Introduction

Spatial relationships lie at the heart of much research on the economic and social organization of craft production. Discussions about the concentration of production activities, a common theme in discussions of craft production for at least 30 years (Costin Reference Costin and Schiffer1991; Miller Reference Miller, Flad and Hruby2007; Sinopoli Reference Sinopoli1988; Stein Reference Stein and Wailes1996), reflect a clear interest in spatial patterning. Yet despite the deep entanglement of spatial issues with interpretations of craft production and a wider recognition of the social meanings of space (e.g. Hillier & Hanson Reference Hillier and Hanson1984), the theoretical consideration of spatial aspects of craft production has remained relatively coarse-grained. The result has been a tendency to draw conclusions about control of production based on spatial proximity between production debris and elite structures in a relatively straightforward fashion. These issues require careful consideration of how social and economic relationships in production systems translate to spatial patterning of craft production. The distribution of raw materials, the technological chaîne opératoire and a range of other factors affect the spatial organization of the crafting landscape. Given recent interest in archaeological landscapes, and the number of projects where the spatial organization of craft production is an explicit concern (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2017; Hendrickson & Evans Reference Hendrickson and Evans2015; Iles Reference Iles2018; Robion-Brunner et al. Reference Robion-Brunner, Serneels, Perret, Humphris and Rehren2013; Shimada & Craig Reference Shimada and Craig2013; Zori et al. Reference Zori, Tropper and Scott2013), the time is ripe for a deeper consideration of these issues.

To be clear, previous discussions of craft production have not been blind to spatial issues. Costin's (Reference Costin and Schiffer1991; Reference Costin, Feinman and Price2001, 293–6) widely cited discussions of various indices of craft production include ‘concentration’ as a key descriptive index, referring to the degree to which production activities range from dispersed to nucleated. Other indices of production also have a spatial component. The scale of production (i.e. the measure of output), another common descriptive index, also carries clear spatial implications with respect to the size and extent of production sites. However, during extensive discussions about craft specialization and the rise of complex societies in the 1980s and ’90s (Brumfiel & Earle Reference Brumfiel, Earle, Brumfiel and Earle1987; Clark Reference Clark1995; Rice Reference Rice1981; Sinopoli Reference Sinopoli1988), the spatial dimensions of craft production did not receive the same degree of scrutiny.

Similarly, ethnoarchaeological research has placed craft production securely within its environmental context, with implications for the spatial manifestations of administrative control. Notable spatial contributions include patterns of resource acquisition in pottery production (Arnold Reference Arnold1985, 32ff) and analysis of ceramic and stone bead workshop spaces (Hasaki Reference Hasaki, Lawall and Lund2011; Kenoyer et al. Reference Kenoyer, Vidale and Bhan1991). Ethnoarchaeological data on metallurgy has also explored how raw materials are acquired, controlled and distributed (Childs Reference Childs, Knapp, Pigott and Herbert1998). Given this wide-ranging literature, my aim here is not to suggest that a spatial approach to craft production is something entirely new. Rather, I aim to (1) interrogate the assumptions that underlie how spatial analyses generate models of economic organization, and (2) develop a set of analytical concepts for investigating crafting landscapes.

While extensive landscape approaches to craft production have produced some notable successes, they face significant methodological challenges. Visibility to the techniques of landscape archaeology is one concern. Clay extraction, mining of placer deposits (e.g. of gold or tin) and the collection of quartz pebbles for glass production are often difficult to identify in archaeological surveys. Even more visible remains such as mineshafts and slag heaps can be difficult to date, especially if they are located away from settlements, have few associated ceramics, or have complex chronologies of reuse. The extensive orientation of many archaeological surveys is therefore in tension with the intensive research sometimes needed to identify, reconstruct and date craft production remains. Nevertheless, sustained multi-disciplinary research has revealed rich and complex crafting landscapes worldwide (de Barros Reference de Barros1986; Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2017; Robion-Brunner et al. Reference Robion-Brunner, Serneels, Perret, Humphris and Rehren2013; Shimada & Craig Reference Shimada and Craig2013; Stöllner et al. Reference Stöllner, von Rüden, Hanning, Lutz, Kluwe, Körlin, Prange, Stöllner and Yalçin2016; Weisgerber Reference Weisgerber, Craddock and Lang2003).

Drawing on ethnoarchaeological craft ecology approaches, landscape-oriented investigations of the chaîne opératoire and the contributions of materials analytical investigations of craft production, I develop a theoretical framework for the spatial investigation of crafting landscapes. I consider what forms power and control take in the context of craft production, while focusing on the spatial implications of these relationships. I show that the spatial patterning of production systems often diverges in important ways from a linear trend between ‘dispersed’ and ‘nucleated/concentrated’, the spatial terms most used to describe craft production systems. Consideration of spatial scale (not to be confused with ‘scale’ as a measure of productive output) and assessments of power projection are essential to any discussion of economic organization, not just for exploring how crafting landscapes are controlled, but also for identifying instances when they are not. Finally, I introduce the concept of articulation between various components of a crafting landscape as a way of moving the analysis of control and administration beyond basic measurements of proximity. This spatial approach to production systems ultimately generates a nuanced understanding of the power relationships between producers and the wider economic apparatus. To illustrate the value of these theoretical approaches for conceptualizing power relationships in crafting landscapes, I discuss the case of late second–early first millennium bc metal production in the Caucasus. Specifically, I show how these theoretical perspectives help delineate a crafting landscape that differs in significant ways from contemporary metallurgical industries elsewhere in the Near East.

Defining the crafting landscape

I define the crafting landscape as the system of workshops, raw materials sources, extraction and processing sites, distribution networks, administrative facilities and consumer sites, bound together by the spatial logics of the chaîne opératoire. The crafting landscape bears some relationship to the concept of a technical system (Lemonnier Reference Lemonnier1986; Reference Lemonnier1992), but they are not identical in scope; the spatial element in the former is far more explicit, while the latter emphasizes the total social context of technological practice.

As noted above, not all aspects of the crafting landscape are equally visible to the archaeologist. Yet it is often possible to investigate these less visible aspects indirectly. Materials analysis, combined with geological and environmental data, can reconstruct patterns of raw material acquisition and sketch aspects of the crafting landscape, even if the mining or extraction sites are imprecisely located. Ceramic materials analysis is notable for sensitivities in this regard (Doherty Reference Doherty2020; Gomez & Doherty Reference Gomez and Doherty2000; Michelaki et al. Reference Michelaki, Braun and Hancock2015), perhaps as a legacy of ceramic ecology approaches (Arnold Reference Arnold1985) and the difficulties of identifying some kinds of ceramic production sites (e.g. manufacturing sites without firing structures and clay/temper extraction sites).

A focus on the crafting landscape helps to situate production within its environmental, geological, technological and social context. Spatial patterning of activities within the crafting landscape is conditioned by the geography of resources, the economic organization of production, social considerations and even ritual beliefs (e.g. Childs & Killick Reference Childs and Killick1993, 328). A well-known contribution of ceramic ecology is data on distances for clay and temper acquisition (Arnold Reference Arnold, Livingstone Smith, Bosquet and Martineau2005). The maximum distances typically travelled have implications for the arrangement of potters’ workshops and kiln sites in relation to sources of raw materials. Analyses of crafting landscapes must consider not just the raw materials that make up the finished product, but also the spatial distributions of fuel, materials for making kilns and furnaces, as well as the availability of labour and support logistics. Smells, fire hazards, and smoke associated with certain pyrotechnologies may force production activities away from elite spaces, even when they are tightly regulated. Careful analysis of these technological and environmental constraints helps to highlight spatial patterns that cannot be explained sufficiently by these considerations alone (e.g. Miller Reference Miller, Flad and Hruby2007, 44). A focus on the landscape dimensions of craft production allows for a clear-eyed assessment of how control is exerted in production systems, and how these relationships manifest in archaeological data. Before continuing, however, it is worth pausing to consider what power and control mean in discussions of craft production.

Power and control in crafting landscapes

Questions about the control of production and the role of attached specialization in the rise of complex societies are major considerations in craft production research (Brumfiel & Earle Reference Brumfiel, Earle, Brumfiel and Earle1987; Clark Reference Clark1995; Clark & Parry Reference Clark and Parry1990; Earle Reference Earle, Preucel and Hodder1996; Lewis Reference Lewis1996; Schortman & Urban Reference Schortman and Urban2004; Stein Reference Stein and Wailes1996). Without relitigating debates about attached production, it is worth emphasizing that power over production is exerted in a range of different ways by a variety of agents. Only some of these power relationships are subsumed within the narrowest definitions of attached production, frequently defined as producers giving up the ‘rights of alienation’ in exchange for support by elite patrons (Clark & Parry Reference Clark and Parry1990, 298; Earle Reference Earle1981; Lewis Reference Lewis1996, 366). Attached craft specialists produce goods—frequently prestige items, but not always (Flad Reference Flad2007)—for elites rather than the open market. There are reasonable arguments for why the terms ‘attached’ and ‘independent’ should refer to binary categories (Flad Reference Flad2007, 111). Equally, there is value in recognizing that control and administration of production varies widely in both form and degree (Costin Reference Costin, Feinman and Price2001, 299). For the purposes of this discussion, attached production is considered to be a specific form of control over production, which can take a wide variety of forms.

Control of production is itself one dimension of power in the context of the production: power over. Craft production is itself a generator of power, derived from the value of its products and often through the ritual acts of creation and transformation themselves (Herbert Reference Herbert1993). Power over production and power from production are distinct but often interdependent: the latter can be the motivation for efforts towards the former. While the focus of this article rests mostly on the spatial manifestations of power over production, it is worth keeping in mind this interdependence. Power over production can be both extensive, in the sense that it extends over large geographic areas, and intensive, in the sense that certain activities are tightly regulated and directly administered. Likewise, power can be exerted directly by individuals or institutions, or act indirectly, a distinction sometimes described as the difference between authoritative and diffused power (Mann Reference Mann1986, 7–8). Because of the interdependence of the constituent parts of the crafting landscape, direct intensive control over one part of the crafting landscape may reverberate through other elements of the network as extensive diffused power.

Because the spatial manifestations of control can be highly variable, it is important to consider what kinds of power and control are involved and where in the crafting landscape they are exercised. In cases where raw material extraction requires significant labour, restricted technological expertise, or where raw materials are intrinsically valuable, elite oversight might extend over the supply of raw materials but involve little direct administration of manufacturing activities. Conversely, in cases where finished products have significant ‘added value’ and raw materials are so ubiquitous that control at the source is infeasible, administration of secondary manufacturing stages may be preferable. Monopoly of the means of water-borne transport in the Santa Barbara Channel Islands gave elites an expedient method of controlling the shell bead industry, even if they did not administer on-island production directly (Arnold & Munns Reference Arnold and Munns1994). At the same time, the existence of an industry making valuable products should not lead to a priori assumptions of elite administration. There may be logistic, political, and even ideological reasons why certain groups may have chosen not to attempt to control production.

Spatial patterning beyond ‘dispersed’ and ‘nucleated’

The spatial distribution of production sites or debris is almost always characterized in terms of its concentration, on a scale ranging between ‘dispersed’ (widely distributed) and ‘nucleated’ (spatially centralized) production (Costin Reference Costin and Schiffer1991). The formulation of a range between two extremes is a useful shorthand, but as the sole way of characterizing crafting landscapes spatially, it also obscures other socially and economically significant forms of spatial order.

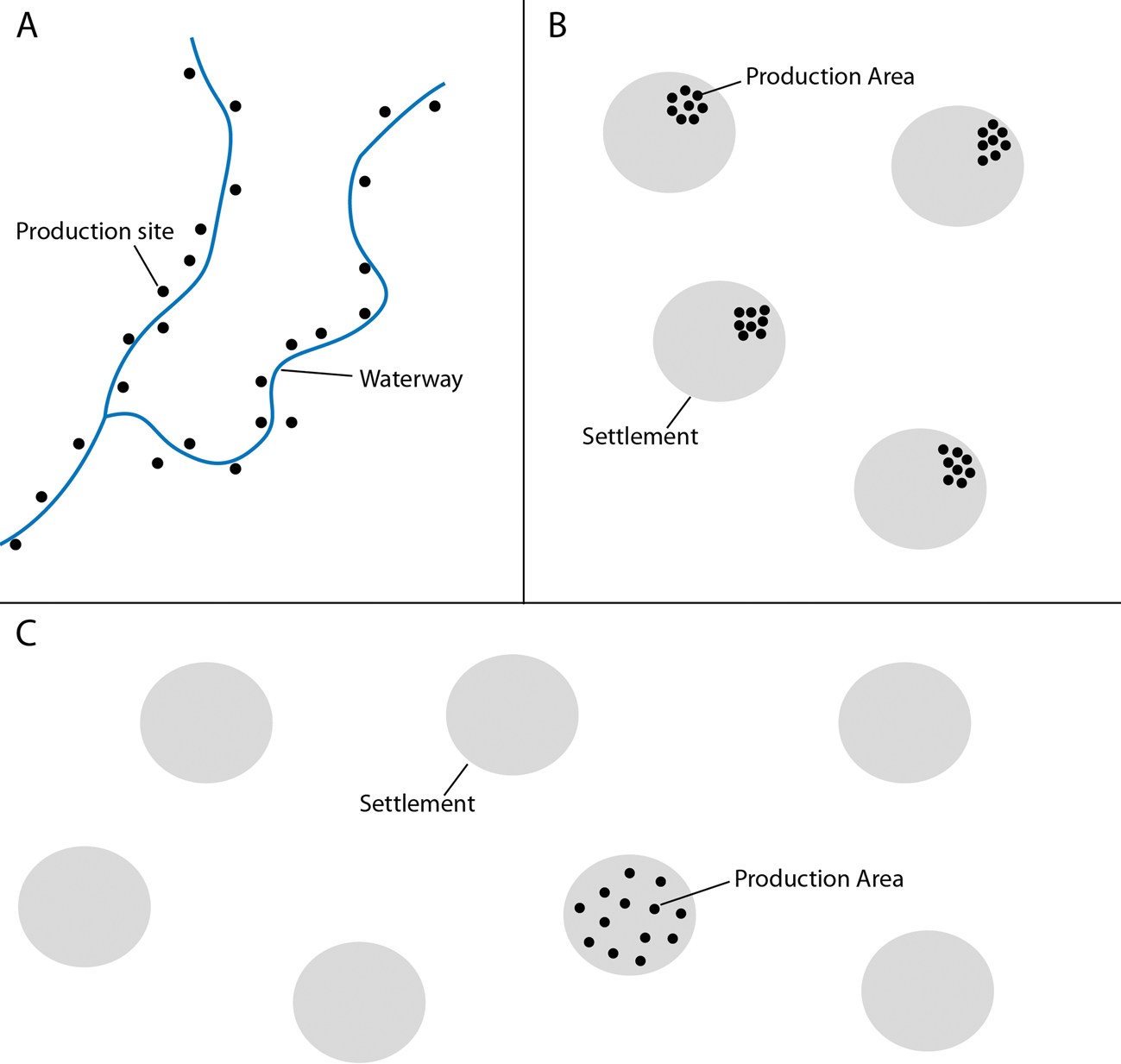

Many possible crafting landscapes cannot be characterized simply as nucleated, dispersed, or some linear intermediate between them. Consider a model where production sites are distributed linearly along a river or shoreline (Fig. 1A) (see e.g. Zori et al. Reference Zori, Tropper and Scott2013). One could equally describe sites distributed in this way as being concentrated near water, or as being dispersed along waterways. Essentially, the degree of concentration is entirely different along different spatial ‘axes’, one parallel to the river and the other orthogonal to it.

Figure 1. Schematic examples of crafting landscapes that illustrate the problems with conceptualizing production systems as gradations on a linear scale ranging between ‘nucleated’ and ‘dispersed’.

Similarly, characterizations of concentration in crafting landscapes must consider the spatial scales of clustering. Production activities may be restricted to certain areas of a settlement (nucleated), but these activities may be found in similar places at every settlement in a region (dispersed) (Fig. 1B). This spatial patterning might result from a system in which production was controlled by specific groups within villages, but without specialization within the broader settlement landscape. Conversely, production activities may be dispersed within a settlement, but that settlement may be the sole producer for the whole region (Fig. 1C). In this case, production may not be restricted to certain groups within the settlement, but the settlement landscape has significant community specialization (Stark Reference Stark1991). Clearly, spatial patterning can be structured in complex ways that make it difficult to categorize some systems as wholly nucleated or dispersed.

This is not merely a pointless definitional exercise. These different kinds of spatial patterning have major implications for how archaeologists interpret the organization of production systems. The ways that spatial ordering plays out across different frames of reference (the household, the settlement, the region) directly impact discussions about the control of production and the place of crafting within the broader economic system.

Segmented production landscapes add another layer of complexity to discussions of spatial patterning. The spatial concentration of different activities may differ significantly among production stages, further defying overall characterization of the system as falling along a linear range between ‘nucleated’ and ‘dispersed’ (Fig. 2). The positioning of raw material extraction sites is often constrained by the natural distribution of the relevant raw material. A large rich source of raw materials is more likely to result in a concentration of extraction sites, regardless of whether the source is under unified administrative control. At the same time, geological and environmental factors do not fully determine the patterning of extraction sites—human factors like the coordination of labour and location of consumers also play a role.

Figure 2. Varying patterns of concentration and dispersion in crafting landscapes where different components of the chaîne opératoire are spatially segmented.

The aim of these elaborations on the theme of spatial patterning is not to excise terms like ‘concentrated’, ‘nucleated’, or ‘dispersed’ from the language used to characterize crafting landscapes. Nevertheless, characterizations of production systems that scale linearly between degrees of concentration elide significant variations in spatial patterning. These observations prompt important questions for any crafting landscape and encourage greater precision when discussing spatial patterning. At what spatial scales are production activities concentrated or dispersed? To what extent are different production stages co-localized? Recognition of these complexities is a necessary step towards a full account of how power and control operate in a crafting landscape.

Spatial scale, power projection and the geographies of control

The preceding section alluded to spatial scale as one of the key under-appreciated elements of interpretation in crafting landscapes. A frame of reference, such as the household, the settlement, or the region, is essential for characterizing spatial relationships. For the questions about control in production systems, the operational spatial scales are those over which individuals or institutions can project power. Administering production, ensuring compliance and maintaining communication networks require infrastructure and labour investments that are not without limits. Power projection is essentially a reflection of the logistical capacity for extensive power (see Mann Reference Mann1986, 9–10). Intensive control frequently (but not always) requires some degree of proximity, while more indirect, less intensive forms of control can be exercised over larger distances.

Power projection is a function of both the internal characteristics of administrative entities and their environments. Distance is an attenuating factor, but topography, ecology and the distribution of natural resources also affect the dynamics of power projection. Efforts towards control are greatly simplified, and can operate over longer distances, if key resources are spatially restricted. For instance, by the mid third millennium bc in Mesopotamia, the prestige value of ceramics had plummeted, while the ubiquity of clay in the alluvial plain made attempts to control ceramic production by the state both needless and futile (Stein & Blackman Reference Stein and Blackman1993). On the other hand, because metal resources are absent from Mesopotamia, control was both more desirable and more feasible, via control of import networks.

Institutions themselves differ in their effectiveness at administering crafting activities. Highly centralized polities have a much wider array of tools at their disposal to encourage or compel acquiescence among craftspeople. For instance, research on the Chinese terracotta warriors has proposed a cellular retainer workshop model for the production of their weaponry (Martinón-Torres et al. Reference Martinón-Torres, Li, Bevan, Xia, Zhao and Rehren2014). Little is known about the spatial distribution of these workshops, though the authors acknowledge the possibility that they might have been geographically dispersed (Martinón-Torres et al. Reference Martinón-Torres, Li, Bevan, Xia, Zhao and Rehren2014, 552). The assumption here—justifiable in light of the assembled evidence for Qin administrative organization—is that the power projection capacity of the state was more than capable of ensuring standardization and compliance across these different production cells, regardless of where they were located.

The examination of power projection is partly an assessment of the technologies of control: the material, infrastructural and social techniques for directing the behaviour of producers. Archaeologically identifiable technologies of control may include road networks, storage facilities, accounting technologies (e.g. writing, seals) and strategic fortifications. While power projection is influenced by environmental factors, the effectiveness of these technologies of control is a primary determinant in an administrative entity's capacity for power projection.

Geographies of control deal with where and how (and if) control is exerted within the crafting landscape. To be clear, I do not want to suggest a quasi-totalitarian model in which all agents in a crafting landscape always exert maximum control up to the administrative, spatial and environmental limits of their power. On the contrary, evaluations of the geographies of (non-)control are just as useful for building arguments against centralized administration. Arguments for independent production often rest on evidence that institutions capable of administering production were too weak to maintain exclusive control, or simply did not consider it worth the costs of doing so. Research on the Aegean Bronze Age has noted the existence of economic agents outside the purview of Mycenaean palatial administration, in the spheres of production and potentially even in long-distance exchange (Shelmerdine Reference Shelmerdine2013; William et al. Reference William, Dimitri and Michael2013). Assessments of (limited) power projection are implicit throughout these discussions.

Considerations of power projection and the geographies of control complicate archaeological interpretations of crafting spaces in relation to elite spaces, administrative buildings, and the physical infrastructure of control. One cannot assume that production activities distant from elite contexts were outside their control without considering the power projection capacity of those institutions. Indeed, one can expect situations where attached specialists may be located some distance away from elite areas (Arnold & Munns Reference Arnold and Munns1994, 476). Throughout most of a centuries-long operation as a major supplier of porcelain to the court under imperial patronage, the imperial kilns at Jingdezhen in southern China were geographically distant from the imperial capital. Though this distance was not without logistical and bureaucratic challenges, the state was heavily involved with the administration and taxation of ceramic production at kilns under their control (Kerr & Wood Reference Kerr and Wood2004, 184–97).

There may be cases where isolation of production activities even facilitates control. Production away from centres of population and production within restricted spaces within settlements (e.g. elite compounds) both limit access by the broader public. Remote desert mining expeditions launched by Egyptian pharaohs and the Roman/Byzantine mining towns in Egypt and the southern Levant are good examples of control facilitated through isolation, though the location of natural resources was the primary factor affecting the geographies of production (Mattingly et al. Reference Mattingly, Newson, Creighton, Barker, Gilbertson and Mattingly2007; Meyer Reference Meyer, Knapp, Pigott and Herbert1998; Shaw Reference Shaw, Knapp, Pigott and Herbert1998). If the logistical difficulties can be overcome and external threats are mitigated, the workforce is easier to control if they are isolated geographically and dependent on an external state apparatus for supply and access to consumers. This is a potentially important consideration, given that slave and convict labour were sometimes employed in Roman mines (Mattingly et al. Reference Mattingly, Newson, Creighton, Barker, Gilbertson and Mattingly2007), but it applies to management of a free workforce as well. Moreover, as was the case for Pharaonic Egypt, logistical challenges of mining expeditions themselves acted as a deterrent to non-royal competitors for the supply of precious materials (Shaw Reference Shaw, Knapp, Pigott and Herbert1998, 251).

Ethnographic research on iron smelting among Bantu-speaking peoples of sub-Saharan Africa recounts how smelting activities are sometimes separated from settlements (Childs Reference Childs1991, 343; Childs & Killick Reference Childs and Killick1993, 325–8; Chirikure Reference Chirikure2015, 88–92). The reasons for this are attributed to the maintenance of ritual purity and protection against sorcery during the technological process. Although discussions of smelting site placement in these areas is not usually framed in terms of control over production in an economic or administrative sense, these choices could be read as reflecting a desire to maintain ritual control over the processes of transformation. This last example highlights an important general observation: the spatial arrangement of production activities is influenced by considerations beyond the geographies of natural resources, the locations of consumer populations and the requirements of any administrative apparatus, if present.

Articulation in crafting landscapes

Many of the cases discussed so far have been primarily framed around interpreting the spatial patterning of production residues with respect to administrative institutions, elite spaces and other power centres. However, measurements of proximity are necessary but not sufficient to define these relationships adequately. It is also necessary to consider the character of relationships between elements of the crafting landscape, a concept I refer to as articulation. The material linkages of the technological chaîne opératoire, the social relations between producers and consumers, and the physical environment (built and natural) all shape these interactions. While the technologies of production impose a certain order on the flows of materials through the crafting landscape, they do not fully determine the articulations of people and activities within the crafting landscape. For this reason, careful attention to articulation allows us to draw out the social significance of spatial patterning in the crafting landscape.

My use of the term articulation is analogous to the use of the term in bioarchaeology. The analogy is useful because articulation has a dimension of spatial proximity, but also refers to a specific configurational order. The skeletal elements of a complete but disarticulated skeleton are all close to one another, but they lack the order provided by the systematic relationships between constituent parts.

In the sense that it focuses on the character of relationships, my discussion of articulation bears some resemblance to some other schools of thought that place emphasis on relationality and interdependence, such as entanglement (Hodder Reference Hodder2012). My intention here, however, is to use ‘articulation’ in a narrower but analytically applicable context, as a way of focusing attention on the complexities of socio-spatial relationships within the crafting landscape. The concept of articulation also appears in work on the archaeology of architectural space, where it is used to refer to a segmented and structured mode of organizing space that is contrasted with an agglutinative mode (Letesson Reference Letesson, Paliou, Lieberwirth and Polla2014). The specific meaning here differs from my own use, but the emphasis on structure in the character of spatial relations is a common theme. While my focus on articulation as an analytical category for craft production is novel, the word ‘articulate’ or ‘articulation’ has occasionally appeared in prior discussions of craft production (Arnold & Munns Reference Arnold and Munns1994, 473; Costin Reference Costin, Feinman and Price2001, 279; Schortman & Urban Reference Schortman and Urban2004, 202). Thus, it sits comfortably within the existing discourse on craft production.

To refine and operationalize the concept of articulation as applied to crafting landscapes, we need to elaborate on two issues: between whom/what can we discuss articulation, and what kinds of variations in the character of these relations can we expect to find in the archaeological record? Articulation is an attribute of relationships among people and activities, investigated primarily through the analysis of physical spaces and material remains associated with the crafting landscape. Relevant people include craftspeople, of course, but also administrators, merchants and consumers. Physical spaces with associated material assemblages might include workshops, domestic structures, administrative buildings, and other locations that intervene in the operation of the crafting landscape. Articulation can therefore be seen as an aspect of a crafting landscape, one that is shaped, but not fully determined, by the chaîne opératoire.

Several different classes of relationships are important for investigating articulation within the crafting landscapes. First, the articulation between producers and elites, whether political leaders or religious authorities, is a paramount consideration for discussions of control. Elites may be consumers, administrators, or agents of redistribution/exchange; the articulation of all three groups with producers is relevant to the analysis of crafting landscapes. It is also important to consider articulation between producers, both within the same industry and in other industries. The relationships between pastoralists and weavers in a textile production landscape, or between smelters and smiths in a metallurgical landscape, are structured by the chaîne opératoire (naturally occurring metals aside, the smith's metal must come from the smelter's furnace), but many configurations of these relationships can exist. One can also examine the articulation between different groups carrying out the same task: do they coordinate their efforts or operate independently? On the other hand, studies of cross-craft interactions are ultimately concerned with articulation between producers in different industries. Moving beyond basic observations about the co-location of different industries, cross-craft approaches probe the nature of interactions, such as complementary use of resources, technology transfer, or sharing of labour (Brysbaert Reference Brysbaert, Antoniadou and Pace2007; Goldstein & Shimada Reference Goldstein, Shimada and Shimada2007).

Having addressed the ‘between whom/what’ aspect of articulation, we can now turn to those aspects relating to variations in the character of socio-spatial relationships. Partiality, exclusivity and temporality are three dimensions of variability in the patterning of socio-spatial relations. Partiality refers to the degree to which a particular association, such as that between producers and elites, extends across different stages of the chaîne opératoire, or just a part of it. A crafting landscape where administrative involvement is visible in every stage of production is quite different from one in which only one part of the chaîne opératoire is carefully controlled. Exclusivity, in the context of relations between elites and producers, refers to the degree to which production occurs only in contexts of close administrative oversight. In the context of articulations between groups of craftspeople involved in different stages of production, exclusivity covers variabilities in the relations of supply. Is a workshop supplied by raw materials from one source, or many? Conversely, are raw materials gathered by one group distributed to many workshops, or just one? Finally, we can consider the temporality of socio-spatial relations, whether such relations are permanent, seasonal, or sporadic. Itinerant craftspeople and industries dependent on periodic exchange between groups are examples of articulations with varying temporality.

How is articulation investigated? Analysis of production debris—its identification, spatial context, and quantity—is clearly one important element. Ethnographic research on South Asian carnelian bead production shows how spatial associations of remains within a workshop reveal the articulations between administrators and craftspeople (Kenoyer et al. Reference Kenoyer, Vidale and Bhan1991, 55–7). While different production stages of carnelian beads took place in various locations, the requirement that workers return unused carnelian debitage to a central workshop meant that the full spectrum of production debris and semi-finished products was found in the workshop of the merchant controlling the entire production chain. The dedication of workshop space to stockpiling of semi-finished products and potentially reusable debitage indicates firm control of valuable raw materials, which are distributed to workers in a regulated manner. Encouragingly, these articulations between administrators and craftspeople have archaeologically visible material correlates.

Research on the technologies and fuel requirements revealed that Sicán pottery and metallurgical industries were more closely articulated than the mere fact of their spatial proximity would suggest, with excess charcoal generated in reduction firing providing fuel for high-temperature metallurgical processes (Goldstein & Shimada Reference Goldstein, Shimada and Shimada2007). Materials analysis—even of finished artifacts—can also uncover the character of these relationships. The discovery that minerals used in Cypriot white-slip pottery are likely to have originated from deposits exposed by sub-surface copper mining (Gomez & Doherty Reference Gomez and Doherty2000) has profound implications for the articulation between the ceramic and the copper metallurgical industries, implying workflow integration in the acquisition of raw materials. The concept of articulation thus forms a useful basis for assessing relationships between components of a crafting landscape in a spatially sensitive manner.

The metal crafting landscape in the Caucasus, 1500–600 bc

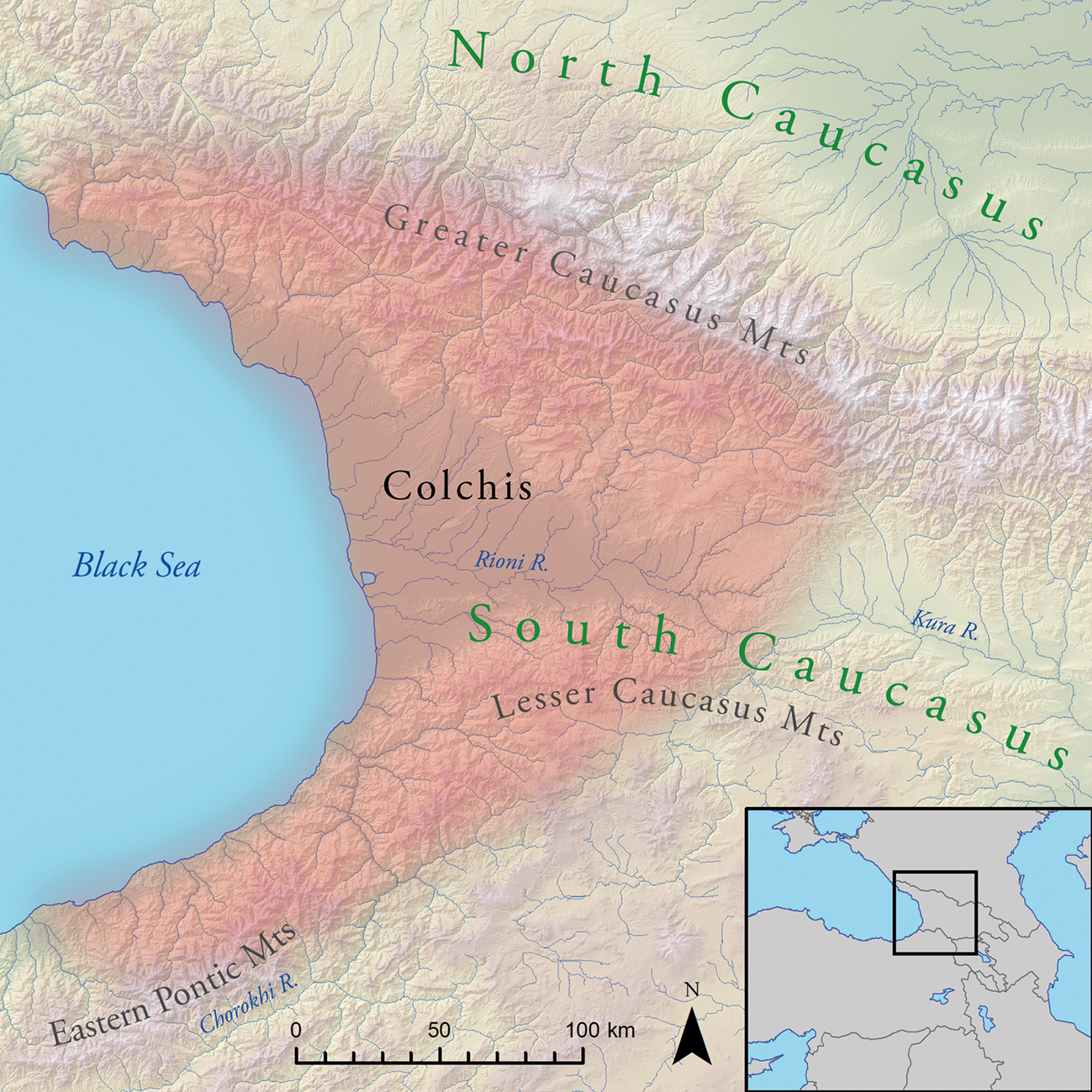

The metallurgical landscapes of the Caucasus illustrate the usefulness of considering spatial scale, power projection and articulation in crafting landscapes. The Late Bronze and pre-Classical Iron Age (LBA–EIA, c. 1500–600 bc) was notable for intense metallurgical activity, with huge assemblages of bronze and, in its later stages, iron artifacts. Metal production sites are reported across the region (Erb-Satullo Reference Erb-Satullo, Anderson, Hopper and Robinson2018; Erb-Satullo et al. Reference Erb-Satullo, Jachvliani, Kakhiani and Newman2020; Gzelishvili Reference Gzelishvili1964), but are particularly well documented in the eastern Black Sea area, a region referred to as Colchis in the Classical era (Fig. 3). Encompassing subtropical lowlands and surrounding mountainous zones, Colchis was characterized by a distinct material culture with tell settlements in marshy lowlands, a reliance on wooden architecture, and distinctive styles of ceramics and metallurgy.

Figure 3. The eastern Black Sea area of the South Caucasus, showing the approximate extent of the region of Colchis.

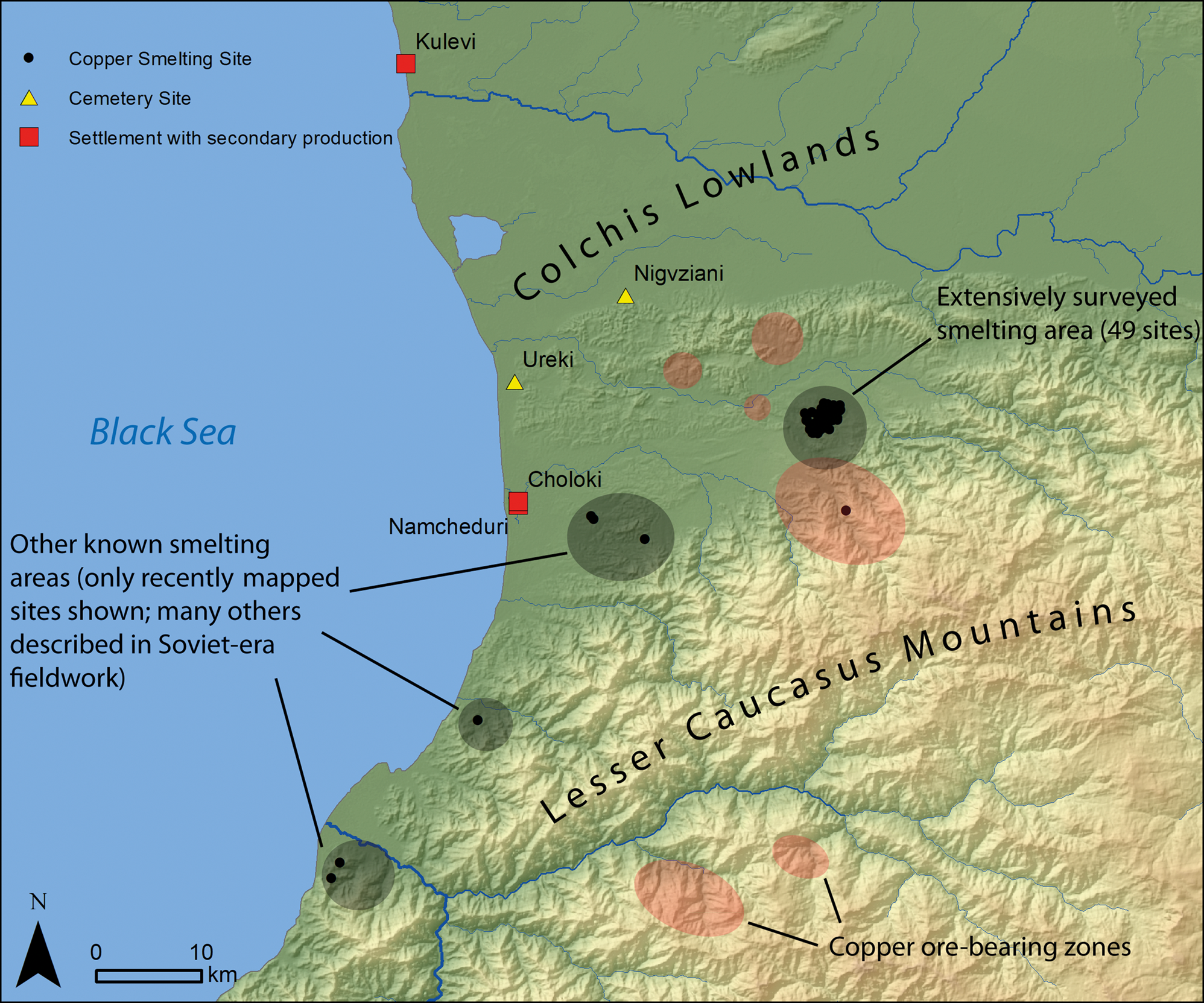

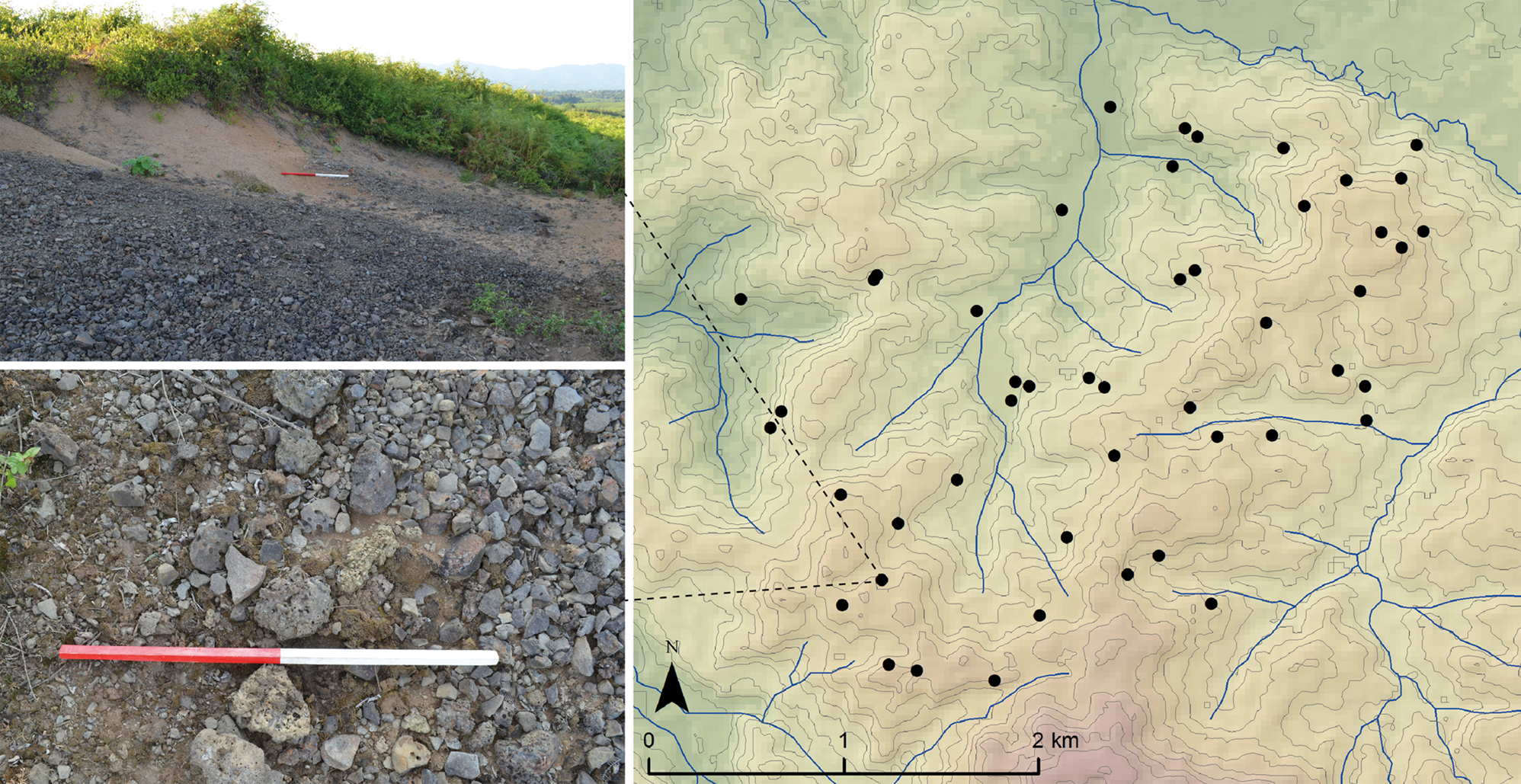

Hundreds of Colchian smelting sites were reported in Soviet-era research, along with mines and secondary casting sites (Chartolani Reference Chartolani1989; Chavleisvhvili Reference Chavleishvili1991; Khakhutaishvili [1987] Reference Khakhutaishvili2009; Mudzhiri Reference Mudzhiri2011) (Fig. 4). Recent research further investigated these landscapes, combining surveys of smelting sites with radiocarbon dating and laboratory analysis of production debris (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2014; Reference Erb-Satullo, Gilmour and Khakhutaishvili2015; Reference Erb-Satullo, Gilmour and Khakhutaishvili2017; Reference Erb-Satullo, Gilmour and Khakhutaishvili2018) (Fig. 5). Though the earlier work identified them as iron smelting sites, the new programme of research linked them unequivocally with copper smelting. This reinterpretation linked the production sites with large assemblages of contemporary bronze artifacts and brought the outlines of the crafting landscape into much sharper focus.

Figure 4. The LBA–EIA metallurgical crafting landscape of Colchis. Locations of copper deposits are derived from Nazarov (Reference Nazarov1966) and Gabunia (Reference Gabunia and Godabrelidze1933).

Figure 5. Local-scale patterning of Late Bronze–Early Iron Age copper-smelting sites (black dots) in the Supsa-Gubazeuli group. Spatial data from Erb-Satullo et al. (Reference Erb-Satullo, Gilmour and Khakhutaishvili2017). Scale bars in photographs are 1 m.

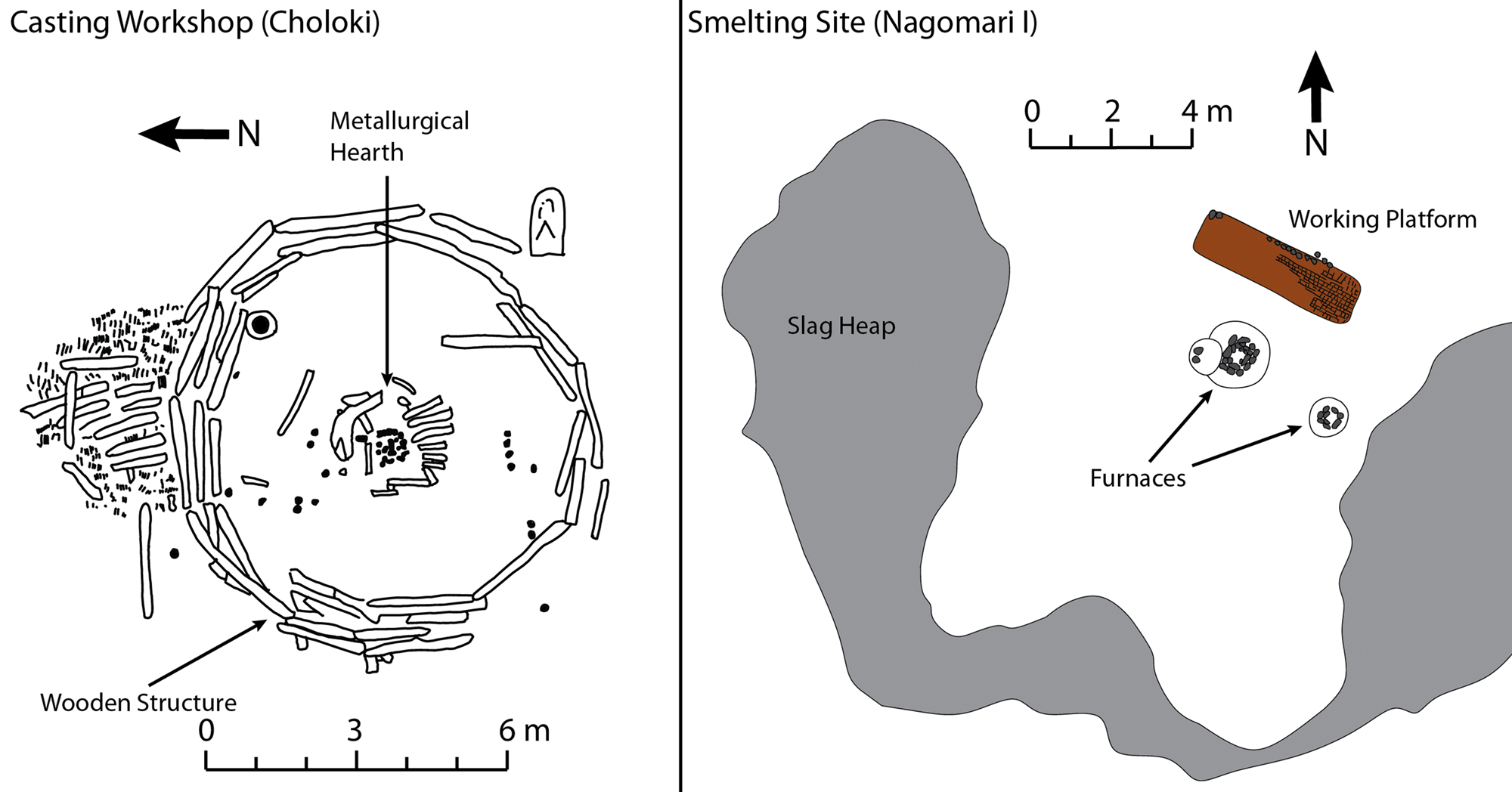

Different production activities are spatially segregated but functionally linked through the chaîne opératoire. Ore was mined from the abundant copper deposits in the foothill and mountain zones. Smelting sites in the foothills are individually small, consisting of one or two furnaces and a working platform, possibly for roasting matte or ores (Fig. 6). Individual slag heaps are not large, with something of the order of 10,000–20,000 kg of slag estimated per site (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2017, 113). On a per site basis, these slag quantities pale in comparison with other Late Bronze and Early Iron Age smelting sites in the Near East, where slag estimates are in the tens of thousands of tons for each site (e.g. Hauptmann Reference Hauptmann2007, 127–31). It is only in aggregate that the scale of the Colchian smelting industry, with its many sites, becomes apparent.

Figure 6. Plan of a secondary production workshop with casting debris (after Chavleishvili Reference Chavleishvili1991, pl. 4) and a copper-smelting site (after Khakhutaishvili [1987] Reference Khakhutaishvili2009, 90).

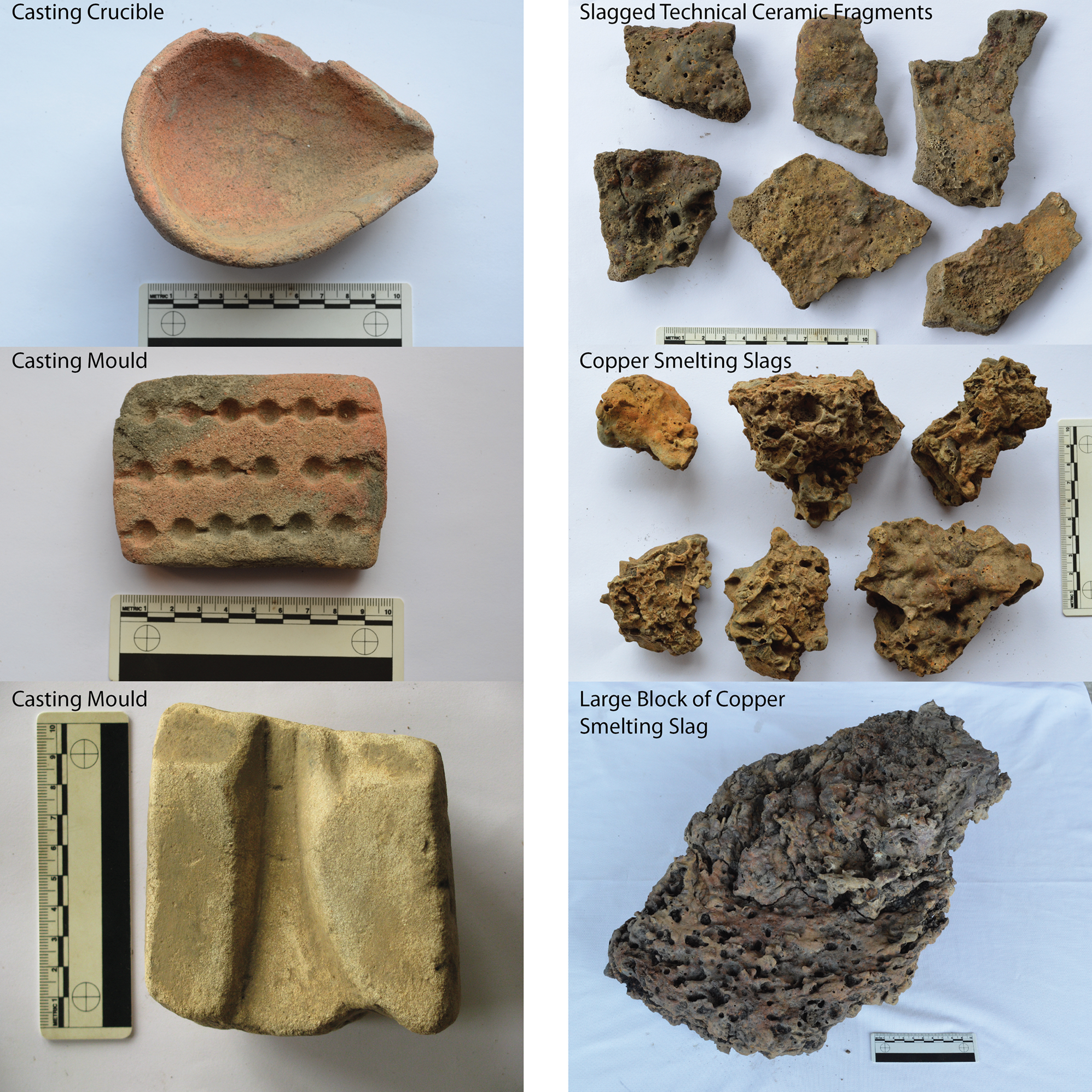

The smelting process produced raw copper, which was probably shipped out from the smelting sites as ingots or chunks of raw copper. Analyses of hundreds of slags, crucibles and furnace fragments yielded only one example of alloying at a smelting site, which involved the mixing of cassiterite with copper metal in a crucible to produce a tin bronze (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2015). Neither recent surveys nor extensive Soviet-era excavations yielded any casting moulds at these smelting sites, further reinforcing the impression that secondary processing and artifact manufacture took place elsewhere. Chemical analysis of ingots and unformed chunks of raw metal recovered in hoards shows that most are relatively pure copper, strongly suggesting that most arsenical copper and tin bronze alloys were produced at secondary sites (Ho & Erb-Satullo Reference Ho and Erb-Satullo2021). The low quantities of non-metallurgical ceramics and the absence of architecture suggest that smelting did not occur within settlements (Fig. 6). In contrast, secondary working debris—moulds, tuyères, and occasionally crucibles—are very common at settlement sites (Chavleishvili Reference Chavleishvili1991; Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2017, 121–2; Mikeladze Reference Mikeladze1990, 26) (Fig. 7). The data paint a picture of a complementary landscape of production sites, linked by flows of people and materials, that connected coastal lowland settlements with an extensive, highly dispersed industrial hinterland.

Figure 7. Metallurgical debris from coastal settlements (left) and foothills smelting sites (right). Scale bars are 10 cm.

Recent research on metallurgy in the eastern Black Sea area makes it possible to analyse the crafting landscape of Colchis as a system. Was metal production centrally administered or controlled? What social institutions or elite groups would have had the capacity to administer production activities in such a dispersed landscape? Is the relatively uniform character of the Colchian smelting sites—their layout, the tools and the techniques of smelting—indicative of top-down organization, or an emergent feature of a shared community of practice? Through a discussion of recent field and laboratory analyses, full details of which have been published elsewhere (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2014; Reference Erb-Satullo, Gilmour and Khakhutaishvili2015; Reference Erb-Satullo, Gilmour and Khakhutaishvili2017; Reference Erb-Satullo, Gilmour and Khakhutaishvili2018), I show how important assessments of spatial scale, power projection and articulation are to answering these questions.

Considerations of spatial scale are central to how one interprets the organization of production in the metal crafting landscapes of Colchis. On a regional scale (scales of tens of kilometres), the LBA–EIA copper smelting sites appear somewhat clustered (Fig. 4). In one intensively surveyed area, the Supsa-Gubazeuli group, nearly 50 smelting sites were identified in one small area of roughly 10 sq. km, a remarkable density of smelting sites (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2017). Within this survey area, however, on the kilometre scale, the sites follow an even, dispersed distribution, with virtually no clustering at all (Fig. 5). In fact, the apparent regional-scale clustering is most likely a product of the patterns of archaeological research. Numerous other LBA–EIA copper smelting areas are known from Soviet-period work and ongoing research (Sulava et al. Reference Sulava, Gilmour, Chagelishvili, Beridze and Rezesidze2020) strongly suggests that there are even more. The overall impression is one of ubiquity; almost everywhere that there are copper deposits, there is nearby evidence for LBA–EIA smelting. While it is reasonable to suspect some degree of regional-scale clustering of smelting sites near copper deposits, the large number of copper deposits means that smelting was widespread in the foothill margins and mountain zones of Colchis. Remarkably, the number of known Late Bronze–Early Iron Age smelting sites in Colchis rivals or exceeds most other areas in the Near East, despite an environment ill-suited to archaeological survey.

Assessments of how patterns of concentration and dispersion play out across different stages of production (cf. Fig. 2) are also central to interpretations of the Colchian metal crafting landscape. Like the primary smelting landscape, the distribution of secondary production debris is also highly dispersed (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2017, 121–2). Casting moulds, and to lesser extent tuyères, are common finds at settlement sites. The best documented secondary workshop is at the coastal site of Choloki, where numerous casting moulds were found around a circular building with a hearth at its centre (Chavleishvili Reference Chavleishvili1991) (Fig. 6). Discoveries of casting moulds of roughly the same period at Namcheduri, just a few hundred metres away (Mikeladze & Khakhutaishvili Reference Mikeladze and Khakhutaishvili1985, pl. 36), underlines the ubiquity of metal manufacturing. Indeed, there seems to be no evidence that metalworking was restricted to just a few settlements (Mikeladze Reference Mikeladze1990, 26). Available evidence makes analysis of intra-settlement patterning and comparisons of output between settlements difficult, so it is not yet possible to say whether the spatial organization might follow a model like the one described in Fig. 1B.

With respect to mining activities, direct and indirect evidence suggests that mining activities were dispersed on both a regional and local scale. In Colchis, Bronze Age mines are best documented in the Greater Caucasus, but there are occasional reports in the Lesser Caucasus as well (Khakhutaishvili [1987] Reference Khakhutaishvili2009, 53; Mudzhiri Reference Mudzhiri2011). Geological surveys documenting widespread copper deposits, and their correspondence with known smelting areas, offer more circumstantial evidence that Bronze Age mining occurred throughout the region. It seems unlikely that ores would be carried long distances from mines to smelting sites, given the greater portability of smelted metal versus ore. Differences in slag compositions at neighbouring, contemporary smelting sites strongly suggest the exploitation of different outcrops by different groups of metalworkers (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2017), an interpretation supported by geological data (Gabunia Reference Gabunia and Godabrelidze1933). Even at a local scale, therefore, mining activities do not seem to be centralized.

The patterns of dispersion in multiple stages of bronze manufacture are crucial to the argument for the lack of centralized administration in the Colchian bronze economy (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2017). The critical point is not only that smelting sites were scattered widely in the region, but that essentially all stages of production were carried out at numerous, individually small-scale sites. Dispersion and concentration need to be considered for different production stages and at different spatial scales.

The articulations between different elements of the Colchian crafting landscape are also vital to interpretations of how the metal economy was organized. Analysis of metallurgical slags (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2014; Reference Erb-Satullo, Gilmour and Khakhutaishvili2017) reveals the articulations between miners and the smelters, and between different groups of smelters. The variable chemistry and mineralogy of smelting slags is a reflection, altered through thermodynamic processes, of the composition of ores. Analysis of the slags, therefore, helps to track the nature of material flows between mining and smelting sites, and ultimately the ways in which these different production components articulated. There is significant latitude for different articulations between the mining and smelting elements of crafting landscape, particularly with regard to exclusivity in the patterns of ore distribution from mining sites to smelting sites. A large-scale spatio-chemical analysis of slags from one well-surveyed local area (Fig. 5) showed that different smelting sites had different ore-use profiles and were probably receiving ores from distinct mining sites within the local copper-bearing zone (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2017). This pattern holds even for contemporary sites with nearly identical radiocarbon dates in close proximity to one another. The articulation between mining and smelting spaces was such that separate mining sites supplied separate smelting sites, rather than a single mine distributing ores to a dispersed network of smelters. Miners and smelters were probably part of the same work groups, with different groups active in the same area. These results also have implications for the articulations between different groups of smelters. In addition to their physical separation, the evidence for discrete networks of ore procurement suggests a workflow segregation as well. Different groups of metalworkers undoubtedly interacted, as the distances between sites are small, but it is likely that access to and control of resources were negotiated on an emergent basis, rather than through any imposed top-down organizational measures. The nature of these interactions, illuminated through spatial and materials analyses, all go beyond simple measurements of spatial proximity—the essence of articulation in crafting landscapes.

Evaluated against the challenges of administering a highly distributed, spatially scattered industry, what were the sources of power and possible ways control could have operated in such a landscape? The social organization and political hierarchy of Colchis in the late second and early first millennium bc is poorly understood. A full discussion is beyond the scope of this paper, but a few key observations will suffice.

The material culture of Bronze Age Colchis differs in significant ways from other regions of the South Caucasus. With some possible exceptions at the region's margins, Colchis lacks the monumental constructions, such as kurgan burials or massive stone fortresses, which characterize the Middle Bronze through Early Iron Age periods in neighbouring regions. Canals around Colchian settlements are occasionally mentioned as examples of large-scale constructions (Apakidze Reference Apakidze2005; Sagona Reference Sagona2018, 452–3), but the size, extent, chronology and mode of construction, and social implications of these systems have yet to be studied in detail. Significant social hierarchy—which is evident much earlier in both the North Caucasus and in other parts of the South Caucasus—appears only in the Iron Age. Elaborate collective graves filled with objects are recorded by the eighth–sixth centuries bc, and rich graves of elites and their retainers in Classical and Hellenistic Colchis attest to the emergence of an elite social stratum during the first millennium bc (Kacharava & Kvirkvelia Reference Kacharava, Kvirkvelia, Kacharava, Kvirkvelia and Chi2008; Papuashvili Reference Papuashvili, Albegova, Bagaev and Korenevskiy2011). Most Late Bronze–Early Iron Age settlements in Colchis appear to be modestly sized farmsteads or villages, sometimes with defensive ditches or palisades, often clustered together in a mosaic of low-density settlement (Apakidze Reference Apakidze2005). Hoards of metal and large ingots suggests that copper alloys were a desirable and probably ritually significant commodity (Lordkipanidze Reference Lordkipanidze2001), but there is little evidence for efforts to control production at the source. The key period of 1300–800 bc, corresponding to the height of copper smelting, lacks clear evidence for significant administrative capacity or power projection capabilities, in the form of large-scale storage facilities, monumental buildings, or other infrastructure, that would be necessary to administer the enormous aggregate output of the highly dispersed bronze production landscape. As such, the evidence suggests that administrative power in Colchis at this time was far too diffuse to exercise exclusive control over primary and probably even secondary metallurgical processes.

In sum, the spatial organization of the crafting landscape, the character of socio-spatial relationships (i.e. articulation) between different groups of miners and metalworkers and the lack of any clear evidence of institutional power projection all point to a lack of top-down control in the bronze economy. When evaluated in light of this accumulated evidence, the relative uniformity in the types of metal artifacts, the technologies of copper smelting and the spatial layout of smelting sites are best explained as a common technological style emerging among independent but interacting groups (Erb-Satullo et al. Reference Erb-Satullo, Gilmour and Khakhutaishvili2017, 123).

Analysis of Colchian metallurgy through the lens of the crafting landscape brings into focus just how distinctive the metallurgical system of the eastern Black Sea was. Unlike other late second- and early first-millennium bc metallurgical systems in the Near East, the Colchian economy's enormous aggregate metallurgical output was the product of a highly decentralized production system. Individual sites are modest in size, but their sheer number places the Colchian metallurgical landscape among the most productive of its time. In contrast, the copper industry of the early Iron Age southern Levant is characterized by fewer, but individually larger copper production sites (Levy et al. Reference Levy, Najjar and Ben-Yosef2014). At these Levantine sites, major fortifications at smelting sites attest to a considerably higher power projection capacity for the nascent Edomite state, and a much closer and more sustained articulation between administrative institutions and metal producers. Late Bronze Age metal production on Cyprus might be a closer model for the Colchian system, but while large numbers of extra-settlement smelting camps are documented in Colchis, only one, about the same size as an individual Colchian smelting workshop, is known from Late Bronze Age Cyprus (Knapp & Kassianidou Reference Knapp, Kassianidou and Yalçin2008). Others probably existed, but they have yet to be identified, and so the organization of Late Bronze Age smelting in the hinterlands of Cyprus remains an outstanding question. The broader context of metal exchange is also significantly different, as Cypriot copper production was linked with the broader eastern Mediterranean exchange system. The balance of local consumption and long-distance exchange in Colchian bronze remains unclear. Nevertheless, the Colchian case illustrates the value of the theoretical concepts discussed earlier as comparative tools for analysing production systems.

Conclusion

The social and economic organization of production impacts the spatial patterning of crafting activities in complex and often indirect ways. Control of production by elites is not always correlated with spatial centralization, nor is the extent of control always reflected by straightforward spatial associations between crafting activities and elite buildings. While the vagaries of archaeological visibility and the difficulties of dating production sites on survey pose methodological challenges, systemic investigations of crafting landscapes are eminently achievable.

The preceding discussion clarifies the theoretical principles and practical considerations used to interpret the social and economic organization of craft production from the spatial analysis of its archaeological residues. First is the recognition that the commonly referenced concentration index, conceptualized as a linear scale between ‘nucleated’ and ‘dispersed’, is often inadequate for describing the spatial patterning in crafting landscapes. Natural and cultural landscape features, such as waterways and settlements, introduce an added layer of structure to these distributions. Second is the importance of spatial scale and its relationship with the power projection and the geographies of control. Implicit assessments are widespread in discussions of power and craft production, but explicit interrogation and analysis of these assumptions strengthens the case for any given production model. Finally, the concept of articulation draws attention to the importance of considering the character of spatial relationships between elements of a production system, prompting us to rethink the casual equation of proximity and control. By laying bare the spatial logics and underlying assumptions involved in assessments of whether and to what extent production was centrally controlled, these principles provide a theoretical toolkit for (re-)evaluating archaeological models for economic organization.

Acknowledgements

Surveys of Colchian metal smelting sites with Brian Gilmour and Nana Khakhutaishvili have proved fertile ground for theorizing about crafting landscapes, and I thank them for their collaborations. The Poti Museum of Colchian Culture and the Batumi Archaeological Museum gave permission to photograph the metallurgical finds from settlements included in Figure 7. Digital elevation data in maps were provided by SRTM and ASTER (a product of METI and NASA). The research discussed in the case study was funded by the National Science Foundation (BSC-1338893), the Davis Center for Russian and Eurasian Studies and the Harvard University Department of Anthropology. Anke Hein, Shadreck Chirikure, David Killick and two anonymous reviews provided helpful suggestions for improving the paper.