Article contents

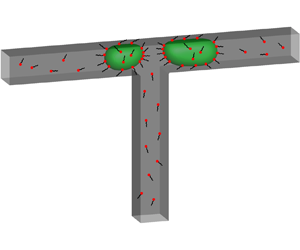

Modelling the passive breakup of a surfactant-contaminated droplet in a T-junction microchannel

Published online by Cambridge University Press: 06 May 2024

Abstract

A lattice Boltzmann method is used to explore the effect of surfactants on the unequal volume breakup of a droplet in a T-junction microchannel, and the asymmetry due to fabrication defects in real-life microchannels is modelled as the pressure difference between the two branch outlets ( $\Delta {P^\ast }$). We first study the effect of the surfactants on the droplet dynamics at different dimensionless initial droplet lengths (

$\Delta {P^\ast }$). We first study the effect of the surfactants on the droplet dynamics at different dimensionless initial droplet lengths ( $l_0^\ast $) and capillary numbers (Ca) under symmetric boundary conditions (

$l_0^\ast $) and capillary numbers (Ca) under symmetric boundary conditions ( $\Delta {P^\ast } = 0$). The results indicate that the presence of surfactants promotes droplet deformation and breakup at small and moderate

$\Delta {P^\ast } = 0$). The results indicate that the presence of surfactants promotes droplet deformation and breakup at small and moderate  $l_0^\ast $ values, while the surfactant effect is weakened at large

$l_0^\ast $ values, while the surfactant effect is weakened at large  $l_0^\ast $ values. When the branch channels are completely blocked by the droplet, a linear relationship is observed between the dimensionless droplet length (

$l_0^\ast $ values. When the branch channels are completely blocked by the droplet, a linear relationship is observed between the dimensionless droplet length ( $l_d^\ast $) and dimensionless time (

$l_d^\ast $) and dimensionless time ( ${t^\ast }$), and two formulas are proposed for predicting the evolution of

${t^\ast }$), and two formulas are proposed for predicting the evolution of  $l_d^\ast $ with

$l_d^\ast $ with  ${t^\ast }$ for the two systems. We then investigate the effect of the surfactants on the droplet breakup at different values of

${t^\ast }$ for the two systems. We then investigate the effect of the surfactants on the droplet breakup at different values of  $\Delta {P^\ast }$ and bulk surfactant concentrations (

$\Delta {P^\ast }$ and bulk surfactant concentrations ( ${\psi _b}$) under asymmetric boundary conditions (

${\psi _b}$) under asymmetric boundary conditions ( $\Delta {P^\ast } \ne 0$). It is observed that, as

$\Delta {P^\ast } \ne 0$). It is observed that, as  $\Delta {P^\ast }$ increases, the volume ratio of the generated droplets (

$\Delta {P^\ast }$ increases, the volume ratio of the generated droplets ( ${V_1}/{V_2}$) decreases to 0 in both systems, while the rate of decrease is higher in the clean system, i.e. the presence of surfactants could cause a decreased pressure difference between the droplet tips. As

${V_1}/{V_2}$) decreases to 0 in both systems, while the rate of decrease is higher in the clean system, i.e. the presence of surfactants could cause a decreased pressure difference between the droplet tips. As  ${\psi _b}$ increases,

${\psi _b}$ increases,  ${V_1}/{V_2}$ first increases rapidly, then remains almost constant and finally decreases slightly. We thus establish a phase diagram that describes the

${V_1}/{V_2}$ first increases rapidly, then remains almost constant and finally decreases slightly. We thus establish a phase diagram that describes the  ${V_1}/{V_2}$ variation with

${V_1}/{V_2}$ variation with  $\Delta {P^\ast }$ and

$\Delta {P^\ast }$ and  ${\psi _b}$.

${\psi _b}$.

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2024. Published by Cambridge University Press

References

- 7

- Cited by