Impact Statement

By highlighting the potential of several mature technological advancements, we envision a transformation shift for the tunneling industry. Tunneling stakeholders should be prepared to embrace this changing paradigm and exploit the possibilities and benefits of emerging technologies. To this end, we identify and match key technological enablers with potential use cases in tunneling. We also identify critical challenges to the take-up of such technologies to motivate future research.

1. Introduction

The increase in global population and urbanization is presenting significant challenges to society: space is becoming increasingly scarce, demand is exceeding capacity for deteriorating infrastructure, transportation is fraught with congestion, and environmental impacts are accelerating. Underground space, including tunnels, has a key role to play in tackling these challenges (Broere, Reference Broere2016; Kaliampakos, Reference Kaliampakos2016). Tunnels have become an essential component of modern transportation and infrastructure systems, offering a sustainable solution for the growing urban demands of society. Tunnels provide a means to create new spaces underground that can accommodate various infrastructures such as transportation, water supply, sewerage, and power distribution while minimizing surface-level disruptions and overcoming natural or artificial barriers like mountains, rivers, and densely populated urban areas. Moreover, tunnels can serve a crucial role in emergency management, providing safe and reliable evacuation routes in times of disaster.

The demand for tunneling worldwide has given rise to various technological advancements over the past several decades. The development of mechanized tunneling, especially face-pressurized tunnel boring machines (TBMs), has spurred the growth of urban tunneling, which can be more challenging since it is commonly done in soft ground conditions underneath densely populated regions. Nevertheless, this growth is often impeded by several challenges, including cost, risk, and the complexity of the processes involved. The cost of underground structures has always been significantly higher than on-ground and elevated structures (Kaliampakos et al., Reference Kaliampakos, Benardos and Mavrikos2016). Underground structures, especially in unfavorable sites, could cost up to six to ten times more than on-ground structures (Godard and Hugonnard, Reference Godard and Hugonnard1989), while underground urban transit systems can cost up to four to six times more than on-ground systems (Fox, Reference Fox2000). According to Efron and Read (Reference Efron and Read2012), excavation costs are the most significant component of tunneling, often constituting more than 50% of the total cost. In this regard, geological conditions are considered the primary governing factor. A statistical study by Membah and Asa (Reference Membah and Asa2015) also showed that the complexity of tunneling processes and the uncertainty of geologic conditions are the top contributing factors that inflate tunnel construction costs. Paraskevopoulou and Boutsis (Reference Paraskevopoulou and Boutsis2020) presented a case study demonstrating that insufficient geological data can result in tunneling costs exceeding their budget by as much as 77%.

The inherent uncertainty of the geologic conditions means tunneling operations are also unpredictable. Ground conditions can vary significantly from site to site and even within the same site. This is highly problematic given the intimate links between ground conditions and optimal TBM control, often necessitating unexpected and sudden reactive changes in the tunneling process. Thus, TBM operators must remain aware of changing ground conditions during tunneling whilst also making real-time decisions to adjust TBM control parameters. Such decisions are based on an interpretation of tunneling operation data generated at a rate in the order of 0.1–1 Hz by a plethora of installed sensors. Human interpretation, judgment, and decisions in various control tasks based on massive streaming data in real time can introduce inconsistency, bias, and errors. Moreover, the data are difficult to interpret due to their high dimensionality and inherent complexity in that they are products of causal effect interactions of human control decisions, TBM behaviors, and ground conditions.

For example, Figure 1 presents a correlation network generated from thousands of variable features of TBM operation data. In this network, each node represents a specific TBM feature, while the links between them indicate the correlations. The colors of the links convey meaning: blue signifies positive correlations, and red denotes negative correlations. The intensity of the color corresponds to the strength of the correlation. When groups of TBM features cluster closely, it indicates strong correlations and potential multicollinearity. This visualization highlights the immensity and complexity of the data. Given this complexity, manually optimizing these parameters in real time becomes unfeasible for future tunneling.

Figure 1. The immensity and complexity of TBM operation data with thousands of variable features, visualized in correlation networks.

The challenges faced in tunneling have motivated continuous technological developments. However, additional step-change innovation is urgently needed to tackle the complexity and unpredictability of the process, reduce the associated risks and costs, and rapidly meet the growing demand for underground infrastructure. Recent technological advancements unlock unprecedented possibilities that have the potential to catalyze radical transformations of tunneling operations; for example, sensor and data acquisition technologies, building information modeling (BIM) and computer vision, machine learning and artificial intelligence (AI), automation and robotic systems, advanced materials and three-dimensional (3D) printing, as well as bio-inspired engineering design (e.g., Davila Delgado et al., Reference Davila Delgado, Oyedele, Ajayi, Akanbi, Akinade, Bilal and Owolabi2019; Huang et al., Reference Huang, Ninić and Zhang2021; Hoult and Soga, Reference Hoult, Soga, Lynch, Sohn and Wang2022; Ma et al., Reference Ma, Buswell, Leal da Silva, Wang, Xu and Jones2022; Martinez et al., Reference Martinez, Dejong, Akin, Aleali, Arson, Atkinson, Bandini, Baser, Borela, Boulanger, Burrall, Chen, Collins, Cortes, Dai, DeJong, Del Dottore, Dorgan, Fragaszy, Frost, Full, Ghayoomi, Goldman, Gravish, Guzman, Hambleton, Hawkes, Helms, Hu, Huang, Huang, Hunt, Irschick, Lin, Lingwall, Marr, Mazzolai, McInroe, Murthy, O’Hara, Porter, Sadek, Sanchez, Santamarina, Shao, Sharp, Stuart, Stutz, Summers, Tao, Tolley, Treers, Turnbull, Valdes, van Paassen, Viggiani, Wilson, Wu, Yu and Zheng2022).

In this paper, we highlight three technological advancements that can potentially be the key enablers to innovate and transform the tunneling industry. These advancements include AI systems, autonomous systems, and bio-inspired systems in tunneling. The advancement of sensor and data acquisition technologies can further boost the amount of tunneling operation data collected to reduce tunneling uncertainty. The emergence of AI and the increase in computing performance in the past few years open extensive opportunities for managing and interpreting “big data” (Jordan and Mitchell, Reference Jordan and Mitchell2015). This technology can leverage these big data in tunneling in an optimal way and form the basis for autonomous systems and advanced robotics to improve productivity. The following sections briefly discuss the concept of each of these developments, their potential impact on the tunneling industry, and the challenges that need to be addressed to ensure their successful implementation.

2. AI Systems

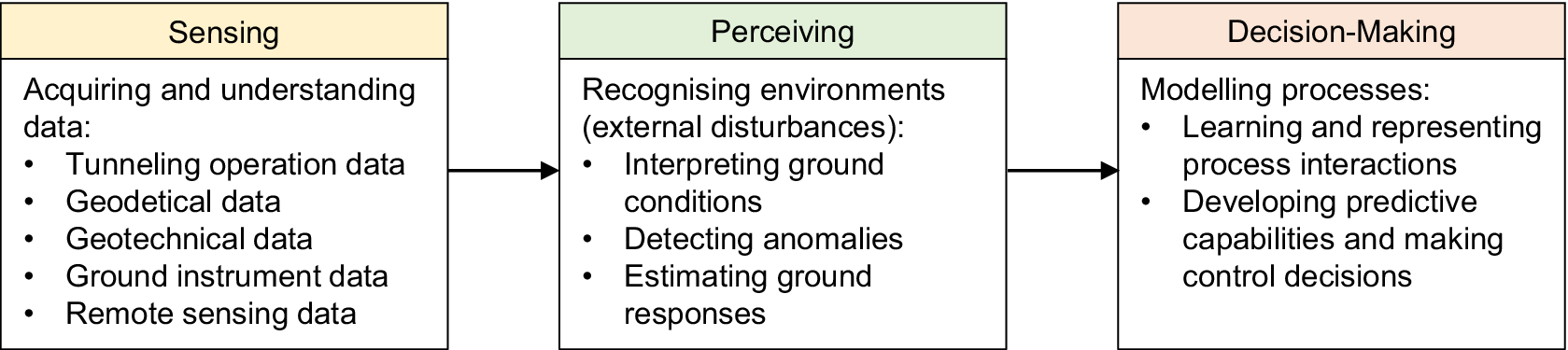

In the foreseeable future, arguably the most promising area for advancement in tunneling systems involves developing and implementing AI-assisted technology. AI systems can be considered computer-based systems that exhibit intelligent behavior, that is mimicking human cognitive and decision-making processes (Figure 2). The sensing system consists of sensors and data acquisition modules to collect data during tunneling. The perceiving system consists of AI systems, such as machine learning modules, that can transform the data into useful information for tunneling processes. The decision-making system consists of AI systems that can model the complexity of interrelated tunneling processes and make optimal decisions for adjusting TBM control parameters.

Figure 2. Cognitive model for AI systems in tunneling.

Machine learning will play a crucial role in developing these AI-assisted technologies. Machine learning is a subset of AI that defines the ability of an algorithmic system to “learn” tasks without being explicitly programmed. Instead of following a set of fixed empirical rules, machine learning algorithms can independently detect hidden structures in data, map patterns, and identify complex systems (Brunton et al., Reference Brunton, Proctor and Kutz2016). Thus, machine learning allows flexible data-driven modeling without predefined assumptions. This can be beneficial for tunneling since the process is governed by complex causal effect interactions of ground conditions, machine behaviors, and human decisions, which may not be possible to be represented in closed-form solutions. Machine learning can also exploit latent information in massive data, enabling better utilization of tunneling operation data.

2.1. Sensing

The sensing system, which consists of sensors and data acquisition modules, has become standard practice in modern TBM tunneling. Typically, a TBM can generate hundreds to thousands of operation data in intervals of seconds during tunneling. The data are produced by a plethora of sensors installed on the TBM, measuring and recording various information related to the tunneling process, such as cutter rotation operations, advance thrust forces and speeds, shield attitudes, and injected ground conditioning system. The TBM operation data serves as the primary element of tunneling data. Integrating these with other data, such as geotechnical (e.g., borehole information), geophysics (e.g., ground penetrating radar), remote sensing (e.g., InSAR), and ground monitoring data (e.g., ground settlements), can provide more comprehensive information to enable a TBM to sense the environment and connect it to its behaviors. However, the data may not be handled by the operators and engineers intuitively in real time during tunneling due to the massive volume and high acquisition velocity. A more systematic approach is required to process the data. Furthermore, despite the advantages of merging multi-source tunneling data into an integrated data framework, limited advancements have been achieved to date. Developing a unified workflow for integrating, managing, and utilizing this data should be the focus of future AI system development in tunneling.

The advancement in sensing and data acquisition technologies will be the catalyst for the more widespread use of BIM and digital twins in tunneling. BIM creates a digital representation of the physical and functional characteristics of a facility. It functions as a shared knowledge repository, establishing a reliable basis for decisions from its inception throughout its entire life cycle (NIBS, 2015; ISO, 2018). A digital twin can be considered an extension, functioning as a virtual replica of its physical counterpart. A digital twin is updated dynamically in light of monitored data to better capture the behavior of the physical twin and can provide feedback to inform decision-making for the physical twin. The integration of sensing data with these technologies has the potential to revolutionize the tunneling industry by providing a platform for data integration, real-time monitoring, modeling, and decision-making. Implementing BIM will enable better integration of tunneling information and design control (Daller et al., Reference Daller, Žibert, Exinger and Lah2016), which can lead to more efficient and effective tunnel design and construction. Digital twins will provide an advanced tool for conducting technical failure and causal effect analyses (Yu et al., Reference Yu, Wang, Mao, Hu, Sugumaran and Wang2021), monitoring the energy usage and health of tunnel systems, and scheduling maintenance tasks (Tijs, Reference Tijs2020).

2.2. Perceiving

The perceiving system transforms the sensing data into meaningful information for the tunneling process using AI. A key role of the perceiving system will be to infer the encountered environment. During tunneling, TBM operators need to adjust appropriate TBM control parameters and maintain the target tunneling performance according to the ground conditions. However, TBM operators can only infer the encountered ground conditions based on the operation data presented in the control monitors since the characteristics of muck (excavated materials) can only be observed with a delay at the end of the screw conveyors. Furthermore, manual interpretation lacks a systematic approach and may lead to human bias and errors. The availability of this AI system will enable systematic identification of the encountered ground condition based on real-time data, increase the reliability and accuracy of the identification, facilitate a quantitative approach to risk profiling and risk management strategies, and in the end, enhance the ability of operators and engineers to make informed decisions regarding safe and efficient TBM operation.

Over the past two decades, the development of data-driven geologic inference systems has made significant progress. Initially, geostatistical methods were utilized to convert drill energy coefficients into rock mass strength and model spatial distribution (Yamamoto et al., Reference Yamamoto, Shirasagi, Yamamoto, Mito and Aoki2003). The subsequent development involved probabilistic graph modeling for the classification of ahead geologic conditions, including rock, soil, or mixed, based on limited TBM operation features (Sousa and Einstein, Reference Sousa and Einstein2012). Several studies followed this by developing data-driven geologic classification systems using various machine learning algorithms. These studies evaluated the performance of different algorithms (Zhang et al., Reference Zhang, Liu and Tan2019; Zhao et al., Reference Zhao, Shi, Hu, Song, Zhang, Tao and Wu2019b) and examined the possibility of implementing a real-time (online) classification system (Erharter et al., Reference Erharter, Marcher, Reinhold, Correia, Tinoco, Cortez and Lamas2020) or anomaly detection system (Cao et al., Reference Cao, Saadallah, Egorov, Freitag, Meschke, Morik, Barla, Di Donna and Sterpi2021). Recent advancements have gone beyond merely categorizing geologic classes to identifying transitions between them. This was achieved through either estimating the classification probability of each geologic class (Apoji et al., Reference Apoji, Fujita, Soga, Lemnitzer and Stuedlein2022b; Yu and Mooney, Reference Yu and Mooney2023) or predicting the numerical regression representation of each geologic layer (Apoji, Reference Apoji2023).

Figure 3 is presented to showcase examples of AI systems that transform TBM operation data into geologic information. The left panel shows the output of a supervised geologic interpretation system compared to a geologic map interpreted by humans (Apoji, Reference Apoji2023). It can be seen that the system can infer important geologic features along the chainage, including the transition and deposits of various geologic units. The right panel shows a 3D embedding of TBM operation data, which can be used as an unsupervised geologic anomaly detection system (Apoji and Soga, Reference Apoji, Soga, Ching, Najjar and Medina-Cetina2023). It can be seen that data points with similar ground conditions tend to cluster together, which indicates that TBM is encountering a geologic anomaly if the produced data point is outside any available geologic unit clusters. The implementation of such AI systems in the industry to assist TBM operators could be a viable option in the near future.

Figure 3. Examples of geologic inference perceiving systems: supervised geologic interpretation (left) (Apoji, Reference Apoji2023) and unsupervised geologic clustering for anomaly detection (right) (Apoji and Soga, Reference Apoji, Soga, Ching, Najjar and Medina-Cetina2023). Both of these perceiving systems utilize tunneling data to generate their results.

The future perceiving system should also connect TBM behaviors and the induced ground responses. TBM behaviors have been widely documented as one of the primary factors governing tunneling-induced ground movements and, in turn, building damage. However, available methods for estimating these movements commonly focus on tunnel geometries and geological conditions as the key inputs, with almost no consideration given to the influence of TBM operation parameters (Cao et al., Reference Cao, Obel, Freitag, Mark and Meschke2020; Mair and Taylor, Reference Mair and Taylor1997; Pinto and Whittle, Reference Pinto and Whittle2014; Pinto et al., Reference Pinto, Zymnis and Whittle2014). The availability of this AI system will provide a quantitative means of linking TBM operation data to the ground monitoring data. This will facilitate investigations into the interactions between TBM control parameters and ground responses and enable real-time estimation of tunneling-induced ground responses based on TBM operation (Apoji et al., Reference Apoji, Ning, Soga, Rathje, Montoya and Wayne2023). Additionally, the system will assist operators in controlling the TBM to limit the induced ground movements.

The development of data-driven system for estimating tunneling-induced ground movements has been ongoing for over two decades. Initial developments focused on estimating the maximum induced ground movement using artificial neural networks (ANN) based on several tunneling factors, including a few TBM operational parameters (Shi et al., Reference Shi, Ortigao and Bai1998; Suwansawat and Einstein, Reference Suwansawat and Einstein2006; Boubou et al., Reference Boubou, Emeriault and Kastner2010). Many studies have since employed machine learning algorithms to further develop the system (Cao et al., Reference Cao, Obel, Freitag, Mark and Meschke2020; Mahmoodzadeh et al., Reference Mahmoodzadeh, Mohammadi, Daraei, Farid Hama Ali, Kameran Al-Salihi and Mohammed Dler Omer2020; Zhang et al., Reference Zhang, Wu, Chen and Chan2020a; Reference Zhang, Li, Wu, Li, Liu and Liu2021; Zhao et al., Reference Zhao, Hölter, König and Alimardani Lavasan2019a). Most of the previous studies argued that their proposed models and selected machine learning algorithms demonstrated excellent prediction performance. However, the comparative studies yielded varying conclusions, with almost every study identifying a different best-performing algorithm. This disparity may be attributed to several factors, including using different tunneling data sets, data preparation methods, feature selections, and hyperparameter tuning. These factors are critical when constructing machine learning models to estimate tunneling-induced ground movements. Recent advancements have expanded the system to model the interaction between longitudinal shield movements and induced ground responses (Cao et al., Reference Cao, Obel, Freitag, Mark and Meschke2020; Zhang et al., Reference Zhang, Wu, Chen, Dai, Meng and Wang2020b). This facilitates real-time estimation of tunneling-induced ground movements based on TBM operation (Apoji, Reference Apoji2023).

Figure 4 presents a simulation depicting real-time estimation of tunneling-induced ground movements using TBM data from a real-world tunneling project (Apoji, Reference Apoji2023). The simulation covers ground movements at approximately 3 meters above the tunnel crown, measured by extensometers (colored points). The black points indicate the estimated ground movements based on TBM operation data. The red-shaded area represents the active prediction region, spanning 50 meters ahead and 100 meters behind the TBM face. The simulation demonstrates the system’s capability to generate a continuous estimation of ground responses along the chainage by leveraging information from the TBM operation, effectively filling in gaps in ground movement measurements typically acquired from sparsely distributed monitoring instruments. The bottom panel showcases the average mean absolute errors (MAE) of the predictions at each TBM location along the chainages. Notably, the figure illustrates a decreasing trend in MAE as the chainages progress, suggesting that the availability of more training data during TBM advances contributes to a continuous enhancement in performance. These recent studies provide confidence in the feasibility of developing comprehensive and reliable perception systems for future tunneling endeavors.

Figure 4. Example of ground response perceiving systems (Apoji, Reference Apoji2023): Simulation of real-time tunneling-induced ground movement predictions by leveraging information from the TBM operation. The colored and black points represent the measured and predicted ground movements, respectively. The red-shaded area represents the active prediction region. The bottom panel shows the average MAE of the predictions at each TBM location.

2.3. Decision-making

The decision-making system should leverage AI to model the complexity of interrelated tunneling processes and optimally adjust TBM control parameters accordingly. In a typical tunneling operation, tunnel engineers prepare TBM operation instructions that specify tunneling target performance prior to each excavation phase. TBM operators endeavor to achieve the target performance through heuristic adjustment of various TBM control parameters. The target performance and the TBM control parameters should be determined based on evidence derived from the operation data. However, the data is inherently nonlinear and complex since it is a product of the causal effect relationship of human-machine-ground interactions (Garcia et al., Reference Garcia, Michau, Einstein and Fink2021; Apoji et al., Reference Apoji, Fujita and Soga2022a). As such, these decision tasks are highly subjective in reality, and the availability of this AI system will empower both engineers and operators to make quantitative and systematic decisions during tunneling.

The development of data-driven decision support systems for TBM tunneling has been an ongoing process for over two decades, with significant progress made more recently due to the increasing availability of data and advancements in data-driven modeling. Most studies have focused on developing an independent decision support system for a specific tunneling partial process, such as advance rate prediction (Mokhtari et al., Reference Mokhtari, Navidi and Mooney2020; Mokhtari and Mooney, Reference Mokhtari and Mooney2020), TBM direction control (Uematsu et al., Reference Uematsu, Nakanishi, Takamizawa, Matsueda, Nanbu and Fukuhara1996; Wada et al., Reference Wada, Sugiyama, Nozawa, Honda, Yamamoto, Santos and Scheer2021), and earth pressure balance control (Gao et al., Reference Gao, Zhang, Shen and Zhou2020; Li and Shao, Reference Li and Shao2015; Liu et al., Reference Liu, Shao, Ma and Liu2011; Liu and Zhang, Reference Liu and Zhang2019; Yu et al., Reference Yu, Zhou, Zhang and Mooney2022). These control systems typically use machine learning as a predictive model combined with optimization algorithms to determine the optimal control parameters. Recent efforts have shifted towards developing an integrated model capable of representing different TBM partial processes (Apoji et al., Reference Apoji, Fujita and Soga2022a; Cao et al., Reference Cao, Heußner, Jodehl, Obel, Salloum, Freitag, König, Mark, Meschke, Thewes, Meschke, Breitenbücher, Freitag, König and Thewes2023). One potential approach is to use probabilistic graph models to provide a quantitative and concise representation of the process complexity, such as using Bayesian network structure learning (BNSL).

Figure 5 presents examples of Bayesian network graphs that model interactions in the TBM excavation process at two different tunneling chainage locations (Apoji et al., Reference Apoji, Fujita and Soga2022a). Each node in the network represents a TBM feature related to the excavation process. The links of the graphs were constructed using a structure learning algorithm, which iteratively refines the network architecture to identify the most probable interactions, indicated by the highest score (in this case, Bayesian information criteria). The figure shows that the structure learning algorithm was able to identify several true (red links) and expected interactions (blue links) between TBM features, based solely on the data. The true interactions were manually computed, while the expected interactions conform to published literature. Furthermore, the graph also exploits possible feature interactions (black links), which may provide insights into how operators controlled the TBM. This demonstrates the potential utilization of BNSL to systematically model the interactions of TBM tunneling decisions and processes in a compact and interpretable representation.

Figure 5. Examples of Bayesian network graphs that model interactions in TBM excavation at two different tunneling chainage locations (Apoji et al., Reference Apoji, Fujita and Soga2022a). The links of the graphs were constructed using a structure learning algorithm. The algorithm could successfully capture several true and expected feature interactions (red and blue links, respectively), as well as exploit possible feature interactions (black links) based solely on TBM operation data.

2.4. Challenges

It is evident that the implementation of AI in tunneling will continue to advance. However, despite the promising future, a number of challenges remain. The first relates to the data. Tunneling data are not openly available, typically kept in isolated data silos by individual stakeholders, and rarely used for retrospective analysis or further research. Furthermore, most research studies also do not publish underpinning data due to confidentiality restrictions imposed by data owners. Therefore, the research landscape has developed in a piecemeal fashion using different data sets of different sizes and relating to different unique project characteristics (Sheil et al., Reference Sheil, Suryasentana, Mooney and Zhu2020). Since data are a fundamental building block of data-driven systems, this data availability issue limits the reproducibility, generalizability, transparency, and, thus, the trustworthiness of the developed models.

Different perspectives come to the forefront in this context. The academic community often leans towards open data sharing, as it facilitates research collaboration and may accelerate advancements in the field. Conversely, the industry may perceive its data as sensitive information and valuable assets, leading to potential hesitation in openly sharing it. This issue points to open questions that are central to transformational change: In what ways can tunneling stakeholders collaborate to make tunneling data accessible in a manner that maximizes its benefits to the public? In addition, how should the data be cleaned, structured and enriched in an optimal way for end-users in both machine learning and tunnel engineering domains? How will the computation requirements associated with unprecedented big data in tunneling be met?

One potential solution could involve the development of a “data bank” that incentivizes entities to securely store their data while also enabling controlled access for other interested parties to benefit from the shared resources. There is a wide range of disparate stakeholders that will have a pivotal role to play in this initiative. Considering that most urban tunneling projects are funded publicly, there is a compelling argument that the public and government should also play an important role. This could potentially be achieved through legal frameworks, regulations, and contract specifications that prioritize the greater societal benefits resulting from increased data sharing. The availability of the “data bank” will allow a more concerted contribution to the advancement of AI for tunneling.

Another strategy to alleviate data size requirements for AI training relates to the use of synthetic data. Research has shown considerable promise for the use of high-fidelity numerical models to generate large data “offline” to train an AI-based surrogate model. Such models can then be deployed in practice to realize real-time behavior prediction, for example, tunnel-induced settlements (Freitag et al., Reference Freitag, Cao, Ninić and Meschke2018). More recently, novel “multi-fidelity” machine learning techniques enable the fusion of large “low-fidelity” (e.g., synthetic) datasets with small “high-fidelity” (e.g., monitored) datasets (Zhang et al., Reference Zhang, Yin, Jin and Sheil2022a; Reference Zhang, Yin, Jin, Yang and Sheil2022b; Reference Zhang, Yin and Sheil2023a). This essentially involves “pre-training” AI models on the large low-fidelity datasets to capture general cause-effect and alleviate data requirements and over-fitting risks. A second training stage involves mapping the low-fidelity and high-fidelity datasets, ultimately achieving high-fidelity predictive accuracy but with less data.

The second challenge relates to the limitations of machine learning itself. Current data scarcity, combined with the cost of mistakes to make prediction uncertainty, is arguably the most important element of future machine learning developments. Deployed machine learning models will also be exposed to constantly changing environments during tunneling. This means the models will regularly operate in a “forecasting” mode by making predictions in new ranges of data, which can lie outside training boundaries. Supervised learning is a powerful interpolator tool that can find complex patterns within high-dimensional data without predefined physical laws and assumptions. However, it has been shown to perform poorly in extrapolation problems where the conditions are outside the training boundaries (Hooker, Reference Hooker2004; Ebert et al., Reference Ebert, Belz and Nelles2014). This leads to further questions: How can machine learning be made more reliable in making predictions for data outside its training boundary? How to evaluate the extrapolation reliability? Or, more radically, can we build machine learning algorithms that can extrapolate? While recent efforts in physics-constrained machine learning offer a promising solution (e.g., Zhang et al., Reference Zhang, Yin and Sheil2023b), developing algorithms that can extrapolate remains an open question in AI and machine learning research communities.

3. Autonomous Systems

Autonomous systems are expected to be another key enabler of future tunneling. Although the notion of implementing autonomous systems in tunneling initially seems implausible due to the substantial risks and severe consequences associated with the errors, recent advancements in self-driving cars and unmanned technologies indicate that the realization of such systems may be closer than anticipated. Notably, the field of tunneling has experienced the emergence of autonomous robotics systems, presenting promising applications in tunnel inspections (e.g., Loupos et al., Reference Loupos, Doulamis, Stentoumis, Protopapadakis, Makantasis, Doulamis, Amditis, Chrobocinski, Victores, Montero, Menendez, Balaguer, Lopez, Cantero, Navarro, Roncaglia, Belsito, Camarinopoulos, Komodakis and Singh2018; Menendez et al., Reference Menendez, Victores, Montero, Martínez and Balaguer2018) and exploration (e.g., Miller et al., Reference Miller, Cladera, Cowley, Shivakumar, Lee, Jarin-Lipschitz, Bhat, Rodrigues, Zhou, Cohen, Kulkarni, Laney, Taylor and Kumar2020; Tranzatto et al., Reference Tranzatto, Mascarich, Bernreiter, Godinho, Camurri, Khattak, Dang, Reijgwart, Löje, Wisth, Zimmermann, Nguyen, Fehr, Solanka, Buchanan, Bjelonic, Khedekar, Valceschini, Jenelten, Dharmadhikari, Homberger, De Petris, Wellhausen, Kulkarni, Miki, Hirsch, Montenegro, Papachristos, Tresoldi, Carius, Valsecchi, Lee, Meyer, Wu, Nieto, Smith, Hutter, Siegwart, Mueller, Fallon and Alexis2022). These applications demonstrate the potential implementation and rapid progress of autonomous systems in the tunneling industry. The development of autonomous TBM is one such system that has gained significant attention in recent years.

3.1. Autonomous TBM

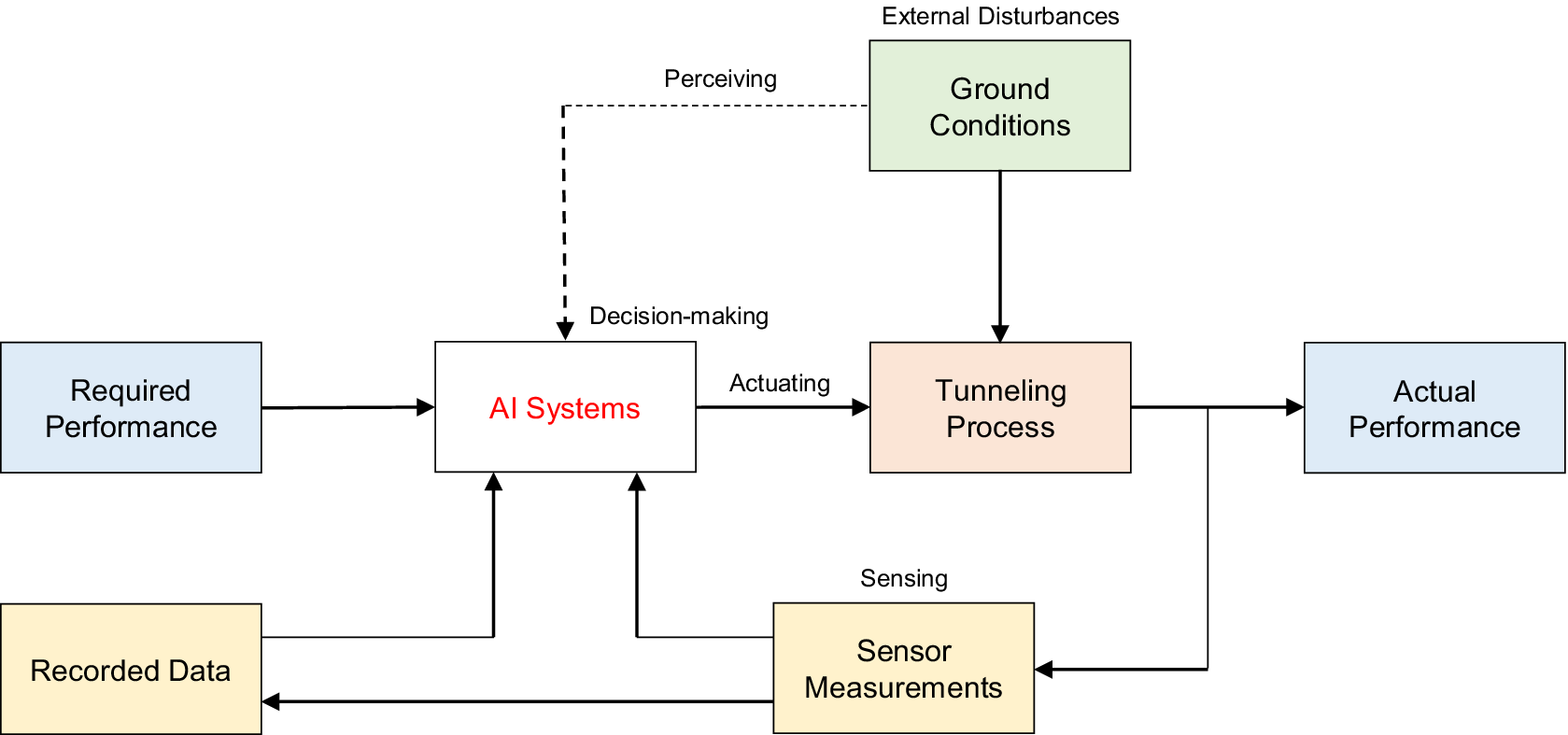

The efforts to build an autonomous TBM system date back to the mid-1990s, with promising developments reported in recent years due to advancements in sensing technologies and machine learning. Due to the high associated risks, the reliability and robustness of the system must be guaranteed. Thus, the backbone of an autonomous TBM system will most likely be the feedback loop control system (see Figure 6), which uses measurement data and a controller to adjust the system’s output. This creates a closed loop of information that allows the system to continuously self-correct its performance and achieve the specified target, in the presence of external disturbances. This is a mature and reliable framework that has contributed significantly to the development of autonomous systems, ranging from cruise control used daily in cars to the autopilot systems employed in aeroplanes. Recent developments aim to integrate AI systems into the feedback loop framework (Schöning et al., Reference Schöning, Riechmann and Pfisterer2022), where these systems serve as the central controller unit and use both real-time measurement and historical record data to make control decisions, adapt to external disturbances, and achieve the specified target.

Figure 6. Framework for autonomous TBM systems with feedback loop as the control system and AI systems as the controller.

It is essential to approach the development of autonomous TBM systems carefully and deliberately to ensure their reliability and safety while also building trust in the technology and addressing concerns about its potential risks. Thus, the development may occur incrementally in stages. This incremental approach can be compared to the levels of self-driving vehicle automation, ranging from a fully manual driving experience (level 0) to a fully autonomous vehicle (level 5) (SAE, 2021).

-

1. The first stage may involve AI-assisted TBM systems, as discussed in the previous section. This will augment the ability of engineers and operators to make more informed and effective decisions in tunneling operations by providing them with condensed highly relevant information. This stage is analogous to levels 1 and 2 of autonomous vehicles, where the self-driving system offers driver assistance.

-

2. The second stage may involve developing a TBM system that requires minimal human intervention. This will enable operations to be controlled from a remote control room, eliminating the need for human workers to remain continuously underground. This approach will provide a safer and healthier working environment for TBM operators and engineers while also improving operation productivity by enabling more efficient and uninterrupted work. This stage is analogous to level 3 of autonomous vehicles, where the self-driving system can control all driving functions but still requires the driver to be prepared to intervene if needed.

-

3. In the third stage, TBMs may reach a level of full autonomy where human intervention is only necessary for exceptional situations as requested by the autonomous system. This will allow multiple TBMs to be managed from a centralized control room, further improving precision, predictability, productivity and efficiency in the tunneling process. This stage is analogous to levels 4 and 5 of autonomous vehicles, where the vehicle can operate in full automation without any human input or oversight in most driving situations.

The development of autonomous TBM systems began over two decades ago but emerged in recent years with several direct applications on real projects, primarily driven by the industry. Early development started when Uematsu et al. (Reference Uematsu, Nakanishi, Takamizawa, Matsueda, Nanbu and Fukuhara1996) reported the development of a rule-based steering control guidance system that specified the thrust jack stroke based on statistical relationships derived from historical data. The system was implemented at the Tsukui headrace tunnel project in Japan by the Joint Venture of Kumagai, Goyo, and Dainippon. Hoshino et al. (Reference Hoshino, Matsubara, Ozawa and Tanaka2020) reported the development of a force-based steering control guidance system, which was implemented by Obayashi Corp. at multiple tunneling sites in Japan. Xiong et al. (Reference Xiong, Shen, Batty and Ho2020) reported the development of an autonomous steering control system, which determined the optimal thrust jack pressure assignments and could operate with minimal human intervention. It appears that the system was developed using rule-based algorithms embedded in a feedback control system. The system was implemented by MMC-Gamuda KVMRT(T) Sdn., Bhd. at the Klang Valley MRT Line 2 tunnel in Kuala Lumpur, Malaysia.

These above-mentioned systems were developed mainly using conventional PID and rule-based controllers. These technologies are mature and reliable but lack the ability to learn and adapt to new environments, posing a significant challenge in tunneling due to the variability and uncertainty of geological conditions. This logically points to the need for AI-based control systems. Wada et al. (Reference Wada, Sugiyama, Nozawa, Honda, Yamamoto, Santos and Scheer2021) reported the development of a machine learning-based steering control system, which guides the shield maneuver by estimating the optimal resultant force point produced by the thrust jacks. The system employed a gradient boosting type of algorithm as the predictive model and was implemented by Shimizu Corp. at an undisclosed tunneling project. Hu et al. (Reference Hu, Wu, Zhou, Wu, Li, Lu, Yu and Qin2022) reported the development of an autonomous control system based on the human performance model (Rasmussen, Reference Rasmussen1983). The system used intelligent modules to access and control various set points and could operate in a limited section without human intervention. The system was implemented by Shanghai Tunnel Engineering Co., Ltd. (STEC) at the intercity railway tunnels between Hangzhou and Shaoxing, China.

Figure 7 presents an example of TBM steering control simulations at five selected ring segments in a tunneling case history using multi-output supervised learning as the AI system (Apoji, Reference Apoji2023). This enables the system to make concurrent decisions in multiple TBM steering control parameters and adapt to the changing target trajectories and ground conditions. The steering control parameters were represented as the assigned pressures on eight thrust jack groups and stroke lengths of four articulation jack groups. The figure compares the average steering control parameters of each ring segment determined by the AI system and the human operator, obtained from real TBM operation data. The system successfully assigned appropriate steering control parameters based on the current and the next TBM position, given the TBM excavation data as a proxy for the ground conditions. This figure demonstrates the capability of the AI system to mimic human operator decisions.

Figure 7. Example of TBM steering control simulations using multi-output supervised learning as the AI system (Apoji, Reference Apoji2023). The AI simulation results are compared to steering control parameters determined by the human operator from real TBM operation data.

3.2. Challenges

As the development of autonomous TBM systems continues to advance, it is clear that the industry is facing several challenges. While many AI systems in other industries focus on achieving high prediction accuracy, AI systems for TBM controllers should also prioritize reliability and robustness. The objective should be to develop stable models that can effectively and consistently perform well in both anticipated and unanticipated conditions and assumptions (Barber and Salido, Reference Barber and Salido2015; Yu and Kumbier, Reference Yu and Kumbier2020). This may require designing novel frameworks customized for tunneling, such as enhancing the modeling workflow and proposing new evaluation metrics.

Furthermore, no matter how advanced the employed autonomous systems are, in the end, human stakeholders hold the liabilities. These stakeholders may not be comfortable being liable for something they cannot comprehend, especially since tunneling presents substantial risks. Unfortunately, machine learning models have been notoriously tagged as “black box” systems, as the way they operate and make decisions is less transparent (Linardatos et al., Reference Linardatos, Papastefanopoulos and Kotsiantis2021). This may lead to questions: What tools are available to scrutinize machine learning models? Are these tools adequate to elucidate and understand how the model arrives at a given prediction? How should machine learning tools be developed or customized for data-driven modeling, specifically in tunneling? Interpretable machine learning is an active research area, even in other AI and machine learning communities (e.g., Ras et al., Reference Ras, Xie, van Gerven and Doran2022). Tunnel engineers and researchers should engage more in this problem since it is critical to facilitate the deployment of AI systems in tunneling.

4. Bio-inspired Systems

Bio-inspired systems in tunneling draw inspiration from nature’s solutions to complex engineering challenges, offering insights for enhanced efficiency, safety, and sustainability. By studying the adaptations and behaviors of organisms in underground environments, we can uncover innovative approaches for future tunneling. This section explores two key aspects: bio-inspired mechanics, focusing on the physical principles of locomotion and support mechanisms, and multi-functional swarm robotic systems, inspired by collective behaviors observed in social insects.

4.1. Bio-inspired mechanics

Soil hosts a wide range of biological organisms and systems. These organisms have developed unique strategies that enable them to perform functions similar to those required in underground engineering systems, such as anchorage, support, penetration, excavation and mass transport (Martinez et al., Reference Martinez, Dejong, Akin, Aleali, Arson, Atkinson, Bandini, Baser, Borela, Boulanger, Burrall, Chen, Collins, Cortes, Dai, DeJong, Del Dottore, Dorgan, Fragaszy, Frost, Full, Ghayoomi, Goldman, Gravish, Guzman, Hambleton, Hawkes, Helms, Hu, Huang, Huang, Hunt, Irschick, Lin, Lingwall, Marr, Mazzolai, McInroe, Murthy, O’Hara, Porter, Sadek, Sanchez, Santamarina, Shao, Sharp, Stuart, Stutz, Summers, Tao, Tolley, Treers, Turnbull, Valdes, van Paassen, Viggiani, Wilson, Wu, Yu and Zheng2022). These strategies have been honed through the process of natural selection and are governed by the same physical laws in both natural and engineered environments. Therefore, they provide a valuable reference for new geotechnical design concepts for future tunneling.

For example, the burrowing processes of marine worms and earthworms have been tailored

![]() $ - $

and are updated “on-the-fly”

$ - $

and are updated “on-the-fly”

![]() $ - $

to the soil conditions, burrow depth and size of the organism itself (Martinez et al., Reference Martinez, Dejong, Akin, Aleali, Arson, Atkinson, Bandini, Baser, Borela, Boulanger, Burrall, Chen, Collins, Cortes, Dai, DeJong, Del Dottore, Dorgan, Fragaszy, Frost, Full, Ghayoomi, Goldman, Gravish, Guzman, Hambleton, Hawkes, Helms, Hu, Huang, Huang, Hunt, Irschick, Lin, Lingwall, Marr, Mazzolai, McInroe, Murthy, O’Hara, Porter, Sadek, Sanchez, Santamarina, Shao, Sharp, Stuart, Stutz, Summers, Tao, Tolley, Treers, Turnbull, Valdes, van Paassen, Viggiani, Wilson, Wu, Yu and Zheng2022). At deeper “tunneling” depths, these organisms adopt a dual technique involving radial expansion and axial elongation (penetration). The radial expansion is highly beneficial for three reasons: (i) the generation of outward radial stresses leads to a relaxation in soil effective stresses at the “burrow” front (Shin and Santamarina, Reference Shin and Santamarina2011), making for easier and more efficient burrowing, (ii) the increased normal contact, and therefore friction, between the burrow and organism body acts to provide sufficient reaction for the thrust required for penetration (Summers and O’reilly, Reference Summers and O’reilly1997), and (iii) the normal contact also acts to stabilize the burrow (Dorgan, Reference Dorgan2018) (see Figure 8). To further reduce effective soil stresses at the burrowing front, other organisms also employ various techniques, such as the use of fluid injection to drive up excess pore pressures and dynamic shell movements to bring local soil particles to failure and draw in water, thereby creating regions of localized fluidization for example, razor clams and other bivalves (Winter et al., Reference Winter, Deits and Hosoi2012). These processes have already inspired the design of various robotic self-burrowing probes (e.g., Huang et al., Reference Huang, Tang, Bagheri, Li, Ardente, Aukes, Marvi and Tao2020; Ortiz et al., Reference Ortiz, Gravish and Tolley2019; Tao et al., Reference Tao, Huang and Tang2019), which demonstrate feasibility for incorporation in future tunneling robots.

$ - $

to the soil conditions, burrow depth and size of the organism itself (Martinez et al., Reference Martinez, Dejong, Akin, Aleali, Arson, Atkinson, Bandini, Baser, Borela, Boulanger, Burrall, Chen, Collins, Cortes, Dai, DeJong, Del Dottore, Dorgan, Fragaszy, Frost, Full, Ghayoomi, Goldman, Gravish, Guzman, Hambleton, Hawkes, Helms, Hu, Huang, Huang, Hunt, Irschick, Lin, Lingwall, Marr, Mazzolai, McInroe, Murthy, O’Hara, Porter, Sadek, Sanchez, Santamarina, Shao, Sharp, Stuart, Stutz, Summers, Tao, Tolley, Treers, Turnbull, Valdes, van Paassen, Viggiani, Wilson, Wu, Yu and Zheng2022). At deeper “tunneling” depths, these organisms adopt a dual technique involving radial expansion and axial elongation (penetration). The radial expansion is highly beneficial for three reasons: (i) the generation of outward radial stresses leads to a relaxation in soil effective stresses at the “burrow” front (Shin and Santamarina, Reference Shin and Santamarina2011), making for easier and more efficient burrowing, (ii) the increased normal contact, and therefore friction, between the burrow and organism body acts to provide sufficient reaction for the thrust required for penetration (Summers and O’reilly, Reference Summers and O’reilly1997), and (iii) the normal contact also acts to stabilize the burrow (Dorgan, Reference Dorgan2018) (see Figure 8). To further reduce effective soil stresses at the burrowing front, other organisms also employ various techniques, such as the use of fluid injection to drive up excess pore pressures and dynamic shell movements to bring local soil particles to failure and draw in water, thereby creating regions of localized fluidization for example, razor clams and other bivalves (Winter et al., Reference Winter, Deits and Hosoi2012). These processes have already inspired the design of various robotic self-burrowing probes (e.g., Huang et al., Reference Huang, Tang, Bagheri, Li, Ardente, Aukes, Marvi and Tao2020; Ortiz et al., Reference Ortiz, Gravish and Tolley2019; Tao et al., Reference Tao, Huang and Tang2019), which demonstrate feasibility for incorporation in future tunneling robots.

Figure 8. Schematic illustration of the mechanics of marine worm and earthworm burrowing.

The soil excavation techniques adopted by ants also offer inspiration for future tunneling techniques. Soga (Reference Soga and Iai2011) noted that the efficiency of ant tunneling is two to four orders of magnitude more efficient than traditional TBMs. Similar to worm burrowing, the form of ant tunneling is also highly customized to the ground conditions. Recent research documented by Buarque de Macedo et al. (Reference Buarque de Macedo, Andò, Joy, Viggiani, Pal, Parker and Andrade2021) showed that ants tunnel in piecewise linear sections. Granular arching in the soil around ant tunnels leads to a significant decrease in intergranular forces near the surface of the excavation. This force re-distribution allows ants to tunnel safely without needing to establish additional structural support by selecting grains at the surface, which are typically under minimal stress and easy to remove. Thus, ants do not need to know which grains to remove as they have a high probability of avoiding structurally critical grains.

Similarly, the processes of root penetration in the soil also make use of radial expansion to reduce the soil resistance at the root tip. Interestingly, plant roots also penetrate in “oscillatory, semicircular movements,” termed circumnutations by Mullen et al. (Reference Mullen, Turk, Johnson, Wolverton, Ishikawa, Simmons, Söll and Evans1998). While there is debate as to the role of this process, Dottore et al. (Reference Dottore, Mondini, Sadeghi, Mattoli and Mazzolai2017) proposed that such movements can significantly reduce penetration resistance. This is supported by recent research on embedded pile foundations which showed that torsion could significantly reduce axial resistance (Georgiadis and Sheil, Reference Georgiadis and Sheil2020).

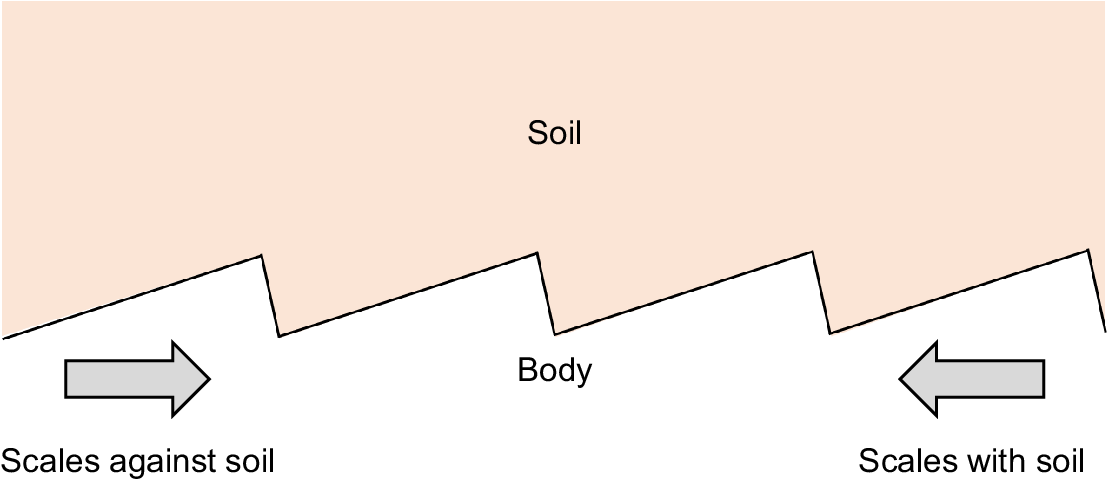

A key aspect of tunneling is optimizing directionally dependent friction: minimizing friction in the direction of penetration and vice versa in the opposite direction to provide sufficient thrust. Various organisms employ directionally dependent friction, including the paws and tongues of various birds and mammals, tree and grass leaves and some mammal and reptile skins. For example, snakes rely on directional dependence of friction between their body and the ground for locomotion (Martinez et al., Reference Martinez, Dejong, Akin, Aleali, Arson, Atkinson, Bandini, Baser, Borela, Boulanger, Burrall, Chen, Collins, Cortes, Dai, DeJong, Del Dottore, Dorgan, Fragaszy, Frost, Full, Ghayoomi, Goldman, Gravish, Guzman, Hambleton, Hawkes, Helms, Hu, Huang, Huang, Hunt, Irschick, Lin, Lingwall, Marr, Mazzolai, McInroe, Murthy, O’Hara, Porter, Sadek, Sanchez, Santamarina, Shao, Sharp, Stuart, Stutz, Summers, Tao, Tolley, Treers, Turnbull, Valdes, van Paassen, Viggiani, Wilson, Wu, Yu and Zheng2022). The direction dependence is achieved using their ventral scales, which are aligned transversely along their body (Figure 9).

Figure 9. Schematic illustration of the directional dependence of the shearing between snakeskin and soil.

4.2. Multi-functional swarm robotic systems

Multi-functional swarm robotic systems are expected to emerge as a promising approach for future tunneling applications. By leveraging the capabilities of multiple autonomous bio-inspired agents working collaboratively, multi-functional swarm robotic systems offer unique advantages in terms of adaptability, robustness, and scalability (Bonani et al., Reference Bonani, Longchamp, Magnenat, Rétornaz, Burnier, Roulet, Vaussard, Bleuler and Mondada2010; Dorigo et al., Reference Dorigo, Birattari and Brambilla2014). These systems have the potential to efficiently tackle complex tasks in challenging underground environments, potentially revolutionizing the field of tunneling.

One key advantage of the systems will be their ability to emulate the cooperative behaviors observed in nature. Social insects, such as ants and bees, exhibit remarkable collective intelligence, where individual agents work together towards a common goal without the need for centralized control (Wilson, Reference Wilson1971). Swarm robotic systems embody this decentralized approach, consisting of numerous small-scale bio-inspired robots capable of communicating, coordinating, and organizing their actions to achieve complex objectives. This flexibility allows the swarm to adapt and respond swiftly to dynamic tunneling conditions, such as varying soil properties or unexpected obstacles.

The concept of division of labor within a swarm is particularly relevant to the field of tunneling. In nature, different individuals within a group often specialize in specific tasks, optimizing efficiency and overall performance. Similarly, multi-functional swarm robotic systems can assign different roles and responsibilities to individual robots based on their capabilities. Some robots may be designed for excavation, while others focus on monitoring, sensing, material transport, or maintenance (see Figure 10). This division of labor allows for the simultaneous execution of multiple tasks, accelerating the tunneling process and enhancing productivity (Brambilla et al., Reference Brambilla, Ferrante, Birattari and Dorigo2013).

Figure 10. Schematic illustration of robotic advances for future tunneling.

The viability of multi-functional swarm robotic systems can be exemplified by the successful development of bio-inspired and multi-functional robotic systems. Researchers have been developing multiple robot systems since the late 1980s when the field of distributed robotics originated. For underground applications, there is considerable precedent for the deployment of swarm robotic systems in the mining sector which have been developed and deployed for over ten years (e.g., Yinka-Banjo et al., Reference Yinka-Banjo, Bagula and Osunmakinde2012) to the point where commercial offerings now exist (e.g., “OffWorld”). Such systems are commonly used for highly repetitive tasks or tasks to be completed in dangerous environments, for example, mine safety inspections (Yinka-Banjo et al., Reference Yinka-Banjo, Osunmakinde and Bagula2014), and emergency and disaster management (Yinka-Banjo et al., Reference Yinka-Banjo, Osunmakinde and Bagula2017). There is, therefore, significant scope for the transfer of technologies and experience from this cognate field.

Another example is the successful development of simple machines that act as autonomous modular robots capable of physically self-reproducing using a set of cubes (Zykov et al., Reference Zykov, Mytilinaios, Adams and Lipson2005). This concept of self-reproducing is fundamental to biological life for long-term sustainability and evolutionary adaptation and holds promise for creating long-term, self-sustaining robotic systems in challenging environments such as space exploration and hazardous conditions, where conventional maintenance approaches are not possible. This concept can be extended to tunneling applications as modular systems that can adapt their shape and configuration to navigate through complex tunnels deep underground.

Another notable example is the development of a bio-inspired hybrid aerial-aquatic microrobot that exhibits the ability to fly, swim, and seamlessly transition between air and water (Chen et al., Reference Chen, Wang, Helbling, Jafferis, Zufferey, Ong, Ma, Gravish, Chirarattananon, Kovac and Wood2017). This multi-functional insect-scale robotic system has demonstrated its potential to navigate through complex multiphase environments, making it applicable to various domains, including environmental exploration and search and rescue missions. These capabilities can be further extended to encompass future tunneling applications, such as mapping and inspection in underground environments, offering new possibilities and advancements in the field.

The capabilities of these bio-inspired agents can be expanded by leveraging advanced communication and coordination mechanisms to build multi-functional swarm robotic systems. The agents can share information, exchange data, and collaborate on decision-making, resulting in collective intelligence that surpasses the capabilities of any individual agent. By integrating sensors and perception capabilities, swarm agents can create a comprehensive picture of the tunneling environment, enabling real-time mapping, hazard detection, and obstacle avoidance (Rubenstein et al., Reference Rubenstein, Cornejo and Nagpal2014).

4.3. Challenges

Whilst there is a considerable body of research on bio-inspired mechanics, the realizations of such techniques in working physical prototypes are scant. Thus, while these imagined bio-inspired tunneling operations are promising, they are also highly complex, posing significant challenges to scaling up for real-world implementation. Compatibility issues, interface complexities, and ensuring seamless integration with conventional methods must be carefully addressed. It is also noteworthy that typical organisms considered in the literature are not restricted to a planned “tunnel trajectory,” and such a constraint may have a detrimental influence on the overall bio-inspired process. These issues point to much needed research exploring how these promising techniques may scale to realistic tunneling scenarios.

For multi-functional swarm robotic systems, ensuring effective and reliable communication and coordination in complex underground environments remains an open research question. For example, the significant attenuation caused by soil is the main challenge for the feasibility of wireless communications below ground (Silva and Vuran, Reference Silva, Vuran, Krishnamachari, Suri, Heinzelman and Mitra2009). Furthermore, as tunneling projects can vary in size and complexity, multi-functional swarm robotic systems must be scalable and adaptable. Developing modular and flexible swarm architectures that can accommodate varying project requirements will be crucial. Underground conditions can also be harsh and unpredictable. The systems need to be resilient to failures, capable of self-repair, and able to adapt to changing conditions to ensure uninterrupted tunneling operations.

While challenges such as designing efficient communication protocols, optimizing coordination strategies, and ensuring robustness against failures or environmental uncertainties exist, ongoing research and advancements in AI, sensing technologies, and swarm algorithms are addressing these issues (Şahin, Reference Şahin, Şahin and Spears2005). This progress paves the way for the widespread adoption of the systems in future tunneling projects. By addressing these challenges, bio-inspired mechanics and multi-functional swarm robotic systems can unlock their full potential and contribute significantly, revolutionizing tunneling with more sustainable, intelligent, and effective techniques to create sustainable and resilient infrastructure for the future.

5. Conclusion

In this paper, we have identified and discussed several technological advancements that hold potential to revolutionize the tunneling industry. These include AI, autonomous, and bio-inspired systems. The availability of AI systems may assist human engineers and operators in making informed decisions systematically and quantitatively based on massive data in real time during tunneling. The autonomous tunneling system may enable precise and predictable tunneling operations with minimal human intervention and facilitate the construction of massive and large-scale underground infrastructure projects. Bio-inspired systems may benefit future tunneling by providing valuable references and strategies for better tunneling design and construction concepts and will allow autonomous swarm construction to offer unique advantages in terms of adaptability, robustness, and scalability.

Although these technological advances may offer a promising future, the research community and industry stakeholders must come together to address several challenges. Restricted access to tunneling operation data limits the reproducibility and generalization of the developed AI models. The efficacy of machine learning in extrapolation problems remains an open research topic. Ensuring model stability, reliability, and robustness are critical in tunneling and may require novel evaluation frameworks. Developing explainable AI models is essential for establishing trust with the human stakeholders who hold responsibilities. Finally, scaling the bio-inspired mechanics to real-world applications and ensuring effective and reliable coordination and communication of multi-functional swarm robotic systems in complex underground environments remain significant challenges.

Tunneling stakeholders need to be ready to adopt the changing paradigm and leverage the opportunities and advantages presented by emerging technologies. However, this paradigm shift may not be a seamless process, as it will likely require a disruptive overhaul of many established practices and norms. This transformation may necessitate radical changes in human skill sets, including the need to acquire knowledge and skills related to data and computing, which will become a critical foundation in the industry. It will be imperative for individuals to gain proficiency in working with AI and autonomous systems, understanding their behaviors, and effectively managing and controlling their performance. By embracing these emerging technologies and addressing the identified challenges, the industry can move forward to safer and more efficient tunneling operations, enabling the creation of underground infrastructure projects that were previously difficult or impossible to achieve with conventional methods, to meet the growing demands of society.

Author contribution

Conceptualization: D.A., B.S., K.S. Methodology: D.A., B.S., K.S. Visualization: D.A., B.S. Writing—original draft: D.A., B.S. Writing—review and editing: D.A., B.S., K.S. All authors approved the final submitted draft.

Competing interest

The authors declare no competing interests exist.

Ethics statement

This paper was written in compliance with ethical guidelines.

Funding statement

This paper was written without receiving any specific grants from funding agencies.

Comments

No Comments have been published for this article.