Published online by Cambridge University Press: 22 October 2015

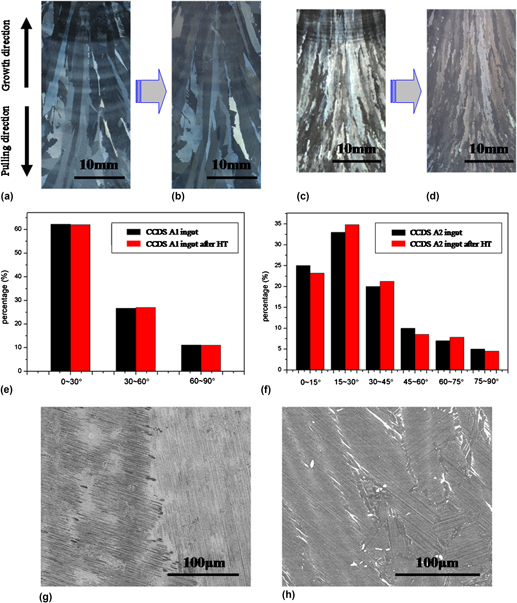

Two kinds of heavy-alloying β-type TiAl-based alloys Ti44Al6Nb1.0Cr2.0V (A1) and Ti44Al6Nb1.0Cr2.0V0.15Y0.1B (A2) are newly designed. They are prepared by vacuum consumable melting (VCM) and cold crucible directional solidification (CCDS). Via the theoretical analysis and tentative experiment, five alternative heat treatment (HT) schedules are proposed and studied that the corresponding microstructure and room temperature (RT) tensile property are investigated, and finally the optimized HT schedules are acquired. After HT5 (heat preservation in β phase region and at 1290 °C, and then ladder cooling), A2 alloy cast by VCM exhibits a better tensile property with average elongation of 1.20%. For the two CCDS ingots, after HT3 (mainly annealing at 1280 °C), B2 phase and (B2 + γ) blocky morphology are reduced, the columnar grains and small angle lamellas are reserved, and the tensile property also has a moderate improvement.

Contributing Editor: Yang-T. Cheng