Article contents

Effect of the shape of microswimmers and slip boundary conditions on the dynamic characteristics of near-wall microswimmers

Published online by Cambridge University Press: 14 November 2024

Abstract

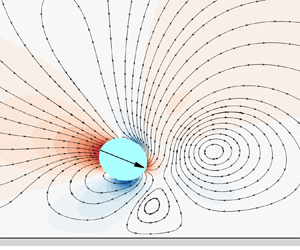

Although the interaction between microswimmers and walls during near-wall swimming has been extensively studied, the effect of microswimmer shapes and slip boundary conditions on the dynamic characteristics of near-wall microswimmers has received less attention. In this study, elliptical microswimmer models have been developed with various aspect ratios based on circular microswimmers. The lattice Boltzmann method has been used for the numerical simulation of the dynamic behaviour of microswimmers near walls. Under slip boundary conditions, the escape or capture of microswimmers by the walls is influenced by the swimming Reynolds number (Res), wall slip length (ls) and the aspect ratio (Cab) of a microswimmer. Changes in the Cab value of a microswimmer considerably affect its swimming state, especially for puller-type microswimmers. The tendency of pullers to be captured by the wall increases with increasing Cab. Moreover, changes in ls within the slip boundary condition of a puller can induce a transition in its movement state from a wall oscillation state to a stable sliding state and eventually to a wall lock-up state, a process influenced by the Cab value of the puller. Pusher-type microswimmers show a considerably increased tendency to escape from walls with increasing Cab and no wall lock-up state is observed, which is opposite to the case of pullers. Pushers and pullers show an increased tendency to be captured by the wall with increasing initial swimming angle of the microswimmer. The findings of this study enhance our understanding of the swimming patterns of natural microswimmers near walls and are of substantial importance for the design of artificial microswimmers and microfluidic devices.

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2024. Published by Cambridge University Press

References

- 3

- Cited by