1. Introduction

A sessile droplet evaporating from a solid substrate is central to a wide variety of processes. Examples range from spray cooling of microelectronics (Bar-Cohen, Arik & Ohadi Reference Bar-Cohen, Arik and Ohadi2006; Kim Reference Kim2007; Deng & Gomez Reference Deng and Gomez2011) to inkjet printing (Calvert Reference Calvert2001; Singh et al. Reference Singh, Haverinen, Dhagat and Jabbour2010), pesticide deposition (Yu et al. Reference Yu, Zhu, Frantz, Reding, Chan and Ozkan2009; Damak et al. Reference Damak, Mahmoudi, Hyder and Varanasi2016) and even disease diagnosis (Sefiane Reference Sefiane2010; Brutin et al. Reference Brutin, Sobac, Loquet and Sampol2011; Chen et al. Reference Chen, Zhang, Zang and Shen2016). An evaporating sessile droplet is rarely at true equilibrium with the limiting mechanism in non-volatile liquids tending to be the diffusion of vapour away from the interface (Bourges-Monnier & Shanahan Reference Bourges-Monnier and Shanahan1995; Hu & Larson Reference Hu and Larson2002). More volatile droplets, however, can be modelled using kinetic theory and interface non-equilibrium effects (Anderson & Davis Reference Anderson and Davis1995; Ajaev Reference Ajaev2005).

Depending on wettability, droplets can either spread completely over the substrate, forming a pancake with a zero contact angle, or they can become pinned at the triple contact line (where solid, liquid and gas meet), settling at an equilibrium contact angle. In both cases, once spreading is finished, evaporation soon takes over and the droplet profile changes, making the non-equilibrium nature of the problem clear. Wettability of a droplet over a substrate can be explained by (1.1) – the well-known Young's equation,

where ![]() $\sigma$ denotes free energy per unit length (or surface tension) and subscripts

$\sigma$ denotes free energy per unit length (or surface tension) and subscripts ![]() $S$,

$S$, ![]() $L$,

$L$, ![]() $V$, refer to the solid, liquid and vapour, respectively. For a partial wetting droplet with a non-zero equilibrium contact angle, the cohesive forces of

$V$, refer to the solid, liquid and vapour, respectively. For a partial wetting droplet with a non-zero equilibrium contact angle, the cohesive forces of ![]() $\sigma _{SL}$ and

$\sigma _{SL}$ and ![]() $\sigma _{LV}$ are larger than the adhesive force of

$\sigma _{LV}$ are larger than the adhesive force of ![]() $\sigma _{SV}$, i.e.

$\sigma _{SV}$, i.e. ![]() $\sigma _{SV} < \sigma _{SL} + \sigma _{LV}$. Therefore, the surface energy is minimised by inward motion of the droplet and results in a finite contact angle. For a completely wetting droplet with zero contact angle (

$\sigma _{SV} < \sigma _{SL} + \sigma _{LV}$. Therefore, the surface energy is minimised by inward motion of the droplet and results in a finite contact angle. For a completely wetting droplet with zero contact angle (![]() $\theta _{eq} = 0$), a special case arises from the fact that

$\theta _{eq} = 0$), a special case arises from the fact that ![]() $\cos \theta _{eq} = 1$, yielding

$\cos \theta _{eq} = 1$, yielding ![]() $\sigma _{SV} = \sigma _{SL} + \sigma _{LV}$, and so the cohesive and adhesive forces are perfectly balanced.

$\sigma _{SV} = \sigma _{SL} + \sigma _{LV}$, and so the cohesive and adhesive forces are perfectly balanced.

Further complexity arises due to the larger number of factors governing sessile droplet dynamics. Behaviour is heavily influenced by properties of the solid substrate, including substrate roughness (Cazabat & Cohen Stuart Reference Cazabat and Cohen Stuart1986; Nakae et al. Reference Nakae, Inui, Hirata and Saito1998; Chen et al. Reference Chen, He, Lee and Patankar2005) and conductivity (Ristenpart et al. Reference Ristenpart, Kim, Domingues, Wan and Stone2007; Dunn et al. Reference Dunn, Wilson, Duffy, David and Sefiane2009); the liquid, including surface tension and volatility (Sefiane et al. Reference Sefiane, Moffat, Matar and Craster2008b; Starov & Sefiane Reference Starov and Sefiane2009); and the surrounding gas, including atmospheric pressure (Sefiane et al. Reference Sefiane, Wilson, David, Dunn and Duffy2009), humidity (Fukatani et al. Reference Fukatani, Orejon, Kita, Takata, Kim and Sefiane2016) and vapour properties (Shahidzadeh-Bonn et al. Reference Shahidzadeh-Bonn, Rafaï, Azouni and Bonn2006). In addition, the dynamics are strongly dependent on the temperature of each phase (Girard & Antoni Reference Girard and Antoni2008; Sobac & Brutin Reference Sobac and Brutin2012; Parsa et al. Reference Parsa, Harmand, Sefiane, Bigerelle and Deltombe2015), droplet shape (Sáenz et al. Reference Sáenz, Sefiane, Kim, Matar and Valluri2015), and gravity becomes important as volume increases (Extrand & Moon Reference Extrand and Moon2010; Srinivasan, Mckinley & Cohen Reference Srinivasan, Mckinley and Cohen2011).

Introduction of miscible and/or immiscible liquids (Christy, Hamamoto & Sefiane Reference Christy, Hamamoto and Sefiane2011; Bennacer & Sefiane Reference Bennacer and Sefiane2014; Tan et al. Reference Tan, Diddens, Lv, Kuerten, Zhang and Lohse2016) complicates matters even further. For droplets close to or below the capillary length (![]() $L_c = \sqrt {\sigma /\rho g}$), the well-known Marangoni effect has a strong influence on the flow field, dictating much of their behaviour (Deegan et al. Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten1997, Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten2000). Correctly identified by Italian physicist Carlo Marangoni, such flows arise due to surface tension gradients owing to both variations in temperature and liquid composition (Scriven & Sternling Reference Scriven and Sternling1960) – known as thermal and solutal Marangoni flow, respectively.

$L_c = \sqrt {\sigma /\rho g}$), the well-known Marangoni effect has a strong influence on the flow field, dictating much of their behaviour (Deegan et al. Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten1997, Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten2000). Correctly identified by Italian physicist Carlo Marangoni, such flows arise due to surface tension gradients owing to both variations in temperature and liquid composition (Scriven & Sternling Reference Scriven and Sternling1960) – known as thermal and solutal Marangoni flow, respectively.

The solutal Marangoni effect causes droplets comprising of binary mixtures to display distinctly different behaviours from the single component equivalent. Early work by Sefiane, Tadrist & Douglas (Reference Sefiane, Tadrist and Douglas2003) found that pinned binary droplets of ethanol–water mixtures displayed non-monotonous behaviour, heavily influenced by the initial concentration. This was unlike pure droplets which displayed a monotonous evolution of evaporation rate and interface profile in time (Picknett & Bexton Reference Picknett and Bexton1977). The internal flow field of ethanol–water droplets has been shown to be inherently more complex and chaotic (Christy, Sefiane & Munro Reference Christy, Sefiane and Munro2010; Christy et al. Reference Christy, Hamamoto and Sefiane2011) due to surface tension differences arising from the uneven concentration as a result of preferential ethanol evaporation. With these early studies confined to axisymmetric droplets, Sáenz et al. (Reference Sáenz, Wray, Che, Matar, Valluri, Kim and Sefiane2017) investigated well-defined non-spherical geometries and found that controlling the interface curvature would cause segregation of the two components. With evaporation proceeding slowest at areas of minimum curvature, ethanol would linger in these areas for the longest times.

An important study on wetting binary droplets by Guéna, Poulard & Cazabat (Reference Guéna, Poulard and Cazabat2007) found the remarkable behaviour that binary alkane mixtures tended to spread and evaporate faster than either of their pure constituents – as studied by Cachile, Be & Cazabat (Reference Cachile, Be and Cazabat2002a) and Cachile et al. (Reference Cachile, Benichou, Poulard and Cazabat2002b). Guéna et al. (Reference Guéna, Poulard and Cazabat2007) noted that spreading would deviate from Tanner's law, with the spreading exponent rising to ![]() $n = 0.3$ (

$n = 0.3$ (![]() $r \propto t^n$). This behaviour was owing to the solutal Marangoni effect. Mixtures were carefully selected so that the less volatile component (LVC) of the mixture had a higher surface tension than the more volatile component (MVC). The preferential evaporation of MVC at the contact line would leave a higher concentration of LVC and, hence, a higher surface tension compared to the bulk. The surface tension gradient would induce Marangoni flows towards the contact line, enhancing the capillary force and, as a result, the spreading rate. Droplets would spread to minimum thickness more quickly than their single components counterparts and reach dry-out faster, even when only LVC remained, due to the thinner droplet profile and increased interfacial surface area enhancing evaporation. Depending on the initial concentration, interesting drying profiles were observed, such as the droplet centre drying out before the contact line, leaving a torus shaped ring.

$r \propto t^n$). This behaviour was owing to the solutal Marangoni effect. Mixtures were carefully selected so that the less volatile component (LVC) of the mixture had a higher surface tension than the more volatile component (MVC). The preferential evaporation of MVC at the contact line would leave a higher concentration of LVC and, hence, a higher surface tension compared to the bulk. The surface tension gradient would induce Marangoni flows towards the contact line, enhancing the capillary force and, as a result, the spreading rate. Droplets would spread to minimum thickness more quickly than their single components counterparts and reach dry-out faster, even when only LVC remained, due to the thinner droplet profile and increased interfacial surface area enhancing evaporation. Depending on the initial concentration, interesting drying profiles were observed, such as the droplet centre drying out before the contact line, leaving a torus shaped ring.

The first complete model to simulate the evaporation of a multicomponent droplet was provided by Diddens et al. (Reference Diddens, Kuerten, van der Geld and Wijshoff2017) who extended the mathematical model of Siregar, Kuerten & Van Der Geld (Reference Siregar, Kuerten and Van Der Geld2013), based on the lubrication approximation and solved using the finite volume method. They considered partially wetting binary droplets of ethanol–water and water–glycerol evaporating from an isothermal substrate at contact angles 6.6![]() $^\circ$–40

$^\circ$–40![]() $^\circ$ using a Navier-slip condition at the contact line. For ethanol–water droplets, Diddens et al. (Reference Diddens, Kuerten, van der Geld and Wijshoff2017) observed that at long times ethanol had almost entirely evaporated but a strong thermal Marangoni flow was still present – validating the hypothesis of Christy et al. (Reference Christy, Hamamoto and Sefiane2011). They noted that when the droplet becomes flat, the surface tension gradient leads to shape deformation with a depression in the droplet centre – similar to the observations of Guéna et al. (Reference Guéna, Poulard and Cazabat2007). Entrapped residual ethanol, previously predicted (Liu, Bonaccurso & Butt Reference Liu, Bonaccurso and Butt2008; Sefiane, David & Shanahan Reference Sefiane, David and Shanahan2008a), could not be noticed, which the authors argue was due to strong convective mixing resulting from the fast Marangoni flow. However, residual amounts of water in glycerol–water droplets (where diffusive transport is slower) were found to remain in the later stages. By then extending the model to non-isothermal heated substrates, Diddens et al. (Reference Diddens, Kuerten, van der Geld and Wijshoff2017) was able to reproduce the flow regimes and transitions reported experimentally by Zhong & Duan (Reference Zhong and Duan2016). Diddens (Reference Diddens2017) also approached the problem using a finite element model to tackle larger contact angles above 90

$^\circ$ using a Navier-slip condition at the contact line. For ethanol–water droplets, Diddens et al. (Reference Diddens, Kuerten, van der Geld and Wijshoff2017) observed that at long times ethanol had almost entirely evaporated but a strong thermal Marangoni flow was still present – validating the hypothesis of Christy et al. (Reference Christy, Hamamoto and Sefiane2011). They noted that when the droplet becomes flat, the surface tension gradient leads to shape deformation with a depression in the droplet centre – similar to the observations of Guéna et al. (Reference Guéna, Poulard and Cazabat2007). Entrapped residual ethanol, previously predicted (Liu, Bonaccurso & Butt Reference Liu, Bonaccurso and Butt2008; Sefiane, David & Shanahan Reference Sefiane, David and Shanahan2008a), could not be noticed, which the authors argue was due to strong convective mixing resulting from the fast Marangoni flow. However, residual amounts of water in glycerol–water droplets (where diffusive transport is slower) were found to remain in the later stages. By then extending the model to non-isothermal heated substrates, Diddens et al. (Reference Diddens, Kuerten, van der Geld and Wijshoff2017) was able to reproduce the flow regimes and transitions reported experimentally by Zhong & Duan (Reference Zhong and Duan2016). Diddens (Reference Diddens2017) also approached the problem using a finite element model to tackle larger contact angles above 90![]() $^\circ$, no longer invoking the lubrication approximation. Thermal convection was also included, accounting for the effects of substrate thickness and evaporative cooling. Here the results showed that the evaporation of the MVC can drastically decrease the interface temperature, causing the ambient vapour of the LVC to condense onto the droplet. The approach used by Diddens (Reference Diddens2017) was compared with the previous lubrication-based model (Diddens et al. Reference Diddens, Kuerten, van der Geld and Wijshoff2017). While the volume evolutions agreed well, even at low contact angles, the lubrication approach overpredicted the regular Marangoni velocities and underpredicted the chaotic velocities in the case of an instability.

$^\circ$, no longer invoking the lubrication approximation. Thermal convection was also included, accounting for the effects of substrate thickness and evaporative cooling. Here the results showed that the evaporation of the MVC can drastically decrease the interface temperature, causing the ambient vapour of the LVC to condense onto the droplet. The approach used by Diddens (Reference Diddens2017) was compared with the previous lubrication-based model (Diddens et al. Reference Diddens, Kuerten, van der Geld and Wijshoff2017). While the volume evolutions agreed well, even at low contact angles, the lubrication approach overpredicted the regular Marangoni velocities and underpredicted the chaotic velocities in the case of an instability.

The evaporation of a ternary mixture droplet was investigated for the first time by Tan et al. (Reference Tan, Diddens, Lv, Kuerten, Zhang and Lohse2016). Specifically, partially wetting droplets of the alcoholic beverage, Ouzo – a mixture of water, ethanol and anise oil. The addition of anise oil adds a further complication of mutual solubility, with the oil being miscible in ethanol but immiscible in water. The evaporation phenomena was revealed to be extremely rich, with evaporation-induced phase separation being observed. Li et al. (Reference Li, Lv, Diddens, Tan, Wijshoff, Versluis and Lohse2018) also recently observed component segregation in binary droplets due to evaporation from the contact line rim being faster than the induced Marangoni flow, resulting in the convection usually caused by Marangoni flows too weak to maintain perfect mixing.

From the short review above, while some aspects of evaporating binary mixture droplets have been reported, the underlying physics of spreading (and retraction) dynamics is still in question. This is particularly important for many applications including cooling and development of self-cleaning solvent mixtures that rely on the volatilities. In this paper we present comprehensive lubrication modelling supported by experiments considering ideal ethanol–water mixtures, far away from azeotropic concentrations. We particularly focus on flat droplets formed due to an underlying hydrophilic substrate. This allows us to not only validate our lubrication model but also to identify spreading regimes whilst at the same time revealing the governing physics. Our simulations elucidate the role of thermal and solutal Marangoni stresses and capillary forces at various stages of the evaporating process. In line with our experimental observations reported herein, it is demonstrated that for a sufficiently high concentration of ethanol, solutal Marangoni stresses drive very fast spreading of the droplet at early stages of evaporation, with spreading exponents that may exceed the value of 1. The enhanced spreading may also be accompanied by the formation of a ridge near the contact line. This behaviour is clearly reminiscent of superspreading reported in surfactant-laden flows (Rafaï et al. Reference Rafaï, Sarker, Bergeron, Meunier and Bonn2002; Karapetsas, Craster & Matar Reference Karapetsas, Craster and Matar2011). As it will be shown below, enhanced spreading of binary mixture droplets is due to the presence of strong Marangoni stresses near the contact line, arising due to the preferential evaporation of ethanol in that region. In contrast to the surfactant-laden flows however, the concentration gradients here arise as a natural consequence of the evaporation process. At later stages, it is shown that the dynamics of the evaporation and droplet shape is dictated by the interplay of thermal and solutal Marangoni stresses and capillary forces.

2. Problem statement and model formulation

2.1. Description of the problem

We study the behaviour of a small and thin sessile droplet consisting of a mixture of two volatile, miscible liquids ![]() $A$ and

$A$ and ![]() $B$ as shown in figure 1. Liquid

$B$ as shown in figure 1. Liquid ![]() $A$ is the more volatile component (MVC) in the mixture and liquid

$A$ is the more volatile component (MVC) in the mixture and liquid ![]() $B$ the less volatile component (LVC). The mixture is assumed to be ideal and the droplet is considered Newtonian with density

$B$ the less volatile component (LVC). The mixture is assumed to be ideal and the droplet is considered Newtonian with density ![]() $\hat {\rho }$, specific heat capacity

$\hat {\rho }$, specific heat capacity ![]() $\hat {c}_p$, thermal conductivity

$\hat {c}_p$, thermal conductivity ![]() $\hat {k}$ and viscosity

$\hat {k}$ and viscosity ![]() $\hat {\mu }$. For simplicity, and because liquids with similar densities will be chosen for components

$\hat {\mu }$. For simplicity, and because liquids with similar densities will be chosen for components ![]() $A$ and

$A$ and ![]() $B$, we assume the liquid mixture to be incompressible and the density of both components equal, such that

$B$, we assume the liquid mixture to be incompressible and the density of both components equal, such that ![]() $\hat {\rho }_A=\hat {\rho }_B=\hat {\rho }$. With the exception of density, the remaining properties vary locally with concentration. We account for this using the following rule of mixtures, shown for generic variable

$\hat {\rho }_A=\hat {\rho }_B=\hat {\rho }$. With the exception of density, the remaining properties vary locally with concentration. We account for this using the following rule of mixtures, shown for generic variable ![]() $\hat {\zeta }$ as

$\hat {\zeta }$ as

where ![]() $\chi _A$ is the mass fraction of component

$\chi _A$ is the mass fraction of component ![]() $A$ in the mixture (hence,

$A$ in the mixture (hence, ![]() $\chi _B = 1 - \chi _A$), while

$\chi _B = 1 - \chi _A$), while ![]() $\hat {\zeta }_A$ and

$\hat {\zeta }_A$ and ![]() $\hat {\zeta }_B$ denote property values of pure component

$\hat {\zeta }_B$ denote property values of pure component ![]() $A$ and

$A$ and ![]() $B$, respectively. Within the liquid mixture, we consider only Fick's law, with the effects of thermodiffusion arising from the Soret effect neglected. At the interface, the surface tension,

$B$, respectively. Within the liquid mixture, we consider only Fick's law, with the effects of thermodiffusion arising from the Soret effect neglected. At the interface, the surface tension, ![]() $\hat {\sigma }$, of the binary mixture has a linear dependence on both the local concentration of each component and the local temperature,

$\hat {\sigma }$, of the binary mixture has a linear dependence on both the local concentration of each component and the local temperature, ![]() $\hat {T}$, taking the form

$\hat {T}$, taking the form

where ![]() $\hat {\gamma }_{T,i} = \partial \hat {\sigma }_{T,i}/\partial \hat {T}$ is the temperature coefficient of surface tension of component

$\hat {\gamma }_{T,i} = \partial \hat {\sigma }_{T,i}/\partial \hat {T}$ is the temperature coefficient of surface tension of component ![]() $i$ (

$i$ (![]() $i = A, B$). Here

$i = A, B$). Here ![]() $\hat {\sigma }_{i,r}$ is the surface tension of component

$\hat {\sigma }_{i,r}$ is the surface tension of component ![]() $i$ at reference temperature

$i$ at reference temperature ![]() $\hat {T}_r$. We assume this to be the temperature of the vapour phase,

$\hat {T}_r$. We assume this to be the temperature of the vapour phase, ![]() $\hat {T}_r = \hat {T}_g$.

$\hat {T}_r = \hat {T}_g$.

Figure 1. Droplet geometry of initial height ![]() $\hat {H}_0$ and radius

$\hat {H}_0$ and radius ![]() $\hat {R}_0$ in the cylindrical coordinate frame. The droplet consisting of miscible components

$\hat {R}_0$ in the cylindrical coordinate frame. The droplet consisting of miscible components ![]() $A$ and

$A$ and ![]() $B$ and resides on a heated substrate at temperature

$B$ and resides on a heated substrate at temperature ![]() $\hat {T}_w$. The droplet is sufficiently thin such that the aspect ratio is much less than unity,

$\hat {T}_w$. The droplet is sufficiently thin such that the aspect ratio is much less than unity, ![]() ${\hat {H}_0}/{\hat {R}_0} \ll 1$. Gas temperature is kept constant at

${\hat {H}_0}/{\hat {R}_0} \ll 1$. Gas temperature is kept constant at ![]() $\hat {T}_g$. Here

$\hat {T}_g$. Here ![]() $\boldsymbol {n}$ and

$\boldsymbol {n}$ and ![]() $\boldsymbol {t}$ denote the outward unit vectors acting in normal and tangential directions to the interface, respectively.

$\boldsymbol {t}$ denote the outward unit vectors acting in normal and tangential directions to the interface, respectively.

The droplet resides on a heated horizontal solid substrate kept at a constant temperature ![]() $\hat {T}_w$ and is released into a thin precursor film consisting solely of the LVC. Evaporation in the film is stabilised by the disjoining pressure which accounts for the attractive van der Waals interactions. The inclusion of the precursor film removes the stress singularity that can arise at the moving contact line. Rather than a purely artificial tool, the precursor film is also a physical effect with experimental verification (de Gennes Reference de Gennes1985). The precursor film is always formed on the solid surface if the droplet is surrounded by its vapour, from which it is adsorbed. The precursor film is sufficiently thin that the liquid molecules are attracted to the substrate by van der Waals interactions, stabilising the film and suppressing evaporation (Ajaev Reference Ajaev2005; Berthier Reference Berthier2013).

$\hat {T}_w$ and is released into a thin precursor film consisting solely of the LVC. Evaporation in the film is stabilised by the disjoining pressure which accounts for the attractive van der Waals interactions. The inclusion of the precursor film removes the stress singularity that can arise at the moving contact line. Rather than a purely artificial tool, the precursor film is also a physical effect with experimental verification (de Gennes Reference de Gennes1985). The precursor film is always formed on the solid surface if the droplet is surrounded by its vapour, from which it is adsorbed. The precursor film is sufficiently thin that the liquid molecules are attracted to the substrate by van der Waals interactions, stabilising the film and suppressing evaporation (Ajaev Reference Ajaev2005; Berthier Reference Berthier2013).

The droplet is in contact with the gas phase which has a bulk temperature of ![]() $\hat {T}_g$. The velocity of the gas and vapour particles is assumed sufficiently low so as to be negligible. The gas phase has density

$\hat {T}_g$. The velocity of the gas and vapour particles is assumed sufficiently low so as to be negligible. The gas phase has density ![]() $\hat {\rho }_v$, viscosity

$\hat {\rho }_v$, viscosity ![]() $\hat {\mu }_v$ and thermal conductivity

$\hat {\mu }_v$ and thermal conductivity ![]() $\hat {k}_v$. These gas-phase properties are assumed to be significantly smaller than their liquid counterparts, such that,

$\hat {k}_v$. These gas-phase properties are assumed to be significantly smaller than their liquid counterparts, such that, ![]() $\hat {\rho }_g \ll \hat {\rho }$,

$\hat {\rho }_g \ll \hat {\rho }$, ![]() $\hat {\mu }_v \ll \hat {\mu }$,

$\hat {\mu }_v \ll \hat {\mu }$, ![]() $\hat {k}_v \ll \hat {k}$ (Burelbach, Bankoff & Davis Reference Burelbach, Bankoff and Davis1988). The same is assumed for the vapour properties. In addition, we assume that the total gas-phase pressure is sufficiently large that it remains constant with evaporation and changing vapour pressure.

$\hat {k}_v \ll \hat {k}$ (Burelbach, Bankoff & Davis Reference Burelbach, Bankoff and Davis1988). The same is assumed for the vapour properties. In addition, we assume that the total gas-phase pressure is sufficiently large that it remains constant with evaporation and changing vapour pressure.

Given these assumptions, we adopt the so called ‘one-sided’ model and focus solely on the liquid phase in this study. The draw of such an approach is the considerably reduced complexity by discounting the vapour phase while including the physics of the liquid phase. A clear limitation is that we are forced to assume evaporation is not vapour-diffusion limited and instead controlled by the transfer of molecules across the liquid–vapour interface. Physically, we are assuming that vapour diffuses rapidly away from the liquid–vapour interface and, therefore, the model is expected to be valid in the regime where there is a well mixed environment and so the phase-transition process is the rate limiting step. Phase transition is modelled using the non-equilibrium Hertz–Knudsen relation from kinetic theory (Plesset & Prosperetti Reference Plesset and Prosperetti1976; Moosman & Homsy Reference Moosman and Homsy1980), written in dimensional form for each ![]() $i$ component as

$i$ component as

\begin{equation} \hat{\!J}_i = \frac{\hat{p}_{v,i} \hat{M}_i}{\hat{R}_g \hat{T}|_h} \left(\frac{\hat{R}_g\hat{T}|_h} {2{\rm \pi}\hat{M}_i}\right)^{{1}/{2}} \left(\alpha_{v,i}\frac{\hat{p}_{v,e,i}} {\hat{p}_{v,i}} - \beta_{v,i}\right), \end{equation}

\begin{equation} \hat{\!J}_i = \frac{\hat{p}_{v,i} \hat{M}_i}{\hat{R}_g \hat{T}|_h} \left(\frac{\hat{R}_g\hat{T}|_h} {2{\rm \pi}\hat{M}_i}\right)^{{1}/{2}} \left(\alpha_{v,i}\frac{\hat{p}_{v,e,i}} {\hat{p}_{v,i}} - \beta_{v,i}\right), \end{equation}

where ![]() $\hat {p}_{v,i}$ is the partial pressure of component

$\hat {p}_{v,i}$ is the partial pressure of component ![]() $i$,

$i$, ![]() $\hat {p}_{v,e,i}$ is its equilibrium vapour pressure and

$\hat {p}_{v,e,i}$ is its equilibrium vapour pressure and ![]() $\hat {M}_i$ its molecular weight. Here

$\hat {M}_i$ its molecular weight. Here ![]() $\hat {T}|_h$ denotes the interfacial temperature of the liquid and

$\hat {T}|_h$ denotes the interfacial temperature of the liquid and ![]() $\hat {R}_g$ is the universal gas constant;

$\hat {R}_g$ is the universal gas constant; ![]() $\alpha _{v,i}$ and

$\alpha _{v,i}$ and ![]() $\beta _{v,i}$ are accommodation coefficients for evaporation and condensation, respectively, giving the probability that a molecule of component

$\beta _{v,i}$ are accommodation coefficients for evaporation and condensation, respectively, giving the probability that a molecule of component ![]() $i$ impinging on the interface will cross over to the other phase (Knudsen Reference Knudsen1950). As reviewed in Murisic & Kondic (Reference Murisic and Kondic2011), the value of accommodation coefficients used in the literature varies over several orders of magnitude from

$i$ impinging on the interface will cross over to the other phase (Knudsen Reference Knudsen1950). As reviewed in Murisic & Kondic (Reference Murisic and Kondic2011), the value of accommodation coefficients used in the literature varies over several orders of magnitude from ![]() $O(10^{-6})$ to

$O(10^{-6})$ to ![]() $O(1)$, with lower values providing a greater barrier to phase change by reducing the probability of a molecule crossing the interface. For simplicity, and in line with other works (Moosman & Homsy Reference Moosman and Homsy1980; Ajaev Reference Ajaev2005; Sultan, Boudaoud & Ben Amar Reference Sultan, Boudaoud and Ben Amar2005), we assume in this study that the accommodation coefficients are constant and nearly equal to each other, such that

$O(1)$, with lower values providing a greater barrier to phase change by reducing the probability of a molecule crossing the interface. For simplicity, and in line with other works (Moosman & Homsy Reference Moosman and Homsy1980; Ajaev Reference Ajaev2005; Sultan, Boudaoud & Ben Amar Reference Sultan, Boudaoud and Ben Amar2005), we assume in this study that the accommodation coefficients are constant and nearly equal to each other, such that ![]() $\alpha _{v,i} = \beta _{v,i} = 1$. Physically this means there is no barrier to phase change and every molecule of vapour or liquid striking the interface transitions to the opposite phase (Persad & Ward Reference Persad and Ward2016).

$\alpha _{v,i} = \beta _{v,i} = 1$. Physically this means there is no barrier to phase change and every molecule of vapour or liquid striking the interface transitions to the opposite phase (Persad & Ward Reference Persad and Ward2016).

Another modelling approach not considered here is the ‘1.5 sided’ or ‘lens’ model; generally used when evaporation is firmly in the vapour-diffusion limited regime. When using this method, the liquid phase is fully resolved with the gas phase being solved for diffusion only and boundary conditions applied along the liquid–vapour interface for the liberation of the liquid to vapour. Murisic & Kondic (Reference Murisic and Kondic2011) have explored when one evaporation model is more appropriate than the other for pure droplets of either water or isopropanol with moving contact line on non-heated surfaces. They concluded that a NEOS model with a small accommodation coefficient, ![]() $\alpha _v$, of

$\alpha _v$, of ![]() $O(10^{-4})$ better reflected the experimental results for pure water droplets while the lens model was more accurate for the isopropanol droplets.

$O(10^{-4})$ better reflected the experimental results for pure water droplets while the lens model was more accurate for the isopropanol droplets.

By using accommodation coefficients close to unity, we expect our model to overpredict the evaporation rates compared to experiment, where the vapour diffusion from the interface to a far-field value is typically several orders of magnitude slower than the liberation of liquid molecules to the vapour phase. In practice, this means while our model will qualitatively simulate evaporation, a quantitative comparison with evaporation fluxes against diffusion-limited experiments is impossible. To achieve a quantitative comparison, a modified accommodation coefficient or more complex models such as those of Sultan et al. (Reference Sultan, Boudaoud and Ben Amar2005) or Sáenz et al. (Reference Sáenz, Sefiane, Kim, Matar and Valluri2015) should be explored. Despite this, one-sided models similar to the one considered here have proved powerful in the prediction of qualitative behaviour for evaporating droplets in the past, for example, the prediction of hydrothermal waves in evaporating pure component droplets (Karapetsas et al. Reference Karapetsas, Matar, Valluri and Sefiane2012).

Initially, we assume that the droplet has maximal thickness ![]() $\hat {H}_0$ and radius

$\hat {H}_0$ and radius ![]() $\hat {R}_0$, in a polar coordinate system

$\hat {R}_0$, in a polar coordinate system ![]() $(\hat {r}, \hat {z}, \hat {\theta })$ representing the radial, axial and azimuthal axes. We consider the droplet to be axisymmetric and very thin. Therefore,

$(\hat {r}, \hat {z}, \hat {\theta })$ representing the radial, axial and azimuthal axes. We consider the droplet to be axisymmetric and very thin. Therefore, ![]() $\hat {R}_0 \gg \hat {H}_0$, so that the droplet aspect ratio,

$\hat {R}_0 \gg \hat {H}_0$, so that the droplet aspect ratio, ![]() $\varepsilon = \hat {H}_0/\hat {R}_0 \ll 1$. This assumption permits the use of lubrication theory, which we will employ to derive the evolution equations. Additionally, we assume the droplet is sufficiently small as to neglect gravitational effects. This means a Bond number of much less than one, requiring the radius of the droplet to be below the capillary length of both liquids in the mixture. A working mixture of ethanol and water is considered. Both liquids are sufficiently volatile on a heated substrate, ethanol being the MVC and possessing a lower surface tension than water. The selection of an ethanol–water mixture also avoids any ‘self-rewetting’ properties (Abe, Iwasaki & Tanaka Reference Abe, Iwasaki and Tanaka2004) present in other alcohol–water mixtures at certain concentrations, for example, butanol–water. The pure component properties of each fluid in the mixture are given in table 1.

$\varepsilon = \hat {H}_0/\hat {R}_0 \ll 1$. This assumption permits the use of lubrication theory, which we will employ to derive the evolution equations. Additionally, we assume the droplet is sufficiently small as to neglect gravitational effects. This means a Bond number of much less than one, requiring the radius of the droplet to be below the capillary length of both liquids in the mixture. A working mixture of ethanol and water is considered. Both liquids are sufficiently volatile on a heated substrate, ethanol being the MVC and possessing a lower surface tension than water. The selection of an ethanol–water mixture also avoids any ‘self-rewetting’ properties (Abe, Iwasaki & Tanaka Reference Abe, Iwasaki and Tanaka2004) present in other alcohol–water mixtures at certain concentrations, for example, butanol–water. The pure component properties of each fluid in the mixture are given in table 1.

Table 1. Physical properties of ethanol (MVC) and water (LVC) at 20![]() $^\circ$ and 1 atm.

$^\circ$ and 1 atm.

2.2. Governing equations and boundary conditions

2.2.1. Scaling

All of the aforementioned variables have taken dimensional form – a hat (![]() $\:\hat {}\:$) signifying the dimensional symbol. We scale the system using the properties of the more volatile component (MVC),

$\:\hat {}\:$) signifying the dimensional symbol. We scale the system using the properties of the more volatile component (MVC), ![]() $A$, and the thermocapillary velocity, defined as

$A$, and the thermocapillary velocity, defined as ![]() $\hat {U} = \varepsilon \hat {\gamma }_l {\rm \Delta} \hat {T} / \hat {\mu }_l$. As such, we now introduce the following scalings:

$\hat {U} = \varepsilon \hat {\gamma }_l {\rm \Delta} \hat {T} / \hat {\mu }_l$. As such, we now introduce the following scalings:

\begin{equation} \left.\begin{array}{l@{}} \displaystyle \hat{r} = \hat{R}_0 r,\quad \hat{z} = \hat{H}_0 z,\quad \hat{t} = \dfrac{\hat{R}_0}{\hat{U}} t,\quad \boldsymbol{\hat{u}} = (\hat{u}, \hat{w}) = \left( \hat{U} u,\dfrac{\hat{H}_0}{\hat{R}_0}\hat{U} w \right); \\ \displaystyle \hat{p} = \hat{p}_{ig} + \dfrac{\hat{\mu}_A\hat{U} \hat{R}_0}{{\hat{H}_0}^2} p,\quad \hat{T} = \hat{T}_0 + T{\rm \Delta}\hat{T},\quad \hat{\!J}_i = \dfrac{\hat{k}_A{\rm \Delta}\hat{T}}{\hat{H}_0\hat{L}_{v,A}} J_i; \\ \displaystyle \hat{\sigma}_i = \hat{\sigma}_{A,0}\sigma_i,\quad \hat{\mu} = \hat{\mu}_A \mu,\quad \hat{k} = \hat{k}_A k,\quad \hat{c}_p = \hat{c}_{p,A} c_p. \end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{l@{}} \displaystyle \hat{r} = \hat{R}_0 r,\quad \hat{z} = \hat{H}_0 z,\quad \hat{t} = \dfrac{\hat{R}_0}{\hat{U}} t,\quad \boldsymbol{\hat{u}} = (\hat{u}, \hat{w}) = \left( \hat{U} u,\dfrac{\hat{H}_0}{\hat{R}_0}\hat{U} w \right); \\ \displaystyle \hat{p} = \hat{p}_{ig} + \dfrac{\hat{\mu}_A\hat{U} \hat{R}_0}{{\hat{H}_0}^2} p,\quad \hat{T} = \hat{T}_0 + T{\rm \Delta}\hat{T},\quad \hat{\!J}_i = \dfrac{\hat{k}_A{\rm \Delta}\hat{T}}{\hat{H}_0\hat{L}_{v,A}} J_i; \\ \displaystyle \hat{\sigma}_i = \hat{\sigma}_{A,0}\sigma_i,\quad \hat{\mu} = \hat{\mu}_A \mu,\quad \hat{k} = \hat{k}_A k,\quad \hat{c}_p = \hat{c}_{p,A} c_p. \end{array}\right\} \end{equation}

Here, ![]() $\hat {t}$ is time,

$\hat {t}$ is time, ![]() $\hat {p}$ is pressure and

$\hat {p}$ is pressure and ![]() $\boldsymbol {\hat {u}}$ is the velocity vector field with components

$\boldsymbol {\hat {u}}$ is the velocity vector field with components ![]() $\hat {u}$ and

$\hat {u}$ and ![]() $\hat {w}$ in the radial and axial directions, respectively. Also,

$\hat {w}$ in the radial and axial directions, respectively. Also, ![]() $\hat {L}_v$ is the latent heat of vapourisation,

$\hat {L}_v$ is the latent heat of vapourisation, ![]() $\hat {\!J}_i$ is the evaporative flux of component

$\hat {\!J}_i$ is the evaporative flux of component ![]() $i$ and

$i$ and ![]() ${\rm \Delta} \hat {T}=\hat {T}_w-\hat {T}_g$. The principal dimensionless numbers arising from the scaling are the Marangoni number,

${\rm \Delta} \hat {T}=\hat {T}_w-\hat {T}_g$. The principal dimensionless numbers arising from the scaling are the Marangoni number, ![]() $Ma = \hat {\gamma }_A {\rm \Delta} \hat {T}/\hat {\sigma }_{A,r}$, the Reynolds number,

$Ma = \hat {\gamma }_A {\rm \Delta} \hat {T}/\hat {\sigma }_{A,r}$, the Reynolds number, ![]() $Re = \hat {\rho }_A \hat {U} \hat {H}_0 / \varepsilon \hat {\mu }_A$, the Prandtl number,

$Re = \hat {\rho }_A \hat {U} \hat {H}_0 / \varepsilon \hat {\mu }_A$, the Prandtl number, ![]() $Pr = \hat {\mu }_A \hat {C}_{p,A} / \hat {k}_A$, the Péclet number,

$Pr = \hat {\mu }_A \hat {C}_{p,A} / \hat {k}_A$, the Péclet number, ![]() $Pe = \hat {U} \hat {R}_0 / \hat {\mathcal {D}}_A$, evaporation number,

$Pe = \hat {U} \hat {R}_0 / \hat {\mathcal {D}}_A$, evaporation number, ![]() $E = \hat {k}_A {\rm \Delta} \hat {T} \hat {R}_0 /{\hat {H}_0}^2 \hat {L}_{v,A} \hat {U} \hat {\rho }$, and the Knudsen number,

$E = \hat {k}_A {\rm \Delta} \hat {T} \hat {R}_0 /{\hat {H}_0}^2 \hat {L}_{v,A} \hat {U} \hat {\rho }$, and the Knudsen number, ![]() $K = \hat {k}_A (2{\rm \pi} {\hat {R}_g}^3 {\hat {T}_g}^5)^{1/2} / \hat {H}_0 \hat {L}^2_{v,A} \hat {p}_{s,A} {\hat {M}_A}^{3/2}$. Here

$K = \hat {k}_A (2{\rm \pi} {\hat {R}_g}^3 {\hat {T}_g}^5)^{1/2} / \hat {H}_0 \hat {L}^2_{v,A} \hat {p}_{s,A} {\hat {M}_A}^{3/2}$. Here ![]() $K$ measures the importance of kinetic effects at the interface and can be thought of as being analogous to the inverse of the Biot number, controlling the heat loss across the interface (Karapetsas et al. Reference Karapetsas, Matar, Valluri and Sefiane2012). In addition, several property ratios unique to the binary mixture also arise from the scaling,

$K$ measures the importance of kinetic effects at the interface and can be thought of as being analogous to the inverse of the Biot number, controlling the heat loss across the interface (Karapetsas et al. Reference Karapetsas, Matar, Valluri and Sefiane2012). In addition, several property ratios unique to the binary mixture also arise from the scaling,

\begin{equation} \left. \begin{array}{l@{}} \displaystyle \sigma_R = \dfrac{\hat{\sigma}_{B,r}} {\hat{\sigma}_{A,r}}, \quad \gamma_R = \dfrac{\hat{\gamma}_{T,B}} {\hat{\gamma}_{T,A}}, \quad \alpha = \dfrac{\hat{p}_{s,B}} {\hat{p}_{s,A}}, \quad k_R = \dfrac{\hat{k}_B} {\hat{k}_A}; \\ \displaystyle \mu_R = \dfrac{\hat{\mu}_B} {\hat{\mu}_A}, \quad c_{p R} = \dfrac{\hat{c}_{p,B}} {\hat{c}_{p,A}}, \quad M_R = \dfrac{\hat{M}_B} {\hat{M}_A}, \quad \varLambda = \dfrac{\hat{L}_{v,B}} {\hat{L}_{v,A}}, \end{array}\right\} \end{equation}

\begin{equation} \left. \begin{array}{l@{}} \displaystyle \sigma_R = \dfrac{\hat{\sigma}_{B,r}} {\hat{\sigma}_{A,r}}, \quad \gamma_R = \dfrac{\hat{\gamma}_{T,B}} {\hat{\gamma}_{T,A}}, \quad \alpha = \dfrac{\hat{p}_{s,B}} {\hat{p}_{s,A}}, \quad k_R = \dfrac{\hat{k}_B} {\hat{k}_A}; \\ \displaystyle \mu_R = \dfrac{\hat{\mu}_B} {\hat{\mu}_A}, \quad c_{p R} = \dfrac{\hat{c}_{p,B}} {\hat{c}_{p,A}}, \quad M_R = \dfrac{\hat{M}_B} {\hat{M}_A}, \quad \varLambda = \dfrac{\hat{L}_{v,B}} {\hat{L}_{v,A}}, \end{array}\right\} \end{equation}

where ![]() $\sigma _R$ is the ratio of surface tensions,

$\sigma _R$ is the ratio of surface tensions, ![]() $\gamma _R$ is the ratio of surface tension temperature coefficients,

$\gamma _R$ is the ratio of surface tension temperature coefficients, ![]() $\alpha$ is the relative volatility (not to be confused with

$\alpha$ is the relative volatility (not to be confused with ![]() $\alpha _v$ in (2.2)),

$\alpha _v$ in (2.2)), ![]() $k_R$ is the ratio of thermal conductivities,

$k_R$ is the ratio of thermal conductivities, ![]() $\mu _R$ is the viscosity ratio,

$\mu _R$ is the viscosity ratio, ![]() $c_{p R}$ is the ratio of specific heats,

$c_{p R}$ is the ratio of specific heats, ![]() $M_R$ is the molar weight ratio and

$M_R$ is the molar weight ratio and ![]() $\varLambda$ is the ratio of latent heats.

$\varLambda$ is the ratio of latent heats.

2.2.2. Dimensionless governing equations

Flow within the droplet is incompressible and governed by the following mass, momentum, energy and concentration equations:

The concentration equation (2.9) is simplified by applying the limit of weak diffusion and assuming ![]() $Pe \approx O(\varepsilon ^{-2})$, as derived by Matar (Reference Matar2002). Therefore, redefining

$Pe \approx O(\varepsilon ^{-2})$, as derived by Matar (Reference Matar2002). Therefore, redefining ![]() $Pe = Pe'\varepsilon ^{-2}$ and substitution into (2.9) yields the amended conservation equation for

$Pe = Pe'\varepsilon ^{-2}$ and substitution into (2.9) yields the amended conservation equation for ![]() $\chi _A$:

$\chi _A$:

Note that contrary to the standard approach of lubrication theory, we do not remove the third term on the left-hand side, despite ![]() $\varepsilon ^2 \ll 1$. Retaining this weak diffusive force along

$\varepsilon ^2 \ll 1$. Retaining this weak diffusive force along ![]() $r$ ensures that the concentration profile remains numerically stable as the solution proceeds. We also explored the limit of rapid vertical diffusion and found no qualitative differences with the simulation presented in this manuscript.

$r$ ensures that the concentration profile remains numerically stable as the solution proceeds. We also explored the limit of rapid vertical diffusion and found no qualitative differences with the simulation presented in this manuscript.

Evaporative effects are modelled using a constitutive equation based on the Hertz–Knudsen expression given by (2.2), written here in dimensionless form as

where ![]() $T \vert _h$ is the temperature of the interface and

$T \vert _h$ is the temperature of the interface and ![]() $\delta = \hat {\mu }_A \hat {U} \hat {R}_0 \hat {T}_g / \hat {\rho }_l {\hat {H}_0}^2 \hat {L}_{v,A} {\rm \Delta} \hat {T}$ accounts for the effects of changes in liquid pressure on the local phase change temperature at the interface (Ajaev Reference Ajaev2005). We partition (2.11) into two separate expressions, yielding the evaporative fluxes of components

$\delta = \hat {\mu }_A \hat {U} \hat {R}_0 \hat {T}_g / \hat {\rho }_l {\hat {H}_0}^2 \hat {L}_{v,A} {\rm \Delta} \hat {T}$ accounts for the effects of changes in liquid pressure on the local phase change temperature at the interface (Ajaev Reference Ajaev2005). We partition (2.11) into two separate expressions, yielding the evaporative fluxes of components ![]() $A$ and

$A$ and ![]() $B$, respectively,

$B$, respectively,

2.2.3. Interfacial boundary conditions

Turning our attention to the remaining interfacial boundary conditions at ![]() $z = h(r,t)$, the evaporative flux boundary condition at the interface takes the form

$z = h(r,t)$, the evaporative flux boundary condition at the interface takes the form

where ![]() $u_s$ and

$u_s$ and ![]() $w_s$ are interface velocities of the liquid and

$w_s$ are interface velocities of the liquid and ![]() $J$ is the total evaporative flux comprising

$J$ is the total evaporative flux comprising ![]() $J_A + J_B$. The associated energy balance is given as

$J_A + J_B$. The associated energy balance is given as

Let us now consider briefly the gas phase, consisting of inert gas and the vapour of both components ![]() $A$ and

$A$ and ![]() $B$. Under Dalton's law, the total gas pressure is written as the sum of the partial pressures of each component,

$B$. Under Dalton's law, the total gas pressure is written as the sum of the partial pressures of each component,

Here, ![]() $\hat {p}_{ig}$,

$\hat {p}_{ig}$, ![]() $\hat {p}_{v,A}$ and

$\hat {p}_{v,A}$ and ![]() $\hat {p}_{v,B}$ indicate the partial pressures of inert gas, component A and component B, respectively. We assume that the surrounding gas phase consists mainly of inert gas rather than vapour, meaning

$\hat {p}_{v,B}$ indicate the partial pressures of inert gas, component A and component B, respectively. We assume that the surrounding gas phase consists mainly of inert gas rather than vapour, meaning ![]() $\hat {p}_{ig} \gg \hat {p}_{v,A}$ and

$\hat {p}_{ig} \gg \hat {p}_{v,A}$ and ![]() $\hat {p}_{ig} \gg \hat {p}_{v,B}$. This leads to the simplification that the total gas-phase pressure is approximately equal to the pressure of the inert gas,

$\hat {p}_{ig} \gg \hat {p}_{v,B}$. This leads to the simplification that the total gas-phase pressure is approximately equal to the pressure of the inert gas,

Additionally, since the droplet is considered to be small, we also ignore the effects of vapour recoil from the gas phase (Larson Reference Larson2014) since this will be relatively weak when compared to the dominating surface tension force. Given these assumptions, the normal stress boundary condition at the interface is defined as

where ![]() $2 \kappa$ is the mean curvature of the interface and

$2 \kappa$ is the mean curvature of the interface and ![]() $\mathcal {A} = \hat {\mathcal {A}} / 6 {\rm \pi}\hat {\mu }_A \hat {U} \hat {R}_0 \hat {H}_0$ is the Hamaker constant, made dimensionless in the disjoining pressure term and accounting for intermolecular interactions near the contact line. The interface height,

$\mathcal {A} = \hat {\mathcal {A}} / 6 {\rm \pi}\hat {\mu }_A \hat {U} \hat {R}_0 \hat {H}_0$ is the Hamaker constant, made dimensionless in the disjoining pressure term and accounting for intermolecular interactions near the contact line. The interface height, ![]() $h$, is handled via the kinematic boundary condition imposed as

$h$, is handled via the kinematic boundary condition imposed as

We now consider the concentration boundary condition along the interface by applying the limit of weak diffusion introduced in (2.10) above. As outlined in Matar (Reference Matar2002), we derive an expression independent of ![]() $z$ by employing an approximate Galerkin expansion for

$z$ by employing an approximate Galerkin expansion for ![]() $\chi _A$, seeking solutions of the form

$\chi _A$, seeking solutions of the form

where ![]() $\chi _{A0}$ corresponds to the mean concentration and

$\chi _{A0}$ corresponds to the mean concentration and ![]() $\chi _{A1}$ is a non-zero mean quadratic fluctuating component. The concentration balance over the interface is given as

$\chi _{A1}$ is a non-zero mean quadratic fluctuating component. The concentration balance over the interface is given as

Differentiation of (2.20) with respect to ![]() $z$ and evaluation at the interface (

$z$ and evaluation at the interface (![]() $z = h$) gives an alternative expression for

$z = h$) gives an alternative expression for ![]() $[{\partial \chi _A}/{\partial z}]_{h}$ in terms of

$[{\partial \chi _A}/{\partial z}]_{h}$ in terms of ![]() $\chi _{A1}$,

$\chi _{A1}$,

Substitution of (2.21) into (2.22) hence constructs an expression for ![]() $\chi _{A}$ in terms of

$\chi _{A}$ in terms of ![]() $\chi _{A1}$,

$\chi _{A1}$,

By evaluating (2.20) at ![]() $z = h$ and substituting in (2.23), we obtain the following expression for

$z = h$ and substituting in (2.23), we obtain the following expression for ![]() $\chi _{A1}$ independent of

$\chi _{A1}$ independent of ![]() $\chi _A$:

$\chi _A$:

\begin{equation} \chi_{A1} = \frac{(J_A - J \chi_{A0})}{2 \left( \dfrac{J}{3} - \dfrac{1}{Pe' E h} \right)}.\end{equation}

\begin{equation} \chi_{A1} = \frac{(J_A - J \chi_{A0})}{2 \left( \dfrac{J}{3} - \dfrac{1}{Pe' E h} \right)}.\end{equation}We arrive at the final form of the concentration balance over the interface in the limit of weak diffusion by substituting (2.24) into (2.22),

\begin{equation} \left[\frac{\partial \chi_{A}}{\partial z} \right]_{h} = \frac{(J_A - J \chi_{A0})}{h \left( \dfrac{J}{3} - \dfrac{1}{Pe' E h} \right)}. \end{equation}

\begin{equation} \left[\frac{\partial \chi_{A}}{\partial z} \right]_{h} = \frac{(J_A - J \chi_{A0})}{h \left( \dfrac{J}{3} - \dfrac{1}{Pe' E h} \right)}. \end{equation}2.3. Solution method and initial conditions

2.3.1. Kármán–Pohlhausen approximation

We now apply the Kármán–Pohlhausen integral approximation whereby we integrate (2.6), (2.7), (2.8) and (2.10) over ![]() $z$ from

$z$ from ![]() $0$ to

$0$ to ![]() $h$. Doing this removes any multiple variable differentials while retaining the inertia and advection terms in the momentum and energy balance equations. First, let us define the integrated forms of

$h$. Doing this removes any multiple variable differentials while retaining the inertia and advection terms in the momentum and energy balance equations. First, let us define the integrated forms of ![]() $f$ and

$f$ and ![]() $\varTheta$ as

$\varTheta$ as

In order to be able to evaluate (2.26a,b), we now need to prescribe the forms of ![]() $u$, and

$u$, and ![]() $T$ as a function of the vertical coordinate. To this end, we assume that each variable can be approximated by a polynomial of the form

$T$ as a function of the vertical coordinate. To this end, we assume that each variable can be approximated by a polynomial of the form ![]() $c_1 + c_2 z + c_3 z^2$. By substituting the corresponding polynomials in (2.26a,b) and applying the appropriate boundary conditions, it is possible to evaluate the polynomial constants and eventually derive the following expressions for

$c_1 + c_2 z + c_3 z^2$. By substituting the corresponding polynomials in (2.26a,b) and applying the appropriate boundary conditions, it is possible to evaluate the polynomial constants and eventually derive the following expressions for ![]() $u$ and

$u$ and ![]() $T$,

$T$,

Integration of the governing equations along with application of the boundary conditions defined in § 2.2.3 yields the following integrated forms of the mass, ![]() $r$-momentum, energy and concentration equation in the limit of weak diffusion:

$r$-momentum, energy and concentration equation in the limit of weak diffusion:

\begin{gather}\varepsilon Re \left(\frac{\partial f}{\partial t} + \frac{1}{r} \frac{\partial}{\partial r} \left(r \int_{0}^{h} u^2 \,\textrm{d} z \right) + u\vert_h EJ \right) = - h \frac{\partial p}{\partial r} + \left[\mu \frac{\partial u}{\partial z} \right]_{0}^{h}, \end{gather}

\begin{gather}\varepsilon Re \left(\frac{\partial f}{\partial t} + \frac{1}{r} \frac{\partial}{\partial r} \left(r \int_{0}^{h} u^2 \,\textrm{d} z \right) + u\vert_h EJ \right) = - h \frac{\partial p}{\partial r} + \left[\mu \frac{\partial u}{\partial z} \right]_{0}^{h}, \end{gather} \begin{gather}\varepsilon Re Pr c_p \left( \frac{\partial \varTheta}{\partial t} + \frac{1}{r} \frac{\partial}{\partial r} \left( r \int_{0}^{h} u T \,\textrm{d} z \right) + T\vert_h EJ \right) = \left[ k \frac{\partial T}{\partial z} \right]_{0}^{h}, \end{gather}

\begin{gather}\varepsilon Re Pr c_p \left( \frac{\partial \varTheta}{\partial t} + \frac{1}{r} \frac{\partial}{\partial r} \left( r \int_{0}^{h} u T \,\textrm{d} z \right) + T\vert_h EJ \right) = \left[ k \frac{\partial T}{\partial z} \right]_{0}^{h}, \end{gather} \begin{gather}\frac{\partial \chi_{A0}}{\partial t} + \frac{f}{h} \frac{\partial \chi_{A0}}{\partial r} = \frac{(J_A - J \chi_{A0})}{ Pe' h^2 \left( \dfrac{J}{3} - \dfrac{1}{Pe' E h} \right)}. \end{gather}

\begin{gather}\frac{\partial \chi_{A0}}{\partial t} + \frac{f}{h} \frac{\partial \chi_{A0}}{\partial r} = \frac{(J_A - J \chi_{A0})}{ Pe' h^2 \left( \dfrac{J}{3} - \dfrac{1}{Pe' E h} \right)}. \end{gather}

Note that in the above expressions, all terms containing ![]() $u$ and

$u$ and ![]() $T$ are evaluated using (2.27) and (2.28) and, therefore, we end up with expressions containing the unknown variables

$T$ are evaluated using (2.27) and (2.28) and, therefore, we end up with expressions containing the unknown variables ![]() $f$ and

$f$ and ![]() $\varTheta$ instead of

$\varTheta$ instead of ![]() $u$ and

$u$ and ![]() $T$.

$T$.

2.3.2. Precursor film and resulting boundary conditions

As previously mentioned, we assume that the droplet is surrounded by a thin precursor film covering the heated substrate upon which it resides. In this region, the fluid is flat with zero mean curvature and sufficiently thin such that evaporation is suppressed by attractive van der Waals forces. We assume the mixture in the precursor region is at equilibrium concentration, ![]() $\chi _{A,\infty } = 0$, meaning that it consists solely of the LVC. Simplifying (2.18) subject to these conditions when

$\chi _{A,\infty } = 0$, meaning that it consists solely of the LVC. Simplifying (2.18) subject to these conditions when ![]() $h = h_\infty$ yields the expression for the precursor layer height:

$h = h_\infty$ yields the expression for the precursor layer height:

\begin{equation} h_\infty = \left( \frac{\mathcal{A} \delta} {\varLambda T \vert _h}\right)^{1/3}. \end{equation}

\begin{equation} h_\infty = \left( \frac{\mathcal{A} \delta} {\varLambda T \vert _h}\right)^{1/3}. \end{equation}

We now turn our attention to the boundary conditions at the bottom wall where the liquid meets the solid substrate (![]() $z = 0$). Here, we impose conditions of no-penetration, no-slip and constant temperature, such that

$z = 0$). Here, we impose conditions of no-penetration, no-slip and constant temperature, such that

Finally, we apply the following boundary conditions to the radial extremes of the domain (![]() $r = 0$ and

$r = 0$ and ![]() $r = r_\infty$):

$r = r_\infty$):

\begin{equation} \left. \begin{array}{l} \displaystyle \dfrac{\partial h}{\partial r}(0,t) = 0, \quad f(0,t) = 0, \quad \dfrac{\partial \varTheta}{\partial r}(0,t) = 0, \quad \dfrac{\partial \chi_A}{\partial r}(0,t) = 0; \\ \displaystyle h(r_\infty,t) = h_\infty, \quad \dfrac{\partial h}{\partial r}(r_\infty,t) = 0, \quad f(r_\infty,t) = 0, \quad \varTheta(r_\infty,0) = h_\infty,\\ \chi_A(r_\infty,t) = 0. \end{array} \right\} \end{equation}

\begin{equation} \left. \begin{array}{l} \displaystyle \dfrac{\partial h}{\partial r}(0,t) = 0, \quad f(0,t) = 0, \quad \dfrac{\partial \varTheta}{\partial r}(0,t) = 0, \quad \dfrac{\partial \chi_A}{\partial r}(0,t) = 0; \\ \displaystyle h(r_\infty,t) = h_\infty, \quad \dfrac{\partial h}{\partial r}(r_\infty,t) = 0, \quad f(r_\infty,t) = 0, \quad \varTheta(r_\infty,0) = h_\infty,\\ \chi_A(r_\infty,t) = 0. \end{array} \right\} \end{equation}2.3.3. Penalty function

Due to our modelling approach, the droplet is deposited onto a thin precursor film. This film is sufficiently thin so that van der Waals interactions in the liquid phase become the dominating force and, hence, suppress further evaporation in this precursor region. It is then logical to assume that the precursor layer consists solely of the LVC since any MVC will have evaporated before the film forms. When testing the model, we noticed that artificial behaviour can occur in the precursor film resulting from the added complexity of a second component. Diffusion of the MVC from the bulk droplet into the precursor film is possible, as is condensation of MVC from the gas phase into the film region. To circumvent this problem, we incorporate a forcing-type penalty function (![]() $\mathcal {P}$) with which we can control the composition of the precursor film. This ensures that the inert precursor region does not interfere with the evaporation of the droplet or induce any artificial behaviour.

$\mathcal {P}$) with which we can control the composition of the precursor film. This ensures that the inert precursor region does not interfere with the evaporation of the droplet or induce any artificial behaviour.

The penalty function itself is applied to the advection–diffusion (concentration) equation and forces the precursor film to solely consist of the LVC, preventing any evaporation or condensation from occurring. It takes the form

where ![]() $\mathcal {M}= 10^3$ is its magnitude and

$\mathcal {M}= 10^3$ is its magnitude and ![]() $\mathcal {B} = 5$. When

$\mathcal {B} = 5$. When ![]() $h > h_\infty$, as is the case in the bulk droplet,

$h > h_\infty$, as is the case in the bulk droplet, ![]() $\mathcal {P}$ is zero regardless of the value of concentration and so has no effect on the solution. The penalty function begins to influence the solution when droplet height approaches that of the precursor. If

$\mathcal {P}$ is zero regardless of the value of concentration and so has no effect on the solution. The penalty function begins to influence the solution when droplet height approaches that of the precursor. If ![]() $h = h_\infty$,

$h = h_\infty$, ![]() $\mathcal {P}$ tends towards

$\mathcal {P}$ tends towards ![]() $\mathcal {M}$. When applied to the conservation equation for concentration,

$\mathcal {M}$. When applied to the conservation equation for concentration, ![]() $\chi _A$ is forced to zero, minimising

$\chi _A$ is forced to zero, minimising ![]() $\mathcal {M}$ and ensuring

$\mathcal {M}$ and ensuring ![]() $\mathcal {P}$ is equal to zero once more. The physical effects of this restriction are twofold. First, it is ensured that there is no artificial condensation of the MVC into the precursor layer. Second, any diffusion of MVC from the bulk droplet to the precursor layer is arrested.

$\mathcal {P}$ is equal to zero once more. The physical effects of this restriction are twofold. First, it is ensured that there is no artificial condensation of the MVC into the precursor layer. Second, any diffusion of MVC from the bulk droplet to the precursor layer is arrested.

2.3.4. Initial conditions

Within the droplet profile (![]() $0 \leq r \leq 1$), the initial conditions are imposed such that

$0 \leq r \leq 1$), the initial conditions are imposed such that

Here, ![]() $\chi _{A0,i}=\chi _A(r,0)$ is the initial uniform concentration within the droplet. Outside of the droplet in the precursor layer region (

$\chi _{A0,i}=\chi _A(r,0)$ is the initial uniform concentration within the droplet. Outside of the droplet in the precursor layer region (![]() $r > 1$), we apply the following:

$r > 1$), we apply the following:

2.3.5. Overview of solution procedure

From our definitions above, we have seven unknown variables; ![]() $h$,

$h$, ![]() $p$,

$p$, ![]() $f$,

$f$, ![]() $\varTheta$,

$\varTheta$, ![]() $J_A$,

$J_A$, ![]() $J_B$ and

$J_B$ and ![]() $\chi _{A0}$ along with seven independent equations. As a broad overview of the solution procedure, we begin with simplifying these equations by applying the Galerkin method of weighted residuals to obtain weak forms for each equation. Derivation and final forms of the weak equations are given in Williams (Reference Williams2018). The domain is discretised from

$\chi _{A0}$ along with seven independent equations. As a broad overview of the solution procedure, we begin with simplifying these equations by applying the Galerkin method of weighted residuals to obtain weak forms for each equation. Derivation and final forms of the weak equations are given in Williams (Reference Williams2018). The domain is discretised from ![]() $0$ to

$0$ to ![]() $r_\infty$ into a uniform mesh of

$r_\infty$ into a uniform mesh of ![]() $N_{r,tot}$ nodes (see figure 2) using the finite element method. Solutions are then obtained using a Newton–Raphson scheme with the simulation evolved forward in time using implicit Euler and an adaptive time step,

$N_{r,tot}$ nodes (see figure 2) using the finite element method. Solutions are then obtained using a Newton–Raphson scheme with the simulation evolved forward in time using implicit Euler and an adaptive time step, ![]() $dt$. The time step is increased or decreased based on the largest residual error of the governing equations from the previous time step. Initial solutions are provided (via the initial conditions in § 2.3.4) and progressively more accurate values iterated to over each time step. The iterative program is written in Fortran, making use of the linear algebra package LAPACK.

$dt$. The time step is increased or decreased based on the largest residual error of the governing equations from the previous time step. Initial solutions are provided (via the initial conditions in § 2.3.4) and progressively more accurate values iterated to over each time step. The iterative program is written in Fortran, making use of the linear algebra package LAPACK.

Figure 2. Illustration of the height, ![]() $h$, variable under initial conditions in a domain where

$h$, variable under initial conditions in a domain where ![]() $r_\infty = 3$. The one-dimensional domain consists of equally spaced

$r_\infty = 3$. The one-dimensional domain consists of equally spaced ![]() $N_r$ nodes, here, the vertical dotted lines represent every tenth node where the total number of nodes

$N_r$ nodes, here, the vertical dotted lines represent every tenth node where the total number of nodes ![]() $N_{r,tot} = 300$. The value of height is stored at every node point and is reconstructed to form the drop profile over the domain. The drop is initialised as a quarter circle in dimensionless space for

$N_{r,tot} = 300$. The value of height is stored at every node point and is reconstructed to form the drop profile over the domain. The drop is initialised as a quarter circle in dimensionless space for ![]() $0 \le r \le 1$, with the precursor layer height,

$0 \le r \le 1$, with the precursor layer height, ![]() $h_\infty$, imposed for

$h_\infty$, imposed for ![]() $r > 1$. Similar profiles along

$r > 1$. Similar profiles along ![]() $r$ are used as initial conditions for the other variables – see § 2.3.4.

$r$ are used as initial conditions for the other variables – see § 2.3.4.

3. Experimental methodology

3.1. Apparatus and experimental procedure

A diagram of the experimental apparatus is shown in figure 3 which centres around a flexible silicone heating pad (Omega SRFR-4/5-P-230V) providing a heat flux of 0.775 W cm![]() $^{-2}$. This sits atop an aluminium mechanical scissor lift platform and is held in place with heavy duty white duct (Gorilla) tape. The temperature of the heater is controlled with a PID controller in a feedback loop; the controller maintains the desired set point measured by a thermocouple attached to the heating pad. The CMOS camera is held in place above the scissor lift platform using a laboratory stand and clamp with liberal amounts of duct tape securing it to the desk. The CMOS camera used is a Point Grey Research Flea3 (FL3-U3-13E4M) with a 18–108 mm/2.5–16 Navigator Zoom 7000 zoom lens. The camera is connected to a PC via USB3 and is controlled through FlyCapture2 software. Optical recording is conducted at 60 fps. The droplet is illuminated from the side using a touch mounted on a large three prong clamp as the light source. To ensure a clear image is captured by the camera, Diall PVC repairing tape, possessing a smooth white surface, is layered on top of the duct tape.

$^{-2}$. This sits atop an aluminium mechanical scissor lift platform and is held in place with heavy duty white duct (Gorilla) tape. The temperature of the heater is controlled with a PID controller in a feedback loop; the controller maintains the desired set point measured by a thermocouple attached to the heating pad. The CMOS camera is held in place above the scissor lift platform using a laboratory stand and clamp with liberal amounts of duct tape securing it to the desk. The CMOS camera used is a Point Grey Research Flea3 (FL3-U3-13E4M) with a 18–108 mm/2.5–16 Navigator Zoom 7000 zoom lens. The camera is connected to a PC via USB3 and is controlled through FlyCapture2 software. Optical recording is conducted at 60 fps. The droplet is illuminated from the side using a touch mounted on a large three prong clamp as the light source. To ensure a clear image is captured by the camera, Diall PVC repairing tape, possessing a smooth white surface, is layered on top of the duct tape.

Figure 3. Schematic diagram of the experimental apparatus.

Borosilicate glass microscope slides (![]() $75\ \textrm {mm} \times 25\ \textrm {mm}$, 1 mm thick) manufactured by RC Components are used as the substrate. These are simply placed on top of the tape holding down the heating pad with the friction between the two materials sufficient to prevent movement. The glass slides consistently demonstrated a low equilibrium contact angle for all fluids tested. High wettability was verified by treating the slides with ‘piranha’ solution – a volatile mixture of sulfuric acid and hydrogen peroxide. Piranha solution is a strong oxidiser and so removes organic matter whilst additionally hydroxylating the surface. The droplets are deposited on the substrate manually using a microliter syringe (Hamilton 701N

$75\ \textrm {mm} \times 25\ \textrm {mm}$, 1 mm thick) manufactured by RC Components are used as the substrate. These are simply placed on top of the tape holding down the heating pad with the friction between the two materials sufficient to prevent movement. The glass slides consistently demonstrated a low equilibrium contact angle for all fluids tested. High wettability was verified by treating the slides with ‘piranha’ solution – a volatile mixture of sulfuric acid and hydrogen peroxide. Piranha solution is a strong oxidiser and so removes organic matter whilst additionally hydroxylating the surface. The droplets are deposited on the substrate manually using a microliter syringe (Hamilton 701N ![]() $10\ \mathrm {\mu }$l) with reading increments of

$10\ \mathrm {\mu }$l) with reading increments of ![]() $0.2\ \mathrm {\mu }$l.

$0.2\ \mathrm {\mu }$l.

We consider ethanol–water mixture droplets of initial volume ![]() $(1.0\pm 0.2)\ \mathrm {\mu }$l. Mixtures ranging from 11 wt.% to 50 wt.% initial ethanol concentration are considered at three substrate temperatures (

$(1.0\pm 0.2)\ \mathrm {\mu }$l. Mixtures ranging from 11 wt.% to 50 wt.% initial ethanol concentration are considered at three substrate temperatures (![]() $T_w$); 30

$T_w$); 30 ![]() $^{\circ }$C, 50

$^{\circ }$C, 50 ![]() $^{\circ }$C and 70

$^{\circ }$C and 70 ![]() $^{\circ }$C. Solutions are prepared in 25 ml volumes and stored in 2 mm diameter jars. Separate syringes of volume (

$^{\circ }$C. Solutions are prepared in 25 ml volumes and stored in 2 mm diameter jars. Separate syringes of volume (![]() $2.50\pm 0.05$) ml were used to collect samples of each pure component for mixing. The mixing volumes of each fluid as well as the initial ethanol concentrations investigated are given in table 2. Once the solutions are prepared, evaporation of the mixtures was kept to a minimum by covering the mouth of the jar with a plastic paraffin film (Parafilm); this allowed the seal to be retained with the lid removed. A sample was taken by piercing the film with the microsyringe, leaving only a small hole and suppressing unwanted evaporation as much as possible. The lid was returned after obtaining each sample. For each mixture concentration deposited on each substrate temperature, a minimum of five experimental runs were conducted to ensure the results are replicable.

$2.50\pm 0.05$) ml were used to collect samples of each pure component for mixing. The mixing volumes of each fluid as well as the initial ethanol concentrations investigated are given in table 2. Once the solutions are prepared, evaporation of the mixtures was kept to a minimum by covering the mouth of the jar with a plastic paraffin film (Parafilm); this allowed the seal to be retained with the lid removed. A sample was taken by piercing the film with the microsyringe, leaving only a small hole and suppressing unwanted evaporation as much as possible. The lid was returned after obtaining each sample. For each mixture concentration deposited on each substrate temperature, a minimum of five experimental runs were conducted to ensure the results are replicable.

Table 2. Mixing volumes of ethanol and water used to prepare the mixtures and the corresponding initial volume and weight percentages of ethanol.

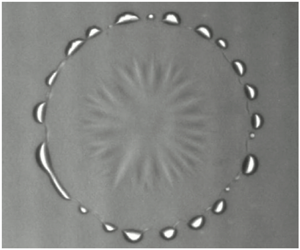

The results are processed by tracking the droplets radius over time, both the initial spreading followed by contact line recession as evaporation takes over. The radius is tracked frame-by-frame using an in-house algorithm written in python, making use of NumPy and OpenCV libraries. The basic overview is to convert each frame to a high contrast image using in-built OpenCV image processing tools and then detect the circular shape of the droplet using the OpenCV Hough Circles Transform. Image processing begins by removing noise from the greyscale images captured by the camera by passing through the GuassianBlur and medianBlur filters. After this, the sharp edges of the image corresponding to the contact line are detected using the adaptive threshold filter and converted to a binary black and white image using the binary threshold filter – see figure 4(b). The Hough Circles Transform is applied to this image, which then determines the best fit circle to the circular-shaped droplet outline and calculates the corresponding centre point and radius – shown in figure 4(c). To set the scale, a circular black sticker of diameter 0.8 mm is affixed to a sample glass slide. With the scale set, the expanding and contracting radius of the droplet as it spreads and recedes is measured directly. A clear limitation of this method is that the droplet must be close to circular to obtain meaningful results. In our case, this is already a requirement since we are comparing to a one-dimensional axisymmetric model where the droplet is perfectly circular. Contact line radius against time for each droplet can then be plotted. The spreading and retraction rates are obtained by analysing the radius-time graphs in the common logarithmic domain using R statistical software (R Core Team 2013) made available under the GNU General Public License (GPL). This method allows linear fits along with breakpoints to be determined in a statistically significant and consistent manner.

Figure 4. Top-down view snapshots of a 1 ml ethanol–water droplet comprising 25 wt.% initial ethanol deposited on a 70![]() $\,^{\circ }$C substrate at

$\,^{\circ }$C substrate at ![]() $t =0.6$ s. Panel (a) shows the original greyscale image captured by the camera, (b) shows the binary image after passing through imaging filters, and (c) shows the best-fit circle (green) to the contact line (black) along with the corresponding centre point (orange) overlaid on (a).

$t =0.6$ s. Panel (a) shows the original greyscale image captured by the camera, (b) shows the binary image after passing through imaging filters, and (c) shows the best-fit circle (green) to the contact line (black) along with the corresponding centre point (orange) overlaid on (a).

3.2. Errors and uncertainty

We briefly discuss the sources of error in the experiment, some more difficult to quantify than others. Table 2 gives the error in measuring the volumes of ethanol and water when preparing the binary mixtures for storage. These are typically low and based on the reading error of the syringes used to prepare the mixtures. The final volume of droplet deposited on the substrate is subject to larger error. Each ![]() $1\ \mathrm {\mu }$l droplet is deposited using a microsyringe with reading increments of

$1\ \mathrm {\mu }$l droplet is deposited using a microsyringe with reading increments of ![]() $0.2\ \mathrm {\mu }$l. Assuming a reading error of

$0.2\ \mathrm {\mu }$l. Assuming a reading error of ![]() ${\pm }0.1\ \mathrm {\mu }$l yields a 10 % relative error in the deposited volume. In addition to this, we noticed that there was often a small amount of liquid residue left on the tip of the syringe after deposition. As such, the relative error in the deposited volume is likely to be larger than 10 %, with a 20 % relative error in the volume deposited being a worst case prediction. The uncertainly from the PID feedback loop can be assumed as

${\pm }0.1\ \mathrm {\mu }$l yields a 10 % relative error in the deposited volume. In addition to this, we noticed that there was often a small amount of liquid residue left on the tip of the syringe after deposition. As such, the relative error in the deposited volume is likely to be larger than 10 %, with a 20 % relative error in the volume deposited being a worst case prediction. The uncertainly from the PID feedback loop can be assumed as ![]() ${\pm }1$ K. However, with the heater and thermocouple buried beneath an insulating plastic tape along with inherently low thermal conductivity of the glass substrate, it is likely that the surface the droplet is deposited onto will be slightly cooler than the displayed value by the controller.

${\pm }1$ K. However, with the heater and thermocouple buried beneath an insulating plastic tape along with inherently low thermal conductivity of the glass substrate, it is likely that the surface the droplet is deposited onto will be slightly cooler than the displayed value by the controller.

Considering imaging errors, a clear droplet image is captured by the angled light source casting a shadow around the contact line. This causes the contact line to appear thicker than in reality. In addition, the formation of a ridge at the contact line in droplets with higher initial ethanol concentration causes this region to appear thicker still. Contact line instabilities also arise in ethanol rich droplets, making accurate resolution even more difficult. Measuring the pixel width of the droplet at its thickest point in the final images provides a reasonable estimate of this error. Our radius detection method relies on the idealistic assumption that droplets are always perfectly circular throughout spreading and recession. In the absence of perfectly consistent curvature around the whole circumference, the algorithm will fit a circle that best fits the largest portion of the droplet circumference. This results in fluctuation of the radius measurement as the algorithm searches for the optimum curvature. The best estimation of this uncertainty comes from the standard error of the linear fit determined by ![]() $R$.

$R$.

To minimise this error for each run, we took several measures to maximise even spreading of the droplets. These include ensuring a completely level surface, the selection of small droplet volumes, and the gentle deposition of the droplets from the microsyringe. Another limitation worth mentioning is that, particularly for higher concentrations of ethanol, droplets do not dry out in a circular shape meaning the exact point of dry-out cannot be measured by our algorithm. Rather, we rely on the visual disappearance of the droplet from the original video footage for this.

4. Experimental findings

4.1. Typical evaporation process

As previously mentioned, we consider only droplets of pure water and water–ethanol mixtures consisting of 11 wt.%, 25 wt.% and 50 wt.% initial ethanol at substrate temperatures of 30 ![]() $^{\circ }$C, 50

$^{\circ }$C, 50 ![]() $^{\circ }$C and 70

$^{\circ }$C and 70 ![]() $^{\circ }$C. In order to maximise the evaporation rate for comparison with our simulations, we restrict our investigations into the effect of concentration variation for a substrate at temperature

$^{\circ }$C. In order to maximise the evaporation rate for comparison with our simulations, we restrict our investigations into the effect of concentration variation for a substrate at temperature ![]() $T_w = 70\,^{\circ }$C only, while effects of temperature variation are restricted to the most volatile binary mixture – 50 wt.% initial ethanol. Higher ethanol concentrations, extending to pure ethanol are not included due to difficulties in capturing a sharp contact line using our imaging method.

$T_w = 70\,^{\circ }$C only, while effects of temperature variation are restricted to the most volatile binary mixture – 50 wt.% initial ethanol. Higher ethanol concentrations, extending to pure ethanol are not included due to difficulties in capturing a sharp contact line using our imaging method.