Article contents

Optimising the flow through a concertinaed filtration membrane

Published online by Cambridge University Press: 26 February 2021

Abstract

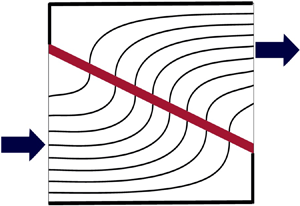

Membrane filtration is a vital industrial process, with applications including air purification and blood filtration. In this paper, we study the optimal design for a concertinaed filtration membrane composed of angled porous membranes and dead ends. The geometry of the filter motivates a lubrication scaling for the flow, leading to a system of coupled (modified) Reynolds equations. By analysing this reduced system, we examine how the filter performance depends on the angle, position, thickness and permeance of the membrane, using a combination of numerical and asymptotic approaches, the latter in the limit of a slightly angled membrane. We find that, for a membrane of fixed angle and physical properties, there can exist multiple membrane positions that maximise the flux for an applied pressure difference. More generally, this shows how coupled problems in lubrication flow can exhibit non-trivial bifurcating optima. For the particular application on which we focus, we show that, while the maximal flux achievable depends on the membrane thickness and permeance, the optimal membrane configuration is always in one of two set-ups: centred and diagonal across the full domain; or angled and in the corner of the domain.

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2021. Published by Cambridge University Press

References

REFERENCES

- 3

- Cited by