Article contents

Emergence of a hexagonal pattern in shear-thickening suspensions under orbital oscillations

Published online by Cambridge University Press: 12 April 2024

Abstract

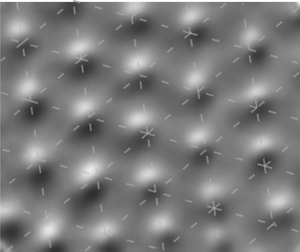

A dense particle suspension under shear may lose its uniform state to large local density and stress fluctuations, which challenge the mean-field description of the system. Here, we explore the novel dynamics of a non-Brownian suspension under orbital oscillations, where localized density waves along the flow direction appear beyond an excitation frequency threshold and self-organize into a hexagonal pattern across the system. The spontaneous occurrence of the inhomogeneity pattern arises from a coupling between particle advection and the shear-thickening nature of the suspension. Through linear stability analysis, we show that they overcome the stabilizing effects of particle pressure at sufficient particle volume fraction and oscillation frequency. In addition, the long-standing density waves degenerate into random fluctuations when replacing the free surface with rigid confinement. It indicates that the shear-thickened state is intrinsically heterogeneous, and the boundary conditions are crucial for developing local disturbance.

JFM classification

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2024. Published by Cambridge University Press

References

Shi et al. supplementary movie 1

Shi et al. supplementary movie 2

Shi et al. supplementary movie 3

- 2

- Cited by