1. Introduction

Evaporation in porous media is a process of particular interest in many applications, such as weathering of monuments and buildings (Derluyn, Moonen & Carmeliet Reference Derluyn, Moonen and Carmeliet2014; Veran-Tissoires & Prat Reference Veran-Tissoires and Prat2014), drainage in proton exchange membrane fuel cells (Wu et al. Reference Wu, Zhao, Tsotsas and Kharaghani2017), mineral precipitation induced by saline evaporation in geological carbon sequestration (Huppert & Neufeld Reference Huppert and Neufeld2014; He, Jiang & Xu Reference He, Jiang and Xu2019), self-assembly of porous materials resulting from the evaporation of colloidal suspensions (Hamon et al. Reference Hamon2012) and transpiration cooling for thermal protection (Huang et al. Reference Huang, Zhu, Jiang and Xiong2015b) to name but a few. Some applications would benefit from controlling the evaporation pattern and rate. For example, in the self-assembly of nanoparticles in porous materials, the evaporation rate affects the generation of self-assembled structures and the evaporation pattern determines how and where the particles accumulate and assemble (Qin et al. Reference Qin, Del Carro, Mazloomi Moqaddam, Kang, Brunschwiler, Derome and Carmeliet2019). In geological carbon sequestration, the brine evaporation pattern determines the salt precipitation, which alters the pore structure and transport properties of the reservoir and therefore impairs the injection process (He et al. Reference He, Xu, Ji and Jiang2022; Yang et al. Reference Yang, Lei, Wang, Xu, Chen and Luo2023). In many others, a common aim is to promote a fast evaporation rate to improve the efficiency of water management and thermal management. Thus, the study of evaporation in porous media, with the focus on deeper understanding of the evaporation rate and pattern, can support the advancement in many fields of science and technology.

The global evaporation kinetics of a porous medium is usually presented by the canonical form, i.e. the drying curve, which shows the change of evaporation rate with respect to the degree of liquid saturation (S). In both experimental and simulation work, a typical transition in the drying curve is often observed (Chen & Pei Reference Chen and Pei1989; Coussot Reference Coussot2000; Chauvet et al. Reference Chauvet, Duru, Geoffroy and Prat2009). During the first period, the evaporation rate is essentially constant (or slightly decreasing) and determined mostly by external conditions; this stage of drying is referred to as the constant rate period (CRP). The last period, called the receding front period (RFP), is limited by transport properties of porous media and characterized by an internal evaporation front receding into the porous medium. The intermediate period in between, the falling rate period (FRP), depends on the interplay between external and internal conditions and is characterized by a fast drop in evaporation rate. The CRP discharges a larger amount of liquid in a shorter time than the other two periods. Increasing the CRP average evaporation rate as high as possible and prolonging its duration as long as possible towards lower saturation levels improves the global drying efficiency. The evaporation rate in CRP can be improved by changing atmospheric conditions, e.g. increasing air flow and decreasing relative humidity (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2022, Reference Fei, Qin, Zhao, Derome and Carmeliet2023). Laurindo & Prat (Reference Laurindo and Prat1998) investigated the evaporation process in a two-dimensional (2-D) quasi-isothermal micromodel of three basic cases, namely in the absence of gravity forces, in a stabilizing gravity field and in a destabilizing gravity field, and found that thin liquid films have significant contributions to the evaporation rate. Alternatively, drying can be improved by optimizing the porous medium itself. Shokri, Lehmann & Or (Reference Shokri, Lehmann and Or2010) conducted drying experiments in layered porous media. The duration of CRP is shown to depend on the thickness of each layer and their layering sequence. A composite characteristic length is proposed to predict the drying front depth at the end of CRP, while drying dynamics at the pore scale could not be observed. Pillai, Prat & Marcoux (Reference Pillai, Prat and Marcoux2009) conducted a pore-network study of evaporation in two bilayered porous media, i.e. one with a larger-pore layer covering a smaller-pore layer, and one with a smaller-pore layer covering a larger-pore layer. In the latter case, evaporation starts simultaneously in the two layers due to evaporation in the smaller-pore layer and capillary pumping from the inner larger-pore layer to the top smaller-pore layer, resulting in a global faster evaporation rate than seen in the former case. Wu, Kharaghani & Tsotsas (Reference Wu, Kharaghani and Tsotsas2016) elaborately designed a 2-D microfluidic network in which the liquid saturation decreases linearly with time during its drying, leading to a perfect CRP throughout the drying phase. However, to induce sufficient capillary pumping, the evaporation rate had to be slow, thus requiring a fine throat connected to the outlet. As a result, drying of the ![]() $8\ {\rm mm} \times 8\ {\rm mm}$ chip takes one week. Qin et al. (Reference Qin, Del Carro, Mazloomi Moqaddam, Kang, Brunschwiler, Derome and Carmeliet2019) designed two synthetic micropore structures, i.e. spiral shaped and gradient shaped, to favour capillary pumping. They aimed to extend the CRP until the end of evaporation, although the evaporation rate is decreasing along the pathways. In addition, such structures are limited to the condition that all four boundaries are open to the environment. Using isothermal lattice Boltzmann (LB) simulations (no evaporative cooling included), Panda et al. (Reference Panda, Paliwal, Sourya, Kharaghani, Tsotsas and Surasani2020a) imposed a temperature gradient on a porous medium. The drying pattern exhibits invasion percolation increasing downwards and the CRP holds until

$8\ {\rm mm} \times 8\ {\rm mm}$ chip takes one week. Qin et al. (Reference Qin, Del Carro, Mazloomi Moqaddam, Kang, Brunschwiler, Derome and Carmeliet2019) designed two synthetic micropore structures, i.e. spiral shaped and gradient shaped, to favour capillary pumping. They aimed to extend the CRP until the end of evaporation, although the evaporation rate is decreasing along the pathways. In addition, such structures are limited to the condition that all four boundaries are open to the environment. Using isothermal lattice Boltzmann (LB) simulations (no evaporative cooling included), Panda et al. (Reference Panda, Paliwal, Sourya, Kharaghani, Tsotsas and Surasani2020a) imposed a temperature gradient on a porous medium. The drying pattern exhibits invasion percolation increasing downwards and the CRP holds until ![]() $S \approx 0.1$. The main challenge of this technique lies in obtaining a linear temperature profile inside the porous media, which seems difficult in practice due to evaporative cooling effects.

$S \approx 0.1$. The main challenge of this technique lies in obtaining a linear temperature profile inside the porous media, which seems difficult in practice due to evaporative cooling effects.

As seen above, the global evaporation rate can be increased by means of boundary conditions, optimization of porous media configuration, i.e. pore size, distribution and layering, and the presence of temperature gradient. Despite these great efforts, specifically, the drying of heterogeneous porous media has received relatively little attention. The objective of the present work is to study the effect of heterogeneous configurations of wettability and of pores of different sizes on convective evaporation in a porous medium, where a gas mixture is blown over the surface of a wet porous medium. We use the common assumption of isothermal conditions, at room temperature, meaning thermal effects due to evaporative cooling are considered negligible (Pillai et al. Reference Pillai, Prat and Marcoux2009; Defraeye et al. Reference Defraeye, Blocken, Derome, Nicolai and Carmeliet2012). Different from the work of Pillai et al. (Reference Pillai, Prat and Marcoux2009) who considers the porous medium divided into two layers, here more general cases with multiple layers are considered. Besides, we investigate scenarios of multiple layers with different contact angles or pore sizes first, followed by more complex cases with combined heterogeneous wettability and pore size distribution. The results are analysed in terms of invasion patterns and evaporation dynamics. The complexity of the study is twofold: (i) multiphysics processes are involved and coupled, including liquid–vapour phase change, multiphase interface dynamics and multicomponent transport inside the porous media, as well as convection/diffusion to the surroundings; (ii) phenomena are typically multiscale spatially and temporally, as the characteristic length ranges from the pore scale to the environment scale and the characteristic time spans from fast convection time scale to slow diffusion time scale. For such a study, pore-scale dynamics need to be documented, however, accurate extraction of the dynamic pore-scale information from experimental work is challenging even with the most advanced experimental techniques. To ensure the detailed elucidation of the underlying mechanisms, we use a multicomponent LB model with the ability to resolve the detailed pore-scale evaporation dynamics and complement this work with theoretical analysis.

The lattice Boltzmann method (LBM) (Qian, d'Humières & Lallemand Reference Qian, d'Humières and Lallemand1992; Succi Reference Succi2018), which solves a specific discrete Boltzmann equation designed to reproduce the continuous Navier–Stokes equations in the low-Mach number limit, has been increasingly used as a very powerful pore-scale model for various flows and transport phenomena in complex porous media (Liu et al. Reference Liu, Kang, Leonardi, Schmieschek, Narváez, Jones, Williams, Valocchi and Harting2016; Chen et al. Reference Chen, He, Zhao, Kang, Li, Carmeliet, Shikazono and Tao2022). The mesoscale nature of LBM allows its natural incorporation of microscale and mesoscale physics, providing insightful access to multiphase/multicomponent interface dynamics (Shan & Chen Reference Shan and Chen1993, Reference Shan and Chen1994; Huang, Sukop & Lu Reference Huang, Sukop and Lu2015a; Li et al. Reference Li, Luo, Kang, He, Chen and Liu2016; Huang, Li & Adams Reference Huang, Li and Adams2022). The bounce-back type of boundary schemes in LBM is very suitable for flows in complex pore structures (Liu et al. Reference Liu, Kang, Leonardi, Schmieschek, Narváez, Jones, Williams, Valocchi and Harting2016; Chen et al. Reference Chen, He, Zhao, Kang, Li, Carmeliet, Shikazono and Tao2022), discarding the need for significant simplification of real geometries as done in pore network models (PNMs) (Fatt Reference Fatt1956; Zhao et al. Reference Zhao2019). In addition, the canonical ‘collision-streaming’ algorithm disentangles nonlinearity and non-locality (Succi Reference Succi2015), i.e. the nonlinear collision operator is entirely local and the non-local streaming is linear towards the discrete distribution, making it highly efficient in large-scale parallel computations (Fei et al. Reference Fei, Yang, Chen, Mo and Luo2020; Luo, Fei & Wang Reference Luo, Fei and Wang2021; Wang, Fei & Luo Reference Wang, Fei and Luo2022). Recently, LBM has been extended to study evaporation in porous media. Qin et al. (Reference Qin, Del Carro, Mazloomi Moqaddam, Kang, Brunschwiler, Derome and Carmeliet2019) proposed a thermal entropic multiple-relaxation-time LBM to study the evaporation in synthetic pore structures and achieved a satisfying agreement with experiment results. The model is hybrid, where the flow and temperature fields are solved by a pseudopotential LB model and a finite difference scheme, respectively. Further coupling with a nanoparticle transport model allows us to investigate nanoparticle depositions resulting from evaporation in porous media (Qin et al. Reference Qin, Su, Zhao, Moqaddam, Del Carro, Brunschwiler, Kang, Song, Derome and Carmeliet2020, Reference Qin, Fei, Zhao, Kang, Derome and Carmeliet2023). To improve the computational efficiency, Zhao et al. (Reference Zhao, Qin, Kang, Derome and Carmeliet2022, Reference Zhao, Liu, Qin, Fei, Wang, Shang, Guo and Zhou2023) proposed a coupled LBM–PNM for isothermal evaporation in porous media by using LBM for two-phase regions and PNM for the single-liquid and single-vapour phase regions, respectively. Nevertheless, the above models are limited to single component phase change processes, e.g. systems with pure water and its vapour, without involving the non-condensable component, e.g. dry air in the gas phase. Based on a multicomponent pseudopotential model, Zachariah, Panda & Surasani (Reference Zachariah, Panda and Surasani2019) proposed a two-component LBM to investigate invasion patterns during convective drying of porous media. The model has also been applied to study micro–macro interactions during the drying of bundles of capillaries (Panda et al. Reference Panda, Supriya, Kharaghani, Tsotsas and Surasani2020b) and stabilizing and destabilizing evaporation fronts induced by surface tension gradient during the drying of porous media (Panda et al. Reference Panda, Paliwal, Sourya, Kharaghani, Tsotsas and Surasani2020a). However, the multicomponent diffusion in the gas phase, a key factor affecting the evaporation patterns, is not clearly described in the model of Zachariah et al. (Reference Zachariah, Panda and Surasani2019), and the used LBM collision operator and forcing scheme limit the convective inflow Reynolds number (![]() $Re$) to very small values (

$Re$) to very small values (![]() ${\sim }0.05$). More recently, Fei et al. (Reference Fei, Qin, Zhao, Derome and Carmeliet2022, Reference Fei, Qin, Zhao, Derome and Carmeliet2023) developed a two-component cascaded LBM for convective evaporation in porous media, which includes the correct binary diffusion mechanism in the gas phase and is suitable for convective drying of porous media with varying contact angles (

${\sim }0.05$). More recently, Fei et al. (Reference Fei, Qin, Zhao, Derome and Carmeliet2022, Reference Fei, Qin, Zhao, Derome and Carmeliet2023) developed a two-component cascaded LBM for convective evaporation in porous media, which includes the correct binary diffusion mechanism in the gas phase and is suitable for convective drying of porous media with varying contact angles (![]() $\theta$) and

$\theta$) and ![]() $Re$. Moreover, the model improves significantly the achievable concentration of the non-condensable gas in the gas phase from 1 %–2 % commonly reported in the literature to 95 %, making it able to simulate the evaporation of porous media in the natural environment. The model has been validated by comparison with the theoretical solution of the Stefan problem and microfluidic evaporation experiments by Wu et al. (Reference Wu, Kharaghani and Tsotsas2016). Using the model, Fei et al. (Reference Fei, Qin, Zhao, Derome and Carmeliet2022, Reference Fei, Qin, Zhao, Derome and Carmeliet2023) investigated the convective evaporation of a dual-porosity medium and reproduced the classical transition from CRP to RFP in the drying curve. A universal scaling formulation is also proposed to predict the evaporation rate during CRP with respect to three governing factors, i.e. relative humidity, contact angle

$Re$. Moreover, the model improves significantly the achievable concentration of the non-condensable gas in the gas phase from 1 %–2 % commonly reported in the literature to 95 %, making it able to simulate the evaporation of porous media in the natural environment. The model has been validated by comparison with the theoretical solution of the Stefan problem and microfluidic evaporation experiments by Wu et al. (Reference Wu, Kharaghani and Tsotsas2016). Using the model, Fei et al. (Reference Fei, Qin, Zhao, Derome and Carmeliet2022, Reference Fei, Qin, Zhao, Derome and Carmeliet2023) investigated the convective evaporation of a dual-porosity medium and reproduced the classical transition from CRP to RFP in the drying curve. A universal scaling formulation is also proposed to predict the evaporation rate during CRP with respect to three governing factors, i.e. relative humidity, contact angle ![]() $\theta$ and

$\theta$ and ![]() $Re$.

$Re$.

Despite much literature on the study of evaporation in porous media, the effect of heterogeneous distribution of wettability and pore size on convective evaporation of layered porous media is still not well understood. In this work, we present a systematic study of such a problem using the pore-scale LBM and theoretical analysis. In § 2, we will give a brief introduction to the employed numerical model. The computational set-up is described in § 3, followed by extensive simulations and analysis in § 4. Finally, in § 5, we conclude the paper.

2. Numerical model

For the sake of completeness, the recent LB model for two-component isothermal evaporation in porous media is briefly introduced in this section, and for more details, interested readers are kindly directed to our previous works (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2022, Reference Fei, Qin, Zhao, Derome and Carmeliet2023). Following the standard LB algorithm, our model consists of two steps: (i) the collision step, representing the time relaxation towards the local equilibrium state due to molecular collisions, and (ii) the streaming step, standing for molecular free streaming. The former depends on the collision models while the latter is trivial, which streams the postcollision density distribution function (DDF) for each component k (![]() $=A,B$) at the present space–time point

$=A,B$) at the present space–time point ![]() $( {\boldsymbol {x},t} )$ exactly to the neighbouring lattice point, along the ith lattice direction by the discrete velocity

$( {\boldsymbol {x},t} )$ exactly to the neighbouring lattice point, along the ith lattice direction by the discrete velocity ![]() ${\boldsymbol {e}_i}$ within one time step

${\boldsymbol {e}_i}$ within one time step ![]() $\delta t$, i.e.

$\delta t$, i.e.

The hydrodynamic variables of the two-component mixture (density ![]() $\rho$ and velocity

$\rho$ and velocity ![]() $\boldsymbol {u}$) are updated after the streaming step by the following definitions:

$\boldsymbol {u}$) are updated after the streaming step by the following definitions:

\begin{equation} \rho = \sum_k {{\rho _k}} = \sum_k {\sum_i {f_i^k} } ,\quad \rho {\boldsymbol{u}} = \sum_k {{\rho _k}{{\boldsymbol{u}}_k}} = \sum_k {\left( {\sum_i {f_i^k} {{\boldsymbol{e}}_i} + 0.5\delta t{{\boldsymbol{F}}^k}} \right)}, \end{equation}

\begin{equation} \rho = \sum_k {{\rho _k}} = \sum_k {\sum_i {f_i^k} } ,\quad \rho {\boldsymbol{u}} = \sum_k {{\rho _k}{{\boldsymbol{u}}_k}} = \sum_k {\left( {\sum_i {f_i^k} {{\boldsymbol{e}}_i} + 0.5\delta t{{\boldsymbol{F}}^k}} \right)}, \end{equation}

where ![]() $\rho _k$ ,

$\rho _k$ , ![]() $\boldsymbol {u}_k$ and

$\boldsymbol {u}_k$ and ![]() ${\boldsymbol {F}}^k$ are the component density, component velocity and the total force imposed on each component, respectively.

${\boldsymbol {F}}^k$ are the component density, component velocity and the total force imposed on each component, respectively.

To suit the problems under investigation, a specific collision model can be selected among the many, such as the single-relaxation-time (Qian et al. Reference Qian, d'Humières and Lallemand1992), multiple-relaxation-time (Lallemand & Luo Reference Lallemand and Luo2000), cascaded or central-moment (Geier, Greiner & Korvink Reference Geier, Greiner and Korvink2006) and the entropic-multiple-relaxation-time schemes (Karlin, Bösch & Chikatamarla Reference Karlin, Bösch and Chikatamarla2014), which have been reviewed in detail and integrated into a unified framework (Luo et al. Reference Luo, Fei and Wang2021). In this work, the cascaded model is employed as it possesses excellent numerical stability (Geier et al. Reference Geier, Greiner and Korvink2006; Fei et al. Reference Fei, Yang, Chen, Mo and Luo2020), while it allows achieving non-slip boundary conditions (Fei & Luo Reference Fei and Luo2017; Fei, Luo & Li Reference Fei, Luo and Li2018) and tuning the Schmidt number (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2022, Reference Fei, Qin, Zhao, Derome and Carmeliet2023). In the cascaded LB model, the DDF is first projected onto the central moment space, then central moments at different orders are relaxed towards their equilibria separately, and finally the postcollision DDF is reconstructed. The three substeps of the collision step can be written concisely as

$$\begin{gather} f_i^{k,*}(\boldsymbol{x},t) = f_i^k(\boldsymbol{x},t) - ({{\boldsymbol{M}}^{ - 1}}{\boldsymbol{N}^{ - 1}}{\boldsymbol{S}}{\boldsymbol{NM}})\left[ {f_i^k(\boldsymbol{x},t) - f_i^{k,eq}(\boldsymbol{x},t)} \right]\nonumber\\ + \,\delta t{{\boldsymbol{M}}^{ - 1}}{\boldsymbol{N}^{ - 1}}({\boldsymbol{I}} - {\boldsymbol{S}}/2){\boldsymbol{NM}}R_i^k(\boldsymbol{x},t), \end{gather}$$

$$\begin{gather} f_i^{k,*}(\boldsymbol{x},t) = f_i^k(\boldsymbol{x},t) - ({{\boldsymbol{M}}^{ - 1}}{\boldsymbol{N}^{ - 1}}{\boldsymbol{S}}{\boldsymbol{NM}})\left[ {f_i^k(\boldsymbol{x},t) - f_i^{k,eq}(\boldsymbol{x},t)} \right]\nonumber\\ + \,\delta t{{\boldsymbol{M}}^{ - 1}}{\boldsymbol{N}^{ - 1}}({\boldsymbol{I}} - {\boldsymbol{S}}/2){\boldsymbol{NM}}R_i^k(\boldsymbol{x},t), \end{gather}$$

where ![]() $f_i^{k,eq}$ is the k-component equilibrium DDF, and

$f_i^{k,eq}$ is the k-component equilibrium DDF, and ![]() $R_i^k$ represents the forcing term in the discrete velocity space, i.e. a function of

$R_i^k$ represents the forcing term in the discrete velocity space, i.e. a function of ![]() ${\boldsymbol {F}}^k$. The transformation matrix

${\boldsymbol {F}}^k$. The transformation matrix ![]() $\boldsymbol {M}$ transfers DDFs to their raw moments, and the shift matrix

$\boldsymbol {M}$ transfers DDFs to their raw moments, and the shift matrix ![]() $\boldsymbol {N}$ shifts raw moments to the corresponding central moments. Here

$\boldsymbol {N}$ shifts raw moments to the corresponding central moments. Here ![]() $\boldsymbol {I}$ is the unit matrix, and

$\boldsymbol {I}$ is the unit matrix, and ![]() $\boldsymbol {S}$ is a diagonal relaxation matrix, whose non-zero elements are the relaxation parameters for different central moments. The explicit formulations of

$\boldsymbol {S}$ is a diagonal relaxation matrix, whose non-zero elements are the relaxation parameters for different central moments. The explicit formulations of ![]() $\boldsymbol {M}$ and

$\boldsymbol {M}$ and ![]() $\boldsymbol {N}$ and their inverses (

$\boldsymbol {N}$ and their inverses (![]() $\boldsymbol {M}^{-1}$ and

$\boldsymbol {M}^{-1}$ and ![]() $\boldsymbol {N}^{-1}$) depend on the discrete velocity model and the selected central moment set. The simulations in the present work are conducted both in two dimensions and three dimensions, and the classical 2-D nine-velocity (D2Q9) and 3-D nineteen-velocity (D3Q19) lattices (Qian et al. Reference Qian, d'Humières and Lallemand1992) are used, respectively. In the numerical implementation, the matrix manipulations on

$\boldsymbol {N}^{-1}$) depend on the discrete velocity model and the selected central moment set. The simulations in the present work are conducted both in two dimensions and three dimensions, and the classical 2-D nine-velocity (D2Q9) and 3-D nineteen-velocity (D3Q19) lattices (Qian et al. Reference Qian, d'Humières and Lallemand1992) are used, respectively. In the numerical implementation, the matrix manipulations on ![]() $f_i^{k,eq}$ and

$f_i^{k,eq}$ and ![]() $R_i^k$ are not needed since their central moments are defined by matching a natural central moment set of the Maxwellian distribution (Fei & Luo Reference Fei and Luo2017; Fei et al. Reference Fei, Luo and Li2018)

$R_i^k$ are not needed since their central moments are defined by matching a natural central moment set of the Maxwellian distribution (Fei & Luo Reference Fei and Luo2017; Fei et al. Reference Fei, Luo and Li2018)

\begin{align} \left. \begin{gathered}

{\rm 2}\hbox{-}{\rm D}\left\{

\begin{array}{@{}l} {\boldsymbol{NM}}f_i^k = {\Big[ {{\rho

_k},0,0,2{\rho _k}c_s^2,0,0,0,0,{\rho _k}c_s^4}

\Big]^{\rm T}},\\ {\boldsymbol{NM}}R_i^k = {\left[

{0,F_x^k,F_y^k,0,0,0,F_y^kc_s^2,F_x^kc_s^2,0} \right]^{\rm

T}}, \end{array} \right.\\ {\rm

3}\hbox{-}{\rm D}\left\{ \begin{array}{@{}l}

{\boldsymbol{NM}}f_i^k = {\Big[ {{\rho

_k},0,0,0,0,0,0,{\rho _k}c_s^2,{\rho _k}c_s^2,{\rho

_k}c_s^2,0,0,0,0,0,0,{\rho _k}c_s^4,{\rho _k}c_s^4,{\rho

_k}c_s^4} \Big]^{\rm T}},\\ {\boldsymbol{NM}}R_i^k =

{\left[

{0,F_x^k,F_y^k,F_z^k,0,0,0,0,0,0,F_x^kc_s^2,F_x^kc_s^2,F_y^kc_s^2,F_z^kc_s^2,F_y^kc_s^2,F_z^kc_s^2,0,0,0}

\right]^{\rm T}}, \end{array} \right.

\end{gathered} \!\!\right\}

\end{align}

\begin{align} \left. \begin{gathered}

{\rm 2}\hbox{-}{\rm D}\left\{

\begin{array}{@{}l} {\boldsymbol{NM}}f_i^k = {\Big[ {{\rho

_k},0,0,2{\rho _k}c_s^2,0,0,0,0,{\rho _k}c_s^4}

\Big]^{\rm T}},\\ {\boldsymbol{NM}}R_i^k = {\left[

{0,F_x^k,F_y^k,0,0,0,F_y^kc_s^2,F_x^kc_s^2,0} \right]^{\rm

T}}, \end{array} \right.\\ {\rm

3}\hbox{-}{\rm D}\left\{ \begin{array}{@{}l}

{\boldsymbol{NM}}f_i^k = {\Big[ {{\rho

_k},0,0,0,0,0,0,{\rho _k}c_s^2,{\rho _k}c_s^2,{\rho

_k}c_s^2,0,0,0,0,0,0,{\rho _k}c_s^4,{\rho _k}c_s^4,{\rho

_k}c_s^4} \Big]^{\rm T}},\\ {\boldsymbol{NM}}R_i^k =

{\left[

{0,F_x^k,F_y^k,F_z^k,0,0,0,0,0,0,F_x^kc_s^2,F_x^kc_s^2,F_y^kc_s^2,F_z^kc_s^2,F_y^kc_s^2,F_z^kc_s^2,0,0,0}

\right]^{\rm T}}, \end{array} \right.

\end{gathered} \!\!\right\}

\end{align}

where ![]() ${c_s} = \sqrt {1/3}$ is the lattice sound speed and

${c_s} = \sqrt {1/3}$ is the lattice sound speed and ![]() ${\rm T}$ denotes the transposition.

${\rm T}$ denotes the transposition.

With the above equations, the following Navier–Stokes and convection–diffusion equations (supplemented by an equation of state, i.e. (2.8)) for the two-component two-phase flows can be reproduced via the Chapman–Enskog analysis in the low-Mach limit (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2023):

\begin{align} \left. \begin{gathered} {\partial _t}\rho + \boldsymbol{\nabla} \boldsymbol{\cdot} (\rho {\boldsymbol{u}}) = 0,\\ {\partial _t}(\rho {\boldsymbol{u}}) + \boldsymbol{\nabla} \boldsymbol{\cdot} (\rho {\boldsymbol{uu}}) =- \boldsymbol{\nabla} (\rho c_s^2) + {\boldsymbol{F}} + \boldsymbol{\nabla} \boldsymbol{\cdot} \left[ {\rho \nu \left( {\boldsymbol{\nabla} {\boldsymbol{u}} + \boldsymbol{\nabla} {{\boldsymbol{u}}^{\rm T}}} \right) + \rho ({\nu _b} - \nu )(\boldsymbol{\nabla} \boldsymbol{\cdot} {\boldsymbol{u}}){\boldsymbol{I}}} \right]\!,\\ {\partial _t}{Y_k} + {\boldsymbol{u}} \boldsymbol{\cdot} \boldsymbol{\nabla} {Y_k} = \alpha {\nabla^2}{Y_k}, \end{gathered} \right\} \end{align}

\begin{align} \left. \begin{gathered} {\partial _t}\rho + \boldsymbol{\nabla} \boldsymbol{\cdot} (\rho {\boldsymbol{u}}) = 0,\\ {\partial _t}(\rho {\boldsymbol{u}}) + \boldsymbol{\nabla} \boldsymbol{\cdot} (\rho {\boldsymbol{uu}}) =- \boldsymbol{\nabla} (\rho c_s^2) + {\boldsymbol{F}} + \boldsymbol{\nabla} \boldsymbol{\cdot} \left[ {\rho \nu \left( {\boldsymbol{\nabla} {\boldsymbol{u}} + \boldsymbol{\nabla} {{\boldsymbol{u}}^{\rm T}}} \right) + \rho ({\nu _b} - \nu )(\boldsymbol{\nabla} \boldsymbol{\cdot} {\boldsymbol{u}}){\boldsymbol{I}}} \right]\!,\\ {\partial _t}{Y_k} + {\boldsymbol{u}} \boldsymbol{\cdot} \boldsymbol{\nabla} {Y_k} = \alpha {\nabla^2}{Y_k}, \end{gathered} \right\} \end{align}

where ![]() $\boldsymbol {F}={\sum }_k {{{\boldsymbol {F}}_k}}$ is the total force field imposed on the system,

$\boldsymbol {F}={\sum }_k {{{\boldsymbol {F}}_k}}$ is the total force field imposed on the system, ![]() $Y_k=\rho _k/\rho$ is the component mass fraction,

$Y_k=\rho _k/\rho$ is the component mass fraction, ![]() $\nu$,

$\nu$, ![]() $\nu _b$ and

$\nu _b$ and ![]() $\alpha$ are the mixture kinetic viscosity, bulk viscosity and binary diffusivity, respectively.

$\alpha$ are the mixture kinetic viscosity, bulk viscosity and binary diffusivity, respectively.

To model the phase/component separation and the liquid–vapour phase change, we propose to appropriately incorporate the two-component two-phase pseudopotential interactions (Shan & Chen Reference Shan and Chen1993, Reference Shan and Chen1994) into the present model. For the phase-change component (water component, denoted as ![]() $k=A$ in the following), an intracomponent force

$k=A$ in the following), an intracomponent force ![]() ${{\boldsymbol {F}}_{AA}}$ between the liquid water and its vapour is needed. The non-condensable dry air component (

${{\boldsymbol {F}}_{AA}}$ between the liquid water and its vapour is needed. The non-condensable dry air component (![]() $k=B$) is miscible with water vapour but almost insoluble in liquid water, which is achieved by a repulsive intercomponent force

$k=B$) is miscible with water vapour but almost insoluble in liquid water, which is achieved by a repulsive intercomponent force ![]() ${{\boldsymbol {F}}_{AB}}$. They are given explicitly as follows:

${{\boldsymbol {F}}_{AB}}$. They are given explicitly as follows:

\begin{equation} \left. \begin{gathered} {{\boldsymbol{F}}_{AA}} =- {G_{AA}}\psi ({\boldsymbol{x}})\sum_i {w\left( {{{\left| {{{\boldsymbol{e}}_i}} \right|}^2}} \right)} \psi ({\boldsymbol{x}} + {{\boldsymbol{e}}_i}\Delta t){{\boldsymbol{e}}_i},\\ {{\boldsymbol{F}}_{AB}} =- {G_{AB}}{\rho _A}({\boldsymbol{x}})\sum_i {w\left( {{{\left| {{{\boldsymbol{e}}_i}} \right|}^2}} \right)} {\rho _B}({\boldsymbol{x}} + {{\boldsymbol{e}}_i}\Delta t){{\boldsymbol{e}}_i}, \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} {{\boldsymbol{F}}_{AA}} =- {G_{AA}}\psi ({\boldsymbol{x}})\sum_i {w\left( {{{\left| {{{\boldsymbol{e}}_i}} \right|}^2}} \right)} \psi ({\boldsymbol{x}} + {{\boldsymbol{e}}_i}\Delta t){{\boldsymbol{e}}_i},\\ {{\boldsymbol{F}}_{AB}} =- {G_{AB}}{\rho _A}({\boldsymbol{x}})\sum_i {w\left( {{{\left| {{{\boldsymbol{e}}_i}} \right|}^2}} \right)} {\rho _B}({\boldsymbol{x}} + {{\boldsymbol{e}}_i}\Delta t){{\boldsymbol{e}}_i}, \end{gathered} \right\} \end{equation}

where ![]() $G_{AA}$ and

$G_{AA}$ and ![]() $G_{AB}$ are the interaction strengths, and

$G_{AB}$ are the interaction strengths, and ![]() $w$ is the interaction weight. If no other forces are considered, we have

$w$ is the interaction weight. If no other forces are considered, we have ![]() ${{\boldsymbol {F}}^{A}}={{\boldsymbol {F}}_{AA}}+{{\boldsymbol {F}}_{AB}}$. For the dry air component (

${{\boldsymbol {F}}^{A}}={{\boldsymbol {F}}_{AA}}+{{\boldsymbol {F}}_{AB}}$. For the dry air component (![]() $k=B$), it is treated as an ideal gas and the intracomponent force for phase separation is not needed, i.e.

$k=B$), it is treated as an ideal gas and the intracomponent force for phase separation is not needed, i.e.

with ![]() $G_{BA}=G_{AB}$ according to Newton's third law. To incorporate the non-ideal equation of state (EOS) into the system, we use the square-root form pseudopotential function

$G_{BA}=G_{AB}$ according to Newton's third law. To incorporate the non-ideal equation of state (EOS) into the system, we use the square-root form pseudopotential function ![]() $\psi = \sqrt {2({\,p_{EOS}} - {\rho _A}c_s^2)/3{G_{AA}}c_s^2}$ with fixed

$\psi = \sqrt {2({\,p_{EOS}} - {\rho _A}c_s^2)/3{G_{AA}}c_s^2}$ with fixed ![]() $G_{AA}=-1$ (Yuan & Schaefer Reference Yuan and Schaefer2006). In the present work, we use the Peng–Robinson (P–R) EOS (Peng & Robinson Reference Peng and Robinson1976),

$G_{AA}=-1$ (Yuan & Schaefer Reference Yuan and Schaefer2006). In the present work, we use the Peng–Robinson (P–R) EOS (Peng & Robinson Reference Peng and Robinson1976),

where ![]() $\varphi (T) = {[1 + (0.37464 + 1.54226\varpi - 0.26992{\varpi ^2})(1 - \sqrt {T/{T_{cr}}} )]^2}$, and R=1 is the gas constant. When the acentric factor is set as

$\varphi (T) = {[1 + (0.37464 + 1.54226\varpi - 0.26992{\varpi ^2})(1 - \sqrt {T/{T_{cr}}} )]^2}$, and R=1 is the gas constant. When the acentric factor is set as ![]() $\varpi =0.344$, the coexistence curve given by the P–R EOS matches the experiment data of saturated water/steam very well (Yuan & Schaefer Reference Yuan and Schaefer2006). Therefore, the P–R EOS is widely used to model boiling and evaporation phenomena (Li et al. Reference Li, Kang, Francois, He and Luo2015, Reference Li, Luo, Kang, He, Chen and Liu2016) in the LB community. The critical pressure

$\varpi =0.344$, the coexistence curve given by the P–R EOS matches the experiment data of saturated water/steam very well (Yuan & Schaefer Reference Yuan and Schaefer2006). Therefore, the P–R EOS is widely used to model boiling and evaporation phenomena (Li et al. Reference Li, Kang, Francois, He and Luo2015, Reference Li, Luo, Kang, He, Chen and Liu2016) in the LB community. The critical pressure ![]() $p_{cr}$ and

$p_{cr}$ and ![]() $T_{cr}$ temperature are determined by

$T_{cr}$ temperature are determined by ![]() $a = 0.4572{R^2}T_{cr}^2/{p_{cr}}$ and

$a = 0.4572{R^2}T_{cr}^2/{p_{cr}}$ and ![]() $b = 0.0778R{T_{cr}}/{p_{cr}}$. With such a choice, the system suffers from the so-called thermodynamic inconsistency that the liquid–vapour coexistence densities by the mechanical stability condition deviate from the theoretical solutions by the Maxwell construction. To solve the problem, a widely used method is to adjust the mechanical stability condition by adding a modification term in the force scheme (Li, Luo & Li Reference Li, Luo and Li2012, Reference Li, Luo and Li2013). For our two-component system, only the central-moment forcing scheme for the phase change component needs to be slightly modified

$b = 0.0778R{T_{cr}}/{p_{cr}}$. With such a choice, the system suffers from the so-called thermodynamic inconsistency that the liquid–vapour coexistence densities by the mechanical stability condition deviate from the theoretical solutions by the Maxwell construction. To solve the problem, a widely used method is to adjust the mechanical stability condition by adding a modification term in the force scheme (Li, Luo & Li Reference Li, Luo and Li2012, Reference Li, Luo and Li2013). For our two-component system, only the central-moment forcing scheme for the phase change component needs to be slightly modified

\begin{align} \left. \begin{gathered}

{\rm 2}\hbox{-}{\rm

D}\qquad{\boldsymbol{NM}}R_i^A = {\left[

{0,F_x^A,F_y^A,\eta ,0,0,F_y^Ac_s^2,F_x^Ac_s^2,0}

\right]^{\rm T}},\\ {\rm 3}\hbox{-}{\rm

D}\qquad{\boldsymbol{NM}}R_i^A = {\left[

{0,F_x^A,F_y^A,F_z^A,0,0,0,\eta ,\eta ,\eta

,F_x^Ac_s^2,F_x^Ac_s^2,F_y^Ac_s^2,F_z^Ac_s^2,F_y^Ac_s^2,F_z^Ac_s^2,0,0,0}

\right]^{\rm T}}, \end{gathered} \right\}

\end{align}

\begin{align} \left. \begin{gathered}

{\rm 2}\hbox{-}{\rm

D}\qquad{\boldsymbol{NM}}R_i^A = {\left[

{0,F_x^A,F_y^A,\eta ,0,0,F_y^Ac_s^2,F_x^Ac_s^2,0}

\right]^{\rm T}},\\ {\rm 3}\hbox{-}{\rm

D}\qquad{\boldsymbol{NM}}R_i^A = {\left[

{0,F_x^A,F_y^A,F_z^A,0,0,0,\eta ,\eta ,\eta

,F_x^Ac_s^2,F_x^Ac_s^2,F_y^Ac_s^2,F_z^Ac_s^2,F_y^Ac_s^2,F_z^Ac_s^2,0,0,0}

\right]^{\rm T}}, \end{gathered} \right\}

\end{align}

where ![]() $\eta = 4\sigma {| {{{\boldsymbol {F}}_{AA}}} |^2}/[{\psi ^2}\Delta t(1/{s_b} - 0.5)]$ and

$\eta = 4\sigma {| {{{\boldsymbol {F}}_{AA}}} |^2}/[{\psi ^2}\Delta t(1/{s_b} - 0.5)]$ and ![]() $\sigma$ is an adjustment factor. Following (Li et al. Reference Li, Kang, Francois, He and Luo2015), the temperature is set as

$\sigma$ is an adjustment factor. Following (Li et al. Reference Li, Kang, Francois, He and Luo2015), the temperature is set as ![]() $T_s=0.86T_{cr}$, leading to the saturated liquid density

$T_s=0.86T_{cr}$, leading to the saturated liquid density ![]() $\rho _l^s\approx 6.5$ and saturated vapour density

$\rho _l^s\approx 6.5$ and saturated vapour density ![]() $\rho _v^s\approx 0.38$. By setting

$\rho _v^s\approx 0.38$. By setting ![]() $a=3/49$ and

$a=3/49$ and ![]() $b=2/21$, the diffused liquid–vapour interface has a width of five lattice spacings (

$b=2/21$, the diffused liquid–vapour interface has a width of five lattice spacings (![]() $\Delta x$). Under this condition, the adjustment factor is chosen as

$\Delta x$). Under this condition, the adjustment factor is chosen as ![]() $\sigma =0.099$ to achieve a thermodynamic consistent mechanical stability condition. We would like to note using such a liquid–vapour density ratio is based on two considerations: (i) the spurious velocity magnitude can be reduced to be

$\sigma =0.099$ to achieve a thermodynamic consistent mechanical stability condition. We would like to note using such a liquid–vapour density ratio is based on two considerations: (i) the spurious velocity magnitude can be reduced to be ![]() $\sim O({10^{ - 3}})$ to suppress its defects and (ii) the evaporation rate is limited by the maximum gas velocity (

$\sim O({10^{ - 3}})$ to suppress its defects and (ii) the evaporation rate is limited by the maximum gas velocity (![]() $\le$0.1) at the low Mach number condition and therefore a smaller density ratio is beneficial for a faster dry out of a given volume of liquid.

$\le$0.1) at the low Mach number condition and therefore a smaller density ratio is beneficial for a faster dry out of a given volume of liquid.

Finally, to deal with the wettability, the geometry-function-based contact angle scheme, originally developed in single-component systems (Ding & Spelt Reference Ding and Spelt2007; Li, Yu & Luo Reference Li, Yu and Luo2019; Qin et al. Reference Qin, Zhao, Kang, Derome and Carmeliet2021), has been extended to two-component systems. Compared with the other contact angle schemes, like the solid–fluid interaction scheme (Martys & Chen Reference Martys and Chen1996; Li et al. Reference Li, Luo, Kang and Chen2014) and virtual-density scheme (Benzi et al. Reference Benzi, Biferale, Sbragaglia, Succi and Toschi2006), the geometry-function-based scheme prescribes the contact angle as an input rather than a measured output, usually yields much smaller spurious currents and does not suffer from the problem of an artificial liquid film near the solid boundary (Li et al. Reference Li, Yu and Luo2019). Moreover, in our extended two-component version, the contact angle can be tuned independently of the vapour mass fraction in the gas phase. For more details, one can refer to Fei et al. (Reference Fei, Qin, Zhao, Derome and Carmeliet2023).

3. Computational set-up

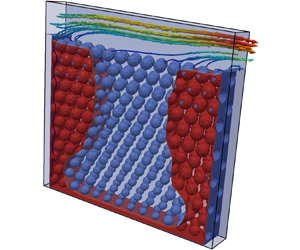

Convective drying occurs when a gas mixture is convectively blown over the surface of a porous medium filled with liquid (Coussot Reference Coussot2000; Defraeye et al. Reference Defraeye, Blocken, Derome, Nicolai and Carmeliet2012). To study the effects of heterogeneity on such evaporation processes, we consider the convective drying system sketched in figure 1(a). The porous medium 1 (PM1) initially fully filled with liquid water is centred in the computational domain. A gas mixture (water vapour and dry air) with a Poiseuille inflow velocity profile is blown from left to right through the top channel over the porous medium. The gas mixture takes away the vapour exiting the porous medium and flows out on the right-hand side. The porous medium, with larger pores in its middle vertical section and smaller pores on both sides, has a global porosity of 0.72, which is designed by filling smaller solid cylinder particles in the middle and larger ones on both sides in a rectangular domain (![]() $L\times H$), respectively. The reference porous medium 1 (PM1) is shown in the schematic diagram (figure 1a). In addition, we also consider other cases with different pore geometry, figure 1(b). Compared with PM1, porous medium 2 (PM2) shows a more uniform pore size distribution. For porous medium 3 (PM3), the upper part pore sizes are slightly decreased, and the lower part is slightly increased. On the contrary, porous medium 4 (PM4) has larger pores on the top and smaller pores at the bottom. Moreover, we consider porous media with multiple layers (three layers in PM5 and four layers in PM6) with increasing pore sizes from the top to the bottom. All porous media have approximately the same porosity, despite varying pore size distributions. We would like to note that the choice of the porosity, 0.72, is mainly following our previous work (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2023), rather than a limitation. In the Appendix, it is shown that the main conclusion of the present study also works for a porous medium with a smaller porosity of 0.59.

$L\times H$), respectively. The reference porous medium 1 (PM1) is shown in the schematic diagram (figure 1a). In addition, we also consider other cases with different pore geometry, figure 1(b). Compared with PM1, porous medium 2 (PM2) shows a more uniform pore size distribution. For porous medium 3 (PM3), the upper part pore sizes are slightly decreased, and the lower part is slightly increased. On the contrary, porous medium 4 (PM4) has larger pores on the top and smaller pores at the bottom. Moreover, we consider porous media with multiple layers (three layers in PM5 and four layers in PM6) with increasing pore sizes from the top to the bottom. All porous media have approximately the same porosity, despite varying pore size distributions. We would like to note that the choice of the porosity, 0.72, is mainly following our previous work (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2023), rather than a limitation. In the Appendix, it is shown that the main conclusion of the present study also works for a porous medium with a smaller porosity of 0.59.

Figure 1. (a) Schematic diagram of the convective drying of porous medium 1 (PM1), where the gas mixture blows through the channel with a Poiseuille velocity profile over the porous medium from left to right. The porous medium is initially filled with liquid water. All porous media have three vertical sections with larger pores in the middle compared with the pores at the sides. Each porous medium is designed by filling solid disks in the domain, and a sketch of the exact disk sizes is given in panel (b). The PM1 and PM2 have vertically uniform pore sizes, whereas PM2 shows a more uniform pore size distribution than PM1. The PM3 and PM4 have two horizontal layers, where in PM3 the pore size increases from top to bottom, and in PM4 the pore size decreases from top to bottom. The PM5 and PM6 have three and four horizontal layers with increasing pore sizes from the top to the bottom, respectively.

To achieve accurate LBM simulations of evaporation dynamics at the pore scale, it is usually needed that the smallest pore/particle size ![]() $l_m$ should be two times larger than the interface thickness (typically five lattice spacings) (Zhao et al. Reference Zhao, Qin, Derome and Carmeliet2020; Qin et al. Reference Qin, Zhao, Kang, Derome and Carmeliet2021). Based on this guideline and a grid resolution test, we observed a system size of

$l_m$ should be two times larger than the interface thickness (typically five lattice spacings) (Zhao et al. Reference Zhao, Qin, Derome and Carmeliet2020; Qin et al. Reference Qin, Zhao, Kang, Derome and Carmeliet2021). Based on this guideline and a grid resolution test, we observed a system size of ![]() $L\times H =481\Delta x \times 401\Delta x$ is fine enough for the present simulations (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2022). The top channel should be wide enough to resolve the fully developed vapour boundary layer, and the inlet/outlet section length

$L\times H =481\Delta x \times 401\Delta x$ is fine enough for the present simulations (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2022). The top channel should be wide enough to resolve the fully developed vapour boundary layer, and the inlet/outlet section length ![]() $L_1/L_2$ needs to be long enough to eliminate the inlet/outlet effects. Following our previous study (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2023), we set the channel width as

$L_1/L_2$ needs to be long enough to eliminate the inlet/outlet effects. Following our previous study (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2023), we set the channel width as ![]() $H_1=100\Delta x$, with

$H_1=100\Delta x$, with ![]() $L_1=L_2/2=H_1$. Our simulations will be mainly carried out in two dimensions, while some three-dimensional (3-D) simulations will also be considered in § 4.3 to support the findings in two dimensions.

$L_1=L_2/2=H_1$. Our simulations will be mainly carried out in two dimensions, while some three-dimensional (3-D) simulations will also be considered in § 4.3 to support the findings in two dimensions.

The ability of our model to simulate evaporation in porous media has been well validated in Fei et al. (Reference Fei, Qin, Zhao, Derome and Carmeliet2023) with the experimental results of Wu et al. (Reference Wu, Kharaghani and Tsotsas2016). A systematic parameter study of the evaporation process in a similar configuration was conducted probing the effects of inflow Reynolds number (![]() $Re={U_m}{H_1}/2\nu$, defined with the peak inflow velocity

$Re={U_m}{H_1}/2\nu$, defined with the peak inflow velocity ![]() $U_m$ and the kinematic viscosity

$U_m$ and the kinematic viscosity ![]() $\nu$), inflow vapour concentration (

$\nu$), inflow vapour concentration (![]() $Y_{vapour,in}=\rho _{A,in}/(\rho _{A,in}+\rho _{B,in})$) and contact angle (

$Y_{vapour,in}=\rho _{A,in}/(\rho _{A,in}+\rho _{B,in})$) and contact angle (![]() $\theta$), where the index A is for the vapour and B for the air component. Simulation results reproduced the typical transition from the CRP at large S to the RFP at small S, with an intermediate FRP in between. We have developed a scaling relation to predict the average evaporation rate in CRP,

$\theta$), where the index A is for the vapour and B for the air component. Simulation results reproduced the typical transition from the CRP at large S to the RFP at small S, with an intermediate FRP in between. We have developed a scaling relation to predict the average evaporation rate in CRP,

where ![]() $B_Y$ is a vapour concentration-based mass transfer number, and

$B_Y$ is a vapour concentration-based mass transfer number, and ![]() $k_1$ and

$k_1$ and ![]() $k_2$ are used to estimate the evaporation rate at

$k_2$ are used to estimate the evaporation rate at ![]() $\theta = {90^\circ }$ and

$\theta = {90^\circ }$ and ![]() ${Re=0}$, respectively. The parameters in the three brackets are dimensionless, and the global scaling parameter

${Re=0}$, respectively. The parameters in the three brackets are dimensionless, and the global scaling parameter ![]() $k_3$ has units of the evaporation rate and includes the effects of the binary diffusion, the surface tension and the porous geometry. The scaling unifies the effects of three key factors on the CRP, namely diffusion from the porous media to the atmosphere, convection which carries away the evaporation-generated vapour and capillary pumping supplying liquid to the evaporation front, as represented by the three bracket terms, respectively. The model has been well validated for isothermal drying of porous media with a laminar inflow blowing over the material surface (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2023). Accordingly, one can increase the evaporation rate by increasing the inlet velocity (

$k_3$ has units of the evaporation rate and includes the effects of the binary diffusion, the surface tension and the porous geometry. The scaling unifies the effects of three key factors on the CRP, namely diffusion from the porous media to the atmosphere, convection which carries away the evaporation-generated vapour and capillary pumping supplying liquid to the evaporation front, as represented by the three bracket terms, respectively. The model has been well validated for isothermal drying of porous media with a laminar inflow blowing over the material surface (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2023). Accordingly, one can increase the evaporation rate by increasing the inlet velocity (![]() $Re$) and decreasing the vapour concentration of the incoming air

$Re$) and decreasing the vapour concentration of the incoming air ![]() $Y_{vapour,in}$ and the contact angle

$Y_{vapour,in}$ and the contact angle ![]() $\theta$, but the evaporation rate plateaus at large

$\theta$, but the evaporation rate plateaus at large ![]() $Re$ and small

$Re$ and small ![]() $Y_{vapour,in}$ and

$Y_{vapour,in}$ and ![]() $\theta$. The present work aims to explore the possibility to further increase the evaporation rate by incorporating heterogeneity in the porous medium, and therefore we start from the maximum evaporation rate achieved before by setting

$\theta$. The present work aims to explore the possibility to further increase the evaporation rate by incorporating heterogeneity in the porous medium, and therefore we start from the maximum evaporation rate achieved before by setting ![]() $Re=100$,

$Re=100$, ![]() $Y_{vapour,in}=0.1$ and

$Y_{vapour,in}=0.1$ and ![]() $\theta =15^\circ$.

$\theta =15^\circ$.

4. Results and analysis

4.1. Effects of heterogeneous contact angle distribution

We first probe the effect of heterogeneous contact angle on the evaporation process in PM1. To this aim, the porous medium is divided into two equal parts horizontally, with different contact angles at the top (![]() $\theta _{top}$) and bottom (

$\theta _{top}$) and bottom (![]() $\theta _{bottom}$). We decrease the contact angle difference

$\theta _{bottom}$). We decrease the contact angle difference ![]() $(\theta _{top}-\theta _{bottom})$ from

$(\theta _{top}-\theta _{bottom})$ from ![]() $90^\circ$ to

$90^\circ$ to ![]() $-90^\circ$ gradually with a fixed interval of

$-90^\circ$ gradually with a fixed interval of ![]() $30^\circ$, starting from

$30^\circ$, starting from ![]() $\theta _{top}=105^\circ$ and

$\theta _{top}=105^\circ$ and ![]() $\theta _{bottom}=15^\circ$ and ending at

$\theta _{bottom}=15^\circ$ and ending at ![]() $\theta _{top}=15^\circ$ and

$\theta _{top}=15^\circ$ and ![]() $\theta _{bottom}=105^\circ$, for a total of seven pairs of contact angle. Snapshots of the convective evaporation processes for four of these cases are shown in figure 2 (see also in Supplementary movies 1–4). For each case, the evaporation front (highlighted by the solid black line) recedes first in the middle region and later in the side regions. As discussed previously (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2022), such a pattern is directly attributed to the capillary pumping effect. According to the Laplace law, capillary pressure

$\theta _{bottom}=105^\circ$, for a total of seven pairs of contact angle. Snapshots of the convective evaporation processes for four of these cases are shown in figure 2 (see also in Supplementary movies 1–4). For each case, the evaporation front (highlighted by the solid black line) recedes first in the middle region and later in the side regions. As discussed previously (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2022), such a pattern is directly attributed to the capillary pumping effect. According to the Laplace law, capillary pressure ![]() ${p_c} = \gamma \cos (\theta )/r$, with

${p_c} = \gamma \cos (\theta )/r$, with ![]() $\gamma$ the surface tension and

$\gamma$ the surface tension and ![]() $r$ the local pore size, is lower in the middle large pores than that in the smaller side pores. Therefore, since the top surface is open to the channel with constant gas pressure

$r$ the local pore size, is lower in the middle large pores than that in the smaller side pores. Therefore, since the top surface is open to the channel with constant gas pressure ![]() $p_g$, the liquid pressure

$p_g$, the liquid pressure ![]() $p_l$ is higher in the middle larger pores than in side smaller pores, leading to a capillary pumping flow from the middle section to the sides, maintaining the liquid–vapour interfacial area in smaller pores at the material surface for some time depending on the strength of the capillary pumping. For the case with

$p_l$ is higher in the middle larger pores than in side smaller pores, leading to a capillary pumping flow from the middle section to the sides, maintaining the liquid–vapour interfacial area in smaller pores at the material surface for some time depending on the strength of the capillary pumping. For the case with ![]() $\theta _{top}=45^\circ$ and

$\theta _{top}=45^\circ$ and ![]() $\theta _{bottom}=15^\circ$, when the evaporation front in the middle reaches the boundary between the top and bottom parts (

$\theta _{bottom}=15^\circ$, when the evaporation front in the middle reaches the boundary between the top and bottom parts (![]() $t=5\times 10^5$), the front also starts to recede in the side regions, as shown in figure 2(a). For the case with uniform contact angle (

$t=5\times 10^5$), the front also starts to recede in the side regions, as shown in figure 2(a). For the case with uniform contact angle (![]() $(\theta _{top}=\theta _{bottom}) =15^\circ$) in figure 2(b), the evaporation front in the side regions starts to recede only when the evaporation front in the middle touches the bottom of the porous medium. For cases with a larger contact angle in the bottom part than in the top part (figure 2c,d), the initial evaporation dynamics are basically the same as in case (figure 2b) while differences appear when the middle evaporation front arrives at the boundary between the top and bottom part at

$(\theta _{top}=\theta _{bottom}) =15^\circ$) in figure 2(b), the evaporation front in the side regions starts to recede only when the evaporation front in the middle touches the bottom of the porous medium. For cases with a larger contact angle in the bottom part than in the top part (figure 2c,d), the initial evaporation dynamics are basically the same as in case (figure 2b) while differences appear when the middle evaporation front arrives at the boundary between the top and bottom part at ![]() $t=5\times 10^5$. The evaporation front in these last two cases penetrates and spreads very fast in the bottom part, pumping liquid to the small pores in the top side regions. As a result, the side-region liquid–vapour interface remains pinned still at

$t=5\times 10^5$. The evaporation front in these last two cases penetrates and spreads very fast in the bottom part, pumping liquid to the small pores in the top side regions. As a result, the side-region liquid–vapour interface remains pinned still at ![]() $t=1\times 10^6$ in figure 2(c). In figure 2(d), we see a similar but even faster spreading behaviour in the bottom part, leading to the break of the connection between the top and bottom drying front at

$t=1\times 10^6$ in figure 2(c). In figure 2(d), we see a similar but even faster spreading behaviour in the bottom part, leading to the break of the connection between the top and bottom drying front at ![]() $t=1\times 10^6$. The top small side pores cannot be supplied with liquid anymore, and therefore the evaporation front recedes from the top surface.

$t=1\times 10^6$. The top small side pores cannot be supplied with liquid anymore, and therefore the evaporation front recedes from the top surface.

Figure 2. Snapshots of convective evaporation in PM1 with contact angles in the top (![]() $\theta _{top}$) and bottom (

$\theta _{top}$) and bottom (![]() $\theta _{bottom}$) parts given as (a)

$\theta _{bottom}$) parts given as (a) ![]() $\theta _{top}=45^\circ$ and

$\theta _{top}=45^\circ$ and ![]() $\theta _{bottom}=15^\circ$; (b)

$\theta _{bottom}=15^\circ$; (b) ![]() $\theta _{top}=15^\circ$ and

$\theta _{top}=15^\circ$ and ![]() $\theta _{bottom}=15^\circ$; (c)

$\theta _{bottom}=15^\circ$; (c) ![]() $\theta _{top}=15^\circ$ and

$\theta _{top}=15^\circ$ and ![]() $\theta _{bottom}=45^\circ$; (d)

$\theta _{bottom}=45^\circ$; (d) ![]() $\theta _{top}=15^\circ$ and

$\theta _{top}=15^\circ$ and ![]() $\theta _{bottom}=105^\circ$. The liquid–vapour interface is highlighted with a black line. The green dash borderline indicates the transition from CRP to RFP, characterized by the receding of evaporation fronts in the side regions of the top layer. The two legends show the contact angle and vapour concentration distributions, respectively, and are shared by all the frames. Full evaporation process documented in Supplementary movies 1–4 available at https://doi.org/10.1017/jfm.2024.138.

$\theta _{bottom}=105^\circ$. The liquid–vapour interface is highlighted with a black line. The green dash borderline indicates the transition from CRP to RFP, characterized by the receding of evaporation fronts in the side regions of the top layer. The two legends show the contact angle and vapour concentration distributions, respectively, and are shared by all the frames. Full evaporation process documented in Supplementary movies 1–4 available at https://doi.org/10.1017/jfm.2024.138.

The evaporation behaviour in the initial stage is similar in figure 2(b–d) and the main differences appear onwards, after the evaporation breaks through the border between the two top and bottom parts. Benefiting from the present model at the pore scale, we can conduct detailed analysis of the underlying mechanisms based on studying the instantaneous dynamics of water front progress at the pore scale. Figure 3 shows that the location of the evaporation front just before arriving at the border (denoted by the red curves) is the same for four cases with the same ![]() $\theta _{top}$ but different

$\theta _{top}$ but different ![]() $\theta _{bottom}$. The black streamlines confirm the occurrence of capillary pumping in the liquid phase, as we explained above. After that, the evaporation front continues to recede in the middle large pores (shown by the red arrows) but remains pinned at the small pores for the uniform contact angle case (figure 3a), indicating the evaporation rate is compensated by the pumping rate. For other cases, the evaporation front recedes faster in the middle, especially for the larger

$\theta _{bottom}$. The black streamlines confirm the occurrence of capillary pumping in the liquid phase, as we explained above. After that, the evaporation front continues to recede in the middle large pores (shown by the red arrows) but remains pinned at the small pores for the uniform contact angle case (figure 3a), indicating the evaporation rate is compensated by the pumping rate. For other cases, the evaporation front recedes faster in the middle, especially for the larger ![]() $\theta _{bottom}$ case, as shown in figure 3(b–d). The underlying mechanisms can be elucidated based on the analysis of the liquid pressure difference between the large pores and small pores at the two moments just before and after crossing the border (indicated by subscripts

$\theta _{bottom}$ case, as shown in figure 3(b–d). The underlying mechanisms can be elucidated based on the analysis of the liquid pressure difference between the large pores and small pores at the two moments just before and after crossing the border (indicated by subscripts ![]() $-$ and +),

$-$ and +),

\begin{equation} \left. \begin{gathered} \Delta {p_ - } = \gamma \left[ {\frac{{\cos ({\theta _{top}})}}{{{r_s}}} - \frac{{\cos ({\theta _{top}})}}{{{r_m}}}} \right]\!,\\ \Delta {p_ + } = \gamma \left[ {\frac{{\cos ({\theta _{top}})}}{{{r_s}}} - \frac{{\cos ({\theta _{bottom}})}}{{{r_m}}}} \right]\!, \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} \Delta {p_ - } = \gamma \left[ {\frac{{\cos ({\theta _{top}})}}{{{r_s}}} - \frac{{\cos ({\theta _{top}})}}{{{r_m}}}} \right]\!,\\ \Delta {p_ + } = \gamma \left[ {\frac{{\cos ({\theta _{top}})}}{{{r_s}}} - \frac{{\cos ({\theta _{bottom}})}}{{{r_m}}}} \right]\!, \end{gathered} \right\} \end{equation}

where subscript s and m represent the side and middle regions, respectively. From these values, we observe that ![]() $(\theta _{top}\neq \theta _{bottom})$ leads to a capillary pressure jump (also pressure difference jump) between the two moments. For a larger

$(\theta _{top}\neq \theta _{bottom})$ leads to a capillary pressure jump (also pressure difference jump) between the two moments. For a larger ![]() $\theta _{bottom}$ case, the jump is more significant, resulting in the evaporation front receding faster in the middle region. Concurrently, the evaporation fronts in the side regions are refilled (advancing), as indicated by the green arrows in figure 3(b–d), showing that the pumping rate is now stronger than the evaporation rate. The advancing behaviour at the top side interfaces is more significant for a larger

$\theta _{bottom}$ case, the jump is more significant, resulting in the evaporation front receding faster in the middle region. Concurrently, the evaporation fronts in the side regions are refilled (advancing), as indicated by the green arrows in figure 3(b–d), showing that the pumping rate is now stronger than the evaporation rate. The advancing behaviour at the top side interfaces is more significant for a larger ![]() $\theta _{bottom}$ case (larger

$\theta _{bottom}$ case (larger ![]() $\Delta {p_ + }-\Delta {p_ - }$), and, notably, is absent at

$\Delta {p_ + }-\Delta {p_ - }$), and, notably, is absent at ![]() $\theta _{top}=\theta _{bottom}$ (

$\theta _{top}=\theta _{bottom}$ (![]() $\Delta {p_ + }-\Delta {p_ - }=0$).

$\Delta {p_ + }-\Delta {p_ - }=0$).

Figure 3. Pore-scale dynamics immediately before (red interface line) and after (green interface line) the evaporation front arrives at the border between the top and bottom part of PM1: (a) ![]() $(\theta _{top}=\theta _{bottom}) =15^\circ$; (b)

$(\theta _{top}=\theta _{bottom}) =15^\circ$; (b) ![]() $\theta _{top}=15^\circ$ and

$\theta _{top}=15^\circ$ and ![]() $\theta _{bottom}=45^\circ$; (c)

$\theta _{bottom}=45^\circ$; (c) ![]() $\theta _{top}=15^\circ$ and

$\theta _{top}=15^\circ$ and ![]() $\theta _{bottom}=75^\circ$; (d)

$\theta _{bottom}=75^\circ$; (d) ![]() $\theta _{top}=15^\circ$ and

$\theta _{top}=15^\circ$ and ![]() $\theta _{bottom}=105^\circ$. The two evaporation fronts are indicated by the solid red and green lines, respectively. The red arrows denote receding events (from red to green), and the green arrows underline advancing events (from green to red). Black lines are streamlines concurrent with the red interface.

$\theta _{bottom}=105^\circ$. The two evaporation fronts are indicated by the solid red and green lines, respectively. The red arrows denote receding events (from red to green), and the green arrows underline advancing events (from green to red). Black lines are streamlines concurrent with the red interface.

The presence of liquid at the top of the porous medium ensures effective evaporation, and the point of receding from the top surface is thus critical to characterizing the drying process. The red and green solid lines in figure 4 show the evaporation front locations at the moments slightly before and after the onset of receding from top surface. The corresponding degrees of saturation (![]() $S$) are also given in each frame, and the transition occurs at S equal to 0.61, 0.47, 0.45 and 0.56 for figure 4(a–d), respectively. This transition

$S$) are also given in each frame, and the transition occurs at S equal to 0.61, 0.47, 0.45 and 0.56 for figure 4(a–d), respectively. This transition ![]() $S$ decreases with increasing

$S$ decreases with increasing ![]() $\theta _{bottom}$, due to the increase of the pressure difference between the bottom middle region and the top side regions according to (4.1). However, when

$\theta _{bottom}$, due to the increase of the pressure difference between the bottom middle region and the top side regions according to (4.1). However, when ![]() $\theta _{bottom}$ is further increased to

$\theta _{bottom}$ is further increased to ![]() $105^\circ$, a hydrophobic case, the transition

$105^\circ$, a hydrophobic case, the transition ![]() $S$ increases again to 0.56, rather than further decreasing. Looking at the bottom of the interfaces, the evaporation front in figure 4(d) is flat compared with the other cases. Such a pattern has also been observed previously, which is due to the competing effect between the larger liquid pressure in smaller pores (negative capillary pressure due to

$S$ increases again to 0.56, rather than further decreasing. Looking at the bottom of the interfaces, the evaporation front in figure 4(d) is flat compared with the other cases. Such a pattern has also been observed previously, which is due to the competing effect between the larger liquid pressure in smaller pores (negative capillary pressure due to ![]() $\theta > {90^ \circ }$) and larger vapour permeability in larger pores (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2023). As a result, the connection between the top and bottom is broken earlier, and the liquid cannot be pumped anymore from bottom to top, shortening the time at which receding occurs in figure 4(d). An almost constant drying rate, the essential feature of CRP, is observed when the small pores remain filled. Thus, the CRP is maintained by sufficient capillary pumping flow from the larger to the smaller pores. Based on the observations at the pore scale of figure 4, the transition from CRP to FRP can be defined as the moment when one of the small pores at the top surface dries out, as highlighted by the dashed black boxes in figure 4. We would like to mention that such a definition generally coincides with the point in time that the drying rate starts to drop.

$\theta > {90^ \circ }$) and larger vapour permeability in larger pores (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2023). As a result, the connection between the top and bottom is broken earlier, and the liquid cannot be pumped anymore from bottom to top, shortening the time at which receding occurs in figure 4(d). An almost constant drying rate, the essential feature of CRP, is observed when the small pores remain filled. Thus, the CRP is maintained by sufficient capillary pumping flow from the larger to the smaller pores. Based on the observations at the pore scale of figure 4, the transition from CRP to FRP can be defined as the moment when one of the small pores at the top surface dries out, as highlighted by the dashed black boxes in figure 4. We would like to mention that such a definition generally coincides with the point in time that the drying rate starts to drop.

Figure 4. Evaporation front locations at the moment slightly before (red line) and after (green line) the transition from CRP to FRP in PM1 with (a) ![]() $(\theta _{top}=\theta _{bottom}) =15^\circ$; (b)

$(\theta _{top}=\theta _{bottom}) =15^\circ$; (b) ![]() $\theta _{top}=15^\circ$ and

$\theta _{top}=15^\circ$ and ![]() $\theta _{bottom}=45^\circ$; (c)

$\theta _{bottom}=45^\circ$; (c) ![]() $\theta _{top}=15^\circ$ and

$\theta _{top}=15^\circ$ and ![]() $\theta _{bottom}=75^\circ$; (d)

$\theta _{bottom}=75^\circ$; (d) ![]() $\theta _{top}=15^\circ$ and

$\theta _{top}=15^\circ$ and ![]() $\theta _{bottom}=105^\circ$. The corresponding degrees of saturation are also given in red and green.

$\theta _{bottom}=105^\circ$. The corresponding degrees of saturation are also given in red and green.

We now consider the global evaporation behaviour. Figure 5(a) gives the time evolution of the residual liquid mass (![]() $= \sum {{\rho _A}}$, where

$= \sum {{\rho _A}}$, where ![]() $\sum$ runs over grid nodes with

$\sum$ runs over grid nodes with ![]() ${\rho _A} > (\rho _l^s + \rho _v^s)/2$) for the different cases, while figure 5(b) gives the drying curves (drying rate versus saturation S). It is seen in figure 5(a) that the residual liquid mass for most of the cases (except for

${\rho _A} > (\rho _l^s + \rho _v^s)/2$) for the different cases, while figure 5(b) gives the drying curves (drying rate versus saturation S). It is seen in figure 5(a) that the residual liquid mass for most of the cases (except for ![]() $\theta _{top}=105^\circ$) drops faster in the beginning but slower in the later stage. Such a change in slope indicates the transition from CRP to FRP. With decreasing

$\theta _{top}=105^\circ$) drops faster in the beginning but slower in the later stage. Such a change in slope indicates the transition from CRP to FRP. With decreasing ![]() $\theta _{top}$ and increasing

$\theta _{top}$ and increasing ![]() $\theta _{bottom}$, the residual liquid mass is almost always lower at any given time, indicating faster evaporation during CRP. One exception is case

$\theta _{bottom}$, the residual liquid mass is almost always lower at any given time, indicating faster evaporation during CRP. One exception is case ![]() $\theta _{bottom}=105^\circ$, where the residual liquid mass surpasses the one of case

$\theta _{bottom}=105^\circ$, where the residual liquid mass surpasses the one of case ![]() $\theta _{bottom}=75^\circ$ after

$\theta _{bottom}=75^\circ$ after ![]() $t=8\times 10^5$, due to the disconnection of liquid filled regions between the top and bottom parts as discussed above. As further confirmed in figure 5(b), for most of the cases, we indeed observe a transition from a relatively high (and constant for some cases) evaporation rate at large

$t=8\times 10^5$, due to the disconnection of liquid filled regions between the top and bottom parts as discussed above. As further confirmed in figure 5(b), for most of the cases, we indeed observe a transition from a relatively high (and constant for some cases) evaporation rate at large ![]() $S$ to a low evaporation rate at small

$S$ to a low evaporation rate at small ![]() $S$. For the case

$S$. For the case ![]() $\theta _{top}=105^\circ$, as discussed previously, the evaporation front is very flat and recedes almost simultaneously in both middle and side regions. The evaporation rate is therefore always falling, without experiencing CRP. The transition (from CRP to FRP)

$\theta _{top}=105^\circ$, as discussed previously, the evaporation front is very flat and recedes almost simultaneously in both middle and side regions. The evaporation rate is therefore always falling, without experiencing CRP. The transition (from CRP to FRP) ![]() $S$ for each case is marked by a black-filled symbol. It is seen that by decreasing

$S$ for each case is marked by a black-filled symbol. It is seen that by decreasing ![]() $\theta _{top}$ and increasing

$\theta _{top}$ and increasing ![]() $\theta _{bottom}$, the CRP can be prolonged from

$\theta _{bottom}$, the CRP can be prolonged from ![]() $S>0.72$ to

$S>0.72$ to ![]() $S>0.42$. The four cases with

$S>0.42$. The four cases with ![]() $\theta _{top}=15^\circ$ behave exactly the same until

$\theta _{top}=15^\circ$ behave exactly the same until ![]() $S=0.83$, indicated by the black arrow in figure 5(b) (corresponding to the red lines in figure 3), after which the capillary pressure jump happens immediately at

$S=0.83$, indicated by the black arrow in figure 5(b) (corresponding to the red lines in figure 3), after which the capillary pressure jump happens immediately at ![]() $\theta _{bottom}>\theta _{top}$, as discussed above. The stronger pumping effect at the next moment leads to an increase in the evaporation rate, especially for the case with high

$\theta _{bottom}>\theta _{top}$, as discussed above. The stronger pumping effect at the next moment leads to an increase in the evaporation rate, especially for the case with high ![]() $\theta _{bottom}$.

$\theta _{bottom}$.

Figure 5. (a) Time evolution of the residual liquid mass for PM1 cases with heterogeneous contact angle distribution. (b) Evaporation rate versus S curves for each case.

In addition, we want to note that the Laplace equation is strictly valid only under hydrostatic conditions, while it is still widely used to study the multiphase flows in porous media dominated by the capillary force (Qin et al. Reference Qin, Del Carro, Mazloomi Moqaddam, Kang, Brunschwiler, Derome and Carmeliet2019; Gu, Liu & Wu Reference Gu, Liu and Wu2021; Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2023). For our cases, the capillary number can be defined as ![]() $Ca = \nu {\rho _l}\bar u/\gamma$, where

$Ca = \nu {\rho _l}\bar u/\gamma$, where ![]() $\gamma = 0.083$ and the pore scale liquid-phase average velocity

$\gamma = 0.083$ and the pore scale liquid-phase average velocity ![]() $\bar u$ can be estimated as

$\bar u$ can be estimated as ![]() $\bar u = E{R_{CRP}}/({\rho _l}{l_p}{n_p})$, using the middle part pore size

$\bar u = E{R_{CRP}}/({\rho _l}{l_p}{n_p})$, using the middle part pore size ![]() ${l_p} = 19\Delta x$ (PM1) and number of pores in the middle

${l_p} = 19\Delta x$ (PM1) and number of pores in the middle ![]() ${n_p} = 7$. For an average CRP evaporation rate

${n_p} = 7$. For an average CRP evaporation rate ![]() $E{R_{CRP}} = 0.5$ in figure 5, we have

$E{R_{CRP}} = 0.5$ in figure 5, we have ![]() $\bar u = 5.8 \times {10^{ - 4}}$ and

$\bar u = 5.8 \times {10^{ - 4}}$ and ![]() $Ca = 1.8 \times {10^{ - 3}}$. Therefore, our cases are generally in the capillary force dominant regime.

$Ca = 1.8 \times {10^{ - 3}}$. Therefore, our cases are generally in the capillary force dominant regime.

4.2. Effects of heterogeneous pore size distribution

In this subsection, we study the effect of heterogeneous pore size distribution on the evaporation in porous media. To do this, we consider convective evaporation in porous media with heterogeneous pore structures (PM2–4 in figure 1). The time evolution of the liquid distribution for each case is shown in figure 6(a–c), respectively (see also Supplementary movies 5, 6 and 7). For all cases, the evaporation front recedes first in the middle region, due to the strong capillary pumping effect in the hydrophilic case, and then in the side regions. For the vertically uniform pore structure, the evaporation front in the small pores starts to recede approximately when the interface reaches the bottom surface at ![]() $t=1.0\times 10^6$ in figure 6(a). For the case with larger pores in the bottom part, the evaporation front in the bottom part expands more significantly, showing a pumping flow from the bottom part to the top at

$t=1.0\times 10^6$ in figure 6(a). For the case with larger pores in the bottom part, the evaporation front in the bottom part expands more significantly, showing a pumping flow from the bottom part to the top at ![]() $t=1.0\times 10^6$ in figure 6(b). This expansion finally results in breaking the connection between the bottom and top liquid-filled parts (

$t=1.0\times 10^6$ in figure 6(b). This expansion finally results in breaking the connection between the bottom and top liquid-filled parts (![]() $t=2.0\times 10^6$), after which the front recedes in the small pores. In contrast, the penetration front expands more within the top region in the case of PM4, as seen at

$t=2.0\times 10^6$), after which the front recedes in the small pores. In contrast, the penetration front expands more within the top region in the case of PM4, as seen at ![]() $t=5.0\times 10^5$ in figure 6(c). The front starts to recede immediately after the top middle pores are dried out, not penetrating through the middle part (

$t=5.0\times 10^5$ in figure 6(c). The front starts to recede immediately after the top middle pores are dried out, not penetrating through the middle part (![]() $t=1.0\times 10^6$).

$t=1.0\times 10^6$).

Figure 6. (a) Snapshots during convective evaporation in heterogeneous porous media with uniform contact angle ![]() $\theta =15^\circ$: (a) vertically uniform pores (PM2); (b) larger pores in the bottom part (PM3); (c) smaller pores in the bottom part (PM4). The full evaporation process is seen in Supplementary movies 5–7. The legend gives vapour concentration levels.

$\theta =15^\circ$: (a) vertically uniform pores (PM2); (b) larger pores in the bottom part (PM3); (c) smaller pores in the bottom part (PM4). The full evaporation process is seen in Supplementary movies 5–7. The legend gives vapour concentration levels.

The different evaporation behaviours for different pore size distributions can also be rationalized based on the analysis of the pore-scale dynamics when the drying front reaches a change of pore size. As shown in figure 7, the pumping flow from larger pores to smaller pores is observed in both PM3 and PM4. The main difference lies in the receding/advancing behaviour, which can be analysed by determining the liquid pressure difference between the large and small pores at the two moments just before and after crossing the border (indicated by subscripts ![]() $-$ and +),

$-$ and +),

\begin{equation} \left. \begin{gathered} \Delta {p_ - } = \gamma \left[ {\frac{{\cos (\theta )}}{{{r_{s,top}}}} - \frac{{\cos (\theta )}}{{{r_{m,top}}}}} \right]\!,\\ \Delta {p_ + } = \gamma \left[ {\frac{{\cos (\theta )}}{{{r_{s,top}}}} - \frac{{\cos (\theta )}}{{{r_{m,bottm}}}}} \right]\!. \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} \Delta {p_ - } = \gamma \left[ {\frac{{\cos (\theta )}}{{{r_{s,top}}}} - \frac{{\cos (\theta )}}{{{r_{m,top}}}}} \right]\!,\\ \Delta {p_ + } = \gamma \left[ {\frac{{\cos (\theta )}}{{{r_{s,top}}}} - \frac{{\cos (\theta )}}{{{r_{m,bottm}}}}} \right]\!. \end{gathered} \right\} \end{equation}

For the case with larger pores in the bottom part (![]() ${r_{m,bottom}} > {r_{m,top}}$), the liquid pressure in the middle pores increases when the front crosses the border between the two parts. Here