Published online by Cambridge University Press: 12 December 2017

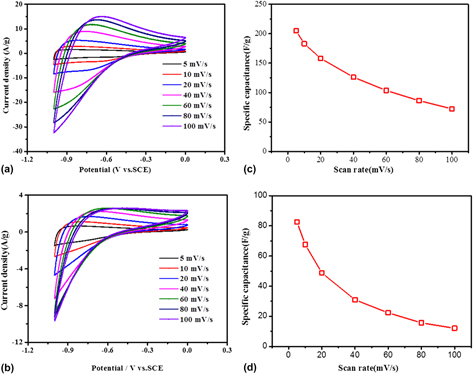

Porous carbon nanomaterials with significant capacitive performance were successfully prepared through a simple two-step process of thermal-polymerization and carbonization without an additional template. As a result, the as-prepared porous carbon nanomaterials of sample-A and sample-B exhibited an amorphous phase with low graphitization. And sample-A showed a moderate specific surface area of 476.39 m2/g, larger than that of sample-B (280.94 m2/g). The relatively high mass specific capacitance of 205.1 F/g at a scan rate of 5 mV/s and 211 F/g at a current density of 4 A/g was obtained by sample-A, which are higher than those of sample-B (82.6 F/g at 5 mV/s and 78.6 F/g at 4 A/g). Sample-A also showed excellent conductivity and superior cyclic stability with 94.19% capacitance retention after 5000 cycles, which are also higher than those of sample-B. This work proposed a cost-effective, green, and promising strategy for the large-scale preparation of porous carbon nanomaterial electrodes.

Contributing Editor: Teng Zhai