1. Introduction

When a wave breaks at sea, it entrains air bubbles below the ocean surface. Those bubbles rise back to the surface and reside for some time before bursting and ejecting drops into the atmosphere. The ejected drops can then evaporate, leaving behind ocean spray aerosol particles composed of salts, biological material and other chemicals found in the ocean. In the atmosphere, these emitted drops and corresponding dry particles affect the radiative balance and can serve as cloud condensation nuclei (Lewis & Schwartz Reference Lewis and Schwartz2004; de Leeuw et al. Reference de Leeuw, Andreas, Anguelova, Fairall, Lewis, O’Dowd, Schulz and Schwartz2011; Veron Reference Veron2015; Cochran et al. Reference Cochran, Ryder, Grassian and Prather2017).

One main difficulty of studying spray generation by bubble bursting is the range of scales involved in the related processes, from the single breaking wave of

![]() $O (1{-}10\, \mathrm{m})$

to entrained bubbles of sizes

$O (1{-}10\, \mathrm{m})$

to entrained bubbles of sizes

![]() $O (0.01{-}10\, \mathrm{mm})$

and emitted drops of sizes

$O (0.01{-}10\, \mathrm{mm})$

and emitted drops of sizes

![]() $O (0.01{-}100\, \unicode{x03BC} \mathrm{m})$

. To predict ocean spray generation from knowledge of the bubble size distribution, we must understand the physical link between underwater bubbles that rise to the ocean surface, surface bubbles that cluster and burst, and the resulting drops they eject (depicted in figure 1 of Deike Reference Deike2022).

$O (0.01{-}100\, \unicode{x03BC} \mathrm{m})$

. To predict ocean spray generation from knowledge of the bubble size distribution, we must understand the physical link between underwater bubbles that rise to the ocean surface, surface bubbles that cluster and burst, and the resulting drops they eject (depicted in figure 1 of Deike Reference Deike2022).

Parameterisations of the sea spray generation function used in large-scale models (as reviewed by Lewis & Schwartz Reference Lewis and Schwartz2004, de Leeuw et al. Reference de Leeuw, Andreas, Anguelova, Fairall, Lewis, O’Dowd, Schulz and Schwartz2011, Veron Reference Veron2015), display large uncertainties of at least an order of magnitude across the full range of emitted drop sizes. These uncertainties come from the difficulty of characterising the drop formation across many processes and scales, as well as from the various empirical ways the parameterisations are developed from interpretation of field measurements or upscaling of laboratory data. In practice, the uncertainties lead to a very different sensitivity to physical parameters such as temperature (Forestieri et al. Reference Forestieri, Moore, Martinez Borrero, Wang, Stokes and Cappa2018) and directly impact the modelled radiative balance and climate sensitivity in climate models (Paulot et al. Reference Paulot, Paynter, Winton, Ginoux, Zhao and Horowitz2020).

Individual bubble bursting has been extensively studied to characterise the production mechanism, size and number of drops produced by the bursting of a single bubble. Previous laboratory experiments have focused either on film drops (Blanchard & Syzdek Reference Blanchard and Syzdek1988; Resch & Afeti Reference Resch and Afeti1991, Reference Resch and Afeti1992; Spiel Reference Spiel1997a , Reference Spiel1998; Lhuissier & Villermaux Reference Lhuissier and Villermaux2012; Jiang et al. Reference Jiang, Rotily, Villermaux and Wang2022) or jet drops (Spiel Reference Spiel1997a , Reference Spiel1998; Ghabache et al. Reference Ghabache, Antkowiak, Josserand and Séon2014; Walls, Henaux & Bird Reference Walls, Henaux and Bird2015; Ghabache & Séon Reference Ghabache and Séon2016; Walls, Henaux & Bird Reference Walls, Henaux and Bird2015; Brasz et al. Reference Brasz, Bartlett, Walls, Flynn, Yu and Bird2018), and numerical simulations have studied jet drop production (Brasz et al. Reference Brasz, Bartlett, Walls, Flynn, Yu and Bird2018; Deike et al. Reference Deike, Ghabache, Liger-Belair, Das, Zaleski, Popinet and Séon2018; Berny et al. Reference Berny, Deike, Séon and Popinet2020, Reference Berny, Popinet, Séon and Deike2021). From those studies, scaling laws have been developed that relate the bursting bubble size to the number and size of drops emitted through jet drop production (Gañán-Calvo Reference Gañán-Calvo2017, Reference Gañán-Calvo2023; Blanco–Rodríguez & Gordillo Reference Blanco–Rodríguez and Gordillo2020), film drop production through a centrifuge mechanism (Lhuissier & Villermaux Reference Lhuissier and Villermaux2012), and film drop production through a proposed flapping mechanism (Jiang et al. Reference Jiang, Rotily, Villermaux and Wang2022, Reference Jiang, Rotily, Villermaux and Wang2024). However, the extent to which these scaling laws, developed for idealised individual bubble bursting, apply to more realistic configurations like clusters of bubbles within ocean whitecaps, remains to be experimentally demonstrated. Combining the above-mentioned individual bubble bursting scaling laws for the various mechanisms with the bubble size distribution under a breaking wave and the statistics of air entrainment at large scale, Deike, Reichl & Paulot (Reference Deike, Reichl and Paulot2022) developed a mechanistic sea spray emissions function and demonstrated the remarkable coherence with empirically-derived emission functions. To obtain the ocean spray emission function, Deike et al. (Reference Deike, Reichl and Paulot2022) integrate over a given bubble size distribution (constrained by the laboratory and numerical studies of Deane & Stokes Reference Deane and Stokes2002; Deike, Melville & Popinet Reference Deike, Melville and Popinet2016; Gao, Deane & Shen Reference Gao, Deane and Shen2021; Mostert, Popinet & Deike Reference Mostert, Popinet and Deike2022), assuming individual bubble bursting scaling laws for the size, number and distribution of emitted drops for each production mechanism. The method uses the integration introduced for film drop production by Lhuissier & Villermaux (Reference Lhuissier and Villermaux2012) and extended to jet drop production in Berny et al. (Reference Berny, Popinet, Séon and Deike2021), and air entrainment volume by breaking waves statistics in the ocean (Deike et al. Reference Deike, Melville and Popinet2016, Reference Deike, Lenain and Melville2017).

The approach from Deike et al. (Reference Deike, Reichl and Paulot2022), as well as past approaches (see the overview in Lewis & Schwartz Reference Lewis and Schwartz2004), assumes that the bubble size distribution under a breaking wave is always of the same shape and does not consider collective bubble bursting or surfactant effects. Physico-chemical properties of the ocean water – such as salinity, temperature, surfactant concentration, and biological composition – bring another layer of complexity to sea spray generation by potentially modulating the bubble processes (i.e. lifetime, coalescence, bursting). Modelling of sea spray organic aerosol emissions in Burrows et al. (Reference Burrows, Ogunro, Frossard, Russell, Rasch and Elliott2014) highlights the numerous chemical and biological factors that are thought to influence spray generation, showing that – despite extensive past experimental efforts – there is still a need for controlled, well-constrained experiments to improve our knowledge of how these realistic factors control the bursting processes while limiting experimental uncertainties.

To investigate the collective bursting relevant to the open ocean context, previous experiments have measured drop production by collections of bubbles generated through different methods in a variety of complex solutions, focusing especially on the measurement of submicron drops/aerosols. The experiments include bursting bubbles generated by both a plunging sheet and nucleation bubbler in natural and artificial seawater (Wang et al. Reference Wang2017), bursting bubble rafts produced in sampled natural seawater through a forced-air venturi channel (Frossard et al. Reference Frossard2019), the investigation of the effect of phytoplankton and bacteria on aerosol production for bubbles generated by laboratory breaking waves in natural seawater (Prather et al. Reference Prather2013), as well as several other experiments involving bursting bubble rafts or foams including those in solutions of different organic content or different salt concentration (Cipriano & Blanchard Reference Cipriano and Blanchard1981; Liger-Belair & Jeandet Reference Liger-Belair and Jeandet2003; Mårtensson et al. Reference Mårtensson, Nilsson, de Leeuw, Cohen and Hansson2003; Sellegri et al. Reference Sellegri, O’Dowd, Yoon, Jennings and de Leeuw2006; Tyree et al. Reference Tyree, Hellion, Alexandrova and Allen2007; Modini et al. Reference Modini, Russell, Deane and Stokes2013; Séon & Liger-Belair Reference Séon and Liger-Belair2017; Zinke et al. Reference Zinke, Nilsson, Zieger and Salter2022; Dubitsky et al. Reference Dubitsky, Stokes, Deane and Bird2023). These studies suggest that ocean physico-chemical parameters modulate the bursting process. However, the complexity of the seawater solution and the lack of complete bulk bubble, surface bubble and drop/dry particle measurements across a wide range of scales make it difficult to compare results from separate studies and to distinguish the specific effects of individual physico-chemical variables among other differences due to varied bubble size distributions or collective bursting.

These uncertainties and their practical consequences on ocean spray emission functions motivate an intermediate-scale collective bursting laboratory experiment, measuring bubbles in the bulk and at the surface as well as the produced drops, as a way to bridge the idealised and the oceanic spray generation configurations. Using a well-characterised set-up with measurements that capture the full size range of bubbles and associated ejected drops, we can maintain precise control over the solution while observing the effect of any changes in the properties on the collective bursting. This idea was introduced through the experiments of Néel & Deike (Reference Néel and Deike2021); Néel et al. (Reference Néel, Erinin and Deike2022), where systematic measurements of millimetric bubbles and supermicron drops were made for solutions of different surfactant concentrations.

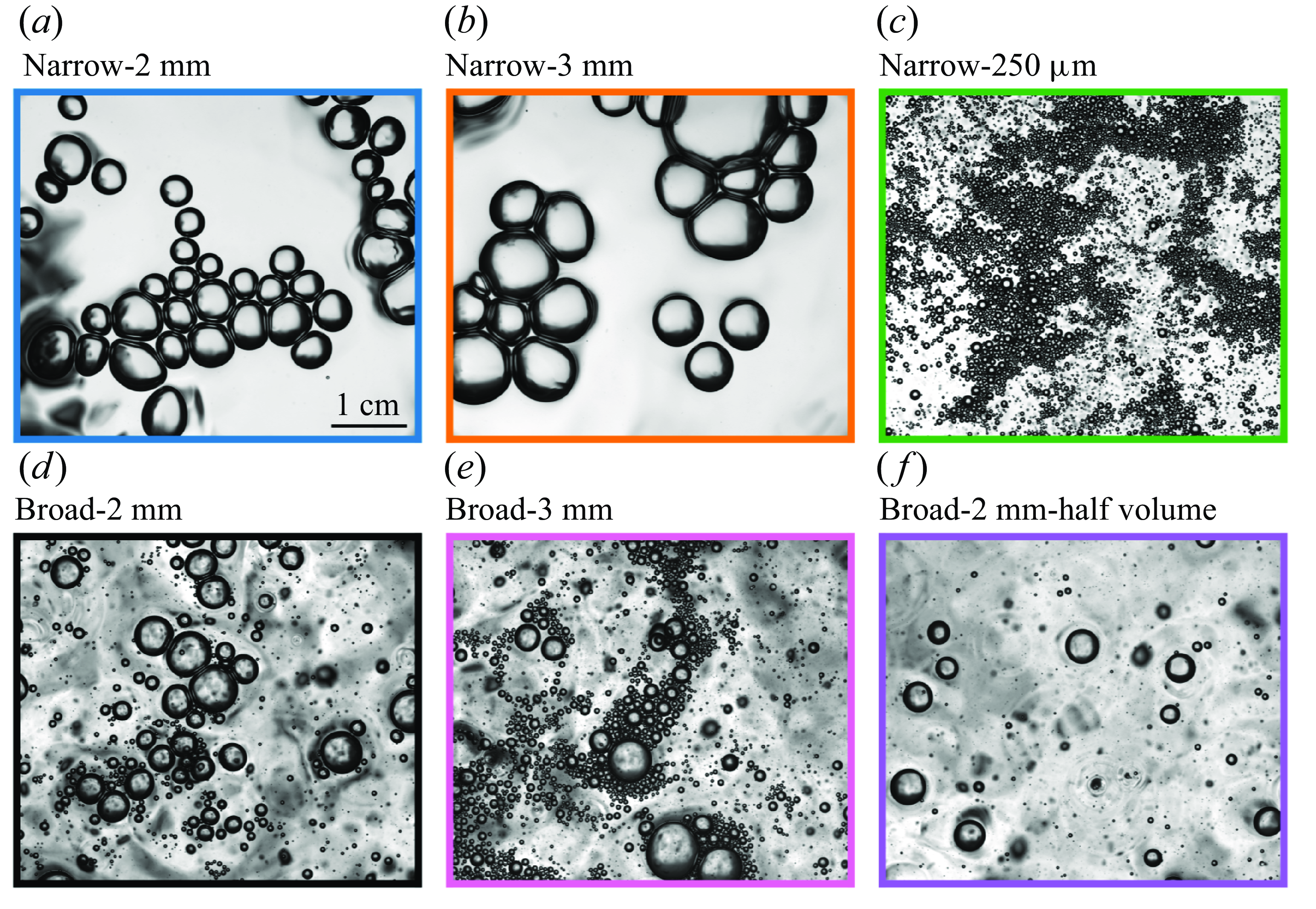

Figure 1. Characteristic images of bubbles on the water surface for six conditions presented in this paper. The top row shows narrower size distributions of clustered bubbles for injection sizes (a)

![]() $2\,\mathrm{mm}$

, (b)

$2\,\mathrm{mm}$

, (b)

![]() $3\,\mathrm{mm}$

and (c)

$3\,\mathrm{mm}$

and (c)

![]() $250\,\unicode{x03BC} \mathrm{m}$

. The bottom row shows broad-banded distributions initially injected as (d, f)

$250\,\unicode{x03BC} \mathrm{m}$

. The bottom row shows broad-banded distributions initially injected as (d, f)

![]() $2\,\mathrm{mm}$

and (e)

$2\,\mathrm{mm}$

and (e)

![]() $3\,\mathrm{mm}$

bubbles before underwater turbulence caused the breakup of these injected bubbles into those spanning a wide range of scales. In (f), half the volume of

$3\,\mathrm{mm}$

bubbles before underwater turbulence caused the breakup of these injected bubbles into those spanning a wide range of scales. In (f), half the volume of

![]() $2\,\mathrm{mm}$

bubbles were injected compared with the other cases (using 16 instead of 32 needles), leading to bubbles that are more isolated instead of clustered at the surface. Details of how bubbles were generated for each case are found in table 1.

$2\,\mathrm{mm}$

bubbles were injected compared with the other cases (using 16 instead of 32 needles), leading to bubbles that are more isolated instead of clustered at the surface. Details of how bubbles were generated for each case are found in table 1.

In this paper, we perform experiments with measurements of all relevant scales of bulk and surface bubbles (radii

![]() $30\,\unicode{x03BC} \mathrm{m}$

to

$30\,\unicode{x03BC} \mathrm{m}$

to

![]() $5\,\mathrm{mm}$

), liquid drops (radii

$5\,\mathrm{mm}$

), liquid drops (radii

![]() $10\,\unicode{x03BC} \mathrm{m}$

to

$10\,\unicode{x03BC} \mathrm{m}$

to

![]() $500\, \unicode{x03BC} \mathrm{m}$

) and salt aerosols (equivalent drop radii

$500\, \unicode{x03BC} \mathrm{m}$

) and salt aerosols (equivalent drop radii

![]() $50\,\mathrm{nm}$

to

$50\,\mathrm{nm}$

to

![]() $10\,\unicode{x03BC} \mathrm{m}$

) for various clustered bubble configurations, allowing us to directly characterise the link between the drop size distribution and the surface bursting bubble distribution. We have designed a bubbling tank experiment (building off the work of Néel & Deike Reference Néel and Deike2021) where bubbles are generated at the bottom of the tank, and statistical measurements are made in the bulk and at the surface. Three measurement techniques are combined to measure drop sizes spanning four orders of magnitude: optical digital inline holography allows the measurement of drops ejected in the air with radii from

$10\,\unicode{x03BC} \mathrm{m}$

) for various clustered bubble configurations, allowing us to directly characterise the link between the drop size distribution and the surface bursting bubble distribution. We have designed a bubbling tank experiment (building off the work of Néel & Deike Reference Néel and Deike2021) where bubbles are generated at the bottom of the tank, and statistical measurements are made in the bulk and at the surface. Three measurement techniques are combined to measure drop sizes spanning four orders of magnitude: optical digital inline holography allows the measurement of drops ejected in the air with radii from

![]() $10\,\unicode{x03BC} \mathrm{m}$

to

$10\,\unicode{x03BC} \mathrm{m}$

to

![]() $500\,\unicode{x03BC} \mathrm{m}$

, while smaller droplets (not accessible with direct imaging techniques) are inferred by drying and measuring the size of the resulting salt crystals, spanning equivalent drop radii of

$500\,\unicode{x03BC} \mathrm{m}$

, while smaller droplets (not accessible with direct imaging techniques) are inferred by drying and measuring the size of the resulting salt crystals, spanning equivalent drop radii of

![]() $50\,\mathrm{nm}$

to

$50\,\mathrm{nm}$

to

![]() $10\,\unicode{x03BC} \mathrm{m}$

. We characterise the spray generation by clusters of bubbles in a precisely controlled solution of artificial seawater, and we vary the bulk bubble size distribution across cases. The bulk bubble size distributions tested include quasi-monodisperse plumes of rising bubbles centered around

$10\,\unicode{x03BC} \mathrm{m}$

. We characterise the spray generation by clusters of bubbles in a precisely controlled solution of artificial seawater, and we vary the bulk bubble size distribution across cases. The bulk bubble size distributions tested include quasi-monodisperse plumes of rising bubbles centered around

![]() $3\,\mathrm{mm}$

,

$3\,\mathrm{mm}$

,

![]() $2\,\mathrm{mm}$

and

$2\,\mathrm{mm}$

and

![]() $250\,\unicode{x03BC} \mathrm{m}$

, as well as broad-banded distributions where bubbles range from

$250\,\unicode{x03BC} \mathrm{m}$

, as well as broad-banded distributions where bubbles range from

![]() $30\,\unicode{x03BC} \mathrm{m}$

to

$30\,\unicode{x03BC} \mathrm{m}$

to

![]() $3\,\mathrm{mm}$

. The broad-banded size distributions mimic the bubble size distribution entrained by breaking waves. As illustrated in figure 1, these bubble size distributions exhibit very different characteristics at the surface, which will control the resulting drop size distribution. We then explore whether we can describe the associated spray generation by these various bubble distributions within a single physical framework.

$3\,\mathrm{mm}$

. The broad-banded size distributions mimic the bubble size distribution entrained by breaking waves. As illustrated in figure 1, these bubble size distributions exhibit very different characteristics at the surface, which will control the resulting drop size distribution. We then explore whether we can describe the associated spray generation by these various bubble distributions within a single physical framework.

The paper is organised as follows. We detail the set-up, experimental methods, and resulting size distribution data in § 2. In § 3, we discuss linking the bulk bubble and surface bubble measurements, followed by the § 4 analysis linking the surface bubble and drop measurements. Section 5 presents the conclusions.

2. Measuring bubbles, drops and dry particles in a bubbling tank

We present the experimental methods, including a description of the bubbling tank, preparation of the artificial seawater solution, measurements of bulk bubbles, surface bubbles and finally drops/dry particles. Sample size distributions from these measurements are then shown and discussed.

2.1. Experimental set-up and conditions

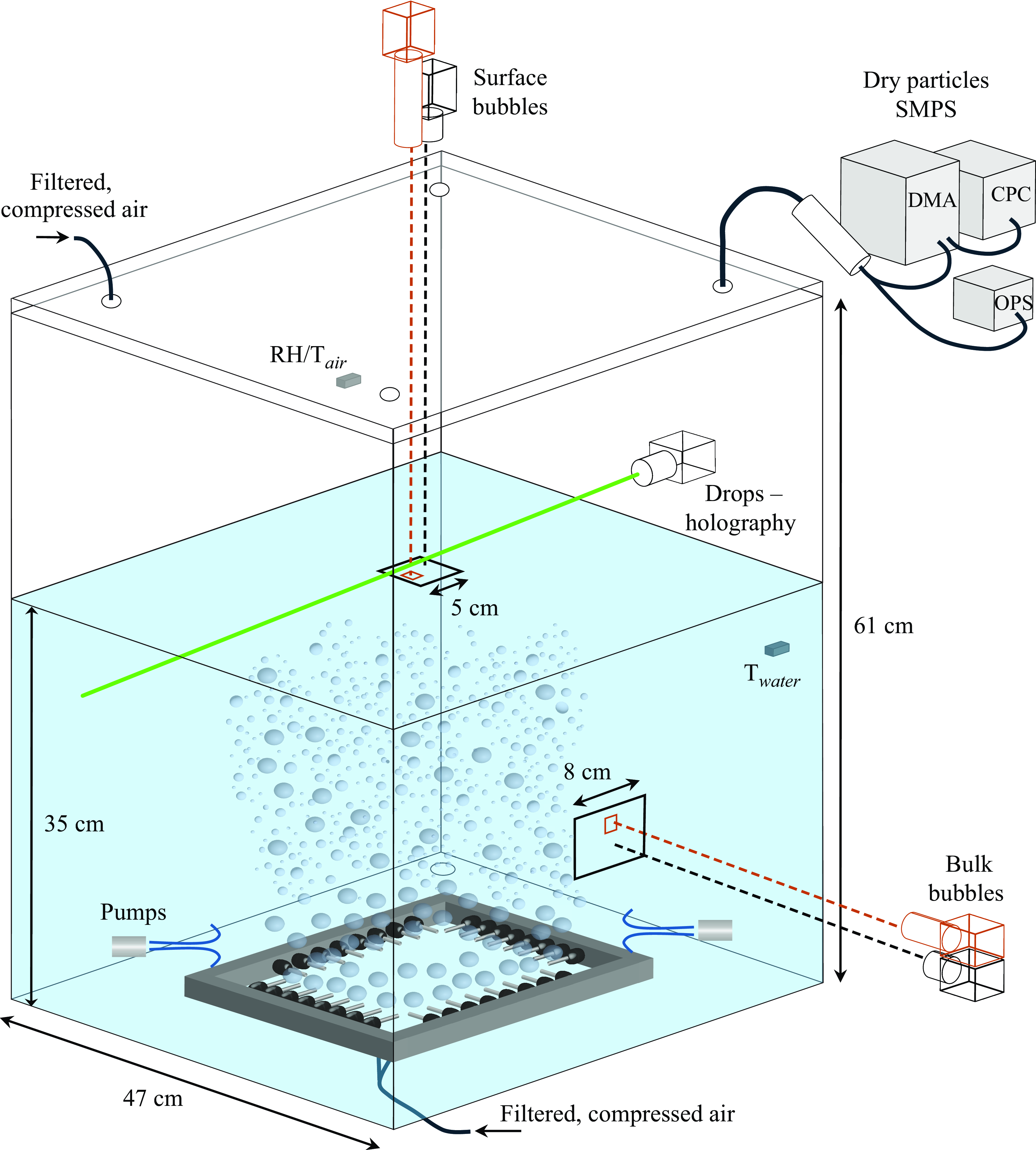

The experimental set-up, shown in figure 2, consists of a polycarbonate tank with inner dimensions

![]() $47 \times 47 \times 61 \,\text{cm}^3$

, similar to the one used by Néel & Deike (Reference Néel and Deike2021), which is filled to a height of

$47 \times 47 \times 61 \,\text{cm}^3$

, similar to the one used by Néel & Deike (Reference Néel and Deike2021), which is filled to a height of

![]() $35\,\text{cm}$

with a solution of artificial seawater (made of deionised (DI) water and artificial sea salt, ASTM D1141-98, Lake Products Company LLC). The water height is chosen so that the waves/fluctations on the water surface remain small and the surface bubbles can be clearly imaged. Bubbles are continuously generated as compressed air flows through the needles positioned at the bottom of the tank, arranged in a square with eight needles extending horizontally from each side. The air flow rate through the needles is controlled at 100 cm

$35\,\text{cm}$

with a solution of artificial seawater (made of deionised (DI) water and artificial sea salt, ASTM D1141-98, Lake Products Company LLC). The water height is chosen so that the waves/fluctations on the water surface remain small and the surface bubbles can be clearly imaged. Bubbles are continuously generated as compressed air flows through the needles positioned at the bottom of the tank, arranged in a square with eight needles extending horizontally from each side. The air flow rate through the needles is controlled at 100 cm

![]() $^3$

min−1 per needle, so that the resulting plume of rising bubbles is fairly monodisperse.

$^3$

min−1 per needle, so that the resulting plume of rising bubbles is fairly monodisperse.

Figure 2. Sketch of the experimental set-up, with measurements of bubbles, drops and dry aerosol particles. Bubbles of nearly identical sizes are generated by compressed air flowing through needles at the bottom of the tank. When two underwater pumps are turned on (as illustrated in the sketch), the injected bubbles are broken up into many smaller bubbles as they rise into the region of turbulence generated by the water jets from the pumps (bubbles not drawn to scale). The bubbles are imaged from the side view to measure the rising bulk bubbles and from the top view to capture the bubbles at the surface. Large fields of view (black) and small fields of view (orange) are drawn approximately to scale and permit the measurement of bubble radii from

![]() $30\,\unicode{x03BC} \mathrm{m}$

to

$30\,\unicode{x03BC} \mathrm{m}$

to

![]() $5\,\mathrm{mm}$

. Liquid drops ejected into the air by bursting bubbles are measured through an inline holographic set-up (measuring liquid drop radii from

$5\,\mathrm{mm}$

. Liquid drops ejected into the air by bursting bubbles are measured through an inline holographic set-up (measuring liquid drop radii from

![]() $10\,\unicode{x03BC} \mathrm{m}$

to

$10\,\unicode{x03BC} \mathrm{m}$

to

![]() $500\,\unicode{x03BC} \mathrm{m}$

), while dry aerosol particles are measured by extracting and drying the liquid drops and analysing them using an optical particle sizer (OPS) and scanning mobility particle sizer (SMPS, composed of a differential mobility analyzer (DMA) and a condensation particle counter (CPC)) (for dry particle radii from

$500\,\unicode{x03BC} \mathrm{m}$

), while dry aerosol particles are measured by extracting and drying the liquid drops and analysing them using an optical particle sizer (OPS) and scanning mobility particle sizer (SMPS, composed of a differential mobility analyzer (DMA) and a condensation particle counter (CPC)) (for dry particle radii from

![]() $20\,\mathrm{nm}$

to

$20\,\mathrm{nm}$

to

![]() $5\,\unicode{x03BC} \mathrm{m}$

). A line of filtered, compressed air is connected to the lid to flush the air above the water surface before the start of each run. Relative humidity and both air and water temperature are monitored throughout the experiments.

$5\,\unicode{x03BC} \mathrm{m}$

). A line of filtered, compressed air is connected to the lid to flush the air above the water surface before the start of each run. Relative humidity and both air and water temperature are monitored throughout the experiments.

The artificial seawater solution is prepared by mixing DI water with ASTM D1141-98 artificial sea salt, which contains the same proportions of elements found in natural seawater in amounts greater than

![]() $0.0004\,\%$

by weight (Lake Products Company LLC). Solutions discussed in this paper were prepared with a salinity of 36 g L−1 (35 g kg−1) to mimic the composition of ocean water. The solution has liquid viscosity

$0.0004\,\%$

by weight (Lake Products Company LLC). Solutions discussed in this paper were prepared with a salinity of 36 g L−1 (35 g kg−1) to mimic the composition of ocean water. The solution has liquid viscosity

![]() $\unicode{x03BC}= 1.001 \,\text{mPa s}$

, liquid density

$\unicode{x03BC}= 1.001 \,\text{mPa s}$

, liquid density

![]() $\rho= 1025 \,\text{kg}\,\text{m}^{-3}$

and static surface tension

$\rho= 1025 \,\text{kg}\,\text{m}^{-3}$

and static surface tension

![]() $\gamma = 52 \,\text{mN m}^{-1}$

. The low static surface tension indicates that the salt mixture likely includes some surfactant. At the beginning and end of each day of experiments, the solution was characterised by measuring the surface tension isotherm with a Langmuir trough (KSV NIMA, model KN 1003). This measurement was used to confirm that the surface properties of the solution remained consistent over multiple days of experiments.

$\gamma = 52 \,\text{mN m}^{-1}$

. The low static surface tension indicates that the salt mixture likely includes some surfactant. At the beginning and end of each day of experiments, the solution was characterised by measuring the surface tension isotherm with a Langmuir trough (KSV NIMA, model KN 1003). This measurement was used to confirm that the surface properties of the solution remained consistent over multiple days of experiments.

Two pumps (Rule 20 DA 800 GPH Bilge Pump) are mounted

![]() $6\,\text{cm}$

above the needle tips, pointed towards each other from opposite corners. When the pumps are turned on, they produce water jets that meet in the center of the tank, creating a region of turbulent flow that causes the rising bubbles to fragment into many smaller bubbles, with turbulence similar to the set-up described in Ruth et al. (Reference Ruth, Aiyer, Rivière, Perrard and Deike2022). Experiments can be performed with or without forced turbulence, where the turbulence has two effects: agitate the flow and break the bubbles, leading to a broad-banded size distribution. Note that bubble imaging occurs above the region of active breakup.

$6\,\text{cm}$

above the needle tips, pointed towards each other from opposite corners. When the pumps are turned on, they produce water jets that meet in the center of the tank, creating a region of turbulent flow that causes the rising bubbles to fragment into many smaller bubbles, with turbulence similar to the set-up described in Ruth et al. (Reference Ruth, Aiyer, Rivière, Perrard and Deike2022). Experiments can be performed with or without forced turbulence, where the turbulence has two effects: agitate the flow and break the bubbles, leading to a broad-banded size distribution. Note that bubble imaging occurs above the region of active breakup.

Three experimental parameters were varied to create different initial bubble size distributions for the different cases run in this experiment: turning the underwater pumps off or on to create either a narrow- or broad-banded bulk bubble distribution, changing the needle size/bubble production method, and reducing the number of needles (which effectively reduces the injected air volume per unit time because the flow rate per needle is kept constant). An aquarium bubbler is also used to generate a plume of submillimetric bubbles centered around

![]() $250\,\unicode{x03BC} \mathrm{m}$

.

$250\,\unicode{x03BC} \mathrm{m}$

.

Figure 1 illustrates the wide range of surface bubble populations explored in this paper, showing representative images of the various conditions detailed in table 1. The surface bubble distributions display marked differences in terms of both sizes and clustering, which will control the emitted drop size distribution. There are also significant differences in the number of bubbles present at the surface in each condition, which are associated with very different numbers of produced drops (see Appendix A for the total number of drops compared with the number of bubbles for each case). Because of the variety in size, number, and clustering of surface bubbles for various conditions, it is necessary to characterise the surface properly through many measurements, across all scales, before attempting to link the bursting surface bubbles to the drops they produce.

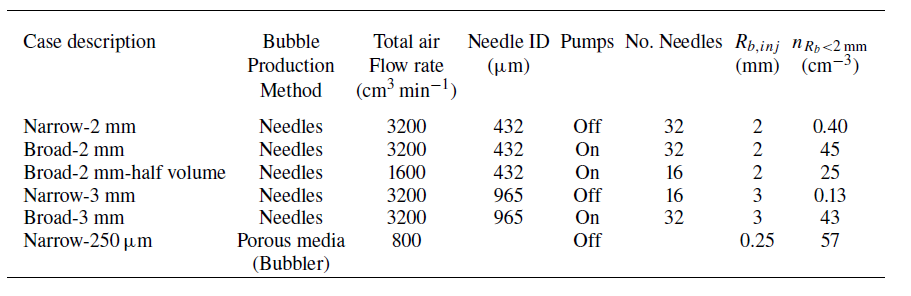

Table 1. Experimental parameters. The bulk bubble size distribution across cases was varied by changing between quiescent and turbulent flow underwater (by turning the underwater pumps off or on, causing the bubbles to break up in the turbulent case), by changing the injection bubble size (using two different needle sizes or an aquarium bubbler) and by halving the volume (using 16 instead of 32 needles with the same air flow rate per needle). Case names describe the range of radii over which a significant number of bubbles are concentrated (narrow, broad) and the initial injection bubble size before any breakup in turbulence (

![]() $2\,\mathrm{mm}$

,

$2\,\mathrm{mm}$

,

![]() $3\,\mathrm{mm}$

,

$3\,\mathrm{mm}$

,

![]() $250\,\unicode{x03BC} \mathrm{m}$

). The broad-

$250\,\unicode{x03BC} \mathrm{m}$

). The broad-

![]() $2\,\mathrm{mm}$

-half volume case is characterised by bubbles arriving at the surface isolated from each other, bursting individually instead of clustered as the smaller number of needles leads to both a reduced volume and increased needle spacing. Here

$2\,\mathrm{mm}$

-half volume case is characterised by bubbles arriving at the surface isolated from each other, bursting individually instead of clustered as the smaller number of needles leads to both a reduced volume and increased needle spacing. Here

![]() $R_{b, inj}$

represents the typical injection bubble size by the needles or bubbler;

$R_{b, inj}$

represents the typical injection bubble size by the needles or bubbler;

![]() $n_{R_b\lt 2\,\textrm{mm}}$

shows the number of bubbles (per unit volume) smaller than radius

$n_{R_b\lt 2\,\textrm{mm}}$

shows the number of bubbles (per unit volume) smaller than radius

![]() $2\,\mathrm{mm}$

, which reinforces the designation of certain cases as narrow- or broad-banded. We provide the total air flow rate through the needles for each case, but we caution that this flow rate value should not be used to approximate the bubble population in our configuration, as it is primarily related to the volume contained in the largest bubbles and does not capture the variations in the bubble size distributions (broad and narrow configurations) necessary when linking bursting bubbles to emitted drops. Bubble size distributions for each case are shown throughout §§ 2.2.4, 4.1 and 4.2. Representative surface bubble images for each case are shown in figure 1.

$2\,\mathrm{mm}$

, which reinforces the designation of certain cases as narrow- or broad-banded. We provide the total air flow rate through the needles for each case, but we caution that this flow rate value should not be used to approximate the bubble population in our configuration, as it is primarily related to the volume contained in the largest bubbles and does not capture the variations in the bubble size distributions (broad and narrow configurations) necessary when linking bursting bubbles to emitted drops. Bubble size distributions for each case are shown throughout §§ 2.2.4, 4.1 and 4.2. Representative surface bubble images for each case are shown in figure 1.

In order to capture the large range of length scales present in the system – spanning bubble radii of

![]() $30{-}5000\,\unicode{x03BC} \mathrm{m}$

and drop sizes of

$30{-}5000\,\unicode{x03BC} \mathrm{m}$

and drop sizes of

![]() $0.05{-}500\,\unicode{x03BC} \mathrm{m}$

– we make multiple measurements of bulk bubbles, surface bubbles, drops and dry particles. Bulk bubbles are imaged in both a large and small field of view by cameras positioned above the region of active breakup. Surface bubbles are also captured in two fields of view by cameras positioned perpendicular to the water surface, where the bubbles cluster near the center of the tank before bursting and ejecting drops into the air above the water surface, which is enclosed in the tank with an acrylic lid.

$0.05{-}500\,\unicode{x03BC} \mathrm{m}$

– we make multiple measurements of bulk bubbles, surface bubbles, drops and dry particles. Bulk bubbles are imaged in both a large and small field of view by cameras positioned above the region of active breakup. Surface bubbles are also captured in two fields of view by cameras positioned perpendicular to the water surface, where the bubbles cluster near the center of the tank before bursting and ejecting drops into the air above the water surface, which is enclosed in the tank with an acrylic lid.

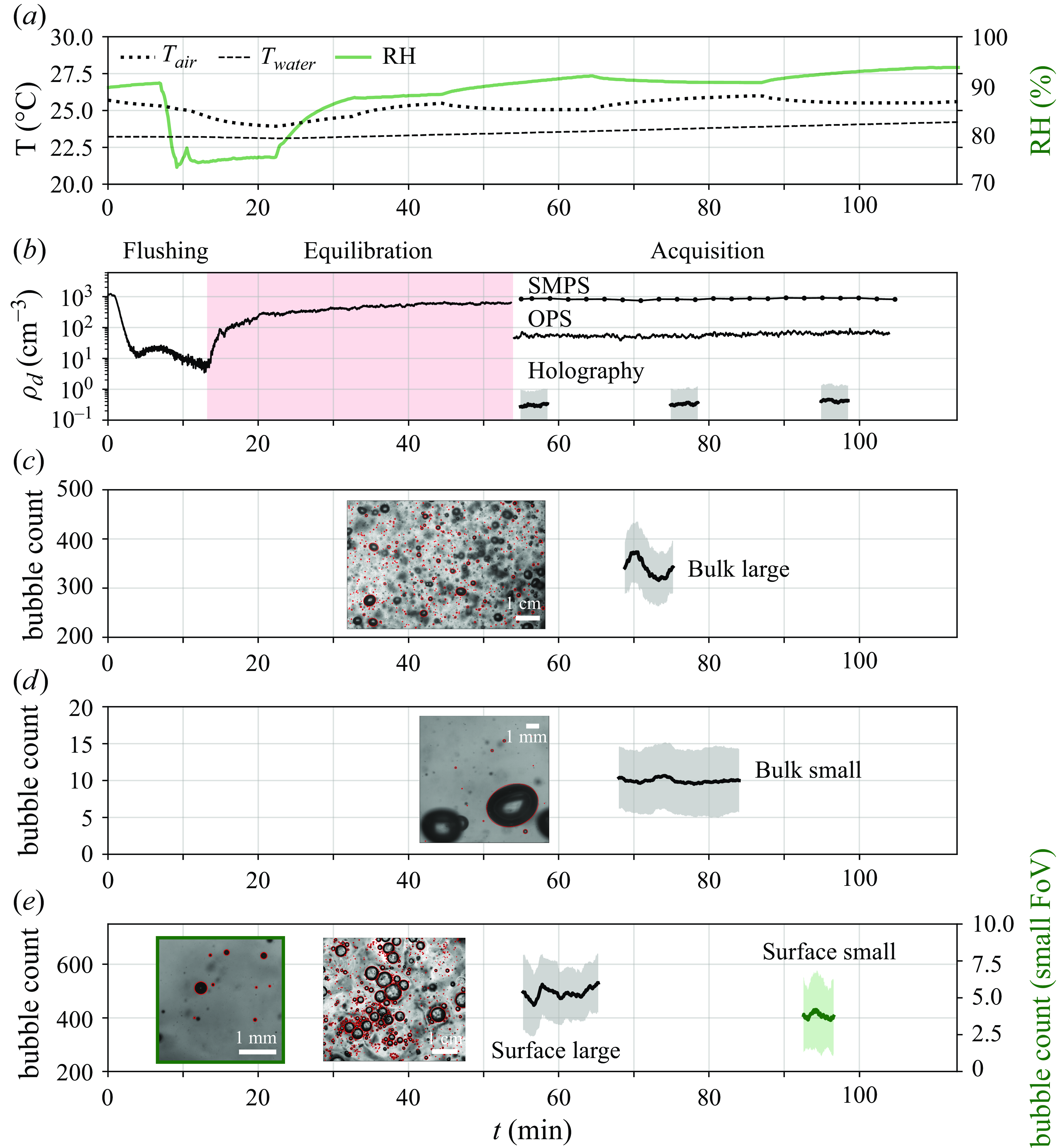

Figure 3. Experimental protocol for data acquisition illustrated by typical time series of temperature, relative humidity, bubbles, drops and dry particles through a single run on a representative case (broad-

![]() $2\,\text{mm}$

in table 1). Sample images are shown with bubble detection overlaid in red (c–e). Scale bars (shown as white lines on images) represent

$2\,\text{mm}$

in table 1). Sample images are shown with bubble detection overlaid in red (c–e). Scale bars (shown as white lines on images) represent

![]() $1\,\text{cm}$

for the bulk and surface large fields of view (c, right image ine) and

$1\,\text{cm}$

for the bulk and surface large fields of view (c, right image ine) and

![]() $1\,\text{mm}$

for the small fields of view (d, left image in e). Panel (a) illustrates the steps in the experimental protocol, showing first flushing to obtain clean air, followed by equilibration during which the relative humidity reaches a value of about

$1\,\text{mm}$

for the small fields of view (d, left image in e). Panel (a) illustrates the steps in the experimental protocol, showing first flushing to obtain clean air, followed by equilibration during which the relative humidity reaches a value of about

![]() $90\,\%$

, followed by a steady state. Air and water temperature are also shown in (a). The dry aerosol particle counts are shown in (b), with the SMPS particle count close to 0 (less than 10 particles per cm

$90\,\%$

, followed by a steady state. Air and water temperature are also shown in (a). The dry aerosol particle counts are shown in (b), with the SMPS particle count close to 0 (less than 10 particles per cm

![]() $^3$

) at the end of the flushing stage, and reaching a steady state during the acquisition stage. Drop measurements from the holography are shown in (b) by a concentration

$^3$

) at the end of the flushing stage, and reaching a steady state during the acquisition stage. Drop measurements from the holography are shown in (b) by a concentration

![]() $\rho _d$

(number per measurement volume), with the rolling mean and standard deviation plotted for each holographic measurement. For the bubble measurements in panels (c–e), the lines represent the rolling mean of the count of bubbles detected in each frame, with shading for the rolling standard deviation. All rolling quantities were computed using a window size equal to

$\rho _d$

(number per measurement volume), with the rolling mean and standard deviation plotted for each holographic measurement. For the bubble measurements in panels (c–e), the lines represent the rolling mean of the count of bubbles detected in each frame, with shading for the rolling standard deviation. All rolling quantities were computed using a window size equal to

![]() $20\,\%$

of the total number of frames in each dataset. Each measurement shows some fluctuations around a rolling mean that remains relatively steady throughout the measurement period.

$20\,\%$

of the total number of frames in each dataset. Each measurement shows some fluctuations around a rolling mean that remains relatively steady throughout the measurement period.

Drops are sized using a combination of an inline holographic system positioned just above the water surface (Erinin et al. Reference Erinin, Wang, Liu, Towle, Liu and Duncan2019, Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023), an optical particle sizer (OPS from TSI, Inc., OPS 3330), and a scanning mobility particle sizer (SMPS from TSI, Inc., which consists of an advanced aerosol neutralizer, model 3088; an electrostatic classifier, model 3082; a differential mobility analyzer, model 3081; and a condensation particle counter (CPC), model 3752). The SMPS operates with an aerosol flow rate of 0.3 L min−1 and sheath flow rate of 2.4 L min−1. The OPS and SMPS are connected through the lid and pull air with suspended drops out of the tank, where they are dried (TSI diffusion dryer, model 3062) and then measured. Relative humidity and air temperature are monitored

![]() $25\,\text{cm}$

above the calm water surface throughout all experimental runs, along with the temperature of the solution.

$25\,\text{cm}$

above the calm water surface throughout all experimental runs, along with the temperature of the solution.

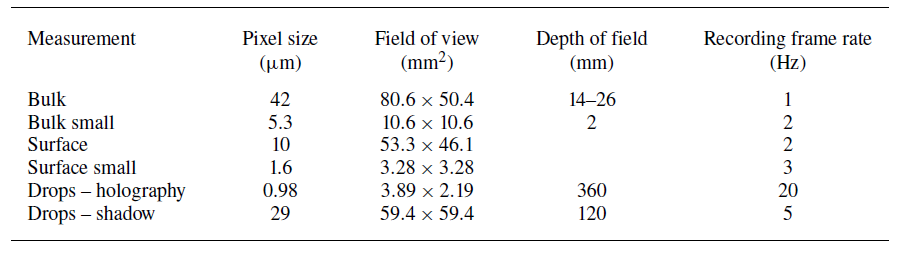

Table 2. Measurement details for imaging of bulk bubbles, surface bubbles, and drops (holography and shadow) in the present experiment. The shadow imaging drop measurement was performed for certain cases (narrow-

![]() $2\,\mathrm{mm}$

, narrow-

$2\,\mathrm{mm}$

, narrow-

![]() $3\,\mathrm{mm}$

, narrow-

$3\,\mathrm{mm}$

, narrow-

![]() $250\,\unicode{x03BC} \mathrm{m}$

and broad-

$250\,\unicode{x03BC} \mathrm{m}$

and broad-

![]() $2\,\mathrm{mm}$

) to allow for the measurement of drops very close to the surface. A range is specified for the depth of field of the bulk measurement resulting from the size-dependent depth-of-field correction, and this range corresponds to the depth of field of bubble radii in the range

$2\,\mathrm{mm}$

) to allow for the measurement of drops very close to the surface. A range is specified for the depth of field of the bulk measurement resulting from the size-dependent depth-of-field correction, and this range corresponds to the depth of field of bubble radii in the range

![]() $R_b= [150, 3000]\,\unicode{x03BC} \mathrm{m}$

(see details in § 2.2.3 and figure 6 of Erinin et al. (Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023)).

$R_b= [150, 3000]\,\unicode{x03BC} \mathrm{m}$

(see details in § 2.2.3 and figure 6 of Erinin et al. (Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023)).

2.2. Experimental protocol and statistically steady-state measurements of bubbles, drops and particles

We present the systematic experimental protocol used to characterize drop production by bubble bursting in the statistically steady-state bubbling tank. Figure 3 illustrates the time series of the various measurements for a typical case (broad-

![]() $2\,\text{mm}$

: broad-banded distribution of bubbles created by underwater turbulence that breaks the bubbles into many smaller sizes).

$2\,\text{mm}$

: broad-banded distribution of bubbles created by underwater turbulence that breaks the bubbles into many smaller sizes).

Once the artificial seawater solution is in the tank, a lid is placed on top to seal the system. A constant stream of filtered, compressed air is then flowed through the air above the water surface to flush aerosols from the system. The background aerosols escape through a single port in the lid, which is left open throughout the run to maintain equilibrium within the system. The flushing continues until the CPC component of the SMPS measures a particle count below 10 particles cm−

![]() $^3$

, as shown in figure 3(b), which can be compared with an ambient particle count of approximately 1000 particles cm−

$^3$

, as shown in figure 3(b), which can be compared with an ambient particle count of approximately 1000 particles cm−

![]() $^3$

. This ensures that the sea salt aerosols we sample in the air are nearly all emitted by bubble bursting. The air through the top of the tank is then turned off, and the system is left to equilibrate for 40 mins. The CPC particle counts from the pre-run period are shown in figure 3(b). We confirm that the particle count and relative humidity level (figure 3

a) have reached a steady state before proceeding with the run. Relative humidity, air temperature and water temperature are tracked throughout the run using a Thorlabs sensor (TSP01, TSP-TH) mounted to the tank lid. Values are comparable to realistic ocean conditions and remain steady throughout the run (temperatures vary by approximately 1 °C throughout the measurement period).

$^3$

. This ensures that the sea salt aerosols we sample in the air are nearly all emitted by bubble bursting. The air through the top of the tank is then turned off, and the system is left to equilibrate for 40 mins. The CPC particle counts from the pre-run period are shown in figure 3(b). We confirm that the particle count and relative humidity level (figure 3

a) have reached a steady state before proceeding with the run. Relative humidity, air temperature and water temperature are tracked throughout the run using a Thorlabs sensor (TSP01, TSP-TH) mounted to the tank lid. Values are comparable to realistic ocean conditions and remain steady throughout the run (temperatures vary by approximately 1 °C throughout the measurement period).

After the system reaches a steady state of particle counts, the SMPS, OPS, and holographic measurements begin simultaneously (shown in terms of the drop concentration in figure 3 b). The SMPS and OPS sample continuously throughout the entire 50 min run. Three independent holographic movies are recorded during the run, with approximately 15 mins of saving time required between each measurement. For the bubbles (figure 3 c,d,e), the large field-of-view surface measurement is made at the start of the run, followed by simultaneous measurements of bulk bubbles for both fields of view. Surface and bulk bubbles are recorded separately so that the backlighting for each measurement does not interfere with the other. Finally, the small field-of-view surface measurement is made at the end of the run. Compared with the large surface measurement, the small surface images provide a significantly more zoomed-in view that requires more light than the large surface view, so the two measurements are made separately. Details of each measurement are given below and summarised in table 2. Representative sample images for each bubble measurement are also shown in figure 3(c–e) with detection overlaid. Some fluctuations are present in the number of bubbles and drops with time, but the magnitude of the fluctuations is fairly consistent throughout the run. Therefore, we consider the system to be running in a statistically steady state.

2.2.1. Details of bulk bubbles

As introduced for the experimental set-up in § 2.1, two cameras measure the bulk bubbles simultaneously with two overlapping fields of view to enable measurement of bubbles with radii spanning

![]() $R_b = [30, 5000]\,\unicode{x03BC} \mathrm{m} $

(large field of view: Basler acA1920-40 with Zeiss Planar T50 lens; small field of view: Basler acA2040-90 with Nikon AF-Micro Nikkor 200 lens and

$R_b = [30, 5000]\,\unicode{x03BC} \mathrm{m} $

(large field of view: Basler acA1920-40 with Zeiss Planar T50 lens; small field of view: Basler acA2040-90 with Nikon AF-Micro Nikkor 200 lens and

![]() $36\,\text{mm}$

extension tube). The recording frame rates of 1 Hz (large) and 2 Hz (small) are chosen so that a single bubble does not appear in multiple frames. Imaging details are provided in table 2.

$36\,\text{mm}$

extension tube). The recording frame rates of 1 Hz (large) and 2 Hz (small) are chosen so that a single bubble does not appear in multiple frames. Imaging details are provided in table 2.

Bulk bubble edge detection was performed using a Canny filter algorithm, which was done in multiple stages for the large field of view to enable successful detection of many sizes of bubbles. An ellipse was fit to each detected region, and the bubble radius

![]() $R_b$

represents the volume-equivalent size of the bulk bubble, assuming axisymmetry around the minor axis of the ellipse. The void fraction

$R_b$

represents the volume-equivalent size of the bulk bubble, assuming axisymmetry around the minor axis of the ellipse. The void fraction

![]() $\phi _b$

is typically between

$\phi _b$

is typically between

![]() $0.1{-}0.5\,\%$

for all cases studied, indicating a dilute region of bubbly flow. Through inspection of dedicated high-speed movies, we confirm that underwater collisions and coalescence in the bulk are very rare. The presence of salt limits the coalescence efficiency so that if bubbles do contact each other, they typically bounce off and do not coalesce.

$0.1{-}0.5\,\%$

for all cases studied, indicating a dilute region of bubbly flow. Through inspection of dedicated high-speed movies, we confirm that underwater collisions and coalescence in the bulk are very rare. The presence of salt limits the coalescence efficiency so that if bubbles do contact each other, they typically bounce off and do not coalesce.

The depth of field for all cases is calibrated to account for its dependence on the size of the bubble, using the method detailed in § 2.2.3 and figure 6 of Erinin et al. (Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023). For the narrow-

![]() $2\,\text{mm}$

and narrow-

$2\,\text{mm}$

and narrow-

![]() $3\,\text{mm}$

cases, the depth of field is additionally adjusted to account for the fact that the bulk bubbles are not evenly distributed throughout the depth (because they are rising from a square array of needles). This adjustment leads to a larger effective depth of field for the narrow-banded cases, which enables comparison to the broad-banded cases where the bubbles are distributed evenly throughout the volume by the underwater pumps. The average relative error on the bubble radius measurement is 6 % at the limits of the depth of field; see Erinin et al. (Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023, § 2.2.3 and figure 7).

$3\,\text{mm}$

cases, the depth of field is additionally adjusted to account for the fact that the bulk bubbles are not evenly distributed throughout the depth (because they are rising from a square array of needles). This adjustment leads to a larger effective depth of field for the narrow-banded cases, which enables comparison to the broad-banded cases where the bubbles are distributed evenly throughout the volume by the underwater pumps. The average relative error on the bubble radius measurement is 6 % at the limits of the depth of field; see Erinin et al. (Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023, § 2.2.3 and figure 7).

2.2.2. Details of surface bubbles

At the surface, measurements of the bubbles are again made in two overlapping fields of view for the same range of bubble radii,

![]() $R_b= [30, 5000]\,\unicode{x03BC} \mathrm{m}$

. The camera for the large field of view (Basler a2A5328–15) captures clusters of bubbles, while the small field-of-view camera (Basler acA2040-90 with Infinity K2 DistaMax microscope lens) zooms in on the smallest bubbles that rise to the surface. The large and small surface measurements were made at 2 Hz and 3 Hz, respectively, and the frame independence of both measurements was checked by downsampling in time. Details are provided in table 2.

$R_b= [30, 5000]\,\unicode{x03BC} \mathrm{m}$

. The camera for the large field of view (Basler a2A5328–15) captures clusters of bubbles, while the small field-of-view camera (Basler acA2040-90 with Infinity K2 DistaMax microscope lens) zooms in on the smallest bubbles that rise to the surface. The large and small surface measurements were made at 2 Hz and 3 Hz, respectively, and the frame independence of both measurements was checked by downsampling in time. Details are provided in table 2.

Surface bubbles are detected using the Hough transform with custom filtering to remove duplicates and misdetection, which enabled detection of both clustered and isolated bubbles within the same frame using a single processing algorithm. The apparent radius of the detected bubbles from the surface measurement is then converted to the volume-equivalent radius

![]() $R_b$

by considering the static shape of the bubble at the surface, as described in Néel & Deike (Reference Néel and Deike2021), based on the work of Toba (Reference Toba1959).

$R_b$

by considering the static shape of the bubble at the surface, as described in Néel & Deike (Reference Néel and Deike2021), based on the work of Toba (Reference Toba1959).

2.2.3. Details of drops and dry particles

As the bubbles burst at the surface, they release drops into the air above the water surface. Three techniques are combined to measure ejected drops with radii spanning four orders of magnitude, in the range

![]() $r_d= [0.05, 500]\,\unicode{x03BC} \mathrm{m} $

. The first measurement is the digital inline holographic imaging set-up (laser: CrystalLaser Nd:YLF QL527-200-L; camera: Phantom VEO4K-990-L; lens: Infinity K2 DistaMax, fully described in Erinin et al. Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023). The holographic set-up is positioned 5.5 cm above the water surface and captures the large sizes of drops in the range

$r_d= [0.05, 500]\,\unicode{x03BC} \mathrm{m} $

. The first measurement is the digital inline holographic imaging set-up (laser: CrystalLaser Nd:YLF QL527-200-L; camera: Phantom VEO4K-990-L; lens: Infinity K2 DistaMax, fully described in Erinin et al. Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023). The holographic set-up is positioned 5.5 cm above the water surface and captures the large sizes of drops in the range

![]() $r_d= [10, 500]\,\unicode{x03BC} \mathrm{m} $

. The small field of view and frame rate of 20 Hz are chosen so that each drop is counted only once, either on the upward or downward part of its trajectory.

$r_d= [10, 500]\,\unicode{x03BC} \mathrm{m} $

. The small field of view and frame rate of 20 Hz are chosen so that each drop is counted only once, either on the upward or downward part of its trajectory.

Drops are then sucked out of the air above the tank and dried. The dry salt particles in the intermediate range of dry particle diameter,

![]() $D_p= [0.3, 10] \,\unicode{x03BC} \mathrm{m}$

, are counted and sized by the OPS. To improve the accuracy of the particle size measurement, an index of refraction of

$D_p= [0.3, 10] \,\unicode{x03BC} \mathrm{m}$

, are counted and sized by the OPS. To improve the accuracy of the particle size measurement, an index of refraction of

![]() $1.5-0i$

is specified for the sea salt and the

$1.5-0i$

is specified for the sea salt and the

![]() $660 \,\text{nm}$

laser of the OPS (Shettle & Fenn Reference Shettle and Fenn1979). The SMPS measures the smallest particles in the range

$660 \,\text{nm}$

laser of the OPS (Shettle & Fenn Reference Shettle and Fenn1979). The SMPS measures the smallest particles in the range

![]() $D_p= [0.02, 0.8]\,\unicode{x03BC} \mathrm{m} $

. The SMPS and OPS measurements have been used for atmospheric applications where the measured particle itself was of interest (Prather et al. Reference Prather2013; Wang et al. Reference Wang2017), as well as in other bubble bursting experiments where the OPS and SMPS measurements of salt particles are used to access the smallest sizes of drops that we are unable to measure using traditional optical methods (Sampath et al. Reference Sampath, Afshar‐Mohajer, Chandrala, Heo, Gilbert, Austin, Koehler and Katz2019; Jiang et al. Reference Jiang, Rotily, Villermaux and Wang2022; Dubitsky et al. Reference Dubitsky, Stokes, Deane and Bird2023). To plot all three drop/aerosol measurements together, we convert the SMPS and OPS measurements of the dry particle diameter to drop radii by assuming conservation of salt mass in the drop and solving for the drop radius:

$D_p= [0.02, 0.8]\,\unicode{x03BC} \mathrm{m} $

. The SMPS and OPS measurements have been used for atmospheric applications where the measured particle itself was of interest (Prather et al. Reference Prather2013; Wang et al. Reference Wang2017), as well as in other bubble bursting experiments where the OPS and SMPS measurements of salt particles are used to access the smallest sizes of drops that we are unable to measure using traditional optical methods (Sampath et al. Reference Sampath, Afshar‐Mohajer, Chandrala, Heo, Gilbert, Austin, Koehler and Katz2019; Jiang et al. Reference Jiang, Rotily, Villermaux and Wang2022; Dubitsky et al. Reference Dubitsky, Stokes, Deane and Bird2023). To plot all three drop/aerosol measurements together, we convert the SMPS and OPS measurements of the dry particle diameter to drop radii by assuming conservation of salt mass in the drop and solving for the drop radius:

![]() $r_d = ({1}/{2})D_p({\rho _{dry}}/\rho _s)^{1/3}$

. From

$r_d = ({1}/{2})D_p({\rho _{dry}}/\rho _s)^{1/3}$

. From

![]() $\rho _s$

= 36 g L−1 and

$\rho _s$

= 36 g L−1 and

![]() $\rho _{dry}$

= 2,056 g L−1, we have

$\rho _{dry}$

= 2,056 g L−1, we have

![]() $r_d \approx 2D_p$

, as discussed in Lewis & Schwartz (Reference Lewis and Schwartz2004), which is a relation classically used to convert between the salt dry particle size and the liquid drop radius.

$r_d \approx 2D_p$

, as discussed in Lewis & Schwartz (Reference Lewis and Schwartz2004), which is a relation classically used to convert between the salt dry particle size and the liquid drop radius.

To quantify the background noise of aerosols remaining in the system, SMPS and OPS measurements were performed for a solution of DI water immediately before each artificial seawater case is run. The calculated background is then subtracted from the size distribution, smoothed using a Savitzky-Golay filter, and cut to the trusted measurement region. In order for all three measurements to be plotted together, the native units output by the SMPS are converted to the normalised concentration

![]() $N_d(r_d)$

, such that integrating the distribution gives a number of particles per unit volume (see Erinin et al. (Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023) for conversion details).

$N_d(r_d)$

, such that integrating the distribution gives a number of particles per unit volume (see Erinin et al. (Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023) for conversion details).

We note that some drops above

![]() $r_d= 200\,\unicode{x03BC} \mathrm{m}$

may not be detected by the holographic measurement because they fall back to the surface before reaching the measurement region (Néel & Deike Reference Deike2022). To confirm the presence of these large drops, the drop measurements were supplemented with a shadow imaging measurement (for drops of radii

$r_d= 200\,\unicode{x03BC} \mathrm{m}$

may not be detected by the holographic measurement because they fall back to the surface before reaching the measurement region (Néel & Deike Reference Deike2022). To confirm the presence of these large drops, the drop measurements were supplemented with a shadow imaging measurement (for drops of radii

![]() $r_d \gt 150 \,\unicode{x03BC} \mathrm{m}$

) for the narrow-

$r_d \gt 150 \,\unicode{x03BC} \mathrm{m}$

) for the narrow-

![]() $2 \,\text{mm}$

, narrow-

$2 \,\text{mm}$

, narrow-

![]() $3 \,\text{mm}$

, narrow-

$3 \,\text{mm}$

, narrow-

![]() $250\,\unicode{x03BC} \mathrm{m}$

and broad-

$250\,\unicode{x03BC} \mathrm{m}$

and broad-

![]() $2 \,\text{mm}$

cases. This measurement was added directly above the level of the water surface to quantify large drops that may not have reached the holographic measurement region (camera: Basler acA2040-90; telecentric lens: Opto-E TC4MHR096-C). Details of the shadow measurement are included in table 2, and the imaging set-up is described for drop measurements in Erinin et al. (Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023).

$2 \,\text{mm}$

cases. This measurement was added directly above the level of the water surface to quantify large drops that may not have reached the holographic measurement region (camera: Basler acA2040-90; telecentric lens: Opto-E TC4MHR096-C). Details of the shadow measurement are included in table 2, and the imaging set-up is described for drop measurements in Erinin et al. (Reference Erinin, Néel, Mazzatenta, Duncan and Deike2023).

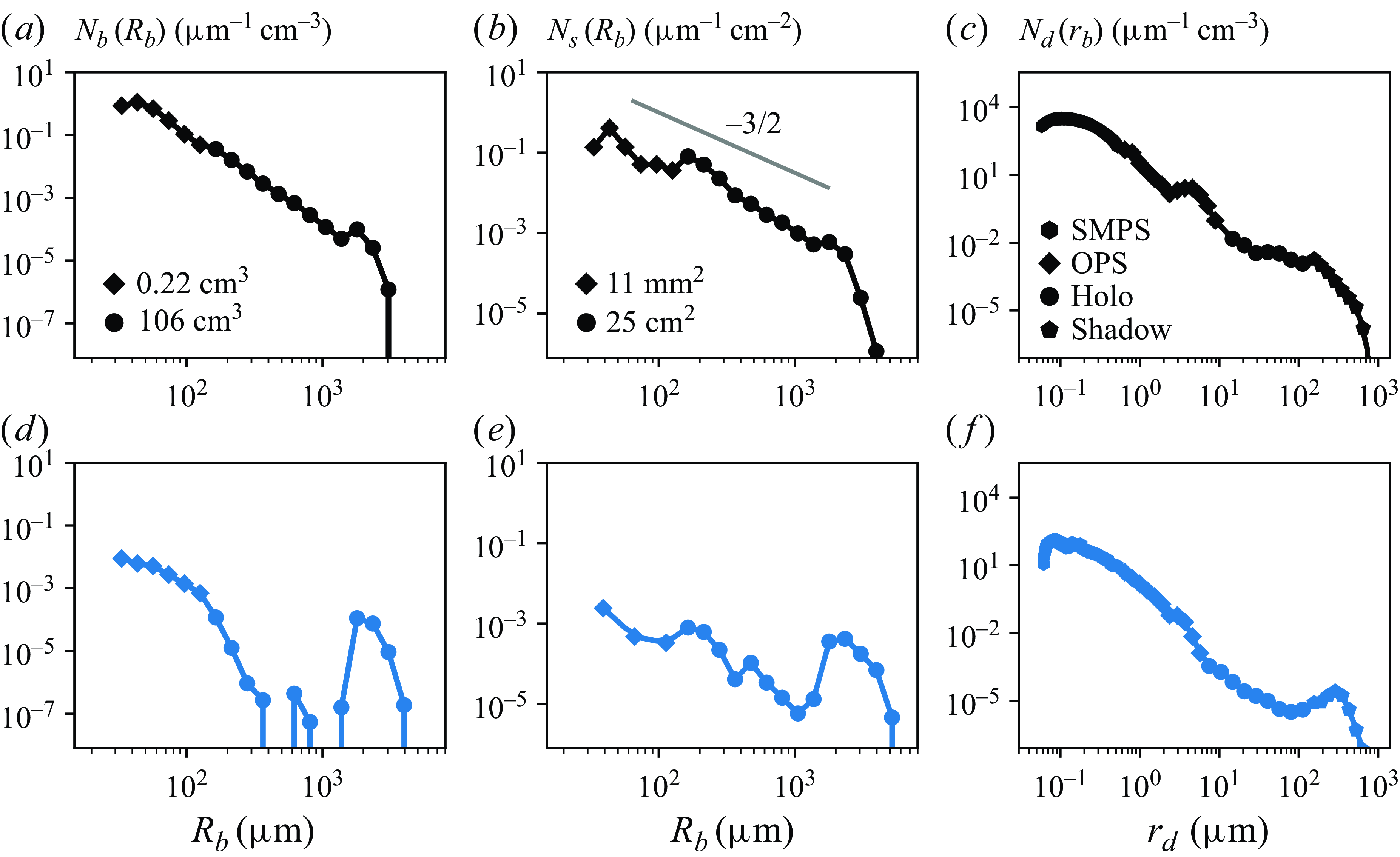

2.2.4. Typical bubble and drop size distributions

The systematic measurements described above for a wide range of scales allow us to extract full size distributions for both drops and bubbles and probe different conditions in a systematic way (conditions summarised in table 1, with sample surface images in figure 1). We illustrate the characterisation of the size distribution for two representative cases in figure 4, the broad-

![]() $2\,\text{mm}$

and narrow-

$2\,\text{mm}$

and narrow-

![]() $2\,\text{mm}$

cases.

$2\,\text{mm}$

cases.

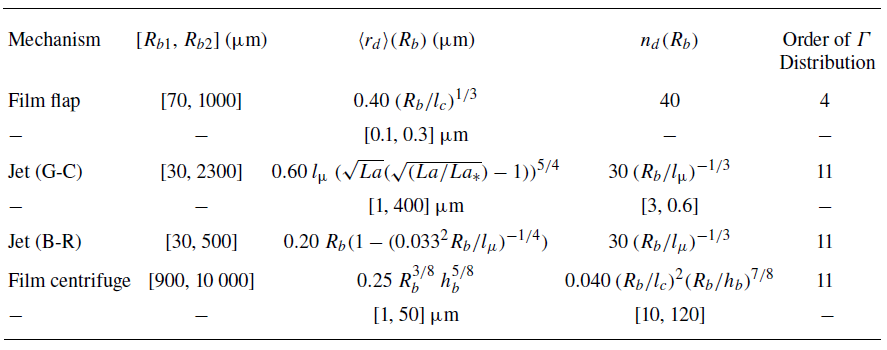

Figure 4. Size distributions of bulk bubbles,

![]() $N_b(R_b)$

(a,d), surface bubbles,

$N_b(R_b)$

(a,d), surface bubbles,

![]() $N_s(R_b)$

(b,e) and drops,

$N_s(R_b)$

(b,e) and drops,

![]() $N_d(r_d)$

(c,f) for broad-banded (a–c) and narrow-banded (d–f) distributions of rising bubbles (see cases broad-

$N_d(r_d)$

(c,f) for broad-banded (a–c) and narrow-banded (d–f) distributions of rising bubbles (see cases broad-

![]() $2\,\text{mm}$

and narrow-

$2\,\text{mm}$

and narrow-

![]() $2\,\text{mm}$

in table 1). Different symbols indicate the different fields of view (bubble measurements) or the different measurement techniques (drop/particle measurements). The drop size distribution is shown in terms of the liquid drop radius,

$2\,\text{mm}$

in table 1). Different symbols indicate the different fields of view (bubble measurements) or the different measurement techniques (drop/particle measurements). The drop size distribution is shown in terms of the liquid drop radius,

![]() $r_d$

. All distributions are interpolated over the logarithmically-spaced bins, with the interpolated distribution plotted over the data points.

$r_d$

. All distributions are interpolated over the logarithmically-spaced bins, with the interpolated distribution plotted over the data points.

Using bubble sizes and counts extracted from the images through the methods described in the previous sections, we plot the size distributions of the detected bulk and surface bubbles,

![]() $N_b(R_b)$

and

$N_b(R_b)$

and

![]() $N_s(R_b)$

, shown in figure 4, normalised by the bin size and by the measurement volume or area, respectively. For both bubble size distributions, data from the large and small field-of-view measurements are represented by different symbols and nicely overlap. Note that the bubble radius

$N_s(R_b)$

, shown in figure 4, normalised by the bin size and by the measurement volume or area, respectively. For both bubble size distributions, data from the large and small field-of-view measurements are represented by different symbols and nicely overlap. Note that the bubble radius

![]() $R_b$

represents the volumetric bubble radius for both the bulk and surface measurements.

$R_b$

represents the volumetric bubble radius for both the bulk and surface measurements.

For the drop size distribution, all measurements are expressed as

![]() $N_d(r_d)$

, the number of drops per unit bin size and unit measurement volume. Data from the SMPS, OPS, holographic imaging, and shadow imaging overlap well, and the combined measurements result in a single distribution that characterizes drops spanning

$N_d(r_d)$

, the number of drops per unit bin size and unit measurement volume. Data from the SMPS, OPS, holographic imaging, and shadow imaging overlap well, and the combined measurements result in a single distribution that characterizes drops spanning

![]() $50\,\text{nm}$

to

$50\,\text{nm}$

to

![]() $500\,\unicode{x03BC} \mathrm{m}$

. For the broad-banded case, we observe a continuum of bubble radii spanning

$500\,\unicode{x03BC} \mathrm{m}$

. For the broad-banded case, we observe a continuum of bubble radii spanning

![]() $R_b= [30, 5000]\,\unicode{x03BC} \mathrm{m}$

in both the bulk and the surface (figure 4

a,b). We see a corresponding continuum of drop radii spanning

$R_b= [30, 5000]\,\unicode{x03BC} \mathrm{m}$

in both the bulk and the surface (figure 4

a,b). We see a corresponding continuum of drop radii spanning

![]() $r_d= [0.05, 500]\,\unicode{x03BC} \mathrm{m} $

(figure 4

c). In the narrow-banded case, we see a narrow peak of bubble sizes around the injection bubble radius,

$r_d= [0.05, 500]\,\unicode{x03BC} \mathrm{m} $

(figure 4

c). In the narrow-banded case, we see a narrow peak of bubble sizes around the injection bubble radius,

![]() $R_b= 2.3 \,\text{mm}$

(figure 4

d,e). We refer to this case as narrow-banded, or nearly monodisperse, because the majority of bubbles are found in this peak around 2 mm. Some amount of smaller bubbles are also present for this narrow-banded case (formed as bubbles pinch off from the needles), and there are also smaller drops, shown in the drop size distribution below

$R_b= 2.3 \,\text{mm}$

(figure 4

d,e). We refer to this case as narrow-banded, or nearly monodisperse, because the majority of bubbles are found in this peak around 2 mm. Some amount of smaller bubbles are also present for this narrow-banded case (formed as bubbles pinch off from the needles), and there are also smaller drops, shown in the drop size distribution below

![]() $r_d \sim 200 \,\unicode{x03BC} \mathrm{m}$

(figure 4

f). The bulk and surface distributions show similar trends in both conditions, suggesting limited coalescence (which is expected for artificial seawater).

$r_d \sim 200 \,\unicode{x03BC} \mathrm{m}$

(figure 4

f). The bulk and surface distributions show similar trends in both conditions, suggesting limited coalescence (which is expected for artificial seawater).

2.3. Summary of the experimental analysis

Having obtained the full size distributions of bubbles and drops, we now analyse the link between the different measurements to systematically quantify the attribution of drops to bursting surface bubbles. In § 3 we link the measured bulk bubble size distribution (which integrates to a number per unit volume) with the surface bubble size distribution (which integrates to a number per unit area) using a simple flux argument involving the bubble rise velocity and the bubble lifetime at the surface. We then analyse the link between bursting bubbles and drops in § 4. We consider a direct attribution of measured drops to measured bubbles in § 4.1, and in § 4.2 we predict a drop size distribution from the measured bubbles using existing scaling laws developed for individual bubble bursting.

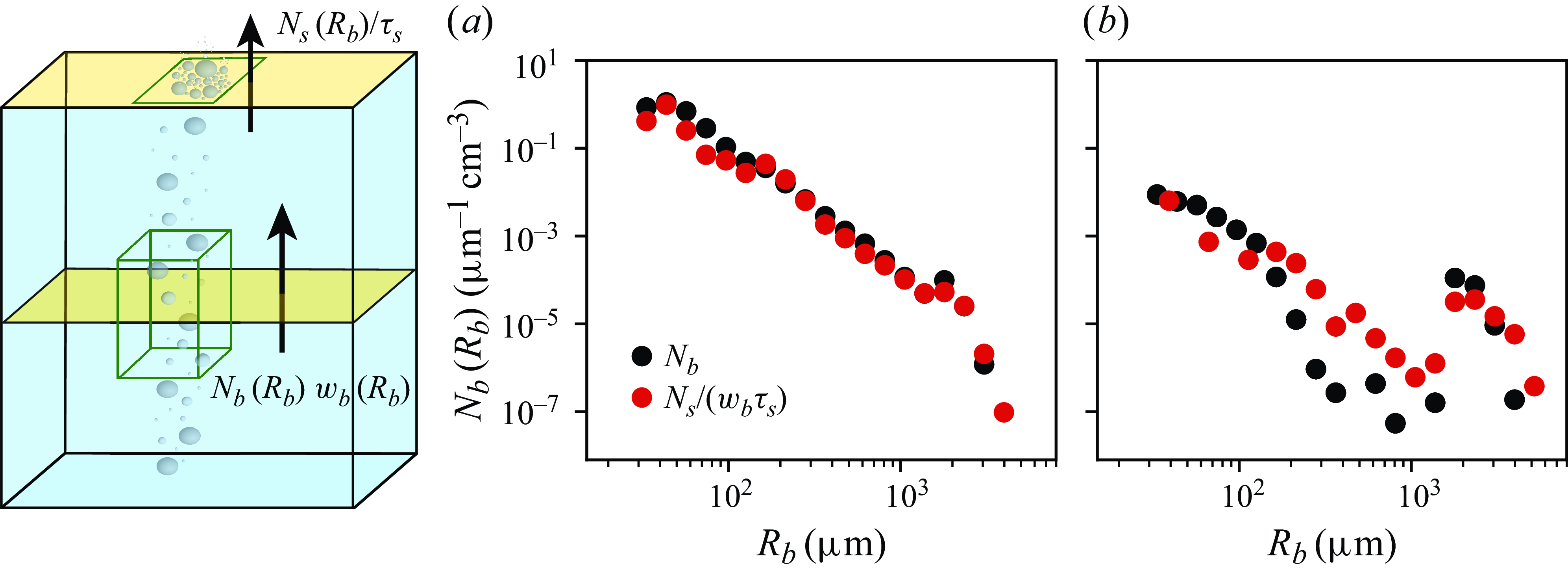

3. Linking bulk and surface bubble size distributions

We now quantitatively connect the bulk bubble and surface bubble size distributions. The size distribution of bubbles bursting at the surface may evolve from the distribution seen in the bulk due to factors like coalescence, formation of child bubbles after bursting, and size-dependent time scales associated with the rising and bursting of the bubbles. For the artificial seawater solution used in this experiment, we demonstrate that the surface and bulk distributions can be related through simple assumptions used to equate a flux of bubbles through a plane in the bulk to a flux of bubbles at the surface, as illustrated by the sketch in figure 5.

Figure 5. Comparison of the measured bulk bubble size distribution

![]() $N_b(R_b)$

to the converted surface bubble size distribution, which is represented as a quantity normalised by a measurement volume following (3.1). The comparison is shown for the medium bubble size cases of (a) broad-banded and (b) narrow-banded bulk bubble size distributions. The sketch illustrates the bulk measurement volume and surface measurement area (outlined in green, not to scale), as well as the fluxes through planes in the bulk (

$N_b(R_b)$

to the converted surface bubble size distribution, which is represented as a quantity normalised by a measurement volume following (3.1). The comparison is shown for the medium bubble size cases of (a) broad-banded and (b) narrow-banded bulk bubble size distributions. The sketch illustrates the bulk measurement volume and surface measurement area (outlined in green, not to scale), as well as the fluxes through planes in the bulk (

![]() $N_b(R_b)w_b$

) and at the surface (

$N_b(R_b)w_b$

) and at the surface (

![]() $N_s(R_b)/\tau _s$

). Bubbles and drops not drawn to scale.

$N_s(R_b)/\tau _s$

). Bubbles and drops not drawn to scale.

The surface bubbles are measured over an area, so that

![]() $N_s(R_b)$

is a number per unit bin size per unit area, while the bulk bubbles are measured in a volume underwater, so that

$N_s(R_b)$

is a number per unit bin size per unit area, while the bulk bubbles are measured in a volume underwater, so that

![]() $N_b(R_b)$

is a number per unit bin size per unit volume. To link the two, we equate the flux of bubbles that rise through a plane underwater,

$N_b(R_b)$

is a number per unit bin size per unit volume. To link the two, we equate the flux of bubbles that rise through a plane underwater,

![]() $N_b(R_b)w_b(R_b)$

, to a flux of bubbles arriving and bursting at the surface,

$N_b(R_b)w_b(R_b)$

, to a flux of bubbles arriving and bursting at the surface,

![]() $N_s(R_b)/\tau _s$

, where

$N_s(R_b)/\tau _s$

, where

![]() $w_b(R_b)$

is the bubble rise velocity and

$w_b(R_b)$

is the bubble rise velocity and

![]() $\tau _s$

the bubble lifetime at the surface. The link between the two distributions reads

$\tau _s$

the bubble lifetime at the surface. The link between the two distributions reads

The bubble rise velocity

![]() $w_b(R_b)$

is a function of the bubble size, and we use the semi-empirical rise velocity parameterisation for contaminated water presented in Clift, Grace & Weber (Reference Clift, Grace and Weber1978, p. 172). The time scale required for the flux of surface bubbles is the bubble lifetime

$w_b(R_b)$

is a function of the bubble size, and we use the semi-empirical rise velocity parameterisation for contaminated water presented in Clift, Grace & Weber (Reference Clift, Grace and Weber1978, p. 172). The time scale required for the flux of surface bubbles is the bubble lifetime

![]() $\tau _s$

. Significant uncertainty remains surrounding the dependence of bubble lifetime on the bubble size and properties of the solution (see table 1 in Poulain, Villermaux & Bourouiba Reference Poulain, Villermaux and Bourouiba2018), so for simplicity, we consider a reasonable estimate of a constant bubble lifetime of

$\tau _s$

. Significant uncertainty remains surrounding the dependence of bubble lifetime on the bubble size and properties of the solution (see table 1 in Poulain, Villermaux & Bourouiba Reference Poulain, Villermaux and Bourouiba2018), so for simplicity, we consider a reasonable estimate of a constant bubble lifetime of

![]() $O(1)$

second (we assume that

$O(1)$

second (we assume that

![]() $\tau _s = 0.6\,\text{s}$

). Equation (3.1) effectively neglects the effect of coalescence at the surface, which is generally an appropriate simplification given the seawater salinity of the solution (effect of salts on bubble coalescence reviewed in Firouzi, Howes & Nguyen Reference Firouzi, Howes and Nguyen2015).

$\tau _s = 0.6\,\text{s}$

). Equation (3.1) effectively neglects the effect of coalescence at the surface, which is generally an appropriate simplification given the seawater salinity of the solution (effect of salts on bubble coalescence reviewed in Firouzi, Howes & Nguyen Reference Firouzi, Howes and Nguyen2015).

The comparison between the bulk size distribution and converted surface distribution (calculated using (3.1)) are shown in figure 5 for the two typical cases presented in the previous section (figure 4 , broad-

![]() $2\,\text{mm}$

and narrow-

$2\,\text{mm}$

and narrow-

![]() $2\,\text{mm}$

). We see good agreement in the overall trends and magnitudes of the measured bulk distributions and the converted surface distributions for both the (a) broad-banded case with turbulence present and (b) narrow-banded distributions with no turbulent flow. This indicates that, for this configuration, (i) coalescence is not a dominant process to account for, and (ii) a constant

$2\,\text{mm}$

). We see good agreement in the overall trends and magnitudes of the measured bulk distributions and the converted surface distributions for both the (a) broad-banded case with turbulence present and (b) narrow-banded distributions with no turbulent flow. This indicates that, for this configuration, (i) coalescence is not a dominant process to account for, and (ii) a constant

![]() $\tau _s$

is a reasonable approximation.

$\tau _s$

is a reasonable approximation.

Some words of caution are required when presenting the flux-based comparison. We have chosen one particular rise velocity parameterisation and a constant bubble lifetime to evaluate the flux argument. Other relations for the rise velocity were also tested, including the parameterisation from Woolf & Thorpe (Reference Woolf and Thorpe1991) that gives a similar result aside from a slightly different velocity for the smallest bubbles. We could also have considered the effect of the background turbulence on the rise velocity, which systematically slows down the rise velocity of the bubbles (Ruth et al. Reference Ruth, Vernet, Perrard and Deike2021; Liu et al. Reference Liu, Farsoiya, Perrard and Deike2024) (we note that a systematically lower rise velocity could be compensated for by a slightly higher value of the bubble lifetime, within the uncertainties of experimentally measured bubble lifetime). Note that by integrating

![]() $\int _A(\int _{R_{b1}}^{R_{b2}} N_b(R_b)({4}/{3})\pi R_b^3w_{b}(R_b)\,{\rm d}R_b)\,{\rm d}A\,$

over the total range of bubbles sizes [

$\int _A(\int _{R_{b1}}^{R_{b2}} N_b(R_b)({4}/{3})\pi R_b^3w_{b}(R_b)\,{\rm d}R_b)\,{\rm d}A\,$

over the total range of bubbles sizes [

![]() $R_{b1}$

,

$R_{b1}$

,

![]() $R_{b2}$

] and the area

$R_{b2}$

] and the area

![]() $A$

of the plane through which the bubbles rise, we do obtain air flow rates that are consistent with the total prescribed air flow rate given in table 1 (and controlled primarily by the largest bubbles). By assuming (3.1) and a rise velocity function, we could also have extracted an effective bubble lifetime function. While uncertainty remains in both the chosen rise velocity and lifetime, we find that we can relate the bulk and surface bubble size distributions well for all the cases presented in the paper, so that we can use the bulk and surface measurements interchangeably by applying (3.1).

$A$

of the plane through which the bubbles rise, we do obtain air flow rates that are consistent with the total prescribed air flow rate given in table 1 (and controlled primarily by the largest bubbles). By assuming (3.1) and a rise velocity function, we could also have extracted an effective bubble lifetime function. While uncertainty remains in both the chosen rise velocity and lifetime, we find that we can relate the bulk and surface bubble size distributions well for all the cases presented in the paper, so that we can use the bulk and surface measurements interchangeably by applying (3.1).

In the following analysis, we use an effective size distribution for bursting bubbles (using both surface and bulk data) to practically relate the bubbles to the drop size distribution, which is measured per unit volume. A direct link between bursting bubbles and emitted drops in terms of fluxes would require measurements of the drop velocity (not available here). To come up with this effective bubble size distribution, the surface bubble distribution is first converted to a quantity of bursting bubbles normalised by a volume, following (3.1). For bubbles below

![]() $R_b= 150\,\unicode{x03BC} \mathrm{m}$

, we use data from the bulk small field-of-view measurement to construct a complete size distribution of bubbles spanning

$R_b= 150\,\unicode{x03BC} \mathrm{m}$

, we use data from the bulk small field-of-view measurement to construct a complete size distribution of bubbles spanning

![]() $R_b= [30, 5000]\,\unicode{x03BC} \mathrm{m} $

. Throughout the rest of the paper, the term

$R_b= [30, 5000]\,\unicode{x03BC} \mathrm{m} $

. Throughout the rest of the paper, the term

![]() $N_b(R_b)$

is used to represent this size distribution of bursting bubbles from the combined measurements, with the exception of the narrow-

$N_b(R_b)$

is used to represent this size distribution of bursting bubbles from the combined measurements, with the exception of the narrow-

![]() $250\,\unicode{x03BC} \mathrm{m}$

case, which uses only the converted surface data due to imaging/detection difficulties for bubbles in the denser bulk plume.

$250\,\unicode{x03BC} \mathrm{m}$

case, which uses only the converted surface data due to imaging/detection difficulties for bubbles in the denser bulk plume.

4. Linking drops and bursting bubbles

We can now analyse the link between the surface bubbles and ejected drops in the collective bursting configuration by examining how the drop size distribution changes as the bubble size distribution is intentionally varied through the different cases.

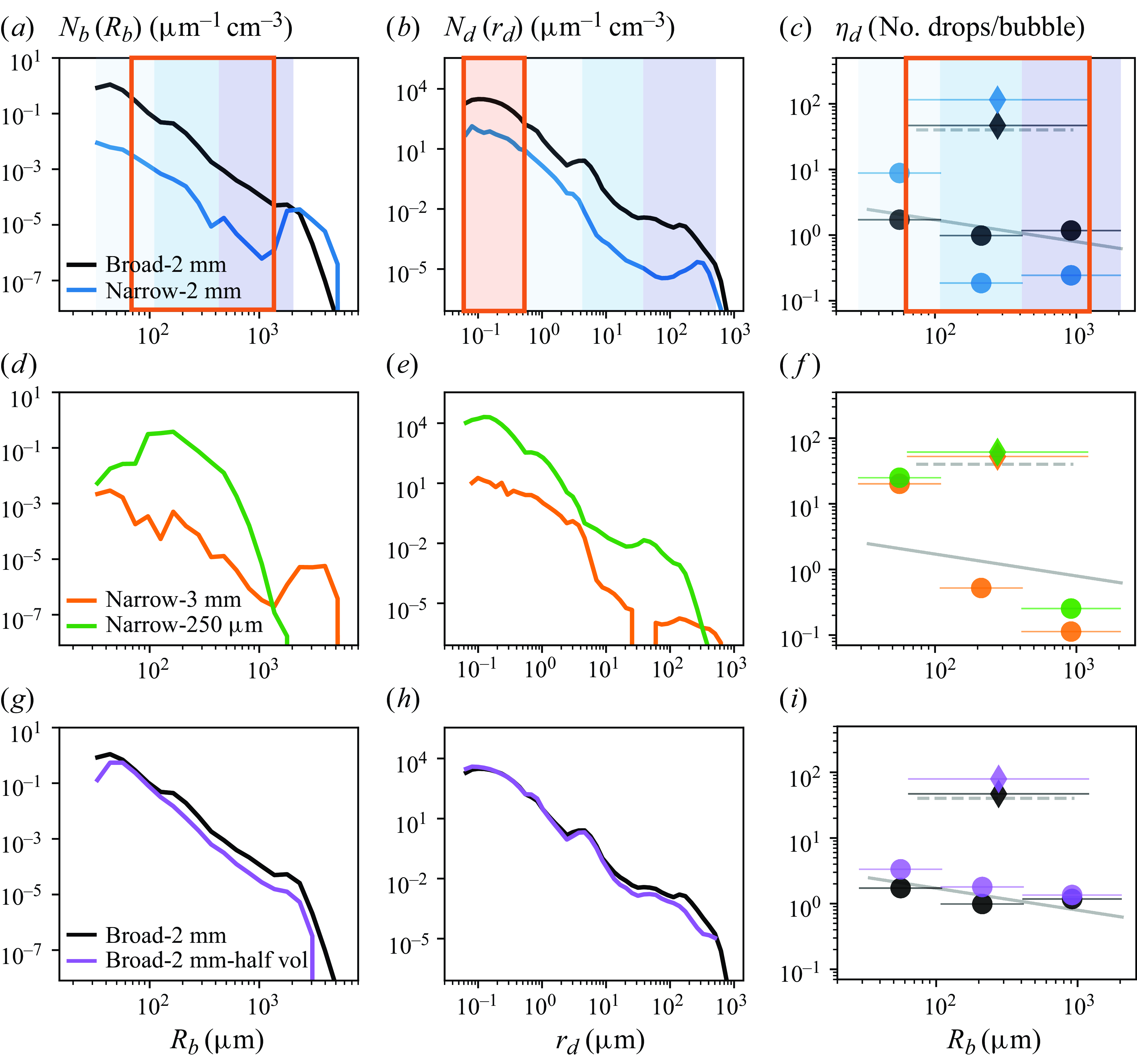

4.1. Direct attribution between measured bubbles and drops

We first show the drop size distributions resulting from various bubble size distributions and discuss how different sizes of drops may be attributed to different sizes of bursting bubbles. Figure 6 shows the size distributions of bursting bubbles,

![]() $N_b(R_b)$

(a,d,g), and drops,

$N_b(R_b)$

(a,d,g), and drops,

![]() $N_d(r_d)$

(b,e,h), as well as the ratio of the number of drops produced per bubble

$N_d(r_d)$

(b,e,h), as well as the ratio of the number of drops produced per bubble

![]() $\eta _d$

(c,f,i), in chosen size ranges.

$\eta _d$

(c,f,i), in chosen size ranges.

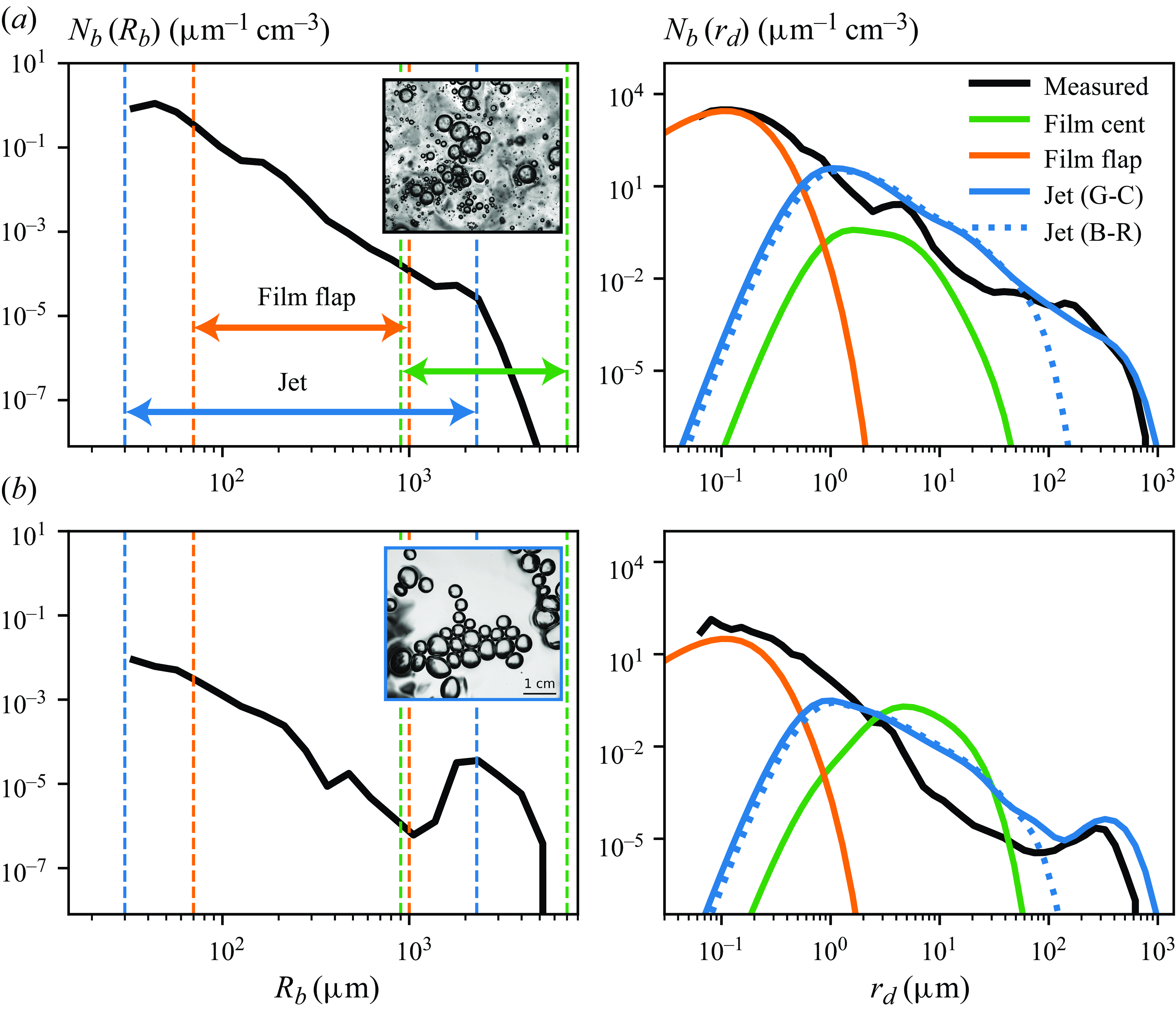

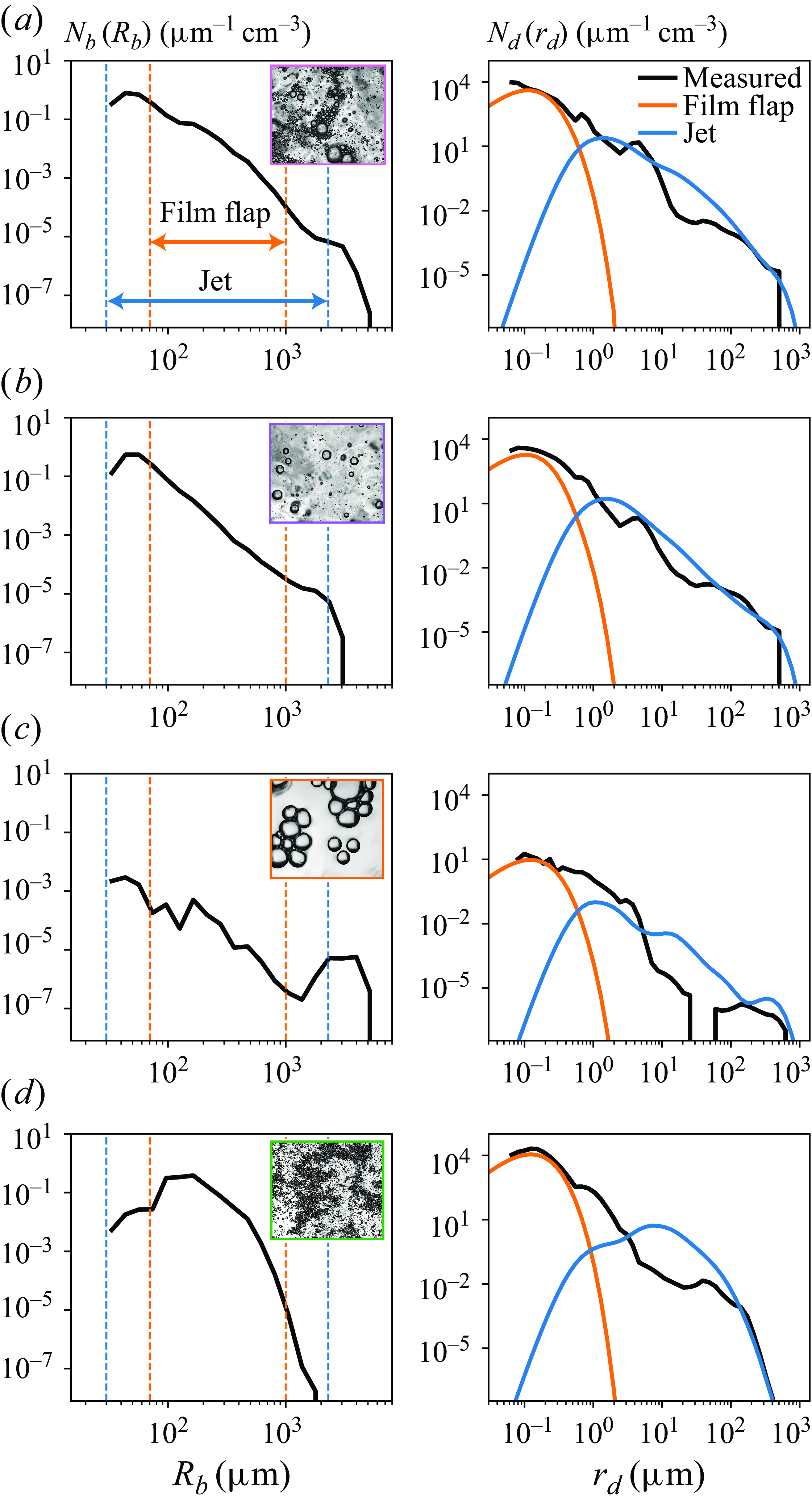

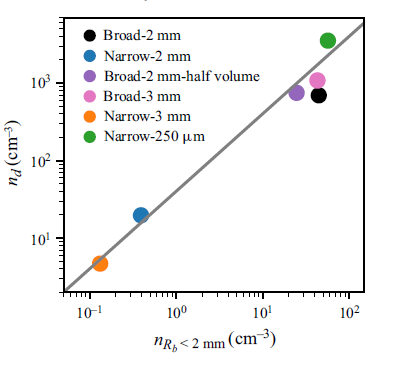

Figure 6. Size distributions of bursting bubbles,

![]() $N_b(R_b)$

(a,d,g), and drops,

$N_b(R_b)$

(a,d,g), and drops,

![]() $N_d(r_d)$

(b,e,h), in terms of the liquid drop radius,

$N_d(r_d)$

(b,e,h), in terms of the liquid drop radius,

![]() $r_d$

, for various case comparisons. The bubble size distributions presented vary significantly, including broad-banded cases and three narrow-banded cases peaking at radii of

$r_d$

, for various case comparisons. The bubble size distributions presented vary significantly, including broad-banded cases and three narrow-banded cases peaking at radii of

![]() $2\,\mathrm{mm}$

,

$2\,\mathrm{mm}$

,

![]() $3\,\mathrm{mm}$

and

$3\,\mathrm{mm}$

and

![]() $250\,\unicode{x03BC} \mathrm{m}$

, with a corresponding variety of drop size distributions. To calculate the drop production efficiency presented in the rightmost column (c,f,i), the bubble and drop size distributions are first integrated in the shaded or outlined size buckets, where the link between the bubble and drop sizes approximates the link suggested by scaling laws for individual bubble bursting. The resulting number of drops in each size range is then divided by the number of bubbles in the corresponding shaded size range (outlined for the film flap range) to obtain an average number of drops produced per bubble in each bubble size bucket (production efficiency

$250\,\unicode{x03BC} \mathrm{m}$

, with a corresponding variety of drop size distributions. To calculate the drop production efficiency presented in the rightmost column (c,f,i), the bubble and drop size distributions are first integrated in the shaded or outlined size buckets, where the link between the bubble and drop sizes approximates the link suggested by scaling laws for individual bubble bursting. The resulting number of drops in each size range is then divided by the number of bubbles in the corresponding shaded size range (outlined for the film flap range) to obtain an average number of drops produced per bubble in each bubble size bucket (production efficiency

![]() $\eta _d$

, shown as circles within the jet drop size range corresponding to the blue shaded regions and diamonds for the assumed film flap drop size range corresponding to the orange boxes). Shaded grey lines show the number of drops per bubble predicted by the individual bubble bursting scalings for jet (solid line) and film flapping (dotted line) production mechanisms (tested in § 4.2; see table 3 for details). Cases shown are (a–c) narrow-

$\eta _d$

, shown as circles within the jet drop size range corresponding to the blue shaded regions and diamonds for the assumed film flap drop size range corresponding to the orange boxes). Shaded grey lines show the number of drops per bubble predicted by the individual bubble bursting scalings for jet (solid line) and film flapping (dotted line) production mechanisms (tested in § 4.2; see table 3 for details). Cases shown are (a–c) narrow-

![]() $2\,\mathrm{mm}$

versus broad-

$2\,\mathrm{mm}$

versus broad-

![]() $2\,\mathrm{mm}$

, (d–f) narrow-

$2\,\mathrm{mm}$

, (d–f) narrow-

![]() $3\,\mathrm{mm}$

versus narrow-

$3\,\mathrm{mm}$

versus narrow-

![]() $250\,\unicode{x03BC} \mathrm{m}$

and (g–i) broad-

$250\,\unicode{x03BC} \mathrm{m}$

and (g–i) broad-

![]() $2\,\mathrm{mm}$

versus broad-

$2\,\mathrm{mm}$

versus broad-

![]() $2\,\mathrm{mm}$

-half volume. Further details of each case are found in table 1, and the uncertainty associated with the production efficiency values shown in (c,f,i) is discussed in Appendix B.

$2\,\mathrm{mm}$

-half volume. Further details of each case are found in table 1, and the uncertainty associated with the production efficiency values shown in (c,f,i) is discussed in Appendix B.

Figure 6(a–c) shows the two sample cases described in § 2.2.4 (figures 4 and 5, narrow- and broad-

![]() $2\,\mathrm{mm}$

injection cases). Both cases use the same needles and flow rate, but in the broad case turbulent flow is created underwater. As described above, turbulence induces bubble breakup and creates a broad-banded bubble size distribution with a continuum of bubbles spanning radii of

$2\,\mathrm{mm}$

injection cases). Both cases use the same needles and flow rate, but in the broad case turbulent flow is created underwater. As described above, turbulence induces bubble breakup and creates a broad-banded bubble size distribution with a continuum of bubbles spanning radii of

![]() $30\,\unicode{x03BC} \mathrm{m}$

to almost

$30\,\unicode{x03BC} \mathrm{m}$

to almost

![]() $5\,\mathrm{mm}$

. Without turbulence, the distribution has a peak around

$5\,\mathrm{mm}$

. Without turbulence, the distribution has a peak around

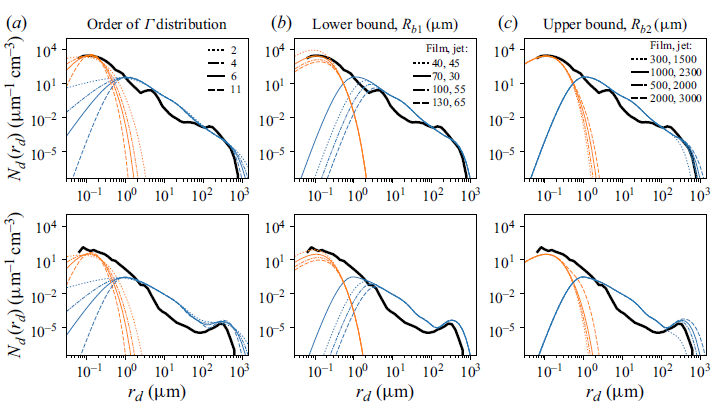

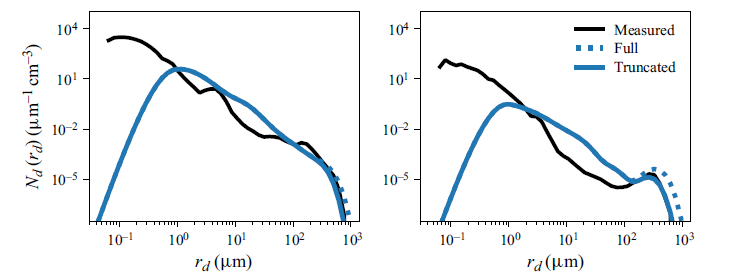

![]() $R_b= 2 \,\text{mm}$