Article contents

Rheological measurements and transition to turbulence for moderate Reynolds number inertial suspensions

Published online by Cambridge University Press: 31 May 2024

Abstract

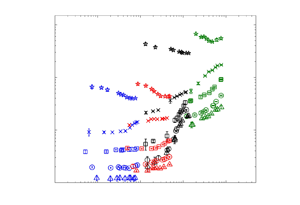

Particulate flows at moderate particle Reynolds numbers are important in critical engineering and geological applications. This experimental study explores neutrally buoyant suspensions in an outer-rotating coaxial rheometer for solid fractions,  $\phi$, from 0.1 to 0.5, and particle Reynolds number,

$\phi$, from 0.1 to 0.5, and particle Reynolds number,  $Re$, from 0.5 to 800, covering laminar, transitional and turbulent regimes;

$Re$, from 0.5 to 800, covering laminar, transitional and turbulent regimes;  $Re$ is defined in terms of the square of the particle diameter and the shear rate. For

$Re$ is defined in terms of the square of the particle diameter and the shear rate. For  $0.1 < \phi < 0.4$ and

$0.1 < \phi < 0.4$ and  $0.5 < Re <10$, the direct torque measurements normalised by the laminar flow torque,

$0.5 < Re <10$, the direct torque measurements normalised by the laminar flow torque,  $M/M_{lam}$, are independent of

$M/M_{lam}$, are independent of  $Re$, but depend on

$Re$, but depend on  $\phi$. For the same range of

$\phi$. For the same range of  $\phi$ and for

$\phi$ and for  $10< Re<100$, the normalised torques depend on both

$10< Re<100$, the normalised torques depend on both  $\phi$ and

$\phi$ and  $Re$, and show an increasing dependence on

$Re$, and show an increasing dependence on  $Re$. As

$Re$. As  $Re$ increases, the flow transitions to turbulence. Small particles delay the turbulent transition for

$Re$ increases, the flow transitions to turbulence. Small particles delay the turbulent transition for  $\phi \leqslant 0.3$, while large particles augment the transition. A modified Reynolds number,

$\phi \leqslant 0.3$, while large particles augment the transition. A modified Reynolds number,  $Re^\prime$, that depends linearly on the particle diameter and the maximum velocity,

$Re^\prime$, that depends linearly on the particle diameter and the maximum velocity,  $U_{o}$, is introduced for both laminar and turbulent flows and shows a better correlation of the results as compared with

$U_{o}$, is introduced for both laminar and turbulent flows and shows a better correlation of the results as compared with  $Re$. For

$Re$. For  $\phi = 50\,\%$, the normalised torque minus the torque at zero rotational speed is nearly independent of

$\phi = 50\,\%$, the normalised torque minus the torque at zero rotational speed is nearly independent of  $Re^\prime$. Rheological models based on

$Re^\prime$. Rheological models based on  $Re^\prime$ and the Krieger–Dougherty relative viscosity are proposed in the laminar regime for

$Re^\prime$ and the Krieger–Dougherty relative viscosity are proposed in the laminar regime for  $10< Re^\prime <500$; in the turbulent regime, a correlation is proposed in terms of

$10< Re^\prime <500$; in the turbulent regime, a correlation is proposed in terms of  $Re^\prime$ and

$Re^\prime$ and  $\phi$ for

$\phi$ for  $1000< Re^\prime < 6000$.

$1000< Re^\prime < 6000$.

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2024. Published by Cambridge University Press

References

- 1

- Cited by