Published online by Cambridge University Press: 10 February 2017

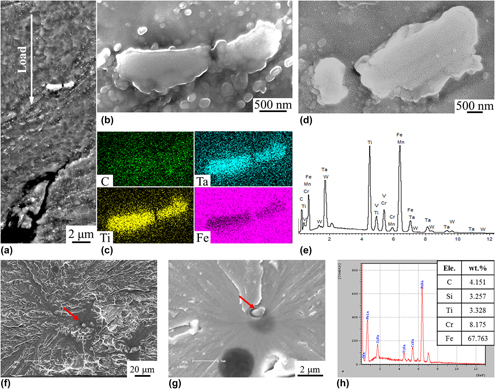

Four 9Cr2WVTa deposited metals with different titanium contents were studied to reveal the role of minor elements titanium, which guide for the design of welding consumables for reduced activation ferritic/martensitic steel and meet for the requirements of accelerator driven systems-lead fusion reactors. The microstructural evolution of 9Cr2WVTa deposited metals was analyzed and discussed. Results show that the surface layer of 9Cr2WVTa deposited metal exhibits the columnar structure and the δ-ferrite is seen as a film distributed along the martensite lath. The microstructures are uniform in the middle of the deposited metal and exhibit the equiaxed structure. The fine stripe δ-ferrite decorates along the prior austenite grain boundaries and therefore, refines the grain size. The primary blocky Ti-enriched particles are the main factor affecting the mechanical properties for the 9Cr2WVTa deposited metal. The 9Cr2WVTa deposited metals obtain good mechanical properties when the titanium content does not exceed 0.08 wt%.

Contributing Editor: Jürgen Eckert