1. Introduction

The linear stability analysis of film-flow solutions predicts whether small disturbances grow or decay in the long term. This is particularly important in the dip-coating industrial process, where growing disturbances make the coating layer uneven, reducing the quality of the final product (Scriven Reference Scriven1988). The dip-coating process consists in applying a thin film of protective material over a solid substrate (Weinstein & Ruschak Reference Weinstein and Ruschak2004), with applications ranging from food industry (Suhag et al. Reference Suhag, Kumar, Petkoska and Upadhyay2020), e.g. coating composed of hydrophilic polymers dissolved in water (Jose, Pareek & Radhakrishnan Reference Jose, Pareek and Radhakrishnan2020), to corrosion-protection material, e.g. zinc coating in hot-dip galvanisation Kuklík & Kudlacek (Reference Kuklík and Kudlacek2016, Chapter 2). The substrate is coated by dipping and then withdrawing it from a liquid bath. Thereby, a liquid film forms on the substrate surface, which then solidifies into a protective layer. The thickness of this liquid film ![]() $\bar {h}$ depends on the withdrawal velocity

$\bar {h}$ depends on the withdrawal velocity ![]() $U_p$ and the action of external control actuators.

$U_p$ and the action of external control actuators.

In the uncontrolled case, known as free-coating or drag-out problem (Wilson Reference Wilson1982), ![]() $\bar {h}$ depends on the ratio between viscous drag forces over surface tension forces at the free surface (capillary number

$\bar {h}$ depends on the ratio between viscous drag forces over surface tension forces at the free surface (capillary number ![]() $Ca=U_p\mu /\sigma$). For small Reynolds numbers (

$Ca=U_p\mu /\sigma$). For small Reynolds numbers (![]() $Re$),

$Re$), ![]() $\bar {h}$ is given by the Landau–Levich–Derjaguin (LLD) solution for

$\bar {h}$ is given by the Landau–Levich–Derjaguin (LLD) solution for ![]() $Ca\ll 1$ (Derjaguin Reference Derjaguin1943; Landau & Levich Reference Landau and Levich1988) and by the Derjaguin (Reference Derjaguin1944) solution for

$Ca\ll 1$ (Derjaguin Reference Derjaguin1943; Landau & Levich Reference Landau and Levich1988) and by the Derjaguin (Reference Derjaguin1944) solution for ![]() $Ca\gg 1$. Both solutions define a monotonically non-decreasing relation between

$Ca\gg 1$. Both solutions define a monotonically non-decreasing relation between ![]() $\bar {h}$ and

$\bar {h}$ and ![]() $U_p$ with thicker films for faster substrates. This contrasts with industrial needs aiming at thin films and fast substrates. To this end, in industrial lines, external actuators are used to remove the liquid excess from the film, e.g. impinging gas jets in the hot-dip galvanisation (Buchlin Reference Buchlin1997; Gosset & Buchlin Reference Gosset and Buchlin2006), allowing the thickness of the coating to be controlled regardless of the substrate velocity (Mendez et al. Reference Mendez, Gosset, Scheid, Balabane and Buchlin2021).

$U_p$ with thicker films for faster substrates. This contrasts with industrial needs aiming at thin films and fast substrates. To this end, in industrial lines, external actuators are used to remove the liquid excess from the film, e.g. impinging gas jets in the hot-dip galvanisation (Buchlin Reference Buchlin1997; Gosset & Buchlin Reference Gosset and Buchlin2006), allowing the thickness of the coating to be controlled regardless of the substrate velocity (Mendez et al. Reference Mendez, Gosset, Scheid, Balabane and Buchlin2021).

Tu & Ellen (Reference Tu and Ellen1986) and Gosset (Reference Gosset2007) studied the stability properties of the controlled liquid film, finding that the cutoff wavenumber is ![]() $\propto \bar {h}^2Re^{1/2}Ca^{1/2}$. They solved the Orr–Sommerfeld eigenvalue problem with an asymptotic long-wave expansion at

$\propto \bar {h}^2Re^{1/2}Ca^{1/2}$. They solved the Orr–Sommerfeld eigenvalue problem with an asymptotic long-wave expansion at ![]() $O(k)$, valid for small Reynolds numbers (Benjamin Reference Benjamin1957; Yih Reference Yih1991). Other authors relied on integral boundary layer models to extend the analysis to larger

$O(k)$, valid for small Reynolds numbers (Benjamin Reference Benjamin1957; Yih Reference Yih1991). Other authors relied on integral boundary layer models to extend the analysis to larger ![]() $Re$ and short wavelengths. Ivanova et al. (Reference Ivanova, Pino, Scheid and Mendez2022) found that the cutoff wavenumber is

$Re$ and short wavelengths. Ivanova et al. (Reference Ivanova, Pino, Scheid and Mendez2022) found that the cutoff wavenumber is ![]() $\propto \bar {h}^{3/2}Re^{1/2}Ca^{1/6}$, whereas Barreiro-Villaverde et al. (Reference Barreiro-Villaverde, Gosset, Lema and Mendez2023) showed that the film is more stable to three-dimensional (3-D) than to two-dimensional (2-D) disturbances. The disagreement between the Orr–Sommerfeld approximated long-wave solution and integral models suggests that a more thorough analysis of the full Orr–Sommerfeld eigenvalue problem is required, which is still absent from the literature.

$\propto \bar {h}^{3/2}Re^{1/2}Ca^{1/6}$, whereas Barreiro-Villaverde et al. (Reference Barreiro-Villaverde, Gosset, Lema and Mendez2023) showed that the film is more stable to three-dimensional (3-D) than to two-dimensional (2-D) disturbances. The disagreement between the Orr–Sommerfeld approximated long-wave solution and integral models suggests that a more thorough analysis of the full Orr–Sommerfeld eigenvalue problem is required, which is still absent from the literature.

An essential aspect of unstable perturbations is the physical mechanism leading to their growth. For a falling liquid film, asymptotic (Smith Reference Smith1990), vorticity and energy arguments (Kelly et al. Reference Kelly, Goussis, Lin and Hsu1989) showed that the motion induced by a small perturbation of the liquid film's free surface feeds the perturbation's energy by the work of shear stresses at the free surface. The extracted energy is stored in the disturbance's kinetic and potential surface tension energy. Understanding the growth mechanism in dip-coating conditions would shed some light on the role of substrate motion.

Another significant result given by the linear stability analysis is the threshold between absolutely and convectively unstable film flows (Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2011, Subsection 7.1.2). Knowing this threshold is essential for the design of control actions, which can affect the whole liquid film or only a part of it (Pier Reference Pier2003). The liquid film's impulse response can produce waves propagating along the flow direction (convectively unstable flow) or everywhere in the domain (absolutely unstable flow). Experiments (Liu, Paul & Gollub Reference Liu, Paul and Gollub1993), analytical and numerical works (Brevdo et al. Reference Brevdo, Laure, Dias and Bridges1999) proved that the falling film is convectively unstable, and the suspended film is absolutely unstable (Sterman-Cohen, Bestehorn & Oron Reference Sterman-Cohen, Bestehorn and Oron2017). Between these two extremes, a critical inclination angle defines the threshold between absolute and convective film flows (Brun et al. Reference Brun, Damiano, Rieu, Balestra and Gallaire2015; Scheid, Kofman & Rohlfs Reference Scheid, Kofman and Rohlfs2016; Pino, Scheid & Mendez Reference Pino, Scheid and Mendez2024). Likewise, a critical liquid-film thickness in dip coating defines the absolute/convective (AC) threshold (Pino, Mendez & Scheid Reference Pino, Mendez and Scheid2024). For small coating thicknesses, the entrainment due to the substrate motion sweeps the instabilities upwards; for large coating thicknesses, the gravitational effects push the instability downwards. For intermediate coating thicknesses, gravity and viscous entrainment should compensate for each other, resulting in a window of absolute instability. Knowing the position of this window in the parameters space is essential for the design of control laws, which can affect the liquid film downstream, upstream or everywhere. Despite its implications, this remains an open question that has not yet been answered and which we address theoretically in this paper.

This work studies the stability of controlled and uncontrolled liquid-film-flow solutions over a substrate moving against gravity. Given the wide variety of coating liquids, going from vegetable oils (Sharmin et al. Reference Sharmin, Zafar, Akram, Alam and Ahmad2015) to liquid metals, this analysis focuses on four liquids with a ratio of surface tension forces to inertial forces (Kapitza number ![]() $Ka$) in the range between

$Ka$) in the range between ![]() $Ka\sim O(1)$ and

$Ka\sim O(1)$ and ![]() $Ka\sim O(10^4)$. We solve the Orr–Sommerfeld eigenvalue problem via the Chebyshev–Tau spectral method (Ortiz Reference Ortiz1969; Lanczos Reference Lanczos1988; Johnson Reference Johnson1996, Chapter VII) and compare the neutral stability conditions for different values of non-dimensional film thickness. Based on the Orr–Sommerfeld solution, we calculate the components of the energy balance equations and compute the AC threshold. Although this holds in linear analysis, it is worth noting that nonlinear mechanisms may affect the spanwise development of initial perturbations, as observed by Barreiro-Villaverde et al. (Reference Barreiro-Villaverde, Gosset, Lema and Mendez2023) in a coating film and by Ledda et al. (Reference Ledda, Balestra, Lerisson, Scheid, Wyart and Gallaire2021) in an inverted film with calcium carbonate deposition.

$Ka\sim O(10^4)$. We solve the Orr–Sommerfeld eigenvalue problem via the Chebyshev–Tau spectral method (Ortiz Reference Ortiz1969; Lanczos Reference Lanczos1988; Johnson Reference Johnson1996, Chapter VII) and compare the neutral stability conditions for different values of non-dimensional film thickness. Based on the Orr–Sommerfeld solution, we calculate the components of the energy balance equations and compute the AC threshold. Although this holds in linear analysis, it is worth noting that nonlinear mechanisms may affect the spanwise development of initial perturbations, as observed by Barreiro-Villaverde et al. (Reference Barreiro-Villaverde, Gosset, Lema and Mendez2023) in a coating film and by Ledda et al. (Reference Ledda, Balestra, Lerisson, Scheid, Wyart and Gallaire2021) in an inverted film with calcium carbonate deposition.

The rest of the article is organised as follows. The problem set-up is described in § 2, and a description of the scaling quantities is given in § 2.1. Section 2.2 reports the governing equations, the eigenvalue problem formulation and the instability energy balance equation. The numerical implementation is reported in § 3 with methods used to solve the Orr–Sommerfeld problem, calculate the energy balance equation and search the AC threshold. Results are presented in § 5 with the stability curves, the perturbation's energy budget and the AC instability threshold. Conclusions and perspectives are given in § 6.

2. Problem description

We consider a 2-D liquid film with density ![]() $\rho$, dynamic viscosity

$\rho$, dynamic viscosity ![]() $\mu$, kinematic viscosity

$\mu$, kinematic viscosity ![]() $\nu$ and surface tension

$\nu$ and surface tension ![]() $\sigma$, over a vertical substrate moving against gravity

$\sigma$, over a vertical substrate moving against gravity ![]() $g$ at constant speed

$g$ at constant speed ![]() $U_{p}$. Table 1 reports the physical properties of the four liquids considered in this work: liquid zinc, water, water–glycerol solution (glycerol concentration 45 % by volume) and corn oil. These cover a broad range of conditions encountered in dip or slot coating (Gosset, Mendez & Buchlin Reference Gosset, Mendez and Buchlin2019; Barreiro-Villaverde et al. Reference Barreiro-Villaverde, Gosset, Lema and Mendez2023). Figure 1(a) shows the fixed reference system (

$U_{p}$. Table 1 reports the physical properties of the four liquids considered in this work: liquid zinc, water, water–glycerol solution (glycerol concentration 45 % by volume) and corn oil. These cover a broad range of conditions encountered in dip or slot coating (Gosset, Mendez & Buchlin Reference Gosset, Mendez and Buchlin2019; Barreiro-Villaverde et al. Reference Barreiro-Villaverde, Gosset, Lema and Mendez2023). Figure 1(a) shows the fixed reference system (![]() $\mathscr {O}xy$) with

$\mathscr {O}xy$) with ![]() $x$ aligned with the plate and pointing in the direction of the gravitational acceleration,

$x$ aligned with the plate and pointing in the direction of the gravitational acceleration, ![]() $y$ along the wall-normal direction towards the free-surface, with the origin

$y$ along the wall-normal direction towards the free-surface, with the origin ![]() $\mathscr {O}$ on an arbitrary point of the substrate, given the translational invariance of the problem.

$\mathscr {O}$ on an arbitrary point of the substrate, given the translational invariance of the problem.

Table 1. Properties of the four liquids considered in the analysis (density, dynamic viscosity and surface tension from left to right), Kapitza number (![]() $Ka$) and range of Reynolds numbers (

$Ka$) and range of Reynolds numbers (![]() $Re$) for substrate velocity

$Re$) for substrate velocity ![]() $U_{p}\in [0.1,3]$ m s

$U_{p}\in [0.1,3]$ m s![]() $^{-1}$ for the four liquids considered in the analysis.

$^{-1}$ for the four liquids considered in the analysis.

Figure 1. (a) Schematic of the investigated configuration with a vertical liquid film over a substrate moving with velocity ![]() $U_p$, where the dimensional liquid-film height

$U_p$, where the dimensional liquid-film height ![]() $h$ can be scaled by

$h$ can be scaled by ![]() $h_{ref}$ and decomposed into a dimensionless base state

$h_{ref}$ and decomposed into a dimensionless base state ![]() $\bar {h}$ and a dimensionless harmonic perturbation

$\bar {h}$ and a dimensionless harmonic perturbation ![]() $\tilde {h}$ of

$\tilde {h}$ of ![]() $O(1)$, with

$O(1)$, with ![]() $\varepsilon \ll 1$. Liquid-film response (red continuous curve) of a (b) convectively and (c) absolutely unstable base state solution to an initial pulse (black dashed line).

$\varepsilon \ll 1$. Liquid-film response (red continuous curve) of a (b) convectively and (c) absolutely unstable base state solution to an initial pulse (black dashed line).

2.1. Scaling quantities

For a given liquid, the two control parameters of the systems are the substrate velocity ![]() $U_{p}$ and the liquid-film thickness

$U_{p}$ and the liquid-film thickness ![]() $h$. We define as reference velocity

$h$. We define as reference velocity ![]() $U_{p}$ and as reference length the film thickness resulting from the steady-state viscous-gravity balance (see Mendez et al. Reference Mendez, Gosset, Scheid, Balabane and Buchlin2021):

$U_{p}$ and as reference length the film thickness resulting from the steady-state viscous-gravity balance (see Mendez et al. Reference Mendez, Gosset, Scheid, Balabane and Buchlin2021):

\begin{equation} u_{ref} = U_{p}, \quad h_{ref} = \sqrt{\frac{\nu U_{p}}{g}}, \end{equation}

\begin{equation} u_{ref} = U_{p}, \quad h_{ref} = \sqrt{\frac{\nu U_{p}}{g}}, \end{equation}

where the subscript ‘![]() ${ref}$’ denotes reference quantities. We define the capillary length

${ref}$’ denotes reference quantities. We define the capillary length ![]() $\ell _{c}$, relating gravity and surface tension, and the viscous length

$\ell _{c}$, relating gravity and surface tension, and the viscous length ![]() $\ell _{\nu }$, relating gravity and viscosity, as

$\ell _{\nu }$, relating gravity and viscosity, as

\begin{equation} \ell_{c} = \sqrt{\frac{\sigma}{\rho g}},\quad \ell_{\nu}=\sqrt[3]{\frac{\nu^2}{g}}. \end{equation}

\begin{equation} \ell_{c} = \sqrt{\frac{\sigma}{\rho g}},\quad \ell_{\nu}=\sqrt[3]{\frac{\nu^2}{g}}. \end{equation}Based on velocity and length scales in (2.1), the dependent and independent variables are scaled accordingly:

where the hat ![]() $\hat {{\cdot }}$ denotes the non-dimensional quantities and

$\hat {{\cdot }}$ denotes the non-dimensional quantities and ![]() $p_{\infty }$ the atmospheric pressure. To make the non-dimensional thickness

$p_{\infty }$ the atmospheric pressure. To make the non-dimensional thickness ![]() $\hat {h}$ independent of

$\hat {h}$ independent of ![]() $U_{p}$ and to have a clearer understanding of the role of the control parameters, we introduce another non-dimensional film thickness

$U_{p}$ and to have a clearer understanding of the role of the control parameters, we introduce another non-dimensional film thickness ![]() $\breve {h}$ based on

$\breve {h}$ based on ![]() $\ell _{\nu }$:

$\ell _{\nu }$:

The non-dimensional groups arising from our scaling are the Reynolds number:

\begin{equation} Re = \frac{u_{ref}h_{ref}}{\nu} = \sqrt{\frac{U_{p}^3}{g\nu}}, \end{equation}

\begin{equation} Re = \frac{u_{ref}h_{ref}}{\nu} = \sqrt{\frac{U_{p}^3}{g\nu}}, \end{equation}which is equivalent to the Froude number defined as

\begin{equation} F = \frac{u_{ref}^2}{g h_{ref}} = \sqrt{\frac{U_{p}^3}{g\nu}}. \end{equation}

\begin{equation} F = \frac{u_{ref}^2}{g h_{ref}} = \sqrt{\frac{U_{p}^3}{g\nu}}. \end{equation}

This means that ![]() $Re$ represents the ratio of inertia over viscous forces and the ratio between inertia and gravitational forces. The other non-dimensional group is the inverse of the capillary number defined as the ratio between surface tension and gravity:

$Re$ represents the ratio of inertia over viscous forces and the ratio between inertia and gravitational forces. The other non-dimensional group is the inverse of the capillary number defined as the ratio between surface tension and gravity:

where ![]() $Ka$ is the Kapitza number defined as

$Ka$ is the Kapitza number defined as

Based on these non-dimensional groups, the non-dimensional capillary and viscous wavenumbers read

Using the scaling in (2.1), the Derjaguin (Reference Derjaguin1944) flat film solution corresponds to ![]() $\hat {h}=1$ and the LLD solution (Derjaguin Reference Derjaguin1943; Landau & Levich Reference Landau and Levich1988; Snoeijer et al. Reference Snoeijer, Ziegler, Andreotti, Fermigier and Eggers2008) corresponds to

$\hat {h}=1$ and the LLD solution (Derjaguin Reference Derjaguin1943; Landau & Levich Reference Landau and Levich1988; Snoeijer et al. Reference Snoeijer, Ziegler, Andreotti, Fermigier and Eggers2008) corresponds to

2.2. Mathematical formulation

The liquid film is governed by the incompressible 2-D Navier–Stokes equations, with a velocity vector ![]() $\boldsymbol {v}=(u(x,y),v(x,y))$ and a pressure field

$\boldsymbol {v}=(u(x,y),v(x,y))$ and a pressure field ![]() $p(x,y)$. The equations are accompanied by the non-slip condition at the substrate

$p(x,y)$. The equations are accompanied by the non-slip condition at the substrate ![]() $\boldsymbol {v}(x,y=0)=(-U_p,0)$ and a set of kinematic and dynamic boundary conditions at the free surface (

$\boldsymbol {v}(x,y=0)=(-U_p,0)$ and a set of kinematic and dynamic boundary conditions at the free surface (![]() $y=h$), accounting for the continuity of the interface, and the normal and tangential force balance (see Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2011, Chapter 2). The non-dimensional steady-state solutions (base states) are given by a flat interface (

$y=h$), accounting for the continuity of the interface, and the normal and tangential force balance (see Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2011, Chapter 2). The non-dimensional steady-state solutions (base states) are given by a flat interface (![]() $\hat {h}=\bar {h}$) and the following velocity and pressure fields:

$\hat {h}=\bar {h}$) and the following velocity and pressure fields:

where ![]() $\bar {{\cdot }}$ denotes the base state quantities. The balance between wall shear stress and gravity, along with the imposed velocity at the boundary, produce a non-monotonic relation between non-dimensional flow rate

$\bar {{\cdot }}$ denotes the base state quantities. The balance between wall shear stress and gravity, along with the imposed velocity at the boundary, produce a non-monotonic relation between non-dimensional flow rate ![]() $\hat {q}=q/(u_{ref}h_{ref})$ and

$\hat {q}=q/(u_{ref}h_{ref})$ and ![]() $\hat {h}$:

$\hat {h}$:

As shown in figure 2(a), this relation entails two branches of steady-state solutions: a thin one (![]() $\bar {h} < 1$) (orange area) and a thick one (

$\bar {h} < 1$) (orange area) and a thick one (![]() $\bar {h} > 1$) (blue area) with the Derjaguin's solution (red dot) and the solution

$\bar {h} > 1$) (blue area) with the Derjaguin's solution (red dot) and the solution ![]() $\bar {h}=\sqrt {3}$ (green square) defining the limit of zero net flow rate, above which we enter the falling film regime, i.e. for

$\bar {h}=\sqrt {3}$ (green square) defining the limit of zero net flow rate, above which we enter the falling film regime, i.e. for ![]() $\bar {h}>\sqrt {3}$. Figure 2(b) shows the non-dimensional streamwise velocity profile

$\bar {h}>\sqrt {3}$. Figure 2(b) shows the non-dimensional streamwise velocity profile ![]() $\bar {u}(\hat {y})$ associated with Dejarguin's solution (continuous red line) and the thin (orange) and thick (blue) film solution (lines with markers).

$\bar {u}(\hat {y})$ associated with Dejarguin's solution (continuous red line) and the thin (orange) and thick (blue) film solution (lines with markers).

Figure 2. (a) Relation between the non-dimensional liquid film ![]() $\hat {h}$ and flow rate

$\hat {h}$ and flow rate ![]() $\hat {q}$ with the Derjaguin solution (red circle), the maximum thickness

$\hat {q}$ with the Derjaguin solution (red circle), the maximum thickness ![]() $\hat h=\sqrt {3}$ (green square) and the thin film (orange shadowed) and thick film (blue shadowed) regions with (b) the associated velocity profiles.

$\hat h=\sqrt {3}$ (green square) and the thin film (orange shadowed) and thick film (blue shadowed) regions with (b) the associated velocity profiles.

To analyse the stability of the base states given by (2.11), we decompose the dependent variables as follows:

where ![]() $\tilde {{\cdot }}$ represents the perturbations of O(1) and

$\tilde {{\cdot }}$ represents the perturbations of O(1) and ![]() $\varepsilon \ll 1$ a small parameter. Inserting (2.13) into the governing equations with the kinematic and dynamic boundary conditions and collecting the term at O

$\varepsilon \ll 1$ a small parameter. Inserting (2.13) into the governing equations with the kinematic and dynamic boundary conditions and collecting the term at O ![]() $(\varepsilon )$ yields the linearised perturbation (Navier–Stokes) equations:

$(\varepsilon )$ yields the linearised perturbation (Navier–Stokes) equations:

where ![]() $D({\cdot })=\partial _{\hat {y}}({\cdot })$ is the wall-normal differential operator. The boundary conditions at the substrate (

$D({\cdot })=\partial _{\hat {y}}({\cdot })$ is the wall-normal differential operator. The boundary conditions at the substrate (![]() $\hat {y}=0$) reads

$\hat {y}=0$) reads

and, at the free surface (![]() $\hat {y}=\hat {h}$),

$\hat {y}=\hat {h}$),

We concatenate the streamwise ![]() $\tilde {u}$ and cross-stream

$\tilde {u}$ and cross-stream ![]() $\tilde {v}$ perturbations, by recasting (2.14) in terms of the stream function

$\tilde {v}$ perturbations, by recasting (2.14) in terms of the stream function ![]() $\varPsi$ defined as

$\varPsi$ defined as

and assuming a normal mode solution of the form

where ![]() $\varphi (\hat {y}) = \varphi _r(\hat {y}) + {\rm i}\varphi _i(\hat {y})$ and

$\varphi (\hat {y}) = \varphi _r(\hat {y}) + {\rm i}\varphi _i(\hat {y})$ and ![]() $\eta$ are the amplitudes of the stream function and the film thickness, respectively,

$\eta$ are the amplitudes of the stream function and the film thickness, respectively, ![]() $k=k_r + {\rm i}k_i$ is the wavenumber,

$k=k_r + {\rm i}k_i$ is the wavenumber, ![]() $\omega = \omega _r + {\rm i}\omega _i$ the angular frequency, and

$\omega = \omega _r + {\rm i}\omega _i$ the angular frequency, and ![]() $c=c_r + {\rm i}c_i=\omega /k$ is the perturbation's complex phase speed. This yields the following Orr–Sommerfeld eigenvalue problem:

$c=c_r + {\rm i}c_i=\omega /k$ is the perturbation's complex phase speed. This yields the following Orr–Sommerfeld eigenvalue problem:

where ![]() $\boldsymbol {A}(k,Re)$ is given by

$\boldsymbol {A}(k,Re)$ is given by

and ![]() $\boldsymbol {B}(k,Re)=\partial _c\boldsymbol {OS}(k,c,Re)$ is given by

$\boldsymbol {B}(k,Re)=\partial _c\boldsymbol {OS}(k,c,Re)$ is given by

with boundary conditions ![]() $\boldsymbol {OS}_{BC}\varphi |_{0,\hat {h}}=0$ defined as

$\boldsymbol {OS}_{BC}\varphi |_{0,\hat {h}}=0$ defined as

where ![]() $a = \bar {u}(\bar {h}) = (\bar {h}^2/2-1)$ is the base-state velocity at the interface.

$a = \bar {u}(\bar {h}) = (\bar {h}^2/2-1)$ is the base-state velocity at the interface.

The solution of the eigenvalue problem sets a relation between the wavenumber ![]() $k$ and angular frequency

$k$ and angular frequency ![]() $\omega$. This is known as the dispersion relation and depends on three parameters:

$\omega$. This is known as the dispersion relation and depends on three parameters:

These solutions are linked to the system's response to a local impulse, known as Green's function (Brevdo et al. Reference Brevdo, Laure, Dias and Bridges1999; Schmid & Henningson Reference Schmid and Henningson2001, pp. 270–271). It can be shown that these are the system's poles (Charru Reference Charru2011, p. 97) and, thus, control whether a disturbance grows or vanishes.

The analysis of poles for varying ![]() $\omega$ with a fixed

$\omega$ with a fixed ![]() $k$ is known as a temporal analysis, whereas the analysis of poles for varying

$k$ is known as a temporal analysis, whereas the analysis of poles for varying ![]() $k$ and fixed

$k$ and fixed ![]() $\omega$ is known as a spatial analysis. The images of any straight lines

$\omega$ is known as a spatial analysis. The images of any straight lines ![]() $k_i=\textit {C}$, where

$k_i=\textit {C}$, where ![]() $\textit {C}$ is an arbitrary constant, are called temporal branches in the complex frequency space, whereas the images of any straight line

$\textit {C}$ is an arbitrary constant, are called temporal branches in the complex frequency space, whereas the images of any straight line ![]() $\omega _i=\textit {E}$, where

$\omega _i=\textit {E}$, where ![]() $\textit {E}$ is an arbitrary constant, are called spatial branches in the complex wavenumber space (Kupfer, Bers & Ram Reference Kupfer, Bers and Ram1987). The points of intersection of spatial branches are called spatial branch points.

$\textit {E}$ is an arbitrary constant, are called spatial branches in the complex wavenumber space (Kupfer, Bers & Ram Reference Kupfer, Bers and Ram1987). The points of intersection of spatial branches are called spatial branch points.

For a real ![]() $k$, a base state is classified as temporally stable or unstable, depending on the value of the growth rate (

$k$, a base state is classified as temporally stable or unstable, depending on the value of the growth rate (![]() $\omega _i$): a state is unstable if

$\omega _i$): a state is unstable if ![]() $\omega _i>0$, as this results in the unbounded temporal growth of infinitesimal perturbation, whereas it is stable if

$\omega _i>0$, as this results in the unbounded temporal growth of infinitesimal perturbation, whereas it is stable if ![]() $\omega _i<0$, as this results in the return of the perturbed liquid film to its steady-state equilibrium conditions for all

$\omega _i<0$, as this results in the return of the perturbed liquid film to its steady-state equilibrium conditions for all ![]() $k$. The locus of points with zero growth rate (

$k$. The locus of points with zero growth rate (![]() $\omega _i=0$) corresponds to the neutral curve, with neither amplified nor damped perturbations.

$\omega _i=0$) corresponds to the neutral curve, with neither amplified nor damped perturbations.

A base state is absolutely unstable if the solution with zero group velocity ![]() $c_g=\partial \omega /\partial k=0$ has

$c_g=\partial \omega /\partial k=0$ has ![]() $\omega _i>0$ (Gaster Reference Gaster1968; Charru Reference Charru2011). The condition

$\omega _i>0$ (Gaster Reference Gaster1968; Charru Reference Charru2011). The condition ![]() $c_g=0$ is equivalent to

$c_g=0$ is equivalent to ![]() $\partial \omega _r/\partial k_r=\partial \omega _i/\partial k_r=0$ or, because of the Cauchy–Riemann relation, to

$\partial \omega _r/\partial k_r=\partial \omega _i/\partial k_r=0$ or, because of the Cauchy–Riemann relation, to ![]() $\partial \omega _i/\partial k_i=\partial \omega _r/\partial k_i=0$. Since both

$\partial \omega _i/\partial k_i=\partial \omega _r/\partial k_i=0$. Since both ![]() $\omega _r$ and

$\omega _r$ and ![]() $\omega _i$ must also satisfy the Laplace equation in the wavenumber domain

$\omega _i$ must also satisfy the Laplace equation in the wavenumber domain ![]() $k$ for a differentiable (holomorphic)

$k$ for a differentiable (holomorphic) ![]() $\omega (k)$, this implies that the condition

$\omega (k)$, this implies that the condition ![]() $c_g=\partial \omega /\partial k=0$ corresponds to a saddle point in the wavenumber domain

$c_g=\partial \omega /\partial k=0$ corresponds to a saddle point in the wavenumber domain ![]() $k$. However, not all saddle points are admissible; we return to this point in § 3.2.

$k$. However, not all saddle points are admissible; we return to this point in § 3.2.

3. Methodology

3.1. Numerical solution of the eigenvalue problem

Before presenting the numerical methods used to solve the Orr–Sommerfeld problem, we remove ![]() $\eta$ from the boundary conditions (2.22), substituting the kinematic condition (2.22b) into the shear stress balance (2.22d) and the original shear stress balance (2.22d) into the normal stress balance (2.22c) (Pelisson Chimetta, Hossain & de Moraes Franklin Reference Pelisson Chimetta, Hossain and de Moraes Franklin2018). The Orr–Sommerfeld eigenvalue problem (2.19) with the modified boundary conditions is solved using the Chebyshev–Tau spectral method (Johnson Reference Johnson1996; Canuto et al. Reference Canuto, Hussaini, Quarteroni and Thomas2012, Section. 3.1). The eigenfunction

$\eta$ from the boundary conditions (2.22), substituting the kinematic condition (2.22b) into the shear stress balance (2.22d) and the original shear stress balance (2.22d) into the normal stress balance (2.22c) (Pelisson Chimetta, Hossain & de Moraes Franklin Reference Pelisson Chimetta, Hossain and de Moraes Franklin2018). The Orr–Sommerfeld eigenvalue problem (2.19) with the modified boundary conditions is solved using the Chebyshev–Tau spectral method (Johnson Reference Johnson1996; Canuto et al. Reference Canuto, Hussaini, Quarteroni and Thomas2012, Section. 3.1). The eigenfunction ![]() $\varphi (\hat {y})$ is approximated with a combination of

$\varphi (\hat {y})$ is approximated with a combination of ![]() $N+1$ Chebyshev polynomials of the first kind, with the coefficients

$N+1$ Chebyshev polynomials of the first kind, with the coefficients ![]() $a_i$ being collected in the vector

$a_i$ being collected in the vector ![]() $\boldsymbol {\phi }=[a_0,a_1,\ldots,a_N]^{\rm T}$. The approximated eigenfunction is introduced in (2.19), and the residual is projected onto another base of Chebyshev polynomials of the first kind. This results in an algebraic system of

$\boldsymbol {\phi }=[a_0,a_1,\ldots,a_N]^{\rm T}$. The approximated eigenfunction is introduced in (2.19), and the residual is projected onto another base of Chebyshev polynomials of the first kind. This results in an algebraic system of ![]() $N+1$ equations representing a generalised eigenvalue problem with eigenvector

$N+1$ equations representing a generalised eigenvalue problem with eigenvector ![]() $\phi$ and eigenvalue

$\phi$ and eigenvalue ![]() $c$:

$c$:

with matrices ![]() $\mathsf{{A}}$ and

$\mathsf{{A}}$ and ![]() $\mathsf{{B}}$ representing the discretisation of the operators

$\mathsf{{B}}$ representing the discretisation of the operators ![]() $\boldsymbol {A}$ in (2.20) and

$\boldsymbol {A}$ in (2.20) and ![]() $\boldsymbol {B}$ in (2.21). Replacing the last four rows of the system in (3.1) with the modified boundary conditions (Boyd Reference Boyd2001, Section 6.4) leads to the generalised eigenvalue problem:

$\boldsymbol {B}$ in (2.21). Replacing the last four rows of the system in (3.1) with the modified boundary conditions (Boyd Reference Boyd2001, Section 6.4) leads to the generalised eigenvalue problem:

with ![]() $\hat {A}$ and

$\hat {A}$ and ![]() $\hat {B}$ representing matrices

$\hat {B}$ representing matrices ![]() $\mathsf{{A}}$ and

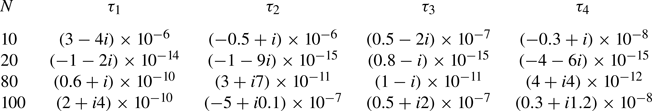

$\mathsf{{A}}$ and ![]() $\mathsf{{B}}$ in (3.1) with the enforced boundary conditions. The eigenvalue problem is solved using Python's function numpy.linalg.eig. The approximation error decreases as the magnitude of the four

$\mathsf{{B}}$ in (3.1) with the enforced boundary conditions. The eigenvalue problem is solved using Python's function numpy.linalg.eig. The approximation error decreases as the magnitude of the four ![]() $\tau$ coefficients is reduced Lanczos (Reference Lanczos1988, Chapter 7, § 12).

$\tau$ coefficients is reduced Lanczos (Reference Lanczos1988, Chapter 7, § 12).

To cope with the spurious eigenvalues (Dawkins, Dunbar & Douglass Reference Dawkins, Dunbar and Douglass1998; Bourne Reference Bourne2003), we solve (3.2) for ![]() $N=20$ and

$N=20$ and ![]() $N=80$, retaining the eigenvalues whose difference in magnitude, using the Euclidean norm (

$N=80$, retaining the eigenvalues whose difference in magnitude, using the Euclidean norm (![]() $\|{\cdot }\|$), is below 0.1 (Gardner, Trogdon & Douglass Reference Gardner, Trogdon and Douglass1989). Among these, that with the largest growth rate

$\|{\cdot }\|$), is below 0.1 (Gardner, Trogdon & Douglass Reference Gardner, Trogdon and Douglass1989). Among these, that with the largest growth rate ![]() $\omega_{i1}^{1}=c_{i1}^{1}/k$ (most unstable) is selected. To further improve the computational accuracy of the associated eigenvector

$\omega_{i1}^{1}=c_{i1}^{1}/k$ (most unstable) is selected. To further improve the computational accuracy of the associated eigenvector ![]() $\phi_{1}^{1}$, we run 10 iterations of the inverse power method (Trefethen & Bau Reference Trefethen and Bau2022, Lecture 27):

$\phi_{1}^{1}$, we run 10 iterations of the inverse power method (Trefethen & Bau Reference Trefethen and Bau2022, Lecture 27):

\begin{equation} \phi^{j+1} = \frac{(C - I/c_1)^{{-}1}\phi^{\{j\}}_{1}}{||(C - I/c_1)^{{-}1}\phi_1^{\{j\}}||}, \end{equation}

\begin{equation} \phi^{j+1} = \frac{(C - I/c_1)^{{-}1}\phi^{\{j\}}_{1}}{||(C - I/c_1)^{{-}1}\phi_1^{\{j\}}||}, \end{equation}

where ![]() $j\in \{1,2,\ldots,9\}$ is the iteration count and

$j\in \{1,2,\ldots,9\}$ is the iteration count and ![]() $C=\hat {A}^{-1}\hat {B}$. We defined

$C=\hat {A}^{-1}\hat {B}$. We defined ![]() $C$ in this way, with the inverse of

$C$ in this way, with the inverse of ![]() $\hat {A}$ rather than the inverse of

$\hat {A}$ rather than the inverse of ![]() $\hat {B}$, because

$\hat {B}$, because ![]() $\hat {B}$ is always singular.

$\hat {B}$ is always singular.

Given ![]() $Ka$ and

$Ka$ and ![]() $\hat {h}$, to compute the neutral stability curves in the

$\hat {h}$, to compute the neutral stability curves in the ![]() $k$–

$k$–![]() $Re$ space with

$Re$ space with ![]() $k\in \mathbb {R}$, we start from the long-wave most-unstable mode (

$k\in \mathbb {R}$, we start from the long-wave most-unstable mode (![]() $(\phi_1,c_1)$ with the largest

$(\phi_1,c_1)$ with the largest ![]() $c_i$), with

$c_i$), with ![]() $k^{\{1\}}=3.5\times 10^{-6}$, and we march it along the discrete

$k^{\{1\}}=3.5\times 10^{-6}$, and we march it along the discrete ![]() $k$ axis running 20 iterations of Rayleigh quotient iteration at every point

$k$ axis running 20 iterations of Rayleigh quotient iteration at every point ![]() $k^{\{j\}}$ and collecting the values of

$k^{\{j\}}$ and collecting the values of ![]() $c^{\{j\}}$:

$c^{\{j\}}$:

\begin{equation} \phi_1^{\{j+1\}} = \frac{(C - I/c_1^{(j)})\phi_1^{\{j\}}}{||(C - 1/c_1^{\{j\}})^{{-}1}\phi_1^{\{j\}}||}, \quad I/c_1^{\{j+1\}} = \frac{\phi_1^{*\{j+1\}}C\phi_1^{\{j+1\}}}{\phi_1^{*\{j+1\}}\phi_1^{\{j+1\}}}, \end{equation}

\begin{equation} \phi_1^{\{j+1\}} = \frac{(C - I/c_1^{(j)})\phi_1^{\{j\}}}{||(C - 1/c_1^{\{j\}})^{{-}1}\phi_1^{\{j\}}||}, \quad I/c_1^{\{j+1\}} = \frac{\phi_1^{*\{j+1\}}C\phi_1^{\{j+1\}}}{\phi_1^{*\{j+1\}}\phi_1^{\{j+1\}}}, \end{equation}

where ![]() ${\cdot }^*$ denotes complex conjugate. Thereby, converting

${\cdot }^*$ denotes complex conjugate. Thereby, converting ![]() $c_i$ into

$c_i$ into ![]() $\omega _i$, we find the growth rate as a function of

$\omega _i$, we find the growth rate as a function of ![]() $k$. The zero of this curve

$k$. The zero of this curve ![]() $k_f$ (

$k_f$ (![]() $k\in \mathbb {R}:\omega _i(k)=0\wedge k\neq 0$), also known as the cutoff frequency, belongs to the neutral curve. The neutral curve is constructed by repeating this procedure varying

$k\in \mathbb {R}:\omega _i(k)=0\wedge k\neq 0$), also known as the cutoff frequency, belongs to the neutral curve. The neutral curve is constructed by repeating this procedure varying ![]() $Re$.

$Re$.

3.2. Numerical method for zero group-velocity perturbation

To assess whether a base state is absolutely or convectively unstable, we follow Brigg's method (outlined in Schmid & Henningson Reference Schmid and Henningson2001, Subsection 7.2.2). This consists of mapping the complex ![]() $k$ space into the complex

$k$ space into the complex ![]() $\omega$ space, identifying the saddle points, and checking a posteriori if these respect the causality condition using the collision criterion (Briggs Reference Briggs1964; Huerre & Monkewitz Reference Huerre and Monkewitz1985; Thual, Thual & Dewitte Reference Thual, Thual and Dewitte2013; Avanci, Rodríguez & Alves Reference Avanci, Rodríguez and Alves2019). According to this criterion, the only valid saddle points arise as spatial branch points, pinching two spatial branches coming from the positive and negative half-planes of the complex wavenumber space. Depending on the value of the growth rate in these points, the base state is convectively (

$\omega$ space, identifying the saddle points, and checking a posteriori if these respect the causality condition using the collision criterion (Briggs Reference Briggs1964; Huerre & Monkewitz Reference Huerre and Monkewitz1985; Thual, Thual & Dewitte Reference Thual, Thual and Dewitte2013; Avanci, Rodríguez & Alves Reference Avanci, Rodríguez and Alves2019). According to this criterion, the only valid saddle points arise as spatial branch points, pinching two spatial branches coming from the positive and negative half-planes of the complex wavenumber space. Depending on the value of the growth rate in these points, the base state is convectively (![]() $\omega _i<0$) or absolutely (

$\omega _i<0$) or absolutely (![]() $\omega _i>0$) unstable.

$\omega _i>0$) unstable.

Given a set of parameters (![]() $Re$,

$Re$, ![]() $Ka$,

$Ka$, ![]() $\hat {h}$), we explore a portion of the complex wavenumber space

$\hat {h}$), we explore a portion of the complex wavenumber space ![]() $k_i\in [k_{i_{min}},k_{i_{max}}]$ and

$k_i\in [k_{i_{min}},k_{i_{max}}]$ and ![]() $k_r\in [k_{r_{min}},k_{r_{max}}]$, discretised with a uniform mesh of

$k_r\in [k_{r_{min}},k_{r_{max}}]$, discretised with a uniform mesh of ![]() $M\times M$ elements with spacing

$M\times M$ elements with spacing ![]() $\Delta k_i$ and

$\Delta k_i$ and ![]() $\Delta k_r$. Starting from the most-unstable mode

$\Delta k_r$. Starting from the most-unstable mode ![]() $(\phi_1,c_1)$, obtained solving the Orr–Sommerfeld problem (3.2) for a given pair (

$(\phi_1,c_1)$, obtained solving the Orr–Sommerfeld problem (3.2) for a given pair (![]() $k_r^{\{1\}},k_i^{\{1\}}$), we march over the discretised wavenumber space running 20 iterations of Rayleigh quotient iteration (3.4) at every point (

$k_r^{\{1\}},k_i^{\{1\}}$), we march over the discretised wavenumber space running 20 iterations of Rayleigh quotient iteration (3.4) at every point (![]() $k_r^{\{j\}},k_i^{\{j\}}$) and collecting the values of

$k_r^{\{j\}},k_i^{\{j\}}$) and collecting the values of ![]() $c^{\{j\}}$. The solution at one point of the grid serves as a starting point for the computation of the solution in the adjacent one. We march over the wavenumber space with a spiral matrix algorithm to avoid two consecutive steps falling outside the iterative method's convergence region. Given the computed mapping

$c^{\{j\}}$. The solution at one point of the grid serves as a starting point for the computation of the solution in the adjacent one. We march over the wavenumber space with a spiral matrix algorithm to avoid two consecutive steps falling outside the iterative method's convergence region. Given the computed mapping ![]() $\omega _r(k_r,k_i),\omega _i(k_r,k_i)$, we calculate the saddle point location using numerical differentiation and checking the collision condition.

$\omega _r(k_r,k_i),\omega _i(k_r,k_i)$, we calculate the saddle point location using numerical differentiation and checking the collision condition.

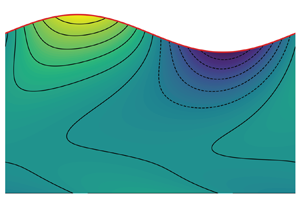

Figure 3(a) presents an example of the mapping, with ![]() $\omega _i$ colour plot and contour map as a function of

$\omega _i$ colour plot and contour map as a function of ![]() $k$, along with the position of the saddle point (red point). To check whether the collision criterion is satisfied, we check the position of the saddle point in the complex

$k$, along with the position of the saddle point (red point). To check whether the collision criterion is satisfied, we check the position of the saddle point in the complex ![]() $\omega$ space. Figure 3(b) shows the saddle point position (red dot) in the complex

$\omega$ space. Figure 3(b) shows the saddle point position (red dot) in the complex ![]() $\omega$ space and the temporal branches of the first five modes (coloured lines), sorted by ascending values of

$\omega$ space and the temporal branches of the first five modes (coloured lines), sorted by ascending values of ![]() $\omega _i$, along the path

$\omega _i$, along the path ![]() $k_i=0$. The collision criterion is respected if the saddle point is surmounted by an odd number of spatial branches (Kupfer et al. Reference Kupfer, Bers and Ram1987; Suslov Reference Suslov2006).

$k_i=0$. The collision criterion is respected if the saddle point is surmounted by an odd number of spatial branches (Kupfer et al. Reference Kupfer, Bers and Ram1987; Suslov Reference Suslov2006).

Figure 3. Position of the saddle point (red dot) for the zinc with ![]() $\hat {h}=0.8885$,

$\hat {h}=0.8885$, ![]() $Re=30$ (a) in the complex

$Re=30$ (a) in the complex ![]() $k$ space with the colourmap of

$k$ space with the colourmap of ![]() $\omega _i$ and (b) in the complex frequency space with the cusp (black dashed line) and the spatial branches of the first four modes (coloured lines), sorted by ascending values of

$\omega _i$ and (b) in the complex frequency space with the cusp (black dashed line) and the spatial branches of the first four modes (coloured lines), sorted by ascending values of ![]() $\omega _i$, obtained solving the Orr–Sommerfeld problem along the path

$\omega _i$, obtained solving the Orr–Sommerfeld problem along the path ![]() $k_i=0$ in the complex wavenumber space.

$k_i=0$ in the complex wavenumber space.

To determine the AC instability threshold (saddle point with ![]() $\omega _i=0$), we explore the parameter spaces (

$\omega _i=0$), we explore the parameter spaces (![]() $Ka$–

$Ka$–![]() $Re$) and (

$Re$) and (![]() $\hat {h}$–

$\hat {h}$–![]() $Re$). We fix

$Re$). We fix ![]() $Re$ and run a line search along the other parameter. A detailed pseudocode description is reported in Appendix A.

$Re$ and run a line search along the other parameter. A detailed pseudocode description is reported in Appendix A.

4. Energy balance and mechanism of the unstable perturbation

To understand the onset mechanism of unstable perturbations, we solve the linearised Navier–Stokes equations via a long-wave asymptotic expansion up to ![]() $O(k^2)$ in § 4.1. In addition, to gain a deeper insight into the growth mechanism of unstable perturbations for any

$O(k^2)$ in § 4.1. In addition, to gain a deeper insight into the growth mechanism of unstable perturbations for any ![]() $k$, we derive the kinetic energy balance for the perturbations in § 4.2.

$k$, we derive the kinetic energy balance for the perturbations in § 4.2.

4.1. Mechanism of long-wave instability in a moving reference frame

We consider a solution of (2.14) with boundary conditions (2.15) and (2.16) in the form of normal modes given by

where the ![]() $\acute {{\cdot }}$ denotes the amplitudes. We consider a reference system moving with the substrate velocity

$\acute {{\cdot }}$ denotes the amplitudes. We consider a reference system moving with the substrate velocity ![]() $U_p$ (

$U_p$ (![]() $\hat {u}=-1$), with the change of variables:

$\hat {u}=-1$), with the change of variables:

where ![]() $\acute {u}_m$,

$\acute {u}_m$, ![]() $c_m$ and

$c_m$ and ![]() $\bar {u}_m$ are the streamwise velocity amplitude, the phase speed and the base state velocity in the moving reference frame. We seek an approximated solution via long-wave expansion of the amplitudes and the phase speed up to

$\bar {u}_m$ are the streamwise velocity amplitude, the phase speed and the base state velocity in the moving reference frame. We seek an approximated solution via long-wave expansion of the amplitudes and the phase speed up to ![]() $O(k)$ (Benjamin Reference Benjamin1957; Yih Reference Yih1963; Smith Reference Smith1990):

$O(k)$ (Benjamin Reference Benjamin1957; Yih Reference Yih1963; Smith Reference Smith1990):

with the normalisation ![]() $\eta _0 = 1$ and

$\eta _0 = 1$ and ![]() $\eta _1=0$. Collecting the terms at

$\eta _1=0$. Collecting the terms at ![]() $O(1)$ gives the system

$O(1)$ gives the system

with boundary conditions

At ![]() $O(k)$, we obtain the system

$O(k)$, we obtain the system

with the boundary conditions

The solution of these systems is presented in § 5.2.

4.2. Energy balance of the perturbation

To study the instability mechanism, we analyse the contributions to the perturbation's kinetic energy equation as in Kelly et al. (Reference Kelly, Goussis, Lin and Hsu1989) and Lin (Reference Lin1970). This equation is obtained by summing up the product of (2.14b) by ![]() $\tilde {u}$ and of (2.14c) by

$\tilde {u}$ and of (2.14c) by ![]() $\tilde {v}$, averaging over a wavelength

$\tilde {v}$, averaging over a wavelength ![]() $\lambda$, integrating over the liquid-film thickness

$\lambda$, integrating over the liquid-film thickness ![]() $\hat {h}$ and then using (2.14a) and the boundary conditions (2.15) and (2.16c) to obtain

$\hat {h}$ and then using (2.14a) and the boundary conditions (2.15) and (2.16c) to obtain

with

\begin{gather} {\rm RKINE} =\frac{1}{2\lambda}\frac{{\rm d}}{{\rm d}t}\int_{0}^{\lambda}\int_{0}^{\hat{h}}(\tilde{u}^2 + \tilde{v}^2)\,{\rm d}\hat{y}\,{\rm d}\hat{x}, \end{gather}

\begin{gather} {\rm RKINE} =\frac{1}{2\lambda}\frac{{\rm d}}{{\rm d}t}\int_{0}^{\lambda}\int_{0}^{\hat{h}}(\tilde{u}^2 + \tilde{v}^2)\,{\rm d}\hat{y}\,{\rm d}\hat{x}, \end{gather} \begin{gather}{\rm REYNS} ={-}\frac{1}{\lambda}\int_{0}^{\lambda}\int_{0}^{\hat{h}}\tilde{u}\tilde{v}D\bar{u}\,{\rm d}\hat{y}\,{\rm d}\hat{x}, \end{gather}

\begin{gather}{\rm REYNS} ={-}\frac{1}{\lambda}\int_{0}^{\lambda}\int_{0}^{\hat{h}}\tilde{u}\tilde{v}D\bar{u}\,{\rm d}\hat{y}\,{\rm d}\hat{x}, \end{gather} The terms on the left-hand side represent the energy stored in the perturbation in the form of kinetic (RKINE) and surface tension potential (SURTE) energies. The terms on the right-hand side represent the energy extracted from the base state through the work of shear stress at the interface (SHEST), Reynolds stress (REYNS) and dissipative viscous effects (DISSI). DISSI encompass the contribution of extensional (![]() ${\rm DISSI}_1$ and

${\rm DISSI}_1$ and ![]() ${\rm DISSI}_3$) and shear terms (

${\rm DISSI}_3$) and shear terms (![]() ${\rm DISSI}_2$), given by

${\rm DISSI}_2$), given by

\begin{gather} {\rm DISSI}_1 ={-}\frac{1}{Re\,\lambda}\int_{0}^{\lambda}\int_{0}^{\hat{h}} 2(\partial_{\hat{x}}\tilde{u})^2 \,{\rm d}\hat{y}\,{\rm d}\hat{x}, \end{gather}

\begin{gather} {\rm DISSI}_1 ={-}\frac{1}{Re\,\lambda}\int_{0}^{\lambda}\int_{0}^{\hat{h}} 2(\partial_{\hat{x}}\tilde{u})^2 \,{\rm d}\hat{y}\,{\rm d}\hat{x}, \end{gather} \begin{gather}{\rm DISSI}_2 ={-}\frac{1}{Re\,\lambda}\int_{0}^{\lambda}\int_{0}^{\hat{h}} \upsilon^2 \,{\rm d}\hat{y}\,{\rm d}\hat{x}, \end{gather}

\begin{gather}{\rm DISSI}_2 ={-}\frac{1}{Re\,\lambda}\int_{0}^{\lambda}\int_{0}^{\hat{h}} \upsilon^2 \,{\rm d}\hat{y}\,{\rm d}\hat{x}, \end{gather} \begin{gather}{\rm DISSI}_3 ={-}\frac{1}{Re\,\lambda}\int_{0}^{\lambda}\int_{0}^{\hat{h}} 2(\partial_{\hat{y}}\tilde{v})^2\,{\rm d}\hat{y}\,{\rm d}\hat{x}, \end{gather}

\begin{gather}{\rm DISSI}_3 ={-}\frac{1}{Re\,\lambda}\int_{0}^{\lambda}\int_{0}^{\hat{h}} 2(\partial_{\hat{y}}\tilde{v})^2\,{\rm d}\hat{y}\,{\rm d}\hat{x}, \end{gather}

where ![]() $\upsilon = \partial _{\hat {y}}\tilde {u} + \partial _{\hat {x}}\tilde {v}$ is proportional to the strain rate. The perturbation quantities are given by

$\upsilon = \partial _{\hat {y}}\tilde {u} + \partial _{\hat {x}}\tilde {v}$ is proportional to the strain rate. The perturbation quantities are given by

with

where ![]() $\tilde {\omega }$ is the perturbation vorticity.

$\tilde {\omega }$ is the perturbation vorticity.

Using the kinematic condition (2.22b), the real ![]() $\eta _r$ and imaginary

$\eta _r$ and imaginary ![]() $\eta _i$ parts of surface deflection are given by

$\eta _i$ parts of surface deflection are given by

where ![]() $\hat {c} = c_r - a$. To have an accurate computation of the terms in (4.8a), we calculate the integral along

$\hat {c} = c_r - a$. To have an accurate computation of the terms in (4.8a), we calculate the integral along ![]() $\hat {x}$ analytically and along

$\hat {x}$ analytically and along ![]() $\hat {y}$ numerically, using the Simpson's rule over a grid of

$\hat {y}$ numerically, using the Simpson's rule over a grid of ![]() $10^4$ equispaced points in the range

$10^4$ equispaced points in the range ![]() $[0,\hat {h}]$ such that the difference in magnitude between the right-hand side and the left-hand side of (4.8a) is below

$[0,\hat {h}]$ such that the difference in magnitude between the right-hand side and the left-hand side of (4.8a) is below ![]() $1\,\%$ of the kinetic energy (RKINE) (Lin, Lian & Creighton Reference Lin, Lian and Creighton1990).

$1\,\%$ of the kinetic energy (RKINE) (Lin, Lian & Creighton Reference Lin, Lian and Creighton1990).

5. Results and discussion

In this section, we report the results of the linear stability analysis in terms of neutral curves and growth rates (§ 5.1), instability mechanism (§ 5.2) and AC threshold (§ 5.3) for the fluids in table 1. Moreover, we compute the threshold for the Derjaguin's flat film solution (![]() $\hat {h}=1$) in the (

$\hat {h}=1$) in the (![]() $Ka$–

$Ka$–![]() $Re$) parameter space.

$Re$) parameter space.

The Orr–Sommerfeld eigenvalue problem (2.19) is solved using ![]() $N=20$ Chebyshev polynomials in the approximation of the stream function amplitude, and a grid spacing for the saddle point search of

$N=20$ Chebyshev polynomials in the approximation of the stream function amplitude, and a grid spacing for the saddle point search of ![]() $\Delta k_r=2.5\times 10^{-4}$ and

$\Delta k_r=2.5\times 10^{-4}$ and ![]() $\Delta k_i=3\times 10^{-4}$ (see Appendix B.1). To verify our implementation, we compare the dispersion relations and the eigenfunctions against a long-wave asymptotic expansion of the Orr–Sommerfeld problem up to the third order in

$\Delta k_i=3\times 10^{-4}$ (see Appendix B.1). To verify our implementation, we compare the dispersion relations and the eigenfunctions against a long-wave asymptotic expansion of the Orr–Sommerfeld problem up to the third order in ![]() $k$ (see Appendix B.2).

$k$ (see Appendix B.2).

5.1. Neutral stability curves and growth rates

First, we compare the neutral stability curves given by the numerical solution of the Orr–Sommerfeld problem and by analytical representation. These representations are obtained by calculating the zeros of the long-wave approximation obtained in Appendix B.1, i.e. cancelling ![]() $c_1^\star$ in (B5), leading to the expression

$c_1^\star$ in (B5), leading to the expression

\begin{equation} k = \sqrt{\frac{2}{5}\frac{\hat{h}^3}{Ka}Re^{5/3}}, \end{equation}

\begin{equation} k = \sqrt{\frac{2}{5}\frac{\hat{h}^3}{Ka}Re^{5/3}}, \end{equation}

for an expansion up to ![]() $O(k)$ with the surface tension correction at leading order (

$O(k)$ with the surface tension correction at leading order (![]() $Ca^{-1} k^2 = O(1)$), and to the expression

$Ca^{-1} k^2 = O(1)$), and to the expression

\begin{equation} k = \frac{24 \sqrt{15015}\hat{h}^{3/2} \sqrt{Re}}{\sqrt{2{\,}427{\,}904 \hat{h}^{11} Re^3+45{\,}463{\,}275 \hat{h}^5Re+21{\,}621{\,}600 \dfrac{Ka}{Re^{2/3}}}}, \end{equation}

\begin{equation} k = \frac{24 \sqrt{15015}\hat{h}^{3/2} \sqrt{Re}}{\sqrt{2{\,}427{\,}904 \hat{h}^{11} Re^3+45{\,}463{\,}275 \hat{h}^5Re+21{\,}621{\,}600 \dfrac{Ka}{Re^{2/3}}}}, \end{equation}

for an expansion up to ![]() $O(k^3)$ without correction. Figure 4 shows the approximated neutral curves and the one obtained with the spectral methods for

$O(k^3)$ without correction. Figure 4 shows the approximated neutral curves and the one obtained with the spectral methods for ![]() $\hat {h}\in [0.2,0.5,0.8]$ considering (a) zinc (

$\hat {h}\in [0.2,0.5,0.8]$ considering (a) zinc (![]() $Ka=11\,525$) and (b) water (

$Ka=11\,525$) and (b) water (![]() $Ka=3400$). The instability region lies between the curve and the

$Ka=3400$). The instability region lies between the curve and the ![]() $k=0$ axis. The analytical expressions agree with the numerics for small values of

$k=0$ axis. The analytical expressions agree with the numerics for small values of ![]() $\hat {h}$. The solution with correction agrees better than the full third-order solution, which highlights the validity of the assumption

$\hat {h}$. The solution with correction agrees better than the full third-order solution, which highlights the validity of the assumption ![]() $Ca^{-1}\times k^2=O(1)$ for large

$Ca^{-1}\times k^2=O(1)$ for large ![]() $Ka$ and small

$Ka$ and small ![]() $\hat {h}$.

$\hat {h}$.

Figure 4. Neutral curves separating the region of stable (above) and unstable (below) wavenumbers, based on asymptotic expansions with surface tension correction up to ![]() $O(k)$ (orange dash-dotted line with triangles) and without correction up to

$O(k)$ (orange dash-dotted line with triangles) and without correction up to ![]() $O(k^3)$ (green dashed line with squares), against the numerical ones (continuous blue line), for

$O(k^3)$ (green dashed line with squares), against the numerical ones (continuous blue line), for ![]() $\hat {h}\in [0.2,0.5,0.8]$ with (a) zinc (

$\hat {h}\in [0.2,0.5,0.8]$ with (a) zinc (![]() $Ka=11\,525$) and (b) water

$Ka=11\,525$) and (b) water ![]() $(Ka=3400)$.

$(Ka=3400)$.

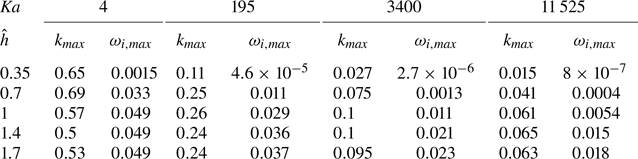

Going into more depth in the analysis of the neutral curves and the dispersion relations, figures 5 and 6 show the numerical neutral curves for different values of ![]() $\hat {h}$ and the dispersion relations with axes normalised with the maximum value of

$\hat {h}$ and the dispersion relations with axes normalised with the maximum value of ![]() $\omega _i$ (

$\omega _i$ (![]() $\max (\omega _i)$) and the cutoff wavenumber

$\max (\omega _i)$) and the cutoff wavenumber ![]() $k_m$ at

$k_m$ at ![]() $Re=30$ for the four liquids. The wavenumber

$Re=30$ for the four liquids. The wavenumber ![]() $k_{max}$ and the magnitudes

$k_{max}$ and the magnitudes ![]() $\omega _{i,max}$ of the growth rate peaks are reported in table 2. For

$\omega _{i,max}$ of the growth rate peaks are reported in table 2. For ![]() $\hat {h}\leq 1$,

$\hat {h}\leq 1$, ![]() $\omega _i$ gradually increases with

$\omega _i$ gradually increases with ![]() $k$, up to the peak, then sharply decreases towards

$k$, up to the peak, then sharply decreases towards ![]() $k_m$. For

$k_m$. For ![]() $\hat {h}>1$,

$\hat {h}>1$, ![]() $\omega _i$ reaches the peak after a steep increase, and then it gently reaches

$\omega _i$ reaches the peak after a steep increase, and then it gently reaches ![]() $k_m$.

$k_m$.

Figure 5. (a,c) Neutral curves for different values of the non-dimensional liquid-film thickness ![]() $\hat {h}$, (b,d) dispersion relations normalised with

$\hat {h}$, (b,d) dispersion relations normalised with ![]() $\max (\omega _i)$ and the cutoff frequency

$\max (\omega _i)$ and the cutoff frequency ![]() $k_c$ for

$k_c$ for ![]() $Re=30$ for (a,b) liquid zinc (

$Re=30$ for (a,b) liquid zinc (![]() $Ka=11\,525$) and (c,d) water

$Ka=11\,525$) and (c,d) water ![]() $(Ka=3400)$.

$(Ka=3400)$.

Figure 6. (a,c) Neutral curve and (b,d) dispersion relations normalised with ![]() $\max (\omega _i)$ and the cutoff frequency

$\max (\omega _i)$ and the cutoff frequency ![]() $k_c$, for

$k_c$, for ![]() $Re=30$ and different values of

$Re=30$ and different values of ![]() $\hat {h}$, for (a,b) liquid water–glycerol (

$\hat {h}$, for (a,b) liquid water–glycerol (![]() $Ka=195$) solution and (c,d) corn oil (

$Ka=195$) solution and (c,d) corn oil (![]() $Ka=4$).

$Ka=4$).

Table 2. Peak of growth rate ![]() $\omega _{i,max}$ and the associated wavenumber

$\omega _{i,max}$ and the associated wavenumber ![]() $k_{max}$ for different liquids and

$k_{max}$ for different liquids and ![]() $\hat {h}$ at

$\hat {h}$ at ![]() $Re =30$.

$Re =30$.

As for the growth rate, ![]() $\hat {h}$ also influences the neutral stability curves. For the four fluids, the instability region enlarges for large

$\hat {h}$ also influences the neutral stability curves. For the four fluids, the instability region enlarges for large ![]() $\hat {h}$ and small

$\hat {h}$ and small ![]() $Ka$, with curves progressively gathering around the same wavenumbers for thick film conditions (

$Ka$, with curves progressively gathering around the same wavenumbers for thick film conditions (![]() $\hat {h}>1$), with the limit case of corn oil (

$\hat {h}>1$), with the limit case of corn oil (![]() $Ka=4$), where the neutral curves are almost superimposed. Similar behaviour is also visible in the dispersion relations. As

$Ka=4$), where the neutral curves are almost superimposed. Similar behaviour is also visible in the dispersion relations. As ![]() $Ka$ decreases, the relative distance between the peaks’ positions for

$Ka$ decreases, the relative distance between the peaks’ positions for ![]() $\hat {h}> 0.35$ shrinks, with the limit case of corn oil (

$\hat {h}> 0.35$ shrinks, with the limit case of corn oil (![]() $Ka=4$) where the curves for

$Ka=4$) where the curves for ![]() $\hat {h}=0.4$ and

$\hat {h}=0.4$ and ![]() $\hat {h}=1$ also change shapes, becoming similar to those for

$\hat {h}=1$ also change shapes, becoming similar to those for ![]() $\hat {h}>1$.

$\hat {h}>1$.

This highlights stabilising mechanisms given by the balance of inertia, viscous and gravitational forces without the effect of surface tension. As ![]() $Ka$ decreases, the stabilising effects of the surface tension diminish compared with the viscous effects. Even when increasing

$Ka$ decreases, the stabilising effects of the surface tension diminish compared with the viscous effects. Even when increasing ![]() $\hat {h}$, the instability region does not expand much. This suggests that neutral modes with

$\hat {h}$, the instability region does not expand much. This suggests that neutral modes with ![]() $k=O(1)$ arise as an equilibrium of mostly viscous and gravitational forces, which is not linked to the velocity of the plate. Indeed, increasing

$k=O(1)$ arise as an equilibrium of mostly viscous and gravitational forces, which is not linked to the velocity of the plate. Indeed, increasing ![]() $Re$ does not change the relative position of the neutral curves; it just brings this equilibrium point to larger

$Re$ does not change the relative position of the neutral curves; it just brings this equilibrium point to larger ![]() $k$.

$k$.

Figure 7 shows the evolution of (a) the ![]() $\omega _i$ peak magnitude

$\omega _i$ peak magnitude ![]() $\max (\omega _i)$ and (b) the wavenumber

$\max (\omega _i)$ and (b) the wavenumber ![]() $k_{max}$ varying

$k_{max}$ varying ![]() $\hat {h}$ for the different fluids. As

$\hat {h}$ for the different fluids. As ![]() $Ka$ decreases, the maximum growth rate increases. Corn oil (

$Ka$ decreases, the maximum growth rate increases. Corn oil (![]() $Ka=4$) has the largest growth rates of all the

$Ka=4$) has the largest growth rates of all the ![]() $\hat {h}$ with its peaks overlapping for

$\hat {h}$ with its peaks overlapping for ![]() $\hat {h}\geq 1$.

$\hat {h}\geq 1$.

Figure 7. Values of (a) the maximum growth rate ![]() $\max (\omega _i)$ and (b) the associated wavenumber

$\max (\omega _i)$ and (b) the associated wavenumber ![]() $k_m$ for different

$k_m$ for different ![]() $\hat {h}$ and liquids at

$\hat {h}$ and liquids at ![]() $Re=30$.

$Re=30$.

Interestingly, the peaks’ locations do not have a monotonic behaviour with ![]() $\hat {h}$. For the corn oil (

$\hat {h}$. For the corn oil (![]() $Ka=4$), the peak position advances towards smaller wavelengths for

$Ka=4$), the peak position advances towards smaller wavelengths for ![]() $\hat {h}=0.7$, and then it goes to longer wavelengths for higher values of

$\hat {h}=0.7$, and then it goes to longer wavelengths for higher values of ![]() $\hat {h}$. As

$\hat {h}$. As ![]() $Ka$ increases, the peak is located at smaller wavenumbers, and it moves to

$Ka$ increases, the peak is located at smaller wavenumbers, and it moves to ![]() $\hat {h}=1.7$ passing through

$\hat {h}=1.7$ passing through ![]() $\hat {h}=1$ for the water–glycerol (

$\hat {h}=1$ for the water–glycerol (![]() $Ka=195$) solution.

$Ka=195$) solution.

The liquid-film height ![]() $\hat {h}$ and the Kapitza number also play a role in the phase speed of the unstable perturbations. Figure 8 shows how the phase speed

$\hat {h}$ and the Kapitza number also play a role in the phase speed of the unstable perturbations. Figure 8 shows how the phase speed ![]() $c_r$ as a function of the wavenumber

$c_r$ as a function of the wavenumber ![]() $k$ and the liquid-film height

$k$ and the liquid-film height ![]() $\hat {h}$ at

$\hat {h}$ at ![]() $Re=30$ with a highlight on the neutral curve (continuous white line) and the positions of the maximum growth rate (white dashed line) for (a) liquid zinc (

$Re=30$ with a highlight on the neutral curve (continuous white line) and the positions of the maximum growth rate (white dashed line) for (a) liquid zinc (![]() $Ka=11\,525$), (b) water (

$Ka=11\,525$), (b) water (![]() $Ka=3400$) and (c) corn oil (

$Ka=3400$) and (c) corn oil (![]() $Ka=4$). As we move along

$Ka=4$). As we move along ![]() $k$ for a fixed

$k$ for a fixed ![]() $\hat {h}$, the phase speed varies first linearly (for small

$\hat {h}$, the phase speed varies first linearly (for small ![]() $\hat {h}$) and then nonlinearly (for large

$\hat {h}$) and then nonlinearly (for large ![]() $\hat {h}$). This relation is quadratic for zinc (

$\hat {h}$). This relation is quadratic for zinc (![]() $Ka=11\,525$) and water, with the minimum at the same wavenumber of the maximum growth rate. In contrast, for the corn oil (

$Ka=11\,525$) and water, with the minimum at the same wavenumber of the maximum growth rate. In contrast, for the corn oil (![]() $Ka=4$), after a steep variation for

$Ka=4$), after a steep variation for ![]() $k\rightarrow 0$, it becomes linear again with a minimum not coinciding with the peak of growth rate. As we move along

$k\rightarrow 0$, it becomes linear again with a minimum not coinciding with the peak of growth rate. As we move along ![]() $\hat {h}$ for a fixed

$\hat {h}$ for a fixed ![]() $k$, the phase speed of long waves varies quadratically with

$k$, the phase speed of long waves varies quadratically with ![]() $\hat {h}$, in accordance with the leading order approximation of the asymptotic expansion (B3) (

$\hat {h}$, in accordance with the leading order approximation of the asymptotic expansion (B3) (![]() $c_r = \hat {h}^2-1$). As we increase

$c_r = \hat {h}^2-1$). As we increase ![]() $k$, this approximation loses validity, with waves propagating slower. This relation tends to become linear as we move to shorter wavelengths. The slope of this relationship changes with

$k$, this approximation loses validity, with waves propagating slower. This relation tends to become linear as we move to shorter wavelengths. The slope of this relationship changes with ![]() $k$ and

$k$ and ![]() $Ka$, becoming almost insensitive to

$Ka$, becoming almost insensitive to ![]() $k$, in the case of corn oil (

$k$, in the case of corn oil (![]() $Ka=4$). High

$Ka=4$). High ![]() $Ka$, the most-unstable mode, travels slower than any other unstable mode.

$Ka$, the most-unstable mode, travels slower than any other unstable mode.

Figure 8. Coloured surface showing the real part of the phase speed ![]() $c_r$ as a function of the wavenumber

$c_r$ as a function of the wavenumber ![]() $k$ and the flat liquid-film height

$k$ and the flat liquid-film height ![]() $\hat {h}$ at

$\hat {h}$ at ![]() $Re=30$ with the neutral curve (white continuous line) and maximum growth rate (white dashed line) for (a) liquid zinc (

$Re=30$ with the neutral curve (white continuous line) and maximum growth rate (white dashed line) for (a) liquid zinc (![]() $Ka=11\,525$), (b) water (

$Ka=11\,525$), (b) water (![]() $Ka=3400$) and (c) corn oil (

$Ka=3400$) and (c) corn oil (![]() $Ka=4$).

$Ka=4$).

5.2. Long-wave mechanism and energy balance of the unstable perturbation

In this subsection, we describe the mechanism behind the growth of unstable perturbations using momentum and vorticity arguments. Moreover, we investigate how the perturbation's energy is extracted and stored depending on the values of the non-dimensional groups and the liquid-film height, highlighting the role of viscous terms. In the falling-liquid-film case, Kelly et al. (Reference Kelly, Goussis, Lin and Hsu1989), with the energy-based approach, and Smith (Reference Smith1990), with asymptotic expansions, showed that the long-wave instability is fed by a streamwise flow field resulting from the base state's shear stress deficiency at the free-surface.

5.2.1. Long-wave instability mechanism

Considering the harmonic disturbance ![]() $\tilde {h}$ over a flat interface

$\tilde {h}$ over a flat interface ![]() $\bar {h}$ (see § 4.1), the shear stress at the perturbed interface is given by a base state and a perturbation contribution. Expanding

$\bar {h}$ (see § 4.1), the shear stress at the perturbed interface is given by a base state and a perturbation contribution. Expanding ![]() $D \hat {u}$ around the base state thickness

$D \hat {u}$ around the base state thickness ![]() $\bar {h}$, we obtain, at first order,

$\bar {h}$, we obtain, at first order,

Since the base state is shear-free at the interface (![]() $D\bar {u}(\bar {h})=0$) and knowing that

$D\bar {u}(\bar {h})=0$) and knowing that ![]() $D^2\bar {u}(\bar {h})=-1$, (5.3) reduces to

$D^2\bar {u}(\bar {h})=-1$, (5.3) reduces to

The equilibrium of forces implies that the disturbance has to generate a positive shear stress ![]() $D\tilde {u}(\bar {h})$ to compensate for

$D\tilde {u}(\bar {h})$ to compensate for ![]() $\tilde {h}$. To analyse this mechanism, we considered a reference frame moving at the substrate velocity

$\tilde {h}$. To analyse this mechanism, we considered a reference frame moving at the substrate velocity ![]() $U_p$ (

$U_p$ (![]() $\hat {u}=-1$), and we expand the streamwise velocity amplitude

$\hat {u}=-1$), and we expand the streamwise velocity amplitude ![]() $\acute {u}$ in a power series of

$\acute {u}$ in a power series of ![]() $k$ assuming long-wave conditions (4.1) (Smith Reference Smith1990). The solution at

$k$ assuming long-wave conditions (4.1) (Smith Reference Smith1990). The solution at ![]() $O(1)$ of (4.4) with boundary conditions (4.5) is given by a linear velocity amplitude

$O(1)$ of (4.4) with boundary conditions (4.5) is given by a linear velocity amplitude ![]() $\acute {u}_{m0}(\hat {y})$ and a positive phase speed

$\acute {u}_{m0}(\hat {y})$ and a positive phase speed ![]() $c_{m0}$:

$c_{m0}$:

The behaviour of ![]() $c_{m0}$ is solely determined by gravity. The thicker the base state, the more gravity is important, and the more the wave travels faster downwards along the

$c_{m0}$ is solely determined by gravity. The thicker the base state, the more gravity is important, and the more the wave travels faster downwards along the ![]() $\hat {x}$ direction.

$\hat {x}$ direction.

Figure 9(a) shows the flow field at leading order as a consequence of a harmonic displacement of the interface (red line). Since the flow field is in phase with the liquid-film displacement, the streamwise velocity is maximum at the peak and minimum at the trough. Considering a control volume in the range ![]() $\theta \in [0,{\rm \pi} /2]$, enclosed between a peak and a node at the interface, this has a positive net flow rate. The velocity field pushes liquid to the right at the crest, with a zero flow rate at the node. In accordance with the continuity equation, this implies a positive displacement of the film interface to accommodate this accumulation of mass, leading to a travelling wave in the positive

$\theta \in [0,{\rm \pi} /2]$, enclosed between a peak and a node at the interface, this has a positive net flow rate. The velocity field pushes liquid to the right at the crest, with a zero flow rate at the node. In accordance with the continuity equation, this implies a positive displacement of the film interface to accommodate this accumulation of mass, leading to a travelling wave in the positive ![]() $\hat {x}$ direction. The solution of (4.6a) gives the normal velocity at

$\hat {x}$ direction. The solution of (4.6a) gives the normal velocity at ![]() $O(k)$:

$O(k)$:

The link between the phase speed and the flow rate is given by the kinematic boundary condition at the interface (4.7b):

\begin{equation} c_{m0} - \bar{u}_m(\hat{h}) = v_{1} =\int_{0}^{\hat{h}}u_{m0}-1\,{\rm d}\hat{y} = \hat{h}^2/2. \end{equation}

\begin{equation} c_{m0} - \bar{u}_m(\hat{h}) = v_{1} =\int_{0}^{\hat{h}}u_{m0}-1\,{\rm d}\hat{y} = \hat{h}^2/2. \end{equation}

Figure 9. Magnitude (greyscale) and vector field (arrows) of the perturbation's velocity field (a) at leading order and (b) at first order in the wavenumber ![]() $k$.

$k$.

This initiating mechanism affects the development of the flow field at ![]() $O(k)$ through two inertial stresses in (4.6b):

$O(k)$ through two inertial stresses in (4.6b):

The first term corresponds to the advection of the reduced leading-order solution by the base state velocity with respect to the reduced leading order wave speed. The second term corresponds to the advection of the base state velocity by the first-order wall-normal velocity ![]() $v_1$. Since the phase speed

$v_1$. Since the phase speed ![]() $c_{m0}$ is larger than any values in

$c_{m0}$ is larger than any values in ![]() $\bar {u}_m(\hat {y})$, and being

$\bar {u}_m(\hat {y})$, and being ![]() $D\bar {u}_m(\hat {y})=-\hat {y} + \hat {h}$ positive for all

$D\bar {u}_m(\hat {y})=-\hat {y} + \hat {h}$ positive for all ![]() $\hat {y}\in [0,\hat {h}]$, these two terms are both negative. This leads to a destabilising flow field given by the solution of the first-order equations (4.6) with boundary conditions (4.7):

$\hat {y}\in [0,\hat {h}]$, these two terms are both negative. This leads to a destabilising flow field given by the solution of the first-order equations (4.6) with boundary conditions (4.7):

Figure 9(b) shows the flow field calculated with (5.9). Since the velocity amplitude ![]() $u_{m1}(\hat {y})$ is imaginary and positive, the flow has a phase shift of

$u_{m1}(\hat {y})$ is imaginary and positive, the flow has a phase shift of ![]() ${\rm \pi} /2$ with respect to the wave displacement. Consequently, the velocity pushes fluid from the troughs to the peaks, sustaining the growth of the perturbation. This renders a growth mechanism based on the extraction of energy contained in the leading-order solution, which, in turn, extracts energy from the base state through the work done by the shear stress at the interface.

${\rm \pi} /2$ with respect to the wave displacement. Consequently, the velocity pushes fluid from the troughs to the peaks, sustaining the growth of the perturbation. This renders a growth mechanism based on the extraction of energy contained in the leading-order solution, which, in turn, extracts energy from the base state through the work done by the shear stress at the interface.

5.2.2. Vorticity perturbation at the free surface and in the bulk

In the previous subsection, we studied the general structure of the instability mechanism. The first-order solution in ![]() $k$, fed by leading-order inertial stresses, generates a destabilising flow from the troughs to the peaks due to a

$k$, fed by leading-order inertial stresses, generates a destabilising flow from the troughs to the peaks due to a ![]() ${\rm \pi} /2$ phase shift to the free-surface displacement. In this section, we go into more detail, analysing how the phase shift and the magnitude of the perturbation change with the wavenumber and the flat liquid-film height. To this end, we look at the growth of the perturbation in terms of the vorticity field. The perturbation's shear stress correction in (5.4) can be seen as a source of vorticity at the free surface

${\rm \pi} /2$ phase shift to the free-surface displacement. In this section, we go into more detail, analysing how the phase shift and the magnitude of the perturbation change with the wavenumber and the flat liquid-film height. To this end, we look at the growth of the perturbation in terms of the vorticity field. The perturbation's shear stress correction in (5.4) can be seen as a source of vorticity at the free surface ![]() $\omega _{FS}$. We consider a reference frame moving with the wave speed

$\omega _{FS}$. We consider a reference frame moving with the wave speed ![]() $c_r$, i.e.

$c_r$, i.e. ![]() $\theta =k(\hat {x}-c_r\hat {t})$, and we assume a sinusoidal displacement of the free surface:

$\theta =k(\hat {x}-c_r\hat {t})$, and we assume a sinusoidal displacement of the free surface:

with ![]() $\theta =0$ at 0, this implies through (4.12a), that

$\theta =0$ at 0, this implies through (4.12a), that

By means of the kinematic boundary condition (2.22b), we scale the eigenfunction such that

The shear stress condition (2.22d) imposes that

By replacing these expressions in (4.10d), we obtain the vorticity at the free surface:

with the amplitude ![]() $\gamma$ and the phase shift

$\gamma$ and the phase shift ![]() $\xi$ given by

$\xi$ given by

Depending on ![]() $\xi$,

$\xi$, ![]() $\omega _{FS}$ stabilises (

$\omega _{FS}$ stabilises (![]() $\xi <0$) or destabilises (

$\xi <0$) or destabilises (![]() $\xi >0$) the free-surface displacement (Kelly et al. Reference Kelly, Goussis, Lin and Hsu1989).

$\xi >0$) the free-surface displacement (Kelly et al. Reference Kelly, Goussis, Lin and Hsu1989).

Figure 10 shows (a,d) the growth rate ![]() $\omega _i$, (b,e) the amplitude

$\omega _i$, (b,e) the amplitude ![]() $\gamma$ and (c,f) the phase shift

$\gamma$ and (c,f) the phase shift ![]() $\xi$ of the free-surface vorticity as a function of the wavenumber

$\xi$ of the free-surface vorticity as a function of the wavenumber ![]() $k$ and the liquid-film thickness

$k$ and the liquid-film thickness ![]() $\hat {h}$ at

$\hat {h}$ at ![]() $Re=30$, with the neutral curve (continuous red line) and the maximum growth rate (dashed red line) for (a–c) the corn oil (