1. Introduction

In 2014, Nicholas Crafts and Nikolaus Wolf examined the geography of the United Kingdom cotton industry to ask why it was concentrated in only one county, Lancashire, why it stayed within the county and why it did not develop elsewhere.Footnote 1 A similar, but as yet unanswered premise, applies to the location of woollen cloth manufacture, the staple industry in England for centuries, in terms of both employment and output, long before cotton rose to importance.Footnote 2 In 1700, woven cloth accounted for over 78 per cent of the value of all English exports.Footnote 3 Over 95 per cent of these exports were from wool and worsted.Footnote 4 Woollens dominated textile production and the value added from cotton only came to exceed wool after c.1800. Thereafter, woollens remained important as the second largest manufacturing sector with an output of two and a half times the size of iron and steel until as late as 1831.Footnote 5

It is known that woollen manufacture, once widespread across large parts of England, declined in eastern, southern, and western counties to become concentrated in the low wage economy of the West Riding of Yorkshire. Despite the importance of the industry, in the absence of data it has not been previously possible for scholars to quantify the scale and timing of the shift and hence provide adequate explanations as to why it occurred.

Our study makes several interesting observations: first, the Yorkshire woollen manufacture was itself of national significance at least as early as the late-fifteenth century. Second, the Yorkshire manufacture began to relocate away from the City of York to settle in places in the west of the county where running water and coal were readily accessible. Third, the manufacture in other counties of England began to de-industrialise in the seventeenth century, initially in those counties with close proximity to London. Fourth, by the mid-eighteenth century, approximately 40 per cent of the male labour force in the English woollen cloth manufacture lived in the West Riding of Yorkshire and by 1817 the share had reached 75 per cent. Fifth, the West Riding of Yorkshire manufacture was already located on the coalfield and well-placed to exploit the need for cheap energy when mechanisation and the application of steam power took off in the last decade of the eighteenth century.

Industrial location is complex and impacted by many factors. In 1979, D. A. Farnie studied the location of the cotton manufacture to suggest that the influences could be classified as either original or acquired advantages.Footnote 6 In the former group, he included poverty, climate, water, textile tradition and mechanical inventions and in the latter, coal, machinery, and labour. These advantages have been examined before and since by others. For instance, Edward Baines and Mary B. Rose believe the pre-industrial woollen and linen manufactures in Lancashire prepared the way for cotton.Footnote 7 Crafts and Wolf agree, their recent study concluding that both original and acquired factors were in play, agreeing in large part with Farnie but also including access to foreign markets. Like H. A. Ogden, Crafts and Wolf dismiss the role played by climate, particularly that of humidity.Footnote 8

Theo Balderstone describes the ‘sun and satellite’ configuration of the mid-eighteenth century Lancashire cotton manufacture centred around Manchester with numerous satellite towns benefitting from local coal.Footnote 9 In 1795, J. Aikin had identified the importance of local coal pre- steam to the cotton manufacture and although he never explained why, Balderstone thinks it likely because it was just accepted that it was so, cheap domestic fuel allowing population density to increase.Footnote 10 Alan Fernihough and Kevin Hjorstshøj O'Rourke suggest that the growth of European cities after 1750 was also dependent on the accessibility of coal.Footnote 11

With regard to woollens and the West Riding of Yorkshire, Pat Hudson notes ‘there has been a long debate about the causes of Yorkshire's success’, citing ‘organisational patterns, commercial links, credit relationships, sorts of cloth produced’.Footnote 12 These factors may explain why the Yorkshire manufacture succeeded, but they do not necessarily explain why there was such a strong shift to Yorkshire in the first place. By examining the temporal location of the West Riding of Yorkshire manufacture our study suggests there were three overriding determinant factors. One was the availability of flowing water, the second was access to cheap coal, and the third the relationship of the latter with poverty and the cost of living.

2. The historiography and the importance of coal to industry

There is an extensive literature that discusses the English industrial revolution and the importance of coal to generate steam power.Footnote 13 Little has been made, however, of the importance of cheap coal before the classical period and some historians have been dismissive of the connection. John Clapham, for instance, largely rejected ‘the old theories of geographical determination’, suggesting coal and water power were insignificant before industrialisation.Footnote 14

G. Wilson noted: ‘clearly, considerations about coal and iron are far less important when applied to the eighteenth century situation’.Footnote 15 Eric L. Jones also believed the connection between early industry and coal to be tenuous.Footnote 16 For him, the high price of coal in southern England did not become a major competitive advantage for the north until the introduction of heavy industry and the coal-fired steam engine.Footnote 17 Others such as Pat Hudson, however, have been less dismissive noting ‘even before steam power was important, coal was required to provide heat in [cloth] dyeing and scouring…coal mining was widespread in the textile area and coal needed by the industry was locally supplied: some manufacturers like John Foster even mined their own’.Footnote 18 Other than from Hudson, this lack of attention to the potential role of coal is surprising given that a number of early commentators clearly recognised the pre-industrial relationship with the woollen manufacture. For instance, in his tour of Yorkshire, published in 1727, Daniel Defoe referred to Halifax in the West Riding where:

Business is the Clothing Trade, for the convenience of which the houses are thus scattered and spread upon the Sides of the Hills, and above, even from the Bottom to the Top; the Reason is this; such has been the bounty of Nature to this otherwise frightful Country, that two Things essential to Business, as well as to the Ease of the People are found here, and that in a Situation that I never saw the like of in any Part of England, and I believe, the like is not to be seen so contrived in any Part of the World; I mean Coals and running Water upon the Tops of the highest Hills: This seems to have been directed by the wise Hand of Providence for the very Purpose which is now served by it, namely the Manufactures, which otherwise could not be carried on, neither indeed could one fifth part of the Inhabitants be supported without them for the land could not maintain them.Footnote 19

In 1748, the Essex historian, Philip Morant wrote that the trade in the city of Colchester in Essex in eastern England ‘had removed in great measure into the west and northern parts of this kingdom where provisions are cheaper, the poor more easily satisfied, and coals are very plentiful’.Footnote 20 A decade later, R. Massey noted the cloth trades had moved ‘Northward where greater Plenty of Firing, and Cheaper Rates of other Common Necessities of Life, or small Taxes, favour their Increase much more than in our Southern Counties’.Footnote 21 No commentator provides a clearer statement as to the reasons why the woollen industry relocated than Adam Smith who, in 1776, wrote explicitly of the need for cheap heating:

In a country where the winters are so cold as in Great Britain, fuel is, during that season, in the strictest sense of the word, a necessity of life, not only for the purpose of dressing victuals, but for the comfortable subsistence of many different sorts of workmen who work within doors; and coals are the cheapest of all fuel. The price of fuel has so important an influence upon that of labour, that all over Great Britain manufactures have confined themselves principally to the coal counties; other parts of the country, on account of the high price of this necessary article, not being able to work so cheap. If a bounty could in any case be reasonable, it might perhaps be so upon the transportation of coals from those parts of the country upon which they abound, to those in which they are wanted. But the legislature, instead of a bounty, has imposed a tax of three shillings and three-pence a ton upon coal carried coastways; which upon most sorts of coal is more than sixty per cent of the original price at the coal-pit. Coals carried either by land or by inland navigation pay no duty. Where they are naturally cheap, they are consumed duty free: where they are naturally dear, they are loaded with a heavy duty.Footnote 22

3. The introduction of steam power in the wool and worsted manufactures

It is key to this study to understand the date by which steam power was first introduced into the two industries. It is well known that some wool processes were mechanized during the eighteenth century, but these were not powered by steam. Kay's flying shuttle for instance, invented in 1733, was a labour-saving innovation that allowed broadcloth weaving to be reduced from a two-person to a one-person operation, but was worked by hand.Footnote 23 James Hargreaves’ spinning jenny, invented in 1764, was also hand operated and remained a domestic machine in the wool manufacture until the nineteenth century. Samuel Crompton's mule, introduced in 1780, was rapidly taken up by cotton spinners. Steam-powered cotton mules were introduced in Lancashire during the 1790s.Footnote 24 The mule, however, had limited application to either wool or worsted at this time.Footnote 25 Similarly, although steam-powered cotton weaving was introduced in the second decade of the nineteenth century, wool yarn was less robust, unsuitable for these early machines, and wool weaving remaining a largely domestic occupation until the 1850s.Footnote 26

Steam power appeared in wool manufacture in the 1780s but these machines were small and used to boost water flow.Footnote 27 It was not until 1792/93 that a steam driven scribbling/fulling manufactory began operation in Leeds in the West Riding of Yorkshire. Steam power was slow to be adopted and as Herbert Heaton noted the West Riding of Yorkshire wool manufacture was ‘still largely in the hands of small independent clothiers’ at the end of the eighteenth century.Footnote 28 These clothiers owned the materials they worked on, and other than fulling, they prepared the yarn, spun, wove, and finished cloth within the household.Footnote 29 This was a domestic industry that needed a cheap source of heat to work a number of processes, notably wool washing, scouring and bleaching, firing kilns to dry yarn, dyeing, but as yet did not need fuel to drive machinery.Footnote 30 In other counties of England, steam power was introduced into the wool manufacture at a later date. Although the West Country industry adopted early scribbling and carding, these were driven by water or by horse.Footnote 31 It was not until the early-nineteenth century that steam power was slowly established.Footnote 32

Some processes utilised in the worsted manufacture also required heat, cheap fuel needed to both heat the combs used to disentangle long-haired wool and to fire presses that were used to impart a shine on some types of cloth. It was not until 1787 that the first worsted spinning mill was opened. The mill used Arkwright's frame, constructed on the River Wharfe in Addingham in the West Riding of Yorkshire, and powered by water.Footnote 33 Other worsted spinning mills were erected during the 1790s but these too were driven either by water or by horse.Footnote 34 Moreover, S. D. Chapman has noted that although there were a number of worsted spinning mills in operation in the West Riding of Yorkshire by 1800, there is no evidence to suggest that any produced yarn in commercial quantities.Footnote 35 Hudson goes further to suggest that mechanical worsted spinning was not widespread until the 1820s.Footnote 36 Once steam power was introduced, Yorkshire worsted yarn was not only used locally but was also sold elsewhere, for instance to the relatively few remaining worsted manufacturers in Norwich where little attempt to produce their own machine spun yarn was made.Footnote 37 Similar to wool, the worsted manufacture was slow to adopt steam powered weaving, which did not take off significantly until the third decade of the nineteenth century.

In summary, eighteenth-century mechanical innovations did not utilise steam until the last decade. The key date for wool is 1792/93, before which all operations were hand- or water- powered. For worsted, steam power was not introduced until the nineteenth century.

4. Primary sources

We use a number of primary sources to locate and then track temporal change in the labour force. None of these sources are perfect. All sources report the work of adult men only, not by our choice but one of necessity because of the paucity of temporal information on the work of women and children. The focus, therefore, is on occupations such as weaver, fuller, and dyer, and not upon spinning. Whilst not ideal, the omission is not considered problematic for the West Riding of Yorkshire wool manufacture because of the way in which it was organised.

Unlike the wool trade in the West Country, where the clothiers tended to be large scale manufacturers who put work out to distant spinners, women and children, the manufacture in the West Riding of Yorkshire was organised largely on a family basis. Wilson noted ‘in the West Riding of Yorkshire the clothier, especially in the woollen industry, was a man of small capital who, with the aid of his family, completed all the processes and then sold his weekly output to local merchants who attended the cloth halls in Leeds, Wakefield and Halifax’.Footnote 38 For these men, putting out work to distant spinners was not therefore an issue. The only processes that these clothiers did not undertake themselves were fulling, for which they used a local public fulling mill, and dyeing.Footnote 39 Dyeing was a specialist process and was concentrated in a relatively few places, particularly in the major towns and the commercial centres. For instance, the 1813–20 baptism registers record 731 dyers in the West Riding of Yorkshire, 43 per cent of whom lived in Leeds and another 30 per cent in Halifax town, Wakefield and Huddersfield combined. These places had running water and cheap coal. Dyeing processes involved heat such that J. U. Nef believed the seventeenth century textile manufacture was one of the top half dozen industries using the largest amounts of coal.Footnote 40

The omission of the work of women and children is more problematic for the worsted manufacture in which we know spinners outnumbered weavers by as many as three or four to one. We also know that the manufacture was organised on a ‘putting out’ basis and although most spinning was undertaken close to the weaver's home, some spinners lived 20, 30, or 40 miles distant. Examination of the Yorkshire Quarter Session records of spinners prosecuted under the Worsted Act for embezzlement shows that while the majority of these spinners lived in woollen parishes on exposed coal measures, some also lived elsewhere notably in the north of the county.Footnote 41 John Sutcliffe, a Halifax worsted manufacturer, had a spinning network 20, 30, and 40 miles distant but compensated for this inconvenience and the time lost in carrying wool and yarn to and fro by paying these spinners less. The warp required to make one piece of cloth cost Sutcliffe 6s 1½d, spinners distant received 1s less.Footnote 42

Our analysis begins with the identification of the location of the cloth manufacture c.1500, for which two primary sources are utilised, namely ulnage accounts and the records of the Court of Common Pleas. The ulnage accounts originated in 1196 when standard measures were introduced in England. One measure required woollen cloth to conform to a specified width and inspectors were appointed to ensure manufacturers complied. The size restriction was lifted in 1353 but inspection remained ‘in order to certify, for the benefit of the buyer, as to the true dimensions of the pieces of cloth submitted’ for sale. A subsidy of 4d per cloth was charged for this service.Footnote 43 Many accounts survive to provide a record of the quantity of cloth sold by county and by place. The records, however, are incomplete and whilst they capture cloth manufactured for sale those produced for home consumption or at the request from another, were exempt. Some cheaper wool cloth, and all worsteds, were also excluded.Footnote 44 Whether ulnage is an accurate reflection of the industry has been questioned, notably by Eleanor Carus-Wilson who believed the returns for the West Country 1467–78 were fraudulent.Footnote 45 There is no evidence to suggest that false practices were systemic across England but we also use a second source, records from the Court of Common Pleas, to confirm location.

The Common Pleas sat four times a year and had exclusive jurisdiction over rights of ownership, debt, and eviction. Jurisdiction over trespass and other breaches of statute was shared with the King's Bench.Footnote 46 The Court of Common Pleas covered most of England but counties with palatinate status such as Durham and Lancashire were excluded. The pleas, a rich source of occupational information, have been transcribed by the University of Houston, Texas, USA.Footnote 47 We have analysed 57,343 pleas recorded 1483–1524. Of these, 69 per cent were for debt, 11 per cent for trespass, and the remaining 10 per cent for a range of other misdemeanours. With some exceptions, all pleas involve men. Few women are recorded, and then often those with an occupation such as Abbess or Prioress. It was not unusual for the occupation of the plaintiff to be left unrecorded, whereas the occupations of defendants were recorded in over 95 per cent of cases. Consequently, our analysis is of the occupations of male defendants only. We analysed pleas for both debt and trespass because they likely represent different strata of society. Those for debt involved significant sums of money, between 40 shillings to thousands of pounds, and are likely to bias towards the more affluent members of the cloth manufacture. Pleas for trespass involved misdemeanours such as assault, theft, and forgery. They were not skewed to the better off and perhaps more representative of the working man.

Since there were fewer ulnage records for the sixteenth century, and occupational data from the Common Pleas of that time are sparse, we locate the English cloth manufacture c.1600, therefore, from other records. Probates, another rich source of occupational information, are used. We are not the first to do so, probates having been used by others to examine structural change in the British economy before the industrial revolution.Footnote 48 Probates are also problematic because they are essentially restricted to men, and socially biased towards those with something of value to leave, rather than by those with relatively little. In their raw form, therefore, probates are skewed towards the wealthy. Sebastian Keibek has abstracted occupations from over 750,000 probates, 1600–1784, and compared them with occupations recorded within parish registers, the latter more socially representative than the former since marriages and baptisms captured a broader cross section of the population.Footnote 49 His methodology shows that the probability of a farmer, for instance, leaving a probate was greater than say that of a butcher who in turn was more likely to do so than was a weaver.Footnote 50 Keibek calculated calibration factors for each occupation to reweigh the probate data and used the methodology to determine the male occupational structure of England and Wales, 1600–1850.Footnote 51 His data is used in this study.

Keibek's work omits Yorkshire, but James Wells has used the same methodology to recalibrate seventeenth-century probate data for that county and this data is used here also.Footnote 52 Wells found eighteenth-century Yorkshire probates to be less accessible than those for other counties and since they are not in the public domain and not all record occupations, his occupational analysis of Yorkshire utilises parish records.

Finally, the 1813–20 baptism registers of England and Wales are used to locate the cloth industry at that time. These are the most reliable data used since the Parochial Registers Act of 1812 changed the manner in which baptisms were recorded and obliged the Church of England by law to record information, including the occupation of the father, on a standardised pro forma. Jews, Quakers, and the Royal family were exempt, but otherwise the baptism registers post- 1812, at least in theory, capture the occupation of the father of every baptised child. Illegitimate children, who accounted for approximately 5 per cent of all births in England and Wales at this time, were also excluded because in the in the eyes of the law, the children were fatherless. The Cambridge Group for the History of Population and Social Structure has collected and coded the records of England and Wales 1813–20 to create a ‘census’ of adult male employment and we use this database to determine the location of the cloth manufacture at that time.Footnote 53 For convenience, the year of these data is referred to as 1817, roughly the mid-point of the years 1813–20.

5. Location of the English cloth manufacture, c.1500

The analysis of the ulnage accounts to locate the main counties for cloth production c.1470 is shown in Table 1. Four key regions are identified, namely the West Country counties of Gloucestershire, Somerset, Wiltshire, Devon, and Dorset, the East Anglian counties of Suffolk, Essex, and Norfolk, the home counties of Berkshire, Hampshire, Kent, Surrey, Sussex, and Middlesex with close proximity to London, and Yorkshire. The relative prominence of these counties is confirmed by the examination of Common Pleas c.1500. Approximately 40,000 common pleas for debt and 11,500 common pleas for trespass, containing 2,800 and 600 entries respectively for male defendants working in the cloth manufacture, have been analysed (Figure 1). Whilst absolute differences between those charged with debt and those charge with trespass are apparent, and not unexpected given that the defendants represent different socio-economic backgrounds, the relative strength of the four regions is clearly shown (Figure 2).

Figure 1. Common Pleas: The location of male defendants working in cloth manufacture, pleas for debt and trespass, 1483–1524. (Expressed as the percentage of those employed in cloth manufacture in each county).

Source: Common Pleas, University of Houston Law Centre.

Figure 2. Distribution of cloth manufacture in England, 1498–1524. (Data expressed as the percentage of textile occupations recorded in each county).

Source: Common Pleas in cases of debt, University of Houston Law Centre.

Table 1. Number of cloths produced by county in c.1470

Notes: Only those counties manufacturing more than 500 cloths are included.

Source: Ulnage accounts, Heaton (1920).

Turning our attention to Yorkshire, the examination of the 1473–75 ulnage accounts show the relative strength of the manufacture in a number of cities and towns (Table 2).Footnote 54 Cloth output by City of York manufacturers was the largest and together with the production by manufacturers in the ecclesiastical city of Ripon to the north, accounted for 52 per cent of the Yorkshire total. The York trade, however, was in decline, common plea data showing that the number of men involved dropped by over 70 per cent between 1450–89 and 1490–1529 (Table 3). By the latter time, more men worked in the industry in each of Wakefield, Halifax parish, and Leeds, than did in York. Other than York, Ripon, and Hull, the chief Yorkshire east coast port, all the places with a significant cloth manufacture sat on exposed coal measures which stretched west to east from Halifax to Pontefract.Footnote 55 Coal was dug from shallow seams or outcrops in Leeds, Barnsley, and Wakefield from the medieval period onwards. It was used locally and often ‘part-time digging on an occasional basis in small holes by farmers and artisans to satisfy their own household or workshop need’.Footnote 56 W. B. Twigg also noted that away from the main coalfield, outcrop coal was found in several townships in Halifax parish, including Brighouse, Elland, Hipperholme, Midgley, Northowram, Rastrick, and Southowram, all of which were home to cloth manufacturers.Footnote 57 Coal, however, was not the only fuel available in Halifax parish. The eighteenth century clergyman John Watson remarked ‘there is plenty of turf earth, which when prepared for fuel, by drying in the sun, is reckoned a wholesome firing’.Footnote 58 Another interesting feature is that the manufacture settled in Halifax parish not on the valley floor, but on the hillside where the surface rocks were millstone grit and coal measures. There were many running streams, the millstone grit holding water on its surface to provide an abundant supply which, in the absence of chalk deposits, was soft.Footnote 59

Table 2. Place of manufacture and the number of cloths sold in Yorkshire, 1473–75

Source: Ulnage accounts, Heaton, (1920).

Table 3. Number of men in the cloth manufacture in selected places in Yorkshire, 1450–1529.

Source: Common Pleas, University of Houston Law Centre.

Sixteenth-century contemporaries were well aware that the cloth manufacture industry shifted from York to places where there was poverty and little alternative work, but where water and coal was readily available. In 1561, the Mayor of York remarked:

I the Mayour of the Citie of York have caused diligent inquyrie and serche to be made what number of weavers and loomes for wollen clothe are within the same; and therapon doo fynd and perceyve that there in the sayd Citie not above tenne weavers, whoo can work both lynen and wollen, and yet there lyvyng is of lynen; also there is presently remaynyng in the sayd Citie iiij wollen weavers onely, whereof Thomas Clerk hath one, Roger Faucet one, William Beiston one, and Abraham Harkay one, which for the most part doo stand unoccupied for lak of work. Moreover one Richard Marshall of the sayd Citie, marchant, did latly sett up draping in the Citie and had one wollen loome here of his owne, but bycause he founde no gaynes at it he hath leaft of. And the cause of the decaye of the sayd weavers etc. as I doo understand and learne is the lak of cloth makying in the sayd Cite as was in the old tyme accustomed, whiche is now encreased and used in the towne of Halyfax, Leeds and Wakefeild for that not onely the commodite of the water mylnes is there nigh hand, but also the poore folk as spynners, carders and other necessary work folks for the sayd webbying may there besyds their hand labour have been kyen, fyre and other relief good and cheap whiche is in this Citie very deare and wanting.Footnote 60

York weavers were faced with ‘the bleak wind of West Riding competition’.Footnote 61 Although coal was brought to the city of York from collieries in Wakefield and the north-east, it was expensive, a proclamation of the citizens in 1579 noted that turves are ‘now the greatest part of our fuel’.Footnote 62

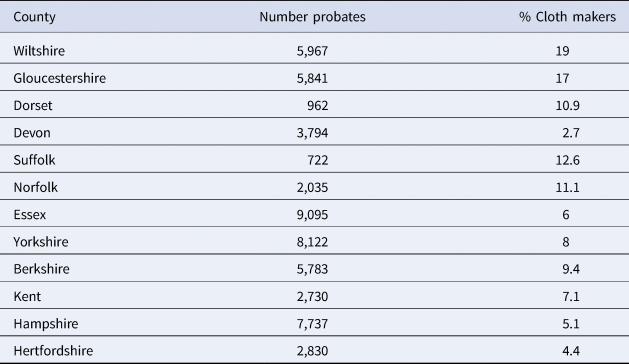

6. Location of the English cloth manufacture, c.1600

Having established the location of cloth manufacture both nationally and locally in Yorkshire c.1500, we now turn attention to locating the industry at the beginning of the seventeenth century. The analysis of the reweighted probates for the years 1580–1620 is shown in Table 4.Footnote 63 Although there are relatively few probates for Suffolk and Dorset, the sample size is considered reasonable, and the analysis suggests there was little change in location from the previous 100 years. These data reflect the relative importance of the manufacture to each county, but they do not necessarily show the national significance because they take no account of the population. To correct for this, the percentage shares are adjusted and converted into estimates of actual number of men in the industry using E. A. Wrigley's population data for 1600 and his determination that 23 per cent of the population was adult males (Table 5).Footnote 64 The estimates can only be rough approximations and as such are treated with caution but they do suggest that around 15,000 men worked in the East Anglian cloth manufacture at this time, and 13,000 men worked in the West Country, excluding Somerset for which no probate data survive.

Table 4. Chief counties for cloth manufacture in England, c.1600

Notes: There are limited data for Somerset, Surrey, Sussex and Warwickshire, hence these counties are excluded from the table.

Sources: Probates, Keibek (2016) and Wells (2018).

Table 5. Estimated number of cloth makers, by county, c.1600

Notes: There are relatively few probates for the East Riding of Yorkshire. The population total for Yorkshire, therefore, is for the North and West Ridings only.

Sources: Probates, Keibek (2016) and Wells (2018).

Approximately 5,500 men worked in each of the industries in Yorkshire and the home counties around London. It is not unreasonable to conclude that the male labour force in East Anglia and the West Country were of similar size, and perhaps three times as large as those in Yorkshire and the home counties.

In Yorkshire, 70 per cent of those men manufacturing cloth lived in the West Riding in the parishes and settlements identified by the Common Pleas (Table 6). The manufacture in Halifax parish continued to expand, and cloth workers were now to be found in other settlements such as Elland, Ovenden, and Shelf where outcrop coal was dug. Essentially all of these cloth makers lived either on or very near the exposed coal measures (Figure 3).Footnote 65 These coal measures are taken from a survey carried out in 2003 and as such could be non-representative of the early seventeenth century, but Nef and Hatcher have both identified numerous places, shown in the figure, where mining activity was ongoing at and before that time. There is a clear proximity between these locations and those where the cloth manufacturers lived.Footnote 66 Moreover, Hatcher notes, ‘not only was [Yorkshire] coal dug in the later Middle Ages in the majority of localities where mining was to take place up to the eighteenth century, the pattern of intensity of medieval mining was essentially similar to that followed in later centuries’.Footnote 67 The Yorkshire manufacture, therefore, was in large part on the coal field long before steam power was utilized.

Table 6. The number of pleas involving men working in the Yorkshire cloth manufacture, by place, c.1600

Source: Probates, Wells (2018).

Figure 3. Location of cloth manufacture and mining activity in the West Riding of Yorkshire c. 1600.

Sources: See the text.

7. Location of the English cloth manufacture, 1661–1817

Analysis of the reweighted probate records, the percentage shares converted into estimates of actual number of adult men using the methodology outlined previously, shows that eastern, southern, and western counties of England began to textile de-industrialize during the seventeenth century. The onset of decline was not consistent across the country but varied by county, some holding up longer than others. There is evidence of fall-off in Kent after 1661, and in Hampshire after 1701 (Figure 4). The decline in these counties is attributed in large part to their close proximity to London where there was a paramount need to feed the population that grew from 400,000 in 1650 to 750,000 by 1750.Footnote 68 Agricultural production within a 60–80 miles radius of London became more profitable than the manufacturing industry, forcing the latter to move to places where food, labour, and fuel were cheaper. According to F. J. Fisher, ‘… the result was to intensify the agricultural nature of south-eastern England and to push the major industrial areas away from the capital even before that process was completed by the use of steam power. In the sixteenth and early seventeenth centuries, there were considerable textile industries in Kent, Surrey, Hampshire and Berkshire…’, but by the end of the seventeenth century those textile industries had virtually disappeared.Footnote 69

Figure 4. Cloth manufacture in Kent and Hampshire, 1661–1817. (Expressed as estimates of number of men in the labour force).

Sources: 1661–1784, probates; 1817 baptism registers.

The decline of the Essex manufacture began at least as early as 1661 and continued throughout the eighteenth century (Figure 5). The town of Colchester, which once controlled a worsted manufacture over a wide rural area, moved away from cloth production after 1700 to become a service centre for local agriculture.Footnote 70

Figure 5. Cloth manufacture in Norfolk, Suffolk, and Essex, 1661–1817. (Expressed as estimates of number of men in the labour force).

Sources: 1661–1784, probates; 1817 baptism registers.

The Norfolk worsted manufacture fell away after 1701. This manufacture had concentrated in the seventeenth century, moving out of rural areas to focus in Norwich, driving the economic prosperity of the city to such an extent that by 1700 it was the third largest city in England, behind London and Bristol.Footnote 71 Thereafter, as the worsted manufacture declined, the population of Norwich stagnated and poor relief rapidly rose.Footnote 72 The demise had a knock-on effect in Suffolk. The Suffolk wool manufacture had previously disappeared, but the woollen industry survived in part by becoming a worsted yarn supply centre for Norwich weavers. When the Norwich industry fell-off so too did the demand for yarn and the Suffolk manufacture collapsed. Concomitantly, it was around the turn of the eighteenth century that worsted woolcombers and weavers began to first appear in the West Riding of Yorkshire, notably in Halifax parish.Footnote 73

In the West Country, the Devon cloth manufacture declined markedly after 1721 (Figure 6). The Wiltshire manufacture did likewise but unlike Devon, it held up during the second half of the eighteenth century albeit at a lower level. Of the West Country counties, only the Gloucestershire manufacture remained relatively stable over the period. This manufacture continued to be successful despite the competition from the West Riding of Yorkshire because of the nature and type of cloth produced; Gloucestershire clothiers were noted for their superior broadcloths not made to the same quality elsewhere.

Figure 6. Cloth manufacture in Devon, Wiltshire, and Gloucestershire, 1661–1817. (Expressed as estimates of number of men in the labour force).

Source: 1661–1784, probates; 1817 baptism registers

The exponential growth of the West Riding of Yorkshire male labour force after 1660 is shown in Figure 7.Footnote 74 There was a 120 per cent increase from 1721–84 and then a further increase of 86 per cent from 1784–1817. This growth is reflected by the rise in output. The West Riding of Yorkshire broadcloth production increased four-fold, 1730–1784, and worsted output rose from essentially nothing in the seventeenth century to equal the value of cloth produced by Norwich weavers by 1784.Footnote 75

Figure 7. Cloth manufacture in the West Riding of Yorkshire, 1660–1817. (Expressed as estimates of number of men in the labour force).

Source: Parish registers.

A comparison of the changes in the adult male labour force by region is summarised in Figure 8. Care needs to be taken because the West Country figures are under-recorded since both Dorset and Somerset are absent. Nonetheless, the growth of the West Rising of Yorkshire and textile de-industrialisation elsewhere is shown to be inexorable. In the eighteenth century the West Riding of Yorkshire manufacture acquired critical mass. We estimate that approximately 40 per cent of English woollen manufacture was located in the county by the mid-eighteenth-century. The share reached 75 per cent by 1817. Pat Hudson notes, the ‘increase in the output of the British wool textile sector by 150% during the entire eighteenth century seems very modest, but this conceals dramatic relocation taking place in favour of the West Riding of Yorkshire whose share of national production rose from around 20% to around 60%’.Footnote 76

Figure 8. Estimates of the number of adult men working in cloth manufacture in selected textile counties of England, c.1660–1817.

Notes: There are limited probate data for Somerset and for eighteenth century Dorset, hence the counties are excluded from this data Lancashire and Cheshire are included for completeness and show the beginning of the rise of the cotton manufacture.

Sources: See the text.

8. Discussion

8.1. Importance of water

Of Farnie's original advantages, poverty and water played significant roles and were key factors in Yorkshire's success. Watson described Halifax parish as ‘great waste and moores where the fertility of the ground is not apt to bring forth any corne, nor good grasse, but in rare places, and by exceeding and great industry of the inhabitants; and the same inhabitants altogether doe live by cloth making; and the great part of them neither getteth corne, nor is able to keepe a horse to carry wools, not yet to buy much wool at once’.Footnote 77 Moreover, the wool manufacture industry could flourish only in those places where running water was available.

Access to clean water for scouring and dyeing raw material, yarn, and cloth was needed and was a prerequisite for cloth milling. The short-haired wool fibres produced a loose weave and the cloth was unsuitable for use until it was shrunk and felted. This process, fulling, involved saturating the cloth with water and clay and then beating. Water-powered mills were employed for this purpose from the thirteenth century onwards and their introduction necessitated the fulling process to be located on or near a flowing stream. R. A. Pelham believed it was the introduction of the fulling mill that allowed the manufacture ‘to migrate from urban centres, where gild organization was all-powerful, and opposition to mechanization correspondingly strong, to rural sites where gilds had no control’.Footnote 78 He mapped early fulling mills in England and Wales to show a preponderance in the Lake District, the West Riding of Yorkshire, and the southern Marches of Wales. Pelham also observed mills ‘concentrated on high ground, avoidance of the lower navigable sections of the main rivers’. He noted an ‘avoidance of the older centres of manufacture, many of which were situated on these lower sections’. A consequence of the rise of the fulling mill was that wool manufacture in the ecclesiastical cities of Bath in Somerset, Winchester in Hampshire, York, and Lincoln became less significant.Footnote 79 Guilds governed and controlled the medieval trade but their influence waned as the woollen manufacture moved to other places. The impact of the introduction of the fulling mill was such that Carus-Wilson described it as an industrial revolution.Footnote 80

Pelham's data aside, there is little other temporal historiographical evidence that examines the location of water mills. Some evidence, however, can be gained from identification of the place of residence of corn millers in the early nineteenth century. The analysis of the 1813-1820 baptism registers shows millers were concentrated in the West Riding of Yorkshire, particularly east of the Pennines in and around Halifax parish and in Leeds, as well as west of the Pennines in Lancashire where running water from hillside streams was also freely available.

These data reflect those observed by Pelham and illustrate that the Pennines held a natural advantage over other places in England. There was an early woollen manufacture in the Lancashire Pennines. Fourteenth-century fulling mills were in operation in Burnley, Colne, and Rochdale, these places linked to the West Riding of Yorkshire, and Halifax parish, via river valleys. W. B. Crump noted that the Lancashire and West Riding of Yorkshire manufactures shared the chief characteristics of running water and access to coal.Footnote 81 The Lancashire wool manufacture, however, was squeezed and marginalised. It did persist on Lancashire Pennine fringes but in response to the sixteenth century demand for other lighter cloths, linen and cotton smallwares industries centred in Manchester became established elsewhere in the county. Cloth woven with a linen warp and a cotton weft began in the early-seventeenth century as a fustian manufacture.Footnote 82 This was the start and basis of the latter Lancashire cotton manufacture.

It is interesting to note that relatively few corn millers were found in Durham and Northumberland, other than on the banks of the River Tyne in Gateshead. The observation helps explain why northeast England, although rich in coal, was not a major cloth producing area even though a basis for it to be so was established in medieval England. Fourteenth-century Newcastle was one of ten staple ports and held a monopoly on the export of Northern wool. Relatively few cloths were woven, however. The local wool was coarse and of low quality, and the city lost its status as a staple port to Calais, a port better geographically situated for trade between southern England and continental Europe.Footnote 83 The demise of the northeastern woollen industry is also shown by analysis of the probate records for Durham and Northumberland. Decline began in 1601; the demise mirrored by the growing importance to the region of mining (Figure 9). The banks of the River Tyne were dominated by the coal trade.Footnote 84 The wages paid to miners in the north east were high, as much as double as those paid to agricultural labourers.Footnote 85 The opportunities for alternative employment were squeezed out.

Figure 9. The decline of the woollen industry and the concomitant growth of mining in Durham and Northumberland, 1600–1800. (Expressed as the percentage of men working in the textile manufacture and in mining).

Source: Probates, Keibek (2016).

8.2. Coal, wages, and the cost of living

Our data show the early temporal association between the location of the West Riding of Yorkshire cloth manufacture and exposed coal measures. D.C. Coleman noted this importance of coal and iron to early industries. In his analysis of 10 proto-industrial regions of England, only four, namely Lancashire, Yorkshire, Trent, and the West Midlands went on to industrialise. The five regions that did not were East Anglia, West Country, Westmorland, Welsh border, and southern regions. Those regions that did industrialise were on or close to a coalfield but ‘nobody, however, would suppose that causation was as simple as that’.Footnote 86 We agree that the shift of the industry was multi-causal and with Derek Gregory who contends that Adam Smith ‘believed that the price of coal affected the location of industry through its effect on the wage bill rather than as a factor of production in its own right’.Footnote 87 For a manufacturer, the minimisation of labour costs, the largest contributor to the cost of cloth production, accounting for at least twice the cost of wool, was a key component for profit maximisation. It would be expected that woollen manufacturing moved to those places where wages were lowest.Footnote 88 Gregory Clark's wage analysis shows that nominal day wages for farm workers in northern England were lower than they were elsewhere in England in the last quarter of the seventeenth century and remained below the national average throughout the eighteenth century.Footnote 89 Similarly, Hunt believes the West Riding of Yorkshire, Lancashire, and Cheshire were still low wage economies until at least c.1770.

Wages, however, are only one component of the cost of living and Stephen Broadberry and his co-authors note, ‘textile manufacture increasingly gravitated towards regions where cheap land kept the costs of provisions and therefore labour low’.Footnote 90 The cost of fuel and its impact upon the household budget were known by contemporaries and their importance should not be underestimated. The Mayor of the City of York, Defoe, Morant, and Smith all remarked upon it. There are other instances where other commentators have also made the link. For example, in 1797, Sir Frederick Morton Eden referred to the Weald of Kent noting ‘300 years ago, the woollen manufactory here was very considerable: it is supposed that the decrease of fuel was the cause of its migrating to the coal counties’.Footnote 91 Morton Eden believed that the household income of an Oxfordshire labourer was around £20 per annum, of which £2 10s was spent on fuel. Eden writes ‘the extreme dearness of fuel, in Oxfordshire, compels him [a labourer] to purchase his dinner at the baker's’.Footnote 92 Nef remarked that in London at the end of the seventeenth century, a man still spent 10 per cent of his wages on coal, ‘even when coal prices in the capital were at their lowest’.Footnote 93 By 1800, the proportion of his income spent on coal had risen to one-seventh. W. G. Hoskins noted that in a typical weekly budget of an eighteenth-century Exeter family with an income of 10s, 1s went on rent, but 1s 6d was needed for fuel and light.Footnote 94 Evidence presented to the House of Commons Committee appointed to inquire into the Petitions presented from Hand-Loom Weavers, albeit in 1838, reaffirms the need of workers for cheap fuel, noting:

Next to bread, perhaps, in this cold and damp climate, the most important necessary of life is fuel; and so indispensable is it to an operative that he should be placed where, during a cold and severe winter, fuel can be obtained upon reasonable terms, that I doubt that anything can prevent the rapid decline of all the principal London manufactures by their removal to the northern counties, unless means can be devised to cheapen here the supply of fuel. The weavers of Manchester, during the hard winter of 1838, were paying for coals but 9d per cwt., for which the silk weavers of Spitalfields were charged 2s 2d… at a time when the thermometer fell to zero, and three-fourths of the looms were idle.Footnote 95

It is perhaps no coincidence that the onset of textile de-industrialisation in England came at the time when coal became significantly cheaper than alternative fuels. Peat and coal were burned in the sixteenth century, especially when close to where they could be readily dug, but heat energy in the main was supplied by firewood sourced from coppiced woodland.Footnote 96 The demand for wood, from industry and from a growing population that near–doubled from 2.8 million to 5.1 million in England, 1541–1641, became so strong that the supply was put under severe pressure.Footnote 97 It was suggested that since the process of dyeing was so wasteful of an already scarce resource, manufacturers should switch to using Newcastle coal.Footnote 98 Similarly, the Privy Council was lobbied for an order to force Exeter dyers to use coal.Footnote 99

The price of coal was lower than that of firewood from the fifteenth century onwards (Figure 10).Footnote 100 Paul Warde calculates that until the end of the eighteenth century, for the same calorific content, firewood cost between two to four times more than coal.Footnote 101 By the seventeenth century, coal was displacing firewood to become the dominant source of heat energy in England.Footnote 102 By 1620, the price of coal at the pit head was approximately half that of firewood and in 1700 it was around one-third.Footnote 103 John Houghton's coal price data for selected towns in the years 1691–1703 further illustrate the marked contrast in prices for a London chaldron of 28 cwt between places close to a coalfield, for example Newcastle, Derby, Nottingham, and those more distant (Table 7).Footnote 104 At the pithead, coal, a high density/low value commodity, was relatively cheap, but the price doubled if carried ten miles by land, whereas for the same cost it could be carried 200 miles by sea.Footnote 105 Every mile that this coal was transported inland by road added 2 shillings to the price per ton, whereas carriage by water added only 7 pence per ton.Footnote 106 Shipment by sea from Newcastle to King's Lynn, doubled the cost. Transport by water further inland, for example from King's Lynn to Cambridge, gave rise to a further increase of around one-fifth.

Figure 10. Prices of firewood and coal in England, 1500–1780.

Source: Clark, (2010).

Table 7. Average retail price (shillings) of a chaldron of coal, by selected place, 1691–1700

Notes: London chaldron, 28cwt. The price data for Southampton is for the years 1698–1703.

Source: Houghton.

Houghton did not collect data from the West Riding of Yorkshire but those prices are available from alternative sources. For instance, the account books of Farnley colliery, Leeds parish, 1690- 1720, indicate that coal cost 0.5d per corve of 200lbs at the pit head, equivalent to approximately 8s for 28 cwt.Footnote 107 Overseers’ Account Books, 1761/62, record that coal in Barkisland, a township in the parish of Halifax, cost 4s per ton, approximately one-sixth of the cost of coal in Norwich and one-eighth of the cost in London. In Leeds, coal ‘would usually be consumed locally within a mile or two of the pithead’.Footnote 108 This coal was transported by pack horse, its price rising by 60 per cent if transported only 5 miles distant.Footnote 109 The net result is that coal prices in the city of York were likely more than three times those in Halifax and Leeds. Interestingly, in the West Country coal was available from the Forest of Dean and the ports along the River Severn, such as Gloucester and Bristol, had access to cheap coal from South Wales, Staffordshire, and Shropshire.

The link between cloth manufacture, cheap fuel and water is observed not only in the West Riding of Yorkshire but also in other parts of the country where cloth manufacture remained locally important. For instance, the town of Kidderminster in the south Midlands, home to 76 per cent of all Worcestershire weavers in 1813, was linked by river to coalfields only a few miles distant. In fifteenth-century Wales the main centres of wool cloth production were the southern counties of Pembrokeshire and Monmouthshire.Footnote 110 By the sixteenth century, the Welsh industry had shifted to mid-Wales, notably to Montgomery, a region with considerable quantities of readily available peat and hence cheap fuel.Footnote 111 T. C. Mendenhall believed the industry left Pembrokeshire because coal was a more exportable commodity than was cloth.Footnote 112

It is interesting to note too that although the woollen manufacture did not locate on the South Yorkshire coalfield, this region did develop a linen industry. Of the 1,836 male linen workers recorded in the 1813–1820 baptism registers of the West Riding of Yorkshire, one-quarter lived in Leeds, but another one-third lived in Barnsley, Silkstone, Royston, and Sheffield, all on the coalfield.

8.3. Other factors

Of the other factors that may have influenced location, access to raw material was not one, at least not after the fifteenth century. The wool trade in medieval England was likely dictated by the availability and nature of the local raw material and people made cloth for their own use only. When export markets grew between the mid-fourteenth and fifteenth centuries, the cloth industry developed and the local wool supply was insufficient to meet demand. By the mid-seventeenth century, the counties producing the most wool, for example Northamptonshire, Lincolnshire, and Cambridge, were not important woollen cloth producers, the wool grown in these counties was sent elsewhere in England to be woven into cloth.Footnote 113 This observation also holds true for the early-nineteenth century. The 1813–1820 baptism registers hold 20 entries for shepherds living in the West Riding of Yorkshire, whereas 404 shepherds lived in Lincolnshire, 376 shepherds lived in Northamptonshire, and 315 shepherds lived in Cambridgeshire. The West Riding of Yorkshire did not hold competitive advantage on the availability of local wool.

Another potential factor to influence location is the cost of transport. The West Riding of Yorkshire was at the vanguard of improvements to eighteenth-century river and canal transportation with the construction of the Aire and Calder Navigation in 1699, the two rivers made navigable to the two major woollen centres of Leeds and Wakefield respectively.Footnote 114 In 1758, an act was passed to extend the navigation of the River Calder as far as Halifax parish in Sowerby.Footnote 115 By 1770, construction began on the Leeds-to-Liverpool canal to link Bradford, Bingley and Keighley to Leeds, and hence to Hull and Liverpool, although not completed until 1816.Footnote 116 The improved waterways developed in conjunction with the growth of woollen manufacture but also allowed the industry to develop in lower lying river valleys, away from the Pennines slopes.

Whereas water transport facilitated the transport of high-density low-cost commodities such as coal, road transport improvements through the construction of turnpikes aided the movement of light, high value goods such as textiles. The number of Turnpike Acts passed in England between 1663–1839 is shown in Figure 11.Footnote 117 The majority were passed after 1740 but the take-off in the proposed road building programme did not occur until the end of the century. Yorkshire and Lancashire were at the vanguard; the eastern, southern, and western counties lagged behind. The drive to build better roads reflected the need to move cloth, wool, and yarn, with significant impact upon productivity and profit, but not necessarily upon location.

Figure 11. The number of new Turnpike Acts, 1663–1839.

Source: Albert (1972).

8.4. Summary

The woollen manufacture in Yorkshire began to concentrate in the West Riding of Yorkshire in Leeds, Wakefield, and Halifax parish by the early-sixteenth century. The manufacture shifted away from the City of York to settle in places where running water and cheap fuel, in the form of outcrop coal, were available. In these places, the cost of living was low and opportunities for alternative employment, particularly in settlements in rural Halifax parish, were few. These West Riding of Yorkshire parishes and settlements to which the manufacture initially shifted remained the key woollen manufacturing centres three hundred years later.

It was to these places that the national industry shifted too when de-industrialisation set in elsewhere. The move to places with accessible coal was driven more by low wages and cheap domestic fuel than it was by production costs. The manufacture did not migrate to the coalfield because of the need to generate steam power. It was already there and ideally placed to take advantage of the cheap energy supply essential to the industrial revolution.

Acknowledgements

The authors would like to thank the several bodies who have funded the Occupational Structure of Britain Project led by the Cambridge Group for the History of Population and Social Structure; The Economic and Social Research Council, The Leverhulme Trust, the British Academy, and the Sir Isaac Newton Trust. Thanks is also given to Tony Wrigley for his guidance during the initial drafting of this paper and to the three referees whose critical comments led to significant improvement.