Article contents

The characteristics of the circular hydraulic jump and vortex structure

Published online by Cambridge University Press: 31 January 2024

Abstract

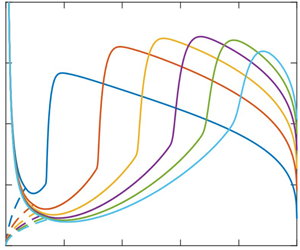

In an effort to capture the continuous hydraulic jump and flow structure for a jet impinging on a disk, we recently proposed a composite mean-field thin-film approach consisting of subdividing the flow domain into three distinct connected regions of increasing gravity strength (Wang et al., J. Fluid Mech., vol. 966, 2023, A15). In the present study, we further validate our approach, and examine the characteristics and structure of the circular jump and recirculation. The influence of the disk radius is found to be significant, especially in the subcritical region. Below a disk radius, the jump transits from type Ia to type 0 after the recirculation zone has faded. The supercritical flow and jump location are insensitive to the disk size, but the jump length and height as well as the vortex size are strongly affected, all decreasing with decreasing disk radius, exhibiting a maximum with the flow rate for a small disk. The jump is relatively steep with a strong recirculation zone for a high obstacle at the disk edge. Comparison against the Navier–Stokes solution of Askarizadeh et al. (Phys. Rev. Fluids, vol. 4, 2019, 114002; Intl J. Heat Mass Transfer, vol. 146, 2020, 118823) for the weak and intermediate surface tension suggests that the surface tension effect is unimportant for a high obstacle for a jump of type 0 or type Ia. The film thickness at the disk edge for a freely draining film is found to comprise, in addition to a static component (capillary length), a dynamic component:  ${h_\infty }\sim {(Fr/{r_\infty })^{2/3}}$ that we establish by minimizing the Gibbs free energy at the disk edge, and, equivalently, is also the consequence of the flow becoming supercritical near the edge. By assuming negligible film slope and curvature at the leading edge of the jump and maximum height at the trailing edge, we show that the jump length is related to the jump radius as

${h_\infty }\sim {(Fr/{r_\infty })^{2/3}}$ that we establish by minimizing the Gibbs free energy at the disk edge, and, equivalently, is also the consequence of the flow becoming supercritical near the edge. By assuming negligible film slope and curvature at the leading edge of the jump and maximum height at the trailing edge, we show that the jump length is related to the jump radius as  ${L_J}\sim Re{(F{r^2}/{r_J}^5)^{1/3}}$. The vortex length follows the same behaviour. The energy loss and conjugate depth ratio exhibit a maximum with the flow rate, which we show to originate from the descending and ascending branches of the supercritical film thickness. The presence of the jump is not necessarily commensurate with that of a recirculation; the existence of the vortex closely depends on the upstream curvature and steepness of the jump. The surface separating the regions of existence/non-existence of the recirculation is given by the universal relation

${L_J}\sim Re{(F{r^2}/{r_J}^5)^{1/3}}$. The vortex length follows the same behaviour. The energy loss and conjugate depth ratio exhibit a maximum with the flow rate, which we show to originate from the descending and ascending branches of the supercritical film thickness. The presence of the jump is not necessarily commensurate with that of a recirculation; the existence of the vortex closely depends on the upstream curvature and steepness of the jump. The surface separating the regions of existence/non-existence of the recirculation is given by the universal relation  $R{e^{10/3}}F{r^2} = 9r_\infty ^9/50$. The jump can be washed off the edge of the disk, particularly at low viscosity and small disk size. The flow in the supercritical region remains insensitive to the change in gravity level and disk size but is greatly affected by viscosity.

$R{e^{10/3}}F{r^2} = 9r_\infty ^9/50$. The jump can be washed off the edge of the disk, particularly at low viscosity and small disk size. The flow in the supercritical region remains insensitive to the change in gravity level and disk size but is greatly affected by viscosity.

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2024. Published by Cambridge University Press

References

- 3

- Cited by