Article contents

High-Strouhal-number pulsatile flow in a curved pipe

Published online by Cambridge University Press: 27 July 2021

Abstract

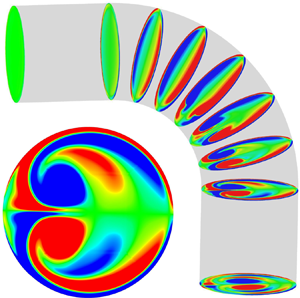

The high-Strouhal-number pulsatile flow in a curved pipe is studied numerically. A general force analysis is developed for the bend force, where the new contribution from flow acceleration is identified and analysed. The mechanisms of secondary flow production are studied by extending Hawthorne's (Proc. R. Soc. Lond. A, vol. 206, issue 1086, 1951, pp. 374–387) model to account for viscous effects and applied to assess the distinct contributions from an inviscid stretching and no-slip condition. A detailed comparison is made between the numerical simulations and models for a pipe flow characterised by a volume flux  $Q=U_b A |\sin \varOmega _p t|$ (where

$Q=U_b A |\sin \varOmega _p t|$ (where  $U_b$ is the maximum bulk velocity,

$U_b$ is the maximum bulk velocity,  $\varOmega _p$ is the angular frequency and

$\varOmega _p$ is the angular frequency and  $A$ is the pipe cross-sectional area). For high-Reynolds-number (

$A$ is the pipe cross-sectional area). For high-Reynolds-number ( $Re_b$) and high-Strouhal-number (

$Re_b$) and high-Strouhal-number ( $St$), the bend force predictions are in good agreement with the numerical results over a wide range of bend curvature (

$St$), the bend force predictions are in good agreement with the numerical results over a wide range of bend curvature ( $R_c/D$; where

$R_c/D$; where  $R_c$ is the bend radius of curvature and

$R_c$ is the bend radius of curvature and  $D$ is the pipe diameter) owing to the influence of the streamwise flow acceleration on the pressure field. At high-

$D$ is the pipe diameter) owing to the influence of the streamwise flow acceleration on the pressure field. At high- $St$, the streamwise vorticity (secondary flow) distribution is steady and close to the low-

$St$, the streamwise vorticity (secondary flow) distribution is steady and close to the low- $St$ case, which is explained using a linear secondary flow model.

$St$ case, which is explained using a linear secondary flow model.

JFM classification

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2021. Published by Cambridge University Press

References

REFERENCES

- 12

- Cited by