No CrossRef data available.

Published online by Cambridge University Press: 24 April 2019

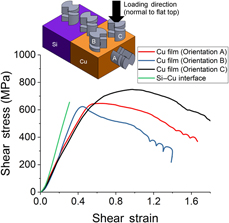

Microscale testing has enjoyed significant developments, with the majority of testing focused on tensile/compression type tests and little focus on shear testing. With the recent advances in macroscale shear testing, we developed a novel shear structure for evaluating shear properties of bulk materials and films at the microscale. The shear response in single-crystal copper oriented along the [111] direction was found to have a yield strength of ∼180 MPa. Nanocrystalline copper specimens with different orientations showed sensitivity to the film texture with a shear yield strength nearly three times that of single-crystal copper. Shear specimens were fabricated with Cu film–Si substrate interface near the middle of the shear region and compressed to fracture. The shear response showed a mixed behavior of the stiff Si substrate and softer nanocrystalline film and failed in a brittle manner, indicating a response unique to the interface.