and Bosch2015). Table 1 presents the AA composition of BSF larvae compared to the common pig protein feed sources, demonstrating a favourable composition for inclusion in pig diets.

Figure 1 Example of black soldier fly larvae reared on different food waste streams for 7 days.

Table 1 Amino acid content (mg/g) of BSF larvae in comparison with common protein feed sources

BSF = black soldier fly.

1 Data based on larvae reared on a pelleted diet containing 89.9% DM; 22.5% CP; and 13.5 MJ/kg DM metabolisable energy.

2 Values obtained from the INRA CIRAD AFZ feed tables.

Drying and processing of larvae will impact the resultant nutrient content and availability due to changes in chemical and physical properties of proteins and lipids. For example, oven-dried larvae (60°C) had a superior AA digestibility compared to microwave-dried larvae (Huang et al., Reference Huang, Feng, Xiong, Wang, Wang, Wang and Yang2019). Conversely, cooking method did not impact CP or fat content of crickets or mealworm larvae, though in vitro DM digestibility was reduced (Poelaert et al., Reference Poelaert, Despret, Sindic, Beckers, Francis, Portetelle, Soyeurt, Théwis and Bindelle2017). Raw mealworms had a greater in vitro CP digestibility compared to cooked mealworms, which was comparable to the CP digestibility of plant proteins (Poelaert et al., Reference Poelaert, Beckers, Despret, Portetelle, Francis and Bindelle2016). However, feeding raw insects may not be feasible for numerous reasons including storage, transportation and product safety. Promisingly, Poelaert et al. (Reference Poelaert, Despret, Sindic, Beckers, Francis, Portetelle, Soyeurt, Théwis and Bindelle2017) conclude that the intestinal fermentation of feeds (insects, meats and plants) in pigs is primarily influenced by the base ingredient composition rather than the cooking methods applied. The quality of insect protein will also be influenced by the age/stage of insect production. This is primarily due to chitin, an indigestible polysaccharide in the cuticle of insects, which is present in greater concentration in adult crickets compared to larvae and leads to a lower in vitro digestibility in adults (Poelaert et al., Reference Poelaert, Beckers, Despret, Portetelle, Francis and Bindelle2016). Chitin has properties that may be beneficial outside of feed production, such as a plant fertiliser, in food processing or as an immune modulator. Insects have also been shown to have antimicrobial properties.

Antimicrobial stewardship is a key focus of agricultural production systems, including pig production systems. Antimicrobial peptides (AMPs) are small and are both constitutively expressed and induced in response to infection or fungal challenge in insects (larvae) and can potentially be fed to production animals as an alternative to antibiotics (Li et al., Reference Li, Xiang, Zhang, Huang and Su2012). Insects have been used as treatments for disease in traditional medicine throughout history. More recently, insects have been shown to possess over 150 AMPs that do not lead to the development of resistance, exhibit activity against bacteria, fungi, parasites and viruses and are safe for supplementation into animal diets (see review by Jozefiak and Engberg, Reference Jozefiak and Engberg2017). While further research is required to determine the mechanisms of expression, action and methods to exploit these insect AMPs properties, insects potentially have nutraceutical benefits in addition to the provision of dietary protein and fat.

Conversely, as reviewed by Mlcek et al. (Reference Mlcek, Rop, Borkovcova and Bednarova2014), insects (particularly their chitin content) have the potential to induce an allergic reaction when consumed. These reactions occur in humans as they would in a typical food allergy whereby a reaction to specific proteins induces a histamine response via the immune system (van der Fels-Klerx et al., Reference van der Fels-Klerx, Camenzuli, Belluco, Meijer and Ricci2018a). These allergies can also develop via cross-reactivity when allergies to related proteins (such as crustaceans) can induce a similar allergic response. Humans working with insects (such as insect producers or endpoint feed manufacturers) may also be vulnerable to allergic reactions via the inhalation of dust or dermal contact with insects (FAO, 2013), though these risks can be reduced by basic protective measures. The ingestion of insects may also initiate allergic responses that may not be prevented by subjecting them to treatments, such as heat treatment, though research into these processes in humans and production animals is scarce. It has been demonstrated that the particle size of the chitin will impact the allergic response, with medium particles initiating allergic inflammation and smaller particles reducing inflammatory responses (van der Fels-Klerx et al., Reference van der Fels-Klerx, Camenzuli, Belluco, Meijer and Ricci2018a). Further research is required into the possible allergic responses to insects as feed and the potential for processing to eliminate or reduce these responses, particularly in pigs.

Insect meal in pig diets

Feeding BSF to pigs has received renewed attention in recent years, though it is not an entirely new concept. Over four decades ago, wild BSF larvae reared on beef cattle faeces and urine were collected, dried and fed to a small number of growing pigs. These studies demonstrated that while fat content may impact palatability and digestibility, BSF larvae are a suitable ingredient for pig diets (Newton et al., Reference Newton, Booram, Barker and Hale1977). Table 2 summarises the few publications to date that have examined the feeding of insects to pigs. Neumann et al. (Reference Neumann, Velten and Liebert2018) compared the complete substitution of soybean meal in piglet and grower pig feed with either BSF larvae (partially defatted) or algae meal (Spirulina platensis) and observed no difference in the growth parameters and a superior apparent N digestibility in the BSF diet. Replacing the soybean meal content of growing/finishing pigs diets with either 50 or 75 and 100% BSF meal (partially defatted; 61% CP and 14% lipid) had no negative effect on the resultant pork quality and sensory parameters with improved juiciness in BSF supplemented groups (Altmann et al., Reference Altmann, Neumann, Rothstein, Liebert and Mörlein2019). Pigs fed diets supplemented with BSF larvae produced back fat with higher polyunsaturated fatty acid content, likely driven by the high-fat content of the larvae (Altmann et al., Reference Altmann, Neumann, Rothstein, Liebert and Mörlein2019). While further larger scale experiments are required to confirm the palatability, inclusion level, growth responses and meat quality of the commercially raised pigs fed insects, the overall initial results are positive.

Table 2 Summary of published growth responses in pigs fed diets containing insects

BSF = black soldier fly; ADG = average daily gain; ADFI = average daily feed intake; PUFA = polyunsaturated fatty acid.

Safety of insect protein

A key consideration of any new feed product is the safety and acceptability of the product, which needs to be free of contaminants such as pathogens, bacteria, chemicals, toxins and heavy metals. These considerations need to be made specific for each species of insect reared and for each species to be fed the insect diets. Unlike other species, BSFs are not disease vectors as they do not lay their eggs on decaying organic materials and the adults do not eat decayed materials (van Huis et al., Reference van Huis, Van Itterbeeck, Klunder, Mertens, Halloran, Muir and Vantomme2013). Feeding animal-derived protein sources to livestock has an inherent risk of disease transfer, for instance, transmissible spongiform encephalopathy (BSE in ruminants) and other prion diseases, which has led to the worldwide prohibition of such proteins from most animal production systems (including Australia). To date there has been no evidence to suggest that insects carry prions, though further specific research are required.

Contaminants in insect rearing feed, particularly if the feed is a waste product, need to be eliminated (if possible) or quantified. Some contaminants such as veterinary drugs and prions need to be completely removed from the rearing diets, while others may be removed by processing. In a review of the risks of chemical contaminants when feeding various fly larvae species, Charlton et al. (Reference Charlton, Dickinson, Wakefield, E. Fitches, Kenis, Han, Zhu, Kone, Grant, Devic, Bruggeman, Prior and Smith2015) demonstrated that heavy metals posed the greatest risk of accumulation in resultant insects. While of the 1140 compounds measured, only 7 were present in larvae, with Cd posing the greatest risk (Charlton et al., Reference Charlton, Dickinson, Wakefield, E. Fitches, Kenis, Han, Zhu, Kone, Grant, Devic, Bruggeman, Prior and Smith2015). Similarly, BSF larvae reared on substrates spiked with heavy metals (As, Cd, Pb, Hg, Cr and Ni) accumulated Cd and Pb in significant quantities, while As in larvae was at the same concentration as that found in the rearing material (Cai et al., Reference Cai, Hu, Zhang, Ma, Zheng, Yu and Zhang2018). Both mealworms and BSF larvae have demonstrated the ability to consume feeds containing mycotoxins and pesticides and remove these toxins, so that the resultant larvae/mealworms do not accumulate the toxins (Cai et al., Reference Cai, Hu, Zhang, Ma, Zheng, Yu and Zhang2018, Van Der Fels-Klerx et al., Reference Van Der Fels-Klerx, Andriessen, Van Schelt, Van Dam, De Rijk and Camenzuli2018b). In addition, pesticides were not accumulated in BSF larvae reared on substrates spiked with pesticides (chlorpyrifos, chlorpyrifos methyl and pirimiphos methyl) (Purschke et al., Reference Purschke, Scheibelberger, Axmann, Adler and Jäger2017).

Rearing insects on manure

Rearing insects on manure is a promising approach for recycling manure waste that can otherwise contribute to environmental issues associated with pollution and GHG emissions. Under the research priorities of the Australian Government, enhanced food production via improved management and use of waste is a key practical challenge for Australia’s future. The reduction in manure dry weight when being consumed by BSF larvae ranges from 30% to 50%; while the larvae can also reduce the N content of the manure by 30% to 80% (Newton et al., Reference Newton, Sheppard, Watson, Burtle and Dove2005, Myers et al., Reference Myers, Tomberlin, Lambert and Kattes2008, Oonincx et al., Reference Oonincx, van Huis and van Loon2015). BSF larvae can also reduce the emission of volatile organic compounds from poultry, pig and dairy cattle manure, by greater than 87%, with up to 100% reductions observed (Beskin et al., Reference Beskin, Holcomb, Cammack, Crippen, Knap, Sweet and Tomberlin2018). The contamination of manure with veterinary medications is one of the greatest risks of the proposition of larvae rearing as animal feed, as demonstrated by contamination of larvae fed manure with a coccidiostat antiprotozoal agent used to treat chickens (Charlton et al., Reference Charlton, Dickinson, Wakefield, E. Fitches, Kenis, Han, Zhu, Kone, Grant, Devic, Bruggeman, Prior and Smith2015). However, BSF larvae are able to reduce the pathogenic bacterial count in pig manure (Elhag et al., Reference Elhag, Xiao, Zheng and Zhang2018), reduce the Escherichia coli counts in dairy manure (Liu et al., Reference Liu, Tomberlin, Brady, Sanford and Yu2008) and E. coli and Salmonella enterica in dairy and chicken manure (Erickson et al., Reference Erickson, Islam, Sheppard, Liao and Doyle2004), though this response was not observed in slightly acidic pig manure. This important finding indicates that BSF larvae can be used to eliminate pathogen loads from manure prior to their use as fertiliser, while the resultant larvae can then potentially be used as an animal feed source.

Conclusion

Insects pose an opportunity to develop a novel sustainable feed source for pig producers in Australia. Inclusion of insects directly in the diet of Western population is likely to be met with resistance, while the inclusion of insects in the diets of production animals is more likely to be accepted widely. The AA and energy contents of insects such as BSF are ideally suited for inclusion in pig diets as a replacement to soybean meal and other feed protein sources. The potential for insects to produce AMPs provides an exciting opportunity to produce feed for production animals as an alternative to antibiotics. While it is technically possible for insects to be included in the commercial diets of production animals, further research is required in the following areas: (•) rearing, processing and storage methods – practices need to be scalable and energetically and economically sustainable; (•) legal frameworks and regulations need to be developed to ensure product safety and reduce risk; (•) large-scale examination of on-farm inclusion of insects in animal diets to confirm palatability, inclusion levels, growth parameters, product quality and safety; (•) examining the possibility and safety of rearing insects on manure; and (•) measurement of bioactive/nutraceutical properties of insects that may have benefits in addition to the provision of nutrients. Although it is unlikely that the production of insects from feed waste alone would be possible on a large enough scale to eliminate the requirement for additional protein sources such as soybean meal, insects provide a valuable opportunity to contribute to the available feed sources. As a side stream or manure management system for the Australian pig production industry, with adequate research and development, insects such as BSF could contribute to producing a sustainable circular economy. While optimal rearing environments and processes are yet to be determined, it is likely that insect production will reduce GHG production, water consumption and land use compared to the traditional protein sources. Determination of novel solutions to meet the feed protein requirements of production animals is key to the development of sustainable farming practices, and insects are an ideal contributor to this goal in the future.

Acknowledgements

The funding provided to Dr DiGiacomo as the recipient of a Veski Sustainable Agriculture grant is greatly acknowledged. The authors gratefully acknowledge Hatch Biosystems (Pty. Ltd) for the provision of BSF larvae.

K. DiGiacomo 0000-0002-6590-3513

Declaration of interest

The authors declare no conflicts of interest.

Ethics statement

Not applicable.

Software and data repository resources

None of the data were deposited in an official repository.