Article contents

Breakup of particle-laden droplets in airflow

Published online by Cambridge University Press: 06 November 2023

Abstract

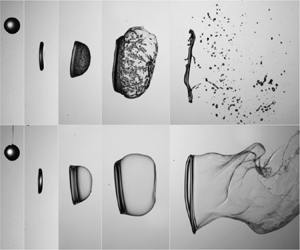

The atomisation of a suspension containing liquid and dispersed particles is prevalent in many applications. Previous studies of droplet breakup mainly focused on homogeneous fluids, and the heterogeneous effect of particles on the breakup progress is unclear. In this study, the breakup of particle-laden droplets in airflow is investigated experimentally. Combining synchronised high-speed images from the side view and the 45 $^\circ$ view, we compare the morphology of particle-laden droplets with that of homogeneous fluids in different breakup modes. The results show that the higher effective viscosity of particle-laden droplets affects the initial deformation, and the heterogeneous effect of particles appears in the later breakup stage. To evaluate the heterogeneous effect of particles quantitatively, we eliminate the effect of the higher effective viscosity of particle-laden droplets by comparing cases corresponding to the same inviscid Weber number. The quantitative comparison reveals that the heterogeneous effect of particles accelerates the fragmentation of the liquid film and promotes localised rapid piercing. A correlation length that depends on the particle diameter and the volume fraction is proposed to characterise the length scale of the concentration fluctuation under the combined effect of the initial flattening and later stretching during the droplet breakup process. Based on this correlation length, the fragment size distributions are analysed, and the scaling results agree well with the experimental data.

$^\circ$ view, we compare the morphology of particle-laden droplets with that of homogeneous fluids in different breakup modes. The results show that the higher effective viscosity of particle-laden droplets affects the initial deformation, and the heterogeneous effect of particles appears in the later breakup stage. To evaluate the heterogeneous effect of particles quantitatively, we eliminate the effect of the higher effective viscosity of particle-laden droplets by comparing cases corresponding to the same inviscid Weber number. The quantitative comparison reveals that the heterogeneous effect of particles accelerates the fragmentation of the liquid film and promotes localised rapid piercing. A correlation length that depends on the particle diameter and the volume fraction is proposed to characterise the length scale of the concentration fluctuation under the combined effect of the initial flattening and later stretching during the droplet breakup process. Based on this correlation length, the fragment size distributions are analysed, and the scaling results agree well with the experimental data.

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2023. Published by Cambridge University Press

References

- 7

- Cited by