1. Introduction

When a flexible or flexibly-mounted bluff body is placed in flow, formation of vortices downstream of the bluff body generates unsteady forces on the body, which in turn cause the structure to oscillate. When the structure oscillates, the shedding frequency and oscillation frequency are synchronized. This synchronization between the shedding frequency and oscillation frequency is called lock-in, and the resulting oscillations are called vortex-induced vibration (VIV). VIV has been studied extensively for the cases where a structure is placed in a Newtonian fluid. When a one-degree-of-freedom (1DOF) cylinder is placed in Newtonian flow and it is free to oscillate in a direction perpendicular to the direction of incoming flow (crossflow (CF) VIV), lock-in is observed for a range of reduced velocities, ![]() $U^*$ (defined as

$U^*$ (defined as ![]() $U^*=U/f_n D$, in which

$U^*=U/f_n D$, in which ![]() $U$ is the velocity of the incoming flow,

$U$ is the velocity of the incoming flow, ![]() $D$ is the cylinder's diameter, and

$D$ is the cylinder's diameter, and ![]() $f_n$ is the natural frequency of the system in vacuum), with amplitudes of oscillations of up to around one cylinder diameter (Sarpkaya Reference Sarpkaya2004; Williamson & Govardhan Reference Williamson and Govardhan2004). In the lock-in region, a 2S shedding pattern (in which two single vortices are shed in the wake of the cylinder in each cycle of oscillations) or a 2P shedding pattern (in which two pairs of vortices are shed in the wake in each cycle of oscillations) is observed. If the 1DOF cylinder is free to oscillate in the direction of flow (inline (IL) VIV) then oscillations are observed over two ranges of

$f_n$ is the natural frequency of the system in vacuum), with amplitudes of oscillations of up to around one cylinder diameter (Sarpkaya Reference Sarpkaya2004; Williamson & Govardhan Reference Williamson and Govardhan2004). In the lock-in region, a 2S shedding pattern (in which two single vortices are shed in the wake of the cylinder in each cycle of oscillations) or a 2P shedding pattern (in which two pairs of vortices are shed in the wake in each cycle of oscillations) is observed. If the 1DOF cylinder is free to oscillate in the direction of flow (inline (IL) VIV) then oscillations are observed over two ranges of ![]() $U^*$ values, with amplitudes of around

$U^*$ values, with amplitudes of around ![]() $0.1D$. The oscillations in the first range of reduced velocities are with a symmetric shedding of vortices in the wake, and in the second range with an asymmetric wake (Cagney & Balabani Reference Cagney and Balabani2013a,Reference Cagney and Balabanib; Gurian, Currier & Modarres-Sadeghi Reference Gurian, Currier and Modarres-Sadeghi2019). When the cylinder is free to oscillate in both the CF and IL directions (2DOF VIV), lock-in occurs in both directions, and figure-eight trajectories are observed in the response of the cylinder together with several different types of vortex shedding patterns, including 2T shedding (in which two triplets of vortices are shed during each cycle of oscillations) (Dahl, Hover & Triantafyllou Reference Dahl, Hover and Triantafyllou2007; Dahl et al. Reference Dahl, Hover, Triantafyllou and Oakley2010). VIV has also been studied for non-circular cross-sections, such as a square prism or a triangular prism, in which cases, besides VIV, galloping response has been observed, due to the non-zero mean lift forces that act on the structure (e.g. Nemes et al. Reference Nemes, Zhao, Lo Jacono and Sheridan2012; Zhao et al. Reference Zhao, Leontini, Lo Jacono and Sheridan2014; Seyed-Aghazadeh, Carlson & Modarres-Sadeghi Reference Seyed-Aghazadeh, Carlson and Modarres-Sadeghi2017; Carlson, Currier & Modarres-Sadeghi Reference Carlson, Currier and Modarres-Sadeghi2021). Studies on VIV have been extended to cases of flexible continuous structures placed in flow, due to the fact that in real-life applications, VIV is observed in long offshore structures such as risers in oil platforms or mooring lines of floating wind turbines. When a flexible structure undergoes VIV, synchronization can be observed between shedding of vortices and several different modes of the structure at different locations along its length, resulting in mono- or multi-modal oscillations of the structure (e.g. Vandiver Reference Vandiver1993; Bourguet et al. Reference Bourguet, Modarres-Sadeghi, Karniadakis and Triantafyllou2011; Wu, Ge & Hong Reference Wu, Ge and Hong2012; Seyed-Aghazadeh, Edraki & Modarres-Sadeghi Reference Seyed-Aghazadeh, Edraki and Modarres-Sadeghi2019).

$0.1D$. The oscillations in the first range of reduced velocities are with a symmetric shedding of vortices in the wake, and in the second range with an asymmetric wake (Cagney & Balabani Reference Cagney and Balabani2013a,Reference Cagney and Balabanib; Gurian, Currier & Modarres-Sadeghi Reference Gurian, Currier and Modarres-Sadeghi2019). When the cylinder is free to oscillate in both the CF and IL directions (2DOF VIV), lock-in occurs in both directions, and figure-eight trajectories are observed in the response of the cylinder together with several different types of vortex shedding patterns, including 2T shedding (in which two triplets of vortices are shed during each cycle of oscillations) (Dahl, Hover & Triantafyllou Reference Dahl, Hover and Triantafyllou2007; Dahl et al. Reference Dahl, Hover, Triantafyllou and Oakley2010). VIV has also been studied for non-circular cross-sections, such as a square prism or a triangular prism, in which cases, besides VIV, galloping response has been observed, due to the non-zero mean lift forces that act on the structure (e.g. Nemes et al. Reference Nemes, Zhao, Lo Jacono and Sheridan2012; Zhao et al. Reference Zhao, Leontini, Lo Jacono and Sheridan2014; Seyed-Aghazadeh, Carlson & Modarres-Sadeghi Reference Seyed-Aghazadeh, Carlson and Modarres-Sadeghi2017; Carlson, Currier & Modarres-Sadeghi Reference Carlson, Currier and Modarres-Sadeghi2021). Studies on VIV have been extended to cases of flexible continuous structures placed in flow, due to the fact that in real-life applications, VIV is observed in long offshore structures such as risers in oil platforms or mooring lines of floating wind turbines. When a flexible structure undergoes VIV, synchronization can be observed between shedding of vortices and several different modes of the structure at different locations along its length, resulting in mono- or multi-modal oscillations of the structure (e.g. Vandiver Reference Vandiver1993; Bourguet et al. Reference Bourguet, Modarres-Sadeghi, Karniadakis and Triantafyllou2011; Wu, Ge & Hong Reference Wu, Ge and Hong2012; Seyed-Aghazadeh, Edraki & Modarres-Sadeghi Reference Seyed-Aghazadeh, Edraki and Modarres-Sadeghi2019).

When a fixed cylinder is placed in a shear-thinning or shear-thickening fluid (i.e. a non-Newtonian fluid for which the viscosity, ![]() $\eta$, varies with shear rate,

$\eta$, varies with shear rate, ![]() $\dot {\gamma }$), there are several differences between the flow behaviour in its wake and that of a cylinder placed in a Newtonian fluid, which result in differences in forces that act on the cylinder in these two cases. The critical Reynolds number (where,

$\dot {\gamma }$), there are several differences between the flow behaviour in its wake and that of a cylinder placed in a Newtonian fluid, which result in differences in forces that act on the cylinder in these two cases. The critical Reynolds number (where, ![]() $Re=\rho U D/\eta$, in which

$Re=\rho U D/\eta$, in which ![]() $\rho$ is the density of the fluid, U is the incoming flow velocity, D is the cylinder diameter, and

$\rho$ is the density of the fluid, U is the incoming flow velocity, D is the cylinder diameter, and ![]() $\eta$ is the dynamic viscosity of the fluid) to observe vortex shedding, which is known to be

$\eta$ is the dynamic viscosity of the fluid) to observe vortex shedding, which is known to be ![]() $Re_{crit} = 47$ for Newtonian fluids (Mathis, Provansal & Boyer Reference Mathis, Provansal and Boyer1984), decreases with shear-thinning effects and increases with shear-thickening effects (Lashgari et al. Reference Lashgari, Pralits, Giannetti and Brandt2012; Şahin and Atalık Reference Şahin and Atalık2019). Critical Reynolds numbers as low as

$Re_{crit} = 47$ for Newtonian fluids (Mathis, Provansal & Boyer Reference Mathis, Provansal and Boyer1984), decreases with shear-thinning effects and increases with shear-thickening effects (Lashgari et al. Reference Lashgari, Pralits, Giannetti and Brandt2012; Şahin and Atalık Reference Şahin and Atalık2019). Critical Reynolds numbers as low as ![]() $Re_{crit} =3$ for shear-thinning fluids and as high as

$Re_{crit} =3$ for shear-thinning fluids and as high as ![]() $Re_{crit} =193$ for shear-thickening fluids have been reported (Lashgari et al. Reference Lashgari, Pralits, Giannetti and Brandt2012), where

$Re_{crit} =193$ for shear-thickening fluids have been reported (Lashgari et al. Reference Lashgari, Pralits, Giannetti and Brandt2012), where ![]() $Re$ is defined based on the zero-shear-rate viscosity,

$Re$ is defined based on the zero-shear-rate viscosity, ![]() $\eta _0$. In the range of Reynolds numbers where the shedding is observed, the vortex shedding frequency increases with shear-thinning effects and decreases with shear-thickening effects (Bailoor, Seo & Mittal Reference Bailoor, Seo and Mittal2019; Şahin and Atalık Reference Şahin and Atalık2019). Shear-thinning effects reduce the formation length in the wake of a fixed cylinder, and shear-thickening effects increase the formation length (Coelho & Pinho Reference Coelho and Pinho2003a,Reference Coelho and Pinhob, Reference Coelho and Pinho2004; Lashgari et al. Reference Lashgari, Pralits, Giannetti and Brandt2012; Bailoor et al. Reference Bailoor, Seo and Mittal2019; Şahin and Atalık Reference Şahin and Atalık2019). Shear-thinning effects reduce the drag coefficient (at least for low Reynolds numbers

$\eta _0$. In the range of Reynolds numbers where the shedding is observed, the vortex shedding frequency increases with shear-thinning effects and decreases with shear-thickening effects (Bailoor, Seo & Mittal Reference Bailoor, Seo and Mittal2019; Şahin and Atalık Reference Şahin and Atalık2019). Shear-thinning effects reduce the formation length in the wake of a fixed cylinder, and shear-thickening effects increase the formation length (Coelho & Pinho Reference Coelho and Pinho2003a,Reference Coelho and Pinhob, Reference Coelho and Pinho2004; Lashgari et al. Reference Lashgari, Pralits, Giannetti and Brandt2012; Bailoor et al. Reference Bailoor, Seo and Mittal2019; Şahin and Atalık Reference Şahin and Atalık2019). Shear-thinning effects reduce the drag coefficient (at least for low Reynolds numbers ![]() $Re \leq 300$) (Lashgari et al. Reference Lashgari, Pralits, Giannetti and Brandt2012; Bailoor et al. Reference Bailoor, Seo and Mittal2019; Alam et al. Reference Alam, Raj, Khan, Kumar and Roy2021) and intensify the magnitude of the vorticity in the region close to the cylinder, due to the reduced shear stress associated with the shear-thinning effects that occur very close to the cylinder (Lashgari et al. Reference Lashgari, Pralits, Giannetti and Brandt2012). In these studies on shear-thinning and shear-thickening fluid, Şahin and Atalık (Reference Şahin and Atalık2019) use a power-law fluid model in which viscosity,

$Re \leq 300$) (Lashgari et al. Reference Lashgari, Pralits, Giannetti and Brandt2012; Bailoor et al. Reference Bailoor, Seo and Mittal2019; Alam et al. Reference Alam, Raj, Khan, Kumar and Roy2021) and intensify the magnitude of the vorticity in the region close to the cylinder, due to the reduced shear stress associated with the shear-thinning effects that occur very close to the cylinder (Lashgari et al. Reference Lashgari, Pralits, Giannetti and Brandt2012). In these studies on shear-thinning and shear-thickening fluid, Şahin and Atalık (Reference Şahin and Atalık2019) use a power-law fluid model in which viscosity, ![]() $\eta$, is proportional to the shear rate,

$\eta$, is proportional to the shear rate, ![]() $\dot {\gamma }$, to the power

$\dot {\gamma }$, to the power ![]() $n-1$, i.e.

$n-1$, i.e. ![]() $\eta =m\dot {\gamma }^{n-1}$, where

$\eta =m\dot {\gamma }^{n-1}$, where ![]() $m$ is the consistency index, and

$m$ is the consistency index, and ![]() $n$ is the power-law coefficient. For Newtonian fluids,

$n$ is the power-law coefficient. For Newtonian fluids, ![]() $n=1$ and

$n=1$ and ![]() $m=\eta$. In other studies mentioned here, the Carreau model is used in which the power-law regime is preceded by a plateau at the zero-shear-rate viscosity and followed by a plateau at the infinite-shear-rate viscosity.

$m=\eta$. In other studies mentioned here, the Carreau model is used in which the power-law regime is preceded by a plateau at the zero-shear-rate viscosity and followed by a plateau at the infinite-shear-rate viscosity.

The wake of a cylinder that is forced to oscillate in a shear-thinning fluid has been investigated very recently as well. Hopkins & de Bruyn (Reference Hopkins and de Bruyn2019) showed that the effective viscosity, determined by averaging the viscosity around the circumference of the cylinder and over one period of oscillations, depends significantly on the driving frequency, and it reaches the minimum at a resonant frequency. Alam et al. (Reference Alam, Raj, Khan, Kumar and Roy2021) studied the vortex dynamics in the locked-in mode and non-locked-in mode of a transversely oscillating cylinder in shear-thinning fluids at ![]() $Re=100$, where

$Re=100$, where ![]() $Re$ is defined based on the zero-shear-rate viscosity. They showed that the vortex separation length is shorter in the shear-thinning fluids compared with the Newtonian fluid due to reduced viscous diffusion near the vortices in the wake. This length decreases with smaller power-law coefficient,

$Re$ is defined based on the zero-shear-rate viscosity. They showed that the vortex separation length is shorter in the shear-thinning fluids compared with the Newtonian fluid due to reduced viscous diffusion near the vortices in the wake. This length decreases with smaller power-law coefficient, ![]() $n$, and larger Carreau numbers,

$n$, and larger Carreau numbers, ![]() $Cu=\lambda U/D$, where

$Cu=\lambda U/D$, where ![]() $\lambda$ is a time constant of the fluid. However, the effect of

$\lambda$ is a time constant of the fluid. However, the effect of ![]() $n$ is smaller at higher

$n$ is smaller at higher ![]() $Cu$. In shear-thinning fluids, the 2S vortex shedding mode is observed during locked-in forced oscillations. The paired counter-rotating vortices (P+S and 2P vortex shedding modes) are observed during non-locked-in forced oscillations. This finding implies that in a self-excited VIV case, only 2S shedding would be observed in the wake. Alam et al. (Reference Alam, Raj, Khan, Kumar and Roy2021) also show that the vortices in a shear-thinning fluid have a stronger asymmetric pattern with higher levels of unsteadiness while departing from the lock-in mode.

$Cu$. In shear-thinning fluids, the 2S vortex shedding mode is observed during locked-in forced oscillations. The paired counter-rotating vortices (P+S and 2P vortex shedding modes) are observed during non-locked-in forced oscillations. This finding implies that in a self-excited VIV case, only 2S shedding would be observed in the wake. Alam et al. (Reference Alam, Raj, Khan, Kumar and Roy2021) also show that the vortices in a shear-thinning fluid have a stronger asymmetric pattern with higher levels of unsteadiness while departing from the lock-in mode.

In the present work, we will study VIV of a 1DOF cylinder free to oscillate in the CF direction and placed in inelastic power-law fluids. The goal is to understand the shear-thinning and shear-thickening effects in the absence of elasticity on the self-excited response of a 1DOF cylinder undergoing VIV, as a model problem in fluid–structure interactions (FSI). We will discuss the effect of system parameters – such as the reduced velocity, the time constant and the power-law coefficient of the fluid – on the VIV response of the cylinder. We will also introduce a characteristic Reynolds number, which considers the local effects due to shear-rate-dependent viscosity, and can collapse the observed response of the cylinder placed in shear-thinning, shear-thickening or Newtonian fluid.

2. Problem formulation

2.1. Governing equations and numerical methods

We consider two-dimensional, incompressible flow of inelastic shear-thinning and shear-thickening fluids in a domain containing a flexibly-mounted cylinder free to oscillate in the crossflow direction. The fluid flow is governed by the unsteady, incompressible Navier–Stokes (N–S) equations

where ![]() ${\textsf{$\boldsymbol{\tau}$}}=\eta {{\dot {\textsf{$\boldsymbol{\gamma}$}}}}$ and

${\textsf{$\boldsymbol{\tau}$}}=\eta {{\dot {\textsf{$\boldsymbol{\gamma}$}}}}$ and ![]() ${{\dot {\textsf{$\boldsymbol{\gamma}$} }}}={\boldsymbol {\nabla }} \boldsymbol{u}+{\boldsymbol {\nabla }} \boldsymbol{u}^T$. Unlike in a Newtonian fluid, here, the viscosity is a function of shear rate. Shear-rate-dependent viscosity has been described using the Carreau model as (Morrison Reference Morrison2001)

${{\dot {\textsf{$\boldsymbol{\gamma}$} }}}={\boldsymbol {\nabla }} \boldsymbol{u}+{\boldsymbol {\nabla }} \boldsymbol{u}^T$. Unlike in a Newtonian fluid, here, the viscosity is a function of shear rate. Shear-rate-dependent viscosity has been described using the Carreau model as (Morrison Reference Morrison2001)

where ![]() $\eta _0$ is the zero-shear-rate viscosity,

$\eta _0$ is the zero-shear-rate viscosity, ![]() $\eta _\infty$ is the infinite-shear-rate viscosity,

$\eta _\infty$ is the infinite-shear-rate viscosity, ![]() $n$ is the power-law coefficient, which describes the slope of increasing or decreasing viscosity curve, and

$n$ is the power-law coefficient, which describes the slope of increasing or decreasing viscosity curve, and ![]() $\lambda$ is a time constant of the fluid. The value of

$\lambda$ is a time constant of the fluid. The value of ![]() $\lambda$ determines the shear rate at which the transition occurs from zero-shear-rate plateau to power-law regime. With increasing time constant, transition occurs at lower shear rates. In the Carreau model,

$\lambda$ determines the shear rate at which the transition occurs from zero-shear-rate plateau to power-law regime. With increasing time constant, transition occurs at lower shear rates. In the Carreau model, ![]() $\dot {\gamma }$ describes the local shear rate based on the second invariant

$\dot {\gamma }$ describes the local shear rate based on the second invariant ![]() $II_{\dot {\gamma }}$ of the strain rate tensor as

$II_{\dot {\gamma }}$ of the strain rate tensor as

Figure 1 shows the shear-rate-dependent viscosity for several time constants of shear-thinning and shear-thickening fluid used here. The characteristic shear rate, defined as the ratio of the incoming flow velocity and the cylinder diameter, ![]() $\dot {\gamma }_{char} = U/D$, is shown in the figure using a vertical line. For all the cases presented here, the maximum shear rate remains in a range such that the viscosity does not reach the infinite-shear-rate viscosity plateau.

$\dot {\gamma }_{char} = U/D$, is shown in the figure using a vertical line. For all the cases presented here, the maximum shear rate remains in a range such that the viscosity does not reach the infinite-shear-rate viscosity plateau.

Figure 1. Steady shear rheology of (a) shear-thinning fluids with ![]() $n=0.36$,

$n=0.36$, ![]() $\eta _0=0.056$ Pa s and

$\eta _0=0.056$ Pa s and ![]() $\eta _\infty =0.0035$ Pa s, and (b) shear-thickening fluids with

$\eta _\infty =0.0035$ Pa s, and (b) shear-thickening fluids with ![]() $n=1.2$,

$n=1.2$, ![]() $\eta _0=0.0035$ Pa s and

$\eta _0=0.0035$ Pa s and ![]() $\eta _0 - \eta _\infty =0.0085$ Pa s, for various time constant values using the Carreau model.

$\eta _0 - \eta _\infty =0.0085$ Pa s, for various time constant values using the Carreau model.

The finite volume method is used to discretize the N–S equations. Unsteady N–S equations are solved using a coupled algorithm where the momentum equation and pressure-based continuity equations are solved together. A quadratic upwind interpolation for convective kinematics (QUICK) scheme has been applied to discretize the convective terms in the momentum equation. The least squares cell-based method is used to spatially discretize the gradients in the convection and diffusion terms. Pressure and velocity are stored at the cell centres. Since momentum equations require the value of pressure at the face between two adjacent cells of the unstructured grid, the PRESTO (PREssure STaggering Option) scheme has been used to interpolate pressure at the face. The PRESTO scheme uses discrete continuity balance for a staggered control volume about the face to compute pressure at the face. A second-order implicit scheme has been used for temporal discretization of the transient derivative terms. Convergence tolerances for continuity and both velocity components are set to ![]() $10^{-6}$. Once the fluid equations are solved, the net force acting on the cylinder in the

$10^{-6}$. Once the fluid equations are solved, the net force acting on the cylinder in the ![]() $y$-direction (the crossflow direction) is used to calculate the displacement of the cylinder using its equation of motion.

$y$-direction (the crossflow direction) is used to calculate the displacement of the cylinder using its equation of motion.

The equation of motion for a flexibly-mounted cylinder is obtained using Newton's second law of motion as

where

\begin{equation} C_y=\frac{\displaystyle\oint [\eta({\boldsymbol{\nabla}}\boldsymbol{u}+{\boldsymbol{\nabla}}\boldsymbol{u}^T)\cdot \boldsymbol{n} + p\boldsymbol{n}]\cdot\boldsymbol{j} \,{\rm d}s}{\frac{1}{2}\rho D U^2}, \end{equation}

\begin{equation} C_y=\frac{\displaystyle\oint [\eta({\boldsymbol{\nabla}}\boldsymbol{u}+{\boldsymbol{\nabla}}\boldsymbol{u}^T)\cdot \boldsymbol{n} + p\boldsymbol{n}]\cdot\boldsymbol{j} \,{\rm d}s}{\frac{1}{2}\rho D U^2}, \end{equation}

in which ![]() $y$ is the position of the centre of the cylinder,

$y$ is the position of the centre of the cylinder, ![]() $m$ is its mass,

$m$ is its mass, ![]() $c$ is a damping coefficient,

$c$ is a damping coefficient, ![]() $k$ is the spring constant,

$k$ is the spring constant, ![]() $\rho$ is the density of the fluid,

$\rho$ is the density of the fluid, ![]() $C_y$ is the force coefficient acting on the cylinder in the

$C_y$ is the force coefficient acting on the cylinder in the ![]() $y$-direction,

$y$-direction, ![]() $\boldsymbol{n}$ is the normal unit vector, and

$\boldsymbol{n}$ is the normal unit vector, and ![]() $\boldsymbol{j}$ is the unit vector in the

$\boldsymbol{j}$ is the unit vector in the ![]() $y$-direction.

$y$-direction.

Using the diameter, ![]() $D$, as a length scale and the incoming flow velocity,

$D$, as a length scale and the incoming flow velocity, ![]() $U$, as a velocity scale, the equation of motion (2.5) can be written in a non-dimensional form as

$U$, as a velocity scale, the equation of motion (2.5) can be written in a non-dimensional form as

where

and

are the mass ratio and the reduced velocity, respectively, where

In (2.7), we have assumed zero structural damping to promote maximum amplitude of oscillations. The second-order ordinary differential equations are converted into two first-order equations and solved using an iterative solver. Following the velocity of the cylinder, the mesh nodes are moved using the diffusion-based smoothing method, in which we solve the modified Laplace equation

where ![]() $\boldsymbol{u}$ is the point velocity field used to modify the position of mesh nodes,

$\boldsymbol{u}$ is the point velocity field used to modify the position of mesh nodes, ![]() $\boldsymbol{x}_{old}$ and

$\boldsymbol{x}_{old}$ and ![]() $\boldsymbol{x}_{new}$ are the point positions before and after the mesh motion, respectively, and

$\boldsymbol{x}_{new}$ are the point positions before and after the mesh motion, respectively, and ![]() $\Delta t$ is the time step. In the modified Laplace equation,

$\Delta t$ is the time step. In the modified Laplace equation, ![]() $\beta$ is a constant or variable diffusion field, chosen to govern the mesh motion. We have defined

$\beta$ is a constant or variable diffusion field, chosen to govern the mesh motion. We have defined ![]() $\beta$ based on the boundary distance, as

$\beta$ based on the boundary distance, as ![]() $\beta ={1}/{l^a}$, where

$\beta ={1}/{l^a}$, where ![]() $l$ is the distance of the cell centre from the selected boundary, and parameter

$l$ is the distance of the cell centre from the selected boundary, and parameter ![]() $a$ describes how the cylinder's motion diffuses through the surrounding mesh:

$a$ describes how the cylinder's motion diffuses through the surrounding mesh: ![]() $a=0$ indicates uniform diffusion, and

$a=0$ indicates uniform diffusion, and ![]() $a=1$ and

$a=1$ and ![]() $a=2$ indicate linear and quadratic diffusion, respectively, where mesh nodes close to the cylinder move more than mesh nodes far from the cylinder. In the present work, we have used uniform diffusion. Re-meshing would occur only if the quality of mesh anywhere in the domain deteriorates below provided tolerance values during the smoothing step. Parameters used in the simulations are shown in table 1.

$a=2$ indicate linear and quadratic diffusion, respectively, where mesh nodes close to the cylinder move more than mesh nodes far from the cylinder. In the present work, we have used uniform diffusion. Re-meshing would occur only if the quality of mesh anywhere in the domain deteriorates below provided tolerance values during the smoothing step. Parameters used in the simulations are shown in table 1.

Table 1. System parameters used in the simulations.

Figure 2 shows the ![]() $30D \times 16D$ two-dimensional domain that is meshed using a structured grid. The total number of grid nodes is

$30D \times 16D$ two-dimensional domain that is meshed using a structured grid. The total number of grid nodes is ![]() $40\,968$. The mesh in the domain comprises two zones: the inner zone and the outer zone. The mesh around the cylinder in the inner zone moves along with it as a rigid body, thus maintaining the quality of the mesh near the cylinder. This arrangement facilitates the deformation of the mesh elements lying in the outer zone due to the cylinder movement. The slip boundary condition (zero velocity gradient) is applied at the top and bottom walls. The flow is uniform and steady at the inlet. At the fluid–solid interface, no slip and no mass flux conditions are applied. The reduced velocity is varied by changing the natural frequency of the system while keeping the mass ratio and the incoming flow velocity constant. This approach of changing the reduced velocity is chosen to keep the Reynolds number

$40\,968$. The mesh in the domain comprises two zones: the inner zone and the outer zone. The mesh around the cylinder in the inner zone moves along with it as a rigid body, thus maintaining the quality of the mesh near the cylinder. This arrangement facilitates the deformation of the mesh elements lying in the outer zone due to the cylinder movement. The slip boundary condition (zero velocity gradient) is applied at the top and bottom walls. The flow is uniform and steady at the inlet. At the fluid–solid interface, no slip and no mass flux conditions are applied. The reduced velocity is varied by changing the natural frequency of the system while keeping the mass ratio and the incoming flow velocity constant. This approach of changing the reduced velocity is chosen to keep the Reynolds number ![]() $Re_0$, defined based on the zero-shear-rate viscosity (

$Re_0$, defined based on the zero-shear-rate viscosity (![]() $Re_0=\rho U D/\eta _0$), constant. The value of the Reynolds number has been chosen such that the maximum local Reynolds number in the domain stays within the laminar flow regime. The simulations are run for approximately 100 oscillation cycles, depending on the onset of the steady state. When the transient is passed, the steady-state results are collected for at least 20 oscillation cycles and used for analysis.

$Re_0=\rho U D/\eta _0$), constant. The value of the Reynolds number has been chosen such that the maximum local Reynolds number in the domain stays within the laminar flow regime. The simulations are run for approximately 100 oscillation cycles, depending on the onset of the steady state. When the transient is passed, the steady-state results are collected for at least 20 oscillation cycles and used for analysis.

Figure 2. Schematic of the domain with mesh and boundary conditions.

3. Verification

We have compared our results with published data for the case of VIV of a Newtonian fluid. This comparison is summarized in figure 3, where the dimensionless amplitude of the cylinder response, ![]() $A^*=A/D$, is plotted versus the reduced velocity,

$A^*=A/D$, is plotted versus the reduced velocity, ![]() $U^*$. In all cases shown in this plot, the Reynolds number is

$U^*$. In all cases shown in this plot, the Reynolds number is ![]() $Re=150$, the mass ratio is

$Re=150$, the mass ratio is ![]() $m^*=2$, and the structural damping is

$m^*=2$, and the structural damping is ![]() $\zeta =0$. In all cases, the amplitude of oscillations increases initially, as the reduced velocity is increased, and then with further increase in the reduced velocity, the amplitude starts decreasing monotonically until it goes to zero. The maximum amplitude of oscillations in the present case and in the results by Borazjani & Sotiropoulos (Reference Borazjani and Sotiropoulos2009) is

$\zeta =0$. In all cases, the amplitude of oscillations increases initially, as the reduced velocity is increased, and then with further increase in the reduced velocity, the amplitude starts decreasing monotonically until it goes to zero. The maximum amplitude of oscillations in the present case and in the results by Borazjani & Sotiropoulos (Reference Borazjani and Sotiropoulos2009) is ![]() $A^*=0.54$, and in the results by Ahn & Kallinderis (Reference Ahn and Kallinderis2006) is only slightly larger,

$A^*=0.54$, and in the results by Ahn & Kallinderis (Reference Ahn and Kallinderis2006) is only slightly larger, ![]() $A^*=0.56$. The onset and the width of the lock-in range are also in agreement among all three sets of results. Toward the end of the lock-in range, the amplitudes of the present results are slightly smaller than those from the other two cases. For all cases, the lock-in range extends from

$A^*=0.56$. The onset and the width of the lock-in range are also in agreement among all three sets of results. Toward the end of the lock-in range, the amplitudes of the present results are slightly smaller than those from the other two cases. For all cases, the lock-in range extends from ![]() $U^*=3$ to

$U^*=3$ to ![]() $U^*=8$, and as soon as the structure starts to oscillate, the shedding frequency follows the oscillation frequency, instead of following the Strouhal law, indicating that lock-in has occurred. Overall, this comparison shows that our results are in agreement with the results of previous studies on predicting the onset and the width of the lock-in range, as well as the amplitude of oscillations.

$U^*=8$, and as soon as the structure starts to oscillate, the shedding frequency follows the oscillation frequency, instead of following the Strouhal law, indicating that lock-in has occurred. Overall, this comparison shows that our results are in agreement with the results of previous studies on predicting the onset and the width of the lock-in range, as well as the amplitude of oscillations.

Figure 3. The dimensionless (a) amplitude, ![]() $A^*$, and (b) frequency,

$A^*$, and (b) frequency, ![]() $f^*$, of the VIV response for a cylinder free to oscillate in the CF direction and placed in Newtonian flow, found in the present study and the published results of Borazjani & Sotiropoulos (Reference Borazjani and Sotiropoulos2009) and Ahn & Kallinderis (Reference Ahn and Kallinderis2006) at

$f^*$, of the VIV response for a cylinder free to oscillate in the CF direction and placed in Newtonian flow, found in the present study and the published results of Borazjani & Sotiropoulos (Reference Borazjani and Sotiropoulos2009) and Ahn & Kallinderis (Reference Ahn and Kallinderis2006) at ![]() $Re = 150$,

$Re = 150$, ![]() $m^*=2$ and

$m^*=2$ and ![]() $\zeta =0$.

$\zeta =0$.

4. Response of a 1DOF cylinder in the flow of shear-thinning fluid

The rheology of shear-thinning fluid used here has been described using a Carreau model as shown in figure 1(a). We have used a zero-shear-rate viscosity of ![]() $\eta _0=0.056$ Pa s, an infinite-shear-viscosity of

$\eta _0=0.056$ Pa s, an infinite-shear-viscosity of ![]() $\eta _{\infty }=0.0035$ Pa s and a power-law coefficient of

$\eta _{\infty }=0.0035$ Pa s and a power-law coefficient of ![]() $n = 0.36$, and we have varied the time constant from

$n = 0.36$, and we have varied the time constant from ![]() $\lambda =0.1$ s to

$\lambda =0.1$ s to ![]() $\lambda =5$ s (

$\lambda =5$ s (![]() $Cu\approx 1$ to

$Cu\approx 1$ to ![]() $Cu\approx 40$). In all the results presented in this section, unless explicitly mentioned, a non-zero displacement (

$Cu\approx 40$). In all the results presented in this section, unless explicitly mentioned, a non-zero displacement (![]() $0.6D$) and a zero velocity are given as the initial conditions of the cylinder. Based on these parameters, the Reynolds number at the inlet of the domain is

$0.6D$) and a zero velocity are given as the initial conditions of the cylinder. Based on these parameters, the Reynolds number at the inlet of the domain is ![]() $Re_0=15$. For a flexibly-mounted cylinder placed in a Newtonian fluid at this Reynolds number, VIV is not expected. For Newtonian fluids, the critical Reynolds number to observe shedding of vortices in the wake of a cylinder is

$Re_0=15$. For a flexibly-mounted cylinder placed in a Newtonian fluid at this Reynolds number, VIV is not expected. For Newtonian fluids, the critical Reynolds number to observe shedding of vortices in the wake of a cylinder is ![]() $Re_{crit}=47$ (Mathis et al. Reference Mathis, Provansal and Boyer1984; Jackson Reference Jackson1987; Dušek, Gal & Fraunié Reference Dušek, Gal and Fraunié1994). However, recent studies have shown that VIV can be observed in the subcritical Reynolds number range, i.e. for

$Re_{crit}=47$ (Mathis et al. Reference Mathis, Provansal and Boyer1984; Jackson Reference Jackson1987; Dušek, Gal & Fraunié Reference Dušek, Gal and Fraunié1994). However, recent studies have shown that VIV can be observed in the subcritical Reynolds number range, i.e. for ![]() $Re<47$ (Mittal & Singh Reference Mittal and Singh2005; Kou et al. Reference Kou, Zhang, Liu and Li2017; Dolci & Carmo Reference Dolci and Carmo2019; Boersma et al. Reference Boersma, Zhao, Rothstein and Modarres-Sadeghi2021). The minimum Reynolds number needed to observe subcritical VIV is

$Re<47$ (Mittal & Singh Reference Mittal and Singh2005; Kou et al. Reference Kou, Zhang, Liu and Li2017; Dolci & Carmo Reference Dolci and Carmo2019; Boersma et al. Reference Boersma, Zhao, Rothstein and Modarres-Sadeghi2021). The minimum Reynolds number needed to observe subcritical VIV is ![]() $Re=18$ (Kou et al. Reference Kou, Zhang, Liu and Li2017), and VIV has been observed experimentally for Reynolds numbers as low as

$Re=18$ (Kou et al. Reference Kou, Zhang, Liu and Li2017), and VIV has been observed experimentally for Reynolds numbers as low as ![]() $Re=19$ (Boersma et al. Reference Boersma, Zhao, Rothstein and Modarres-Sadeghi2021). As a result, with an incoming Reynolds number of

$Re=19$ (Boersma et al. Reference Boersma, Zhao, Rothstein and Modarres-Sadeghi2021). As a result, with an incoming Reynolds number of ![]() $Re_0=15$ in the present work, any observed oscillations will be purely due to the shear-thinning effects of the fluid. In a Newtonian fluid, when VIV starts at

$Re_0=15$ in the present work, any observed oscillations will be purely due to the shear-thinning effects of the fluid. In a Newtonian fluid, when VIV starts at ![]() $Re=19$, its response amplitude increases with Reynolds number up to

$Re=19$, its response amplitude increases with Reynolds number up to ![]() $Re=33$, after which the response reaches a plateau (Boersma et al. Reference Boersma, Zhao, Rothstein and Modarres-Sadeghi2021).

$Re=33$, after which the response reaches a plateau (Boersma et al. Reference Boersma, Zhao, Rothstein and Modarres-Sadeghi2021).

4.1. The observed response for different time constants

Figure 4 shows the dimensionless amplitude, ![]() $A^*$, and frequency,

$A^*$, and frequency, ![]() $f^*$, of the cylinder's displacements (figure 4a,b) and the transverse (CF) force coefficient,

$f^*$, of the cylinder's displacements (figure 4a,b) and the transverse (CF) force coefficient, ![]() $C_y$, and frequency,

$C_y$, and frequency, ![]() $f^*_{C_y}$, that act on the cylinder (figure 4c,d) as a function of reduced velocity,

$f^*_{C_y}$, that act on the cylinder (figure 4c,d) as a function of reduced velocity, ![]() $U^*$, for time constants varying from

$U^*$, for time constants varying from ![]() $\lambda =0.15$ s to

$\lambda =0.15$ s to ![]() $\lambda =5$ s (

$\lambda =5$ s (![]() $Cu=1.2$ to

$Cu=1.2$ to ![]() $Cu=40$). The amplitude of oscillations is normalized by the cylinder diameter,

$Cu=40$). The amplitude of oscillations is normalized by the cylinder diameter, ![]() $D$, and the frequency is normalized by the natural frequency of the system in vacuum,

$D$, and the frequency is normalized by the natural frequency of the system in vacuum, ![]() $f_n$.

$f_n$.

Figure 4. The dimensionless (a) oscillation amplitude, ![]() $A^*$, and (b) oscillation frequency,

$A^*$, and (b) oscillation frequency, ![]() $f^*$, as well as (c) the force coefficient in the CF direction,

$f^*$, as well as (c) the force coefficient in the CF direction, ![]() $C_y$, and (d) the force frequency,

$C_y$, and (d) the force frequency, ![]() $f^*_{C_y}$, versus the reduced velocity,

$f^*_{C_y}$, versus the reduced velocity, ![]() $U^*$, for shear-thinning fluids with different time constants,

$U^*$, for shear-thinning fluids with different time constants, ![]() $\lambda$.

$\lambda$.

For the fluid with the largest time constant presented here, ![]() $\lambda =5$ s (

$\lambda =5$ s (![]() $Cu=40$), the amplitude response of the cylinder in figure 4(a) resembles a typical VIV response for a Newtonian fluid, albeit at an incoming Reynolds number lower than the minimum Reynolds number for which VIV can be observed for a Newtonian fluid. As the time constant is decreased, however, the amplitude of oscillations, as well as the width of the lock-in range, decreases. At

$Cu=40$), the amplitude response of the cylinder in figure 4(a) resembles a typical VIV response for a Newtonian fluid, albeit at an incoming Reynolds number lower than the minimum Reynolds number for which VIV can be observed for a Newtonian fluid. As the time constant is decreased, however, the amplitude of oscillations, as well as the width of the lock-in range, decreases. At ![]() $\lambda =0.15$ s (

$\lambda =0.15$ s (![]() $Cu=1.2$), no oscillation is observed, and VIV is completely suppressed for all reduced velocities. For all cases where oscillations are observed, the oscillation frequency stays constant at a value close to

$Cu=1.2$), no oscillation is observed, and VIV is completely suppressed for all reduced velocities. For all cases where oscillations are observed, the oscillation frequency stays constant at a value close to ![]() $f^*=f_o/f_n=1$ (figure 4b). In this range, the frequency of fluctuating force in the direction of oscillation,

$f^*=f_o/f_n=1$ (figure 4b). In this range, the frequency of fluctuating force in the direction of oscillation, ![]() $f^*_{C_y}$, stays close to

$f^*_{C_y}$, stays close to ![]() $f^*=1$ as well (figure 4d), indicating that the shedding frequency and the oscillation frequency are synchronized, lock-in is observed, and the observed oscillations are indeed VIV. The magnitude of the CF force coefficients shown in figure 4(c) amplifies when the cylinder starts oscillating for all cases with different time constants. The largest magnitude of the CF force coefficient is observed for the largest time constant tested.

$f^*=1$ as well (figure 4d), indicating that the shedding frequency and the oscillation frequency are synchronized, lock-in is observed, and the observed oscillations are indeed VIV. The magnitude of the CF force coefficients shown in figure 4(c) amplifies when the cylinder starts oscillating for all cases with different time constants. The largest magnitude of the CF force coefficient is observed for the largest time constant tested.

The onset of oscillations for ![]() $\lambda =5$ s (

$\lambda =5$ s (![]() $Cu=40$) is at

$Cu=40$) is at ![]() $U^*=3$ (figure 4a), and it is delayed with decreasing time constant. Consequently, the width of the lock-in range decreases in the case of shear-thinning fluid with decreasing time constant. The onset of VIV depends on the Strouhal number associated with the shear-thinning fluid. As shown by Bailoor et al. (Reference Bailoor, Seo and Mittal2019), the Strouhal number (

$U^*=3$ (figure 4a), and it is delayed with decreasing time constant. Consequently, the width of the lock-in range decreases in the case of shear-thinning fluid with decreasing time constant. The onset of VIV depends on the Strouhal number associated with the shear-thinning fluid. As shown by Bailoor et al. (Reference Bailoor, Seo and Mittal2019), the Strouhal number (![]() $St=f_sD/U$) increases for stronger shear-thinning effects (i.e. larger time constant,

$St=f_sD/U$) increases for stronger shear-thinning effects (i.e. larger time constant, ![]() $\lambda$, or smaller power-law coefficient,

$\lambda$, or smaller power-law coefficient, ![]() $n$). This suggests that as the time constant is decreased in the cases discussed here, the Strouhal number decreases, and as a result the shedding frequency decreases for a constant incoming flow velocity. Then the shedding frequency matches the natural frequency of the system at higher reduced velocities, and the onset of lock-in is delayed, as observed in the results of figure 4(a).

$n$). This suggests that as the time constant is decreased in the cases discussed here, the Strouhal number decreases, and as a result the shedding frequency decreases for a constant incoming flow velocity. Then the shedding frequency matches the natural frequency of the system at higher reduced velocities, and the onset of lock-in is delayed, as observed in the results of figure 4(a).

4.2. Distribution of local Reynolds numbers

As shown in figure 1, the time constant of a fluid determines the onset of transition from the zero-shear-rate viscosity plateau to the power-law regime. With increasing ![]() $\lambda$, shear thinning of the viscosity occurs at lower shear rates. As a result, the fluid around the cylinder has a viscosity that depends on both the local shear rate (defined in equation (2.4)) and the time constant of the fluid. This can be observed in figure 5, where the spatial distribution of the local Reynolds number, defined as

$\lambda$, shear thinning of the viscosity occurs at lower shear rates. As a result, the fluid around the cylinder has a viscosity that depends on both the local shear rate (defined in equation (2.4)) and the time constant of the fluid. This can be observed in figure 5, where the spatial distribution of the local Reynolds number, defined as ![]() $Re=\rho U D/\eta$, where

$Re=\rho U D/\eta$, where ![]() $\eta$ is the local viscosity of the fluid calculated from the shear rate at that location, is presented for a constant reduced velocity, and four different values of

$\eta$ is the local viscosity of the fluid calculated from the shear rate at that location, is presented for a constant reduced velocity, and four different values of ![]() $\lambda$: one corresponding to a case with no oscillations (figure 5a) and others corresponding to cases with oscillations (figure 5b–d). The contours of local Reynolds number shown in figure 5 indicate the variation in the viscosity depending on the shear rate in the domain. The time constant determines how far from the cylinder the shear-thinning effect extends. A smaller time constant corresponds to a shear-thinning effect only in close proximity to the cylinder. From the figure, we observe that the shear-thinning effect extends up to a considerable distance downstream from the cylinder for a larger time constant. The reach of the shear-thinning effect in the domain can be understood from the histograms of local Reynolds number for various time constant values. A fixed rectangular bounding box of size

$\lambda$: one corresponding to a case with no oscillations (figure 5a) and others corresponding to cases with oscillations (figure 5b–d). The contours of local Reynolds number shown in figure 5 indicate the variation in the viscosity depending on the shear rate in the domain. The time constant determines how far from the cylinder the shear-thinning effect extends. A smaller time constant corresponds to a shear-thinning effect only in close proximity to the cylinder. From the figure, we observe that the shear-thinning effect extends up to a considerable distance downstream from the cylinder for a larger time constant. The reach of the shear-thinning effect in the domain can be understood from the histograms of local Reynolds number for various time constant values. A fixed rectangular bounding box of size ![]() $15D \times 7D$ has been created around the cylinder, and the local Reynolds number at each grid-cell inside the box is calculated. Histograms of the local Reynolds number inside the bounding box for four different time constant values are shown in figure 5. For

$15D \times 7D$ has been created around the cylinder, and the local Reynolds number at each grid-cell inside the box is calculated. Histograms of the local Reynolds number inside the bounding box for four different time constant values are shown in figure 5. For ![]() $\lambda = 0.4$ s (

$\lambda = 0.4$ s (![]() $Cu=3$), where no oscillation is observed, most of the flow is dominated with Reynolds numbers below

$Cu=3$), where no oscillation is observed, most of the flow is dominated with Reynolds numbers below ![]() $Re = 20$, because shear-thinning occurs only in the regions very close to the cylinder where the shear rate is maximum. As the time constant is increased and the shear rate needed for shear thinning to occur is decreased, the percentage of the flow at large local Reynolds numbers gradually increases until the flow is sufficiently dominated by inertial effects for vortices to separate and shed from the cylinder and drive VIV. We have used the percentage of grid-cells to plot the histograms of local Reynolds number. Since the grid is concentrated close to the cylinder, the results are biased towards the viscosity close to the cylinder.

$Re = 20$, because shear-thinning occurs only in the regions very close to the cylinder where the shear rate is maximum. As the time constant is increased and the shear rate needed for shear thinning to occur is decreased, the percentage of the flow at large local Reynolds numbers gradually increases until the flow is sufficiently dominated by inertial effects for vortices to separate and shed from the cylinder and drive VIV. We have used the percentage of grid-cells to plot the histograms of local Reynolds number. Since the grid is concentrated close to the cylinder, the results are biased towards the viscosity close to the cylinder.

Figure 5. Histograms of the local Reynolds numbers around a cylinder undergoing VIV in a shear-thinning fluid with (a) ![]() $\lambda = 0.4$ s (

$\lambda = 0.4$ s (![]() $Cu=3$), (b)

$Cu=3$), (b) ![]() $\lambda = 1.5$ s (

$\lambda = 1.5$ s (![]() $Cu=12$), (c)

$Cu=12$), (c) ![]() $\lambda = 5$ s (

$\lambda = 5$ s (![]() $Cu=40$), and (d)

$Cu=40$), and (d) ![]() $\lambda = 20$ s (

$\lambda = 20$ s (![]() $Cu=158$), all at

$Cu=158$), all at ![]() $U^*=4$. The incoming Reynolds number is

$U^*=4$. The incoming Reynolds number is ![]() $Re_0=15$ for all cases. All the cells inside the bounding box (dashed blue rectangle) of size

$Re_0=15$ for all cases. All the cells inside the bounding box (dashed blue rectangle) of size ![]() $15D \times 7D$ have been used to create the histograms. A snapshot of the spatial distribution of the local Reynolds numbers is shown for each case. The bin size is 5 in these histograms.

$15D \times 7D$ have been used to create the histograms. A snapshot of the spatial distribution of the local Reynolds numbers is shown for each case. The bin size is 5 in these histograms.

Note that the incoming Reynolds number, ![]() $Re_0$, which is defined based on zero-shear-rate viscosity, is the same for all cases shown in figure 5, but the distribution of the local Reynolds number in proximity to the cylinder is quite different. Thus this definition of Reynolds number does not describe the local flow sufficiently and, as a result, it is incapable of predicting a priori the critical conditions necessary for vortex separation and shedding for a shear-thinning fluid. Instead, a new dimensionless parameter is needed that takes the local effects into account by considering the local shear rate and the fluid rheology. Here we define a characteristic Reynolds number,

$Re_0$, which is defined based on zero-shear-rate viscosity, is the same for all cases shown in figure 5, but the distribution of the local Reynolds number in proximity to the cylinder is quite different. Thus this definition of Reynolds number does not describe the local flow sufficiently and, as a result, it is incapable of predicting a priori the critical conditions necessary for vortex separation and shedding for a shear-thinning fluid. Instead, a new dimensionless parameter is needed that takes the local effects into account by considering the local shear rate and the fluid rheology. Here we define a characteristic Reynolds number, ![]() $Re_{char}=\rho U D/\eta _{char}$, based on a characteristic viscosity,

$Re_{char}=\rho U D/\eta _{char}$, based on a characteristic viscosity, ![]() $\eta _{char}$, of the flow. The characteristic viscosity is evaluated using the Carreau model at the characteristic shear rate defined by the ratio of the incoming flow velocity and the cylinder diameter,

$\eta _{char}$, of the flow. The characteristic viscosity is evaluated using the Carreau model at the characteristic shear rate defined by the ratio of the incoming flow velocity and the cylinder diameter, ![]() $\dot {\gamma }_{char} = U/D$. At a given

$\dot {\gamma }_{char} = U/D$. At a given ![]() $Re_0$, the characteristic Reynolds number increases with increasing time constant for shear-thinning fluids. The characteristic Reynolds numbers for the four cases shown in figure 5 are (a)

$Re_0$, the characteristic Reynolds number increases with increasing time constant for shear-thinning fluids. The characteristic Reynolds numbers for the four cases shown in figure 5 are (a) ![]() $Re_{char}=30$, (b)

$Re_{char}=30$, (b) ![]() $Re_{char}=59$, (c)

$Re_{char}=59$, (c) ![]() $Re_{char}=100$, and (d)

$Re_{char}=100$, and (d) ![]() $Re_{char}=152$. When compared with the histograms in each of the subplots,

$Re_{char}=152$. When compared with the histograms in each of the subplots, ![]() $Re_{char}$ closely approximates the peak in the local Reynolds number resulting from shear thinning of the fluid close to the cylinder wall. Based on this definition of the characteristic Reynolds number, VIV is not observed for

$Re_{char}$ closely approximates the peak in the local Reynolds number resulting from shear thinning of the fluid close to the cylinder wall. Based on this definition of the characteristic Reynolds number, VIV is not observed for ![]() $Re_{char}=30$, but is observed for

$Re_{char}=30$, but is observed for ![]() $Re_{char}=59$ and larger, indicating that similar to what has been observed for the Newtonian case, a critical characteristic Reynolds number exists for the onset of VIV in shear-thinning fluids.

$Re_{char}=59$ and larger, indicating that similar to what has been observed for the Newtonian case, a critical characteristic Reynolds number exists for the onset of VIV in shear-thinning fluids.

The shedding of vortices at ![]() $Re_0=15$ in a shear-thinning fluid is purely a result of the shear-thinning effect. How far these vortices are sustained in the wake of a cylinder, and their strength, depend upon the type of shear-thinning fluid. If the shear-thinning effect for a fluid is not strong enough (i.e. the time constant of the fluid is not large enough), then the vortices are observed only in close proximity to the cylinder. The strength of these vortices is not enough to generate large-amplitude oscillations of the cylinder as observed in a Newtonian fluid. Thus we observe reduction in the amplitude of oscillations as the time constant is decreased in a shear-thinning fluid, as observed in figure 4(a).

$Re_0=15$ in a shear-thinning fluid is purely a result of the shear-thinning effect. How far these vortices are sustained in the wake of a cylinder, and their strength, depend upon the type of shear-thinning fluid. If the shear-thinning effect for a fluid is not strong enough (i.e. the time constant of the fluid is not large enough), then the vortices are observed only in close proximity to the cylinder. The strength of these vortices is not enough to generate large-amplitude oscillations of the cylinder as observed in a Newtonian fluid. Thus we observe reduction in the amplitude of oscillations as the time constant is decreased in a shear-thinning fluid, as observed in figure 4(a).

4.3. The response at constant reduced velocities and for varying time constants

In the previous subsection, we discussed the response of a 1DOF system placed in a shear-thinning fluid as the reduced velocity was varied. In this subsection, we focus on the influence of fluid rheology on the system's response as other system parameters stay constant. To do so, we use the time constant, ![]() $\lambda$, as an independent variable and investigate how the response of the system changes for two constant reduced velocities of

$\lambda$, as an independent variable and investigate how the response of the system changes for two constant reduced velocities of ![]() $U^*=4$ and

$U^*=4$ and ![]() $U^*=6$, as two sample cases. The Reynolds number has been kept constant at

$U^*=6$, as two sample cases. The Reynolds number has been kept constant at ![]() $Re_0=15$ for all these cases. Figure 6 shows the amplitude,

$Re_0=15$ for all these cases. Figure 6 shows the amplitude, ![]() $A^*$, and frequency,

$A^*$, and frequency, ![]() $f^*$, of response, the CF force coefficient,

$f^*$, of response, the CF force coefficient, ![]() $C_y$, the ratio of the third harmonic to the first harmonic of the CF forces,

$C_y$, the ratio of the third harmonic to the first harmonic of the CF forces, ![]() $C_{y,3}/C_{y,1}$, and the phase between the displacement and the CF force,

$C_{y,3}/C_{y,1}$, and the phase between the displacement and the CF force, ![]() $\phi$, for the two sample reduced velocities as

$\phi$, for the two sample reduced velocities as ![]() $\lambda$ is varied from

$\lambda$ is varied from ![]() $\lambda =0$ s to

$\lambda =0$ s to ![]() $\lambda =5$ s (

$\lambda =5$ s (![]() $Cu=0$ to

$Cu=0$ to ![]() $Cu=40$).

$Cu=40$).

Figure 6. The dimensionless (a) amplitude, ![]() $A^*$, and (b) frequency,

$A^*$, and (b) frequency, ![]() $f^*$, of oscillations, as well as (c) the CF force coefficient,

$f^*$, of oscillations, as well as (c) the CF force coefficient, ![]() $C_y$, (d) the ratio of the third harmonic to the first harmonic force in the CF direction,

$C_y$, (d) the ratio of the third harmonic to the first harmonic force in the CF direction, ![]() $C_{y,3}/C_{y,1}$, and (e) the phase difference between the CF displacement and the CF force,

$C_{y,3}/C_{y,1}$, and (e) the phase difference between the CF displacement and the CF force, ![]() $\phi$, for

$\phi$, for ![]() $U^*=4$ and

$U^*=4$ and ![]() $U^*=6$ versus the time constant,

$U^*=6$ versus the time constant, ![]() $\lambda$.

$\lambda$.

As shown in figure 6(a), the onset of VIV is at ![]() $\lambda = 0.5$ s (

$\lambda = 0.5$ s (![]() $Cu\approx 4$,

$Cu\approx 4$, ![]() $Re_{char}\approx 34$) and

$Re_{char}\approx 34$) and ![]() $\lambda = 0.2$ s (

$\lambda = 0.2$ s (![]() $Cu\approx 2$,

$Cu\approx 2$, ![]() $Re_{char}\approx 22$) for

$Re_{char}\approx 22$) for ![]() $U^* = 4$ and

$U^* = 4$ and ![]() $U^* = 6$, respectively. The critical value for characteristic Reynolds number is different for different

$U^* = 6$, respectively. The critical value for characteristic Reynolds number is different for different ![]() $U^*$. The VIV amplitude increases rapidly before it reaches its peak at

$U^*$. The VIV amplitude increases rapidly before it reaches its peak at ![]() $\lambda = 1.5$ s (

$\lambda = 1.5$ s (![]() $Cu\approx 12$,

$Cu\approx 12$, ![]() $Re_{char}\approx 59$) and

$Re_{char}\approx 59$) and ![]() $\lambda = 0.8$ s (

$\lambda = 0.8$ s (![]() $Cu\approx 6$,

$Cu\approx 6$, ![]() $Re_{char}\approx 43$) for

$Re_{char}\approx 43$) for ![]() $U^* = 4$ and

$U^* = 4$ and ![]() $U^* = 6$, respectively. By increasing the time constant further, the amplitude decreases slightly for both reduced velocities. The decrease in amplitude is more noticeable in the case of

$U^* = 6$, respectively. By increasing the time constant further, the amplitude decreases slightly for both reduced velocities. The decrease in amplitude is more noticeable in the case of ![]() $U^* = 6$. When the time constant of the shear-thinning fluid approaches the largest values tested (approximately at

$U^* = 6$. When the time constant of the shear-thinning fluid approaches the largest values tested (approximately at ![]() $\lambda =20$ s,

$\lambda =20$ s, ![]() $Cu=158$), most of the fluid in the wake of the cylinder is at the infinite-shear-rate viscosity and, as a result, the fluid essentially is no longer shear-thinning and the VIV response of the cylinder approaches Newtonian-like behaviour. This is manifested in the form of a plateau in the amplitude at higher time constants. Figure 6(b) shows the variation of frequency of oscillations with time constant for

$Cu=158$), most of the fluid in the wake of the cylinder is at the infinite-shear-rate viscosity and, as a result, the fluid essentially is no longer shear-thinning and the VIV response of the cylinder approaches Newtonian-like behaviour. This is manifested in the form of a plateau in the amplitude at higher time constants. Figure 6(b) shows the variation of frequency of oscillations with time constant for ![]() $U^* = 4$ and

$U^* = 4$ and ![]() $U^* = 6$, where the frequency of oscillations is normalized by the natural frequency of the system in vacuum. The

$U^* = 6$, where the frequency of oscillations is normalized by the natural frequency of the system in vacuum. The ![]() $f^*$ behaviour in the case of

$f^*$ behaviour in the case of ![]() $U^*=6$ is very similar to the

$U^*=6$ is very similar to the ![]() $f^*$ behaviour that is typically observed in a Newtonian case when

$f^*$ behaviour that is typically observed in a Newtonian case when ![]() $f^*$ is plotted versus

$f^*$ is plotted versus ![]() $U^*$. Initially,

$U^*$. Initially, ![]() $f^*$ is smaller than 1. Then, as

$f^*$ is smaller than 1. Then, as ![]() $\lambda$ is increased,

$\lambda$ is increased, ![]() $f^*$ crosses 1. This point of crossing 1 corresponds to a switch in the phase between the displacement and force from

$f^*$ crosses 1. This point of crossing 1 corresponds to a switch in the phase between the displacement and force from ![]() $\phi =0^{\circ }$ to

$\phi =0^{\circ }$ to ![]() $\phi =180^{\circ }$, and the appearance of a large contribution of the third harmonic force (at values of around

$\phi =180^{\circ }$, and the appearance of a large contribution of the third harmonic force (at values of around ![]() $\lambda =2.4$ s (

$\lambda =2.4$ s (![]() $Cu=19$) in the present case). The slight decrease in the amplitude of oscillations for larger values of

$Cu=19$) in the present case). The slight decrease in the amplitude of oscillations for larger values of ![]() $\lambda$ in this case can also be explained by the sudden change in the phase difference, since the displacement of the cylinder and the CF force are out of phase when

$\lambda$ in this case can also be explained by the sudden change in the phase difference, since the displacement of the cylinder and the CF force are out of phase when ![]() $\lambda > 2.4$ s (

$\lambda > 2.4$ s (![]() $Cu>19$).

$Cu>19$).

In the case of ![]() $U^* = 4$, however,

$U^* = 4$, however, ![]() $f^*$ remains lower than 1 for all values of

$f^*$ remains lower than 1 for all values of ![]() $\lambda$, and the large third harmonic component of the force and the sudden phase shift are not observed in the response. For this reduced velocity, the amplitude of oscillations stays constant for larger

$\lambda$, and the large third harmonic component of the force and the sudden phase shift are not observed in the response. For this reduced velocity, the amplitude of oscillations stays constant for larger ![]() $\lambda$ values, since the CF displacement and the CF force stay in phase.

$\lambda$ values, since the CF displacement and the CF force stay in phase.

Figure 7 shows the Lissajous curves for several different values of the time constant. As the time constant increases, the Lissajous curves rotate in the counterclockwise direction. For ![]() $U^* = 4$ (figure 7a), the Lissajous curves are located in the first and third quadrants, corresponding to a phase difference of

$U^* = 4$ (figure 7a), the Lissajous curves are located in the first and third quadrants, corresponding to a phase difference of ![]() $\phi =0^{\circ }$, which means that the displacement and the force coefficient are positively correlated. For

$\phi =0^{\circ }$, which means that the displacement and the force coefficient are positively correlated. For ![]() $U^* = 6$ (figure 7b), the Lissajous curves move to the second and fourth quadrants for

$U^* = 6$ (figure 7b), the Lissajous curves move to the second and fourth quadrants for ![]() $\lambda > 2.4$ s (

$\lambda > 2.4$ s (![]() $Cu>19$). This corresponds to the phase jump to

$Cu>19$). This corresponds to the phase jump to ![]() $\phi =180^{\circ }$, which means that the displacement and the force coefficient are negatively correlated. The two lobes at the extreme ends in the Lissajous curves represent the third harmonic contribution of the force. It is clear from figure 7 that the contribution of the third harmonic increases for increasing time constants, when the Lissajous curves stay in the first and third quadrants. In figure 7(b), the maximum contribution of the third harmonic is observed when the Lissajous curve crosses the vertical axis and enters the second quadrant, after which the forcing and displacement become out of phase, and the contribution of higher harmonics decreases.

$\phi =180^{\circ }$, which means that the displacement and the force coefficient are negatively correlated. The two lobes at the extreme ends in the Lissajous curves represent the third harmonic contribution of the force. It is clear from figure 7 that the contribution of the third harmonic increases for increasing time constants, when the Lissajous curves stay in the first and third quadrants. In figure 7(b), the maximum contribution of the third harmonic is observed when the Lissajous curve crosses the vertical axis and enters the second quadrant, after which the forcing and displacement become out of phase, and the contribution of higher harmonics decreases.

Figure 7. Lissajous curves of the CF displacement of the cylinder versus the coefficient of the CF force for shear-thinning fluids with different time constants ![]() $\lambda$ at (a)

$\lambda$ at (a) ![]() $U^* = 4$, and (b)

$U^* = 4$, and (b) ![]() $U^* = 6$. The incoming Reynolds number is

$U^* = 6$. The incoming Reynolds number is ![]() $Re_0=15$ for all cases.

$Re_0=15$ for all cases.

4.4. Subcritical instability in shear-thinning fluids

The results presented in the previous subsections were all for cases where a non-zero initial displacement was given to the structure. Over a range of ![]() $\lambda$ values, we found that oscillations are not observed if the structural initial conditions stay at zero. Figure 8(a) shows a sample amplitude plot for

$\lambda$ values, we found that oscillations are not observed if the structural initial conditions stay at zero. Figure 8(a) shows a sample amplitude plot for ![]() $U^*=4$ in which the amplitude of response is plotted versus

$U^*=4$ in which the amplitude of response is plotted versus ![]() $\lambda$ for cases with both zero and non-zero initial conditions. A range is observed in the figure from

$\lambda$ for cases with both zero and non-zero initial conditions. A range is observed in the figure from ![]() $\lambda = 0.5$ s (

$\lambda = 0.5$ s (![]() $Cu\approx 4$,

$Cu\approx 4$, ![]() $Re_{char}\approx 34$) to

$Re_{char}\approx 34$) to ![]() $\lambda = 0.7$ s (

$\lambda = 0.7$ s (![]() $Cu\approx 6$,

$Cu\approx 6$, ![]() $Re_{char}\approx 40$) for which two stable solutions exist: a zero response, and a non-zero response. This plot exhibits a subcritical instability for the flexibly-mounted structure. Similarly to the subcritical VIV that have been observed in a 1DOF system placed in a Newtonian fluid (Mittal & Singh Reference Mittal and Singh2005; Boersma et al. Reference Boersma, Zhao, Rothstein and Modarres-Sadeghi2021), if the cylinder is not given non-zero initial conditions in this range of

$Re_{char}\approx 40$) for which two stable solutions exist: a zero response, and a non-zero response. This plot exhibits a subcritical instability for the flexibly-mounted structure. Similarly to the subcritical VIV that have been observed in a 1DOF system placed in a Newtonian fluid (Mittal & Singh Reference Mittal and Singh2005; Boersma et al. Reference Boersma, Zhao, Rothstein and Modarres-Sadeghi2021), if the cylinder is not given non-zero initial conditions in this range of ![]() $\lambda$ values, then it remains at its initial equilibrium position and no vortices are shed in its wake (figure 8b). If, however, the cylinder is given an initial disturbance, then its wake becomes unstable, vortices are shed, and the cylinder undergoes VIV (figure 8c). The initial disturbance provides an additional shear rate due to the relative motion of the cylinder, which drives the Reynolds number up in regions close to the cylinder and pushes it past the critical

$\lambda$ values, then it remains at its initial equilibrium position and no vortices are shed in its wake (figure 8b). If, however, the cylinder is given an initial disturbance, then its wake becomes unstable, vortices are shed, and the cylinder undergoes VIV (figure 8c). The initial disturbance provides an additional shear rate due to the relative motion of the cylinder, which drives the Reynolds number up in regions close to the cylinder and pushes it past the critical ![]() $Re$ that is needed to observe VIV. By analysing the histograms of local Reynolds numbers inside a bounding box of

$Re$ that is needed to observe VIV. By analysing the histograms of local Reynolds numbers inside a bounding box of ![]() $15D\times 7D$ for two cases where oscillations are observed – i.e.

$15D\times 7D$ for two cases where oscillations are observed – i.e. ![]() $\lambda =0.5$ s (

$\lambda =0.5$ s (![]() $Cu\approx 4$) with an initial disturbance, and

$Cu\approx 4$) with an initial disturbance, and ![]() $\lambda =0.75$ s (

$\lambda =0.75$ s (![]() $Cu\approx 6$) without any initial disturbance – we find that the distributions are quite similar, with comparable maximum

$Cu\approx 6$) without any initial disturbance – we find that the distributions are quite similar, with comparable maximum ![]() $Re$ values of

$Re$ values of ![]() $116$ and

$116$ and ![]() $127$, respectively.

$127$, respectively.

Figure 8. (a) Dimensionless amplitudes of the CF response, ![]() $A^*$, versus the time constant,

$A^*$, versus the time constant, ![]() $\lambda$, for simulations with zero and non-zero initial conditions (IC) at

$\lambda$, for simulations with zero and non-zero initial conditions (IC) at ![]() $U^* = 4$. Vorticity fields for

$U^* = 4$. Vorticity fields for ![]() $\lambda = 0.6$ s (

$\lambda = 0.6$ s (![]() $Cu\approx 5$) when (b) zero or (c) non-zero initial displacement is given. The incoming Reynolds number is

$Cu\approx 5$) when (b) zero or (c) non-zero initial displacement is given. The incoming Reynolds number is ![]() $Re_0=15$ for all cases. In the figure,

$Re_0=15$ for all cases. In the figure, ![]() $\omega_z$ is the z-component of the vorticity.

$\omega_z$ is the z-component of the vorticity.

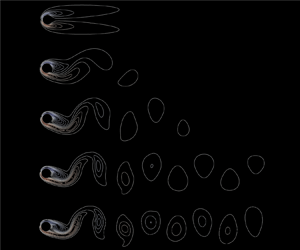

4.5. Wake for shear-thinning fluids

In this subsection, we discuss the flow pattern in the wake of the cylinder as it undergoes VIV. The Reynolds number is kept constant at ![]() $Re_0=15$ for all cases. The vorticity contours are plotted for various time constants of the fluid in figure 9, where wake patterns are shown for increasing time constants from top to bottom for

$Re_0=15$ for all cases. The vorticity contours are plotted for various time constants of the fluid in figure 9, where wake patterns are shown for increasing time constants from top to bottom for ![]() $U^* = 4$ (a–e) and

$U^* = 4$ (a–e) and ![]() $U^* = 6$ (f–j). The snapshots in each row are at different time constants, but they are chosen such that in each row, the extent of the wake is similar. Vortex shedding is not observed for the first sample cases for each reduced velocity, and the cylinder does not oscillate. For all the other cases the cylinder oscillates, and vortex shedding is observed in the wake. For all these cases, a 2S shedding pattern is observed in the wake, in which one single vortex is shed from each side of the cylinder during each cycle of oscillations (Williamson & Roshko Reference Williamson and Roshko1988). The vortex shedding frequency and the amplitude of oscillations for

$U^* = 6$ (f–j). The snapshots in each row are at different time constants, but they are chosen such that in each row, the extent of the wake is similar. Vortex shedding is not observed for the first sample cases for each reduced velocity, and the cylinder does not oscillate. For all the other cases the cylinder oscillates, and vortex shedding is observed in the wake. For all these cases, a 2S shedding pattern is observed in the wake, in which one single vortex is shed from each side of the cylinder during each cycle of oscillations (Williamson & Roshko Reference Williamson and Roshko1988). The vortex shedding frequency and the amplitude of oscillations for ![]() $U^* = 4$ are higher than those for

$U^* = 4$ are higher than those for ![]() $U^* = 6$. The lateral distance between counter-rotating vortices is larger for

$U^* = 6$. The lateral distance between counter-rotating vortices is larger for ![]() $U^* = 4$ due to higher amplitude of oscillations. The length of recirculation bubble is larger for

$U^* = 4$ due to higher amplitude of oscillations. The length of recirculation bubble is larger for ![]() $U^* = 6$, because the oscillation frequency is lower at this reduced velocity when compared with

$U^* = 6$, because the oscillation frequency is lower at this reduced velocity when compared with ![]() $U^* = 4$, and the shear layers are cut at a slower rate by the cylinder and they can stretch themselves farther in the wake of the cylinder. The strength of generated vortices depends on the time constant of the fluid. For small time constants, the vorticity generated is small (since a smaller time constant results in a smaller characteristic Reynolds number and therefore a smaller vorticity) and very localized, and it diffuses faster without making an impact on the energy transferred to the cylinder. Therefore, the VIV amplitude is small for low values of the time constant and it increases with increasing time constant due to the increase in the strength of vortices. As the time constant is increased, the vorticity diffusion decreases due to the reduction in viscous dissipation, and the vortices advect farther until reaching the Newtonian limit.

$U^* = 4$, and the shear layers are cut at a slower rate by the cylinder and they can stretch themselves farther in the wake of the cylinder. The strength of generated vortices depends on the time constant of the fluid. For small time constants, the vorticity generated is small (since a smaller time constant results in a smaller characteristic Reynolds number and therefore a smaller vorticity) and very localized, and it diffuses faster without making an impact on the energy transferred to the cylinder. Therefore, the VIV amplitude is small for low values of the time constant and it increases with increasing time constant due to the increase in the strength of vortices. As the time constant is increased, the vorticity diffusion decreases due to the reduction in viscous dissipation, and the vortices advect farther until reaching the Newtonian limit.

Figure 9. Wake patterns for shear-thinning fluids at ![]() $U^* = 4$ (a–e) and

$U^* = 4$ (a–e) and ![]() $U^* = 6$ (f–j) at different

$U^* = 6$ (f–j) at different ![]() $\lambda$ and

$\lambda$ and ![]() $Re_{char}$ values. For all cases, the snapshot is taken when the cylinder is at the centre and moving up. The incoming Reynolds number is

$Re_{char}$ values. For all cases, the snapshot is taken when the cylinder is at the centre and moving up. The incoming Reynolds number is ![]() $Re_0=15$ for all cases.

$Re_0=15$ for all cases.

5. Response of a 1DOF cylinder in the flow of shear-thickening fluids

In this section, we consider the response of a 1DOF flexibly-mounted cylinder placed in the flow of shear-thickening fluids. The rheology of the shear-thickening fluid has been described using the Carreau model as shown in figure 1(b). We have used a zero-shear-rate viscosity of ![]() $\eta _0=0.0035$ Pa s and a power-law coefficient of

$\eta _0=0.0035$ Pa s and a power-law coefficient of ![]() $n = 1.2$, and we have set the Reynolds number based on the incoming flow to be

$n = 1.2$, and we have set the Reynolds number based on the incoming flow to be ![]() $Re_0 = 200$.

$Re_0 = 200$.

5.1. Lock-in for shear-thickening fluids

We have conducted VIV simulations for shear-thickening fluids for time constants varying from ![]() $\lambda = 1.5$ s (

$\lambda = 1.5$ s (![]() $Cu\approx 10$) to

$Cu\approx 10$) to ![]() $\lambda = 650$ s (

$\lambda = 650$ s (![]() $Cu\approx 4293$). The dimensionless amplitude and frequency of oscillations, as well as the CF force coefficient and frequency, are shown in figure 10. Since the incoming Reynolds number,

$Cu\approx 4293$). The dimensionless amplitude and frequency of oscillations, as well as the CF force coefficient and frequency, are shown in figure 10. Since the incoming Reynolds number, ![]() $Re_0$, in this case is larger than the minimum required to observe VIV in a Newtonian fluid, we have added the response of the system in a Newtonian fluid to figure 10 as well (

$Re_0$, in this case is larger than the minimum required to observe VIV in a Newtonian fluid, we have added the response of the system in a Newtonian fluid to figure 10 as well (![]() $\lambda =0$,

$\lambda =0$, ![]() $Cu=0$). The response of the system in shear-thickening fluids is qualitatively very similar to the Newtonian response; however, the lock-in range is shifted to the right and the amplitude of oscillations is decreased as the time constant is increased. The shift of the onset of the lock-in range to the right is due to the fact that the Strouhal number decreases with increasing shear-thickening effects, opposite to what we discussed for the shear-thinning fluid in § 4. For shear-thickening fluid, we observe that the largest amplitude of oscillations occurs at the smallest value of the time constant, as opposed to what we observed for the shear-thinning fluid. For all cases where oscillations are observed, the shedding frequency and the oscillation frequency are synchronized and lock-in is observed. The width of the lock-in range and the VIV amplitude decrease with increasing time constant. Oscillations are observed for