1 Introduction

Fiber lasers, known for their superior beam quality, high efficiency, compact design and effective heat dissipation, have been widely adopted in various fields[ Reference Jauregui, Limpert and Tünnermann 1 – Reference Zuo and Lin 3 ] such as industrial processing[ Reference Kawahito, Wang, Katayama and Sumimori 4 , Reference Lee, Cho, Kim and Lee 5 ], medical applications[ Reference La, Ülgen, Shnaiderman and Ntziachristos 6 , Reference Sun, Kuschmierz, Katz, Koukourakis and Czarske 7 ], telecommunications[ Reference Fu, Davidson, Mousavi, Mulvad, Wheeler, Xu, Poletti and Richardson 8 , Reference Wang, Wang, Jiang, Wang, Wang, Yan and Qin 9 ] and scientific research[ Reference Yu, Yao, Zhou, Yu, Zhuang, Qi and Xiong 10 , Reference Dai, Jia, Zhu, Li, Fei, Guo, Yuan, Wang, Jia, Zhao, Kang, Chen, Zhu, Wu, Xie and Zhang 11 ]. The swift evolution of semiconductor lasers, fiber optics and fiber devices has catalyzed remarkable advancements in the development and deployment of high-power fiber lasers. Notably, rare-earth-ion-doped fiber lasers[ Reference Zervas and Codemard 12 , Reference Sohail, Yin, Abdullah, Younis, Anjum, Sohail, Alroobaea, Ahmad and Peiguang 13 ], exemplified by ytterbium-doped varieties[ Reference Dominic, MacCormack, Waarts, Sanders, Bicknese, Doble, Wolak, Yeh and Zucker 14 – Reference O’Connor, Gapontsev, Fomin, Abramov and Ferin 16 ], have risen to prominence in research circles due to their prowess in delivering high-power outputs, with these lasers now attaining tens of kilowatt output capabilities. However, these lasers are inherently limited to achieving high-power output within a narrow wavelength spectrum because of the specific energy-level radiation characteristics of rare-earth ions. Raman fiber lasers, taking advantage of the stimulated Raman scattering (SRS) effect, present a compelling alternative[ Reference Supradeepa, Feng and Nicholson 17 , Reference Yao, Fan, Hao, Li, Huang, Zhang, Xu, Ye, Leng and Zhou 18 ]. They offer an expansive gain bandwidth and capacity for cascade operation, facilitating a broad spectrum of Raman frequency shifts. By strategically selecting an appropriate pump source, it is theoretically feasible to achieve lasers across any wavelength supported by the fiber, rendering Raman fiber lasers an optimal solution for combining arbitrary wavelength flexibility with high-power capabilities[ Reference Supradeepa and Nicholson 19 – Reference Zheng, Wu and Dai 24 ].

Raman oscillators, particularly those based on fiber Bragg gratings, have reaped the benefits of advancements in fiber technology, boasting a simple structure and achieving power outputs that span from hundreds of watts to several kilowatts. Initially, Raman fiber lasers were primarily based on small-core step-index fibers, a structure that limited the injection power of pump light and, due to the high-power density of signal light within the core, resulted in a lower threshold for second-order Raman light. This restricted further increases in laser power, with the maximum output power mostly remaining at the 100-W level[ Reference Feng, Taylor and Calia 25 , Reference Zhang, Xiao, Zhou, Wang and Xu 26 ]. With the application of cladding pumping schemes in Raman fiber oscillators, the injectable pump power was effectively increased, enabling the output power of Raman fiber oscillators to jump from the 100-W level[ Reference Codemard, Ji, Sahu and Nilsson 27 ] to several hundred watts[ Reference Shamir, Glick, Aviel, Attias and Pearl 28 ] or even into the kilowatt range[ Reference Glick, Shamir, Aviel, Sintov, Goldring, Shafir and Pearl 29 ]. However, cladding pumping schemes require special fiber design, and the SRS of pump light in the cladding may lead to a decline in laser output quality. In contrast, the core-pumping scheme based on large-core multimodal graded-index fibers not only enhances the injectable pump power but also achieves high-power, high-beam-quality Raman fiber laser output through various brightness enhancement mechanisms, such as beam purification and resonant cavity mode selection. Currently, the maximum output power of Raman oscillators based on multimodal fiber core pumping has evolved from the 100-W level to the kilowatt level[ Reference Glick, Fromzel, Zhang, Dahan, Ter-Gabrielyan, Pattnaik and Dubinskii 30 – Reference Evmenova, Kablukov, Nemov, Wolf, Dostovalov, Tyrtyshnyy, Myasnikov and Babin 33 ], with the current record reaching 1780 W[ Reference Fan, Fu, Hao, Huang, Li, Chen, Leng, Yao and Zhou 34 ].

On the other hand, Raman amplifiers, despite their increased structural complexity, possess a clear advantage when it comes to achieving high-power outputs. Utilizing specialized fiber designs, high-power pump sources and sophisticated fiber devices, these lasers have successively achieved output powers of hundreds of watts[ Reference Supradeepa and Nicholson 19 , Reference Chen, Leng, Xiao, Yao, Xu and Zhou 35 ]. By continuously optimizing fiber devices such as couplers and employing multi-mode fibers with larger core diameters, the output power has rapidly escalated to the kilowatt level[ Reference Chen, Yao, Xiao, Leng and Zhou 36 , Reference Chen, Leng, Xiao, Yao and Zhou 37 ]. With the enhancement of metal coating technology, the radial heat conduction capability of Raman fibers has been significantly improved. This effective cooling of the Raman fibers at high power levels has led to a further increase in the output power of the laser. The current maximum output power has reached 3000 W[ Reference Chen, Yao, Xiao, Leng and Zhou 38 ]. While Raman fiber lasers have seen rapid development, their power enhancement is primarily constrained by the emergence and rapid growth of second-order Raman scattering. This scattering not only leads to a decrease in laser efficiency but can also result in thermal damage and nonlinear effects within the laser, impacting its stability and output power. Existing methods to suppress higher-order Raman scattering include using fibers with larger mode field areas and shorter lengths[ Reference Chen, Yao, Xiao, Leng and Zhou 38 ], employing cladding pumping with special optimization of the core-to-cladding ratio[ Reference Glick, Shamir, Aviel, Sintov, Goldring, Shafir and Pearl 29 ] and optimizing the pump structure in amplifiers to use pump light with better temporal stability[ Reference Fan, Xiao, Yao, Xu, Chen, Leng and Zhou 39 ]. In addition, designing seed light power and mode characteristics is also an effective method to suppress second-order Raman scattering[ Reference Fan, Li, Hao, Yao, Leng and Zhou 40 ]. However, these methods all have certain limitations, such as high costs, complexity and low efficiency. Therefore, there is an urgent need to explore further high-order Raman suppression schemes to achieve higher power output in Raman fiber lasers.

In this paper, we investigate the impact of pump brightness on laser output characteristics and validate a feasible scheme for achieving high-power output using high-brightness pumping combined with large-core graded-index fibers. Building on this, we propose a new scheme to suppress higher-order Raman scattering. By utilizing dual-wavelength seed lasers to induce four-wave mixing, new frequency light components are generated in the fiber amplifier, causing the second-order Raman light to interact with the new frequency light components. This interaction transfers part of the optical power to the new frequency components, thereby suppressing the growth of second-order Raman power. Ultimately, we have achieved a 4 kW Raman fiber amplifier in an all-fiber structure, representing the highest output power of Raman fiber lasers to date. This research not only provides new technical avenues for the development of high-power Raman fiber lasers but also expands the possibilities for further applications of fiber lasers.

2 Experimental setup

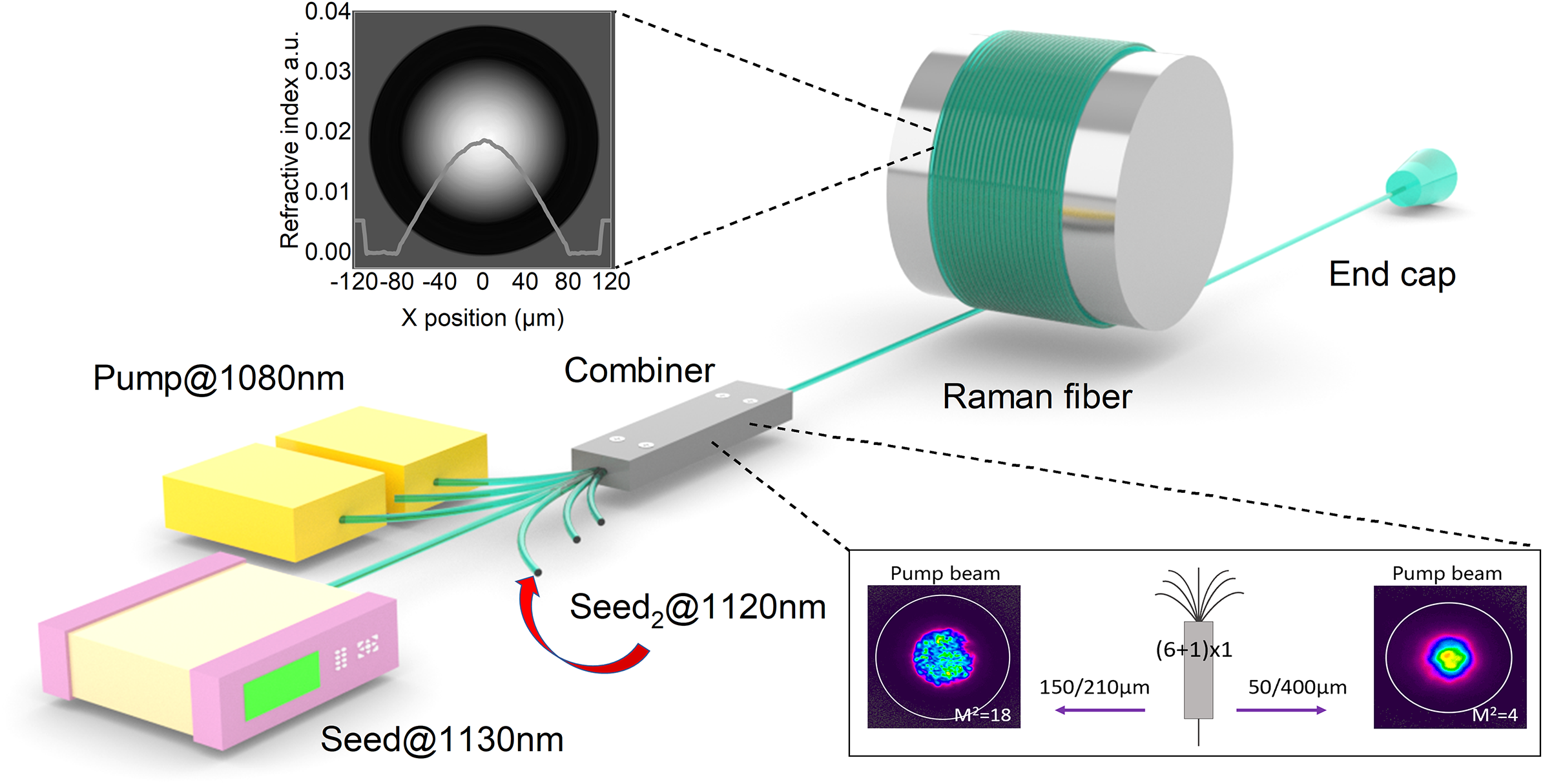

To achieve high-power Raman laser output, we have built an all-fiberized Raman amplifier as depicted in Figure 1. The seed light is an Yb-doped oscillator with a central wavelength of 1130 nm. The pump light is provided by four high-power Yb-doped oscillators with a central wavelength of 1080 nm. The pump light is injected into the amplifier through a home-made (6 + 1) × 1 signal/pump combiner, with a maximum combined pump power of over 5 kW. The input fibers of the combiner for both the signal and pump have the same core/cladding diameter of 20/130 μm, and the output pigtail is connected to a section of Raman gain fiber with a graded refractive index distribution. Considering our previous research, it has been observed that large-core multi-mode fibers with a core diameter exceeding 100 μm can also achieve near-single-mode output[ Reference Fan, Xiao, Yao, Xu, Chen, Leng and Zhou 39 ]. This is primarily due to the inherent beam-cleaning capability[ Reference Krupa, Tonello, Shalaby, Fabert, Barthélémy, Millot, Wabnitz and Couderc 41 ] of graded refractive index fibers and the higher gain of SRS for lower-order modes[ Reference Terry, Alley and Russell 42 ]. In high-power Raman lasers based on large-core fibers, further power enhancement is mainly limited by the emergence and rapid growth of higher-order Raman scattering. To effectively suppress higher-order Raman scattering while maintaining the quality of the output beam, we have specially designed the Raman gain fiber. We have increased the core diameter while appropriately reducing the numerical aperture (NA) of the core. This fiber has a core/cladding diameter of 150/210 μm and the NA of the core is 0.25. The refractive index distribution, as shown in the inset of Figure 1, exhibits a parabolic profile. The inherent beam cleaning provided by this graded refractive index distribution is an important guarantee for achieving high-brightness signal light output. To protect the system from the adverse effects of back reflections generated within the amplifier, we have spliced an end cap with an anti-reflective coating that spans the 900–1200 nm range at the output end. This design helps to protect the system from the effects of back reflections, ensuring the stability and safety of the system.

Figure 1 Experimental setup of the Raman fiber amplifier. The inset in the top shows the refractive index distribution and the illustration at the bottom of the figure shows the output beam profiles of the pump light after coupling through combiners with different output fibers.

3 Impact of pump brightness on laser output

In the amplifier structure, pump light serves as the primary power source for Raman conversion, and its optical characteristics significantly influence the output signal light. Specifically, pump sources with broader spectral linewidths and better temporal stability tend to markedly enhance the output performance of the signal light. Detailed findings of these studies can be found in the literature[ Reference Chen, Song, Ye, Yao, Xu, Xiao, Leng and Zhou 43 ]. The brightness of the pump light also plays a crucial role in the Raman threshold, conversion efficiency and output power of the laser. To further investigate the influence of pump brightness on the output characteristics of the laser, we employed fiber combiners with different output tail fiber diameters to inject pump light. Specifically, we compared fiber combiners with output tail fibers of 150/210 μm (with a core NA of 0.25) and 50/400 μm (with a core NA of 0.1). The output beam profiles of the 1080 nm pump light after coupling through these combiners are shown in the inset of Figure 1. When the pump light passes through the combiner with a 150 μm core, the output fiber has a large core diameter and NA, resulting in a huge number of high-order modes within the fiber. Consequently, the pump light brightness at the output end of the combiner is quite low, leading to a diffuse near-field beam profile distribution. In contrast, after passing through the 50/400 μm combiner, the pump light exhibits higher brightness and better beam quality. The near-field pump light spot intensity distribution at the output end of the combiner is illustrated on the right, showing a more concentrated energy distribution.

3.1 Raman fiber amplifier under low-brightness pumping

Initially, the fiber combiner with a large core diameter of 150 μm, which has lower brightness, was used for pump injection and the output power and spectrum were measured. The seed light is provided by an ytterbium-doped fiber laser with a central wavelength of 1130 nm and an output power of 130 W. Concurrently, we optimized the length of the fiber within the amplifier by progressively shortening the fiber length. To better investigate the impact of fiber length and pump light brightness on the laser’s output characteristics, we defined the maximum output power of the laser under a specific configuration as the point where the intensity of the second-order Raman spectral peak reaches –40 dB relative to the signal light. Further increase of second-order Raman light will reduce the power of the signal light and, additionally, the backward transmission of second-order Raman light can affect the stability of the preceding system.

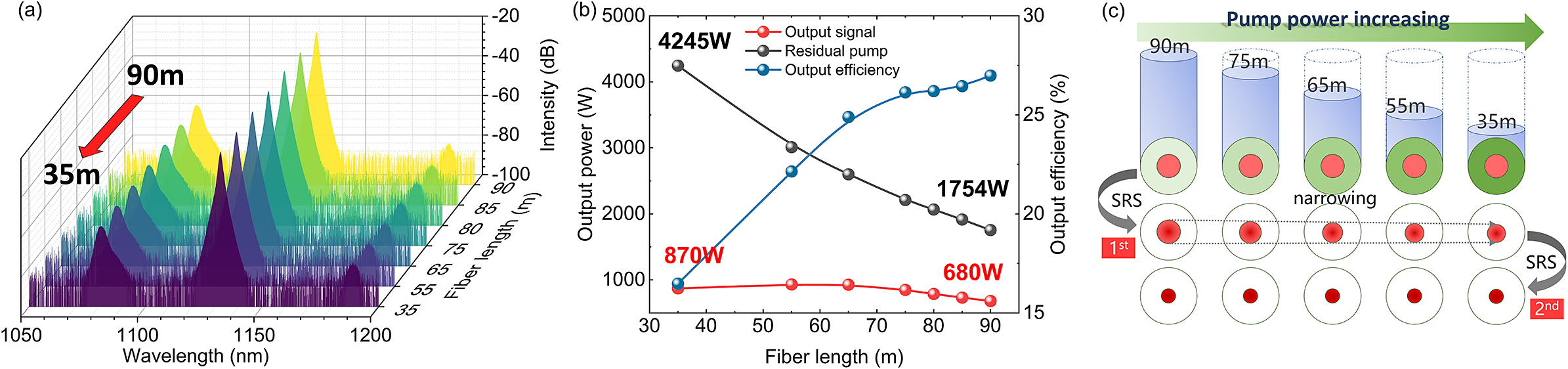

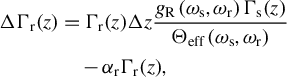

Figure 2 illustrates the maximum output power achievable by the Raman amplifier at various fiber lengths, along with the corresponding output spectra at maximum power. At a fiber length of 90 m, the maximum pump power that can be injected is 2520 W, resulting in a total laser output power of 2434 W. This includes a signal power of 680 W and a remaining pump power of 1754 W, corresponding to a Raman conversion efficiency of 26.9%. As the length of the Raman fiber decreases, the threshold for first-order SRS increases, necessitating higher pump powers for Raman conversion. As depicted in Figure 2(b), a reduction in fiber length leads to a significant increase in the injectable pump power, which in turn causes a continuous growth in the total laser output power. However, the laser’s output efficiency significantly decreases. When the fiber length is reduced to 35 m, the maximum injectable pump power reaches 5280 W and the maximum output power of the laser is 5115 W. The signal power is 870 W, and the remaining pump power is 4245 W, corresponding to a Raman conversion efficiency of only 16.5%. The results clearly indicate that when using a low-brightness pump source, the laser’s efficiency is low, and it further decreases with the reduction of fiber length. Moreover, the maximum achievable signal power consistently remains at the 800-W level, at which point the power is further limited by second-order Raman scattering.

Figure 2 The maximum achievable output power at different fiber lengths with corresponding output spectrum of the Raman fiber amplifier pumped by a lower-brightness laser. (a) Output spectral power under maximum power at various fiber lengths. (b) The evolution of output power and efficiency. (c) The physical process behind the constant second-order Raman threshold under low-brightness pumping.

Figure 2(c) demonstrates the physical process behind the constant second-order Raman threshold under low-brightness pumping. Since the response of the SRS process is related to the peak power of the beam, we assume that the pump light has a nearly Gaussian intensity distribution within the core, being stronger in the center and weaker around the edges. Therefore, as the pump power increases, the higher-intensity pump light closer to the fiber core will reach the SRS threshold first, undergoing frequency conversion. With the reduction in fiber length, the increased injected pump power means that the same output signal light power at the output end implies that more energy from the pump light closer to the core region has achieved stimulated Raman conversion first. In other words, in shorter fibers, the signal light is converted from the higher-brightness pump closer to the core, resulting in a relatively stronger signal light brightness. The higher brightness of the signal light at the same power compensates for the reduction in second-order Raman scattering due to the shorter fiber. Thus, when the fiber length is shortened, the threshold of second-order Raman scattering exhibits a phenomenon of not changing with fiber length. The main reason for this result is that the fiber core diameter is too large, and the pump brightness in the regions far from the center is too low to reach the SRS threshold and cannot achieve frequency conversion through SRS. Therefore, we attempted to use a combiner with smaller output fiber core diameters and NA to provide higher-brightness pump light.

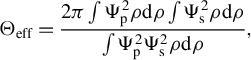

3.2 Raman fiber amplifier under high-brightness pumping

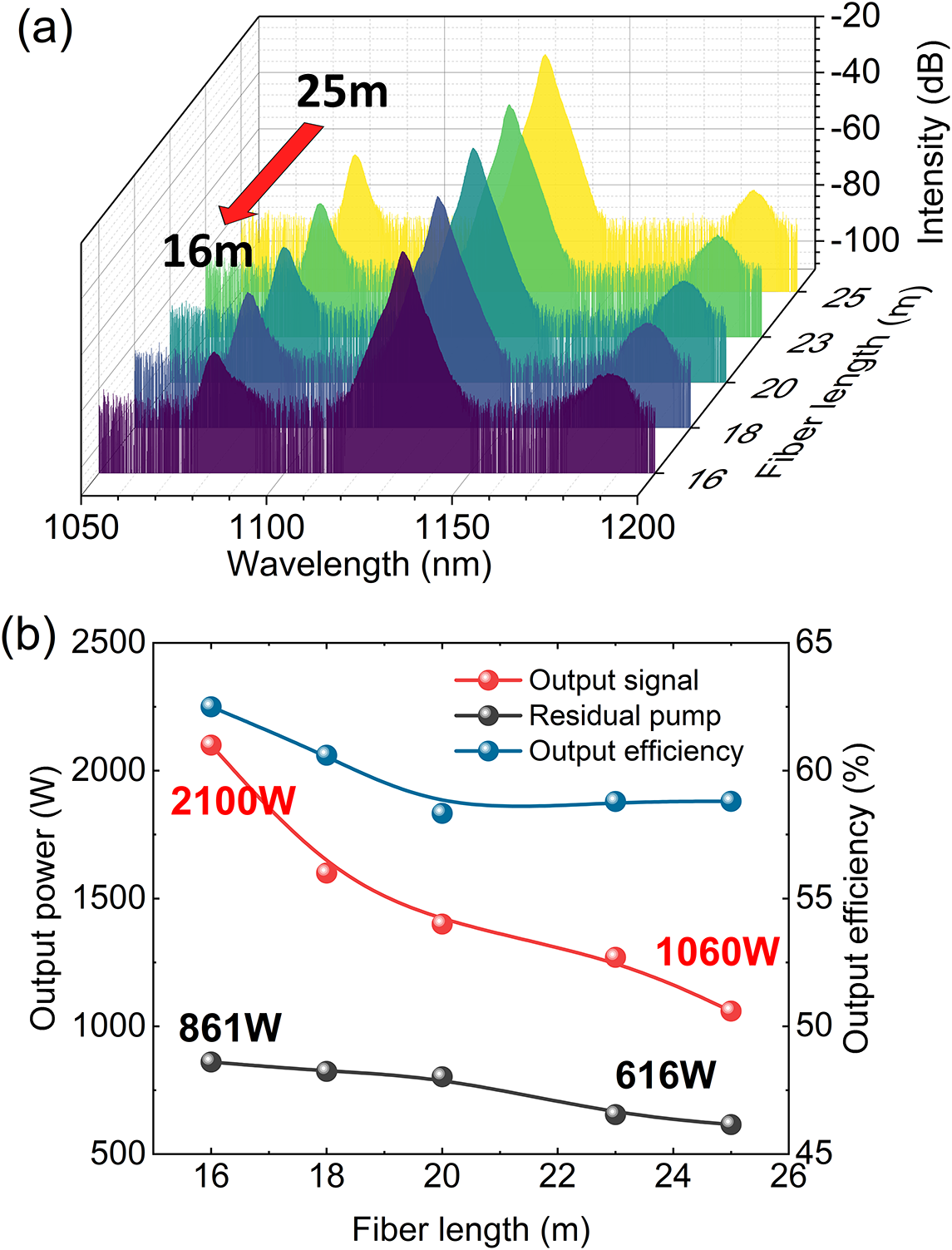

Subsequently, the fiber combiner with a smaller core diameter of 50 μm, which has higher brightness, was used for pump injection. We further optimized the fiber system by incrementally reducing the fiber length while maintaining a constant intensity for the second-order Raman light. The maximum achievable output power at different fiber lengths with corresponding output spectrum of the Raman fiber amplifier pumped by the lower-brightness laser is shown in Figure 3. With an initial fiber length of 25 m, the maximum pump power we could inject was 1800 W. The seed light of 130 W, amplified through SRS within the fiber, resulted in a signal power output of 1060 W, with a remaining pump power of 616 W, achieving a Raman conversion efficiency of 58.8%. As the fiber length decreased, the injectable pump power kept increasing, which in turn boosted the total output power of the laser. Contrary to a structure with low-brightness pump sources, the use of a higher-brightness pump source led to an improvement in Raman conversion efficiency as the injectable pump power was increased, resulting in a steady climb in signal power. Upon reducing the fiber length to 16 m, the maximum injectable pump power reached 3360 W, resulting in a maximum output power of 2961 W, which included a signal power of 2100 W and a remaining pump power of 861 W, corresponding to a Raman conversion efficiency of 62.5%. The experimental results indicate that in Raman amplifiers based on large-core graded-index fibers, augmenting pump brightness is conducive to improving conversion efficiency. Moreover, as the fiber length is shortened, the threshold for second-order Raman scattering continuously rises. Therefore, when pumping with higher-brightness lasers, the signal output power can be increased by shortening the fiber length to suppress second-order Raman scattering.

Figure 3 The maximum achievable output power at different fiber lengths with corresponding output spectrum of the Raman fiber amplifier pumped by a lower-brightness laser. (a) Output spectral power under maximum power at various fiber lengths. (b) The evolution of output power and efficiency.

3.3 Simulation of the Raman fiber amplifier

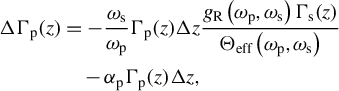

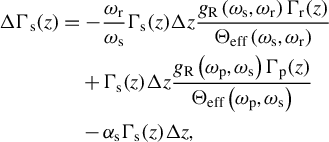

To further clarify the influence of pump brightness on laser performance, we conducted simulations of the Raman conversion process within the amplifier. In the context of Raman fiber amplifiers, the power evolution can be intricately described by a set of equations that capture the dynamics of pump depletion and signal gain. The corresponding power evolution equation, which encapsulates the essence of the Raman amplification process, can be expressed as follows:

$$\begin{align}{\Delta \Gamma}_{\mathrm{p}}(z)&=-\frac{\omega_{\mathrm{s}}}{\omega_{\mathrm{p}}}{\Gamma}_{\mathrm{p}}(z)\Delta z\frac{g_{\mathrm{R}}\left({\omega}_{\mathrm{p}},{\omega}_{\mathrm{s}}\right){\Gamma}_{\mathrm{s}}(z)}{\Theta_{\mathrm{eff}}\left({\omega}_{\mathrm{p}},{\omega}_{\mathrm{s}}\right)}\nonumber\\& \quad -{\alpha}_{\mathrm{p}}{\Gamma}_{\mathrm{p}}(z)\Delta z,\end{align}$$

$$\begin{align}{\Delta \Gamma}_{\mathrm{p}}(z)&=-\frac{\omega_{\mathrm{s}}}{\omega_{\mathrm{p}}}{\Gamma}_{\mathrm{p}}(z)\Delta z\frac{g_{\mathrm{R}}\left({\omega}_{\mathrm{p}},{\omega}_{\mathrm{s}}\right){\Gamma}_{\mathrm{s}}(z)}{\Theta_{\mathrm{eff}}\left({\omega}_{\mathrm{p}},{\omega}_{\mathrm{s}}\right)}\nonumber\\& \quad -{\alpha}_{\mathrm{p}}{\Gamma}_{\mathrm{p}}(z)\Delta z,\end{align}$$

$$\begin{align}{\Delta \Gamma}_{\mathrm{s}}(z)&=-\frac{\omega_{\mathrm{r}}}{\omega_{\mathrm{s}}}{\Gamma}_{\mathrm{s}}(z)\Delta z\frac{g_{\mathrm{R}}\left({\omega}_{\mathrm{s}},{\omega}_{\mathrm{r}}\right){\Gamma}_{\mathrm{r}}(z)}{\Theta_{\mathrm{eff}}\left({\omega}_{\mathrm{s}},{\omega}_{\mathrm{r}}\right)}\nonumber\\& \quad +{\Gamma}_{\mathrm{s}}(z)\Delta z\frac{g_{\mathrm{R}}\left({\omega}_{\mathrm{p}},{\omega}_{\mathrm{s}}\right){\Gamma}_{\mathrm{p}}(z)}{\Theta_{\mathrm{eff}}\left({\omega}_{\mathrm{p}},{\omega}_{\mathrm{s}}\right)}\nonumber\\& \quad -{\alpha}_{\mathrm{s}}{\Gamma}_{\mathrm{s}}(z)\Delta z, \end{align}$$

$$\begin{align}{\Delta \Gamma}_{\mathrm{s}}(z)&=-\frac{\omega_{\mathrm{r}}}{\omega_{\mathrm{s}}}{\Gamma}_{\mathrm{s}}(z)\Delta z\frac{g_{\mathrm{R}}\left({\omega}_{\mathrm{s}},{\omega}_{\mathrm{r}}\right){\Gamma}_{\mathrm{r}}(z)}{\Theta_{\mathrm{eff}}\left({\omega}_{\mathrm{s}},{\omega}_{\mathrm{r}}\right)}\nonumber\\& \quad +{\Gamma}_{\mathrm{s}}(z)\Delta z\frac{g_{\mathrm{R}}\left({\omega}_{\mathrm{p}},{\omega}_{\mathrm{s}}\right){\Gamma}_{\mathrm{p}}(z)}{\Theta_{\mathrm{eff}}\left({\omega}_{\mathrm{p}},{\omega}_{\mathrm{s}}\right)}\nonumber\\& \quad -{\alpha}_{\mathrm{s}}{\Gamma}_{\mathrm{s}}(z)\Delta z, \end{align}$$

$$\begin{align}{\Delta \Gamma}_{\mathrm{r}}(z)&={\Gamma}_{\mathrm{r}}(z)\Delta z\frac{g_{\mathrm{R}}\left({\omega}_{\mathrm{s}},{\omega}_{\mathrm{r}}\right){\Gamma}_{\mathrm{s}}(z)}{\Theta_{\mathrm{eff}}\left({\omega}_{\mathrm{s}},{\omega}_{\mathrm{r}}\right)}\nonumber\\& \quad -{\alpha}_{\mathrm{r}}{\Gamma}_{\mathrm{r}}(z),\end{align}$$

$$\begin{align}{\Delta \Gamma}_{\mathrm{r}}(z)&={\Gamma}_{\mathrm{r}}(z)\Delta z\frac{g_{\mathrm{R}}\left({\omega}_{\mathrm{s}},{\omega}_{\mathrm{r}}\right){\Gamma}_{\mathrm{s}}(z)}{\Theta_{\mathrm{eff}}\left({\omega}_{\mathrm{s}},{\omega}_{\mathrm{r}}\right)}\nonumber\\& \quad -{\alpha}_{\mathrm{r}}{\Gamma}_{\mathrm{r}}(z),\end{align}$$

where

![]() $\Delta \Gamma$

represents the variation in optical power of the pump (p), signal (s) and second-order Raman light (r). In addition

$\Delta \Gamma$

represents the variation in optical power of the pump (p), signal (s) and second-order Raman light (r). In addition

![]() $g$

and

$g$

and

![]() $\alpha$

represent the gain and loss of the mode. The effective area is correlated with the intensity distribution of the two laser components involved in Raman coupling, expressed as follows:

$\alpha$

represent the gain and loss of the mode. The effective area is correlated with the intensity distribution of the two laser components involved in Raman coupling, expressed as follows:

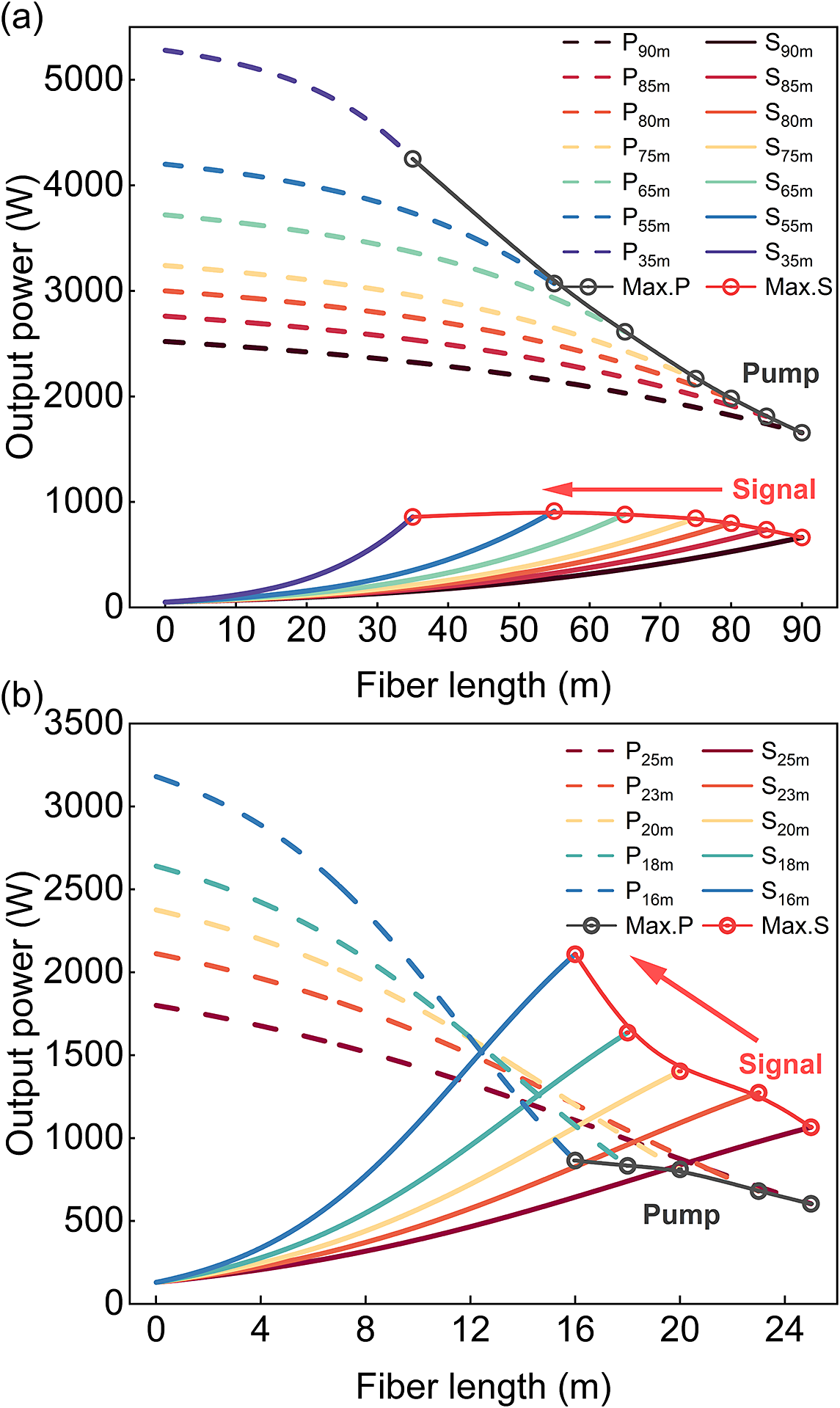

$$\begin{align}{\Theta}_{\mathrm{eff}}=\frac{2\pi \int {\Psi}_{\mathrm{p}}^2\rho \mathrm{d}\rho \int {\Psi}_{\mathrm{s}}^2\rho \mathrm{d}\rho}{\int {\Psi}_{\mathrm{p}}^2{\Psi}_{\mathrm{s}}^2\rho \mathrm{d}\rho}, \end{align}$$

$$\begin{align}{\Theta}_{\mathrm{eff}}=\frac{2\pi \int {\Psi}_{\mathrm{p}}^2\rho \mathrm{d}\rho \int {\Psi}_{\mathrm{s}}^2\rho \mathrm{d}\rho}{\int {\Psi}_{\mathrm{p}}^2{\Psi}_{\mathrm{s}}^2\rho \mathrm{d}\rho}, \end{align}$$

where

![]() $\Psi$

represents the modal field distribution of the laser and

$\Psi$

represents the modal field distribution of the laser and

![]() $\rho$

denotes the radial coordinate. For ease of calculation and considering the experimental setup utilizes a core-pumping structure, when low-brightness pumping is employed, the mode field area was approximated by the core area of the fiber, as the pump light predominantly fills the core. For cases with higher pump brightness, the mode field area was scaled by a factor of 0.9 to account for the tighter confinement of the pump light within the core. In our system, the peak Raman gain coefficient

$\rho$

denotes the radial coordinate. For ease of calculation and considering the experimental setup utilizes a core-pumping structure, when low-brightness pumping is employed, the mode field area was approximated by the core area of the fiber, as the pump light predominantly fills the core. For cases with higher pump brightness, the mode field area was scaled by a factor of 0.9 to account for the tighter confinement of the pump light within the core. In our system, the peak Raman gain coefficient

![]() ${g}_{\mathrm{R}}$

was set to

${g}_{\mathrm{R}}$

was set to

![]() $1\times {10}^{-13}\ \mathrm{m}/\mathrm{W}$

, which is close to the values reported in the literature for silica-based multi-mode fibers[

Reference Polley and Ralph

44

]. The fiber losses were set to 0.002 dB/m for all wavelengths in the numerical model, based on the specifications of commercially available graded-index multi-mode fibers, and adjusted to align with experimental results.

$1\times {10}^{-13}\ \mathrm{m}/\mathrm{W}$

, which is close to the values reported in the literature for silica-based multi-mode fibers[

Reference Polley and Ralph

44

]. The fiber losses were set to 0.002 dB/m for all wavelengths in the numerical model, based on the specifications of commercially available graded-index multi-mode fibers, and adjusted to align with experimental results.

The brightness of the pump light, which is essentially the intensity of the light per unit area, plays a pivotal role in the SRS process within a Raman fiber amplifier. When the pump light exits the combiner, it carries a specific brightness that determines how the light interacts with the signal light within the amplifier. This interaction is crucial as it dictates the transfer of energy from the pump to the signal light, which is the foundation of the amplification process. The effective area over which this energy transfer occurs is influenced by the brightness of the pump light. As the brightness changes, so does the area where the pump and signal lights interact effectively, altering the dynamics of the SRS process and, consequently, the power evolution of the laser system. To facilitate a more precise comparison with our experimental results, we ensured that the simulation parameters closely mirrored those used in the experiments, specifically regarding seed light power, pump power and fiber specifications. Figures 4(a) and 4(b) depict the power evolution of the amplifier across various fiber lengths under low- and high-brightness pumping conditions, respectively. Concurrently, we plotted the data points of the maximum residual pump (Max.P) power and signal power (Max.S) at the laser output for various fiber lengths and connected them with lines to facilitate comparison with previous experimental findings. In Figure 4(a), it is evident that when low-brightness pumping is employed, the injectable pump power increases as the fiber length is shortened. However, this increase in pump power is accompanied by a significant decline in laser efficiency, resulting in the output signal power not achieving any meaningful enhancement. This suggests that while more pump power is available, the low brightness limits the effectiveness of the SRS process, ultimately constraining the overall performance of the laser. Conversely, Figure 4(b) illustrates the scenario with high-brightness pumping. In this case, as the fiber length decreases, the injectable pump power not only rises but also leads to an improvement in Raman conversion efficiency. This enhancement translates into a substantial increase in the output power of the signal light. The results from our simulations align closely with the experimental data, reinforcing the validity of our modeling approach and highlighting the critical role that pump brightness plays in optimizing laser performance. Through our experiments and simulations, we can draw an initial conclusion that in Raman amplifiers based on large-core graded-index fibers, a higher pump brightness is conducive to enhancing the Raman conversion efficiency, thereby achieving a higher output power of signal light.

Figure 4 The output power evolution of the Raman amplifier under various fiber lengths when pumped by lasers with different brightness. (a) Result of lower-brightness pumping. (b) Result of higher-brightness pumping.

4 Suppression of second-order Raman emissions for further power scaling

In the quest to augment the power of lasers, the advent of high-order Raman emissions not only diminishes the output efficiency but also poses a grave risk to system integrity due to the backward propagation of high-order Raman light. This, in turn, constrains the potential for boosting the output power in Raman fiber lasers. To mitigate the deleterious effects of high-order Raman emissions, we have implemented a pioneering strategy: injecting a seed source at a wavelength of 1120 nm with power of 130 W into the amplifier through the pump arm, as illustrated in Figure 1. This extra seed induces four-wave mixing within the spectral region inhabited by high-order Raman wavelengths, thereby suppressing the rapid growth of high-order Raman light.

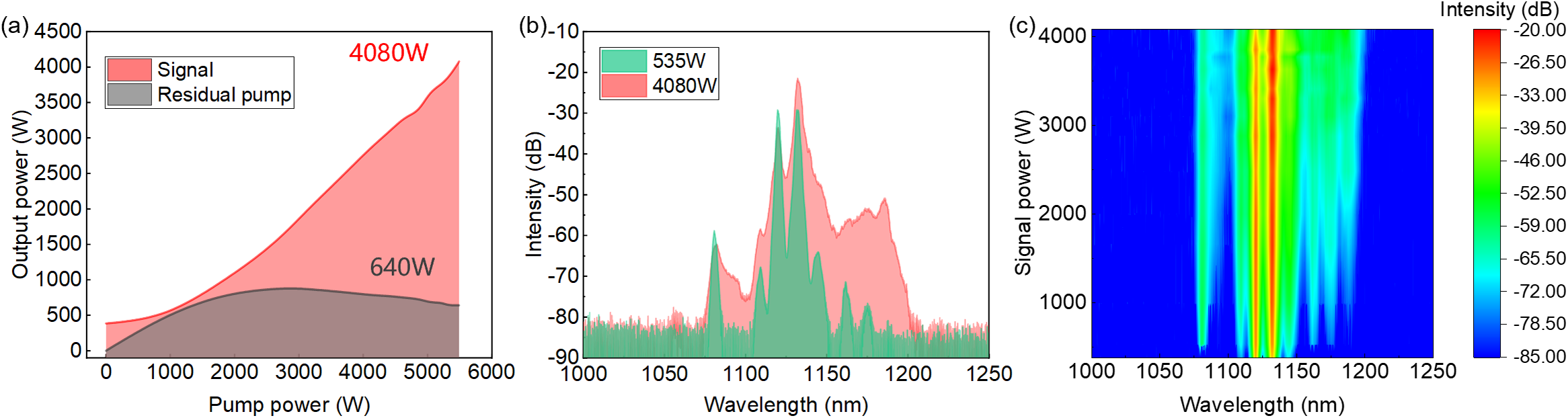

Figure 5(b) presents the output spectral distribution of the Raman amplifier, which incorporates an additional seed source injection. The spectrum reveals the interplay of the 1130 nm seed, 1120 nm seed and 1080 nm pump within the fiber amplifier, giving rise to new optical frequency components via a nonlinear four-wave mixing process. These newly generated frequency components are observed at 1109, 1145, 1161 and 1175 nm. As the power of the 1130 nm signal light increases, the second-order Raman light at 1185 nm is expected to surge rapidly upon surpassing its threshold. Nevertheless, the emergence of these new frequency components leads to a further nonlinear four-wave mixing interaction between the second-order Raman light and the components at 1161 and 1175 nm. This interaction results in the redistribution of power from the second-order Raman light to these new optical frequency components, thereby effectively mitigating the growth of the second-order Raman light at 1185 nm and markedly augmenting the output power of the signal light. Figure 5(c) provides a detailed representation of the Raman amplifier’s output spectrum at varying output powers. It is evident that with the increment of output power, the second-order Raman light power is broadened across the 1160–1190 nm spectral band due to four-wave mixing. Concurrently, the growth in intensity of the second-order Raman light exhibits a tendency toward gradual moderation. At the peak output power, the intensity of the second-order Raman light is reduced to –30 dB relative to the signal light. Figure 5(a) depicts the evolution of the output power in relation to the injected pump power. Owing to the effective suppression of the second-order Raman light, when the pump power reaches 5.49 kW, the output power of the signal light is increased to 4.08 kW, with the remaining pump light at 640 W, corresponding to a Raman conversion efficiency of 74.3%. Compared to using a single-wavelength seed, the output power of the amplifier has doubled, the conversion efficiency has increased by 11.8% and the second-order Raman effect has been significantly suppressed.

Figure 5 The output power and spectral evolution of the Raman fiber amplifier with extra seed. (a) The evolution of output power. (b) Output spectra at 500 W and 4 kW. (c) The evolution of output spectra.

5 Conclusion

In our comprehensive study combining theoretical analysis with experimental validation, we have explored the impact of pump brightness on the output characteristics of Raman amplifiers utilizing large-core fibers. The experimental outcomes have demonstrated that insufficient pump brightness not only fails to suppress higher-order Raman effects but also significantly degrades the system’s conversion efficiency. By integrating a high-brightness pump source with large-core multimodal fibers, we have effectively mitigated high-order Raman scattering while achieving efficient SRS. Building on this foundation, we have pioneered the approach of using multi-wavelength seed light to induce four-wave mixing, which has effectively curbed the rapid growth of second-order Raman light. This innovation has culminated in the realization of a 4 kW Raman fiber laser output in an all-fiber structure, setting a new record for the highest reported output power to date. The methodologies and insights presented in this work offer a novel avenue for enhancing the output power of Raman fiber lasers. Moreover, this research is anticipated to have broader applications in the realms of high-power lasers, ultrafast optics and nonlinear optics

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 12174445 and 62061136013).