Published online by Cambridge University Press: 29 September 2023

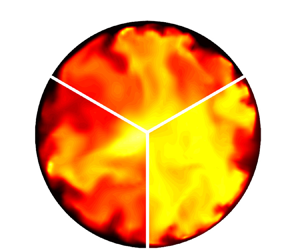

The purpose of this research was to provide further understanding of turbulent dynamics and heat transfer mechanisms in accelerating flows with thermophysical variations and pressure drops in micron tubes. Direct numerical simulations were conducted to investigate the turbulence to supercritical pressure  ${\rm CO}_2$ in heated micron tubes with inner diameter

${\rm CO}_2$ in heated micron tubes with inner diameter  $99.2~\mathrm {\mu }$m. In general, the turbulent heat transfer enhancement/deterioration at supercritical pressure is dominated by variations in thermophysical properties, buoyancy and thermal acceleration; however, the mechanism differs in micron tubes (

$99.2~\mathrm {\mu }$m. In general, the turbulent heat transfer enhancement/deterioration at supercritical pressure is dominated by variations in thermophysical properties, buoyancy and thermal acceleration; however, the mechanism differs in micron tubes ( $d^* < 100\ \mathrm {\mu }$m). The results showed that the pressure drop and scale effect made significant contributions to the development of turbulence flows heated at supercritical pressure in micron tubes, leading to the prominent property change and flow acceleration in the inlet fully developed turbulent flow. The deviation on temperature distribution because of pressure changes was non-negligible. The primary contribution of the acceleration was the decay of a boundary layer, which significantly suppressed the production of turbulence and decreased heat transfer. The acceleration had stabilizing effects on the ejection and sweep motions of the turbulent flow. The high-speed fluid contributed to a new disturbance scenario of the flow with a larger spanwise wavenumber superimposed on existing perturbations. The high-speed streak width in the quasilaminar region was approximately

$d^* < 100\ \mathrm {\mu }$m). The results showed that the pressure drop and scale effect made significant contributions to the development of turbulence flows heated at supercritical pressure in micron tubes, leading to the prominent property change and flow acceleration in the inlet fully developed turbulent flow. The deviation on temperature distribution because of pressure changes was non-negligible. The primary contribution of the acceleration was the decay of a boundary layer, which significantly suppressed the production of turbulence and decreased heat transfer. The acceleration had stabilizing effects on the ejection and sweep motions of the turbulent flow. The high-speed fluid contributed to a new disturbance scenario of the flow with a larger spanwise wavenumber superimposed on existing perturbations. The high-speed streak width in the quasilaminar region was approximately  $150$–

$150$– $160\nu /u_\tau$ in accelerating flow. In the micron tubes, the Reynolds stress events of quadrant Q4 contributed 60 % of the Reynolds stress, greater than those of quadrant Q2.

$160\nu /u_\tau$ in accelerating flow. In the micron tubes, the Reynolds stress events of quadrant Q4 contributed 60 % of the Reynolds stress, greater than those of quadrant Q2.