No CrossRef data available.

Article contents

Influence of silicon content on the volume deficit characteristic of cast Al–Si alloys

Published online by Cambridge University Press: 16 December 2013

Abstract

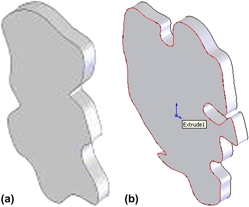

Aluminum alloy castings find extensive applications in automobile and other engineering industries. Production of defect-free castings requires a good understanding of the volume deficit characteristic. The volume deficit of a casting depends on the casting material and casting conditions. Patterson and Engler have classified the volume deficit into four types namely, macrocavities, internal porosity, surface sinking, and volumetric contraction. The influence of process parameters on the characteristics determines the casting quality. The process parameters considered in this study are bottom chill, casting shape, and pouring temperature. Two basic shapes rectangle and cylinder are considered. The volume deficit decreases with an increase in the silicon content. The AA 356.0 alloy shows more amount of volume deficit than AA 413.0 alloy. X-ray computer tomography (XCT) helps to reveal the size, shape, and location of defects in castings. Quantification of internal closed porosity of AA 413.0 casting is done using XCT and successfully validated through destructive testing of castings.

Information

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2013