1. Introduction

The free motion of a body rolling along a plane wall is of practical interest in many fluid dynamics applications, such as the transport of sediment in rivers, the design of viscous micro-pumps and the motion of leukocytes near vessel walls. Although these practical flows typically feature irregular and varied geometries, much research has focused on simplified geometries, including spheres (Carty Reference Carty1957; Jan & Shen Reference Jan and Shen1995) and infinite cylinders (see Thompson, Leweke & Hourigan (Reference Thompson, Leweke and Hourigan2021) for a detailed review). The present authors have recently highlighted the importance of surface roughness in determining the drag on rolling spheres (Nanayakkara et al. Reference Nanayakkara, Zhao, Terrington, Thompson and Hourigan2024). In particular, surface roughness elements generate an effective hydrodynamic gap between the sphere and the wall, and the drag coefficient (![]() $C_{D}$) can be approximately predicted based on this effective gap. We anticipate that this proposed mechanism of rolling motion applies to other rolling body geometries. Therefore, the present article presents an experimental investigation into the influence of surface roughness on the motion of finite-span rolling cylinders, where the contact area is far more extensive than for a sphere. Our results strongly support the hypothesis that surface roughness introduces an effective hydrodynamic gap between the cylinder and the wall, and the effective drag coefficient can be determined from this hydrodynamic gap using lubrication theory.

$C_{D}$) can be approximately predicted based on this effective gap. We anticipate that this proposed mechanism of rolling motion applies to other rolling body geometries. Therefore, the present article presents an experimental investigation into the influence of surface roughness on the motion of finite-span rolling cylinders, where the contact area is far more extensive than for a sphere. Our results strongly support the hypothesis that surface roughness introduces an effective hydrodynamic gap between the cylinder and the wall, and the effective drag coefficient can be determined from this hydrodynamic gap using lubrication theory.

The paradox of rolling motion arises from the theoretical prediction for an incompressible fluid that a perfectly smooth sphere or cylinder should be incapable of rolling while in contact with a smooth wall. This theoretical expectation contradicts experimental observations of rolling motion for both spheres (Carty Reference Carty1957; Jan & Shen Reference Jan and Shen1995; Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) and cylinders (Rao et al. Reference Rao, Stewart, Thompson, Leweke and Hourigan2011). Specifically, analytic expressions for the force and moment applied to either a sphere (Goldman, Cox & Brenner Reference Goldman, Cox and Brenner1967; O'Neill Reference O'Neill1967; O'Neill & Stewartson Reference O'Neill and Stewartson1967) or cylinder (Jeffrey & Onishi Reference Jeffrey and Onishi1981; Merlen & Frankiewicz Reference Merlen and Frankiewicz2011) translating and rotating near a plane wall predict an infinite drag force when the body is in contact with the wall. A resolution to this paradox is to introduce an effective gap between the rolling body and the wall, thereby resulting in a finite drag force. Proposed mechanisms to introduce this effective gap include cavitation (Prokunin Reference Prokunin2003; Ashmore, Pino & Mullin Reference Ashmore, Pino and Mullin2005; Seddon & Mullin Reference Seddon and Mullin2006), compressibility (Terrington, Thompson & Hourigan Reference Terrington, Thompson and Hourigan2022) and surface roughness (Smart & Leighton Reference Smart and Leighton1989; Galvin, Zhao & Davis Reference Galvin, Zhao and Davis2001; Zhao, Galvin & Davis Reference Zhao, Galvin and Davis2002; Nanayakkara et al. Reference Nanayakkara, Zhao, Terrington, Thompson and Hourigan2024). Which of these mechanisms is relevant for establishing the effective gap depends on the experimental parameters (Terrington et al. Reference Terrington, Thompson and Hourigan2022). For example, although cavitation has been observed in some experiments, for both spheres (Ashmore et al. Reference Ashmore, Pino and Mullin2005; Yang et al. Reference Yang, Seddon, Mullin, Pino and Ashmore2006) and cylinders (Seddon & Mullin Reference Seddon and Mullin2006), cavitation is entirely absent in others (Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023; Nanayakkara et al. Reference Nanayakkara, Zhao, Terrington, Thompson and Hourigan2024).

In cases where cavitation is responsible for the motion (Ashmore et al. Reference Ashmore, Pino and Mullin2005; Seddon & Mullin Reference Seddon and Mullin2006), the formation of a cavitation bubble produces a lift force that results in the sphere or cylinder losing contact with the wall. In such cases, there are no contact forces between the body and the wall, and the sphere or cylinder experiences a rotation rate different from that required to roll without slipping (Ashmore et al. Reference Ashmore, Pino and Mullin2005; Seddon & Mullin Reference Seddon and Mullin2006).

When cavitation and compressibility effects are either weak or absent, the effective gap is a result of surface roughness. The rolling body and the wall maintain contact via surface asperities, and this produces an average gap proportional to the height of surface asperities. In such cases, the body may roll without slipping along the wall, due to contact forces between the body and the wall. For the rolling sphere flow, this hypothesis is supported by experimental measurements in both the Stokes flow (Smart, Beimfohr & Leighton Reference Smart, Beimfohr and Leighton1993; Galvin et al. Reference Galvin, Zhao and Davis2001; Zhao et al. Reference Zhao, Galvin and Davis2002) and inertial flow regimes (Thompson et al. Reference Thompson, Leweke and Hourigan2021; Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023; Nanayakkara et al. Reference Nanayakkara, Zhao, Terrington, Thompson and Hourigan2024). However, this proposed mechanism has not yet been shown to apply to other geometries, such as the rolling cylinder. Importantly, the nominal contact between a cylinder and the wall occurs at a line, whereas contact between a sphere and a wall occurs at a single point, and this could influence the mechanism of rolling motion. The present article presents experimental results that demonstrate the occurrence of the same mechanism in the motion of finite-span circular cylinders.

Although extensive experimental studies of isolated cylinders have been conducted, including both long-span (Bénard Reference Bénard1908; Von Kármán Reference Von Kármán1911; Taneda Reference Taneda1965) and finite-span (Norberg Reference Norberg1994; Williamson Reference Williamson1996) cylinders, experimental measurements of cylinders rolling in close proximity to a plane wall remain relatively scarce. Bearman & Zdravkovich (Reference Bearman and Zdravkovich1978) and Zdravkovich (Reference Zdravkovich1985) considered the related problem of flow past a stationary cylinder near a plane wall, with gap-to-diameter ratio (![]() $G/D$) in the range

$G/D$) in the range ![]() $0\leq G/D \leq 2$. The flow structures (Bearman & Zdravkovich Reference Bearman and Zdravkovich1978) and both the drag and lift coefficients (Zdravkovich Reference Zdravkovich1985) were found to vary significantly with

$0\leq G/D \leq 2$. The flow structures (Bearman & Zdravkovich Reference Bearman and Zdravkovich1978) and both the drag and lift coefficients (Zdravkovich Reference Zdravkovich1985) were found to vary significantly with ![]() $G/D$, whereas the Strouhal number (

$G/D$, whereas the Strouhal number (![]() $St$) was insensitive to

$St$) was insensitive to ![]() $G/D$.

$G/D$.

Although few experimental investigations of rolling cylinders at low and moderate ![]() $\overline {Re}$ have been performed, this problem has been widely examined using both analytical and computational approaches. Jeffrey & Onishi (Reference Jeffrey and Onishi1981) obtained expressions for the force and moment applied to a circular cylinder both rotating and translating near a plane wall in Stokes flow, which are valid for any

$\overline {Re}$ have been performed, this problem has been widely examined using both analytical and computational approaches. Jeffrey & Onishi (Reference Jeffrey and Onishi1981) obtained expressions for the force and moment applied to a circular cylinder both rotating and translating near a plane wall in Stokes flow, which are valid for any ![]() $G/D$. Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011) found corresponding expressions valid in the limit

$G/D$. Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011) found corresponding expressions valid in the limit ![]() $G/D\ll 1$ using lubrication theory. These solutions are accurate only for Stokes flow (

$G/D\ll 1$ using lubrication theory. These solutions are accurate only for Stokes flow (![]() $\overline {Re} = 0$), and under-predict the drag coefficient at non-zero

$\overline {Re} = 0$), and under-predict the drag coefficient at non-zero ![]() $\overline {Re}$, since inertial effects such as wake formation are neglected.

$\overline {Re}$, since inertial effects such as wake formation are neglected.

To account for inertial effects at non-zero ![]() $\overline {Re}$, numerical simulations have been employed (Stewart et al. Reference Stewart, Hourigan, Thompson and Leweke2006, Reference Stewart, Thompson, Leweke and Hourigan2010b; Rao et al. Reference Rao, Stewart, Thompson, Leweke and Hourigan2011; Houdroge et al. Reference Houdroge, Leweke, Hourigan and Thompson2017, Reference Houdroge, Leweke, Hourigan and Thompson2020; Wang et al. Reference Wang, Liu, Zhu, Zhou, Bao and Xu2021). These studies typically consider only a single value of

$\overline {Re}$, numerical simulations have been employed (Stewart et al. Reference Stewart, Hourigan, Thompson and Leweke2006, Reference Stewart, Thompson, Leweke and Hourigan2010b; Rao et al. Reference Rao, Stewart, Thompson, Leweke and Hourigan2011; Houdroge et al. Reference Houdroge, Leweke, Hourigan and Thompson2017, Reference Houdroge, Leweke, Hourigan and Thompson2020; Wang et al. Reference Wang, Liu, Zhu, Zhou, Bao and Xu2021). These studies typically consider only a single value of ![]() $G/D$, noting that the flow outside the gap region is insensitive to

$G/D$, noting that the flow outside the gap region is insensitive to ![]() $G/D$, when

$G/D$, when ![]() $G/D$ is small. Although this approach is sufficient to determine the wake dynamics and transitions, the drag coefficient appears to be highly sensitive to

$G/D$ is small. Although this approach is sufficient to determine the wake dynamics and transitions, the drag coefficient appears to be highly sensitive to ![]() $G/D$, and therefore simulations must be performed for a range of

$G/D$, and therefore simulations must be performed for a range of ![]() $G/D$ to completely determine the drag coefficient. To avoid performing simulations for multiple

$G/D$ to completely determine the drag coefficient. To avoid performing simulations for multiple ![]() $G/D$, Terrington, Thompson & Hourigan (Reference Terrington, Thompson and Hourigan2023) have introduced a combined analytical–numerical approach, where the gap-dependent drag (

$G/D$, Terrington, Thompson & Hourigan (Reference Terrington, Thompson and Hourigan2023) have introduced a combined analytical–numerical approach, where the gap-dependent drag (![]() $C_{D,pred, gap}$) for the two-dimensional flow over a circular cylinder is obtained using the analytical lubrication solution, whereas the wake drag (

$C_{D,pred, gap}$) for the two-dimensional flow over a circular cylinder is obtained using the analytical lubrication solution, whereas the wake drag (![]() $C_{D,pred, wake}$), which is independent of

$C_{D,pred, wake}$), which is independent of ![]() $G/D$, is obtained using numerical simulations. The total predicted drag coefficient is the sum of the gap-dependent and wake drag coefficients; this predicted drag coefficient will be denoted as

$G/D$, is obtained using numerical simulations. The total predicted drag coefficient is the sum of the gap-dependent and wake drag coefficients; this predicted drag coefficient will be denoted as ![]() $C_{D,pred}$.

$C_{D,pred}$.

The gap-dependent drag coefficient obtained by Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011) is for the infinite cylinder flow. Saintyves et al. (Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020) computed the correction to this expression due to end effects for a finite-span cylinder with a large aspect ratio. Teng et al. (Reference Teng, Rallabandi, Stone and Ault2022) extended this analysis, computing the correction to the gap-dependent drag valid for all aspect ratios. The end effects result in a reduction in the gap-dependent drag coefficient compared with the two-dimensional theory, particularly for small aspect ratios and larger ![]() $G/D$.

$G/D$.

Although Teng et al. (Reference Teng, Rallabandi, Stone and Ault2022) provided expressions for the gap-dependent drag for a finite-span cylinder, solutions for the gap-independent wake drag for a finite-span rolling cylinder have not been obtained in the existing literature. Although both Pirozzoli, Orlandi & Bernardini (Reference Pirozzoli, Orlandi and Bernardini2012) and Javadi (Reference Javadi2022) performed numerical simulations for low-aspect-ratio finite-span cylinders (wheels) in contact with a plane wall, neither of these studies discussed the numerical treatment of the contact point, nor the infinite pressures that should arise in that region. Both studies reported finite ![]() $C_{D,pred}$ at

$C_{D,pred}$ at ![]() $G/D = 0$, in contrast with the infinite drag predicted by lubrication theory. As discussed by Terrington et al. (Reference Terrington, Thompson and Hourigan2023), this is likely due to low grid resolution at the point of contact. The

$G/D = 0$, in contrast with the infinite drag predicted by lubrication theory. As discussed by Terrington et al. (Reference Terrington, Thompson and Hourigan2023), this is likely due to low grid resolution at the point of contact. The ![]() $C_{D,pred}$ values reported by these works are therefore likely to be unreliable.

$C_{D,pred}$ values reported by these works are therefore likely to be unreliable.

The effect of cylinder aspect ratio on the wake structures behind a freely rolling finite-span cylinder has also not been documented in the existing literature. Zdravkovich et al. (Reference Zdravkovich, Brand, Mathew and Weston1989) conducted experiments on isolated cylinders with ![]() $AR \leq 1$ and showed that

$AR \leq 1$ and showed that ![]() $\bar {C}_{D}$ increases for decreasing

$\bar {C}_{D}$ increases for decreasing ![]() $AR$, for high

$AR$, for high ![]() $\overline {Re}$ (approximately

$\overline {Re}$ (approximately ![]() $10^{5}$). Computational studies by Inoue & Sakuragi (Reference Inoue and Sakuragi2008) investigated the effects of both

$10^{5}$). Computational studies by Inoue & Sakuragi (Reference Inoue and Sakuragi2008) investigated the effects of both ![]() $Re$ and

$Re$ and ![]() $AR$ on isolated stationary cylinders, and found five basic patterns of vortex shedding. The authors reported that these patterns are dependent on both

$AR$ on isolated stationary cylinders, and found five basic patterns of vortex shedding. The authors reported that these patterns are dependent on both ![]() $Re$ and

$Re$ and ![]() $AR$ of the cylinders, and end effects also play a role in the flow patterns observed. Inoue & Sakuragi (Reference Inoue and Sakuragi2008) also observed double-sided hairpin-like vortex patterns for moderate

$AR$ of the cylinders, and end effects also play a role in the flow patterns observed. Inoue & Sakuragi (Reference Inoue and Sakuragi2008) also observed double-sided hairpin-like vortex patterns for moderate ![]() $AR$ (2–10) and moderate

$AR$ (2–10) and moderate ![]() $Re$ (50–200). Recent computational analysis by Yang, Feng & Zhang (Reference Yang, Feng and Zhang2022) found a similar behaviour for a cylinder with

$Re$ (50–200). Recent computational analysis by Yang, Feng & Zhang (Reference Yang, Feng and Zhang2022) found a similar behaviour for a cylinder with ![]() $AR$ ranging from

$AR$ ranging from ![]() $0.5$ to

$0.5$ to ![]() $2$, at lower

$2$, at lower ![]() $Re$ (0–300). It is noted that their results also indicate that the difference in

$Re$ (0–300). It is noted that their results also indicate that the difference in ![]() $C_{D,pred}$ for varied

$C_{D,pred}$ for varied ![]() $AR$ is higher at low

$AR$ is higher at low ![]() $\overline {Re}$, and the curves seem to converge together at

$\overline {Re}$, and the curves seem to converge together at ![]() $Re \approx 500$. In the present article we experimentally investigate the effect of

$Re \approx 500$. In the present article we experimentally investigate the effect of ![]() $AR$ on the wake structures formed behind a rolling circular cylinder.

$AR$ on the wake structures formed behind a rolling circular cylinder.

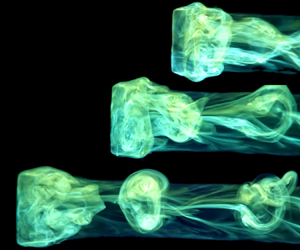

Numerical studies (Stewart et al. Reference Stewart, Thompson, Leweke and Hourigan2010a; Rao et al. Reference Rao, Stewart, Thompson, Leweke and Hourigan2011; Houdroge et al. Reference Houdroge, Leweke, Hourigan and Thompson2017, Reference Houdroge, Leweke, Hourigan and Thompson2020) have also investigated the influence of gap size on the wake dynamics and vortex shedding of a freely rolling infinitely long cylinder. Although a vanishing gap size has a strong influence on the forces acting on the cylinder, at least for small gap ratios, the gap height has minimal effects on the wake and wake transitions. Houdroge et al. (Reference Houdroge, Leweke, Hourigan and Thompson2020) visualised the pressure distribution of a cylinder with large and small gaps, and showed that the pressure coefficients were nearly identical, at the top and sides of the cylinder, even when the gap size was reduced by a factor of 32. However, it is important to note that given the coupling between a freely rolling cylinder and the flow, where the cylinder motion responds to changes in drag forces as vortices are shed into the wake, the dependence of drag force on the gap size has an indirect effect on the wake dynamics. A detailed discussion of relevant literature regarding the wake–structure interaction of cylinders rolling on a plane is given in § 5.1.

In this study, we experimentally investigate the effects of surface roughness on the drag coefficient of finite-span cylinders freely rolling without slipping. Our primary focus is on the low- to moderate-Reynolds-number regime (![]() $30<\overline {Re}<1800$), where the present literature lacks experimental evidence of the dependence of

$30<\overline {Re}<1800$), where the present literature lacks experimental evidence of the dependence of ![]() $\bar {C}_{D}$ on surface roughness. We aim to provide experimental evidence that the time-mean drag coefficient (

$\bar {C}_{D}$ on surface roughness. We aim to provide experimental evidence that the time-mean drag coefficient (![]() $\bar {C}_{D}$) is dependent on both cylinder and panel surface roughness, and the effective gap (

$\bar {C}_{D}$) is dependent on both cylinder and panel surface roughness, and the effective gap (![]() $G_{eff}$) between the panel and cylinder can be estimated using roughness parameters. Moreover, we show that gap heights approximately equated to peak roughness (

$G_{eff}$) between the panel and cylinder can be estimated using roughness parameters. Moreover, we show that gap heights approximately equated to peak roughness (![]() $R_{p}$) for rough cylinders, or one standard deviation above the mean peak roughness (

$R_{p}$) for rough cylinders, or one standard deviation above the mean peak roughness (![]() $R_{p, 1\sigma }$) for smooth cylinders, yield predicted drag coefficients in general agreement with measured values. This is the main finding of the present investigation and forms a basis on which the drag coefficient of a cylinder can be predicted using a combined analytical–numerical approach and using peak surface roughness as the gap height. The difference between the two types of cylinders and the use of two different roughness statistics are discussed in § 4.5.2.

$R_{p, 1\sigma }$) for smooth cylinders, yield predicted drag coefficients in general agreement with measured values. This is the main finding of the present investigation and forms a basis on which the drag coefficient of a cylinder can be predicted using a combined analytical–numerical approach and using peak surface roughness as the gap height. The difference between the two types of cylinders and the use of two different roughness statistics are discussed in § 4.5.2.

A limited set of experiments were conducted in air using foam cylinders to demonstrate that cavitation is not required to allow cylinder motion in this ![]() $\overline {Re}$ range and that similar drag trends are observed. Additional dependence of

$\overline {Re}$ range and that similar drag trends are observed. Additional dependence of ![]() $\bar {C}_{D}$ on cylinder aspect ratio (

$\bar {C}_{D}$ on cylinder aspect ratio (![]() $AR$) is also investigated and compared with analytical predictions. Furthermore, experimental flow visualisations are employed to identify and validate critical flow transitions that have been previously observed in numerical studies.

$AR$) is also investigated and compared with analytical predictions. Furthermore, experimental flow visualisations are employed to identify and validate critical flow transitions that have been previously observed in numerical studies.

This paper is organised as follows. Section 2 describes the problem and the existing analytical solutions, and § 3 presents a summary of the experimental method. Section 4 presents detailed experimental results of the investigation together with a discussion of results. Wake–structure interactions including experimental flow visualisations are given in § 5. Finally, § 6 draws final conclusions and points to future studies.

2. Problem description

Figure 1 illustrates a cylinder with a diameter ![]() $D$ undergoing free rolling without slip on an inclined plane set at an angle

$D$ undergoing free rolling without slip on an inclined plane set at an angle ![]() $\theta$ relative to the horizontal axis. The cylinder density is denoted as

$\theta$ relative to the horizontal axis. The cylinder density is denoted as ![]() $\rho _{s}$, and the fluid density is represented as

$\rho _{s}$, and the fluid density is represented as ![]() $\rho _{f}$. The typical relationship

$\rho _{f}$. The typical relationship ![]() $\rho _{s} > \rho _{f}$ indicates negative buoyancy and a mass ratio is given by

$\rho _{s} > \rho _{f}$ indicates negative buoyancy and a mass ratio is given by ![]() $\beta = \rho _{s}/\rho _{f}$. The coordinate system is anchored at the centre of the body.

$\beta = \rho _{s}/\rho _{f}$. The coordinate system is anchored at the centre of the body.

Figure 1. Schematic free body diagram of a freely rolling cylinder, on an inclined plane under the influence of gravity.

After the cylinder attains a quasi-steady state, it adopts a time-mean terminal velocity ![]() $\bar {U}$ in the

$\bar {U}$ in the ![]() $x$ direction and a time-mean angular velocity

$x$ direction and a time-mean angular velocity ![]() $\bar {\omega }$ around the

$\bar {\omega }$ around the ![]() $y$ direction, as indicated in the figure (referred to as prograde rolling). Here, the

$y$ direction, as indicated in the figure (referred to as prograde rolling). Here, the ![]() $x$ direction corresponds to the down-slope, whereas the

$x$ direction corresponds to the down-slope, whereas the ![]() $y$ direction represents the cross-slope. The buoyant weight of the body, denoted as

$y$ direction represents the cross-slope. The buoyant weight of the body, denoted as ![]() $W_{B}$, is calculated as

$W_{B}$, is calculated as ![]() $W_{B} = {\rm \pi}D^{2}L (\rho _{s}-\rho _{f})/4$, where

$W_{B} = {\rm \pi}D^{2}L (\rho _{s}-\rho _{f})/4$, where ![]() $L$ is the span of the cylinder.

$L$ is the span of the cylinder.

We assume that the cylinder is offset from the wall by an effective gap, ![]() $G_{eff}$, which is characterised by the non-dimensional parameter

$G_{eff}$, which is characterised by the non-dimensional parameter ![]() $\hat {G}=G_{eff}/D$. We propose that the effective gap

$\hat {G}=G_{eff}/D$. We propose that the effective gap ![]() $\hat {G}$ can be determined from the measured surface roughness. This is discussed further in §§ 2.2 and 4.

$\hat {G}$ can be determined from the measured surface roughness. This is discussed further in §§ 2.2 and 4.

Furthermore, ![]() $F_D$,

$F_D$, ![]() $F_L$ and

$F_L$ and ![]() $T_{y}$ are the instantaneous hydrodynamic drag, lift and torque, respectively, applied to the body, whereas the time-mean counterparts of these parameters are represented by

$T_{y}$ are the instantaneous hydrodynamic drag, lift and torque, respectively, applied to the body, whereas the time-mean counterparts of these parameters are represented by ![]() $\bar {F}_D$,

$\bar {F}_D$, ![]() $\bar {F}_L$ and

$\bar {F}_L$ and ![]() $\bar {T}_{y}$, respectively. Correspondingly,

$\bar {T}_{y}$, respectively. Correspondingly, ![]() $N,\bar {N}$ and

$N,\bar {N}$ and ![]() $F_C, \bar {F}_C$ are the instantaneous and time-mean normal and contact forces, respectively. Finally, the time-mean Reynolds number of the cylinder is expressed as

$F_C, \bar {F}_C$ are the instantaneous and time-mean normal and contact forces, respectively. Finally, the time-mean Reynolds number of the cylinder is expressed as ![]() $\overline {Re}= \bar {U}D/ \nu _f$, where

$\overline {Re}= \bar {U}D/ \nu _f$, where ![]() $\nu _f$ is the kinematic viscosity of the fluid.

$\nu _f$ is the kinematic viscosity of the fluid.

The drag coefficient considered in this study includes both hydrodynamic drag force ![]() $\bar {F}_{D}$ and the contact force

$\bar {F}_{D}$ and the contact force ![]() $\bar {F}_C$, as

$\bar {F}_C$, as

\begin{equation} \bar{C}_D = \frac{\bar{F}_{D}+\bar{F}_C}{\dfrac{1}{2}DL \rho_{f}\bar{U}^{2}}. \end{equation}

\begin{equation} \bar{C}_D = \frac{\bar{F}_{D}+\bar{F}_C}{\dfrac{1}{2}DL \rho_{f}\bar{U}^{2}}. \end{equation}

Considering the time-mean force balance parallel to the plane wall (![]() $\bar {F}_{D}+\bar {F}_{C}=W_B g \sin \theta$), the drag coefficient can be expressed as

$\bar {F}_{D}+\bar {F}_{C}=W_B g \sin \theta$), the drag coefficient can be expressed as

\begin{equation} \bar{C}_D = \frac{W_B g \sin\theta}{\dfrac{1}{2}DL \rho_{f}\bar{U}^{2}} = \frac{1}{2} \frac{D(\beta-1)g {\rm \pi}}{{ \bar{U}^{2}}}\sin \theta. \end{equation}

\begin{equation} \bar{C}_D = \frac{W_B g \sin\theta}{\dfrac{1}{2}DL \rho_{f}\bar{U}^{2}} = \frac{1}{2} \frac{D(\beta-1)g {\rm \pi}}{{ \bar{U}^{2}}}\sin \theta. \end{equation}Equation (2.2) is used to calculate the drag coefficient in experiments.

2.1. Combined analytical–numerical predictions

Assuming the cylinder is rolling without slipping, the total drag coefficient can be determined from the hydrodynamic force and torque coefficients. Assuming quasi-steady motion, the balance of torques applied to the cylinder is

and therefore the effective predicted drag coefficient is written as

where ![]() ${C}_{F,fluid} = \bar {F}_D/(\frac {1}{2}DL \rho _{f}\bar {U}^{2})$ and

${C}_{F,fluid} = \bar {F}_D/(\frac {1}{2}DL \rho _{f}\bar {U}^{2})$ and ![]() ${C}_{T, fluid} = (\bar {T}_y/ {D}/{2})/(\frac {1}{2}DL \rho _{f}\bar {U}^{2})$ represent the hydrodynamic force and moment coefficients, respectively. In this study, (2.4) is used to predict the drag coefficient from numerical simulations.

${C}_{T, fluid} = (\bar {T}_y/ {D}/{2})/(\frac {1}{2}DL \rho _{f}\bar {U}^{2})$ represent the hydrodynamic force and moment coefficients, respectively. In this study, (2.4) is used to predict the drag coefficient from numerical simulations.

For two-dimensional flow over a rolling circular cylinder, Terrington et al. (Reference Terrington, Thompson and Hourigan2023) decompose the force and moment coefficients into a gap-dependent term and a gap-independent ‘wake-drag’ term. Here, we express this result as a combined predicted drag coefficient:

The gap-dependent drag for an infinite cylinder is obtained using lubrication theory, valid for small gap heights (![]() $G/D \ll 1$) (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011; Terrington et al. Reference Terrington, Thompson and Hourigan2023):

$G/D \ll 1$) (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011; Terrington et al. Reference Terrington, Thompson and Hourigan2023):

whereas the wake-drag term was obtained by Terrington et al. (Reference Terrington, Thompson and Hourigan2023) using numerical simulations for steady-state flow. We obtain the following empirical fit to their numerical data:

This equation is valid for ![]() $10< Re<200$ (see Terrington et al. Reference Terrington, Thompson and Hourigan2023).

$10< Re<200$ (see Terrington et al. Reference Terrington, Thompson and Hourigan2023).

Teng et al. (Reference Teng, Rallabandi, Stone and Ault2022) compute the gap-dependent force and moment contributions for a finite-span circular cylinder, both translating and rotating near a plane wall. When expressed as an effective drag coefficient, their solution is given by

where the integral ![]() $\mathcal {I}$ can be approximated using the following rapidly converging series:

$\mathcal {I}$ can be approximated using the following rapidly converging series:

\begin{align} \mathcal{I} = \frac{64 }{3 {\rm \pi}} \sinh^{{-}1} \left(\frac{AR}{\sqrt{G/D}}\right) - 16 AR + \sum_{n=1,3,5,\ldots} 64 \exp({-n{\rm \pi}/2AR}) \left(\frac{1}{3n{\rm \pi}} + \frac{2AR}{n^{2} {\rm \pi}^{2}}\right). \end{align}

\begin{align} \mathcal{I} = \frac{64 }{3 {\rm \pi}} \sinh^{{-}1} \left(\frac{AR}{\sqrt{G/D}}\right) - 16 AR + \sum_{n=1,3,5,\ldots} 64 \exp({-n{\rm \pi}/2AR}) \left(\frac{1}{3n{\rm \pi}} + \frac{2AR}{n^{2} {\rm \pi}^{2}}\right). \end{align}Equation (2.8) represents the influence of the lubrication flow in a narrow gap between the cylinder and the wall on the total predicted drag coefficient. The first term on the right-hand side is the drag coefficient corresponding to two-dimensional flow (infinite-span cylinder), whereas the second term is a correction representing the effect of a finite aspect ratio. However, this expression does not include the influence of outer-flow effects such as wake formation and shedding. To account for these effects, the total predicted drag coefficient will be given by

where ![]() $C_{D,pred, wake(3D)}$ is a function of both

$C_{D,pred, wake(3D)}$ is a function of both ![]() $Re$ and

$Re$ and ![]() $AR$, but not

$AR$, but not ![]() $G/D$. Unfortunately, analytical or numerical results for

$G/D$. Unfortunately, analytical or numerical results for ![]() $C_{D,pred, wake(3D)}$ have not been reported in the literature.

$C_{D,pred, wake(3D)}$ have not been reported in the literature.

A detailed numerical study is required to obtain accurate estimates of ![]() $C_{D,pred, wake(3D)}$, but is outside the scope of the present work. In the absence of a reliable estimate for

$C_{D,pred, wake(3D)}$, but is outside the scope of the present work. In the absence of a reliable estimate for ![]() $C_{D,pred, wake(3D)}$, we assume it will be approximately the same order of magnitude as the wake drag coefficient for the two-dimensional cylinder flow (

$C_{D,pred, wake(3D)}$, we assume it will be approximately the same order of magnitude as the wake drag coefficient for the two-dimensional cylinder flow (![]() $C_{D,pred, wake(2D)}$). This is a rough approximation only and is likely to introduce significant and unquantified errors into our estimate of the wake drag coefficient. Fortunately, at the low and moderate Reynolds numbers considered in the present study, the wake drag represents a relatively small contribution to the total drag (10–20 % depending on

$C_{D,pred, wake(2D)}$). This is a rough approximation only and is likely to introduce significant and unquantified errors into our estimate of the wake drag coefficient. Fortunately, at the low and moderate Reynolds numbers considered in the present study, the wake drag represents a relatively small contribution to the total drag (10–20 % depending on ![]() $\overline {Re}$), so reasonable predictions of the total drag coefficient may still be obtained.

$\overline {Re}$), so reasonable predictions of the total drag coefficient may still be obtained.

In addition, we note that the wake drag coefficient for the two-dimensional cylinder flow is ![]() $1.5\le C_{D,pred, wake(2D)} \le 3$ (Terrington et al. Reference Terrington, Thompson and Hourigan2023) and the wake drag coefficient for the rolling sphere flow is

$1.5\le C_{D,pred, wake(2D)} \le 3$ (Terrington et al. Reference Terrington, Thompson and Hourigan2023) and the wake drag coefficient for the rolling sphere flow is ![]() $1.0\le C_{D,sph, wake} \le 1.5$ (Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) for

$1.0\le C_{D,sph, wake} \le 1.5$ (Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023) for ![]() $10\le \overline {Re} \le 200$. Given that the three-dimensional sphere also exhibits a similar range of wake drag values as the two-dimensional cylinder, our assumption that the three-dimensional wake drag of a cylinder will be similar to the two-dimensional wake drag (

$10\le \overline {Re} \le 200$. Given that the three-dimensional sphere also exhibits a similar range of wake drag values as the two-dimensional cylinder, our assumption that the three-dimensional wake drag of a cylinder will be similar to the two-dimensional wake drag (![]() $C_{D,pred, wake(3D)} \approx C_{D,pred, wake(2D)}$) is sufficiently accurate. This approximation will enable an effective comparison between measured

$C_{D,pred, wake(3D)} \approx C_{D,pred, wake(2D)}$) is sufficiently accurate. This approximation will enable an effective comparison between measured ![]() $\bar {C}_{D}$ and

$\bar {C}_{D}$ and ![]() $C_{D,pred}$.

$C_{D,pred}$.

2.2. Relationship between gap and surface roughness

The primary objective of this investigation is to establish the correlation between surface roughness parameters and the effective gap (![]() $G_{eff}$) required to determine the drag force acting on the cylinder. The British Standard Geometric Product Specifications (GPS) - Surface texture: Profile method - Terms, definitions, and surface texture parameters, BS ISO 4287:1997 provides a comprehensive framework to characterise surface roughness. Among these parameters, the most frequently used are the mean absolute deviation, root mean square (r.m.s.) and the peak roughness, which are denoted by

$G_{eff}$) required to determine the drag force acting on the cylinder. The British Standard Geometric Product Specifications (GPS) - Surface texture: Profile method - Terms, definitions, and surface texture parameters, BS ISO 4287:1997 provides a comprehensive framework to characterise surface roughness. Among these parameters, the most frequently used are the mean absolute deviation, root mean square (r.m.s.) and the peak roughness, which are denoted by ![]() $R_{a}$,

$R_{a}$, ![]() $R_{q}$ and

$R_{q}$ and ![]() $R_{p}$, respectively. Figure 2 indicates these parameters for a sample profile from a cylinder. See Gadelmawla et al. (Reference Gadelmawla, Koura, Maksoud, Elewa and Soliman2002) for detailed descriptions and analytical expressions for typical roughness statistics.

$R_{p}$, respectively. Figure 2 indicates these parameters for a sample profile from a cylinder. See Gadelmawla et al. (Reference Gadelmawla, Koura, Maksoud, Elewa and Soliman2002) for detailed descriptions and analytical expressions for typical roughness statistics.

Figure 2. Visual representation of the three roughness statistics on a sample cylinder profile.

Drawing upon these roughness parameters, a new non-dimensional relative roughness denoted by ![]() $\xi$ is introduced as follows:

$\xi$ is introduced as follows:

where ![]() $R_{panel}$ and

$R_{panel}$ and ![]() $R_{cylinder}$ denote the roughness parameters corresponding to the panel and cylinder surfaces, respectively. A subscript is employed to indicate the specific surface-roughness statistic used to compute

$R_{cylinder}$ denote the roughness parameters corresponding to the panel and cylinder surfaces, respectively. A subscript is employed to indicate the specific surface-roughness statistic used to compute ![]() $\xi$. For instance,

$\xi$. For instance, ![]() $\xi _p$, is the non-dimensional roughness determined using the peak roughness of both the panel (

$\xi _p$, is the non-dimensional roughness determined using the peak roughness of both the panel (![]() $R_{p,panel}$) and the cylinder (

$R_{p,panel}$) and the cylinder (![]() $R_{p,cylinder}$), whereas

$R_{p,cylinder}$), whereas ![]() $\xi _a$ and

$\xi _a$ and ![]() $\xi _q$ are calculated using the mean absolute deviation and r.m.s. roughnesses, respectively.

$\xi _q$ are calculated using the mean absolute deviation and r.m.s. roughnesses, respectively.

Equation (2.11) assumes that the effective gap at the point of contact results from a linear summation of two simple roughness statistics. In general, elementary roughness statistics such as ![]() $R_p$ may be insufficient to completely describe the complex nature of the surface, and a linear summation of surface roughness statistics may not fully describe the interaction between two complex surfaces. The accuracy of these assumptions and simplified measurements are discussed in detail in § 4.5.

$R_p$ may be insufficient to completely describe the complex nature of the surface, and a linear summation of surface roughness statistics may not fully describe the interaction between two complex surfaces. The accuracy of these assumptions and simplified measurements are discussed in detail in § 4.5.

3. Experimental set-up and methodology

The rolling cylinder experiments were conducted within the Fluids Laboratory for Aeronautical and Industrial Research (FLAIR laboratory) at Monash University. A detailed review of the experimental set-up and methodology used for the present study can be found in the previous work of Nanayakkara et al. (Reference Nanayakkara, Zhao, Terrington, Thompson and Hourigan2024). A summary is provided in the following.

3.1. Summary of experimental set-up and methodology

The present experiments were conducted in a water tank with a glass panel mounted on an adjustable stainless steel frame. Other test panels with various surface roughnesses were also adopted. The inclination angle ranged from ![]() $1.5^{\circ }$ to

$1.5^{\circ }$ to ![]() $23^{\circ }$. Panel flatness was determined by measuring surface height variation at discrete points, revealing that panel non-flatness was negligible compared with the panel's downward slope. The test cylinders were pre-soaked underwater, with air bubbles removed by vibration and stirring, prior to carrying out the experiments. The cylinders were then placed on a collection port on the plane and gently released to minimise water surface disturbances. A waiting period of at least 2 min followed any water perturbation before measurements were taken, ensuring the water had adequately settled. Regular cleaning of the water tank prevented dust or fibre deposition on the panel surface.

$23^{\circ }$. Panel flatness was determined by measuring surface height variation at discrete points, revealing that panel non-flatness was negligible compared with the panel's downward slope. The test cylinders were pre-soaked underwater, with air bubbles removed by vibration and stirring, prior to carrying out the experiments. The cylinders were then placed on a collection port on the plane and gently released to minimise water surface disturbances. A waiting period of at least 2 min followed any water perturbation before measurements were taken, ensuring the water had adequately settled. Regular cleaning of the water tank prevented dust or fibre deposition on the panel surface.

The velocity of rolling cylinders was determined by timing their travel over a fixed distance. A minimum of ![]() $20 D$ rolling distance was allowed prior to measurements to ensure the cylinders attained their time-mean terminal velocity. Initially, a stopwatch measured the time for a 200 mm distance on the removable panel (constituting

$20 D$ rolling distance was allowed prior to measurements to ensure the cylinders attained their time-mean terminal velocity. Initially, a stopwatch measured the time for a 200 mm distance on the removable panel (constituting ![]() $30\,\%$ of data). Later, a system with three laser-based object detectors was introduced for improved accuracy and efficiency (

$30\,\%$ of data). Later, a system with three laser-based object detectors was introduced for improved accuracy and efficiency (![]() $70\,\%$ of data). The results presented in the present study incorporate both data sets, and an uncertainty analysis in Appendix B accounts for measurement errors from both methods. Specifications of the tested panels and cylinders are provided in tables 1 and 2, respectively, in Appendix A. Table 2 specifies unique identifiers for each group of cylinders used with the same diameter and aspect ratio. These identifiers are used herein to refer to distinct cylinders.

$70\,\%$ of data). The results presented in the present study incorporate both data sets, and an uncertainty analysis in Appendix B accounts for measurement errors from both methods. Specifications of the tested panels and cylinders are provided in tables 1 and 2, respectively, in Appendix A. Table 2 specifies unique identifiers for each group of cylinders used with the same diameter and aspect ratio. These identifiers are used herein to refer to distinct cylinders.

Table 1. Panel types used as inclined planes are detailed here. Max. deviation is the maximum absolute deviation of surface height measurements from the mean plane. Max. gradient is the maximum cross-slope gradient over a minimum cross-slope measurement distance of 50 mm.

Table 2. Specifications of cylinders used for experimental evaluation. Each cylinder diameter corresponds to a set of 10 individual cylinders, and 3 measurements of cylinder diameter and 1 measurement of cylinder span was measured for each cylinder. The mean values of diameter and span including the error for each set is shown above. Refer to Appendix B for details on error analysis.

The data outlined in § 4 represent average measurements obtained from eight separate runs using cylinders of similar diameter and density. Furthermore, occasional checks were performed at randomised locations on the curve to confirm the consistency of the data, even when the fluid temperature varied. Table 2 indicates that the uncertainty regarding the cylinder diameter within each group of cylinders was generally below ![]() $1\,\%$. To prevent any distortion caused by water absorption, the cylinders and panels were regularly removed from the water tank outside measurement intervals and dried.

$1\,\%$. To prevent any distortion caused by water absorption, the cylinders and panels were regularly removed from the water tank outside measurement intervals and dried.

The uncertainty in cylinder diameter was used to estimate deviations in roundness. Given that the uncertainties in the diameter cylinders were generally below ![]() $1\,\%$, it was assumed that deviations in the roundness of cylinders could be neglected.

$1\,\%$, it was assumed that deviations in the roundness of cylinders could be neglected.

Preliminary experiments were conducted with a selection of cylinders at various inclination angles ranging from ![]() $2^{\circ }$ to

$2^{\circ }$ to ![]() $23^{\circ }$ to examine potential cylinder slippage in our trials. A marker was placed on the surface of the cylinder, and the cylinder rolling motion was then recorded using a digital camera. The calculated rotational speed was compared to the measured linear down-slope velocity, revealing no significant difference between the two velocities (less than

$23^{\circ }$ to examine potential cylinder slippage in our trials. A marker was placed on the surface of the cylinder, and the cylinder rolling motion was then recorded using a digital camera. The calculated rotational speed was compared to the measured linear down-slope velocity, revealing no significant difference between the two velocities (less than ![]() $1\,\%$). As such, any slippage between the cylinder and the surface was considered to be negligible.

$1\,\%$). As such, any slippage between the cylinder and the surface was considered to be negligible.

To establish the effects of cylinder deformation due to the normal contact force, Hertzian contact theory was used. A simple case of a two-dimensional spherical body in contact with a flat plate was assumed, and the formula for plastic deformation is found in textbooks such as Johnson (Reference Johnson1985). For an acrylic cylinder of ![]() $D=19.7$ mm rolling at

$D=19.7$ mm rolling at ![]() $\theta =2^{\circ }$ on a glass plate, where the largest normal contact force is acting on the cylinder, the calculated deformation of the cylinder was in the order of

$\theta =2^{\circ }$ on a glass plate, where the largest normal contact force is acting on the cylinder, the calculated deformation of the cylinder was in the order of ![]() $10^{-12}$ m. This deformation is small compared with the height of asperities (typically

$10^{-12}$ m. This deformation is small compared with the height of asperities (typically ![]() $10^{-6}$ m), hence the effect of cylinder deformation on the gap imposed by surface asperities was deemed negligible.

$10^{-6}$ m), hence the effect of cylinder deformation on the gap imposed by surface asperities was deemed negligible.

3.2. Surface roughness measurements

Non-contact surface roughness measurements for both the cylinders and panels were acquired using an optical profilometer, specifically the Bruker Contour GT-I. This instrument is housed at the Melbourne Centre for Nanofabrication (MCN), situated within the Victorian Node of the Australian National Fabrication Facility (ANFF). The measurements were performed with a 50![]() $\times$ magnification, employing the vertical scanning interferometry (VSI) technique. VSI relies on a broadband light source and is particularly accurate for evaluating surfaces that are rough. The obtained measurements are detailed in tables 3 and 4 in Appendix A.

$\times$ magnification, employing the vertical scanning interferometry (VSI) technique. VSI relies on a broadband light source and is particularly accurate for evaluating surfaces that are rough. The obtained measurements are detailed in tables 3 and 4 in Appendix A.

Table 3. Measured surface roughness values of panels. Values presented are the arithmetic mean of five individual measurements. The measurement area of one measurement is ![]() $0.25\times 0.25\,{\rm mm}^{2}$ (12 measurements under

$0.25\times 0.25\,{\rm mm}^{2}$ (12 measurements under ![]() $50\times 1$ magnification joined together).

$50\times 1$ magnification joined together).

*Measurement area of ![]() $10\times 10\,{\rm mm}^{2}$ was used for the rough ceramic panel which was obtained by stitching together 100 profile scans using a stylus profilometer. No waviness correction was used.

$10\times 10\,{\rm mm}^{2}$ was used for the rough ceramic panel which was obtained by stitching together 100 profile scans using a stylus profilometer. No waviness correction was used.

Table 4. Measured surface roughness of cylinders. Values presented are arithmetic mean of four (or more) individual measurements of four separate cylinders of the same diameter. The measurement area of each presented measurement is ![]() $0.4\times 0.4\,{\rm mm}^{2}$ for all diameters (24 measurements under

$0.4\times 0.4\,{\rm mm}^{2}$ for all diameters (24 measurements under ![]() $50\times 1$ magnification joined together). All measurements were corrected for cylinder curvature prior to obtaining roughness statistics.

$50\times 1$ magnification joined together). All measurements were corrected for cylinder curvature prior to obtaining roughness statistics.

In the present work, roughness statistics, such as ![]() $R_p$, were obtained for a minimum of four different samples. Each sample was generated using the combination of 24 individual measurements conducted under

$R_p$, were obtained for a minimum of four different samples. Each sample was generated using the combination of 24 individual measurements conducted under ![]() $50 \times 1$ magnification of each surface. The reported values represent the average across all samples. This means that the peak roughness (

$50 \times 1$ magnification of each surface. The reported values represent the average across all samples. This means that the peak roughness (![]() $R_p$) reported in this study is a sample-averaged value, and does not represent the highest peak observed across all samples. In addition to the sample-averaged peak roughness, it is also useful to report the parameter

$R_p$) reported in this study is a sample-averaged value, and does not represent the highest peak observed across all samples. In addition to the sample-averaged peak roughness, it is also useful to report the parameter ![]() $R_{p, 1\sigma }$, signifying one standard deviation above the sample-mean peak roughness. This parameter will be used to differentiate the gap imposed by two types of roughness textures observed, which will be elaborated on further in § 4.5.

$R_{p, 1\sigma }$, signifying one standard deviation above the sample-mean peak roughness. This parameter will be used to differentiate the gap imposed by two types of roughness textures observed, which will be elaborated on further in § 4.5.

Figure 3 presents the surface roughness measurements obtained from two panels and four cylinders that were employed in the present experimental investigations. The surface roughness profiles of the acrylic panel depicted in figure 3(a) span a range from ![]() $-1.0$ to

$-1.0$ to ![]() $0.7\,\mathrm {\mu } {\rm m}$, which is indicative of a typically smooth surface. The ceramic panel surface displayed in figure 3(b) displays notably higher asperities and deeper valleys, with some reaching heights as large as

$0.7\,\mathrm {\mu } {\rm m}$, which is indicative of a typically smooth surface. The ceramic panel surface displayed in figure 3(b) displays notably higher asperities and deeper valleys, with some reaching heights as large as ![]() $2\,\mathrm {\mu } {\rm m}$ and valleys as deep as

$2\,\mathrm {\mu } {\rm m}$ and valleys as deep as ![]() $-4.6\,\mathrm {\mu } {\rm m}$, characteristic of a typical rough surface.

$-4.6\,\mathrm {\mu } {\rm m}$, characteristic of a typical rough surface.

Figure 3. Surface roughness profiles obtained using the optical profilometer, under 50![]() $\times$ magnification: (a) acrylic panel; (b) ceramic panel; (c) D4.7-A2.2 cylinder; (d) D7.7-A1.3 cylinder; (e) D11.7-A0.9 cylinder; (f) D19.7-A0.5 cylinder. The arrow at the top right corner of each panel image indicates the approximate down-slope direction, whereas for cylinder images, the arrow shows the direction of rolling of each cylinder, with respect to the directional surface textures.

$\times$ magnification: (a) acrylic panel; (b) ceramic panel; (c) D4.7-A2.2 cylinder; (d) D7.7-A1.3 cylinder; (e) D11.7-A0.9 cylinder; (f) D19.7-A0.5 cylinder. The arrow at the top right corner of each panel image indicates the approximate down-slope direction, whereas for cylinder images, the arrow shows the direction of rolling of each cylinder, with respect to the directional surface textures.

The surface roughnesses observed in all four cylinders shown in figure 3 display pronounced directional characteristics, with a series of ridges and valleys aligned parallel to the direction of cylinder rolling. These ridges arise from the fabrication process, where the acrylic cylinders were produced using a lathe. Comparatively, the two smaller diameter cylinders shown in figures 3(c) and 3(d) possess a smoother surface compared to the larger cylinders in figures 3(e) and 3(f). In the case of the larger cylinders, the peaks of the ridge-like structures typically exceed ![]() $4\,\mu {\rm m}$, whereas the smaller cylinders exhibit peaks within the

$4\,\mu {\rm m}$, whereas the smaller cylinders exhibit peaks within the ![]() $1\unicode{x2013}2\,\mathrm {\mu } {\rm m}$ range.

$1\unicode{x2013}2\,\mathrm {\mu } {\rm m}$ range.

4. Results and discussion

This section presents the experimental results of the effect of surface roughness on the mean effective drag coefficient. The drag coefficient for experimental measurements is determined using (2.2), and it is compared with analytical evaluations under the assumption that the effective gap is equal to the peak surface roughness.

This section is structured as follows. First, we present the observed variations of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $\overline {Re}$ for a set of cylinders with a fixed span in § 4.1. Note that maintaining a constant cylinder span (

$\overline {Re}$ for a set of cylinders with a fixed span in § 4.1. Note that maintaining a constant cylinder span (![]() $L$) while varying the cylinder diameter (

$L$) while varying the cylinder diameter (![]() $D$) leads to a variation in aspect ratios. Subsequently, the influence of aspect ratio (

$D$) leads to a variation in aspect ratios. Subsequently, the influence of aspect ratio (![]() $AR$) on

$AR$) on ![]() $\bar {C}_{D}$ is discussed in § 4.2. Furthermore, § 4.3 discusses the role of cavitation (or lack thereof) on cylinder motion and the limited set of results obtained for foam cylinders rolling in air. In § 4.4 the variation of

$\bar {C}_{D}$ is discussed in § 4.2. Furthermore, § 4.3 discusses the role of cavitation (or lack thereof) on cylinder motion and the limited set of results obtained for foam cylinders rolling in air. In § 4.4 the variation of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $\xi$ is discussed, whereas § 4.5 discusses the relationship between peak roughness and effective gap. § 4.6 presents additional considerations that may influence cylinder

$\xi$ is discussed, whereas § 4.5 discusses the relationship between peak roughness and effective gap. § 4.6 presents additional considerations that may influence cylinder ![]() $\bar {C}_{D}$. Finally, § 4.7 compares the

$\bar {C}_{D}$. Finally, § 4.7 compares the ![]() $\bar {C}_{D}$–

$\bar {C}_{D}$–![]() $\overline {Re}$ relationships between a cylinder and a sphere.

$\overline {Re}$ relationships between a cylinder and a sphere.

4.1. Measurements of  $\bar{C}_{D}$ as a function of

$\bar{C}_{D}$ as a function of  $\overline {Re}$ for cylinders with a fixed span (in water)

$\overline {Re}$ for cylinders with a fixed span (in water)

To investigate the effects of surface roughness on ![]() $\bar {C}_{D}$ of a rolling cylinder, a set of

$\bar {C}_{D}$ of a rolling cylinder, a set of ![]() $\bar {C}_{D}$ measurements were obtained with a fixed span (

$\bar {C}_{D}$ measurements were obtained with a fixed span (![]() $L=10.1\,\mathrm {mm}$), while the cylinder diameter and surface roughness of the panel were varied. This approach ensures that the contact region between the panel and cylinder remains constant which enables the comparison of the effects of surface roughness on

$L=10.1\,\mathrm {mm}$), while the cylinder diameter and surface roughness of the panel were varied. This approach ensures that the contact region between the panel and cylinder remains constant which enables the comparison of the effects of surface roughness on ![]() $\bar {C}_{D}$ of cylinders with varying

$\bar {C}_{D}$ of cylinders with varying ![]() $D$. Figure 4 presents the measured

$D$. Figure 4 presents the measured ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $\overline {Re}$ values within

$\overline {Re}$ values within ![]() $20<\overline {Re}<1800$ for these fixed-span cases. Given the fixed span and variations in

$20<\overline {Re}<1800$ for these fixed-span cases. Given the fixed span and variations in ![]() $D$, the

$D$, the ![]() $AR$ of these cylinders varies from 0.51–2.15. The influence of

$AR$ of these cylinders varies from 0.51–2.15. The influence of ![]() $AR$ on

$AR$ on ![]() $\bar {C}_{D}$ is considered in § 4.2. Any variation in

$\bar {C}_{D}$ is considered in § 4.2. Any variation in ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $AR$ is less than the scatter in the data, at least for the experimental parameters considered in this study.

$AR$ is less than the scatter in the data, at least for the experimental parameters considered in this study.

Figure 4. Variation of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $\overline {Re}$ for the five types of panels,

$\overline {Re}$ for the five types of panels, ![]() $\overline {Re} = 20\unicode{x2013}1800$ range in log–log scale. The cylinder span was fixed at 10.1 mm which results in varied

$\overline {Re} = 20\unicode{x2013}1800$ range in log–log scale. The cylinder span was fixed at 10.1 mm which results in varied ![]() $AR$ ranging from 0.51–2.15.

$AR$ ranging from 0.51–2.15.

Figure 4 shows all of the data gathered, with the legend indicating the marker shapes corresponding to seven cylinder diameters, and marker colours corresponding to the five panels used. The measured ![]() $\bar {C}_{D}$ data exhibit a clear inverse relationship with

$\bar {C}_{D}$ data exhibit a clear inverse relationship with ![]() $\overline {Re}$, particularly evident at low

$\overline {Re}$, particularly evident at low ![]() $\overline {Re}$, as depicted by the grey dashed line in figure 4. In addition, there is a noticeable degree of scatter in the measured

$\overline {Re}$, as depicted by the grey dashed line in figure 4. In addition, there is a noticeable degree of scatter in the measured ![]() $\bar {C}_{D}$ with different surface finishes. This scatter is more significant at low

$\bar {C}_{D}$ with different surface finishes. This scatter is more significant at low ![]() $\overline {Re}$, but decreases with increasing

$\overline {Re}$, but decreases with increasing ![]() $\overline {Re}$. Specifically, there is a difference of

$\overline {Re}$. Specifically, there is a difference of ![]() $70\,\%$ between the smallest and largest

$70\,\%$ between the smallest and largest ![]() $\bar {C}_{D}$ values at

$\bar {C}_{D}$ values at ![]() $\overline {Re} = 100$; however, this scatter is reduced to

$\overline {Re} = 100$; however, this scatter is reduced to ![]() $60\,\%$ by

$60\,\%$ by ![]() $\overline {Re} = 400$.

$\overline {Re} = 400$.

The results of foam cylinders are not included in figure 4, but are presented in § 4.3.1.

These observations can be explained using the decomposition of ![]() $\bar {C}_{D}$ into gap-dependent and wake drag contributions (2.10). Specifically, the gap-dependent drag is approximately proportional to

$\bar {C}_{D}$ into gap-dependent and wake drag contributions (2.10). Specifically, the gap-dependent drag is approximately proportional to ![]() $1/\overline {Re}$, while the wake drag is expected to have an order of magnitude (

$1/\overline {Re}$, while the wake drag is expected to have an order of magnitude (![]() $O(1)$) dependence on

$O(1)$) dependence on ![]() $\overline {Re}$ at moderate to large Reynolds numbers (Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023; Nanayakkara et al. Reference Nanayakkara, Zhao, Terrington, Thompson and Hourigan2024). Therefore, the gap-dependent drag is dominant over the wake drag for small

$\overline {Re}$ at moderate to large Reynolds numbers (Houdroge et al. Reference Houdroge, Zhao, Terrington, Leweke, Hourigan and Thompson2023; Nanayakkara et al. Reference Nanayakkara, Zhao, Terrington, Thompson and Hourigan2024). Therefore, the gap-dependent drag is dominant over the wake drag for small ![]() $\overline {Re}$, leading to the observed

$\overline {Re}$, leading to the observed ![]() $1/\overline {Re}$ dependence and large scatter.

$1/\overline {Re}$ dependence and large scatter.

The scatter in the experimental ![]() $\bar {C}_{D}$ data arises from differences in surface roughness. To illustrate this point, figure 5 depicts the

$\bar {C}_{D}$ data arises from differences in surface roughness. To illustrate this point, figure 5 depicts the ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $\overline {Re}$ curves for a single cylinder D19.7-A0.5 rolling on five tested panels. Each of the panels yields a different

$\overline {Re}$ curves for a single cylinder D19.7-A0.5 rolling on five tested panels. Each of the panels yields a different ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $\overline {Re}$ profile. In particular,

$\overline {Re}$ profile. In particular, ![]() $\bar {C}_{D}$ decreases with an increase in the panel roughness (or increasing

$\bar {C}_{D}$ decreases with an increase in the panel roughness (or increasing ![]() $\xi _p$). Corresponding

$\xi _p$). Corresponding ![]() $\xi _p$ values are also indicated in the figure. This behaviour can be attributed to the larger roughness producing a larger effective gap, resulting in a reduction of gap-dependent drag.

$\xi _p$ values are also indicated in the figure. This behaviour can be attributed to the larger roughness producing a larger effective gap, resulting in a reduction of gap-dependent drag.

Figure 5. Variation of ![]() $\bar {C}_{D}$ against

$\bar {C}_{D}$ against ![]() $\overline {Re}$ for a cylinder with a fixed diameter and aspect ratio, D19.7-A0.5, while varying the panel surface roughness. Least-squares lines of the form

$\overline {Re}$ for a cylinder with a fixed diameter and aspect ratio, D19.7-A0.5, while varying the panel surface roughness. Least-squares lines of the form ![]() $a+b/Re$ have been fitted through data that correspond to individual panels. The coefficient of determination

$a+b/Re$ have been fitted through data that correspond to individual panels. The coefficient of determination ![]() $R^{2}$ values are approximately

$R^{2}$ values are approximately ![]() $0.9$.

$0.9$.

Figure 6 presents profiles of ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $\overline {Re}$ for cylinders of various diameters rolling on two separate panels. Figure 6(a) is for the cylinders rolling on a glass panel (

$\overline {Re}$ for cylinders of various diameters rolling on two separate panels. Figure 6(a) is for the cylinders rolling on a glass panel (![]() $R_p=0.308\,\mathrm {\mu } {\rm m}$), while figure 6(b) is for the rough ceramic panel (

$R_p=0.308\,\mathrm {\mu } {\rm m}$), while figure 6(b) is for the rough ceramic panel (![]() $R_p=33.18\,\mathrm {\mu } {\rm m}$). The

$R_p=33.18\,\mathrm {\mu } {\rm m}$). The ![]() $\xi _p$ values corresponding to each cylinder are indicated in the figure legend. These figures demonstrate that, for a fixed panel roughness,

$\xi _p$ values corresponding to each cylinder are indicated in the figure legend. These figures demonstrate that, for a fixed panel roughness, ![]() $\bar {C}_{D}$ increases with increasing cylinder diameter. Despite an approximately 45-fold difference in peak roughness between the two panels, a similar increase of

$\bar {C}_{D}$ increases with increasing cylinder diameter. Despite an approximately 45-fold difference in peak roughness between the two panels, a similar increase of ![]() $\bar {C}_{D}$ with increasing

$\bar {C}_{D}$ with increasing ![]() $D$ was observed. This held true for all panels examined in this study.

$D$ was observed. This held true for all panels examined in this study.

Figure 6. Variation of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $\overline {Re}$ for cylinders of different diameter rolling on the (a) glass panel and (b) rough ceramic panel. Least-squares lines of the form

$\overline {Re}$ for cylinders of different diameter rolling on the (a) glass panel and (b) rough ceramic panel. Least-squares lines of the form ![]() $a+b/Re$ have been fitted through data that correspond to the individual diameters of the cylinders used. The

$a+b/Re$ have been fitted through data that correspond to the individual diameters of the cylinders used. The ![]() $R^{2}$ values are approximately

$R^{2}$ values are approximately ![]() $0.9$. Error bar indicate bias error only.

$0.9$. Error bar indicate bias error only.

Assuming the effective gap is proportional to the surface roughness, the dimensionless surface roughness ![]() $\xi _p$ reduces with increasing cylinder diameter, resulting in increased gap-dependent drag.

$\xi _p$ reduces with increasing cylinder diameter, resulting in increased gap-dependent drag.

Figure 7 presents a comparison between experimentally measured drag coefficients and analytical evaluations using lubrication theory. The dashed green lines represent the gap-dependent drag (as per (2.8)) using ![]() $G/D = \xi _{p, 1 \sigma }$ for the D4.7-A2.2 cylinder, and

$G/D = \xi _{p, 1 \sigma }$ for the D4.7-A2.2 cylinder, and ![]() $G/D = \xi _{p}$ for the D7.7-A1.3 cylinder. The difference in roughness statistics is associated with a difference between the surface textures of the two cylinders, as discussed further in § 4.5. It is worth noting that the gap-dependent drag generally under-evaluates the drag coefficient since it does not include the wake-drag effects and possibly other sources of drag such as rolling resistance that is discussed further in § 4.6. The wake-drag coefficients for a finite-span cylinder are not available in the literature. For now, we use the wake-drag coefficient for two-dimensional flow (2.7). The solid red lines in figure 7 represent the sum of the gap-dependent and wake drag components, which is in good agreement with the measured

$G/D = \xi _{p}$ for the D7.7-A1.3 cylinder. The difference in roughness statistics is associated with a difference between the surface textures of the two cylinders, as discussed further in § 4.5. It is worth noting that the gap-dependent drag generally under-evaluates the drag coefficient since it does not include the wake-drag effects and possibly other sources of drag such as rolling resistance that is discussed further in § 4.6. The wake-drag coefficients for a finite-span cylinder are not available in the literature. For now, we use the wake-drag coefficient for two-dimensional flow (2.7). The solid red lines in figure 7 represent the sum of the gap-dependent and wake drag components, which is in good agreement with the measured ![]() $\bar {C}_{D}$.

$\bar {C}_{D}$.

Figure 7. Comparison of ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $\overline {Re}$ of two cylinders rolling on a glass panel against analytical prediction (2.8). The total drag when two-dimensional

$\overline {Re}$ of two cylinders rolling on a glass panel against analytical prediction (2.8). The total drag when two-dimensional ![]() $C_{D,pred, wake}$ predictions from (2.7) is added to (2.8) is also indicated in the figure. Physical parameters are (a)

$C_{D,pred, wake}$ predictions from (2.7) is added to (2.8) is also indicated in the figure. Physical parameters are (a) ![]() $\xi _{p, 1\sigma } = 0.00096$ and

$\xi _{p, 1\sigma } = 0.00096$ and ![]() $AR = 2.16$ and (b)

$AR = 2.16$ and (b) ![]() $\xi _{p} = 0.00035$ and

$\xi _{p} = 0.00035$ and ![]() $AR = 1.31$.

$AR = 1.31$.

4.2. Effects of aspect ratio on  $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs  $\overline {Re}$

$\overline {Re}$

To investigate the effect of cylinder aspect ratio on ![]() $\bar {C}_{D}$, a series of experiments was conducted with a consistent cylinder diameter of

$\bar {C}_{D}$, a series of experiments was conducted with a consistent cylinder diameter of ![]() $D\approx 4.7\,{\rm mm}$ while the cylinder span

$D\approx 4.7\,{\rm mm}$ while the cylinder span ![]() $L$ was varied.

$L$ was varied.

Figure 8(a) presents the relationship between ![]() $\bar {C}_{D}$ and

$\bar {C}_{D}$ and ![]() $\overline {Re}$ for cylinders with

$\overline {Re}$ for cylinders with ![]() $AR$ ranging from

$AR$ ranging from ![]() $0.5$ to

$0.5$ to ![]() $6.02$ rolling on a glass panel (

$6.02$ rolling on a glass panel (![]() $R_p = 0.308\,\mathrm {\mu } {\rm m}$). In general, all cylinders with varying aspect ratios follow the previously observed

$R_p = 0.308\,\mathrm {\mu } {\rm m}$). In general, all cylinders with varying aspect ratios follow the previously observed ![]() $1/\overline {Re}$ trend outlined in § 4.1. In addition, the same convergence of

$1/\overline {Re}$ trend outlined in § 4.1. In addition, the same convergence of ![]() $\bar {C}_{D}$ at high

$\bar {C}_{D}$ at high ![]() $\overline {Re}$ is observed, regardless of the cylinder aspect ratio. This behaviour implies that the influence of end effects on

$\overline {Re}$ is observed, regardless of the cylinder aspect ratio. This behaviour implies that the influence of end effects on ![]() $\bar {C}_{D}$ also decreases with increasing

$\bar {C}_{D}$ also decreases with increasing ![]() $\overline {Re}$.

$\overline {Re}$.

Figure 8. Cylinder ![]() $\bar {C}_{D}$ variation with

$\bar {C}_{D}$ variation with ![]() $AR$. (a) Variation of

$AR$. (a) Variation of ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $\overline {Re}$ for a fixed diameter cylinder (

$\overline {Re}$ for a fixed diameter cylinder (![]() $D\approx 4.7\,{\rm mm}$) with varied

$D\approx 4.7\,{\rm mm}$) with varied ![]() $AR$. All measurements were obtained on the glass panel with

$AR$. All measurements were obtained on the glass panel with ![]() $R_{p, {\rm 1}\sigma }=0.46\,\mathrm {\mu } {\rm m}$. Least-squares lines of the form

$R_{p, {\rm 1}\sigma }=0.46\,\mathrm {\mu } {\rm m}$. Least-squares lines of the form ![]() $a/Re+b$ have been fitted through the data points corresponding to fixed

$a/Re+b$ have been fitted through the data points corresponding to fixed ![]() $AR$. (b) Variation of

$AR$. (b) Variation of ![]() $\bar {C}_{D}$ vs

$\bar {C}_{D}$ vs ![]() $AR$ for a fixed diameter (

$AR$ for a fixed diameter (![]() $D\approx 4.7\,{\rm mm}$) cylinder for three constant values of

$D\approx 4.7\,{\rm mm}$) cylinder for three constant values of ![]() $\overline {Re}(50,100,150)$.

$\overline {Re}(50,100,150)$. ![]() $G/D=0.008$ value was used for

$G/D=0.008$ value was used for ![]() $C_{D,pred}$ shown which corresponds to the cylinders rolling on the rough ceramic panel.

$C_{D,pred}$ shown which corresponds to the cylinders rolling on the rough ceramic panel.

There is a significant amount of scatter in the experimental data shown in figure 8(a). To investigate whether this scatter is due to aspect ratio effects, figure 8(b) plots the variation of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $AR$ for three constant Reynolds numbers,

$AR$ for three constant Reynolds numbers, ![]() $\overline {Re} = 50$,

$\overline {Re} = 50$, ![]() $100$ and

$100$ and ![]() $150$. Since the surface roughness values of the cylinders varied (table 4), the rough ceramic panel was used to obtain the data in this figure. The roughness of this panel is approximately 10 times larger than the cylinder roughness values, which maintains a consistent

$150$. Since the surface roughness values of the cylinders varied (table 4), the rough ceramic panel was used to obtain the data in this figure. The roughness of this panel is approximately 10 times larger than the cylinder roughness values, which maintains a consistent ![]() $\xi _p$ across the different

$\xi _p$ across the different ![]() $AR$s. The

$AR$s. The ![]() $\bar {C}_{D}$ values corresponding to each

$\bar {C}_{D}$ values corresponding to each ![]() $\overline {Re}$ were determined through linear interpolation from the nearest neighbouring

$\overline {Re}$ were determined through linear interpolation from the nearest neighbouring ![]() $\overline {Re}$. We observe no significant variation of

$\overline {Re}$. We observe no significant variation of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $AR$.

$AR$.

Solid lines in figure 8(b) indicate the predicted drag obtained by adding the estimated wake drag to the gap drag (2.10). The approximate peak roughness of the rough ceramic panel ![]() $R_{p}/D=0.008$ was used to approximate

$R_{p}/D=0.008$ was used to approximate ![]() $G/D$ to calculate

$G/D$ to calculate ![]() $C_{D,pred}$. We observe reasonable agreement between measured and predicted values, particularly at higher

$C_{D,pred}$. We observe reasonable agreement between measured and predicted values, particularly at higher ![]() $AR$ and higher

$AR$ and higher ![]() $\overline {Re}$. The predicted

$\overline {Re}$. The predicted ![]() $C_{D,pred}$ increases with

$C_{D,pred}$ increases with ![]() $AR$, and approaches a constant value in the limit

$AR$, and approaches a constant value in the limit ![]() $AR \rightarrow \infty$. However, the predicted change in

$AR \rightarrow \infty$. However, the predicted change in ![]() $\bar {C}_{D}$ against

$\bar {C}_{D}$ against ![]() $AR$, using (2.8), is relatively small over the range of

$AR$, using (2.8), is relatively small over the range of ![]() $AR$ considered in this study and is within the variation in

$AR$ considered in this study and is within the variation in ![]() $\bar {C}_{D}$ observed. There is a marginal increasing trend in

$\bar {C}_{D}$ observed. There is a marginal increasing trend in ![]() $\bar {C}_{D}$ against decreasing

$\bar {C}_{D}$ against decreasing ![]() $AR$, in contrast to the decreasing trend predicted by theory. We attribute the difference in drag at small aspect ratios (

$AR$, in contrast to the decreasing trend predicted by theory. We attribute the difference in drag at small aspect ratios (![]() $AR < 1$) to the use of two-dimensional wake drag in (2.10). While this assumption is valid for larger

$AR < 1$) to the use of two-dimensional wake drag in (2.10). While this assumption is valid for larger ![]() $AR$ cylinders, it becomes less accurate for smaller

$AR$ cylinders, it becomes less accurate for smaller ![]() $AR$ cylinders where three-dimensional effects are more prominent. Further, the influence of the large roughness of the panel on the cylinder motion also increases for the smaller

$AR$ cylinders where three-dimensional effects are more prominent. Further, the influence of the large roughness of the panel on the cylinder motion also increases for the smaller ![]() $AR$ cylinders. Small

$AR$ cylinders. Small ![]() $AR$ cylinders were observed to change directions easily following collisions with large asperities, and increased vortex-induced oscillations were also observed. The theoretical model does not consider these added effects. Extending the range of

$AR$ cylinders were observed to change directions easily following collisions with large asperities, and increased vortex-induced oscillations were also observed. The theoretical model does not consider these added effects. Extending the range of ![]() $AR$ to smaller than 0.5 may produce useful insights, which we recommend as future works.

$AR$ to smaller than 0.5 may produce useful insights, which we recommend as future works.

In addition, the wake drag was estimated by assuming it to be equal to the wake drag of an infinite cylinder. The true wake drag for a finite-length cylinder is unknown, and it may also vary with ![]() $AR$. If the wake drag were to decrease with

$AR$. If the wake drag were to decrease with ![]() $AR$, then the total drag may be approximately constant with respect to

$AR$, then the total drag may be approximately constant with respect to ![]() $AR$. For a finite length cylinder in an unbounded flow, Yang et al. (Reference Yang, Feng and Zhang2022) observed a reduction of

$AR$. For a finite length cylinder in an unbounded flow, Yang et al. (Reference Yang, Feng and Zhang2022) observed a reduction of ![]() $\bar {C}_{D}$ from approximately

$\bar {C}_{D}$ from approximately ![]() $1.5$ to approximately

$1.5$ to approximately ![]() $1$ for an increase of

$1$ for an increase of ![]() $AR$ from

$AR$ from ![]() $0.5$ to

$0.5$ to ![]() $2.0$ at

$2.0$ at ![]() $\overline {Re}=100$. The wake drag behind a rolling cylinder might be expected to follow a similar trend in

$\overline {Re}=100$. The wake drag behind a rolling cylinder might be expected to follow a similar trend in ![]() $AR$. However, the wake will be modified by both the presence of the wall and the rotation of the cylinder. Numerical simulations of the flow over finite-length cylinders rolling near plane walls are needed to determine the true variation of the wake drag with

$AR$. However, the wake will be modified by both the presence of the wall and the rotation of the cylinder. Numerical simulations of the flow over finite-length cylinders rolling near plane walls are needed to determine the true variation of the wake drag with ![]() $AR$. Further, the numerical study on the variation of

$AR$. Further, the numerical study on the variation of ![]() $\bar {C}_{D}$ with

$\bar {C}_{D}$ with ![]() $AR$ for the same